Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1553results about How to "Improve technical effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

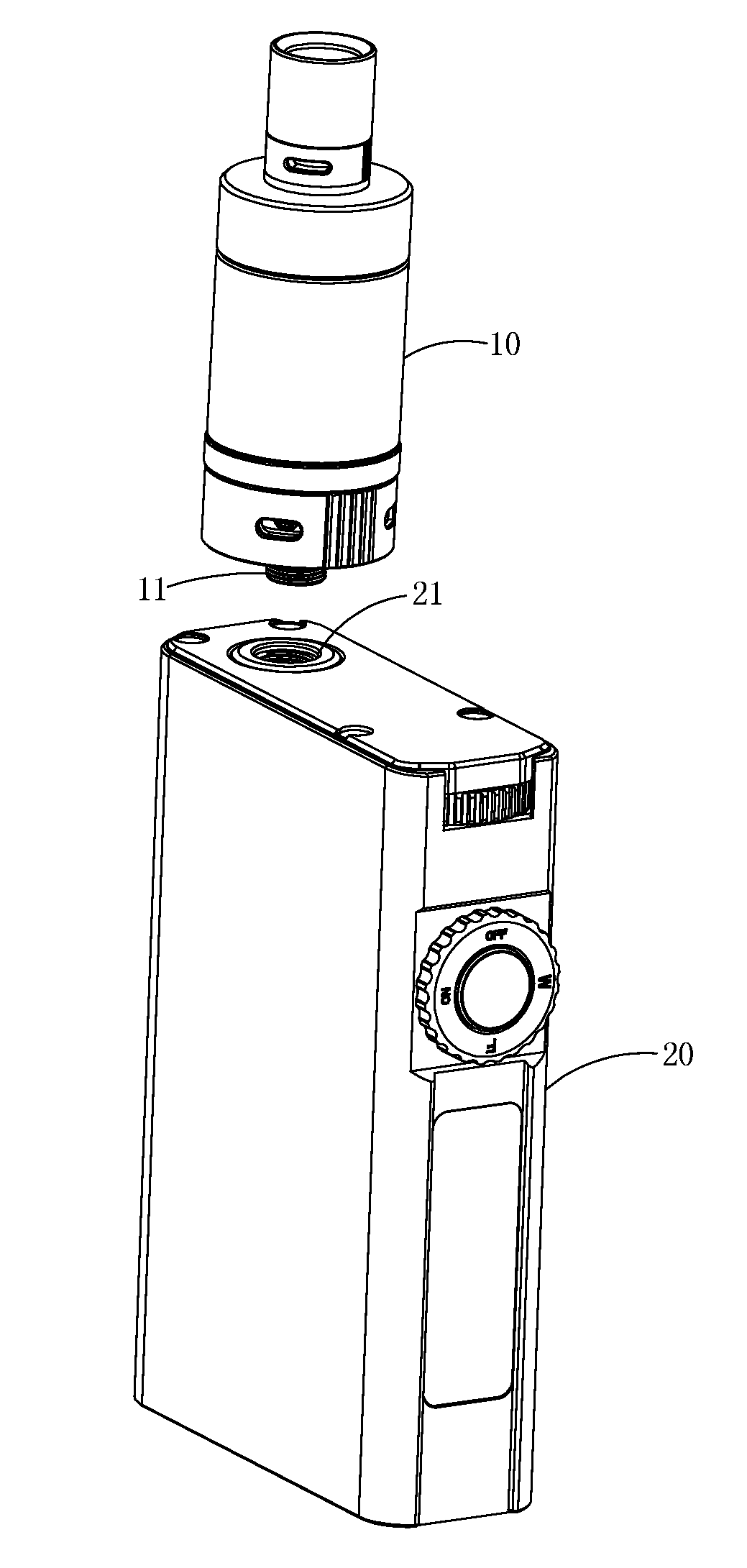

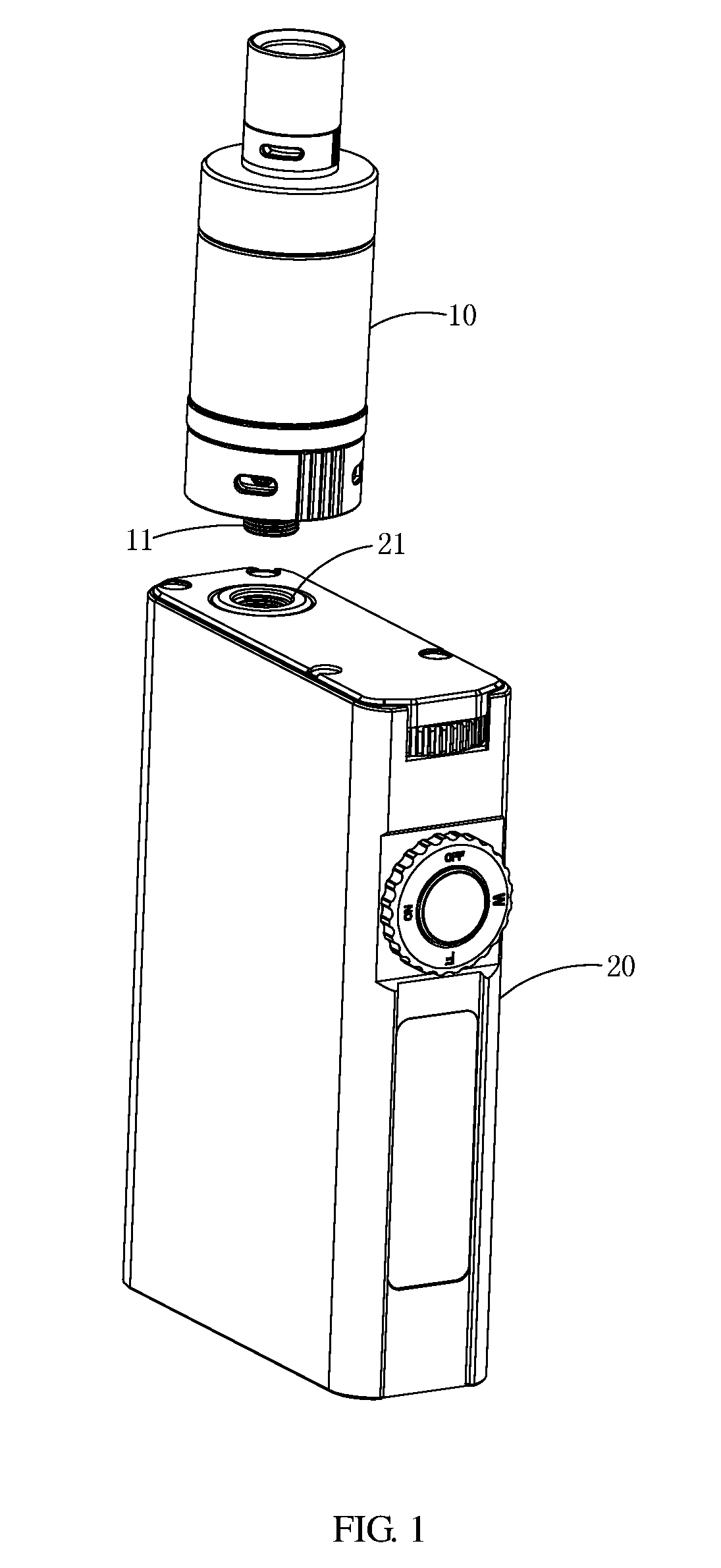

Power supply device for electronic atomizer

InactiveUS20170079327A1Improve technical effectImprove operational convenienceElectric heatingTobacco devicesMicrocontrollerElectricity

Disclosed is a power supply device for electronic atomizer, which includes a housing having a battery compartment formed therein, at least a battery installed in the battery compartment and a control circuit having an input side electrically connected with the battery and an output side electrically connected with an output electrode terminal. The control circuit includes a microcontroller unit, a mode selection module connected with the microcontroller unit for selecting working mode of the electronic atomizer, a regulation module connected with the microcontroller unit for regulating working parameter of the electronic atomizer and a start button connected with the microcontroller unit for controlling whether the electronic atomizer starts up. The mode selection module is a multi-position switch and the microcontroller unit is able to being triggered to start corresponding working modes by switching the multi-position switch to be different positions. The present invention has the advantage of convenient to use.

Owner:SHENZHEN JIESHIBO TECH

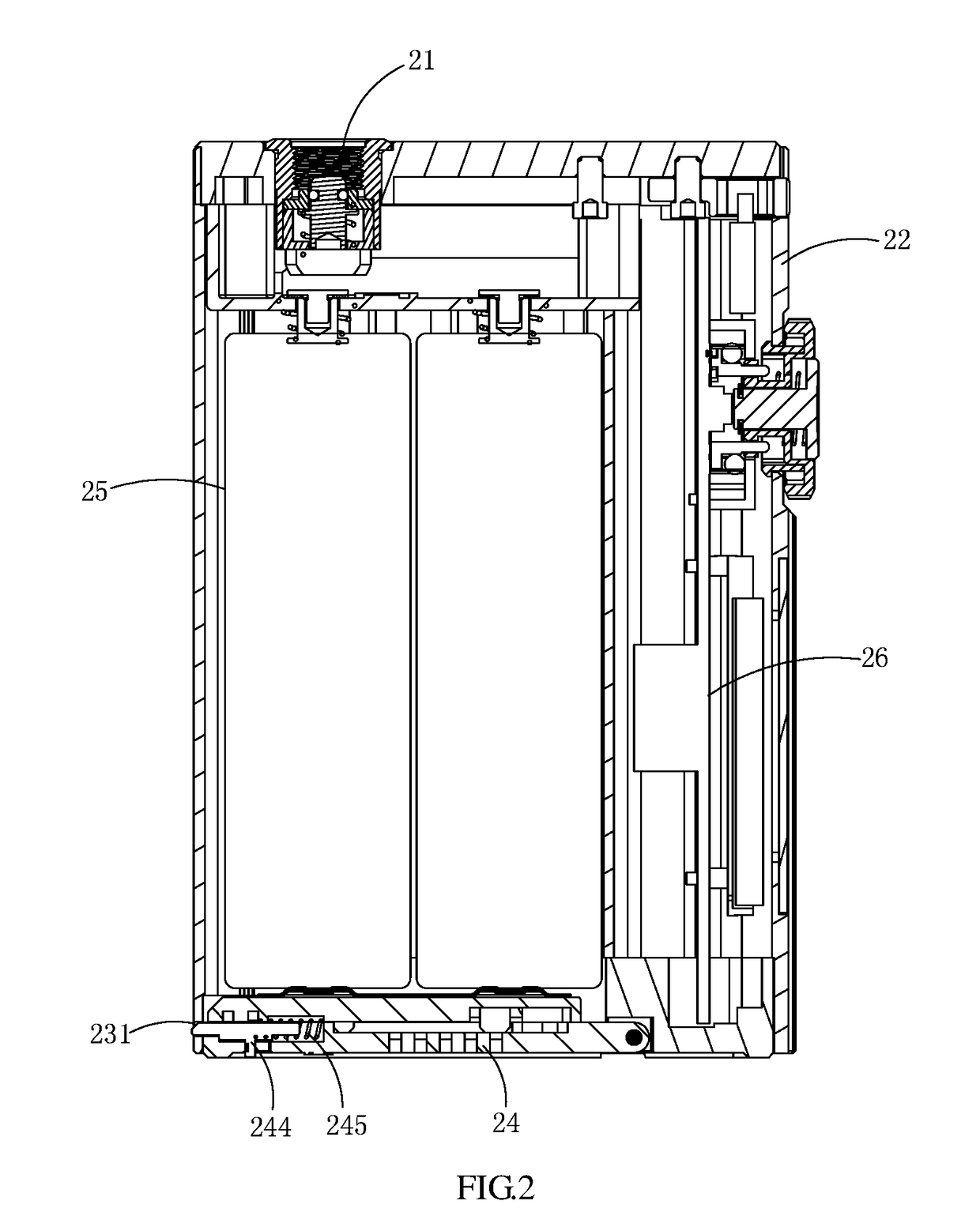

Safe and environment-friendly method for protecting storage tanks

InactiveCN104370000AShort processReduce dosageLarge containersEnvironmental resistancePositive pressure

The invention relates to a safe and environment-friendly method for protecting storage tanks to mainly solve the problems that in the prior art, the gas consumption of nitrogen protection is excessively large, cost is high, and sulfur-containing gas and other peculiar smell gas are hard to treat. According to the safe and environment-friendly method for protecting the storage tanks, the gas produced by liquid in the storage tanks enters a compressor (18) through a main gas pipe (19) and an inflation pipe (21), the gas is pressurized by the compressor (18) and stored in a buffering tank (5) to serve as one part of positive-pressure protection gas, when the gas stored in the buffering tank (5) cannot meet the positive-pressure protection of all storage tanks, the nitrogen from a nitrogen inlet pipeline (22) is used for performing supplementation, and when the pressure stored in the buffering tank (5) exceeds the designed pressure, the residual gas is sent to a torch or combustion furnace through a torch or combustion furnace leading pipeline (22), the problems are well solved through the technical scheme, and the method can be used in storage tank protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength multifunctional pressure-bearing pot cover

InactiveCN106859298AOvercoming indecent structuresReduce thermal efficiencyPressure-cookersEngineeringEnergy conservation

The invention relates to a high-strength multifunctional pressure-bearing pot cover. A main body, an arc-shaped groove plate, a main cover handle, a manual valve, an automatic valve, a main cover body, a pot edge groove, a movable rod, a movable rod clip, a movable shaft, sealing bolts and a handle fixing nail are organically arranged, wherein the arc-shaped groove plate is arranged in an arc-shaped plate on the upper end of the pot edge groove and in a hollow-out arc-shaped groove shape; the main cover handle is placed in the upper side of the main cover body; the manual valve is hidden in the main cover handle; an inlet and an outlet respectively communicate with the lower side of the main cover body and the lower side of the main cover handle; the automatic valve is hidden into the main cover handle; an inlet and an outlet respectively communicate with the lower side of the main cover body and the lower side of the main cover handle; the main cover body is arranged in an end port of a pressure cooker and in the pot edge groove; the pot edge groove is arranged in the pressure cooker end port and the lower side of the main cover body; the movable rod is disposed in the arc-shaped groove plate; the movable rod clip is disposed in a movable rod recessed pit; the inner side of the movable shaft is connected with one side of the main cover body via the fixing nail; the sealing bolts are symmetrically arranged on the lower side of the main cover body; and the handle fixing nail is hidden into the main cover handle. Therefore, the high-strength multifunctional pressure-bearing pot cover can be safely used and has obvious comprehensive energy conservation effect.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

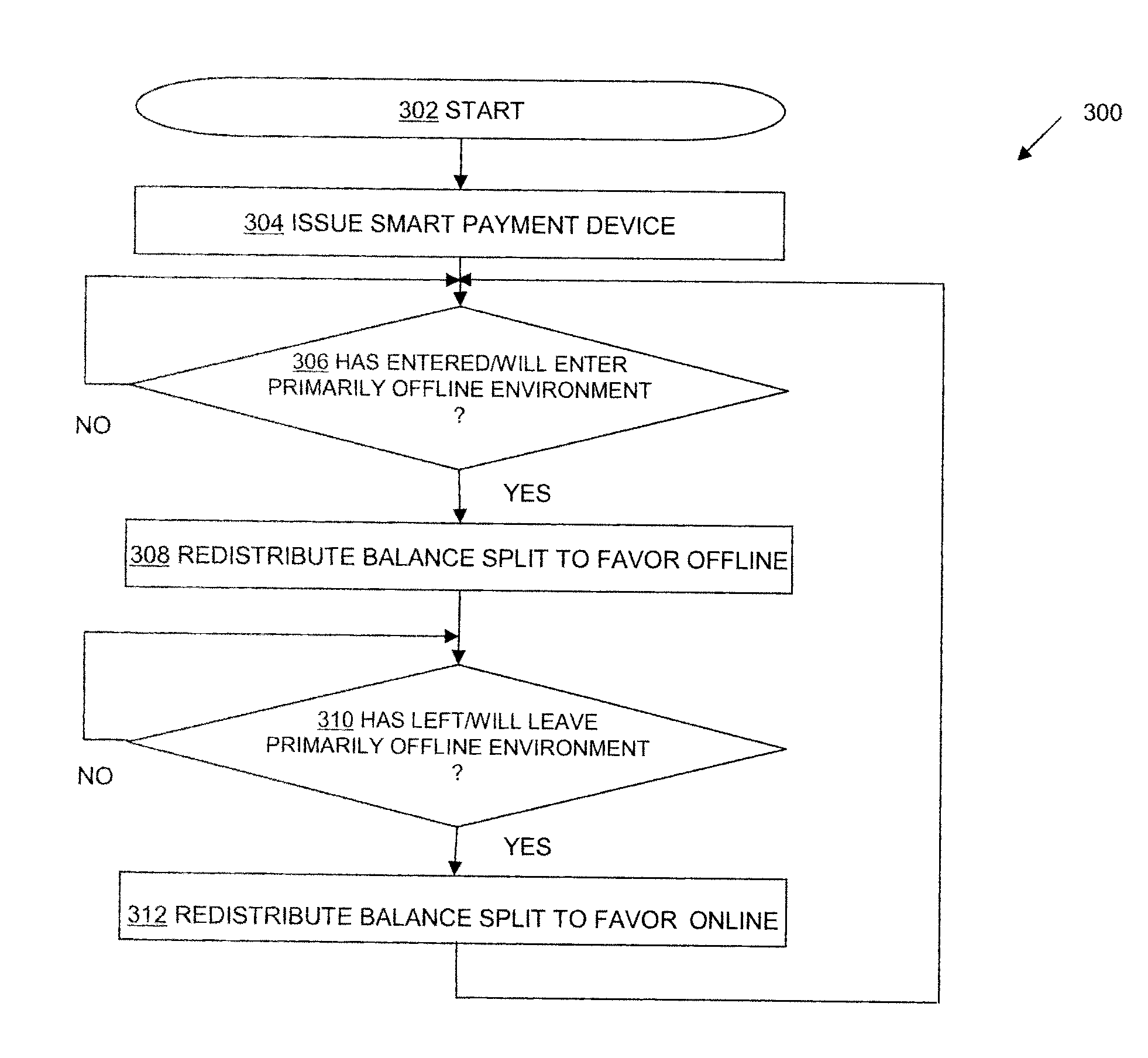

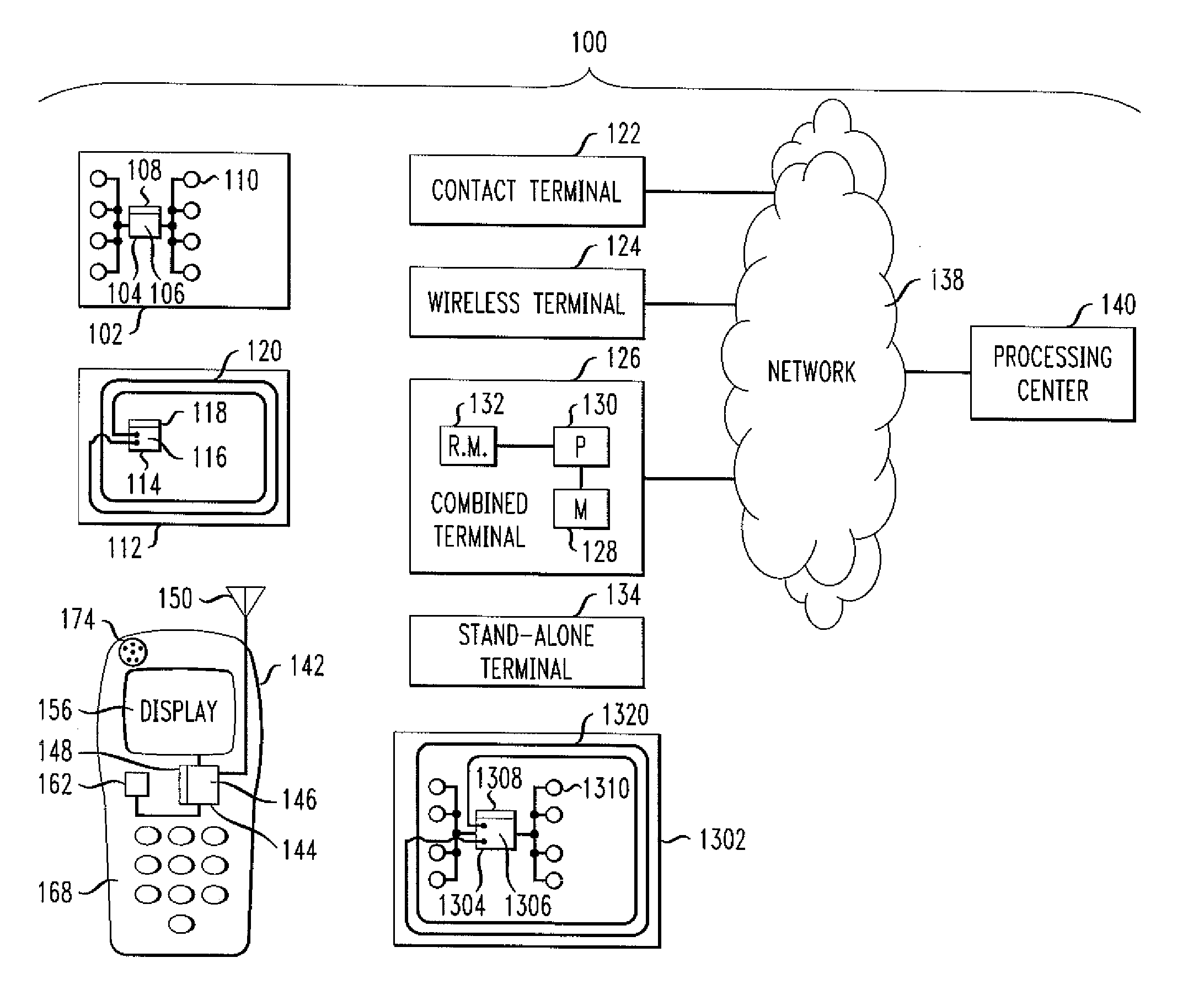

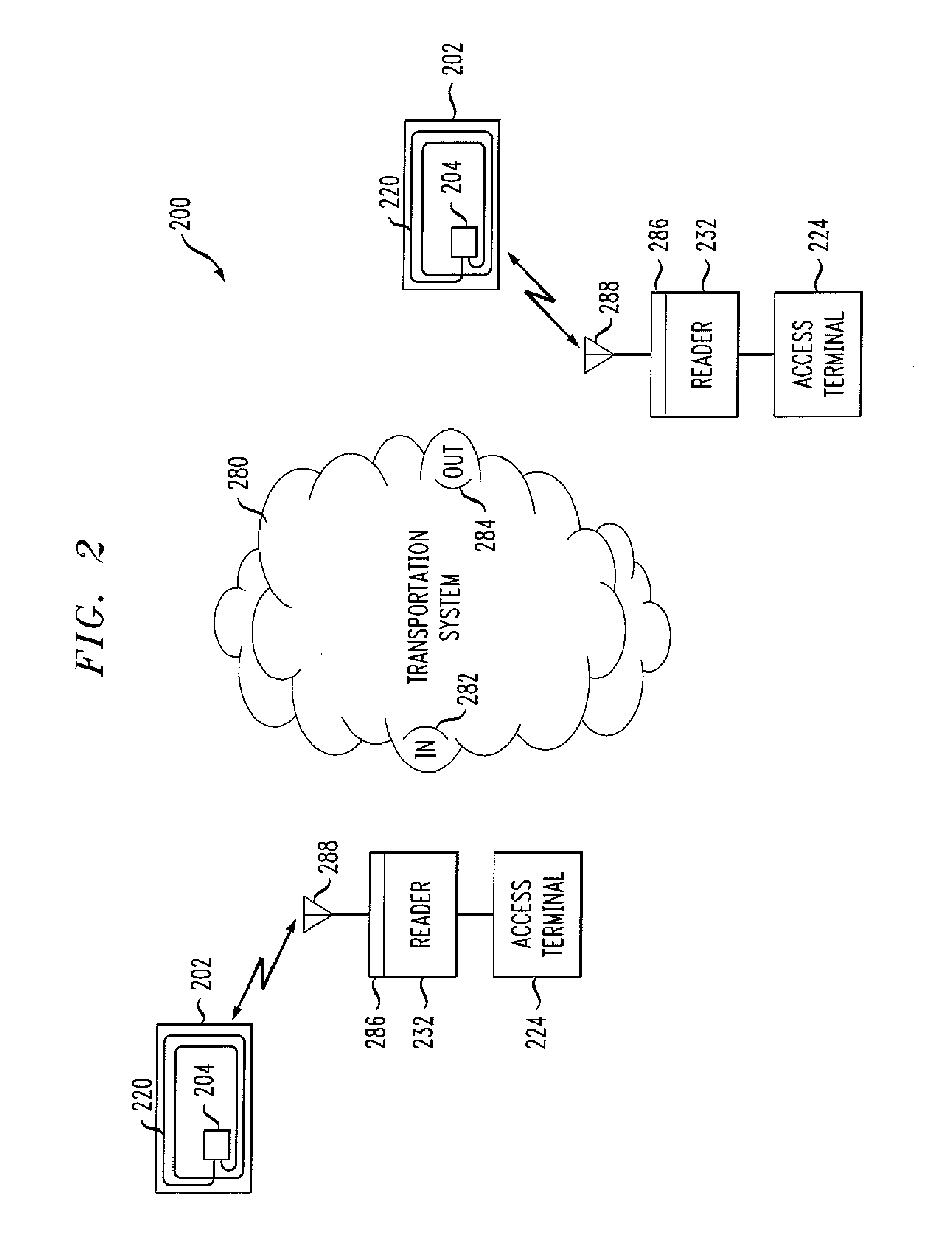

Apparatus and Method for Dynamic Offline Balance Management for Preauthorized Smart Cards

A smart payment device is issued to a user; the device is capable of both offline and online transactions and has a total available balance split. The split is between an available offline balance and an available online balance. It is determined whether the user has entered a primarily offline environment or will imminently enter a primarily offline environment. If this is so, the total available balance split is redistributed to favor offline transactions.

Owner:MASTERCARD INT INC

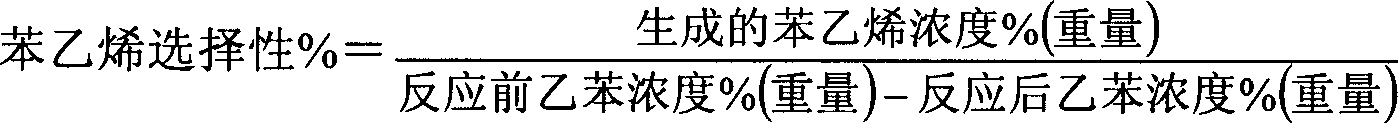

Method for preparing olefin by conversion of methanol

ActiveCN1704390AHigh selectivityImprove catalytic performanceHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveReaction temperature

The invention relates to a method for preparing olefin by conversion of methanol by using Zn-SAPO-34 molecular sieve and bonding agent as the catalyst for alkene production through methanol converstion, and employing a reaction temperature of 300-500 deg. C, a reaction pressure of atmospheric pressure, methanol weight space velocity of 1.0-10hr-1, the prepared low carbon alkene can be used in the industrial production of alkene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

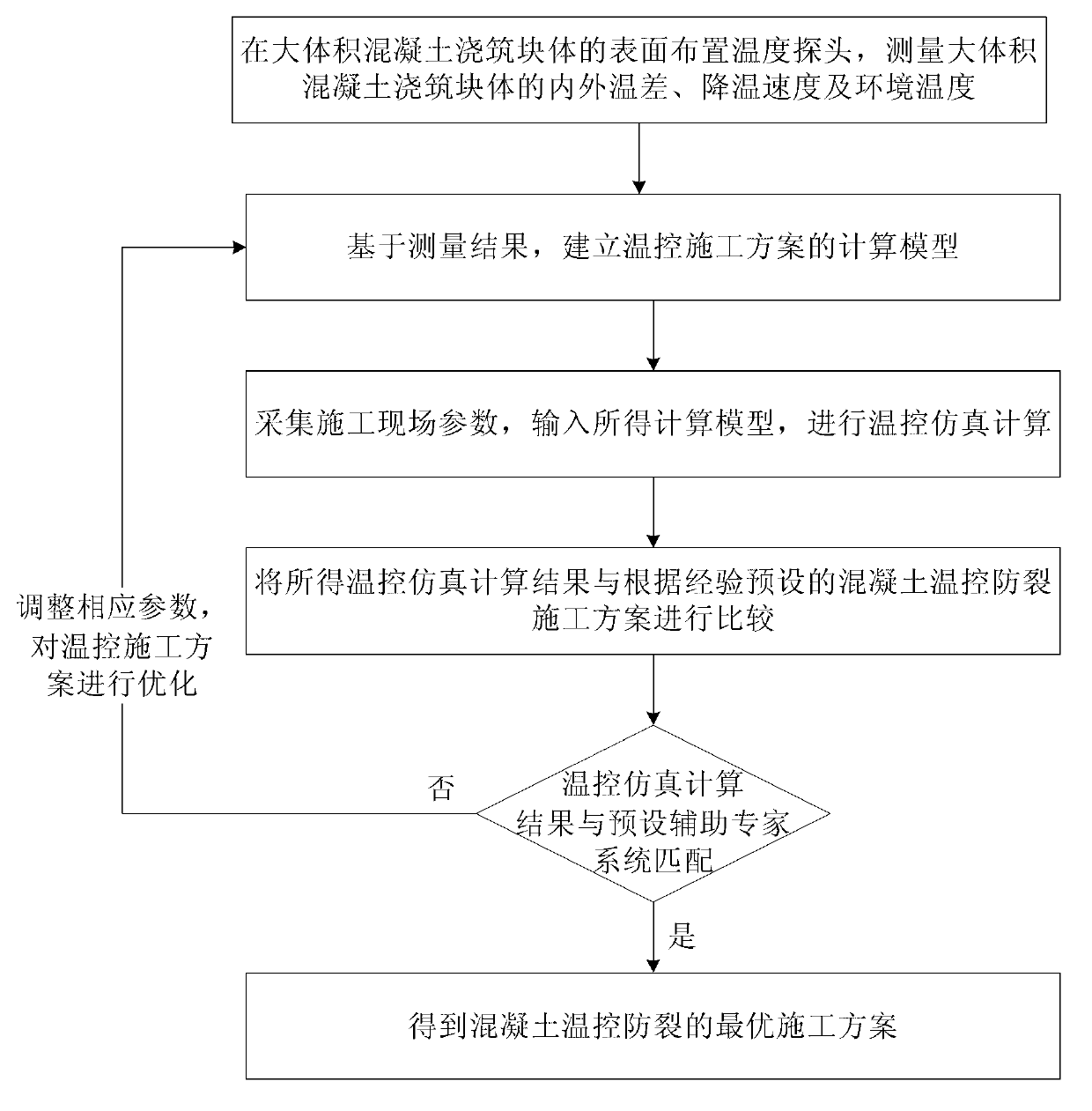

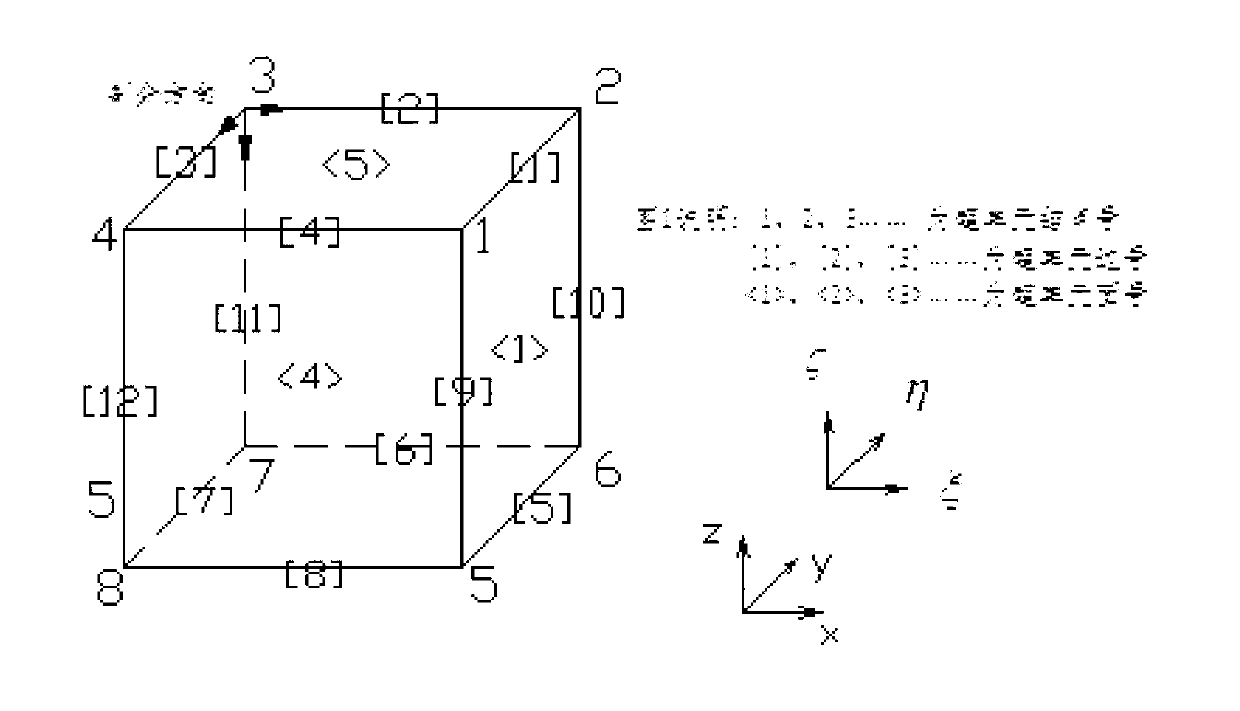

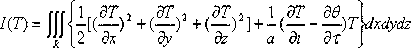

Temperature-controlled crack prevention construction method for concrete structure

ActiveCN102979307AOvercoming easy cracksOvercoming reliabilityFoundation engineeringBuilding material handlingTemperature controlTemperature difference

The invention discloses a temperature-controlled crack prevention construction method for a concrete structure. The method comprises the steps of (1) arranging temperature probes on the surface of a large-size concrete pouring block to measure the temperature difference between inside and outside, the cooling rate of the large-size concrete pouring block and the environment temperature; (2) establishing a calculation model for the temperature-controlled construction scheme based on the obtained measuring result; (3) collecting the construction site parameters, and inputting the parameters into the obtained calculation model for temperature-controlled simulation calculation; and (4) comparing the temperature-controlled simulation calculation result obtained in the step (3) with the preset auxiliary expert system, repeating the step (2) to adjust the corresponding parameters when the temperature-controlled simulation calculation result obtained in the step (3) and the preset auxiliary expert system mismatch, and optimizing the temperature-controlled crack prevention construction scheme for concrete preset based on experience until the optimal temperature-controlled crack prevention construction scheme for the concrete is obtained. The temperature-controlled crack prevention construction method for the concrete structure disclosed by the invention has the advantages that the concrete is not prone to crack, the crack prevention reliability is high, and the crack prevention commonality is good.

Owner:JINLAI CONSTR ENG TECH RES & DEV CO LTD OF THE XINJIANG PRODION & CONSTR CORPS

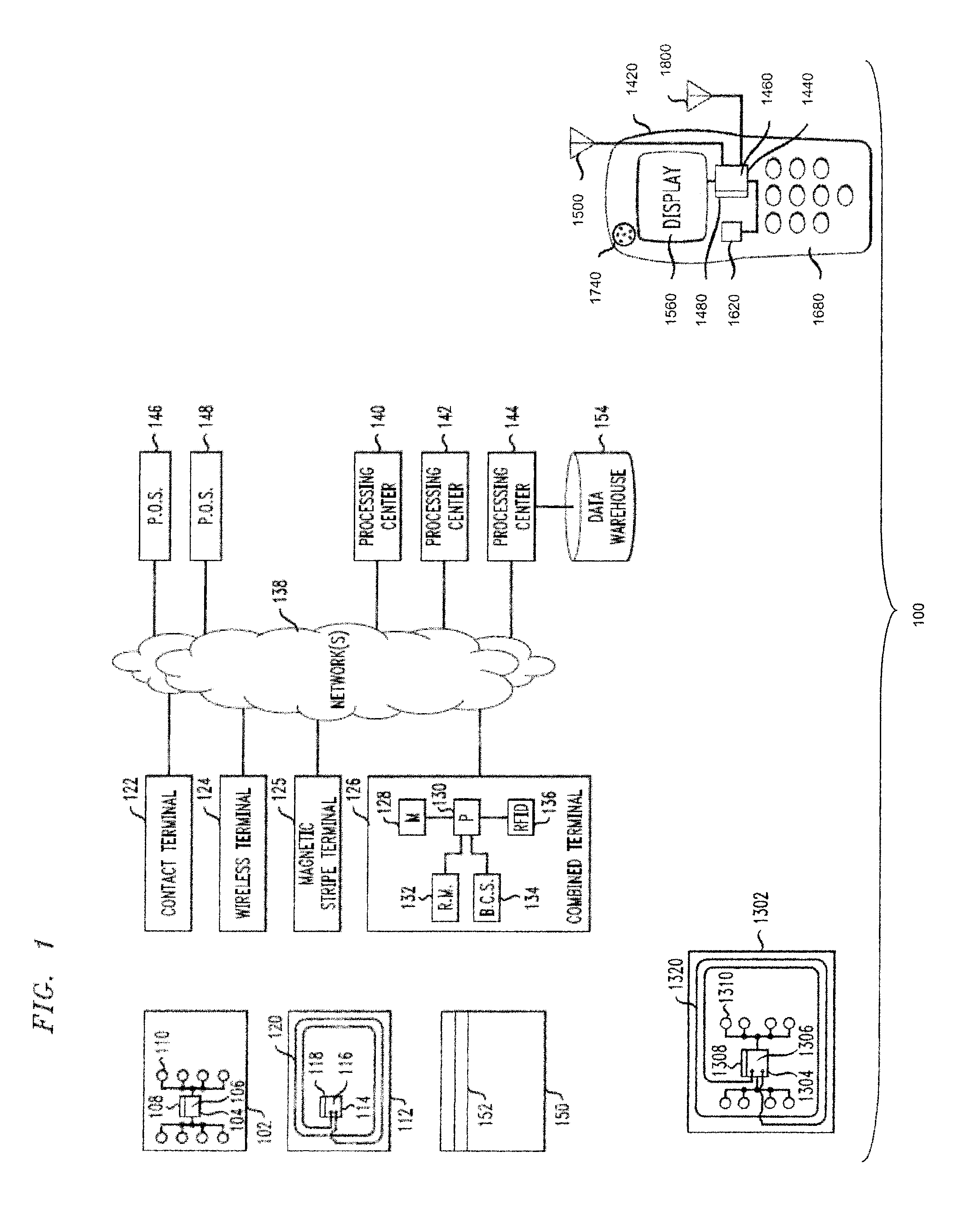

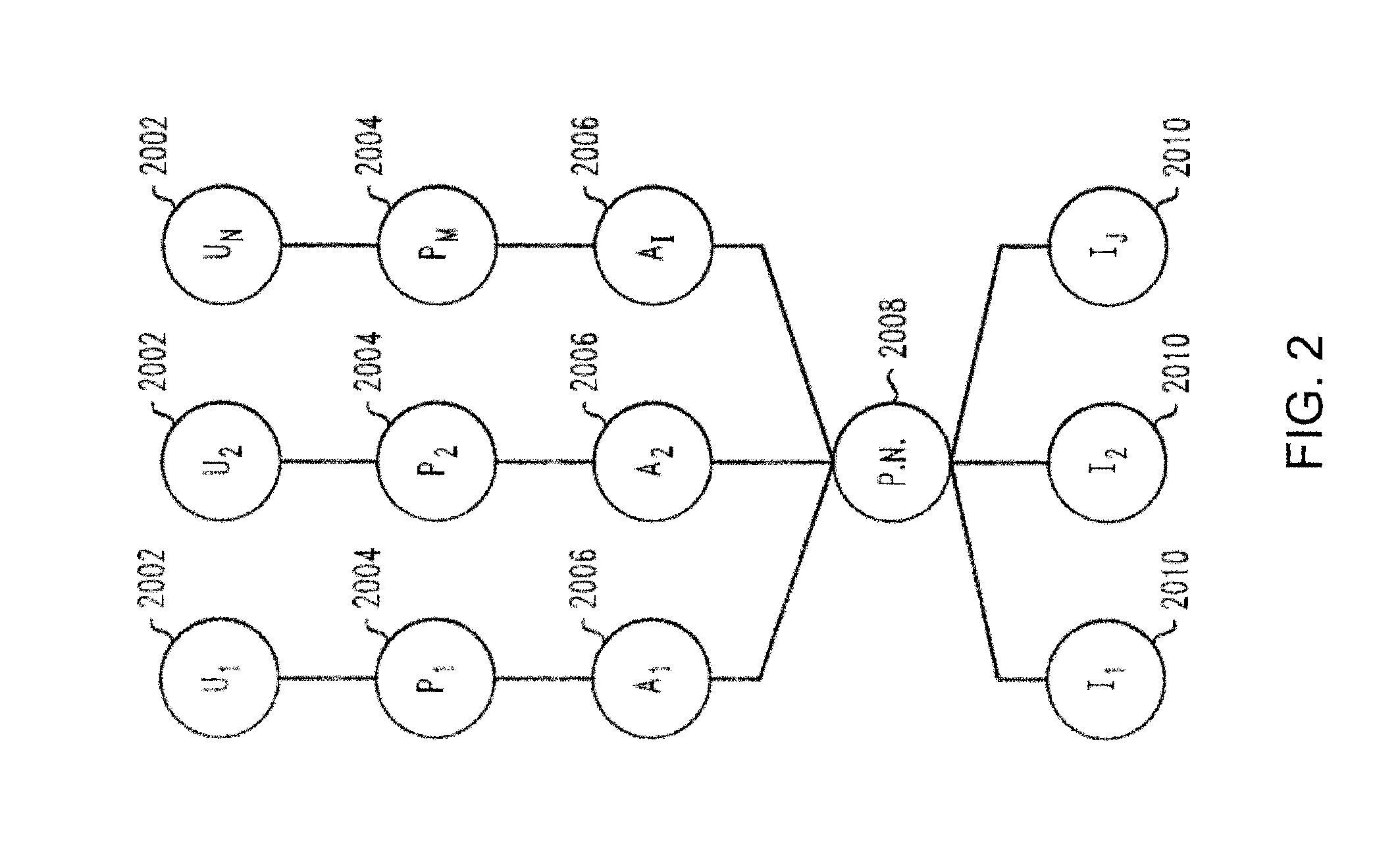

Techniques for co-existence of multiple stored value applications on a single payment device managing a shared balance

ActiveUS20070131761A1No longer accessibleKeep for a long timeAcutation objectsFinancePaymentApplication software

A method of managing a first stored value application having a first application balance and a second stored value application having a second application balance, can include the steps of facilitating conducting of a first transaction by the first stored value application, and synchronizing the second stored value application with the first stored value application. The synchronization can be substantially contemporaneous with the transaction. The applications can reside on the same portable payment device.

Owner:MASTERCARD INT INC

Composition of insulating mold coating in use for glass, and preparation method

InactiveCN101050065ACurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyFatty alcohol

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

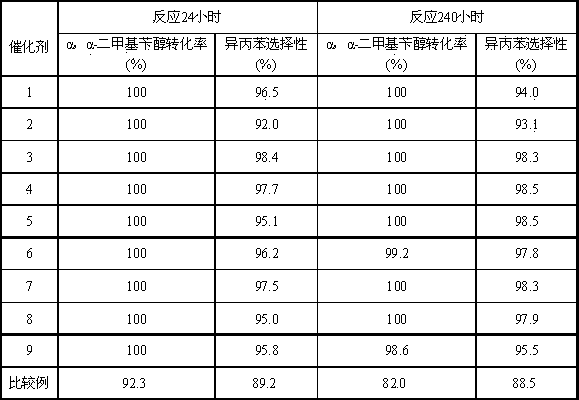

Alpha, alpha-dimethylbenzyl alcohol hydrogenolysis method for preparing isopropyl benzene

InactiveCN104230640AImprove technical effectHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogenAlcohol

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problems of poor stability of catalyst and serious environmental pollution in the isopropyl benzene production process. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethylbenzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.1-2.0 parts of Pd metal or oxide; b) 85.0 to 97.0 parts of SiO2; c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, and Cu or oxide thereof; and d) 1.0 to 5.0 parts of at least one selected from Mg or oxide thereof, Ca or oxide thereof and Ba or oxide thereof. The method can be used in industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

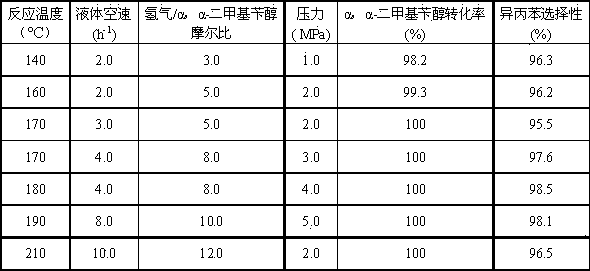

Starting method of reaction-regenerative device for preparing low carbon olefin form methanol

ActiveCN101333142AImprove technical effectMolecular sieve catalystsCatalyst regeneration/reactivationCombustion chamberReaction zone

The invention relates to a starting method for a reaction-regeneration device which uses methanol to prepare low-carbon olefin, mainly comprising the following steps: a. using an auxiliary combustion chamber to heat air, and then entering the reaction-regeneration device; heating the dense phase temperature of a regenerator to 400-600 DEG C, and heating the temperature of a reactor reaction zone to 150-350 DEG C; b. switching the catalyst from a catalyst storage tank into the regenerator, and injecting the combustion oil to maintain the temperature of the regenerator; c. switching the catalyst from the regenerator into the reactor, and establishing reaction catalyst circulation between the reactor and the regenerator; d. heating the reactor reaction zone to a temperature not less than 350 DEG C, and putting the raw materials containing the methanol in the reactor to contact with the catalyst so as to generate the products containing low-carbon olefin and also form a carbon deposit on the catalyst; e. stop injecting combustion oil to the regenerator; f. stop using the auxiliary combustion chamber. The method has short starting period and light catalyst damage degree, which can be used for low-carbon olefin industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing MCM-22 molecular sieves

InactiveCN1500722ALower synthesis costEliminate pollutionMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveOrganic chemistry

The present invention relates to the preparation process of MCM-22 molecular sieve and solves the problems in the preparation process, including high synthesis cost and environmental pollution. The technological scheme of the present invention is that during the preparation of MCM-22 molecular sieve, partial or all the template agent comes from MCM-22 molecular sieve crystallizing mother liquid. The present invention may be used in industrial preparation.

Owner:CHINA PETROLEUM & CHEM CORP +1

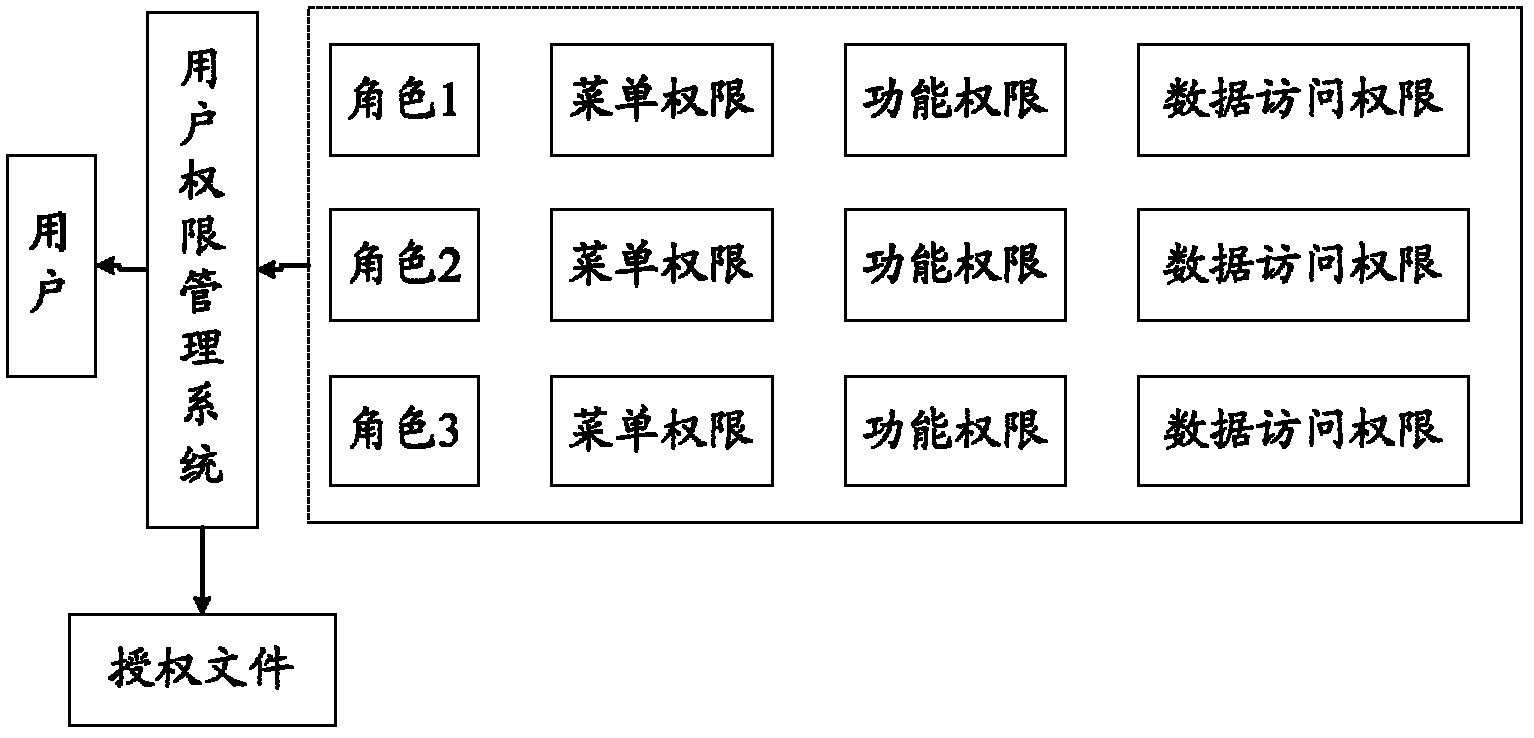

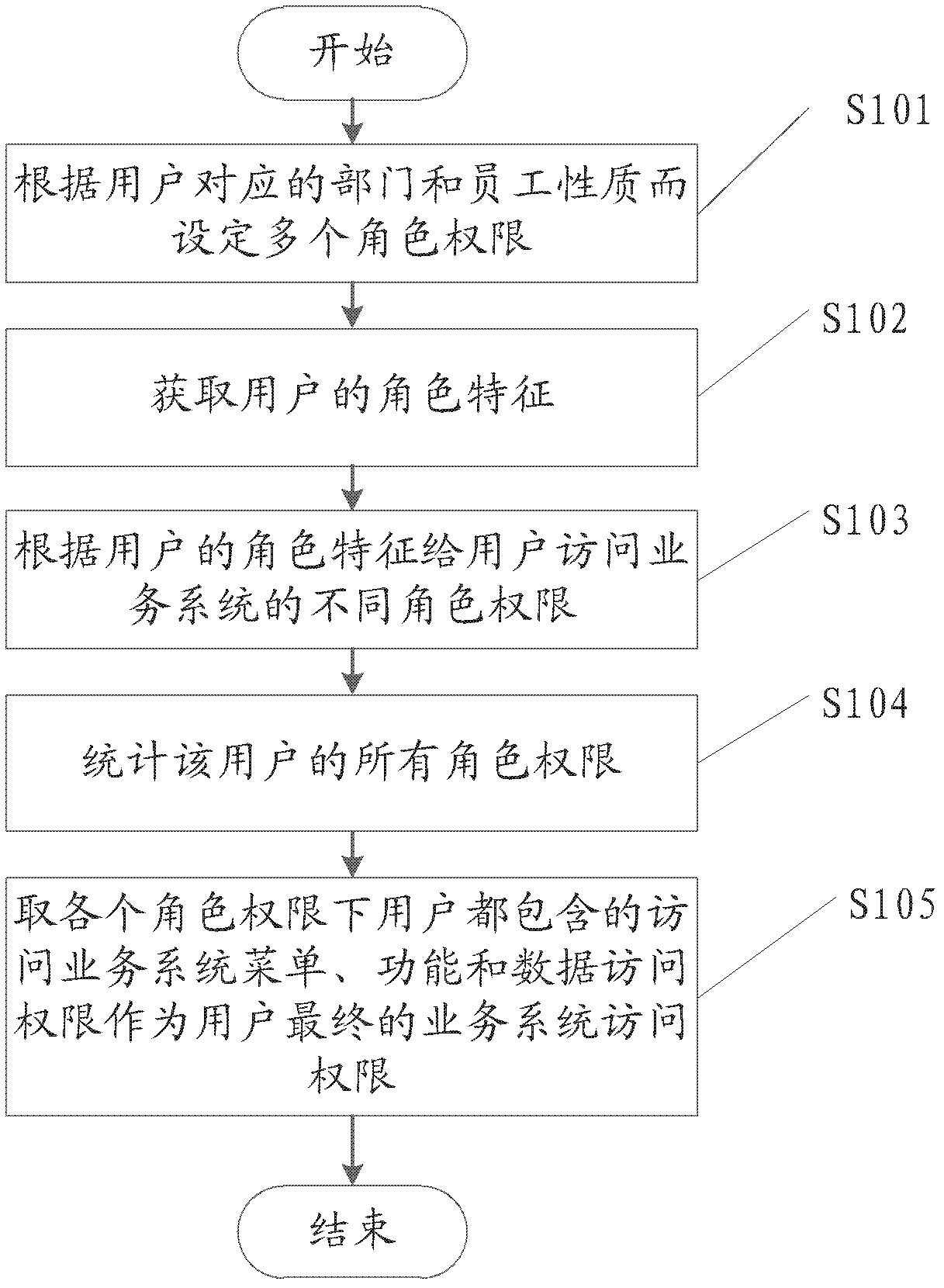

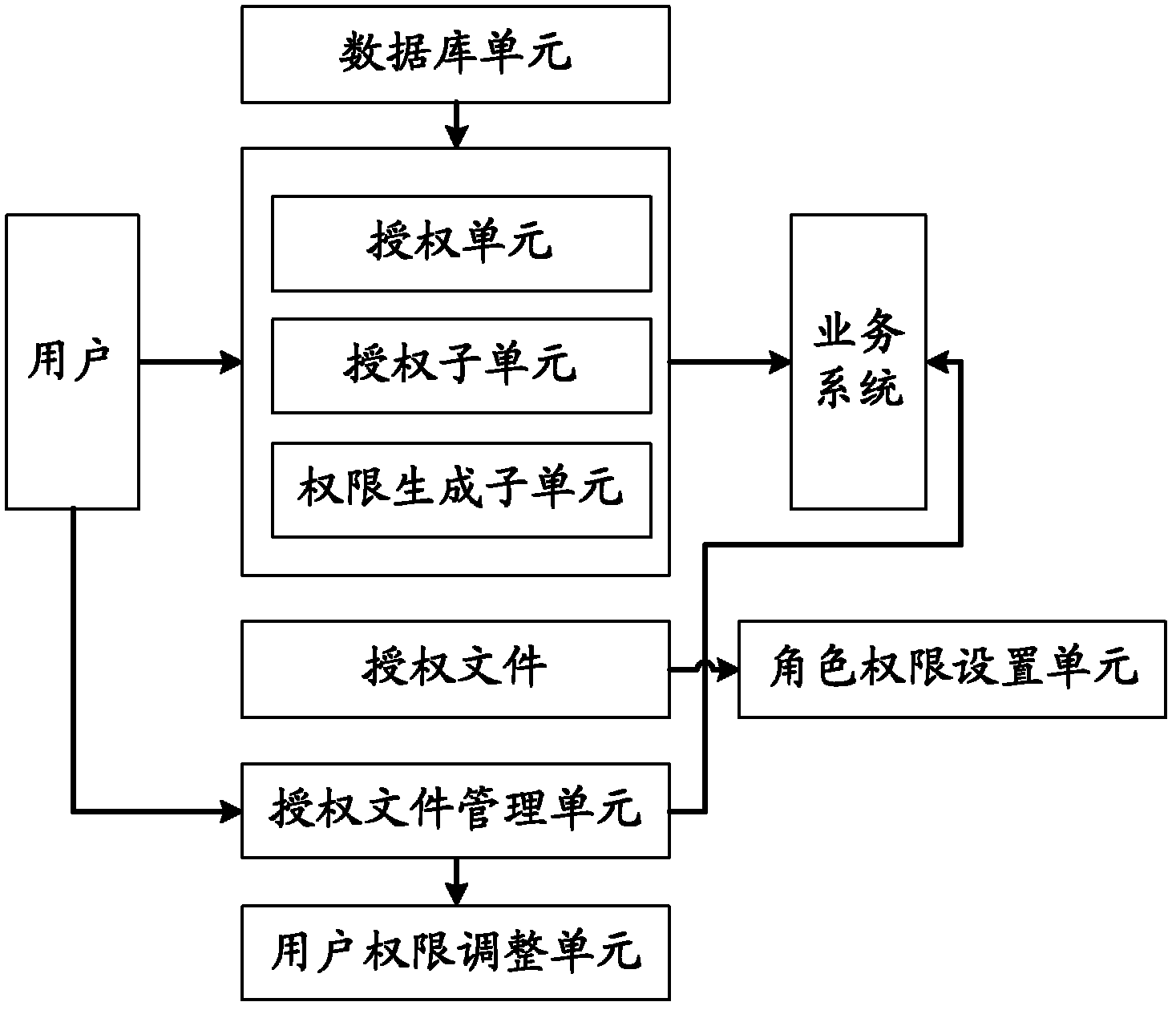

User authority management method and system in business system

The invention discloses a user authority management method in a business system. The user authority management method comprising the steps of assigning different role authorities for a user visit business system according to role features of a user, wherein each role authority comprises a business system menu and functions and data visit authority which can be visited by users in the role; making statistics on all the role authorities of the user when forming the final user authority, and taking the visit business system menu and the function and data visit authority included by the users in all the role authorities as the final business system visit authority of the user. According to the invention, the users need not to be set independently, and different role authorities can be endowed to the users according to different role features of the users, so as to achieve the final user authority setting. In addition, the invention also discloses a user authority management system in the business system.

Owner:阿里巴巴(成都)软件技术有限公司

Method for improving butene double bond isomerization reaction

ActiveCN101475432AHigh selectivityImprove technical effectHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

The invention relates to a method for improving reaction selectivity of isomerization of double bonds of butylene. The method mainly solves the problem of poor reaction selectivity in the prior art. Through a technical proposal that butylenes-1, butylenes-2 or a mixture which contains the butylenes-1 and butylenes-2 and does not meet a thermodynamic equilibrium value is used as a raw material; carbon-predeposited aluminosilicate is used as a catalyst, wherein the amount of predeposited carbon is 0.01 to 5 percent counted by the weight of the catalyst; and under the conditions of reaction temperature of between 50 and 480 DEG C, reaction pressure of between -0.08 and 10MPa and weight space velocity of between 0.1 and 100 hours<-1>, the raw material and the catalyst contact and have the isomerization reaction of the double bonds of the butylene to generate an effluent substance with the molar ratio of butylenes-1 to butylenes-2 close to the thermodynamic equilibrium value, and the method well solves the problems and can be applied to industrial production of isomerization of double bonds of butylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selectivity hydrogenation method for whole fraction crack petroleum

ActiveCN101121899AGood activity at low temperatureGood choiceRefining by selective hydrogenationRefining by aromatic hydrocarbon hydrogenationPore distributionReaction temperature

The invention relates to a method for selective hydrogenation of full-run pyrolysis gasoline, which mainly solves the technical problem in the prior art that it is difficult to selectively hydrogenate full-run pyrolysis gasoline with high colloid and free water content. The present invention adopts the pyrolysis gasoline and hydrogen of the hydrocarbon compound fraction with C5 hydrocarbon to dry point of 204 DEG C as raw materials, the reaction temperature is 30 to 80 DEG C, the reaction pressure is 2.0 to 3.0 MPa, and the fresh oil space velocity is 2.5 to 5.0 hour-1, under the condition that the hydrogen / oil volume ratio is 60-120:1, the raw material is contacted with the catalyst and reacts to convert the diolefin and alkenyl aromatic components in the raw material into monoolefin and alkylaromatic. Including alumina support, active component metal palladium or its oxide, at least one element selected from IA or IIA in the periodic table or its oxide, at least one element selected from IVA or VA in the periodic table or its oxide Oxide, the specific surface area of the carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the carrier has a technical solution of composite pore distribution, which solves this problem well and can be used for full-run pyrolysis gasoline In the industrial production of selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic silicon micro-pore zeolite and synthesizing method thereof

ActiveCN101121523AImprove technical effectMolecular sieve catalystsOther chemical processesAlkaneSorbent

The present invention relates to a silicone microporous zeolite and the synthesis method of the silicone microporous zeolite, used to solve the problem that a frame structure of the microporous zeolite synthesized by the prior technology does not contain the silicone and to provide the microporous zeolite, in which the frame structure contains the silicone. The present invention contains the following mol relation: In the formula of (1 / n) Al2O3: SiO2: (m / n) R, n is equal to 5-1000 and m is equal to 0.01-300. R is an alkyl, an alkane alkenyl or a phenyl. A solid nuclear magnetic map of Si29NMR is between -80ppm and +50ppm and includes at least one nuclear magnetic resonance spectral peak of Si29. A diffraction pattern of x-ray has a d-spacing maximum at the position of 11.14 plus or minus 0.05, 9.99 plus or minus 0.05, 9.74 plus or minus 0.05, 6.36 plus or minus 0.05, 5.99 plus or minus 0.05, 5.70 plus or minus 0.05, 5.57 plus or minus 0.05, 4.98 plus or minus 0.05, 4.26 plus or minus 0.05, 3.83 plus or minus 0.05, 3.75 plus or minus 0.05, 3.72 plus or minus 0.05, 3.65 plus or minus 0.05, 3.44 plus or minus 0.05, 3.32 plus or minus 0.05 angstrom and 3.05 plus or minus 0.05 angstrom. The microporous zeolite can serve as a sorbent or an activator component used in the transformation of the organic compounds.

Owner:CHINA PETROLEUM & CHEM CORP +1

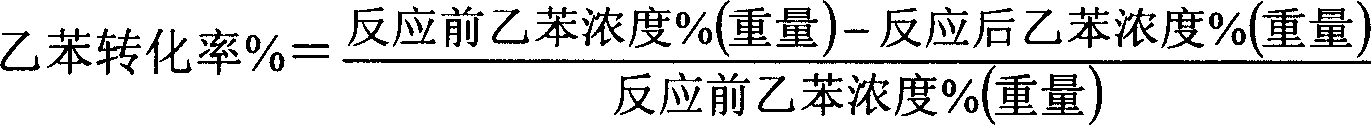

Low-water ratio ethylbenzene dehydrogenation catalyst

ActiveCN1981929AIncrease alkalinityHigh activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationRare earth

A catalyst for dehydrogenating ethylbenzene in the condition of low water ratio is prepared through adding at least two compounds of light RE elements other than Ce, and at least one oxide of metal chosen from Ca, Mg, Ba, B, Sn, Pb, Cu, Zn, Ti, Zr, V and Mo to the Fe-K-Ce-W system. It has high stability and activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

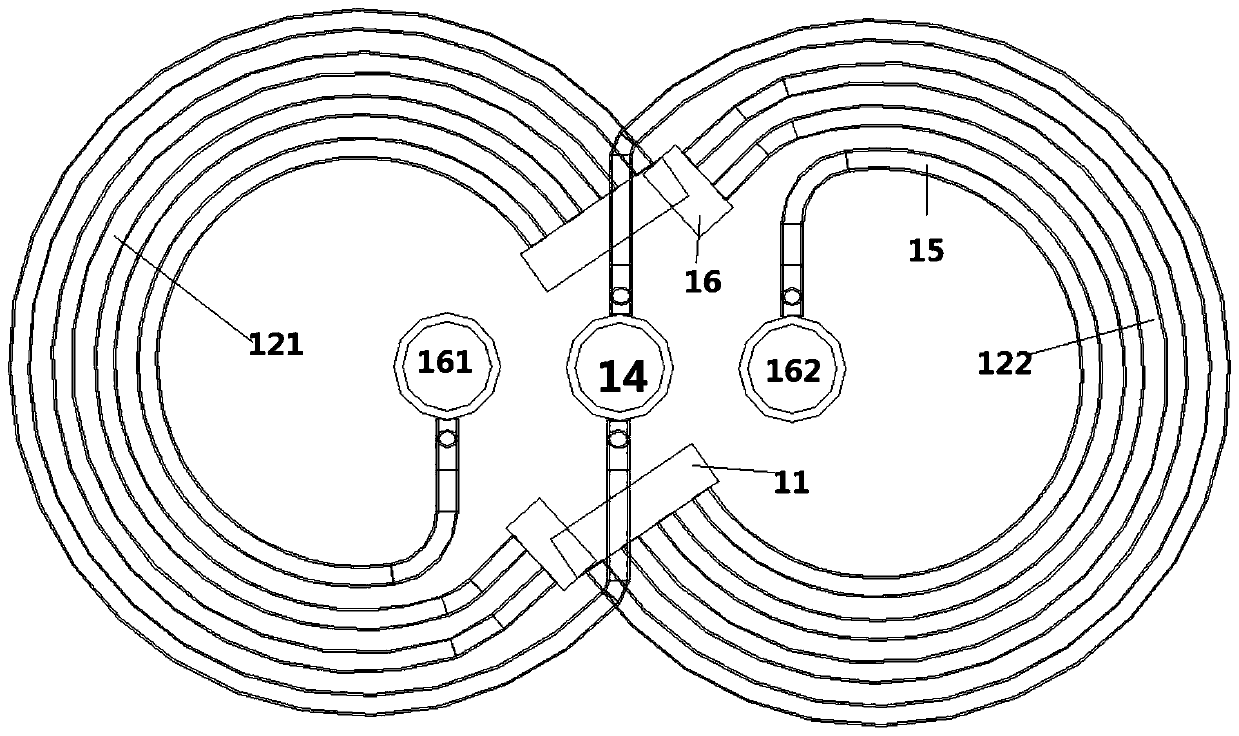

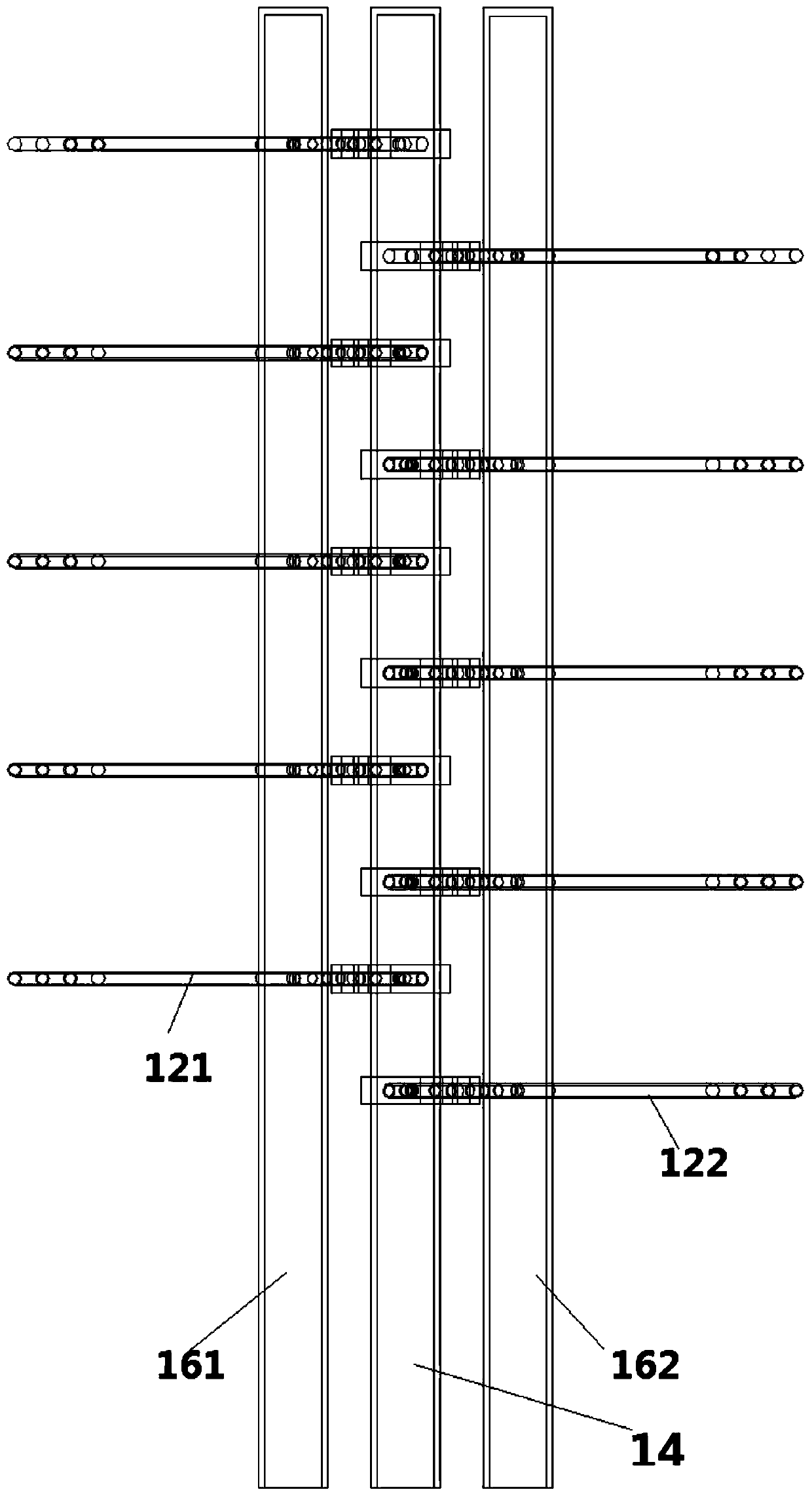

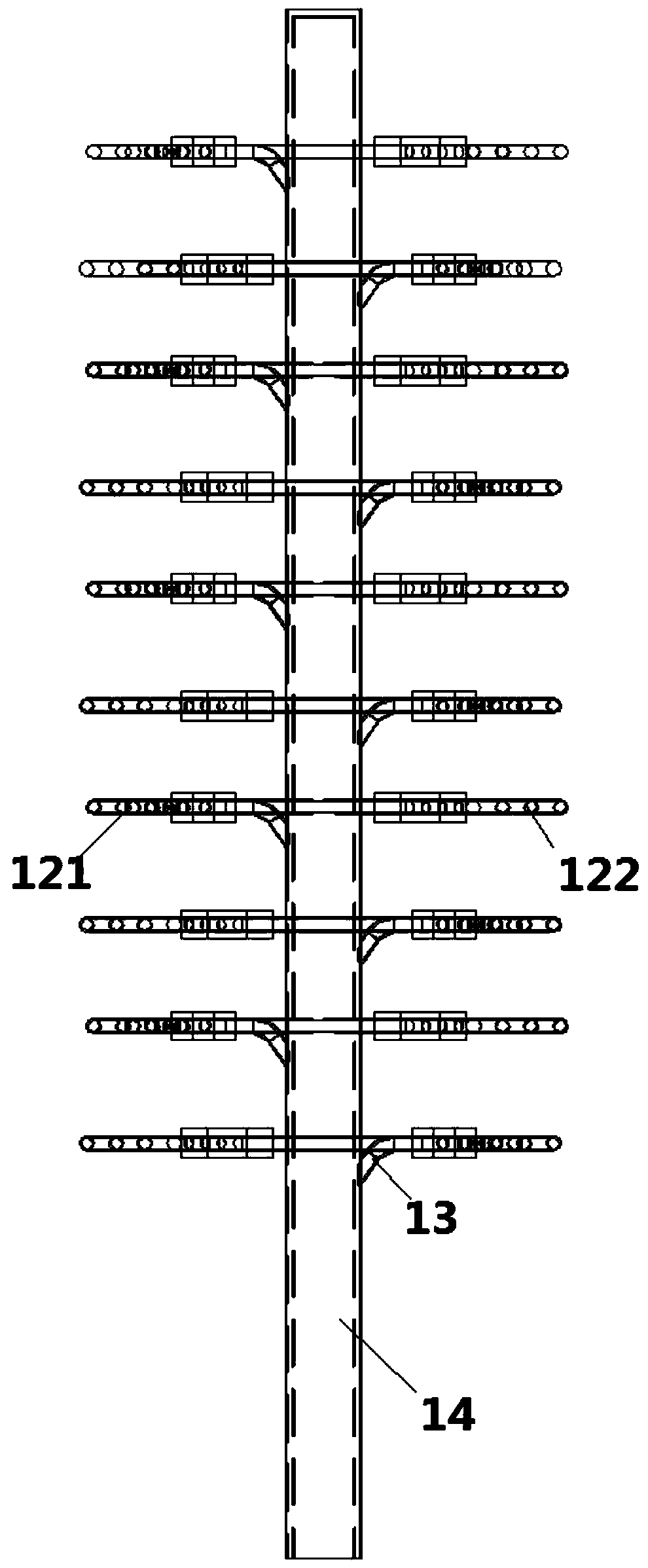

Three-riser pulsating tube bundle

ActiveCN110081739AIncreased vibration rangeImprove heat transfer performanceHeat storage plantsStationary tubular conduit assembliesEngineeringHeat transfer

The invention provides a three-riser pulsating tube bundle. The three-riser pulsating tube bundle comprises a middle riser, a left risers, a right riser and a plurality of coil tubes, wherein each coil tube comprises a plurality of arc-shaped heat exchange tubes, the ends of adjacent heat exchange tubes communicate, the plurality of heat exchange tubes form a series structure, the ends of the heatexchange tubes form free ends of the heat exchange tubes, the inlet of the middle riser is connected with a pulsating flow generating device for generating pulsating flow in the heat exchange tubes,the coil tubes comprise a left coil tube and a right coil tube, one side of the middle riser is connected with the inlet of the left coil tube, the other side is connected with the inlet of the rightcoil tube, the outlet of the left coil tube is connected with the left riser, and the outlet of the right coil tube is connected with the right riser. According to the pulsating tube bundle with the novel structure, more coil tubes are arranged in a limited space to increase the vibration range of the pulsating tube bundle, so that heat transfer and descaling are enhanced.

Owner:SHANDONG UNIV

Catalyst for producing low-carbon olefin by using synthesis gas and preparation method of catalyst

ActiveCN104148106AHighly uniform dispersionIncrease the number ofOrganic chemistryMolecular sieve catalystsActive componentLanthanide

The invention relates to a catalyst for producing low-carbon olefin by using synthesis gas and a preparation method of the catalyst, and is mainly used for solving the problem of low CO conversion rate and low low-carbon olefin selectivity in reaction for preparing the low-carbon olefin by using the synthesis gas in the prior art. The catalyst consists of a composite carrier and active components, wherein the composite carrier consists of alpha-aluminium oxide and a ZSM-5 molecular sieve; the silicon-aluminium ratio of the ZSM-5 molecular sieve is 40-200; the active components are loaded on the composite carrier and comprise the following compounds with chemical formulas by atomic ratio: Fe100AaBbCcOx, A is at least one of transition metals of Cu and Mn, B is at least one of lanthanide La and Ce, and C is at least one of alkaline metals of K and Cs; the weight of the composite carrier is 20%-80% of the weight of catalyst; by weight percent of the composite carrier, the weight of alpha-aluminium oxide is 20%-99% of the weight of the composite carrier. With the adoption of the technical scheme, the problem is well solved; the catalyst can be used for industrial production of the low-carbon olefin produced by using the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

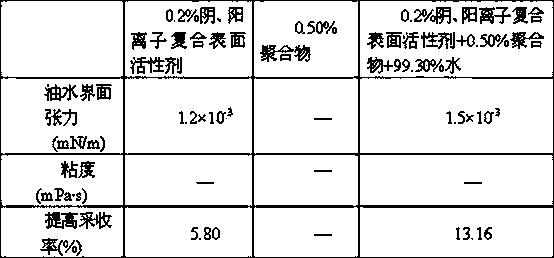

Method of displacing oil by anionic-cationic composite surfactant

ActiveCN103422840ALarge adsorption capacityLow critical micelle concentrationFluid removalDrilling compositionSURFACTANT BLENDOil well

The invention relates to a method of displacing oil by anionic-cationic composite surfactant and mainly solves the problems that the prior method of displacing oil by surfactant is low in oil displacement efficiency in tertiary oil recovery and an oil displacement system containing inorganic base is harmful to stratums and oil wells, corrosive to equipment and pipelines and difficult for demulsification. According to the technical scheme, crude oil is allowed to contact with oil-displacing agent, and the oil-displacing agent comprises, by weight percent, 0.01-5.0% of anionic-cationic composite surfactant, 0.01-3.0% of polymer, and 92.0-99.98% of injected water. The problems are solved well. The method is applicable to tertiary oil recovery for oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel catalyst for selective hydrogenation

ActiveCN101147871AGood activity at low temperatureGood choiceHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementNickel catalyst

The present invention relates to a nickel catalyst for selective hydrogenation. The catalyst composition includes the following components: (by wt%) (a), 5.0-40.0% of metal nickel or its oxide; (b), 0.01-20.0% of at least one element selected from molybdenum or tungsten or its oxide; (c), 0.01-10.0% of at least one element selected from rare earth elements or its oxide; (d), 0.01-2.0% of at least one element selected from IA or IIA of periodic table of chemical elements or its oxide; (e), 0-15.0% of at least one element selected from Si, P, B or F or its oxide; (f), 0-10.0% of at least one element selected from IVB of periodic table of chemical elements or its oxide; and (g), the rest is aluminium oxide. Said catalyst can be used for pyrolysis gasoline hydrotreating production.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Aluminium oxide carrier with composite holes structure and preparation method thereof

ActiveCN101121120AImprove hydrogenation activityExcellent high-resistant gelatinPhysical/chemical process catalystsRefining to eliminate hetero atomsPore distributionPore diameter

The invention relates to an alumina carrier with a composite pore structure and a preparation method thereof. The method mainly solves the technical problem that it is difficult to obtain macroporous alumina carriers with different pore distributions above 20 nanometers and the preparation method thereof in the prior art. In the present invention, the specific surface area of the alumina carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the pore volume with a pore diameter of less than 30 nanometers accounts for 5-60% of the total pore volume. The pore volume of 30 to 60 nanometers accounts for 20 to 75% of the total pore volume, and the pore volume with a pore diameter > 60 nanometers accounts for 20 to 60% of the total pore volume as a composite carrier; the preparation method of the composite carrier adopts firstly alumina A Mixing with alumina B, molding, drying at 50-100°C for 1-24 hours, and then roasting at 800-1150°C for 1-10 hours to obtain a technical solution to the composite carrier solves this problem well, and can be used for pyrolysis gasoline In the industrial production of hydrogen catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene by ethanol dehydration

ActiveCN101121624AReduce carbon deposition rateExtended service lifeMolecular sieve catalystsHydrocarbonsDegree CelsiusReaction temperature

The present invention relates to a preparation method of ethylene using the dehydration of ethanol, which is to solve the problem in the prior technology that: the reaction temperature is higher; the hollow speed is lower and the energy consumption is higher. The present invention uses ethanol as the raw material and water as the thinner; under the condition that the reaction temperature is 200- 400 Celsius system, the reaction pressure calculated by a pressure meter is 0-2MPa and the reaction weight hollow speed is 0.1-10 hours, the raw material is contacted with ZSM molecule screen catalyzer to produce a ethylene flow; thereinto the molar ratio between water and ethanol is 0-10: 1. The technical scheme can solve the problem greatly, which can be used in the industrial production of ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

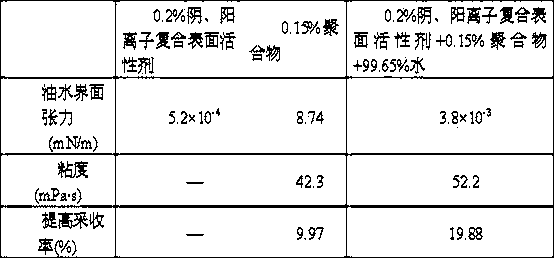

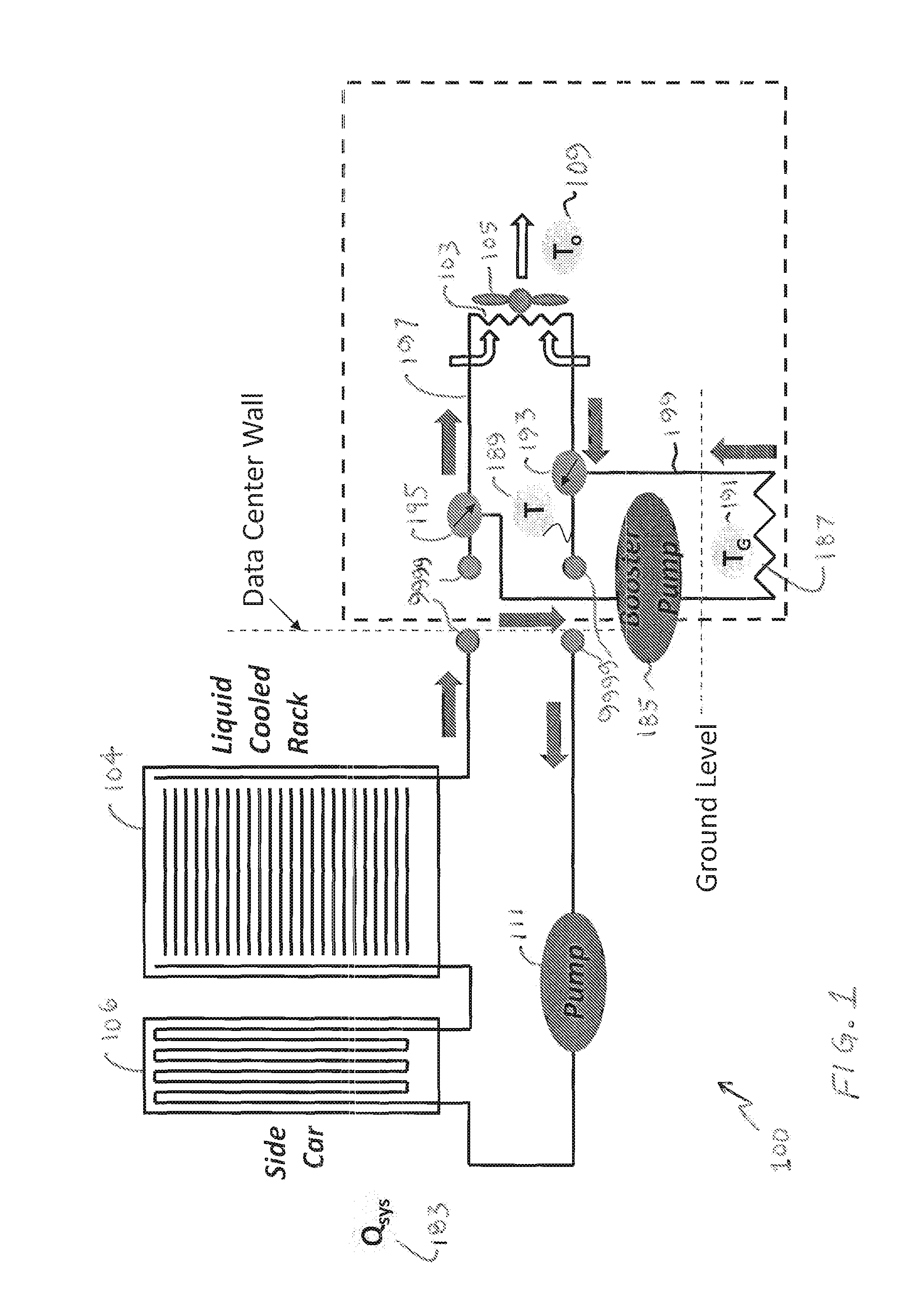

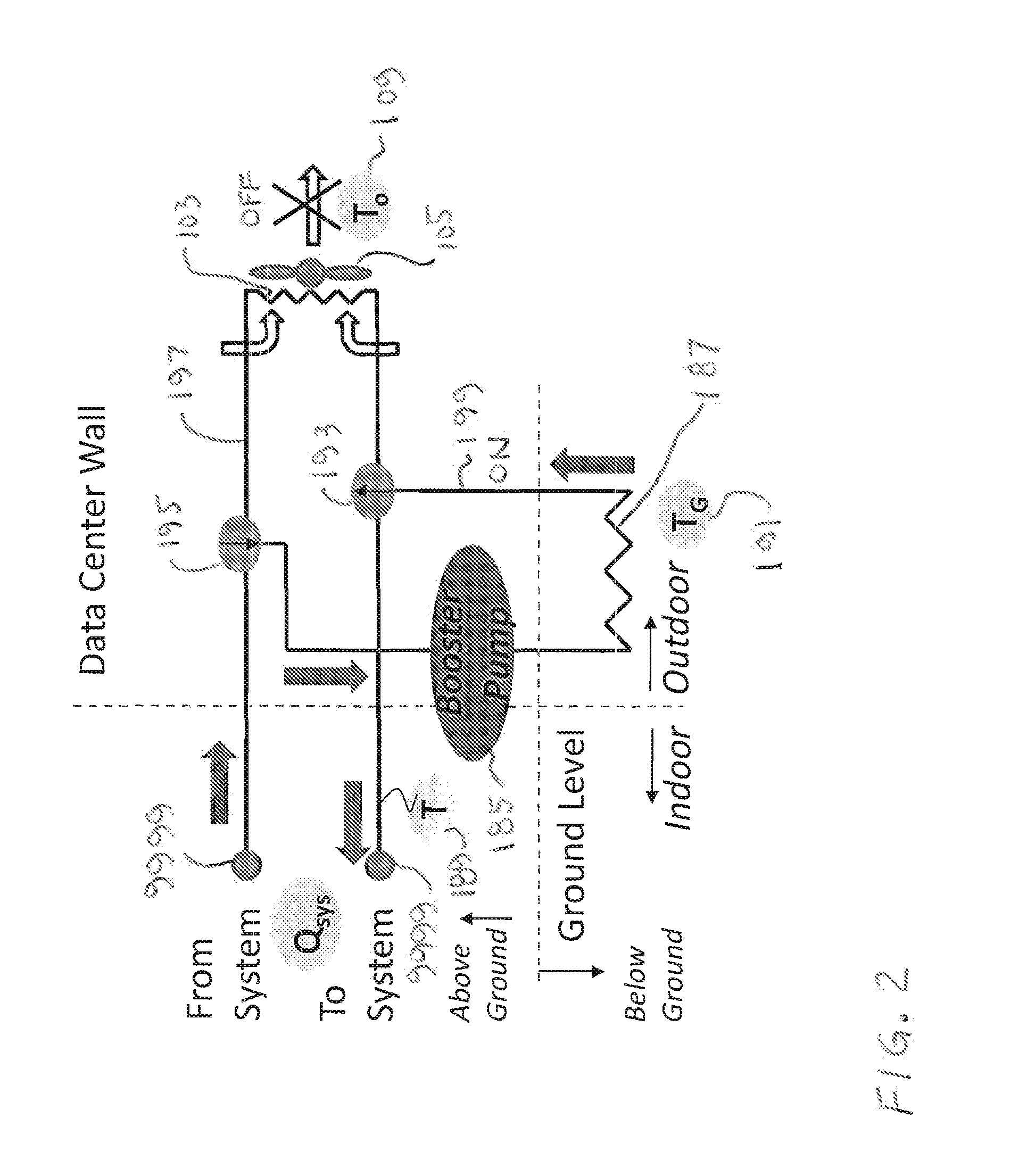

Energy efficient data center liquid cooling with geothermal enhancement

ActiveUS20130081781A1Improve cooling effectImprove technical effectOther heat production devicesDigital data processing detailsHeat transfer fluidEngineering

A data center cooling system is operated in a first mode, and has an indoor portion wherein heat is absorbed from components in the data center by a heat transfer fluid, and an outdoor heat exchanger portion and a geothermal heat exchanger portion. The first mode includes ambient air cooling of the heat transfer fluid in the outdoor heat exchanger portion and / or geothermal cooling of the heat transfer fluid in the geothermal heat exchanger portion. Based on an appropriate metric, a determination is made that a switch should be made from the first mode to a second mode; and, in response, the data center cooling system is switched to the second mode. The second mode is different than the first mode.

Owner:IBM CORP

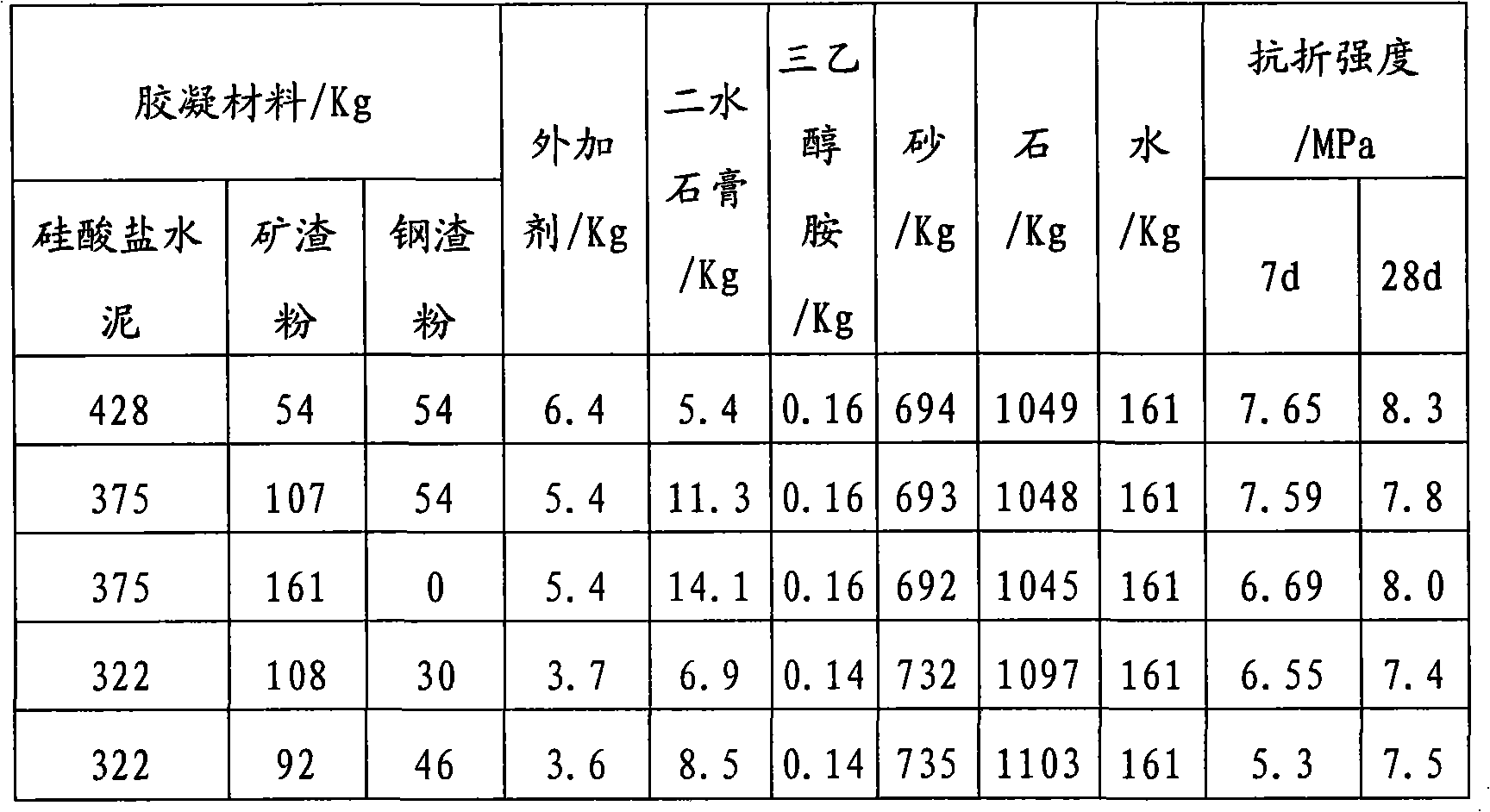

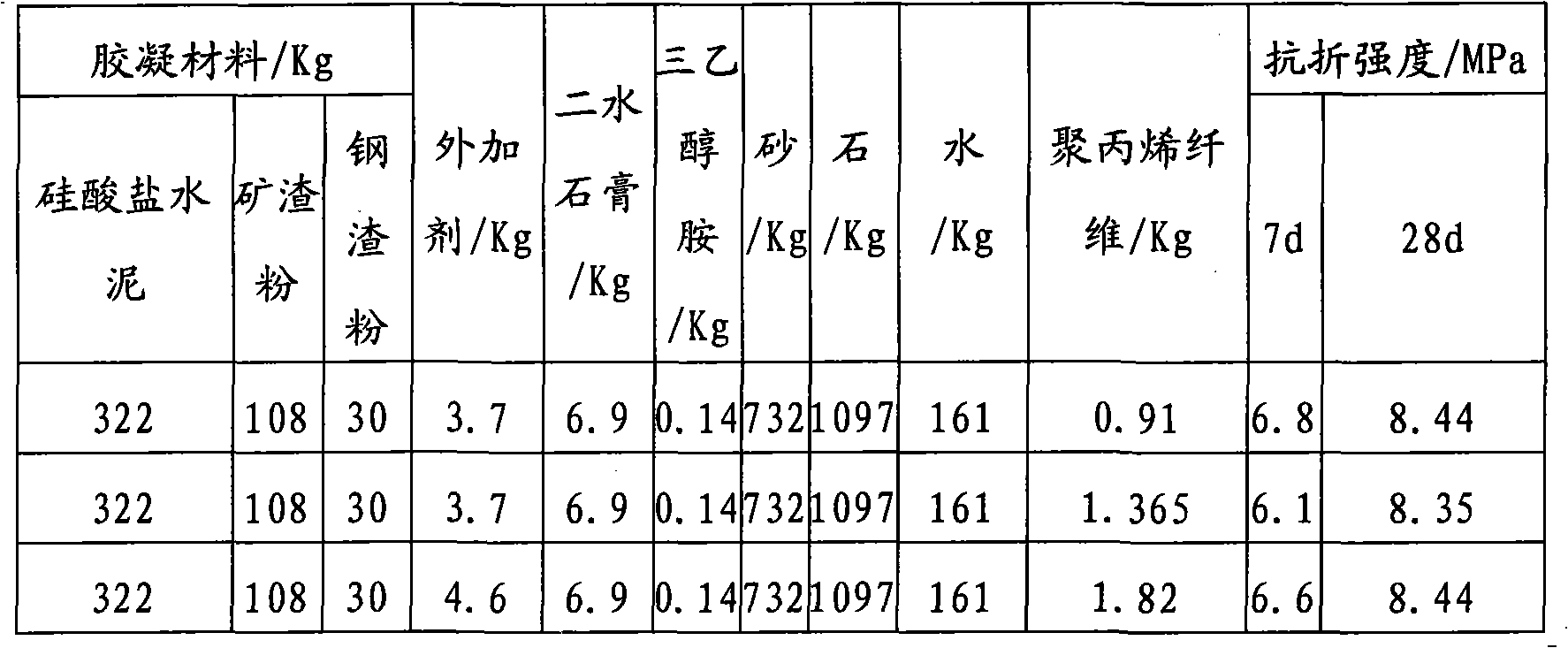

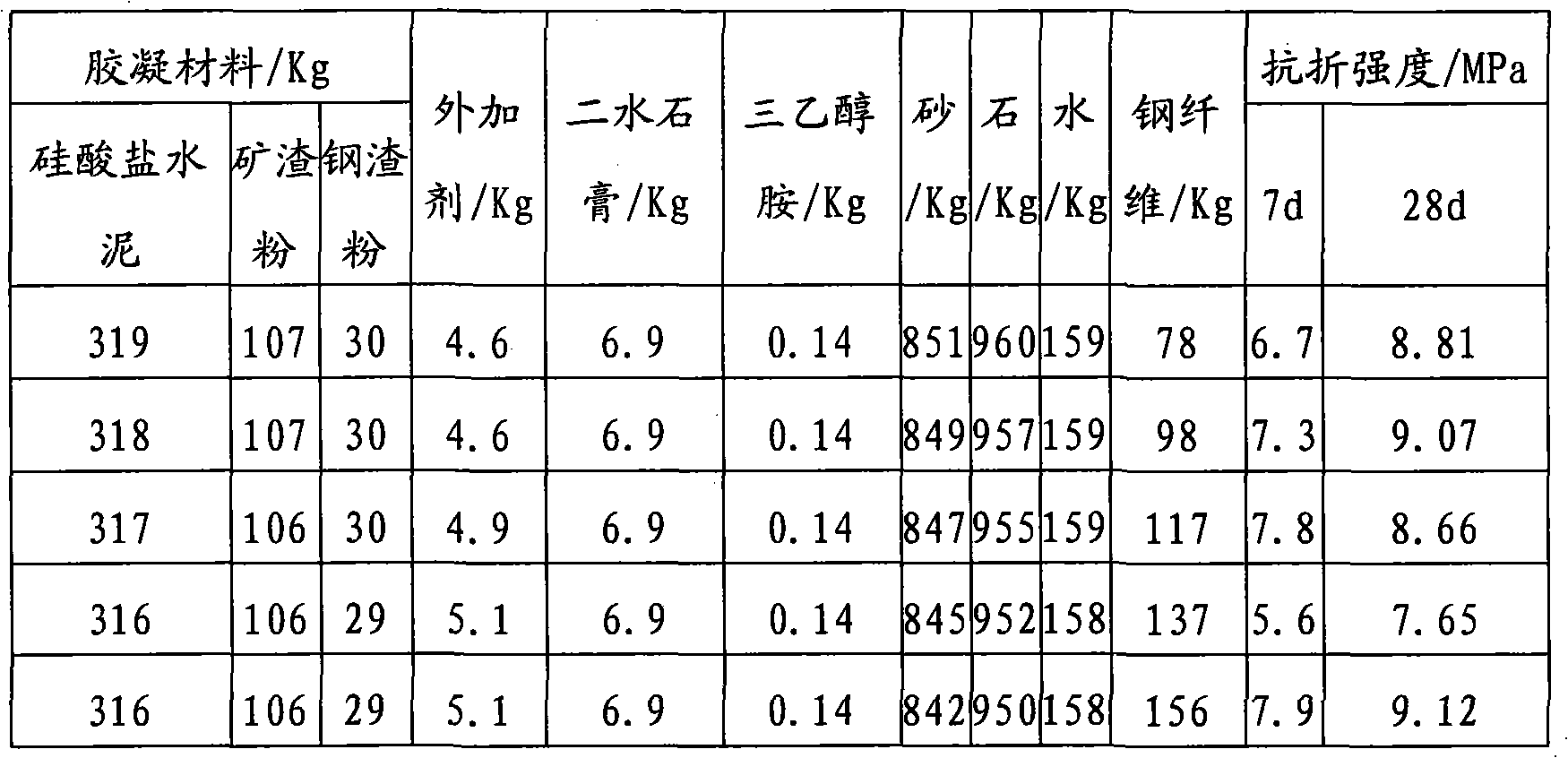

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066AImprove compactnessImprove flexural strengthSolid waste managementSlagSodium fluoride

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

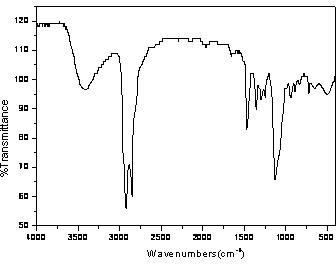

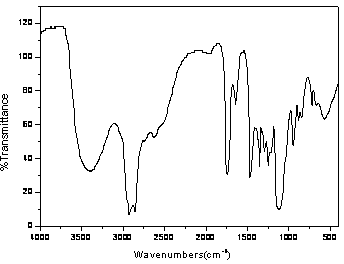

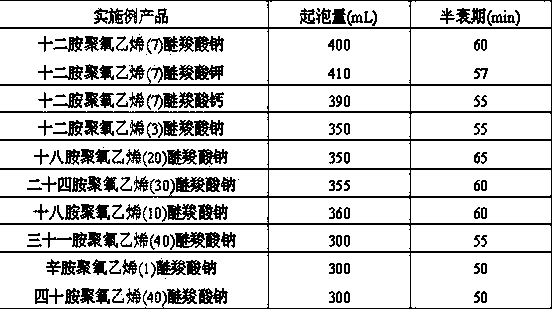

Fatty amine polyoxyethylene ether carboxylate and preparation method thereof

ActiveCN103421174AImprove hydrophilicityImprove stabilityOrganic compound preparationDrilling compositionAlkaline earth metalPolymer science

The present invention relates to a fatty amine polyoxyethylene ether carboxylate and a preparation method thereof, wherein problems that the foaming agent has poor thermal stability, produces precipitate after contacting divalent ions, and can not meet requirements of high temperature and high salinity stratum foam flooding in the existing foam flooding enhanced oil extraction technology are mainly solved with the present invention. The technical scheme comprises that: a fatty amine polyoxyethylene ether carboxylate having a molecule general formula (I) and a preparation method thereof are adopted, wherein M is one selected from an alkali metal, an alkaline earth metal or an ammonium group, R is a C8-C40 alkyl, and the sum of m and n is an integer of 1-40. With the technical scheme, the problems in the prior art are well solved, and the fatty amine polyoxyethylene ether carboxylate can be used for foam flooding enhanced oil extraction. The formula (I) is as the follow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene glycol

ActiveCN101475443AImprove technical effectOrganic compound preparationHydroxy compound preparationOxalateHydrogen

The invention relates to a method for producing glycol, which mainly solves the problem that catalysts in the prior art are poor in stability and short in regeneration period. By adopting a technical proposal of taking oxalate as raw material, taking polar or nonpolar solvent as thinner and allowing the raw material to be in contact with and react with a copper-bearing catalyst so as to form glycol-containing effluent at a temperature between 120 and 300 DEG C, at a weight space velocity between 0.01 and 10 hours, with the hydrogen / ester molar ratio of 5-300:1, under the reaction pressure between 0.1 and 10.0 MPa, under the condition that the mass fraction of the oxalate is between 0.1 and 100 percent, the method solves the problem well, and can be used in the industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

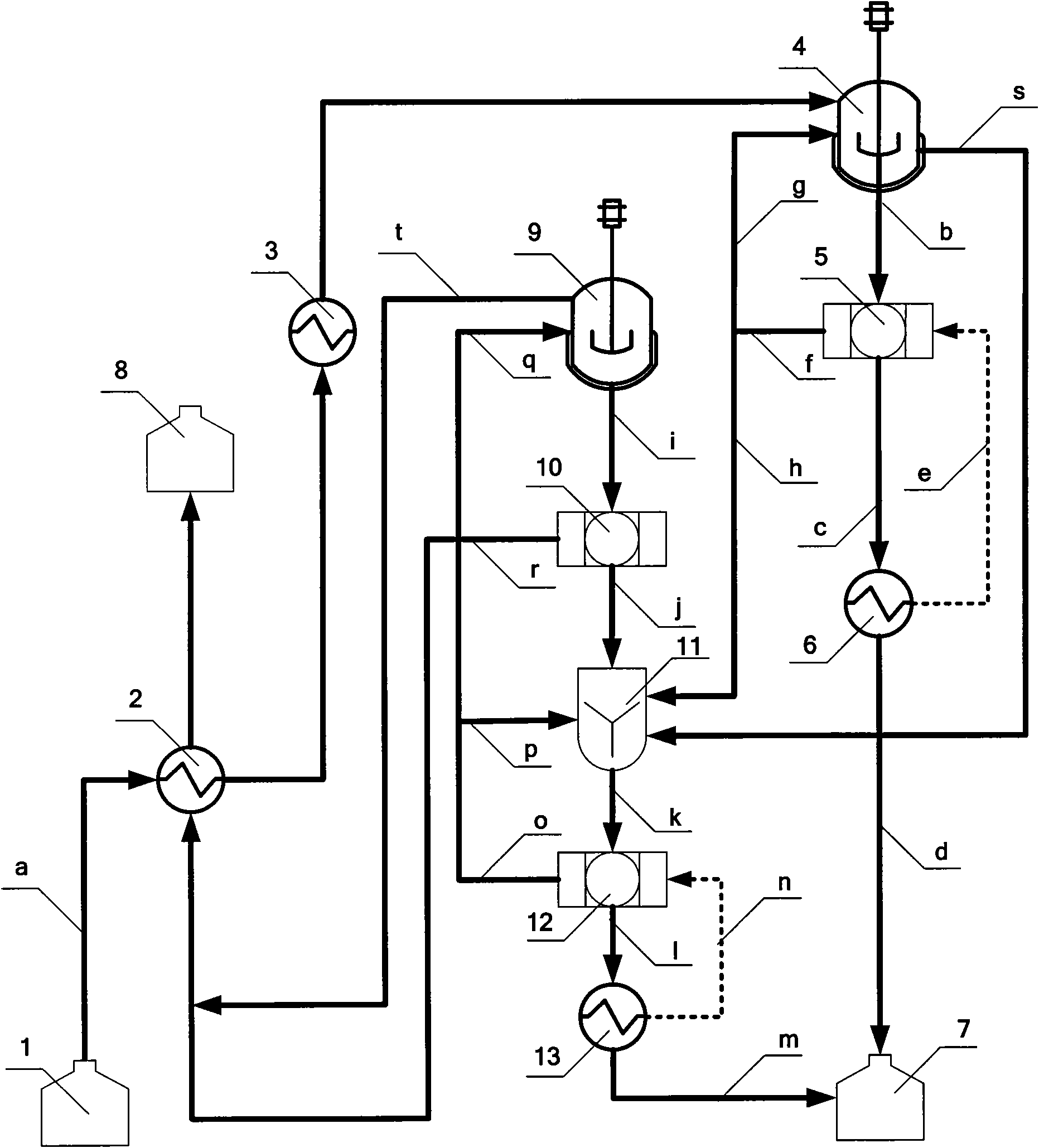

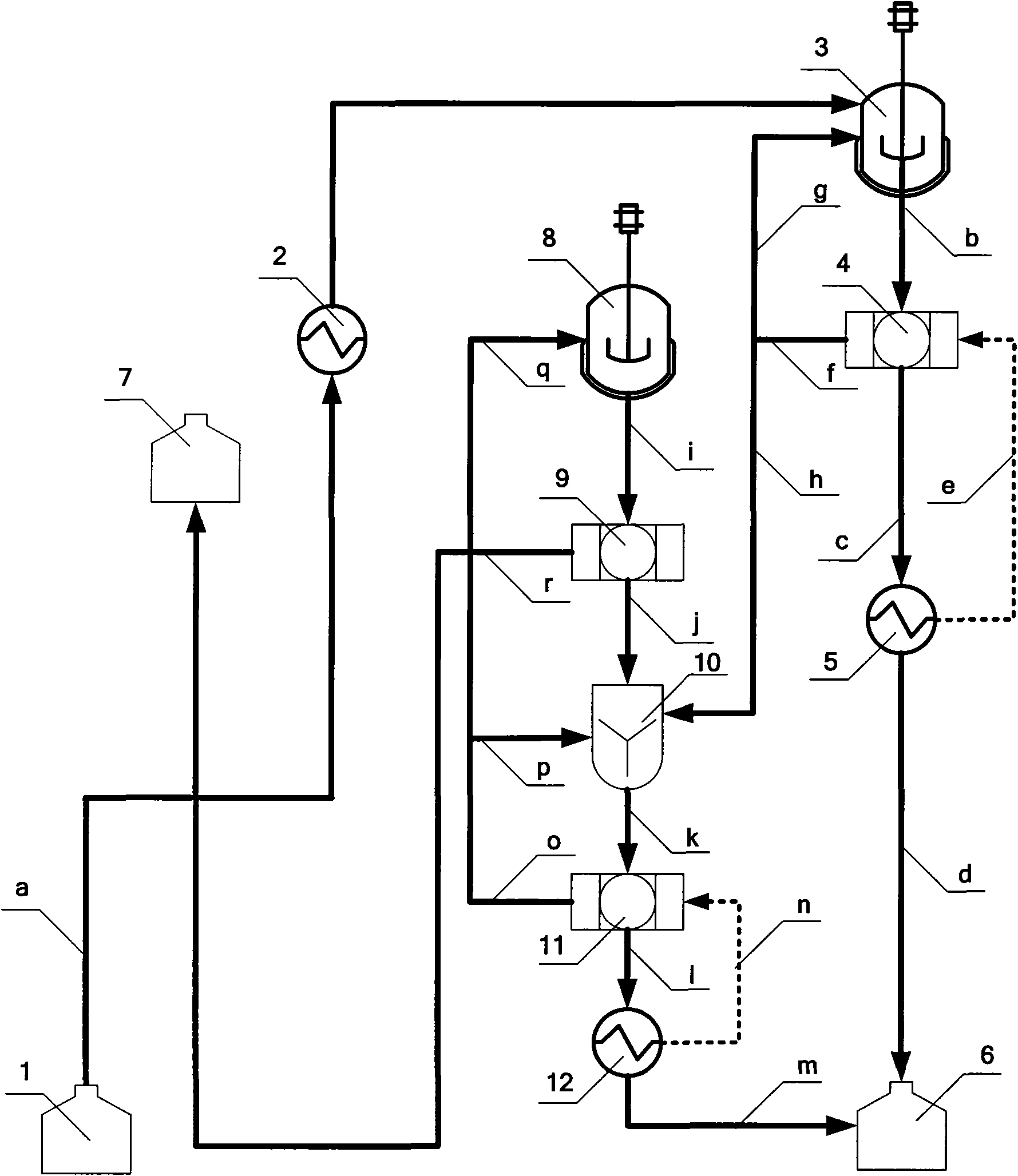

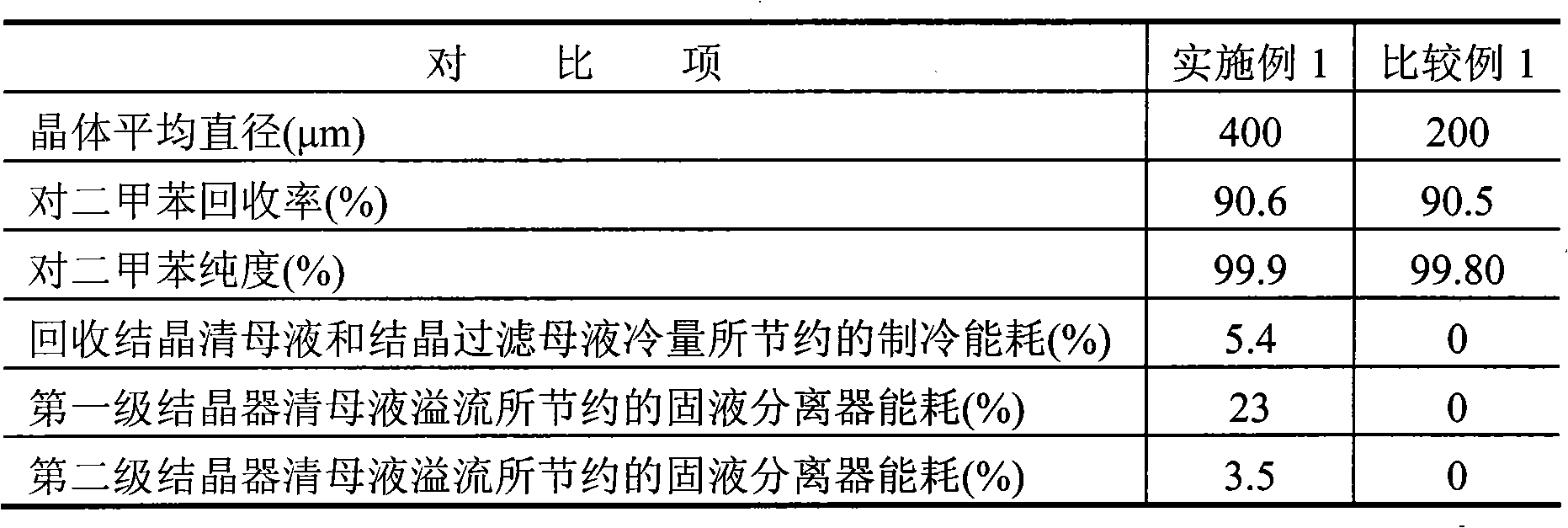

Method for preparing p-xylene by separating and crystallizing mixed xylenes

ActiveCN101941883AReduce energy consumptionReduce cooling energy consumptionHydrocarbonsCrystallisation purification/separationEnergy consumptionCrystallization

The invention relates to a method for preparing p-xylene by separating and crystallizing mixed xylenes, and mainly solves the problem of large energy consumption in a crystal separating process in the prior art. To well solve the problem, the invention adopts the following technical scheme of preparing the p-xylene by separating and crystallizing the mixed xylenes that: p-xylene crystal I and crystallization filtered stock I are obtained by crystallizing mixed xylenes in a primary crystallizer and separating crystal mush; the crystal I is melted by heat exchange, is partially returned to a first solid-liquid separator, and partially enters a product tank; the crystallization filtered stock I is separated into two streams, one stream returns to the crystallizer, and the other stream entersa pulping tank; one part of crystal mush in the primary crystallizer is cleared so as to obtain clear crystallization stock I which enters the pulping tank; p-xylene crystal II and crystallization filtered stock II are obtained by separating the crystal mush in a secondary crystallizer by a second solid-liquid separator; the crystal II enters the pulping tank, and separated after mixed heat exchange so as to obtain p-xylene crystal III and crystallization filtered stock III; the crystal III is melted by heat exchange, is partially returned to a third solid-liquid separator to be used as cleaning solution, and partially enters the product tank; the crystallization filtered stock II is separated into two streams, one stream returns to the secondary crystallizer, and the other stream enters the pulping tank; the crystallization filtered stock II and the mixed xylenes are subject to heat exchange and enter a stock tank; and the clear crystallization stock II and the mixed xylenes are subjected to heat exchange and enter the stock tank. The method can be used in p-xylene industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polydisperse polyacrylamide microsphere system and preparation method thereof

ActiveCN106866880AHigh effective solid contentSatisfies the characteristics of severely heterogeneous strataDrilling compositionPolymer scienceMicrosphere

The invention relates to a polydisperse polyacrylamide microsphere system and a preparation method thereof. The invention mainly overcomes the problem that nanometer, micrometer and millimeter polyacrylamide microspheres cannot be prepared in a same system in the prior art. The preparation method comprises the following steps: preparing nanometer polymer microspheres by using a multi-step polymerization method according to the mechanism of reversed-phase microemulsion polymerization; then supplementing a water phase, adjusting a ratio of an oil phase to an emulsifier to the water phase and the usage amount of an initiator and synthesizing submicron polymer microspheres according to the mechanism of reversed-phase emulsion polymerization; and supplementing the water phase and the initiator and continuing synthesis of micrometer to millimeter polymer particles. Thus, the above-mentioned problem is overcome; and the prepared polydisperse polyacrylamide microsphere system has the characteristics of high effective solid content, inclusion of nanometer, micrometer and millimeter polymer microspheres and capacity of meeting requirements of severe heterogeneous formations, and can be directly used or cooperatively used with other oil-field chemicals on site for in-depth profile control, water plugging, oil displacement or other recovery-efficiency-improving operations for tertiary oil recovery in an oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

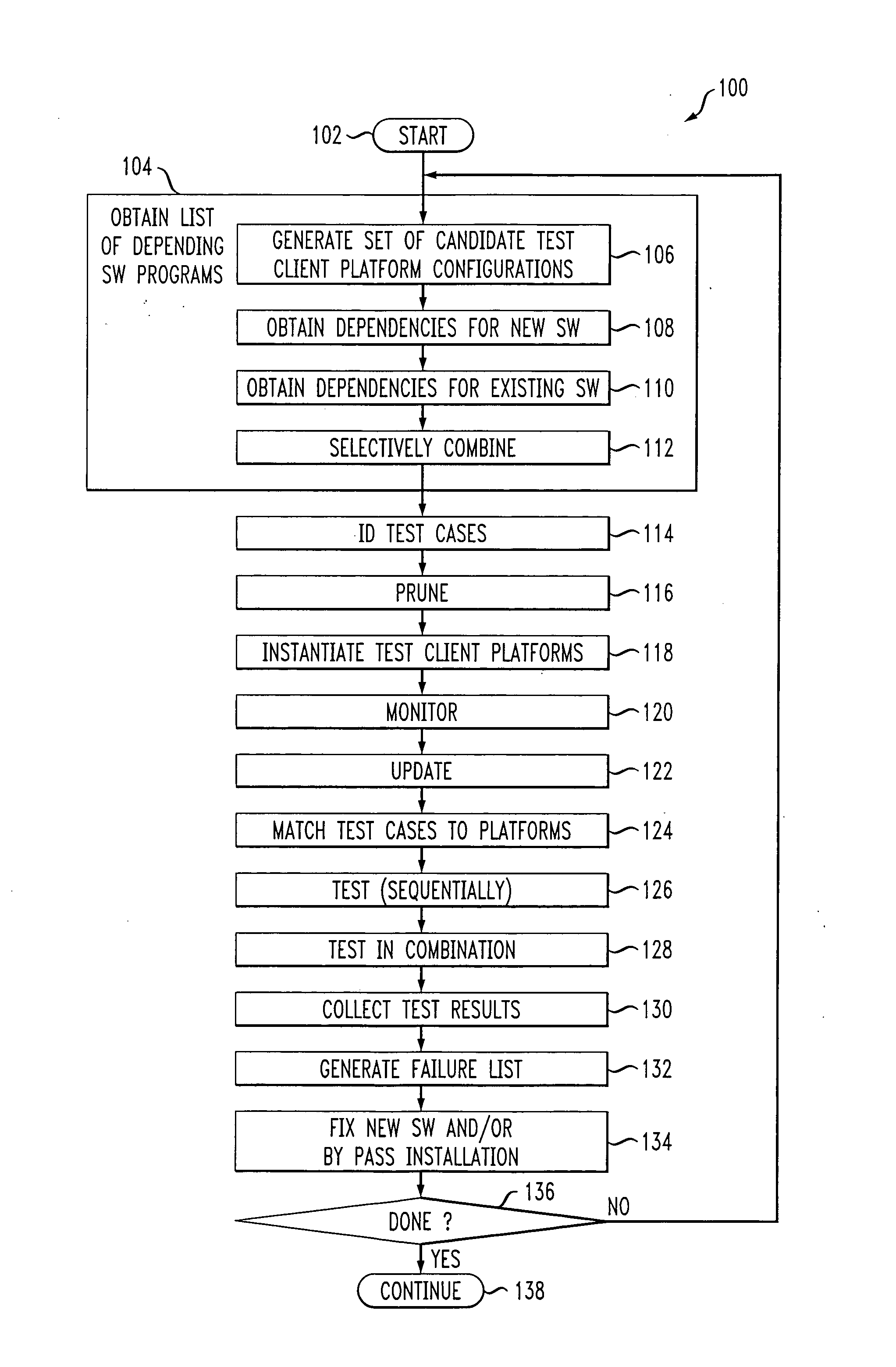

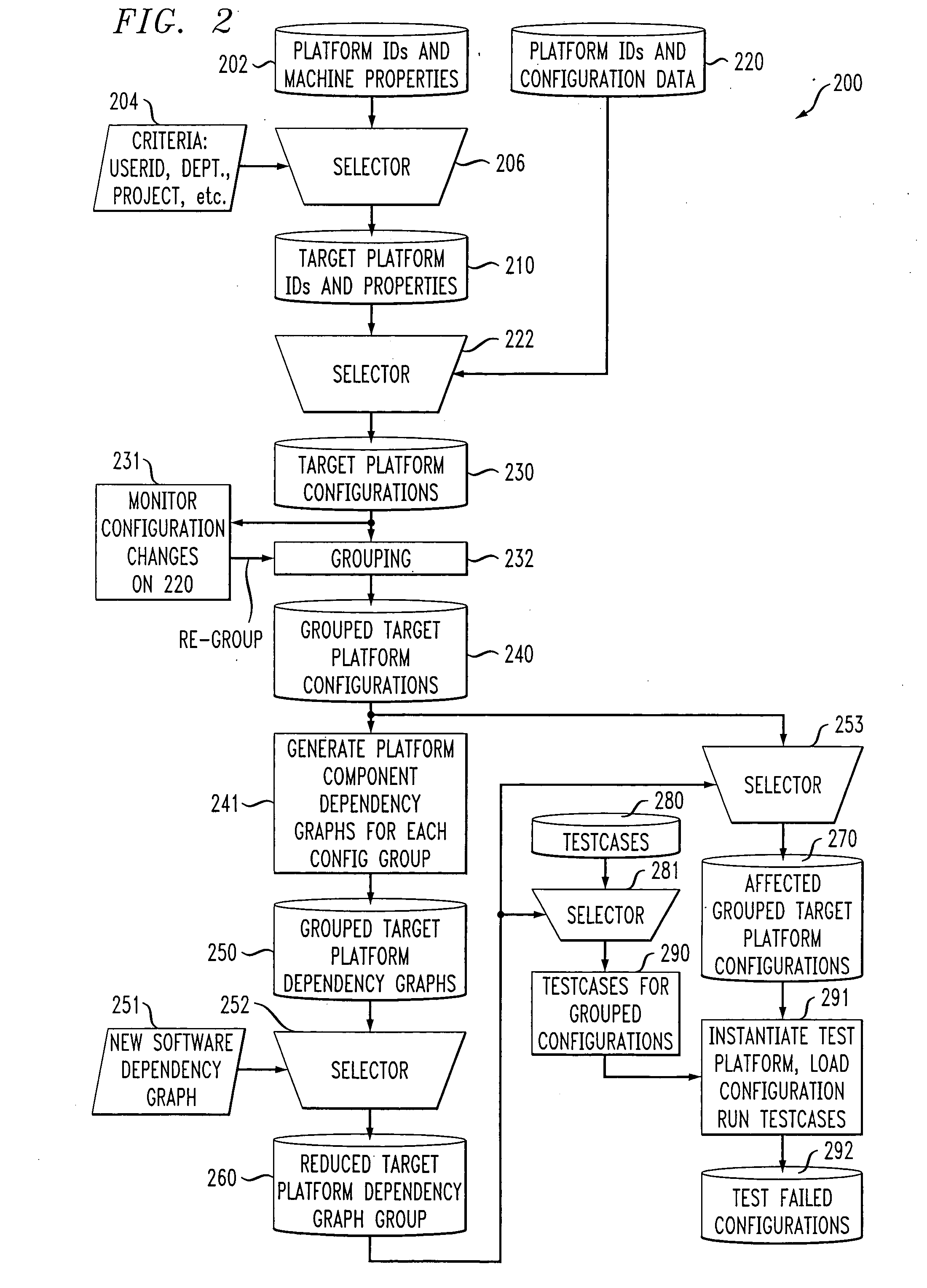

Method and apparatus for testing software

InactiveUS20070214391A1Shorten test timeImprove technical effectError detection/correctionProgram planningClient-side

Techniques are provided for testing new software slated to be deployed on a target machine population with a number of target machines having a number of existing software programs. Method steps can include obtaining a list of depending software programs on selected ones of the target machines. The list can include those of the existing software programs which depend on the new software and / or those of tile existing software programs on which the new software depends. The steps can further include identifying relevant test cases based on the list of depending software programs, instantiating a plurality of test client platforms characteristic of the target machine population, and testing the relevant test cases on the plurality of test client platforms to identify failures.

Owner:IBM CORP

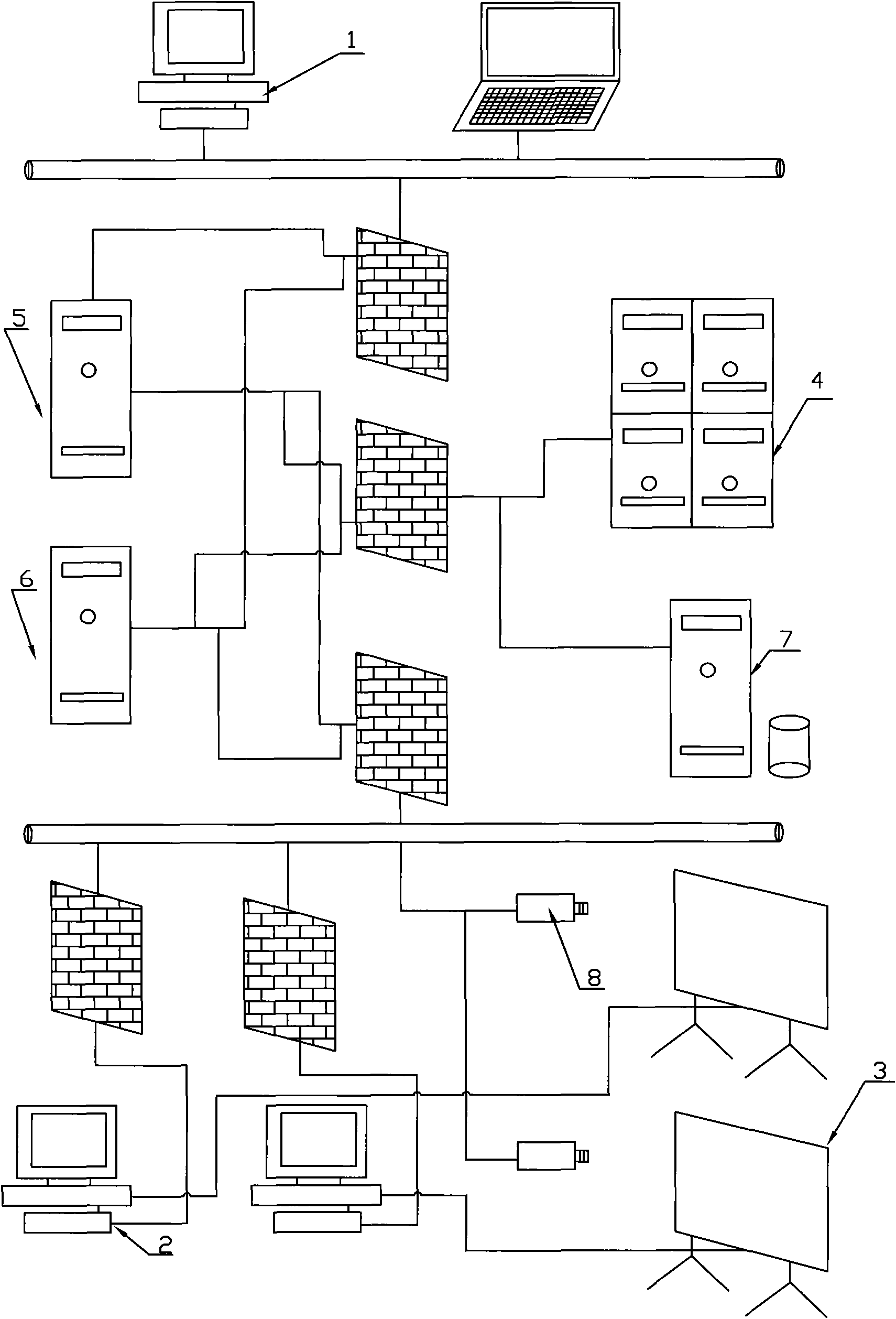

Remote information issuing and monitoring system based on wide area network and control method thereof

ActiveCN101888409AImprove technical effectOvercome the conditions of the harsh natural environmentClosed circuit television systemsTransmissionMonitoring siteGraphics

The invention provides a remote information issuing and monitoring system based on a wide area network and a control method thereof. As the wide area network remotely controls (a local area network or the wide area network) to issue caution, publicity, rebroadcasting and other information, such as display text, characters and graphics, video, and the like according to user instructions, the system can realize that remote broadcasting control, field monitoring and playing content feedback are carried out on a display screen at any online websites, can provide real-time display situations of all websites for user viewing; and the invention greatly reduces the manufacturing, operation and maintenance cost of system hardware, has simple management and convenient use, is a new-generation LED networking multimedia control playing system management tool and can be widely applied to display and issue various media information at the real time.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com