Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about How to "Reduce carbon deposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

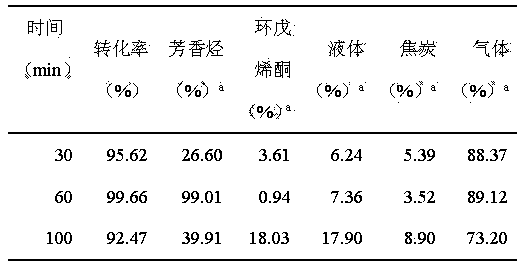

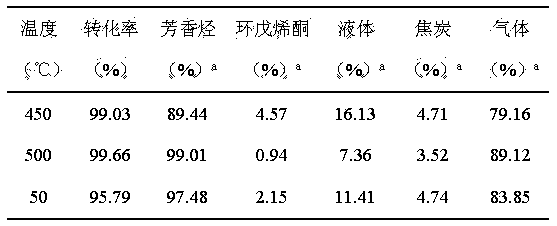

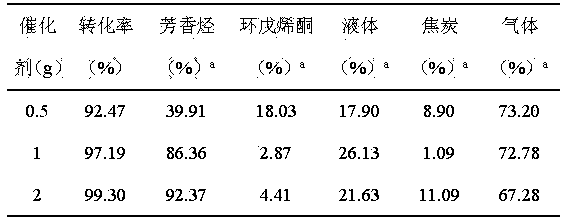

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

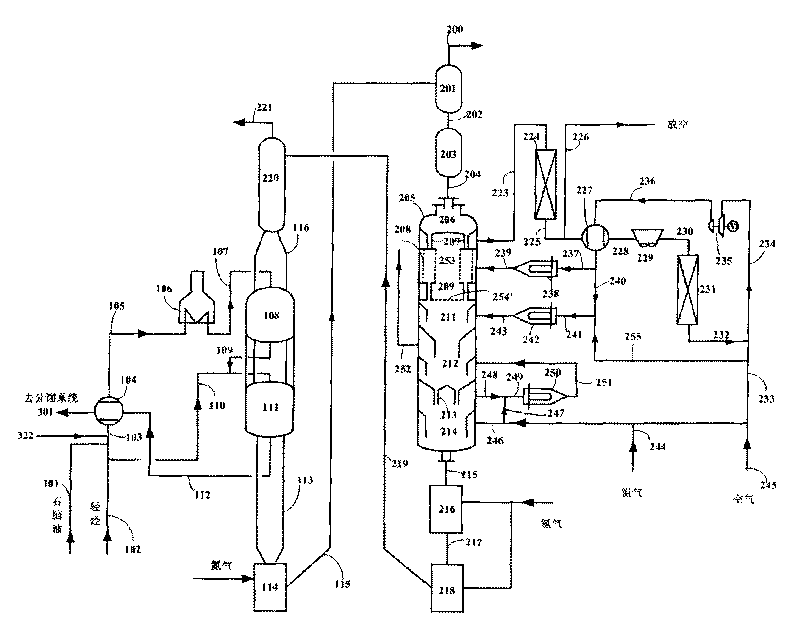

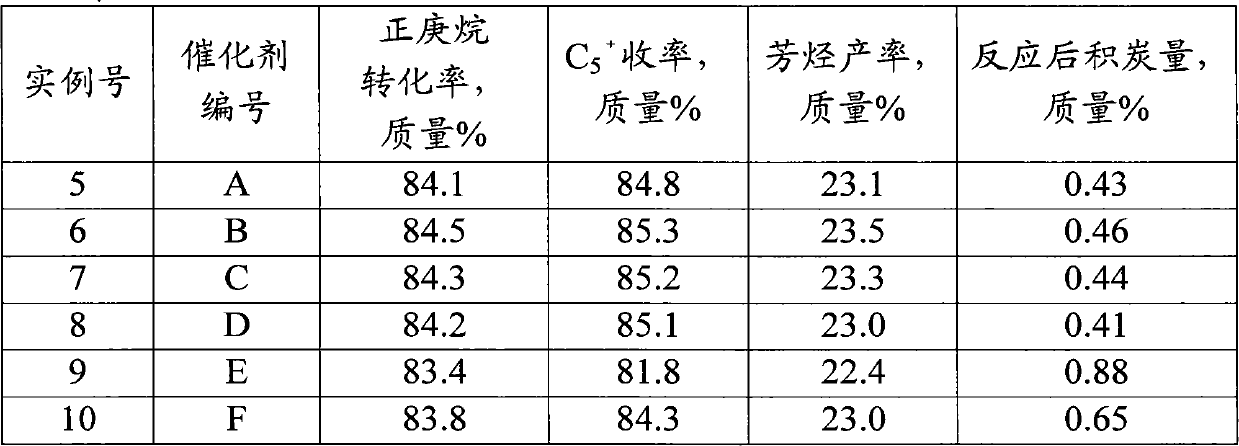

Modifying method for naphtha and light hydrocarbon aromatization

ActiveCN101747933ALower end pointReduce carbon deposition rateCatalytic naphtha reformingLiquid productHydrogen

A modifying method for naphtha and light hydrocarbon aromatization comprises: contacting naphtha and C3-C5 light hydrocarbon with aromatization catalyst in the presence of hydrogen-containing gas to carry out aromatization modifying reaction, wherein the reaction temperature is 250-600 DEG C, and the volume ratio of hydrogen to naphtha is 20-400. The method can convert naphtha with low octane value and low-carbon hydrocarbon into gasoline component with high octane value and excellent liquefied gas, the final distilling point of liquid product and the carbon-accumulating speed of catalyst areobviously reduced, and the service life of catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

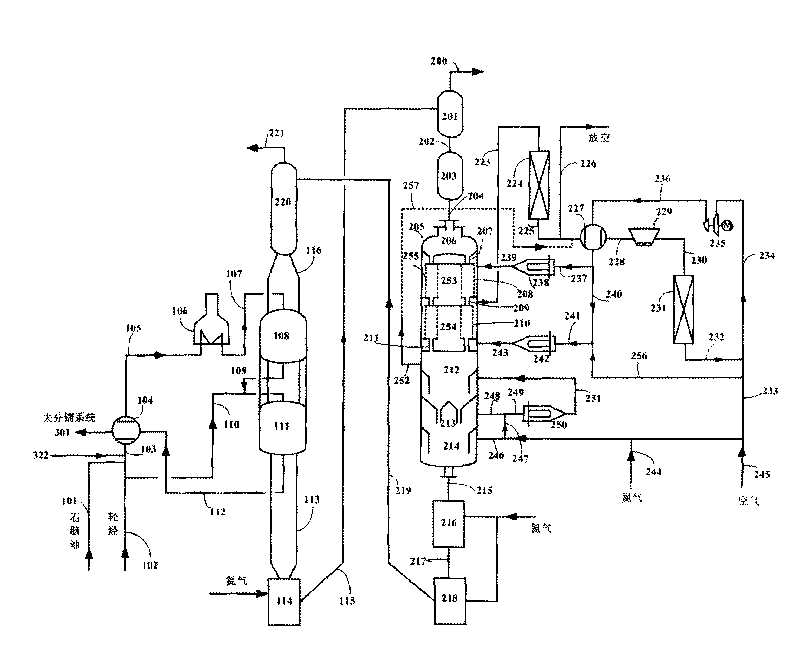

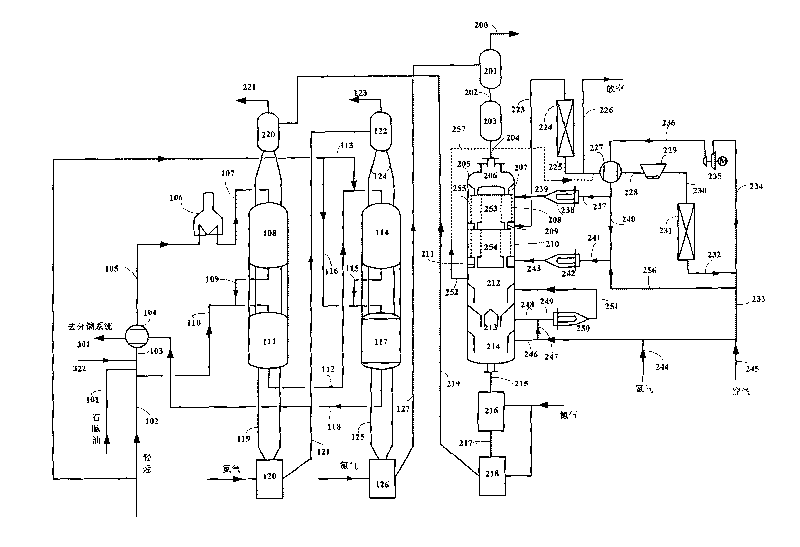

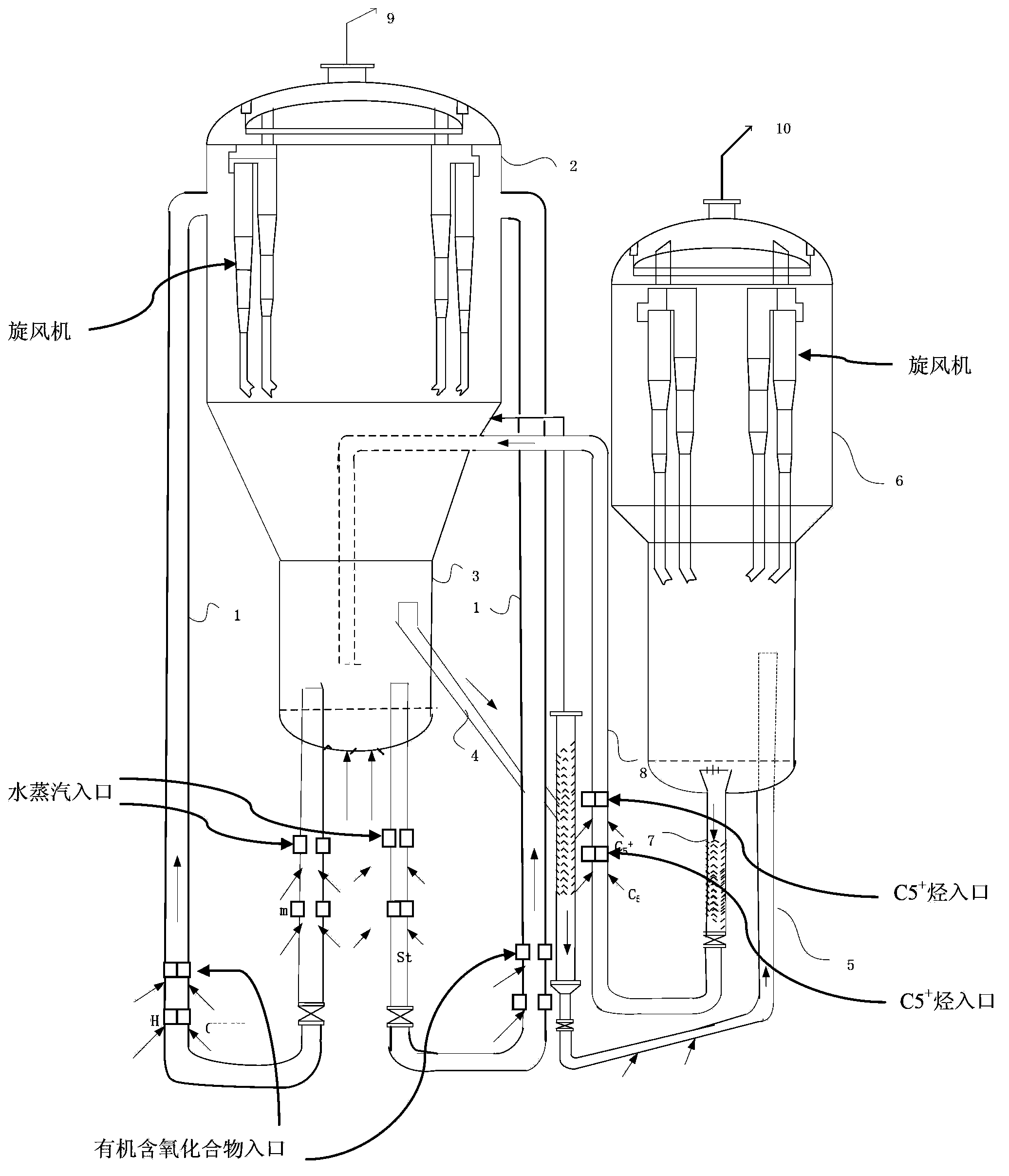

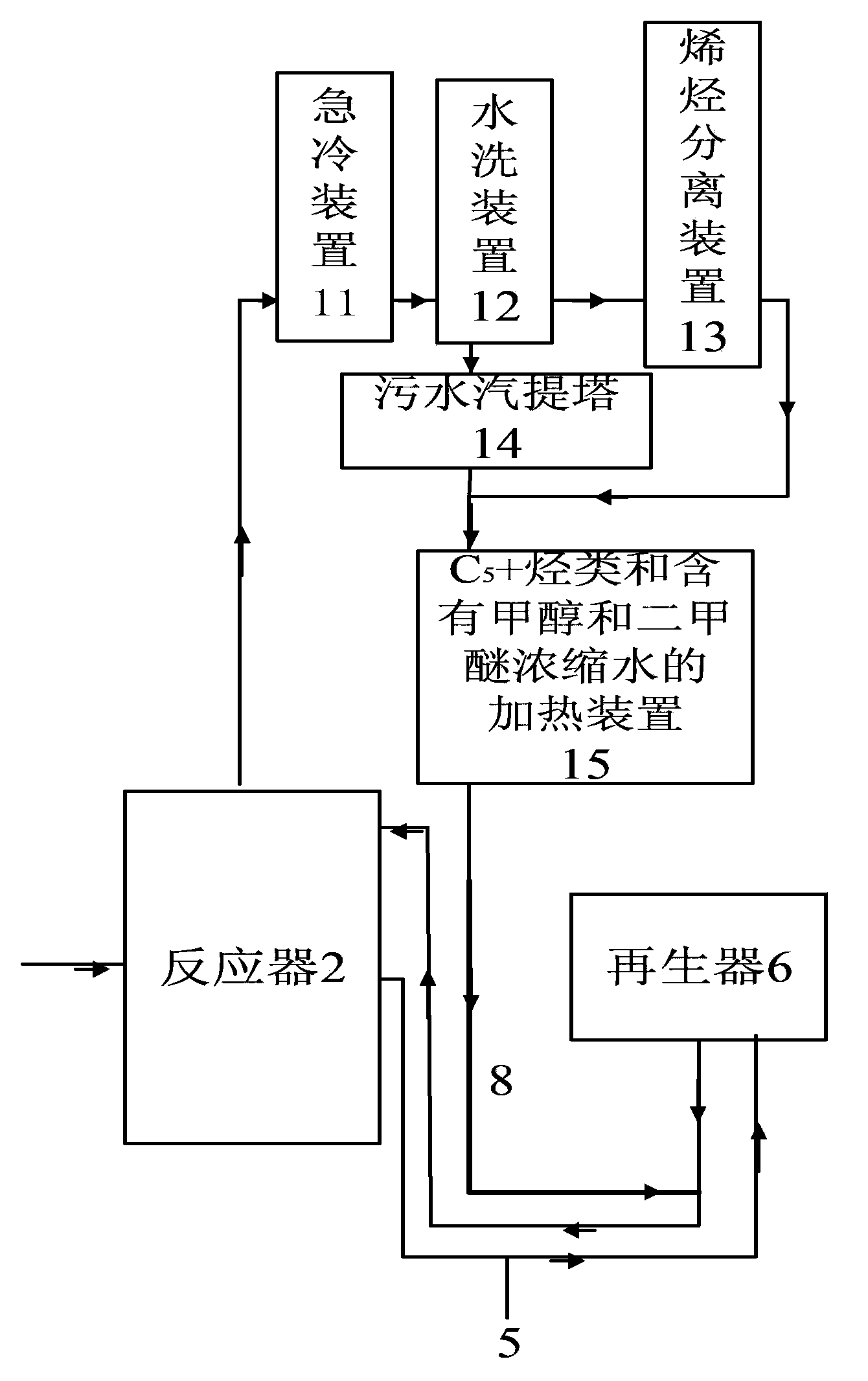

Catalytic cracking coupling process for preparing low-carbon olefin and C<5+> hydrocarbon by using organic oxygen-containing compound

ActiveCN103804110AHigh yieldLow yieldHydrocarbon from oxygen organic compoundsEthylene productionActive carbonCatalyst regeneration

The invention discloses a catalytic cracking coupling process for preparing low-carbon olefin and C<5+> hydrocarbon by using an organic oxygen-containing compound. The catalytic cracking coupling process comprises the following steps: converting the organic oxygen-containing compound into the low-carbon olefin under the effect of a catalyst in a reactor for preparing the low-carbon olefin by the organic oxygen-containing compound; in a catalyst regenerator, heating for oxidizing and decarbonizing a waste catalyst which enters the catalyst regenerator through a waste catalyst conveying pipeline from the reactor so as to regenerate a regenerated catalyst; conveying the regenerated catalyst back into the reactor by a regenerated catalyst conveying pipeline; introducing the C<5+> hydrocarbon into the regenerated catalyst conveying pipeline; under the catalytic effect of the catalyst, catalytically cracking the C<5+> hydrocarbon into the low-carbon olefin; and conveying the generated low-carbon olefin and the regenerated catalyst into the reactor by the regenerated catalyst conveying pipeline. According to the process disclosed by the invention, the high temperature of the regenerated catalyst is effectively utilized and the C<5+> hydrocarbon is cracked into the low-carbon olefin to form active hydrocarbon tank species, so as to shorten a reaction induction period, reduce the selectivity of converting the organic oxygen-containing compound into active carbon tank species and improve the yield of the low-carbon olefin.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

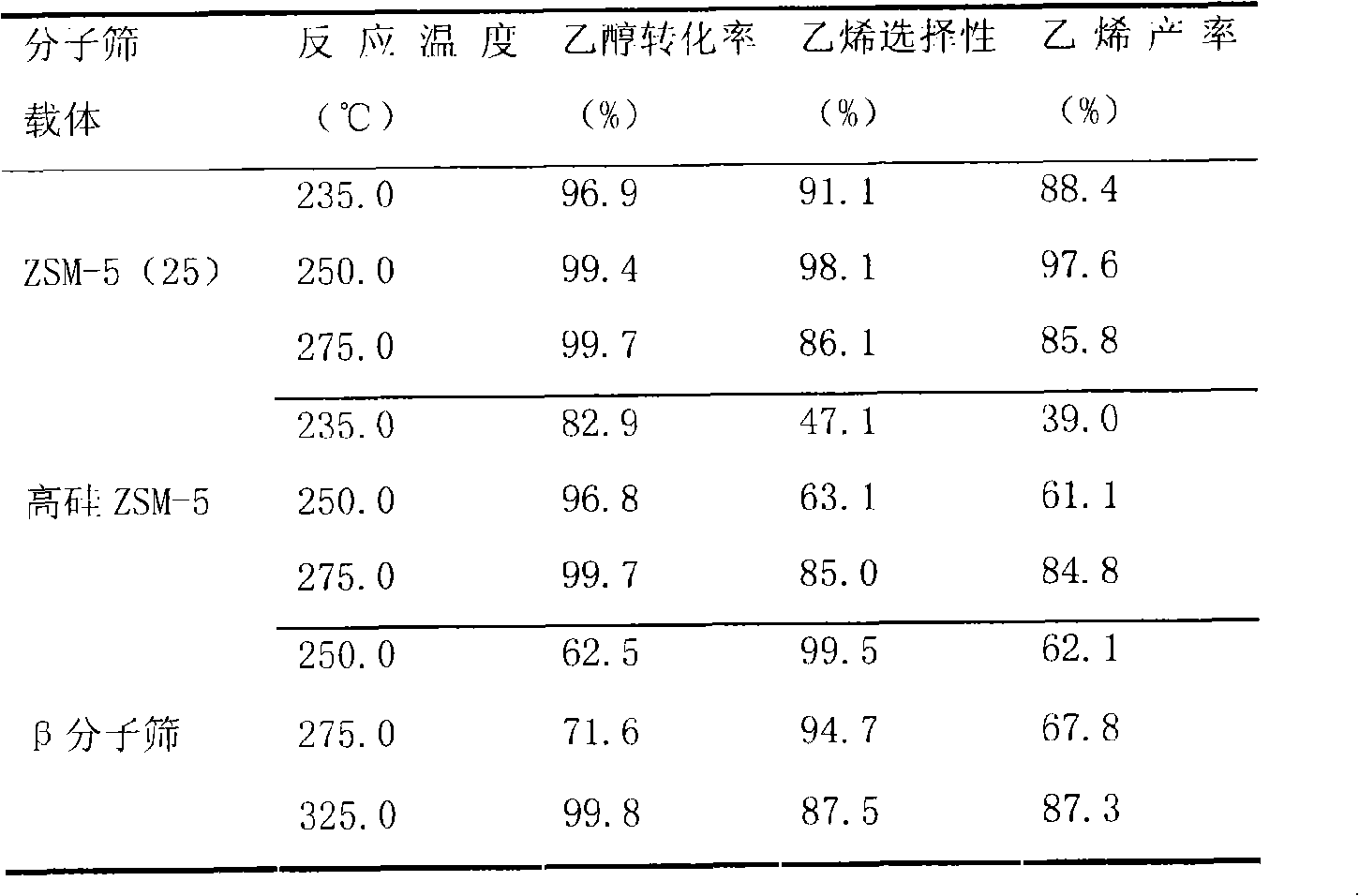

Method for preparing ethylene by ethanol dehydration

ActiveCN101121624AReduce carbon deposition rateExtended service lifeMolecular sieve catalystsHydrocarbonsDegree CelsiusReaction temperature

The present invention relates to a preparation method of ethylene using the dehydration of ethanol, which is to solve the problem in the prior technology that: the reaction temperature is higher; the hollow speed is lower and the energy consumption is higher. The present invention uses ethanol as the raw material and water as the thinner; under the condition that the reaction temperature is 200- 400 Celsius system, the reaction pressure calculated by a pressure meter is 0-2MPa and the reaction weight hollow speed is 0.1-10 hours, the raw material is contacted with ZSM molecule screen catalyzer to produce a ethylene flow; thereinto the molar ratio between water and ethanol is 0-10: 1. The technical scheme can solve the problem greatly, which can be used in the industrial production of ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

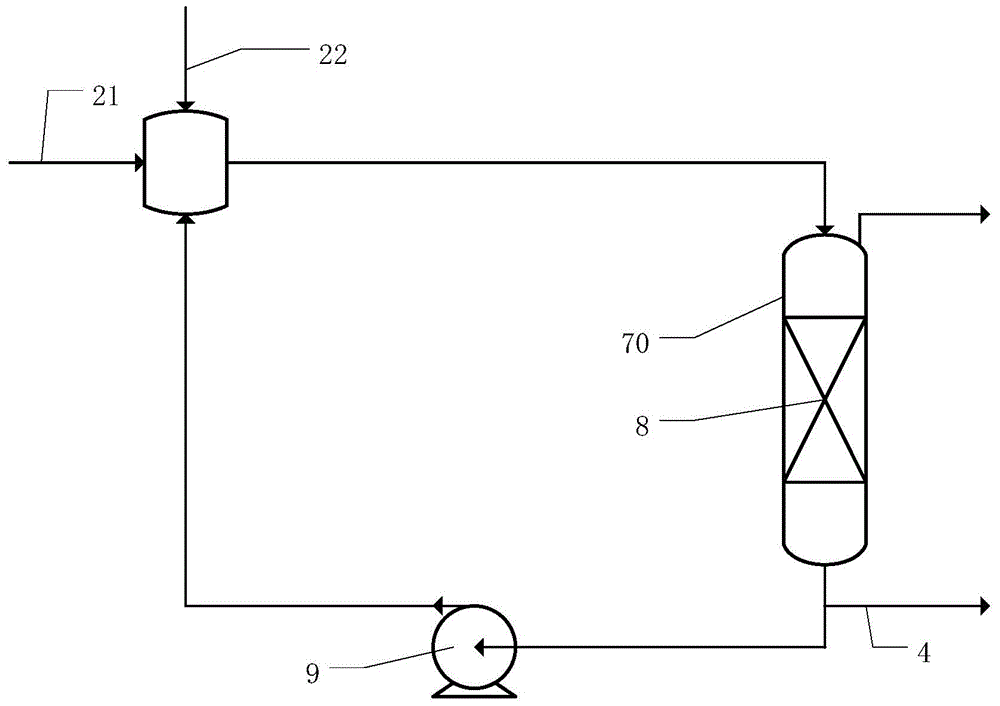

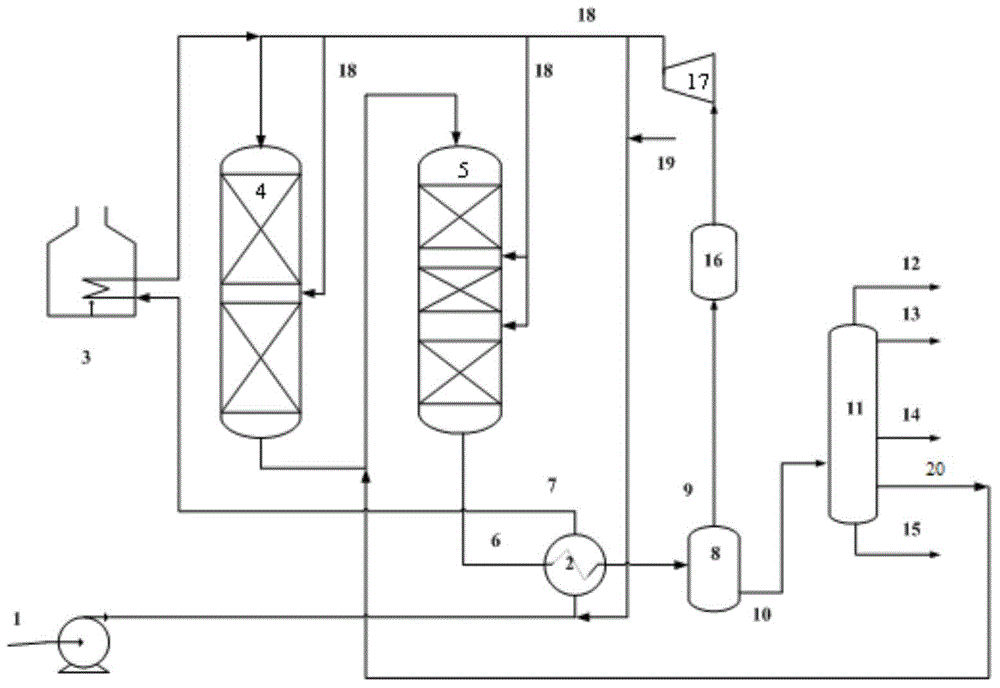

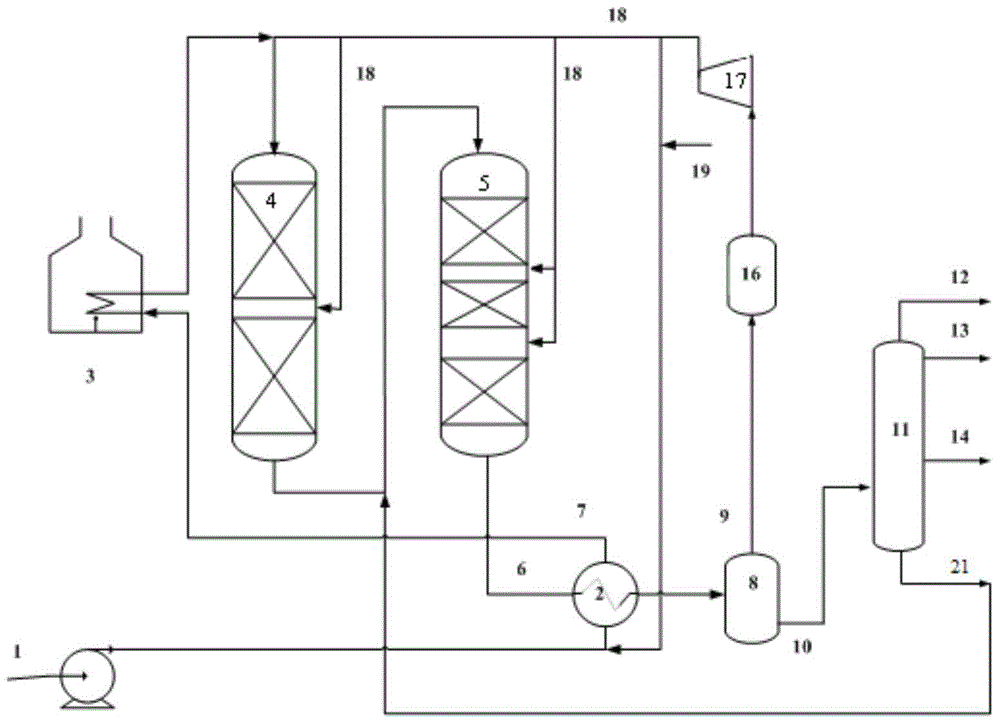

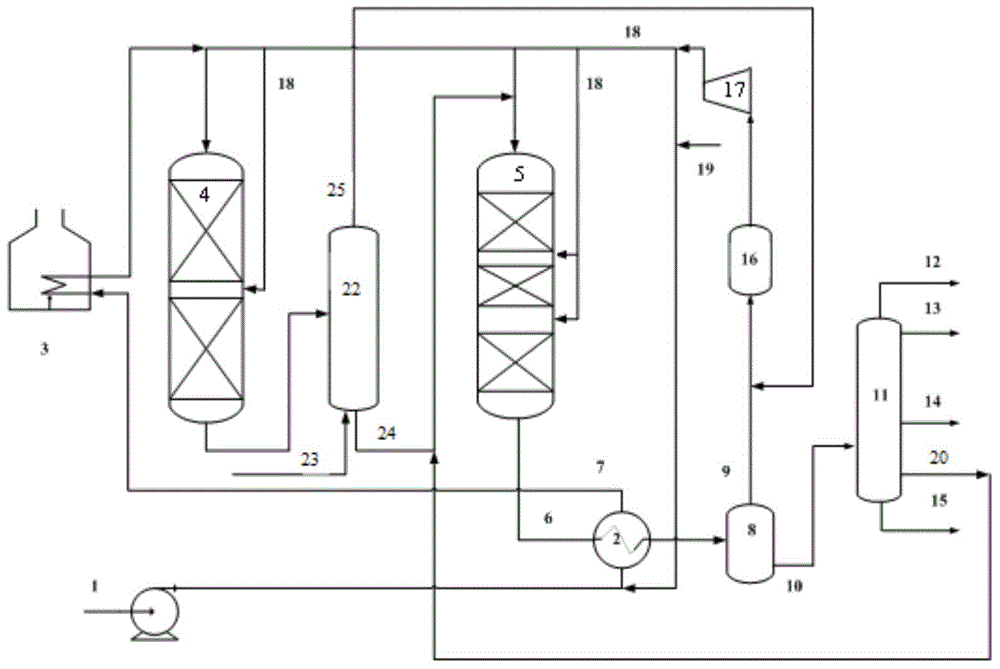

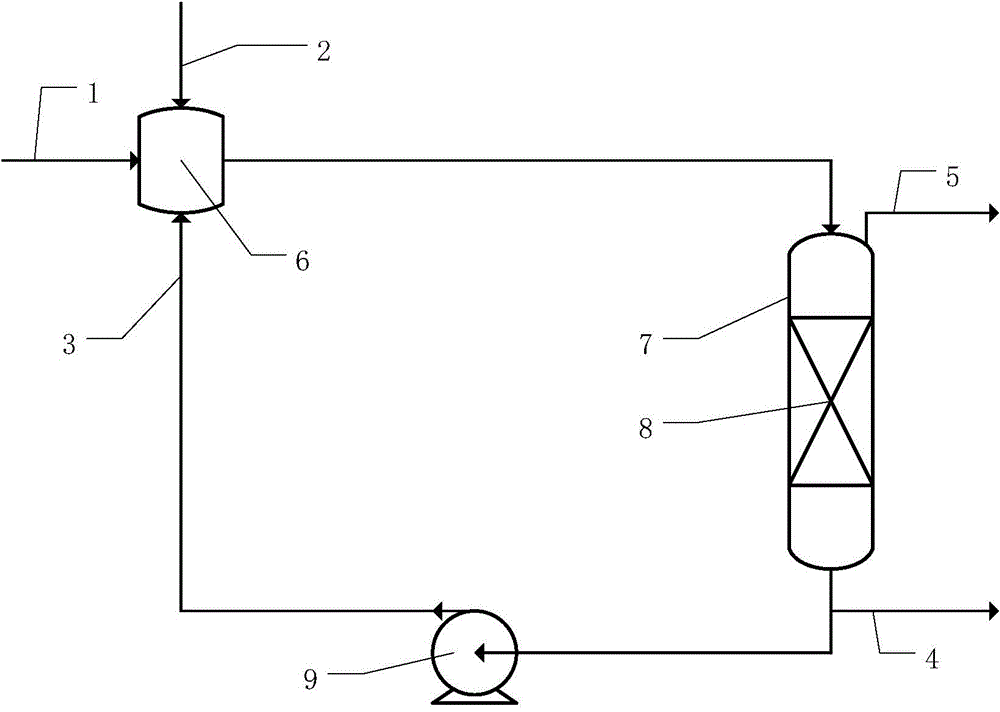

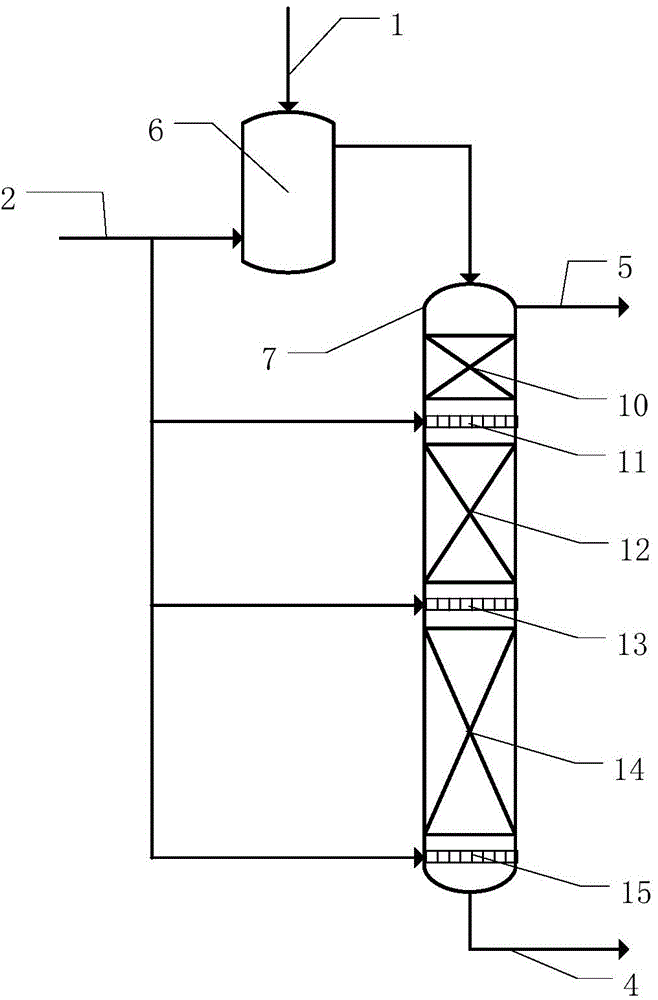

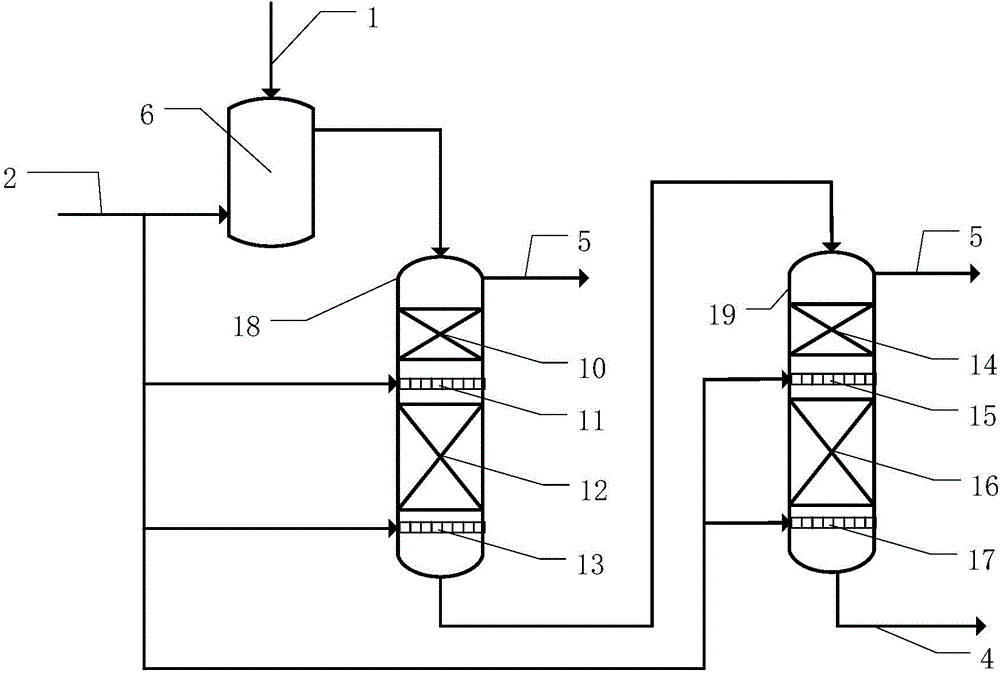

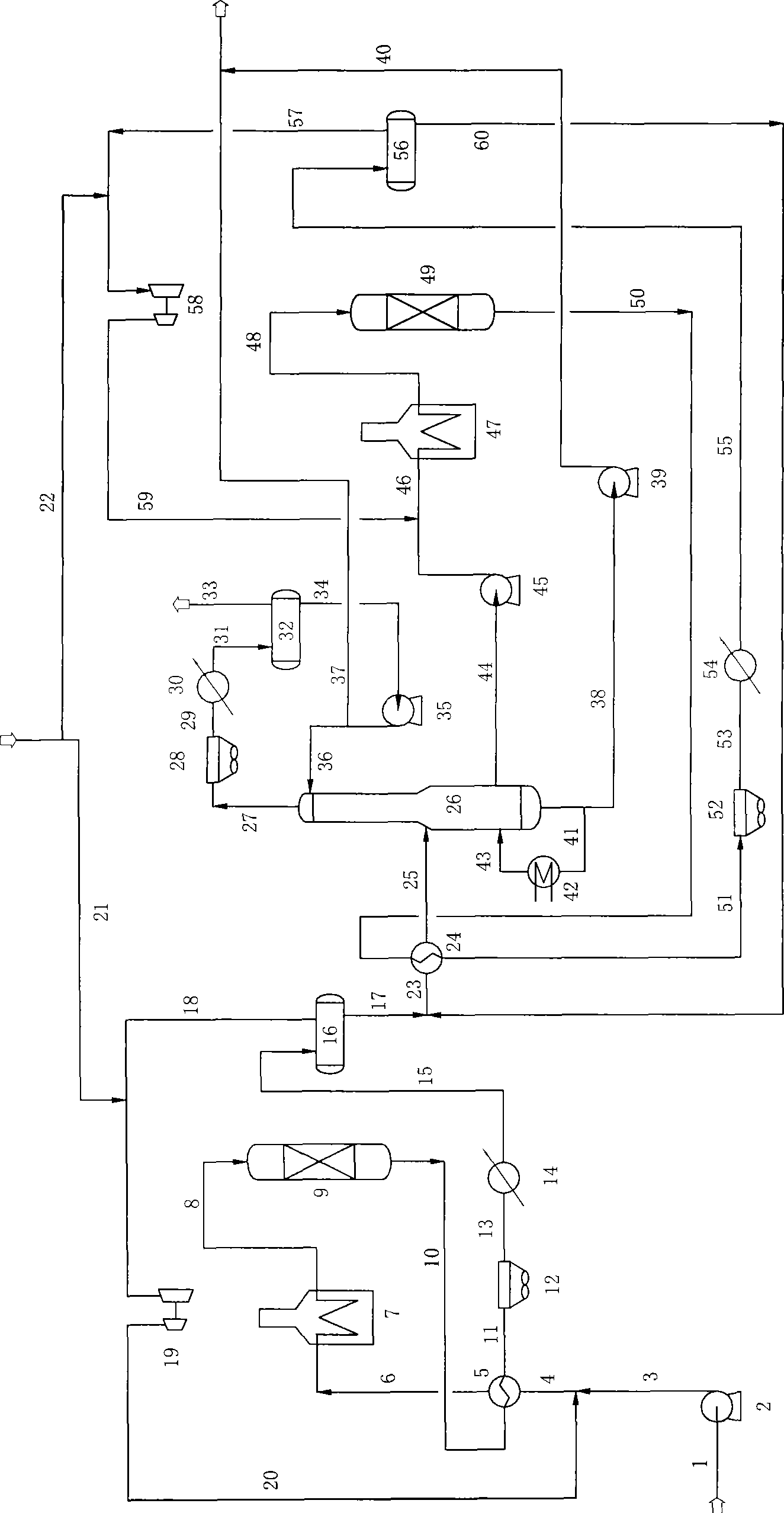

Hydrocarbon continuous liquid phase hydrogenation process method and device

ActiveCN105647577AReduce volumeThe possibility of "flying temperature" is reducedTreatment with hydrotreatment processesChemical/physical processesHydrogenation reactionHydrogenation process

The invention discloses a hydrocarbon continuous liquid phase hydrogenation process method which includes a gas-liquid mixing step, to be more specific, a liquid phase material flow is fully mixed with hydrogen to obtain a dissolved-hydrogen-saturated liquid phase material flow by use of a gas-liquid mixer; and a hydrogenation reaction step, to be more specific, the dissolved-hydrogen-saturated liquid phase material flow flowing into a reactor flows in the direction of from the top of the reactor to the bottom of the reactor for liquid phase contact reaction with every stages of catalyst bed layers, and at the same time, new hydrogen is injected into the liquid phase material flow by a hydrogen distributor so as to realize the efficient hydrocarbon reaction of the liquid phase material flow. The present invention also discloses a hydrocarbon continuous liquid phase hydrogenation device which includes one gas-liquid mixer and one multiplestage reactor, the multiplestage reactor is connected with the gas-liquid mixer, each stage of the reactor comprises at least two stages of catalyst bed layers, and one hydrogen gas distributor is arranged between adjacent catalyst bed layers,.

Owner:PETROCHINA CO LTD

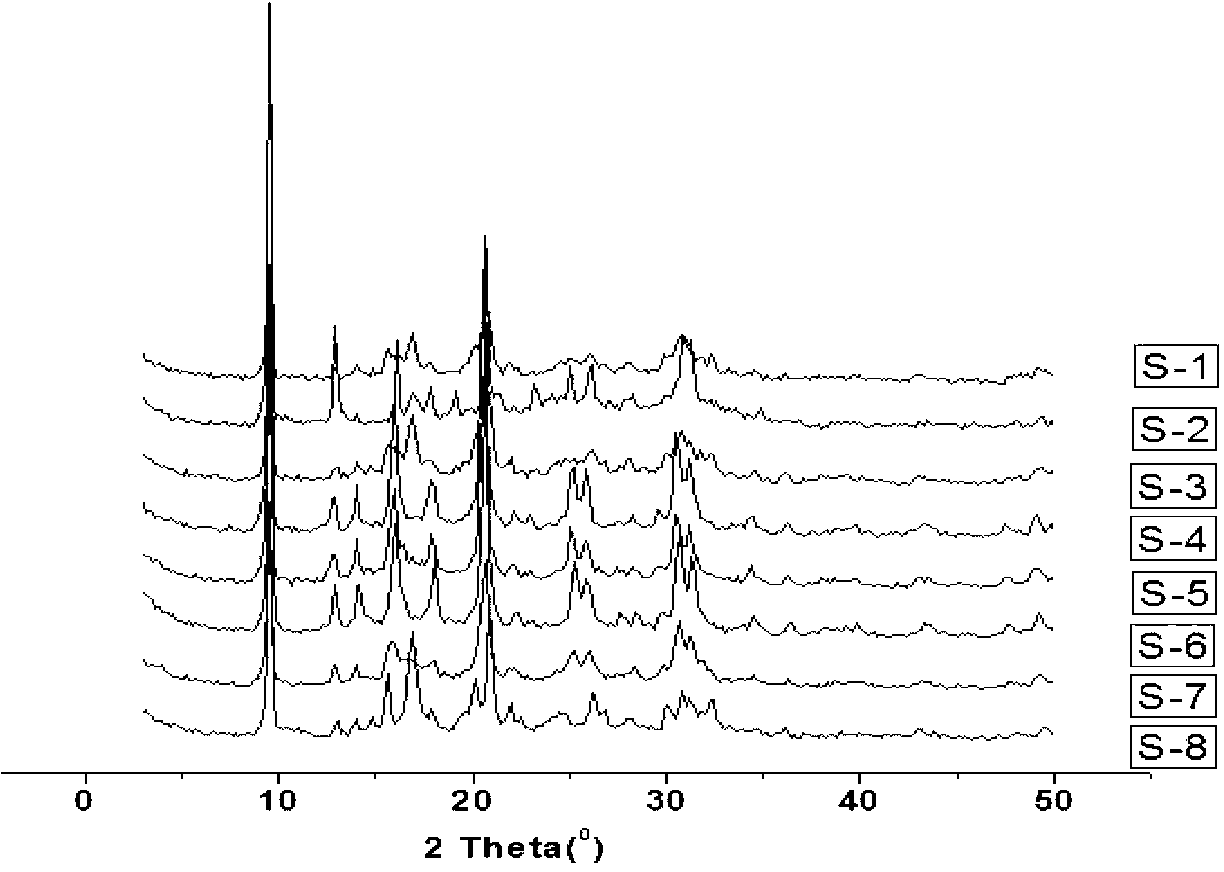

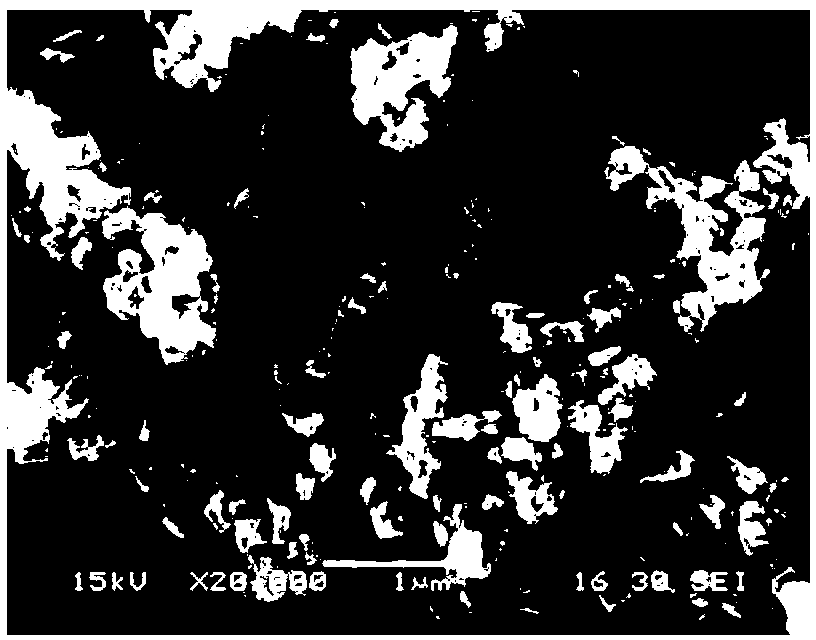

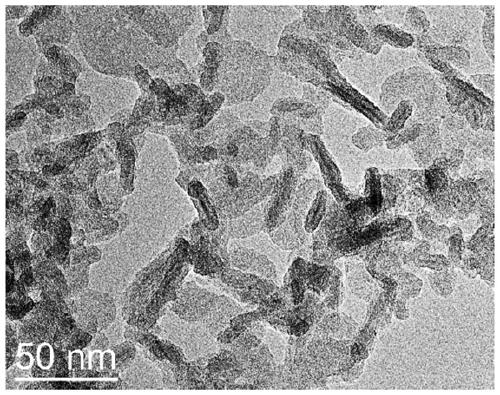

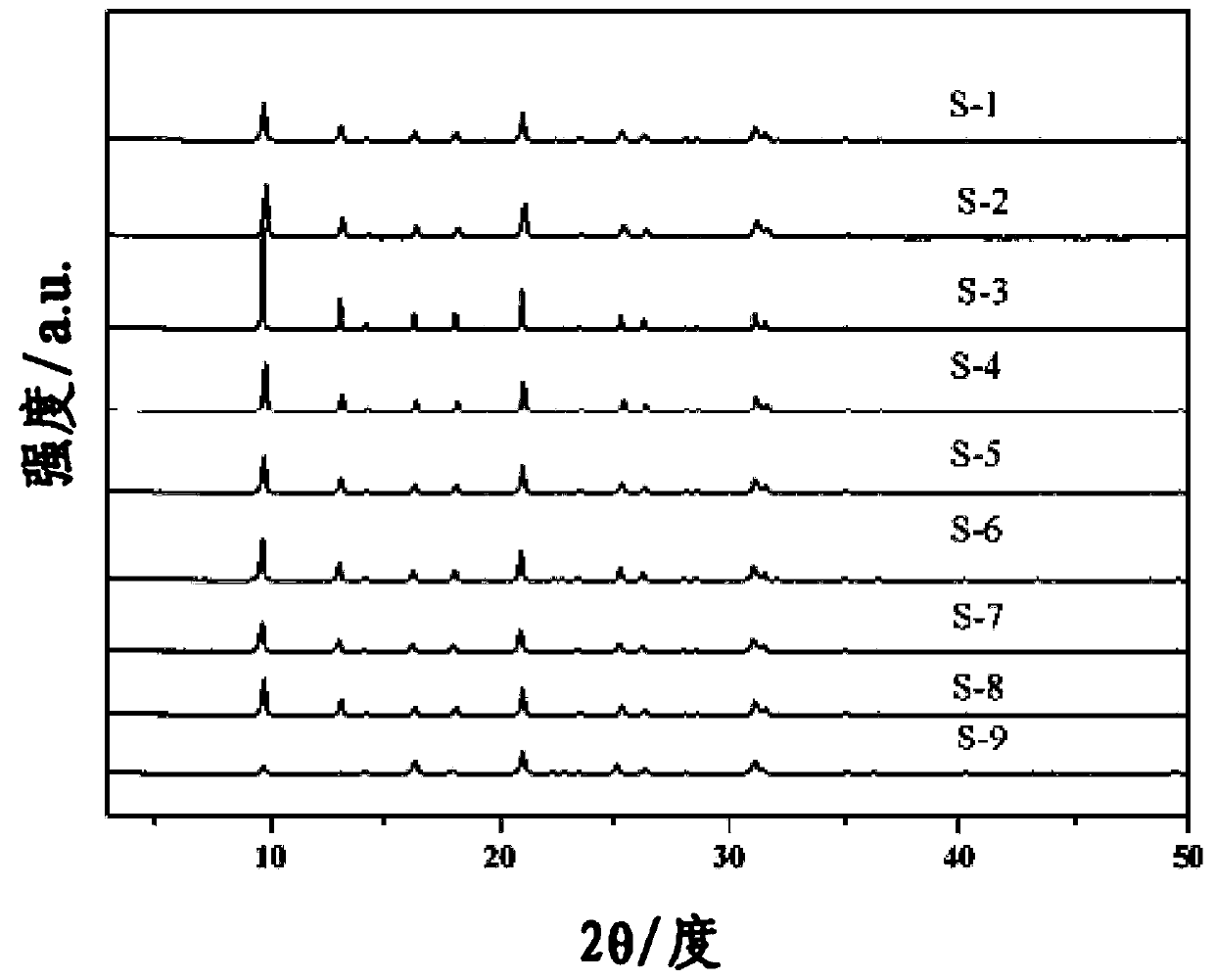

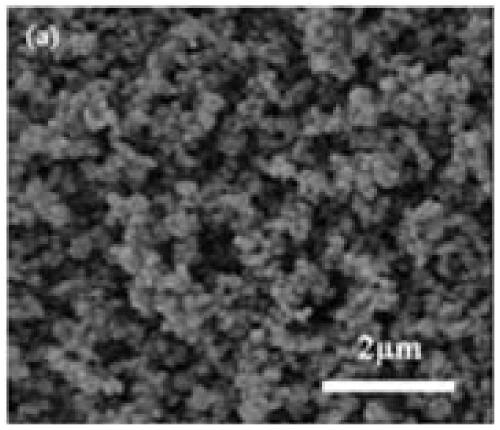

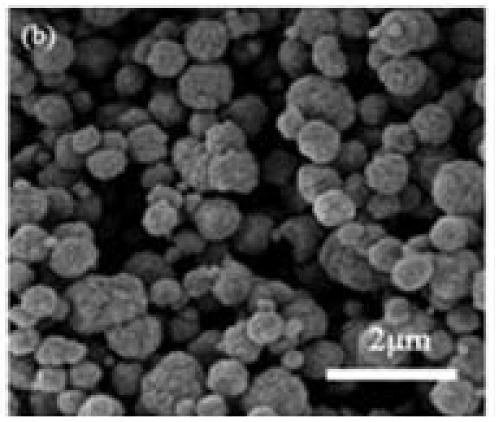

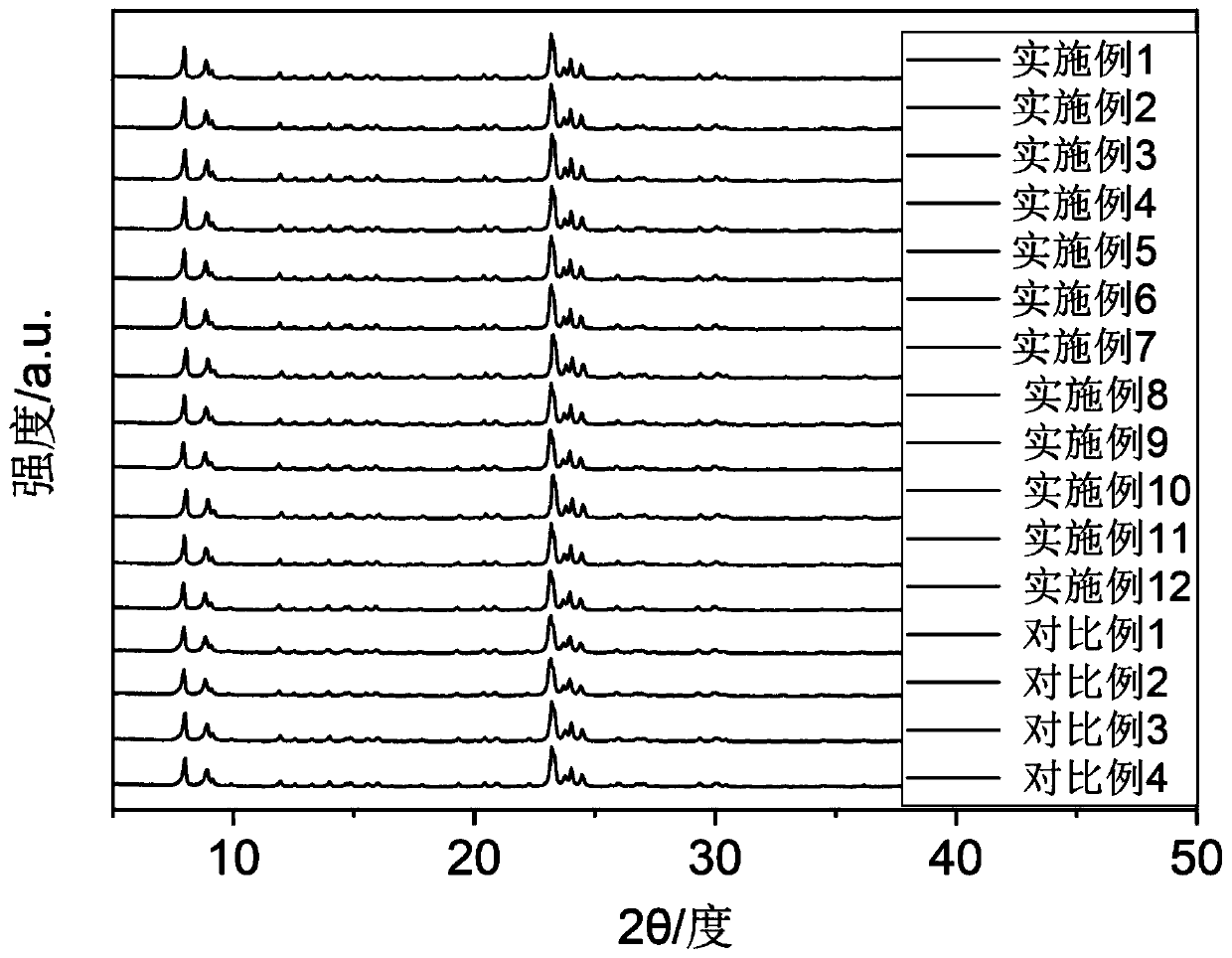

Synthesis method of low-silicon nano SAPO-34 molecular sieve

ActiveCN103130241AShorten the timeLower crystallization temperatureMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesSynthesis methodsHigh pressure

The invention relates to a synthesis method of a low-silicon nano SAPO-34 molecular sieve, which comprises the following steps: sequentially mixing a silicon source, an aluminum source, a template agent R, deionized water and a phosphorus source to obtain a gel mixture; placing the gel mixture in a stainless steel high-pressure reaction kettle of which the liner is made of polytetrafluoroethylene, sealing, putting into a drying oven, and performing primary traditional hydrothermal crystallization; adding a dispersant agent S into the primary traditional hydrothermal crystallization solution, stirring for 0.5-4 hours, transferring into the reaction kettle of which the liner is made of polytetrafluoroethylene, sealing, putting into a microwave reactor, and performing secondary microwave hydrothermal crystallization; and washing, drying, and roasting to obtain the nano SAPO-34 molecular sieve. Compared with the prior art, the invention greatly lowers the crystallization temperature and shortens the time of the whole synthesis process. The nano molecular sieve can be widely used for conversion, separation and absorption of hydrocarbons, and especially has the advantages of high conversion rate, high low-carbon alkene selectivity, low carbon deposition rate, long reaction life and the like in the process of preparing alkene from methanol.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Method for preparing dimethyl ether from methanol

ActiveCN1907932ACarbon deposition slows downExtend your lifeChemical industryEther preparation by compound dehydrationChemistryCatalytic distillation

This invention relates to a preparation method for dimethyl ether by dehydrating methanol under liquid phase or gas-liquid mixing state in a catalytic distillation tower loaded with a solid acid catalyst in reaction section, wherein the methanol has a content of 5~99.99 wt.%. Catalytic distillation tower operating conditions include pressure of 0.6~5.0 MPa, column top temperature of 30~124DEG C, reaction section central temperature of 120~220DEG C, column reactor temperature of 160~270DEG C, the reflux ratio at 3~50, and feed volume space velocity of 0.1-10 ml methanol / ml catalyst, Or the reactions are carried out in one fixed bed rector or 2~4 fixed bed reactors in series with reaction conditions of temperature 120~220DEG C, pressure 0.6~8.0 MPa, and feed volume space velocity 0.1-10 ml methanol / ml catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing molecular sieve solid acid catalyst used for preparing ethylene by ethanol dehydration

InactiveCN101579637ARaw materials are cheap and easy to getSimple processMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a method for preparing a molecular sieve super solid acid catalyst used for preparing ethylene by ethanol dehydration, belonging to the technical field of chemical product preparation, wherein the method comprises immersion method and hydro-thermal method, and the molecular sieve solid acid catalyst is prepared with ZSM-5 hydrogen as a carrier by loading Fe3 metallic ion. The invention also provides a technical process that ethanol is dehydrated and converted into ethylene at a low temperature under the action of molecular sieve solid acid catalyst. In the invention, the catalyst used for preparing ethylene by ethanol dehydration can dehydrate the ethanol with different concentrations at a temperature of 220 DEG C to prepare the ethylene, and the conversion rate can reach 98.4%. The catalyst has high activity at a low temperature, thus solving the technical problems of high temperature and low airspeed existed in the present industrial production.

Owner:TSINGHUA UNIV

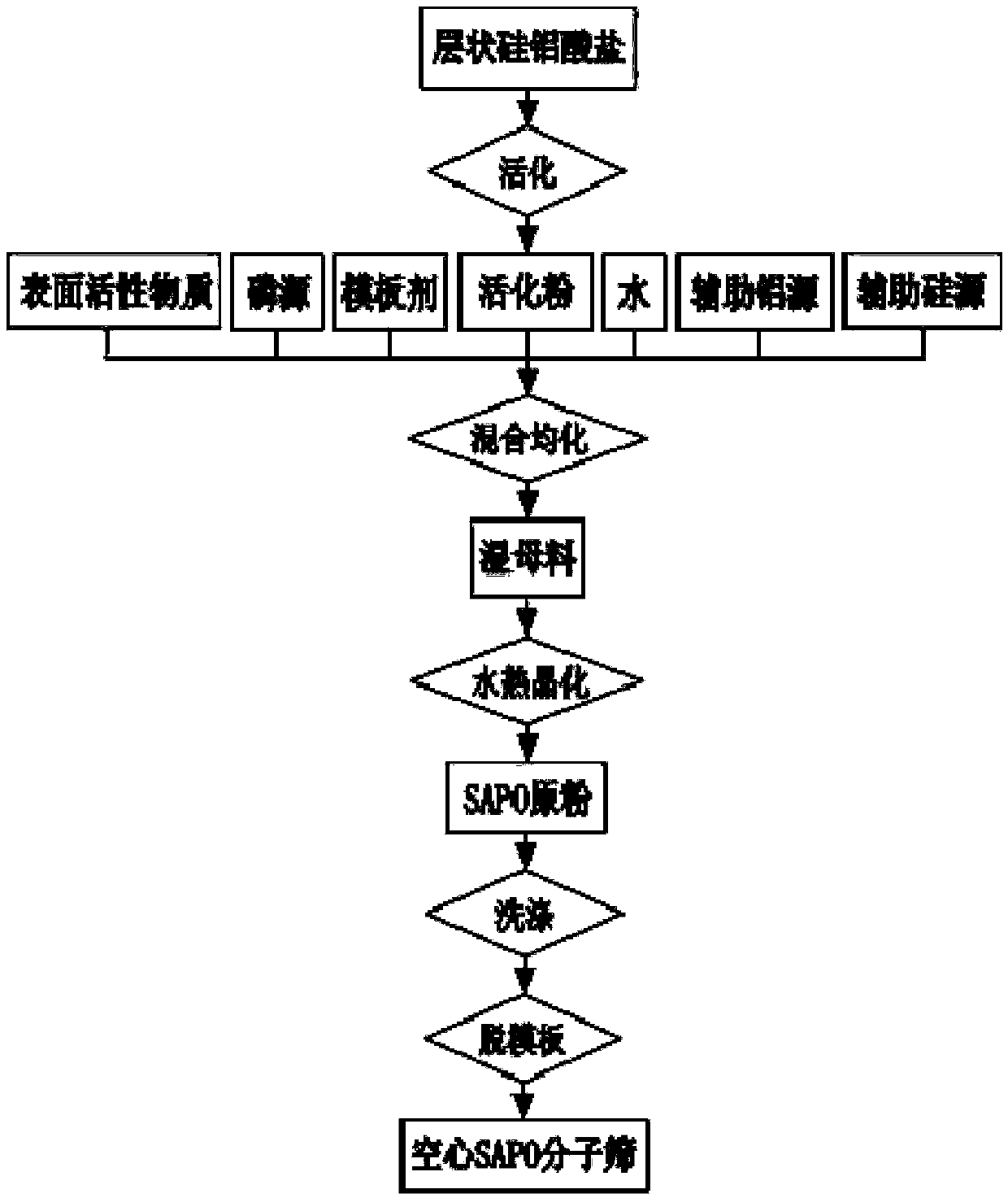

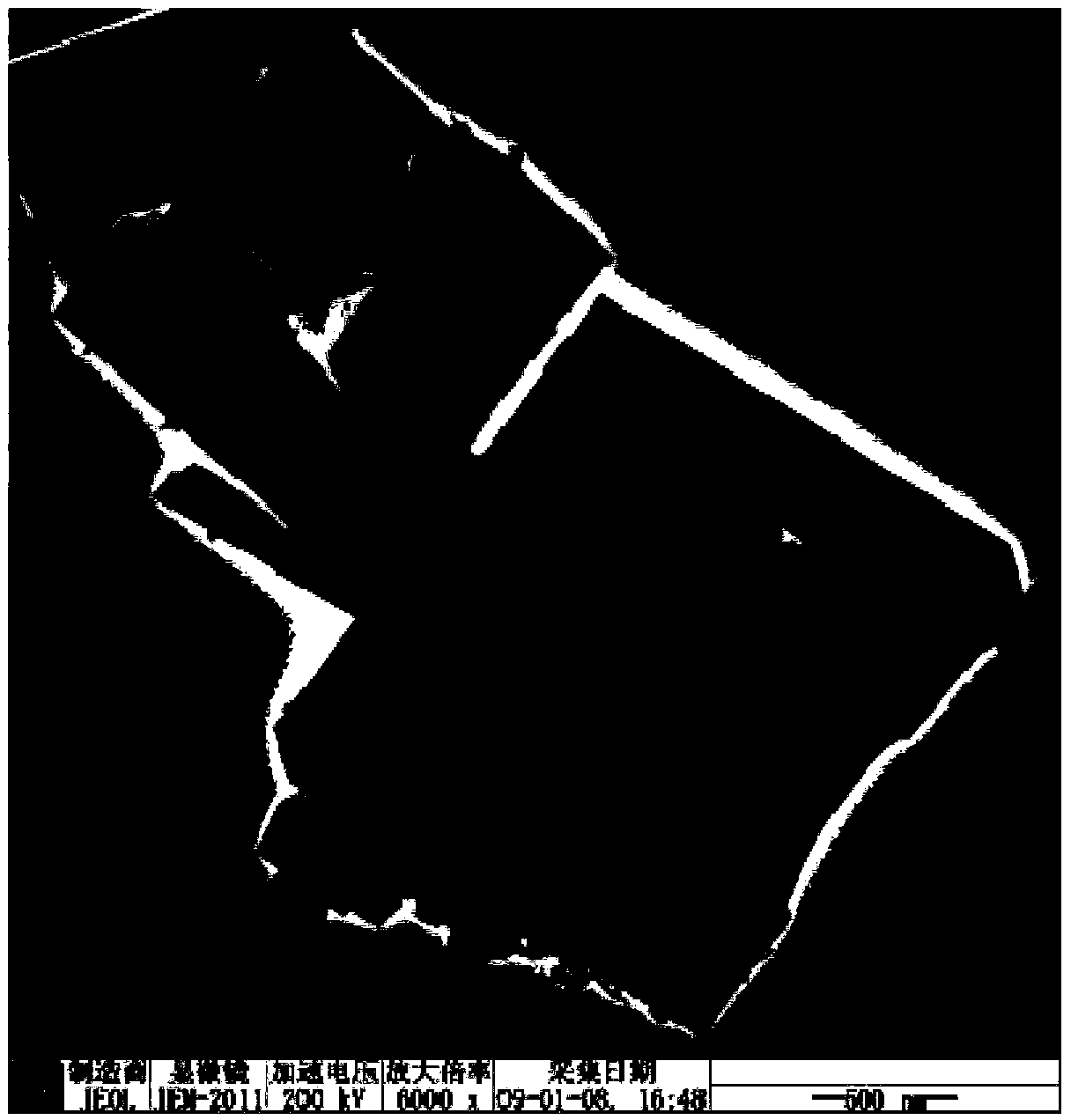

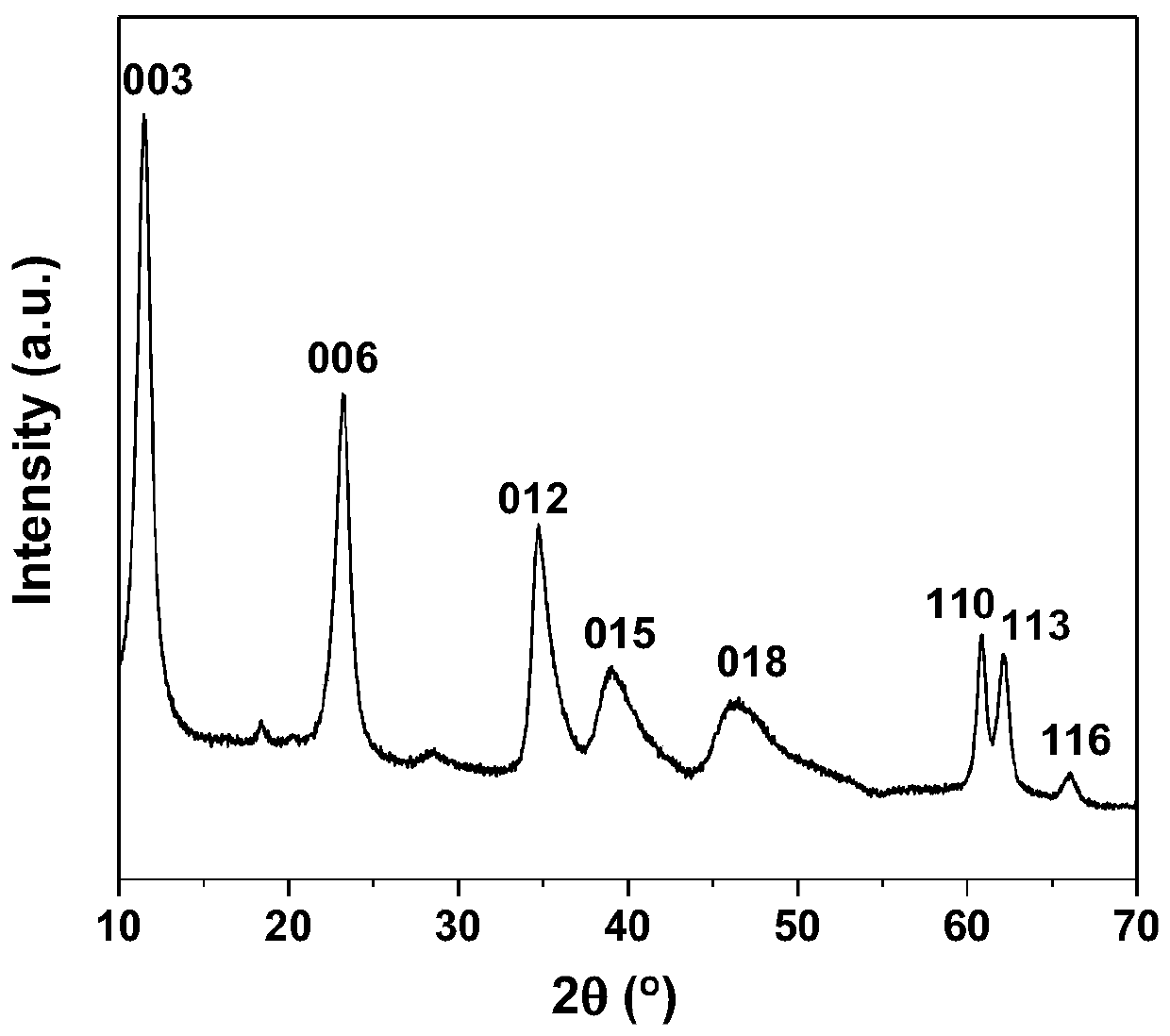

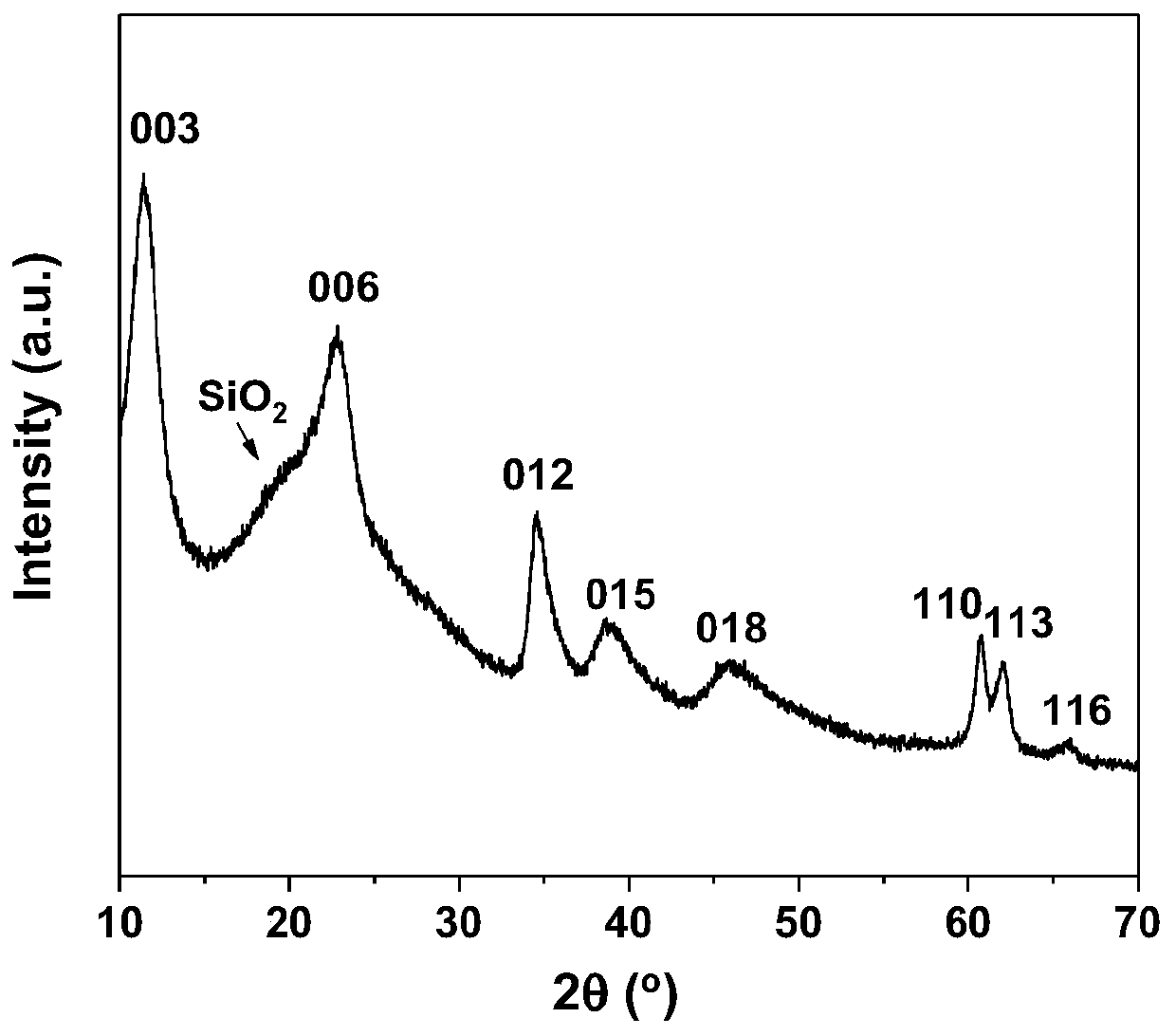

SAPO molecular sieve, and preparation method and purpose thereof

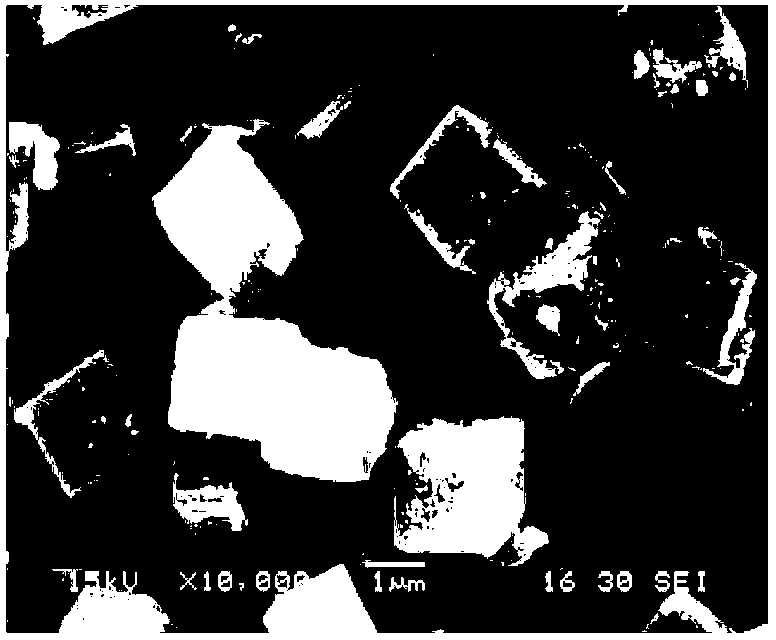

ActiveCN103964456ASuitable for acidityExtend your lifeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveSingle crystal

The invention discloses an SAPO molecular sieve, which has hollow single crystals. The SAPO molecular sieve has optional pore structure, adjustable silicon content and distribution, controllable strength and density of acid site, and long service life of catalyst. The invention also discloses a preparation method of the SAPO molecular sieve. The method uses layered silicate as a raw material, which is subjected to activation, and mixed and homogenized with a phosphorus source, an auxiliary aluminum source and water to obtain a wet masterbatch; and the wet masterbatch is subjected to hydrothermal crystallization to obtain a raw powder of the hollow SAPO molecular sieve, wherein the molar ratio of Al and Si in the wet masterbatch is higher than 1. The method use easily available raw materials, has low cost and can be prepare the SAPO molecular sieve with hollow structure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

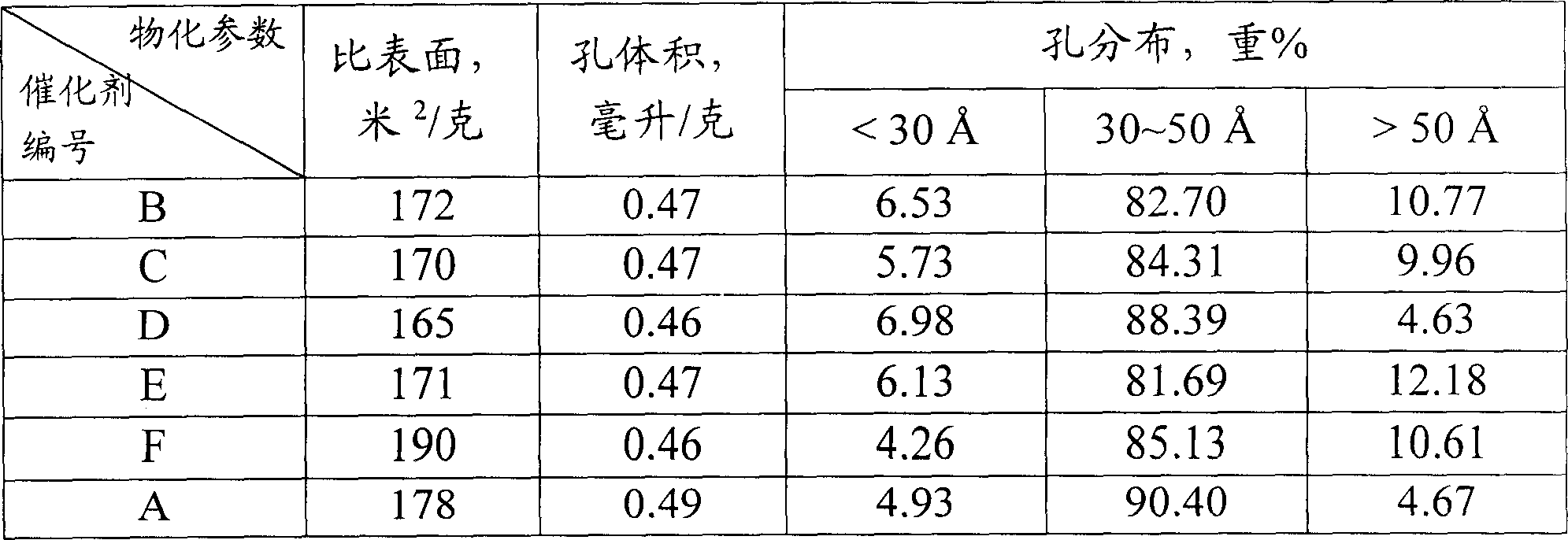

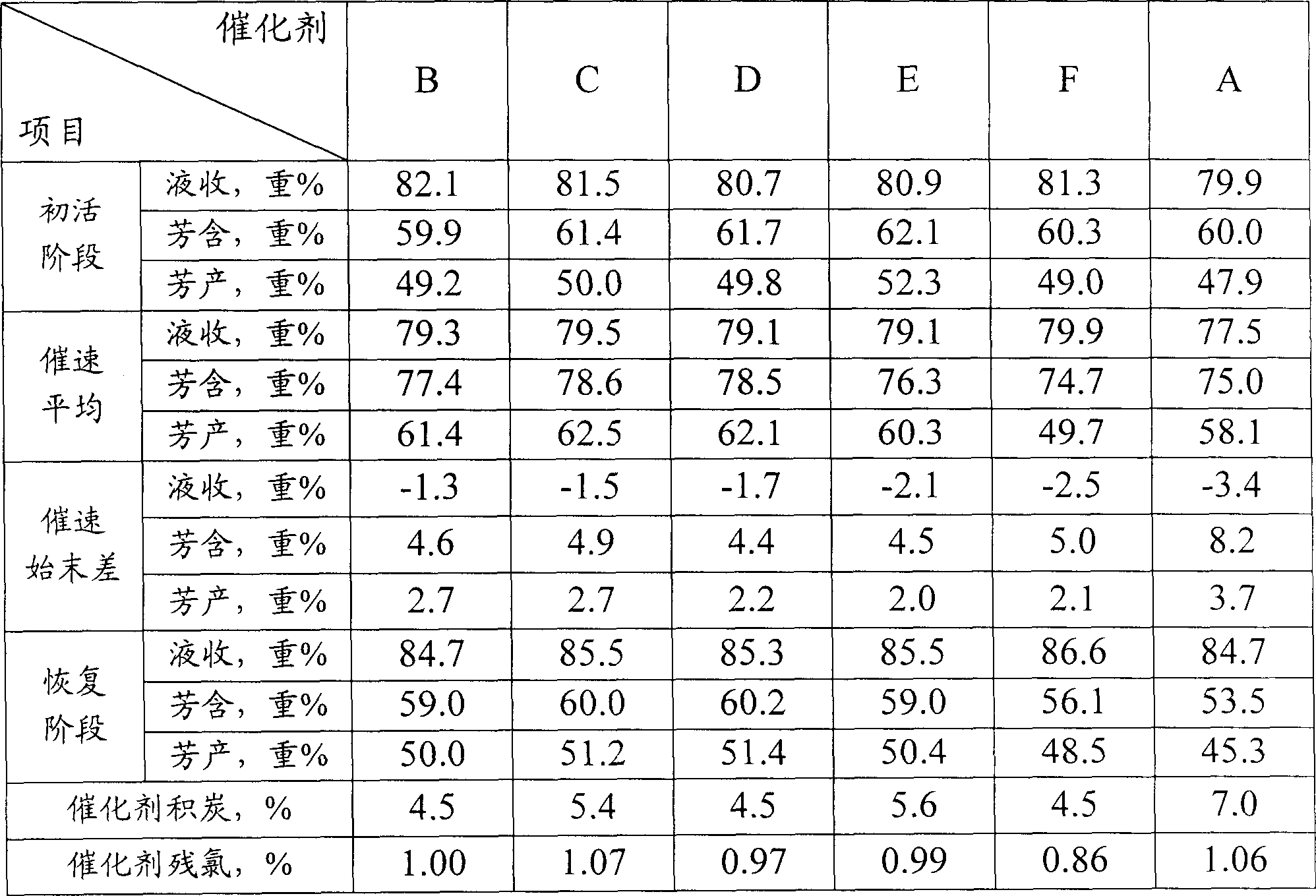

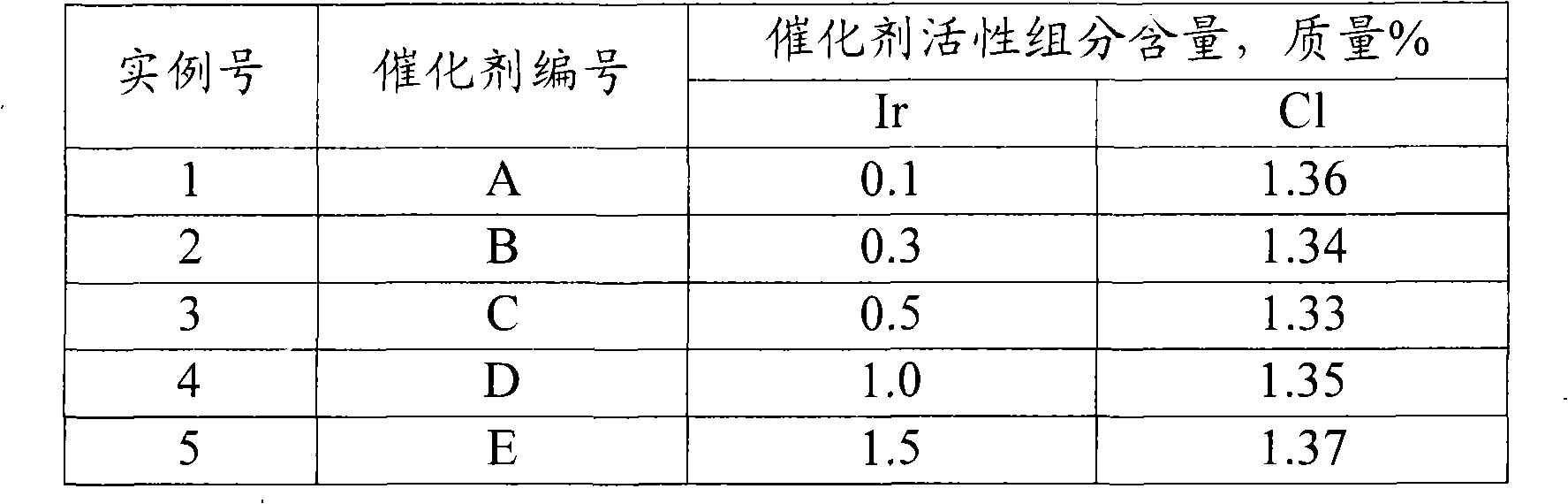

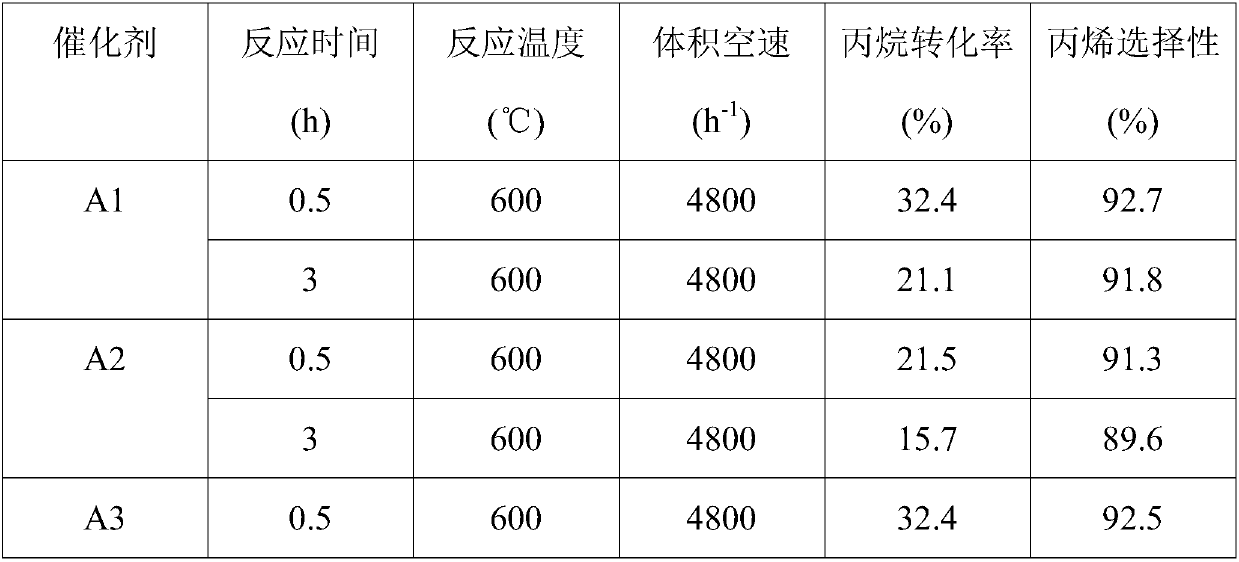

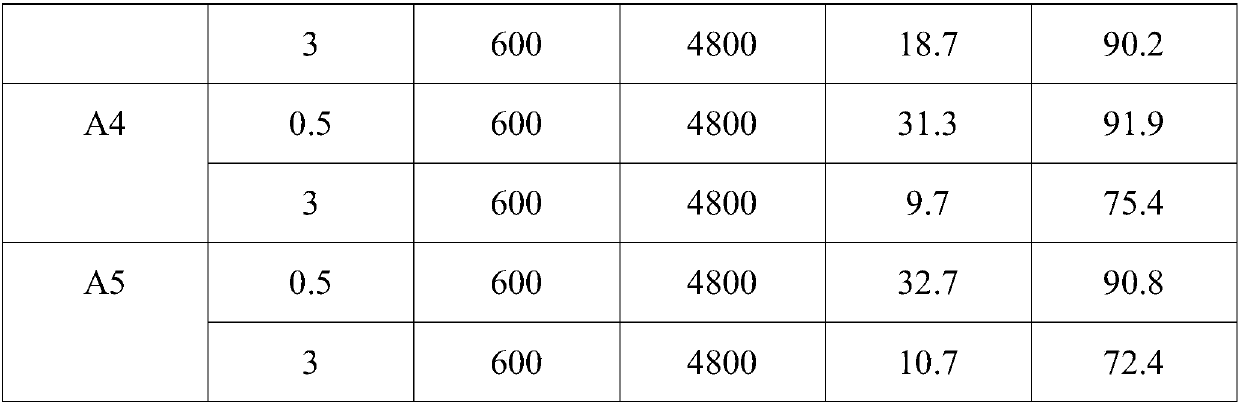

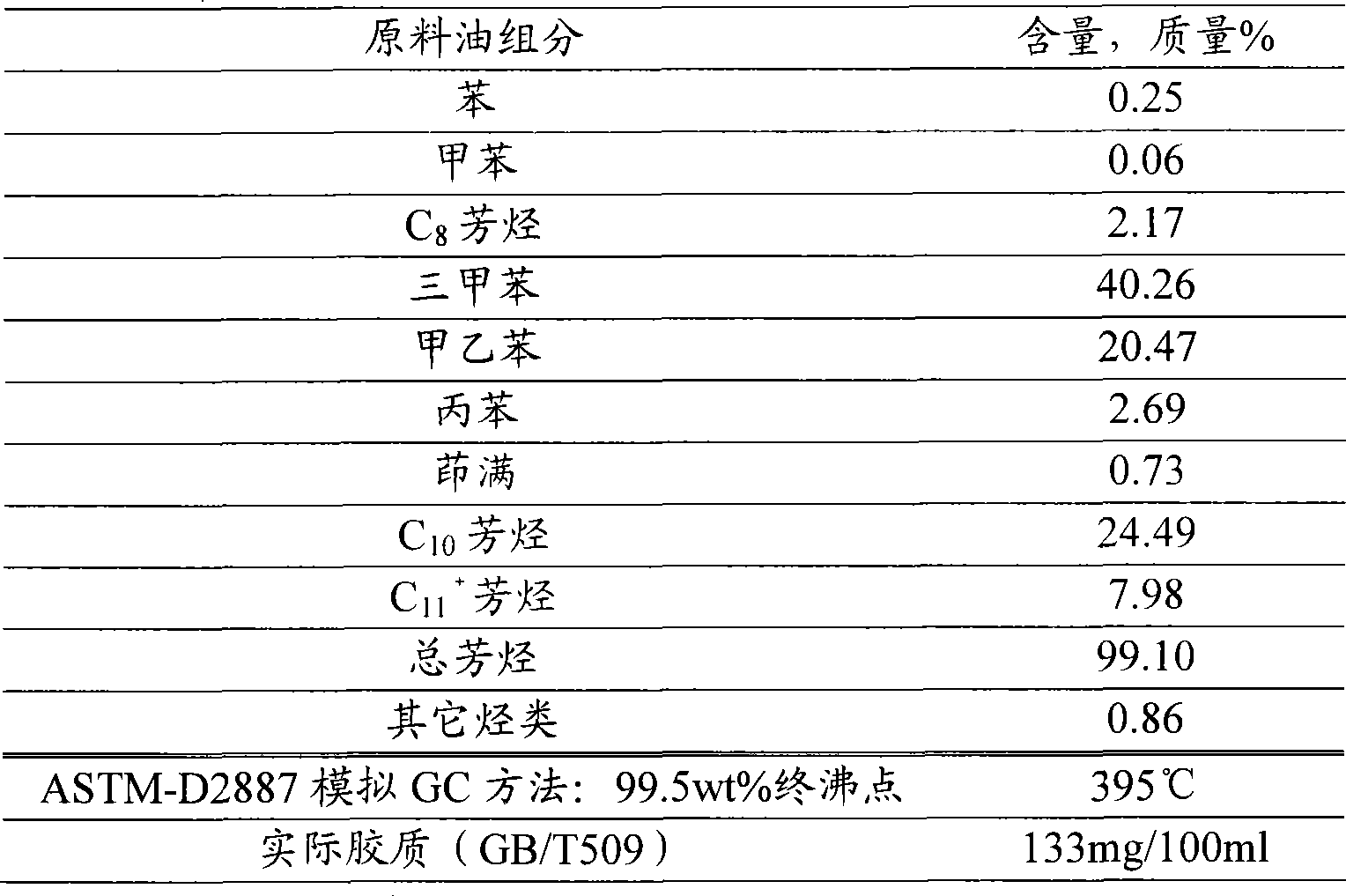

Hydrocarbons process liquid production upgrading catalyzer and upgrading method thereof

ActiveCN101134167AIncreased light aromatics contentReduce carbon deposition ratePhysical/chemical process catalystsNaphtha reformingIridiumNaphtha

The liquid hydrocarbon modifying catalyst consists of heat resisting inorganic oxide, Ir in 0.1-5.0 wt% of the inorganic oxide, and halogen in 0.01-3.0 wt% of the inorganic oxide. The catalyst is used in modifying naphtha product, and can raise benzene, toluene and xylene contents in the modified product, raise ethyl benzene converting rate, and lower the carbon deposit during the reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bimetal reforming catalyst and its preparing process

InactiveCN1393513AGood choiceImprove anti-coking performanceCatalyst activation/preparationNaphtha reformingCatalytic reformingGasoline

A reforming bimetal catalyst for gasoline fraction contains VIII-family metal (0.1-1.0 wt.%), VIIB-family metal (0.1-1.0), phosphorus (0.1-5.0), chlorine (0.6-3.0) and gamma-Al2O3 as carrier (90-99.1). Its advantages are low carbon depositing speed, high stability of activity and high selectivity of arylhydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

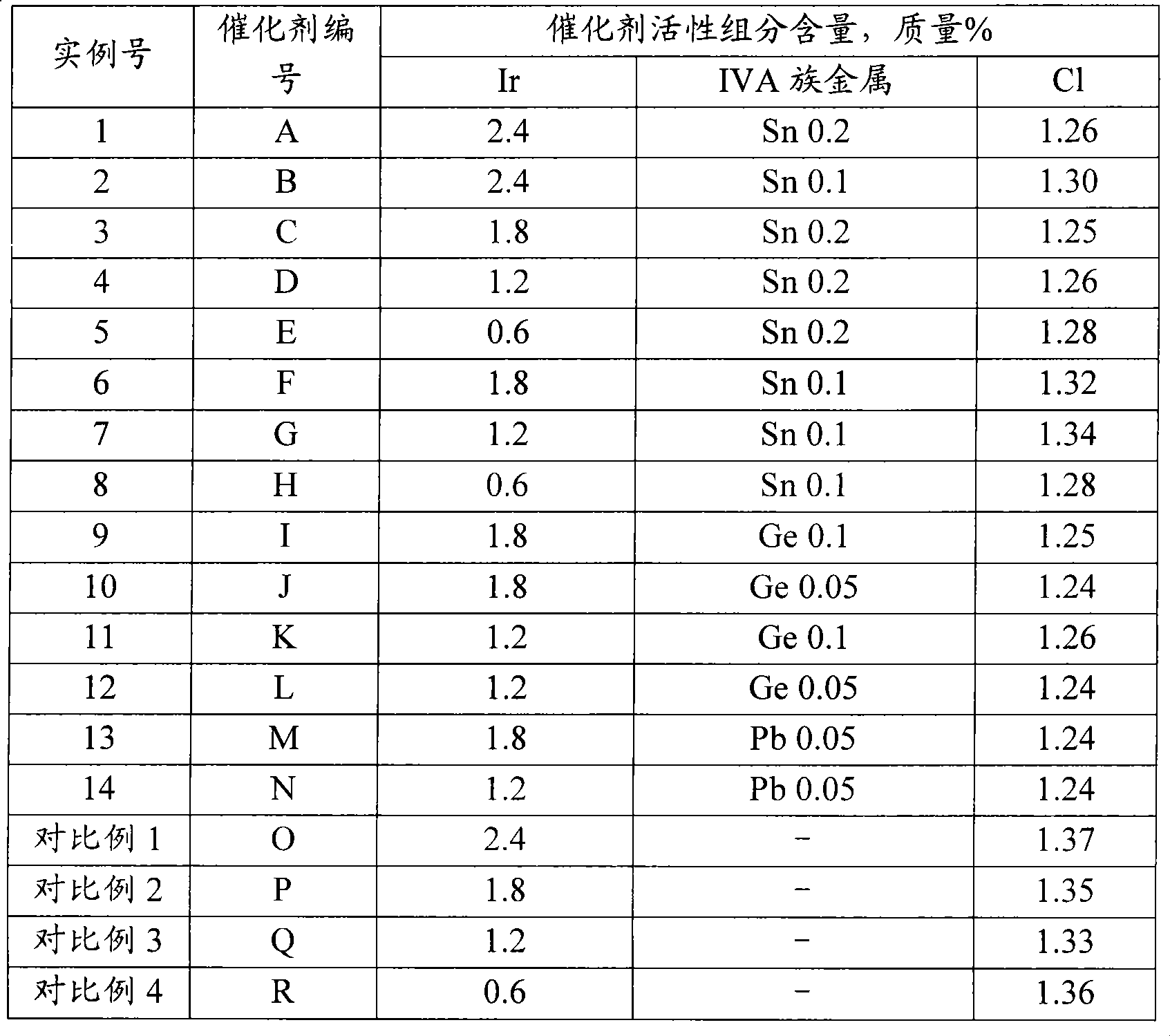

Jet fuel production method

ActiveCN105419865ALow aromatic contentReduce carbon deposition rateTreatment with hydrotreatment processesContact reactionJet fuel

The present invention discloses a jet fuel production method, which comprises that (1) hydrogen gas, raw material oil and a hydrorefining catalyst are subjected to a contact reaction; (3) the effluent of the hydrorefining catalyst and a hydrocracking catalyst are directly subjected to a contact reaction, or after the gas phase stream is separated, a contact reaction is performed with a hydrocracking catalyst; (4) the effluent of the hydrocracking catalyst is separated to obtain a jet fuel and diesel oil; and (5) at least partial diesel oil and the raw material oil are mixed, or at least partial diesel oil and the feeding liquid of the hydrocracking catalyst are mixed, wherein the aromatic hydrocarbon content of the raw material oil is more than or equal to 40 wt%, the contact reaction condition of the step (1) makes the bicyclic aromatic hydrocarbon saturation rate in the raw material oil be 70-90%, and the contact reaction conditions of the step (3) makes the monocyclic aromatic hydrocarbon saturation rate in the feeding liquid of the step (3) be 75-95%. According to the present invention, the catalytic cracking diesel oil can be used as the raw material so as to achieve the high yield production of the high density jet fuel meeting the GJB1603 6# jet fuel standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

High activity and carbon deposition resistant catalyst for reforming of dry methane gas and preparation method thereof

ActiveCN109967081AAchieve directed assemblyReduce usageHydrogenHydrogen/synthetic gas productionWater-gas shift reactionDehydrogenation

The invention discloses a high activity and carbon deposition resistant catalyst for the reforming of dry methane gas and a preparation method thereof. Specifically, stable sol with a nano laminated structure is prepared through a precipitation method; then a second component is in-situ coated; and after drying, burning, and reduction-activating, the catalyst with a nano laminated coated structureis obtained. The catalyst has high activity in the reforming reactions of dry methane gas, has a strong carbon deposition resistant performance, can continuously play a catalyst role at a temperatureof 400 to 900 DEG C, and is resistant to inactivation. The raw materials are easily available, the technology is simple, and the catalyst can also be applied to reforming of methane water steam, carbon dioxide assisted dehydrogenation of ethane and propane, and water-gas shift reaction.

Owner:DALIAN UNIV OF TECH

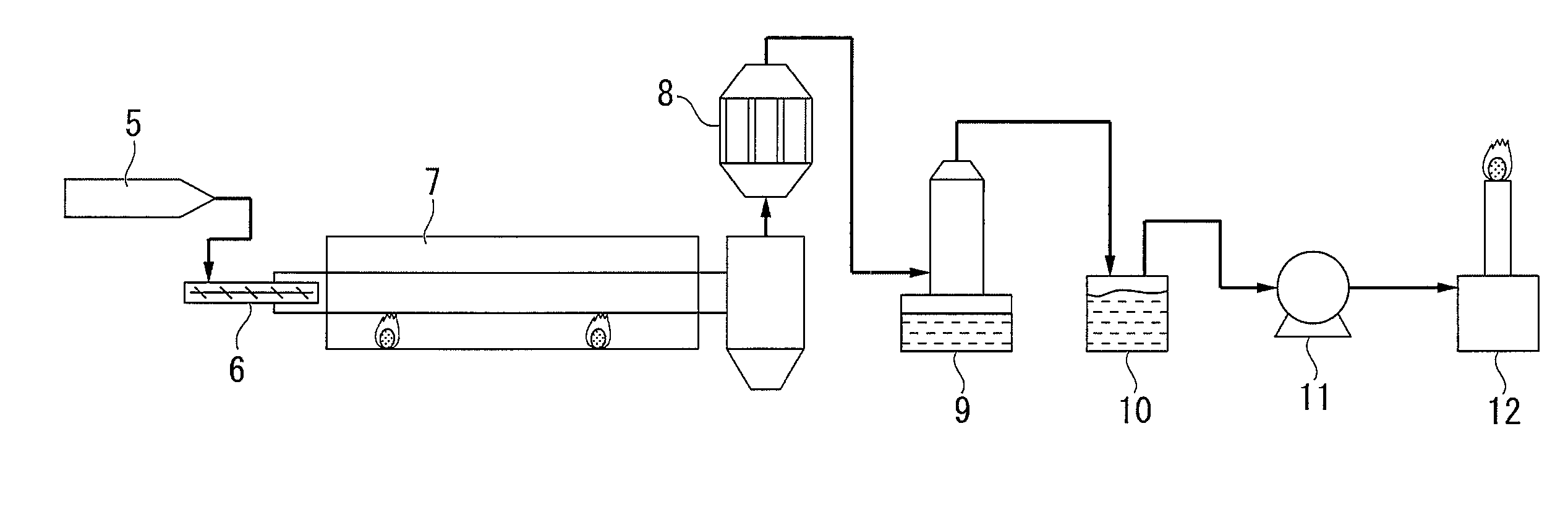

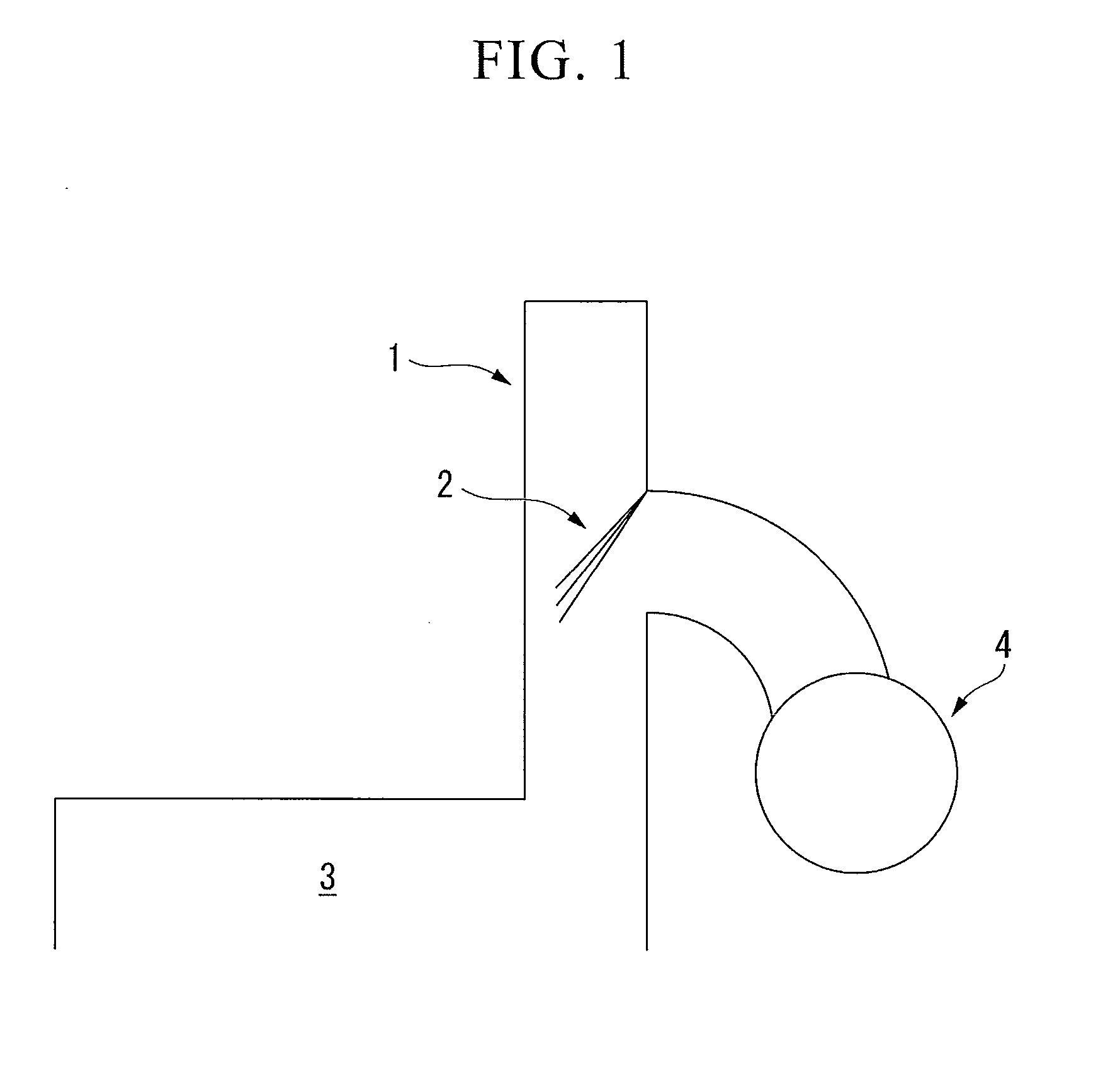

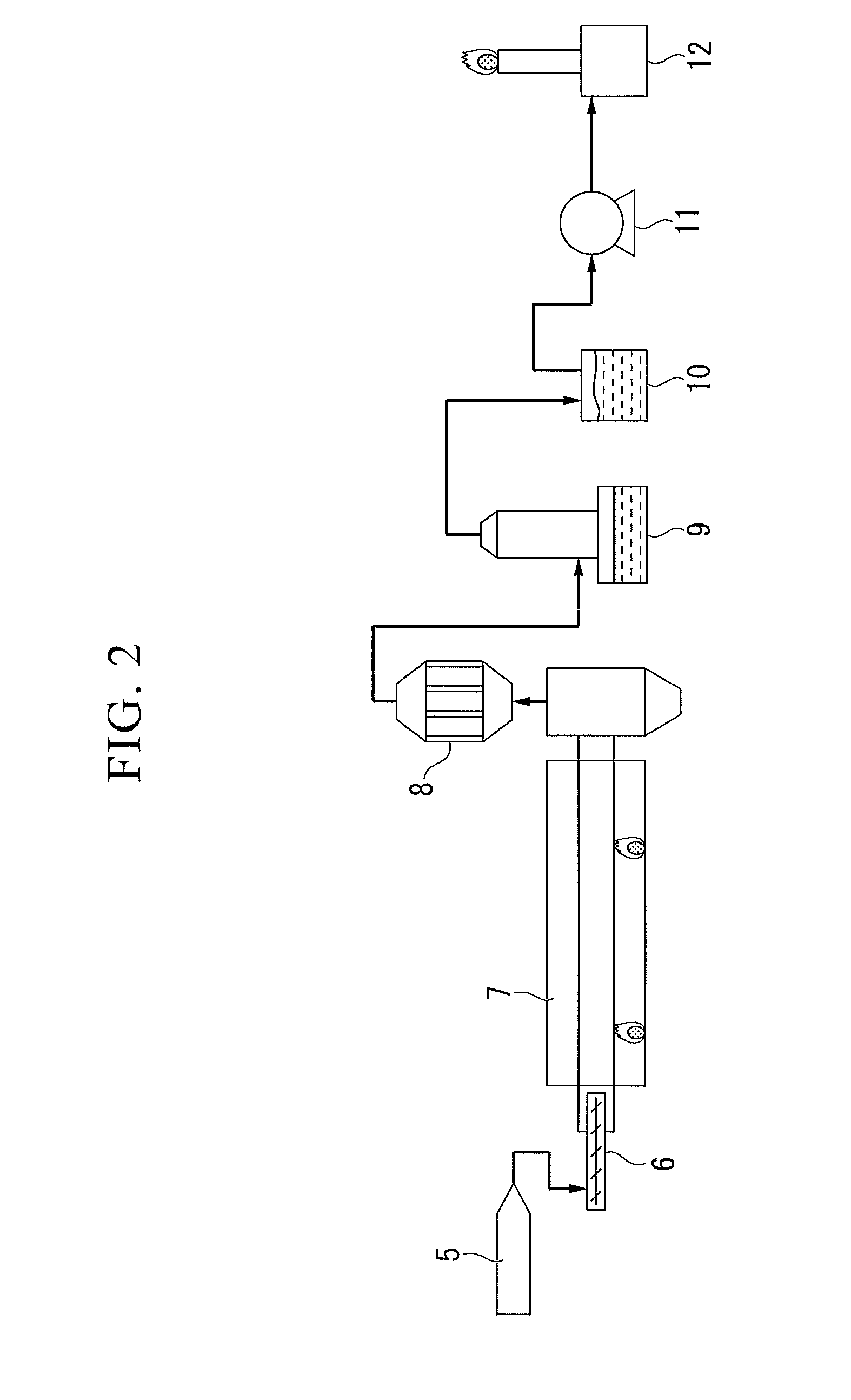

Catalyst for reforming tar-containing gas, method for preparing catalyst for reforming tar containing gas, method for reforming tar-containing gas using catalyst for reforming tar-containing gas, and method for regenerating catalyst for reforming tar-containing gas

ActiveUS20120058030A1Highly efficiently and stably convertedHigh tar-containing gas reformation activityMaterial nanotechnologyUsing liquid separation agentCeriumTar

Owner:NIPPON STEEL CORP

Nickel-based catalyst for obtaining synthetic gas through carbon dioxide reforming of methane and preparation method for nickel-based catalyst

ActiveCN102389801AHigh conversion rate of methaneExtend your lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to the technical field of catalysts for obtaining synthetic gas through carbon dioxide reforming of methane, and discloses a nickel-based catalyst for obtaining the synthetic gas through the carbon dioxide reforming of the methane and a preparation method for the nickel-based catalyst. The nickel-based catalyst for obtaining the synthetic gas through the carbon dioxide reforming of the methane consists of NiO, MgO and gamma-Al2O3. The preparation method comprises the following steps of: 1, preparing a mixed solution; and 2, preparing the nickel-based catalyst. Compared with the prior art, the method has the advantages that: the methane conversion rate of the nickel-based catalyst is greatly improved, the service life is also greatly prolonged, and the carbon deposition rate is greatly reduced; and the nickel-based catalyst is low in cost and has better economy.

Owner:XINJIANG UNIVERSITY

Aromatic olefin-reducing catalyst and use thereof

InactiveCN105080592AImproves carbon build-up resistanceReduce carbon deposition rateMolecular sieve catalystsRefining with metal saltsPore diameterOxide

The present invention relates to an aromatic olefin-reducing catalyst mainly solving the problems of short carclazyte life, frequent replacement, large labor intensity, and serious environmental pollution when the carclazyte is used for removing trace olefins in an aromatic material in current industry. The aromatic olefin-reducing catalyst is used, the average pore diameter of the aromatic olefin-reducing catalyst is 5-30nm, the aromatic olefin-reducing catalyst comprises the following components by weight: 0 to 15% of lanthanide elements or a mixture thereof; 0 to 20% of oxides of one or more elements selected from Ca, Zn , Mg and Ti; and 30 to 90% of a molecular sieve, the molecular sieve is at least one selected from mordenite, Y zeolite, ZSM-5 molecular sieve, MCM-22 molecular sieve, MCM-56 molecular sieve, and beta-molecular sieve; and a carrier is one substance selected from alumina and silica or a mixture thereof, and by the technical scheme, the problem is preferably solved, and the method can be used for aromatic olefin-reducing industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

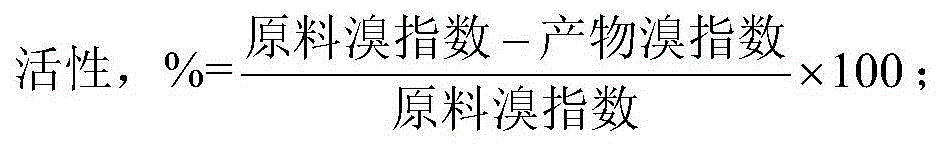

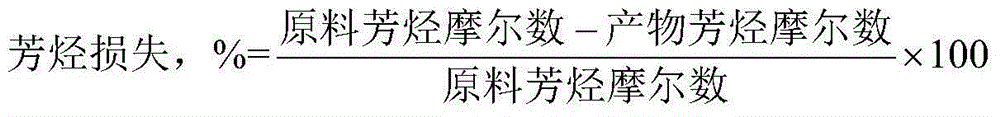

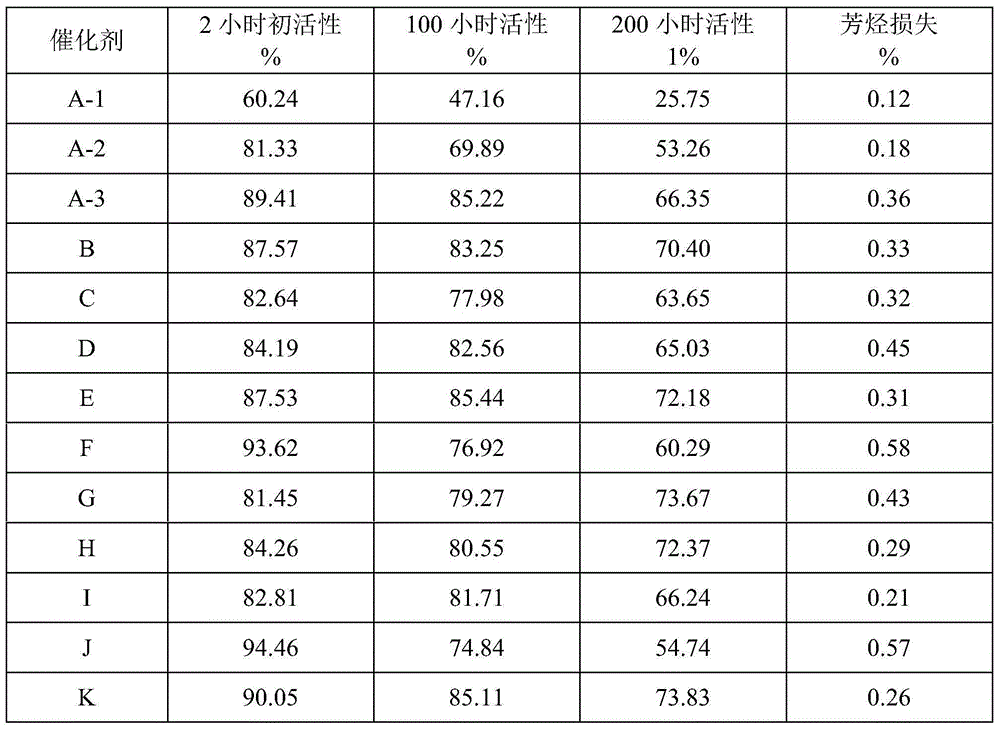

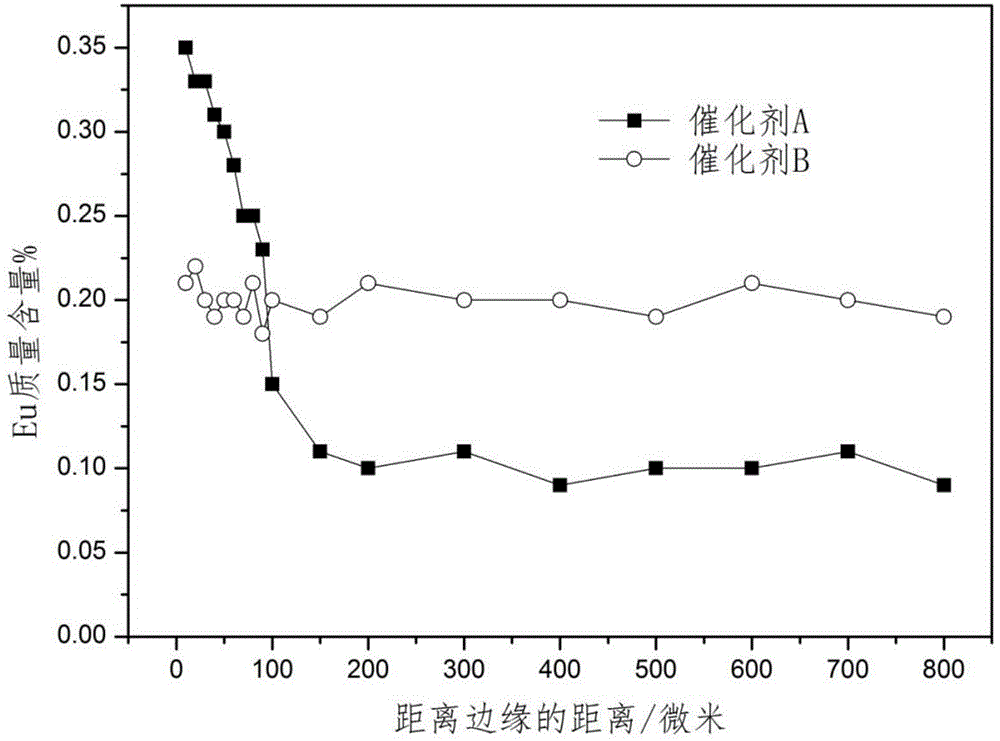

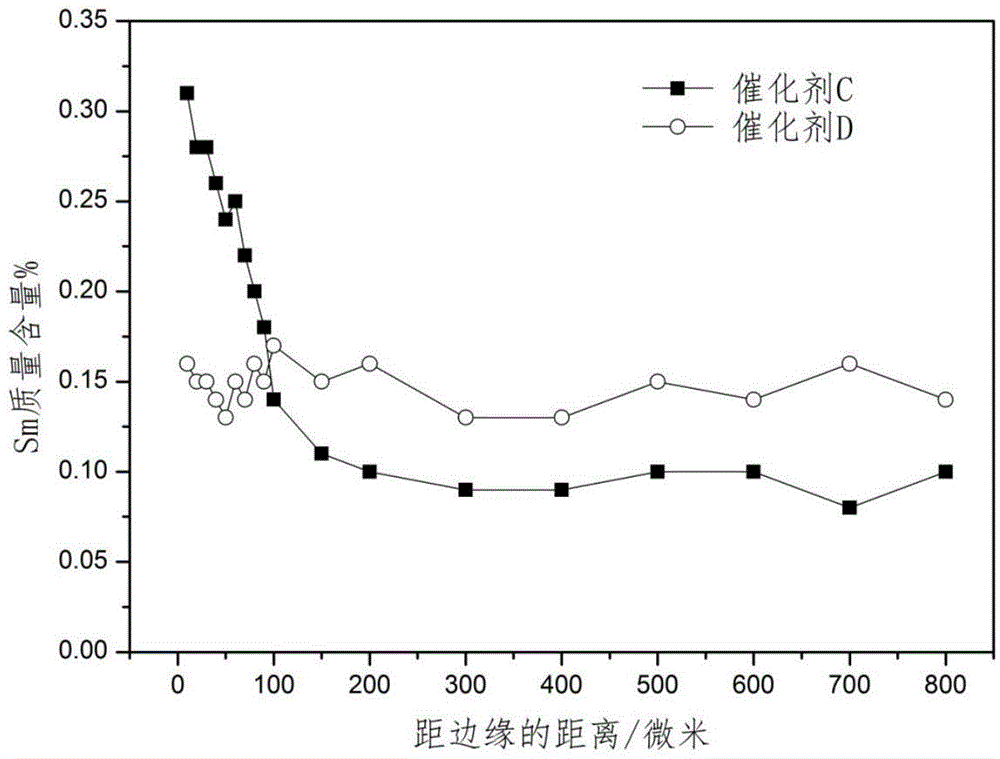

Preparation method of polymetallic reforming catalyst

ActiveCN105562043AHigh activityImprove stabilityPhysical/chemical process catalystsCatalytic naphtha reformingPlatinumRare earth

A preparation method of a polymetallic reforming catalyst comprises the following steps: allowing platinum, tin and rare earth metal uniformly-supported small catalyst spheres to be in solid contact with rare earth metal salt powder, and roasting the obtained mixture in air or water-containing air to obtain a reforming catalyst with rare earth metals enriched in the shell area of the catalyst, wherein the average content of rare earth metals in the shell area is 2-5 times the average content of rare earth metals in a center area, the catalyst shell area is an area from the outer edge of the small catalyst sphere to the center and with the thickness of 150[mu]m, the solid phase supported catalyst comprises an alumina carrier, platinum accounting for 0.1-2.0% of the mass of the alumina carrier, tin accounting for 0.1-2.0% of the mass of the alumina carrier, rare earth metals accounting for 0.05-1.0% of the mass of the alumina carrier, and chlorine accounting for 0.5-5.0% of the mass of the alumina carrier. The catalyst prepared through the method has good activity and stability and low carbon depositing rate in reforming reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon continuous liquid-phase hydrogenation process

ActiveCN105713659AReduce volumeThe possibility of "flying temperature" is reducedTreatment with hydrotreatment processesHydrogenation processOxygen

A hydrocarbon continuous liquid-phase hydrogenation process includes: hydrocarbon raw material and hydrogen are fully mixed through a gas-liquid mixer to form liquid-phase material flow saturated in dissolved oxygen, the liquid-phase material flow is sequentially in contact reaction with each level of catalyst bed liquid from top to bottom in a reactor containing at least two levels of catalysts, hydrogen is injected into a hydrogen distributor on the lower portion of each level of catalyst bed, and products are guided out from the reactor and subjected to subsequent treatment.

Owner:PETROCHINA CO LTD

Preparation method of Pt-Sn reforming catalyst

ActiveCN103316675AAchieving Directional LoadReduce carbon deposition rateCatalytic naphtha reformingMetal/metal-oxides/metal-hydroxide catalystsPlatinumAlkane

The invention relates to a preparation method of a Pt-Sn reforming catalyst, which comprises an alumina carrier, and calculated on the basis of the alumina carrier, 0.1-1.0 mass% of platinum, 0.1-2.0 mass% of tin and 0.5-5.0 mass% of chlorine. The preparation method of the catalyst includes: making the dried tin-containing alumina carrier adsorb a proper amount of water, which accounts for 3-30% of the pore volume of the tin-containing alumina carrier in terms of volume at 25DEG C, then using platinum acetylacetonate-containing alkane of C7-C9 as an impregnation solution to impregnate the tin-containing alumina carrier with absorbed water, and then subjecting the impregnated solid to drying, water chlorine activation and reduction. The method can make metal platinum directionally loaded to large holes above certain aperture. The prepared catalyst has good activity and stability in the reforming reaction, and has a low carbon deposition rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

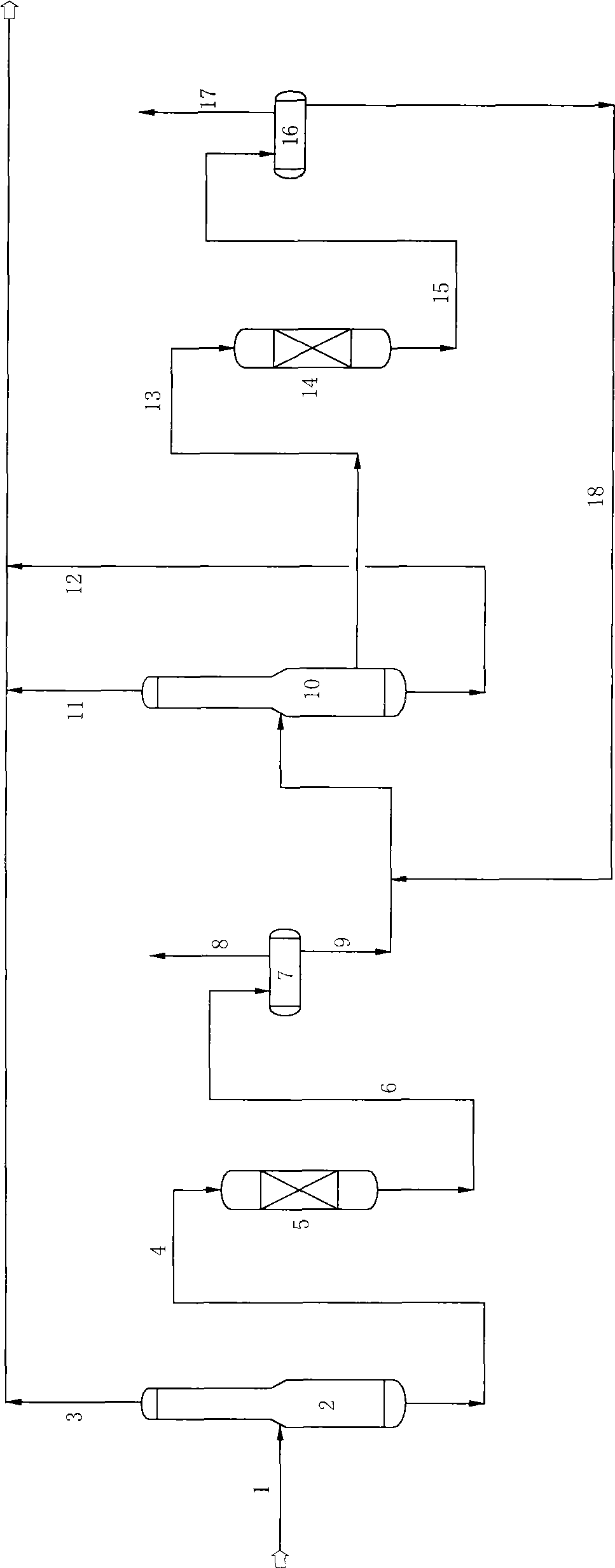

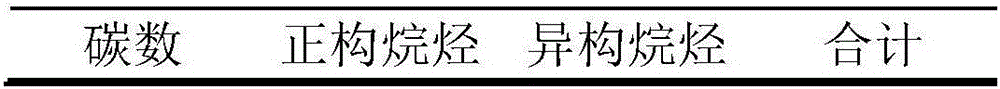

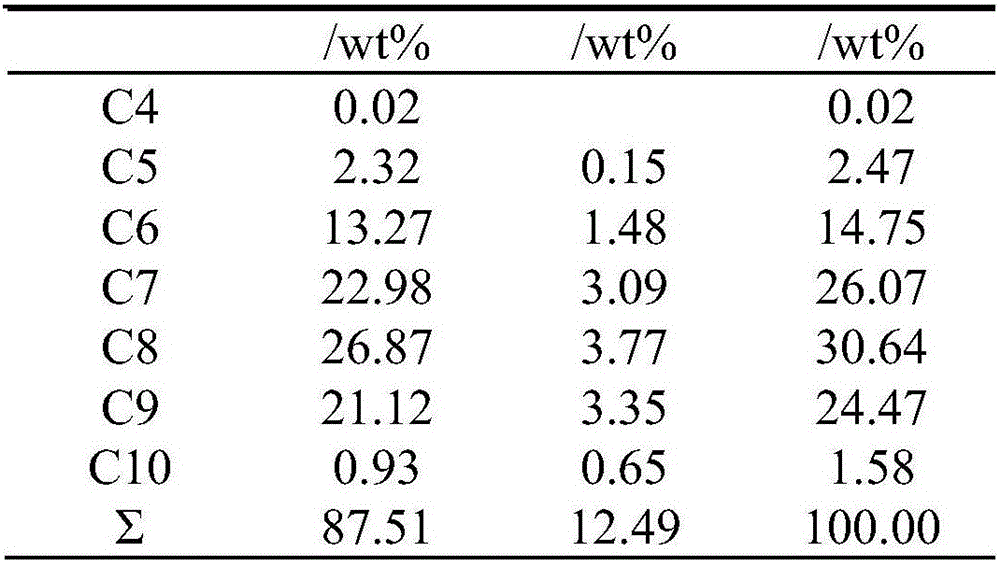

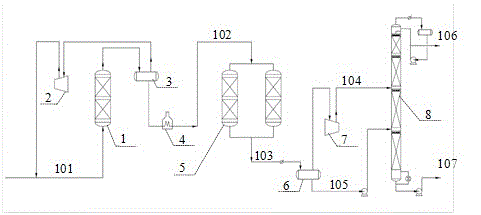

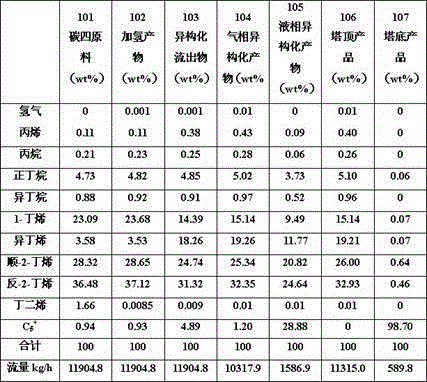

Light hydrocarbon isomerization method

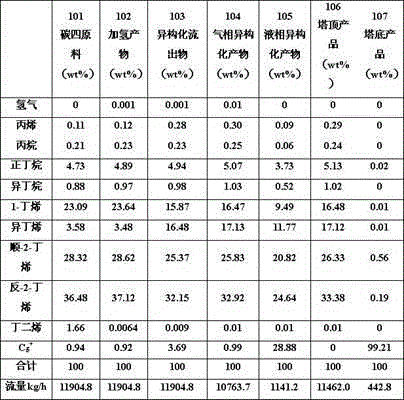

ActiveCN101544905AIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

The invention relates to a light hydrocarbon isomerization method comprising the following steps: light hydrocarbon materials are firstly separated by a de-isopentane tower, tower top streams are extracted as isomerization products, and tower bottom streams enter a front isomerization reactor to generate isomerization reaction; liquid phase streams obtained by the gas-liquid separation of outlet streams of the front reactor are separated in a de-isohexane tower, and tower top streams and tower bottom streams of the de-isohexane tower are extracted and then mixed with the tower top streams of the de-isopentane tower and are together taken as a gasoline-stripping stabilization system of the isomerization products; siding streams of the de-isohexane tower are extracted into a rear isomerization reactor; and liquid phase streams obtained by the gas-liquid separation of reaction streams of the rear isomerization reactor completely return and are mixed with the liquid phase streams of a gas-liquid separator of the front isomerization reaction system and together taken as feeding materials of the de-isohexane tower. The method has higher normal paraffin isomerization ratio, wherein the C6 normal paraffin realizes the complete isomerization basically, thereby greatly improving the octane number of the light hydrocarbon materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of SSZ-13 molecular sieve

PendingCN110156046AInhibition of growth rateShorten the timeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPolyacrylamideSilicon

The invention provides a preparation method and application of an SSZ-13 molecular sieve. The preparation method comprises the following steps: (1) dissolving sodium hydroxide, an aluminum source, a silicon source and a template in water so as to obtain a mixture 1, wherein in the mixture 1, the molar ratio of water, an alkali source, the aluminum source, the silicon source and the template is (30-50):(0.1-0.3):(0.02-0.01):1:(0.1-0.3), and the template is organic amine; (2) adding polyacrylamide to the mixture 1 so as to obtain a mixture 2; (3) performing a crystallization reaction on the mixture 2 so as to obtain an initial product; (4) performing acquisition of SSZ-13 molecular sieve raw powder; and (5) performing baking for a certain period of time so as to obtain the SSZ-13 molecular sieve. The preparation method has the advantages that polyacrylamide is introduced, the growth rate of SSZ-13 molecular sieve grains is inhibited, and the small-grain SSZ-13 molecular sieve has higherselectivity to low-carbon olefin, a lower carbon deposition rate and a longer single-pass reaction life.

Owner:EAST CHINA UNIV OF SCI & TECH

Isomerization method for light hydrocarbon

ActiveCN101497815AGuaranteed isomerization rateImprove liquid yieldRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationAlkaneIsomerization

The invention relates to a light hydrocarbon isomerization method. Isomerization reaction is performed for light hydrocarbon raw material in an isomerization reactor at the front part, gas-liquid separation is performed for the outlet stream of the reactor at the front part, the obtained liquid phase stream is separated in an isohexane removing tower, the overhead stream mainly comprising C5 cut fraction and dimethyl C6 alkane is mixed with the bottom stream mainly comprising C7 and cut fractions more than C7 so as to be used as isomate to enter into a gasoline stabilizer, the side stream mainly comprising C6 n-alkane and monomethyl C6 alkane is led into an isomerization reactor at the rear part; after the reaction stream of the isomerization reactor at the rear part is separated, the liquid phase stream all returns and is mixed with the liquid phase stream of a gas-liquid separator of the isomerization reactor at the front part so as to be used as the feeding of the isohexane removing tower. The method has higher n-alkane isomerization ratio and greatly improves the octane number of the light hydrocarbons raw material because the C6 n-alkane basically realizes the full isomerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

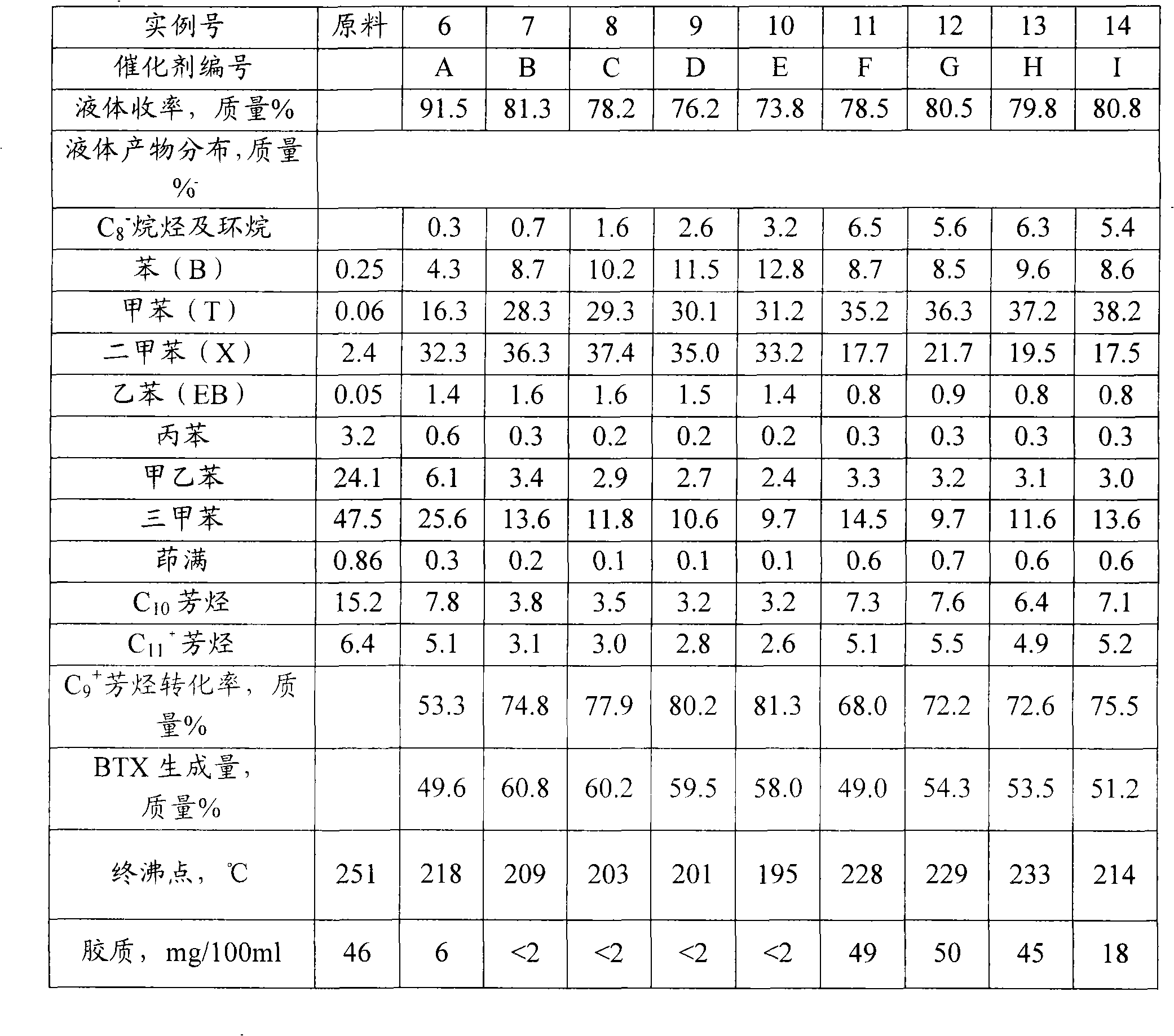

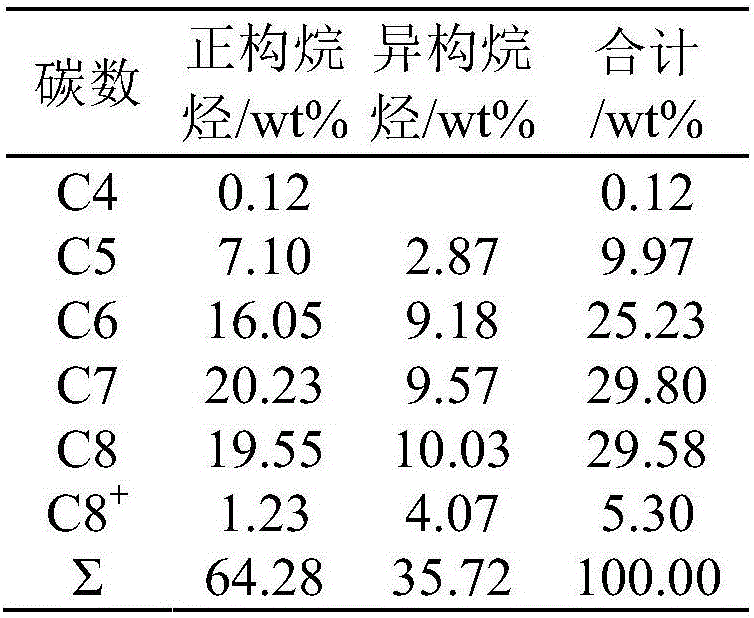

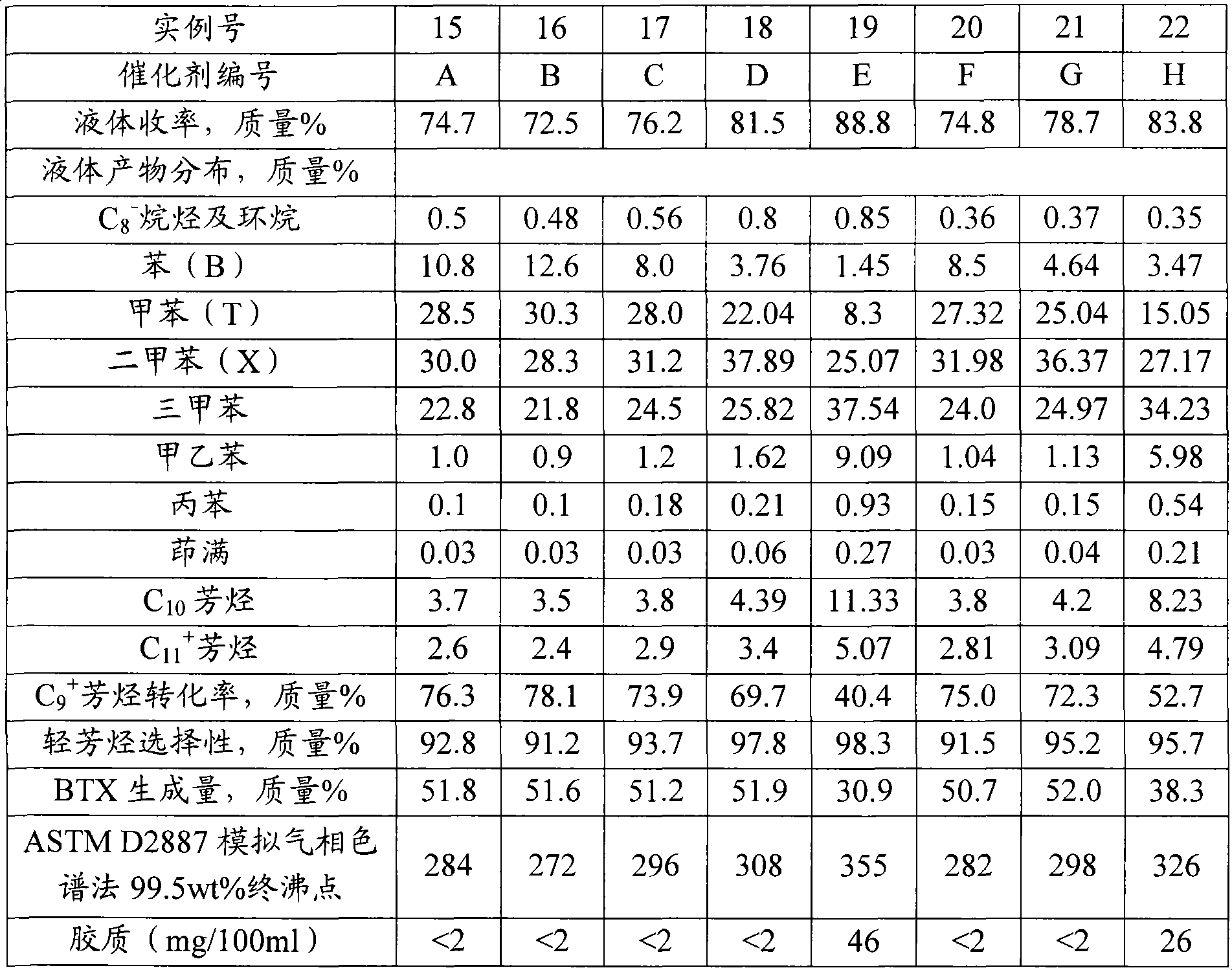

Method for conveying C<+>9 heavy aromatics to light aromatics

ActiveCN101357876AReduce carbon deposition rateImprove conversion ratePhysical/chemical process catalystsHydrocarbonsIridiumHydrogen

The invention provides a method for lightening heavy aromatic hydrocarbon C9<+>; the method comprises that the heavy aromatic hydrocarbon C9<+> is lightened by contacting and taking react with catalysts under the hydrogen with the temperature of 380 to 600 DEG C and the pressure of 0.1 to 5.0MPa. The catalysts comprise high temperature resistance inorganic oxide carriers, and 0.01 to 3.0 percent of halogen and 0.01 to 5.0 percent of iridium by mass percentage by taking carriers as calculation standards. The method is used for lightening heavy aromatic hydrocarbon C9<+>, and is characterized by high light conversion, high yield of dimethyl benzene, little carbon deposition of catalysts and effectively reducing the end boiling point and gum content of the heavy aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Naphtha reforming catalyst, and preparation method thereof

ActiveCN106391098AHigh activityHigh yieldMolecular sieve catalystsNaphtha reformingMolecular sieveAlkane

The invention discloses a naphtha reforming catalyst, and a preparation method thereof. The naphtha reforming catalyst comprises, by mass, 93.0 to 99.9 parts of a carrier, 0.1 to 2.0 parts of a metal, 0 to 5.0 parts of carbon, wherein the mass amount of carbon is higher than 0. According to the preparation method, a certain amount of a monosaccharide is added in preparation process of the Pt-KL reforming catalyst, so that metal Pt dispersion is improved, carbon deposition rate of the catalyst in reaction process is reduced, and Pt-KL catalyst reforming reaction performance is improved; the naphtha reforming catalyst possesses relatively high paraffin aromatization reaction activity and reforming liquid yield; when active metal component Pt is introduced in the preparation method, a dipping liquid is alkaline, pH value is controlled to be 10 to 13, adsorption effect of Pt precursor ion with carrier KL molecular sieve is improved, so that it is beneficial for dispersion of metal Pt.

Owner:SYNFUELS CHINA TECH CO LTD

Anti-carbon-formation chromium-based catalyst for preparing propylene from propane through oxydehydrogenation, and preparation method and application thereof

ActiveCN107715862AImprove stabilityHigh mechanical strengthHeterogenous catalyst chemical elementsCatalystsActive componentDehydrogenation

The invention provides an anti-carbon-formation chromium-based catalyst for preparing propylene from propane through oxydehydrogenation, and a preparation method and application thereof, belonging tothe technical field of chemical catalysis. According to the invention, rod-like alumina originated from ZL201110196192.4 and rich in unsaturated ligand is used as a carrier; since the surface of the Al2O3 has a great number of hydroxyl unsaturated ligand Al<3+>, the active component Cr2O3 can be better anchored, strong interaction among the Cr2O3 and the Al2O3 is formed, agglomeration of the Cr2O3during a reaction is prevented, side reactions are inhibited, and propylene is prevented from carbon formation due to further dehydrogenation and polymerization; thus, the catalyst is allowed to maintain high propylene selectivity and is improved in stability. Therefore, the Al2O3 used as the carrier is helpful for improving the selectivity and inactivation resistance of the catalyst. Compared with conventional catalysts, the catalyst provided by the invention is high in propylene selectivity, slow in carbon formation and inactivation rates, high in stability and greatly improved in mechanical strength, and has good industrial application prospects.

Owner:DALIAN UNIV OF TECH

C9 aromatic hydrocarbon lightening catalyst and lightening method thereof

ActiveCN101444732AReduce carbon deposition rateImprove transformation activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsIridiumHalogen

The invention relates to a C9<+> aromatic hydrocarbon lightening catalyst, comprising a high-temperature-resistant inorganic oxide carrier and the following components accounted by taking the dry basis carrier as benchmark: 0.01-10.0 weight percent of hydrogenation metal, 0.01-1.0 weight percent of IVA-group metal and 0.1-5.0 weight percent of halogen; wherein, the hydrogenation metal is selected from iron, cobalt, nickel and iridium. The catalyst is used for lightening C9<+> heavy aromatic hydrocarbon. The catalyst has high lightening transformation ratio, high aromatic hydrocarbon yield and less carbon deposition; and the catalyst can effectively lower final boiling point and gum level of the heavy aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

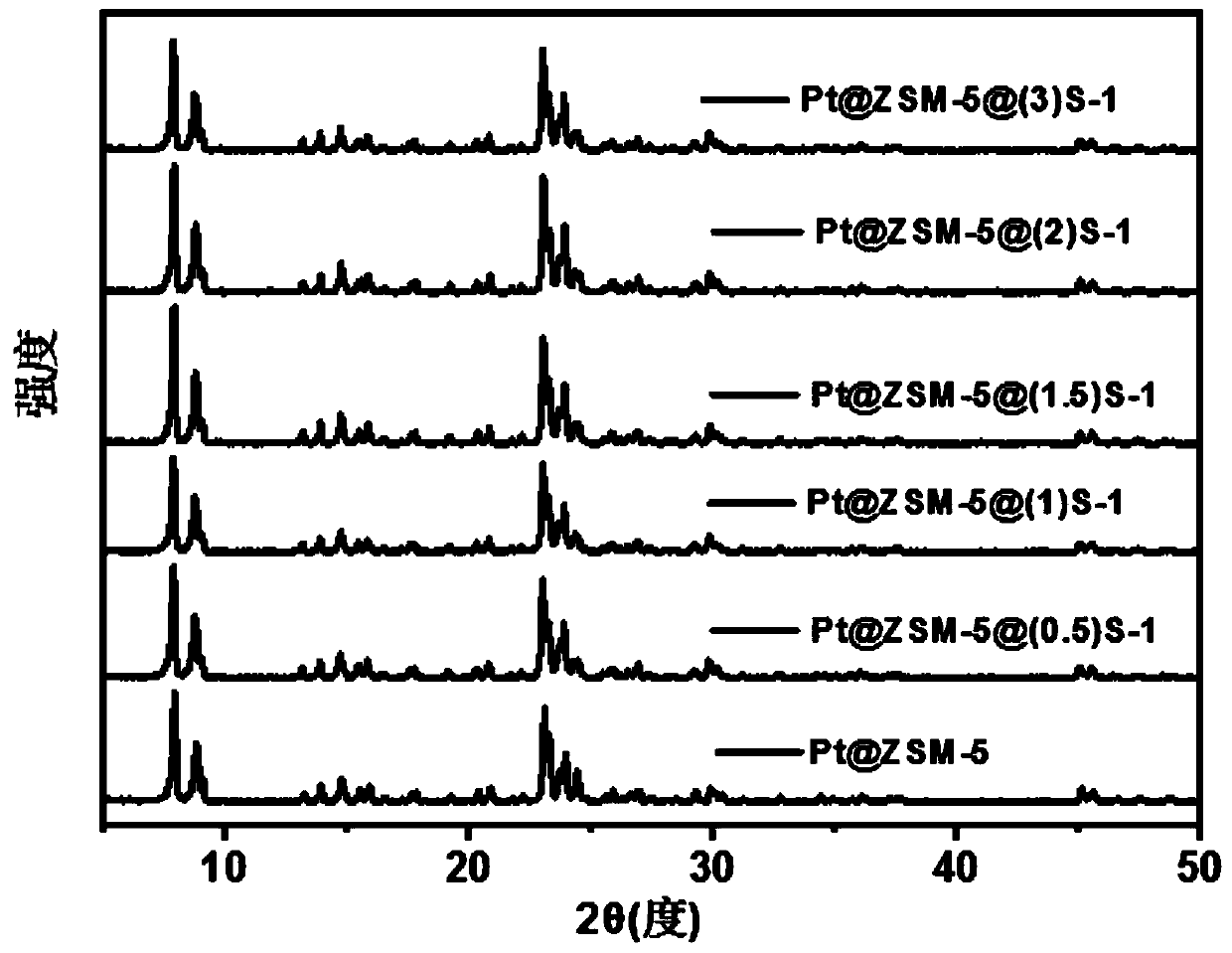

Catalyst for preparing p-xylene as well as preparation method and application thereof

PendingCN111569935AAvoid secondary isomerization side reactionsGood choiceMolecular sieve catalystsHydrocarbonsMolecular sievePtru catalyst

The invention relates to a catalyst for preparing p-xylene as well as a preparation method and application of the catalyst. The catalyst is a core-shell structure molecular sieve and comprises an inner core molecular sieve and a shell layer molecular sieve coating the surface of the inner core molecular sieve, wherein the inner core molecular sieve is a ZSM-5 molecular sieve, the shell layer molecular sieve is an S-1 molecular sieve, and hydrogenation metal is packaged in the inner core molecular sieve; the catalyst has high conversion rate and selectivity to the product p-xylene in the process of catalyzing the alkylation reaction of toluene and methanol, the carbon deposition rate of the catalyst in the catalytic process is obviously reduced, and the catalyst has high stability.

Owner:CHINA NAT OFFSHORE OIL CORP +4

Method for producing isobutene from MTO byproduct C4

ActiveCN105712832ALow costHigh activityHydrocarbon by isomerisationMolecular sieve catalystsLiquid productButene

The invention discloses a method for producing isobutene from an MTO byproduct C4. The method comprises the following steps: (1) an MTO byproduct C4 raw material and hydrogen enters a hydrogenation reactor, and the content of butadiene is allowed to decrease to less than 100 ppm under the action of a selective hydrogenation catalyst; (2) hydrogen is separated from hydrogenation products and enters an n-butene skeletal isomerization reactor, and n-butene is isomerized into isobutene under the action of an isomerization catalyst; and (3) an isomerization product enters a gas-liquid separation tank and is cooled, a separated gaseous product and a separated liquid product both enter a fractionate tower, wherein the distance between the gaseous product and the top of the fractionate tower is 1 / 4 to 1 / 3 of the height of the fractionate tower and the distance between the liquid product and the top of the fractionate tower is 2 / 3 to 3 / 4 of the height of the fractionate tower, a mixed C4 product containing isobutene is extracted from the top of the fractionate tower, and C5<+> gasoline is extracted from the bottom of the fractionate tower. The method has the advantages of a low oil-generating ratio, short regeneration time and capability of processing a C4 raw material with high butadiene content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal-modified MFI@MFI core-shell molecular sieve catalyst and preparation thereof

ActiveCN110882718AReduce churn rateReduce strong acid densityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a metal-modified MFI@MFI core-shell molecular sieve catalyst and preparation thereof. The preparation method includes (1) subjecting a ZSM-5 molecular sieve to metal oxide modification by adopting a nano metal oxide and through a solvothermal method to obtain a modified ZSM-5 molecular sieve, with the metal being one of or a mixture of more selected from Mn, Ce, Fe, Co, Ni,La, Ga and W; (2) subjecting the modified ZSM-5 molecular sieve obtained in the step (1) to secondary hydro-thermal synthesis in a crystallization liquid of a Silicalite-1 molecular sieve or B-ZSM-5 molecular sieve to obtain the metal-modified MFI@MFI core-shell molecular sieve catalyst. The catalyst can greatly reduce the coking rate of a methanol-to-propylene reaction, and improve the propyleneselectivity and catalytic lifetime, and the modification effect is improved more than the traditional method.

Owner:DALIAN HAIXIN CHEM IND

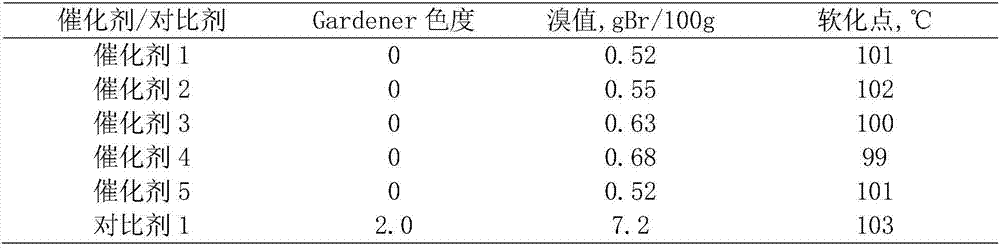

Catalyst for C5 petroleum resin hydrogenation and preparation method thereof

InactiveCN106861730AOrderly accumulationAvoid the problem of needing high temperature roasting to fix zinc oxidePhysical/chemical process catalystsPtru catalystHigh activity

The invention discloses a catalyst for C5 petroleum resin hydrogenation and a preparation method thereof. The catalyst comprises the following components by mass: 78.0-96.0wt% of a composite carrier containing zinc oxide-alumina, 1.0-8.0wt% of an active component, 1.0-15.0wt% of nickel phosphide, and 0.1-2.5wt% of lanthanum oxide. C5 petroleum resin has high hydrogenation activity and good activity stability, the catalyst active center loss rate is low, and the operation period is long.

Owner:QINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com