SAPO molecular sieve, and preparation method and purpose thereof

A molecular sieve, hollow technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problem that catalyst particle size and acidity cannot reach long life, molecular sieve acid site density is low, silicon is not complete Utilization and other issues, to achieve the effect of reducing concentration and residence time, increasing utilization efficiency, and increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

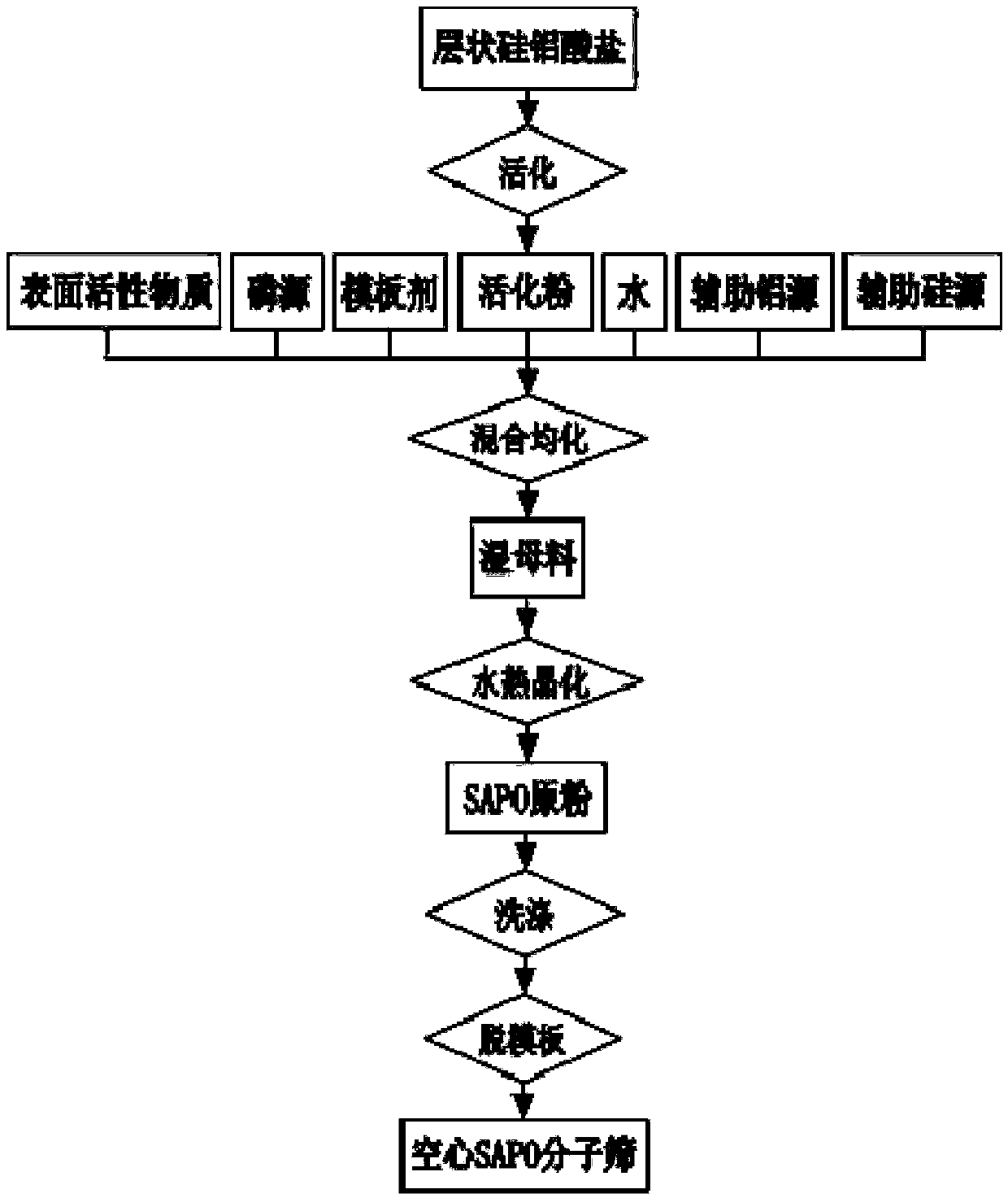

[0096] As an embodiment of the present invention, the preparation method of sheet SAPO molecular sieve of the present invention comprises the following steps:

[0097] (1) Activated layered aluminosilicate;

[0098] (2) Mix and homogenize the activated layered aluminosilicate, phosphorus source, auxiliary aluminum source, auxiliary silicon source and water to prepare a wet masterbatch; wherein, the molar ratio of Al and Si in the wet masterbatch is 1.2~100; SiO 2 、Al 2 o 3 ,P 2 o 5 、H 2 The molar ratio of O and templating agent is (0.01-2):(0.1-1.5):(0.1-1.5):(1-500):(0.1-10);

[0099] (3) After hydrothermal crystallization of the wet masterbatch, cooling, filtering, washing and drying, the obtained solid is SAPO molecular sieve raw powder;

[0100] Optionally,

[0101] (5) The raw SAPO molecular sieve powder is treated with a release agent to obtain a SAPO molecular sieve.

[0102] figure 1 It is a process flow chart of the production method of sheet-shaped SAPO mol...

Embodiment 1

[0105] A kind of preparation method of flaky SAPO molecular sieve comprises the steps:

[0106] (1) Grinding Suzhou kaolin (90.5% kaolinite content) to an average particle size of less than 0.5 μm to obtain a grinding activated powder;

[0107] (2) Take 30.0g of ground activated powder and add it to 200.0g of deionized water, then add 52.0g of 85.0% concentrated phosphoric acid, 16.4g of pseudo-boehmite (78.2% alumina content), and 60.0g of morpholine , stirred vigorously to obtain a wet masterbatch; in the wet masterbatch, SiO 2 、Al 2 o 3 ,P 2 o 5 、H 2 The mol ratio of O and templating agent is 0.210:0.231:0.226:11.111:0.689;

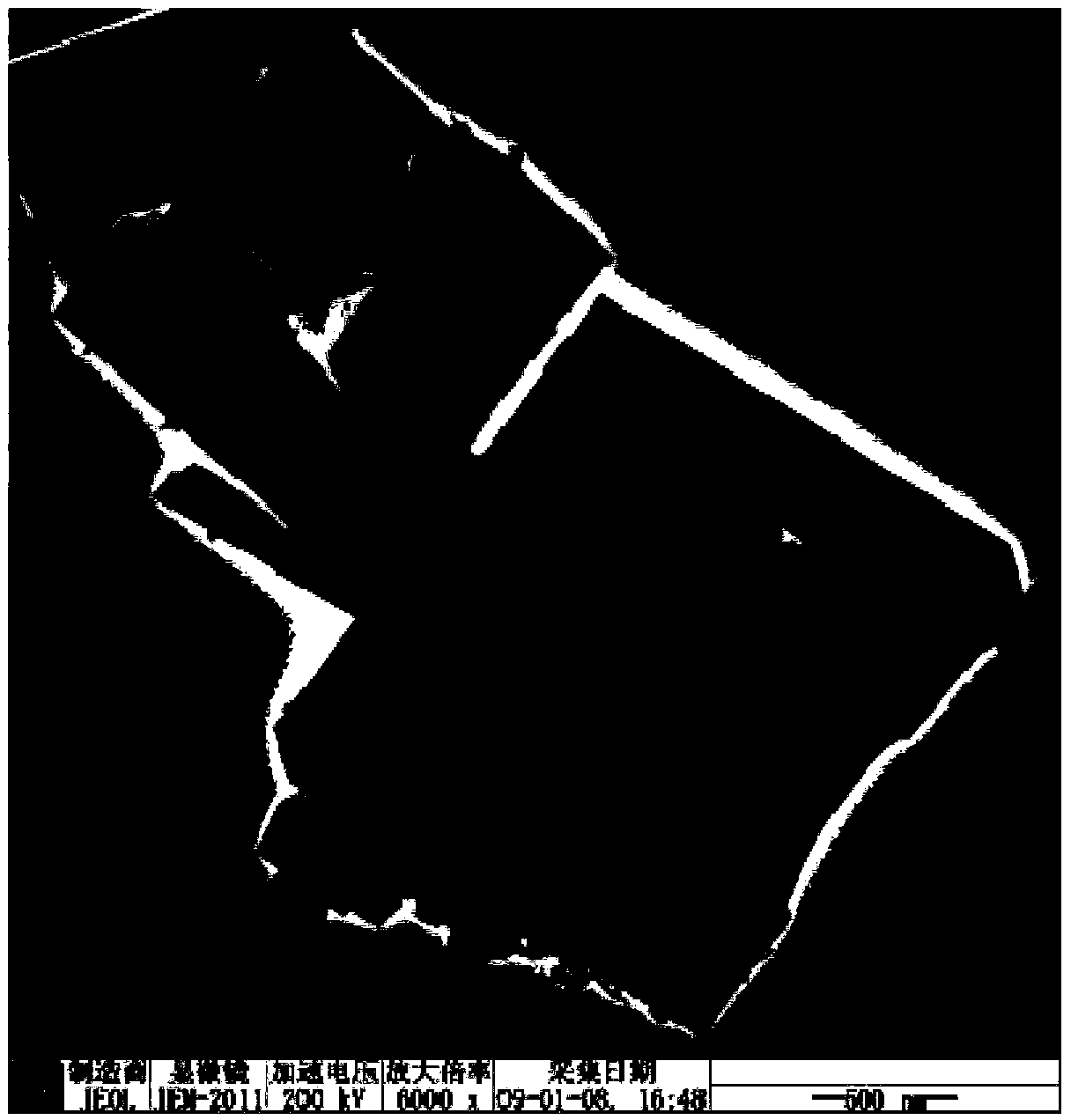

[0108] (3) Put 40.0g of the above wet masterbatch in a self-pressurized reaction kettle, distill and crystallize at 200°C for 20h, cool, and after solid-liquid separation, wash and dry the obtained solid, the obtained solid is hollow SAPO- 34 molecular sieve raw powder;

[0109] (4) Put the hollow SAPO-34 molecular sieve raw powder in a muffle ...

Embodiment 2

[0113] A kind of preparation method of flaky SAPO molecular sieve comprises the steps:

[0114] (1) Grinding Suzhou kaolin (90.5% kaolinite content) to an average particle size of less than 0.3 μm to obtain a grinding activated powder;

[0115] (2) Take 30.0g of ground activated powder and add it to 200.0g of deionized water, then add 52.0g of 85.0% concentrated phosphoric acid, 16.4g of pseudo-boehmite (78.2% alumina content), and 70.0g of morpholine , stirred vigorously to obtain a wet masterbatch; in the wet masterbatch, SiO 2 、Al 2 o 3 ,P 2 o 5 、H 2 The mol ratio of O and templating agent is 0.210:0.231:0.226:11.111:0.803;

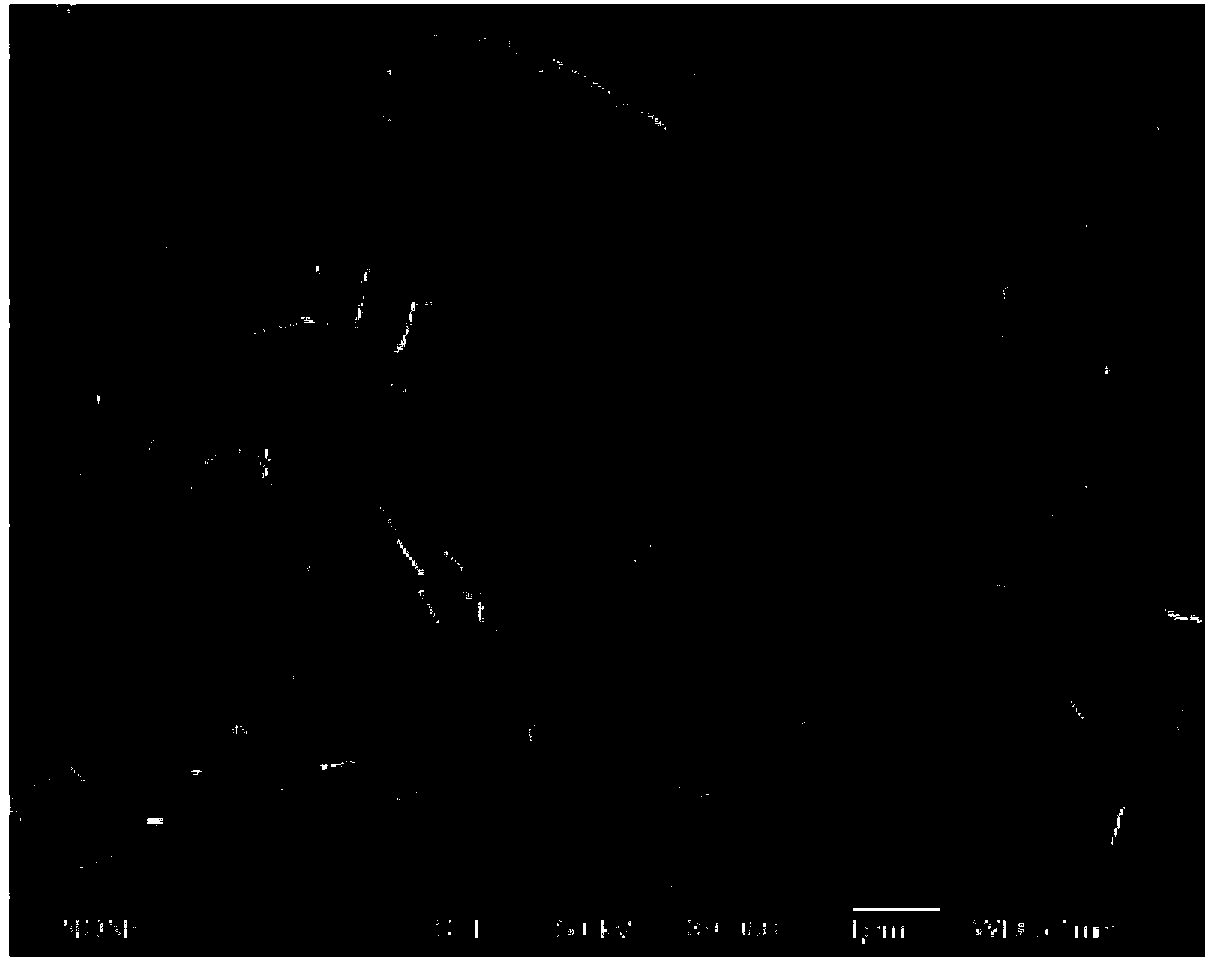

[0116] (3) Put 40.0 g of the above wet masterbatch in a self-pressurized reaction kettle, distill and crystallize at 160°C for 50 days, cool, and the obtained solid is hollow SAPO-34 molecular sieve raw powder;

[0117] (4) Put the hollow SAPO-34 molecular sieve raw powder in a muffle furnace, raise the temperature to 900°C in flowing air at 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com