Patents

Literature

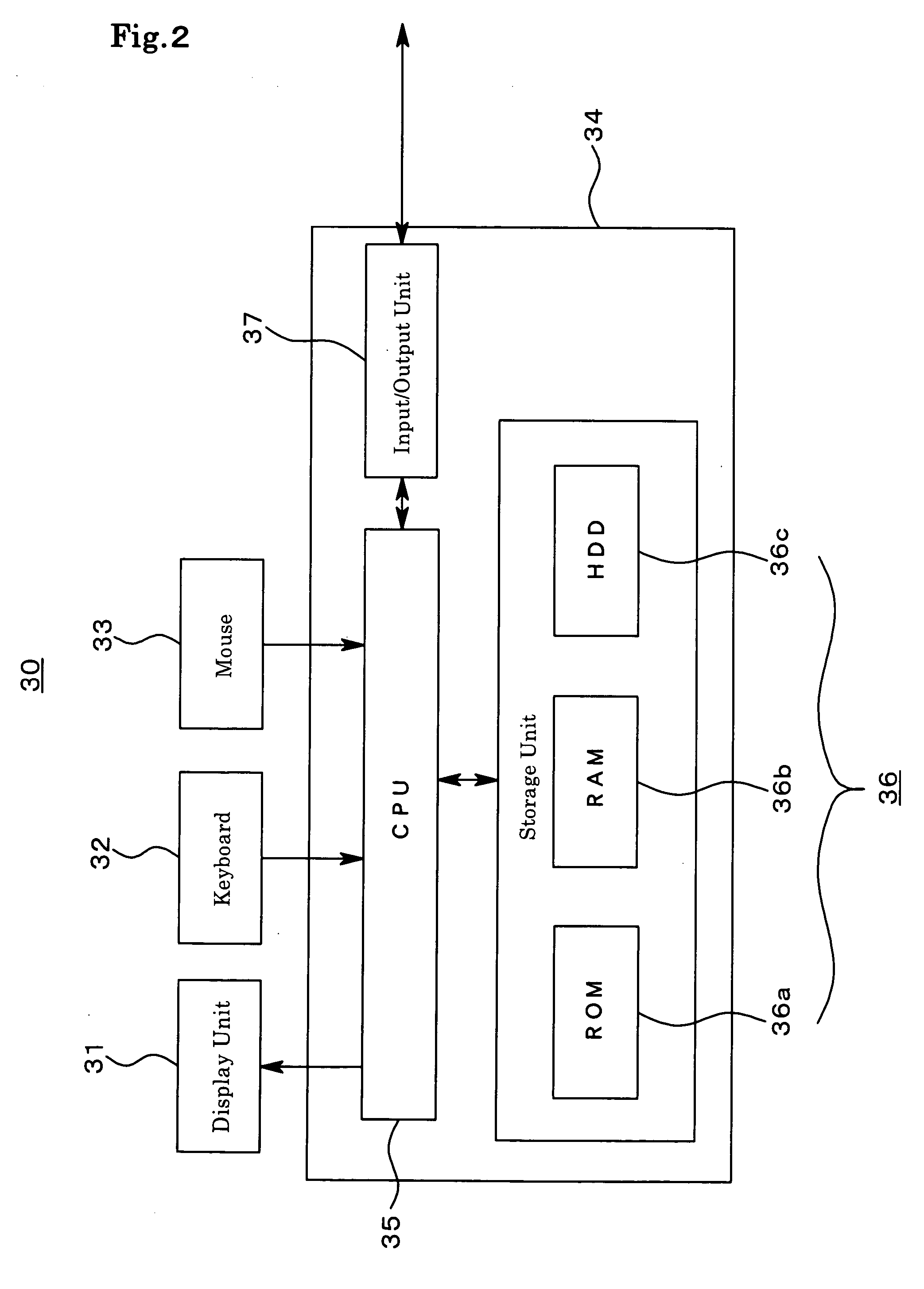

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

380results about How to "Adjustable density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano porous high-temperature-insulating material taking thixotropic colloid as template agent and preparation method for high-temperature-insulating material

InactiveCN105314999AAvoid reunion and scatter problemsSimple preparation processCeramicwareThermal conductivityAerospace

The invention relates to a high-temperature-insulating material and a preparation method therefor and particularly relates to the high-temperature-insulating material, which has a nano porous structure, prepared through forming an aqueous-phase uniform three-dimensional-network nano porous structure by taking thixotropic colloid as a template agent and adding a binding agent, aggregates, powder materials, an opacifier and admixtures. The preparation method for the high-temperature-insulating material, disclosed by the invention, is simple and easy in operation, low in production cost and environment-friendly and safe in process, does not need high-pressure special equipment, is free of combustible and explosive or other harmful substances and is beneficial to mass production. The high-temperature-insulating material disclosed by the invention has the characteristics of light weight, high strength and low coefficient of thermal conductivity, can be used for preparing high-temperature-insulating bricks, heat-insulating plates, special-shaped pieces and coating materials and can be applied to the heat insulating protection of equipment such as high-temperature furnace hearths, pipelines and valves in the fields of aerospace and military industries, metallurgical forging, petroleum refining, electric power and the like, so that the safety of use and the level of energy saving and consumption lowering are improved.

Owner:浙江圣润纳米科技有限公司

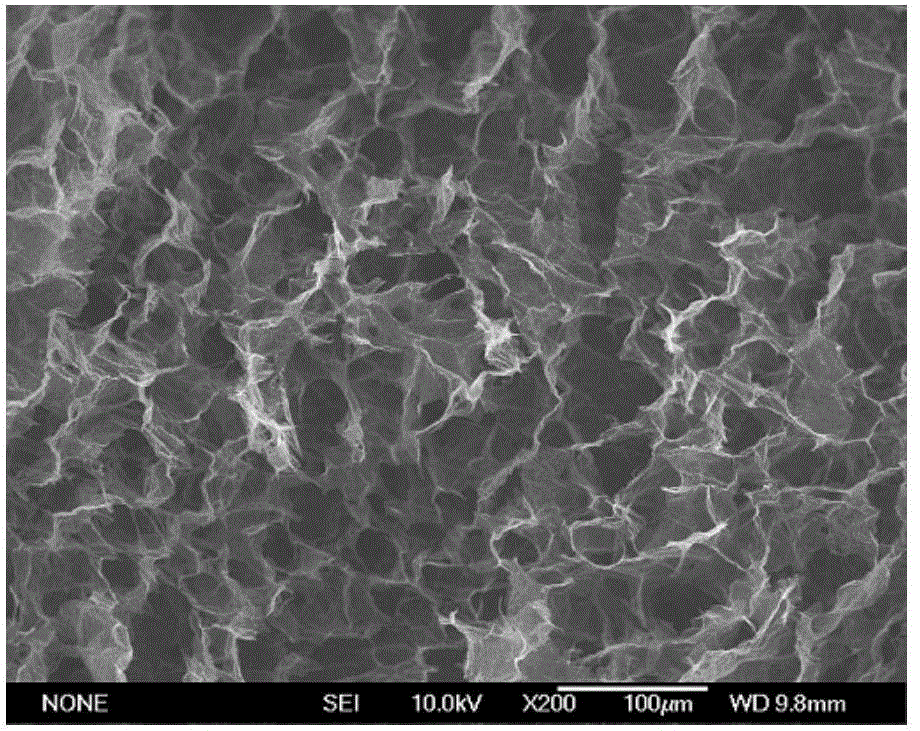

Graphene aerogel as well as preparation method and application thereof

The invention discloses graphene aerogel and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing graphene oxide dispersion liquid with an amine water-soluble compound to obtain graphene oxide mixed liquid, wherein the amine water-soluble compound is selected from one or more of diethylamine, ethidene diamine, propane diamine, butane diamine, diethylene triamine, triethylene tetramine, tetraethylene pentamine, allylamine polymer and N,N'-bis(2-aminoethyl)-1,3-propane diamine; (2) irradiating the graphene oxide mixed liquid by high-energy rays under the anaerobic condition to obtain amino-modified graphene aerogel; (3) performing freeze-drying or supercritical CO2 drying to obtain the graphene aerogel. The graphene aerogel adopts a porous and macroporous structure, is relatively uniform in structure, and can be used for adsorbing an organic solvent; moreover, the preparation method is simple and environment-friendly.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

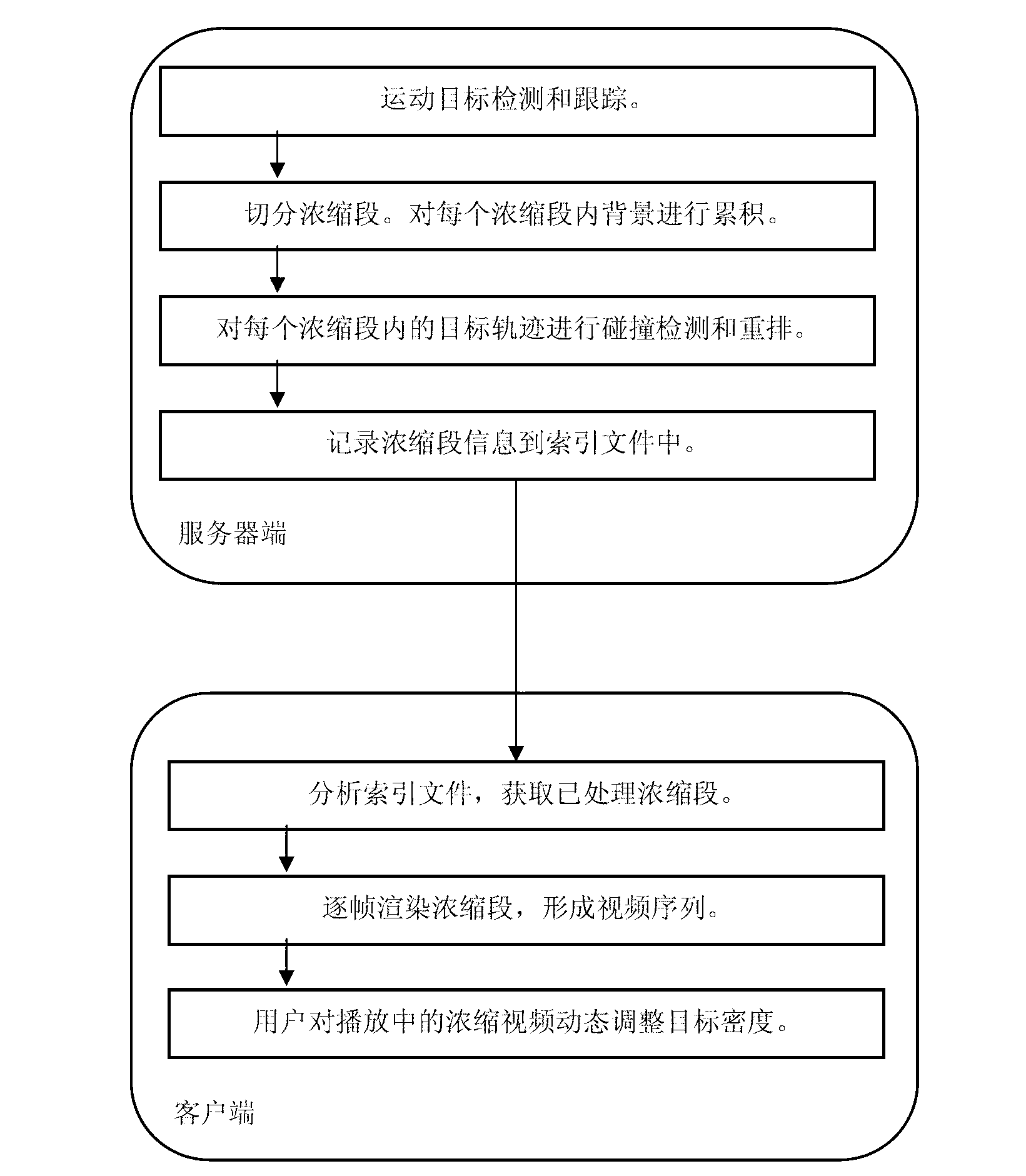

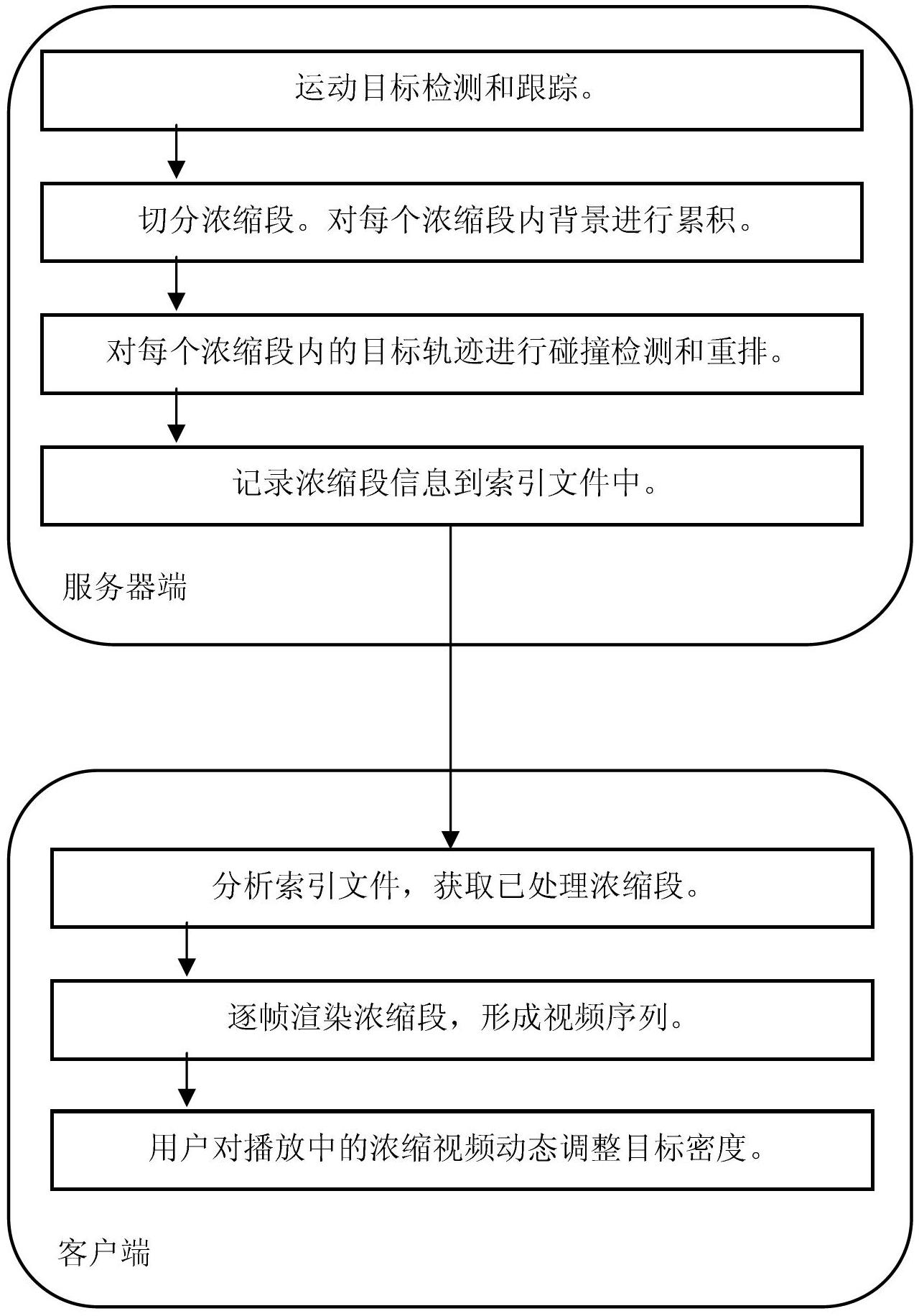

Rapid video concentration abstracting method

ActiveCN102708182AGood tracking target continuityContour area completeSpecial data processing applicationsCollision detectionVideo sequence

The invention relates to a rapid video concentration abstracting method. The conventional video concentration technology is poor in detection rate and tracking rate to a moving target, and cannot effectively concentrate the video length. The rapid video concentration abstracting method is characterized in that a server side detects and tracks the moving target in a pretreatment video, judges according to the length of the video or the number of the detection targets in the video, cuts the video into multiple concentration segments, performs collision detection and rearrangement on the target tracks in each concentration segment, and then, records the concentration segment information and enters in an index file; and a client side analyzes the index file stored in the server side, obtains the treated concentration segments, renders the concentration segments frame by frame to form a video sequence, and dynamically regulates the target density in the played concentrated video. According to the method, the target tracking continuity is excellent, profile region is complete, the detection rate is high, the false detecting rate is low, and the target density at each time point of the concentrated video is substantially consistent.

Owner:ZHEJIANG ICARE VISION TECH

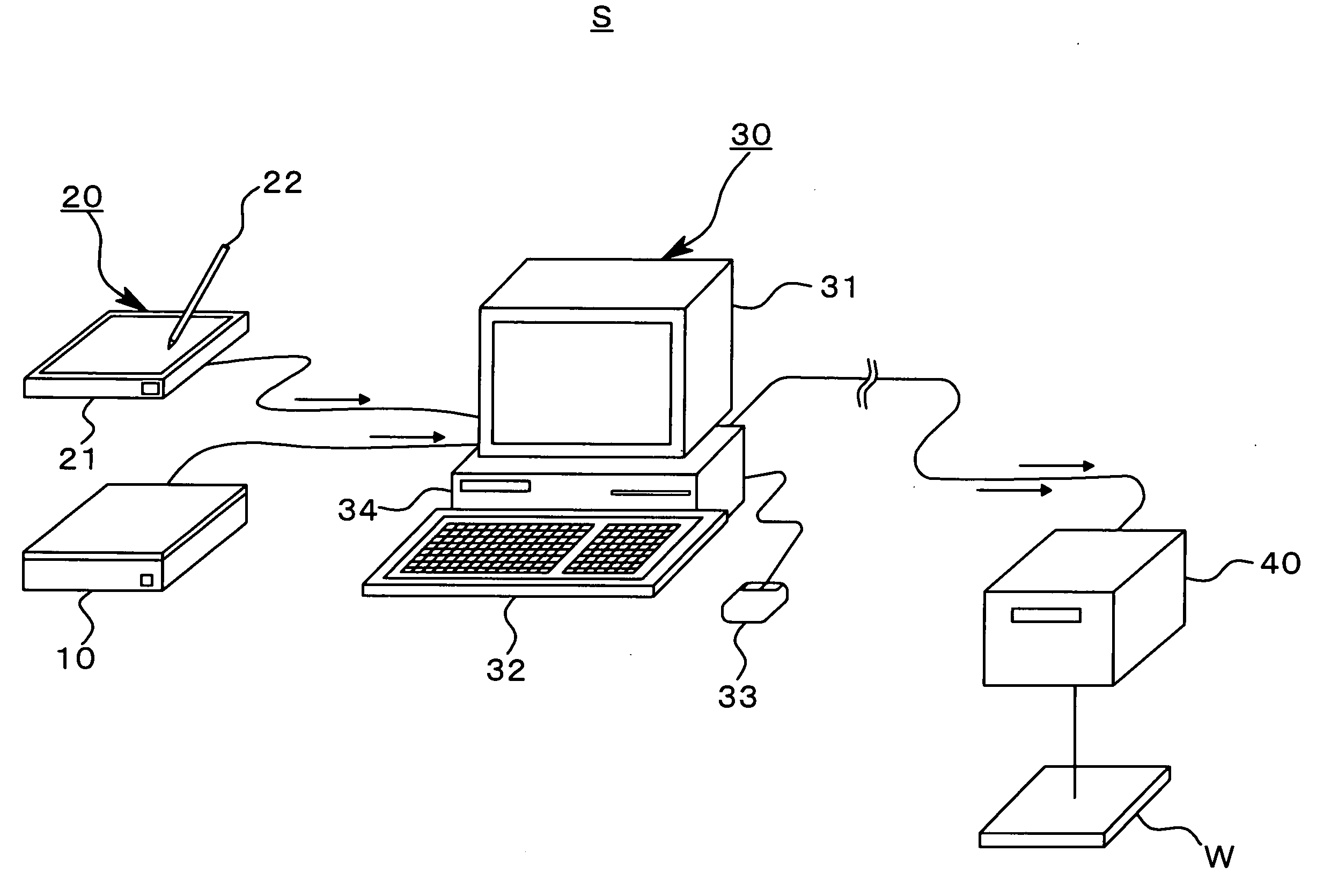

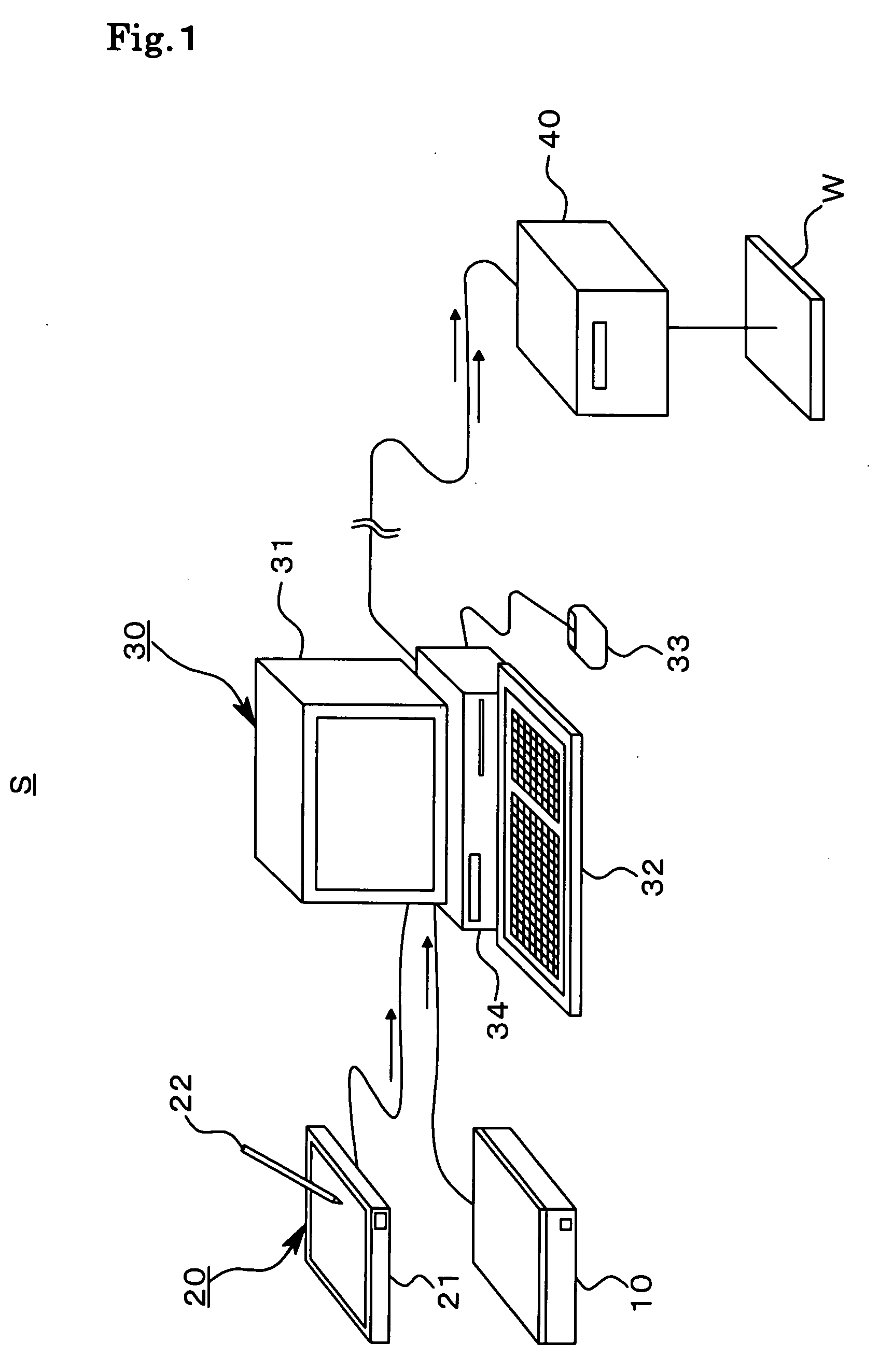

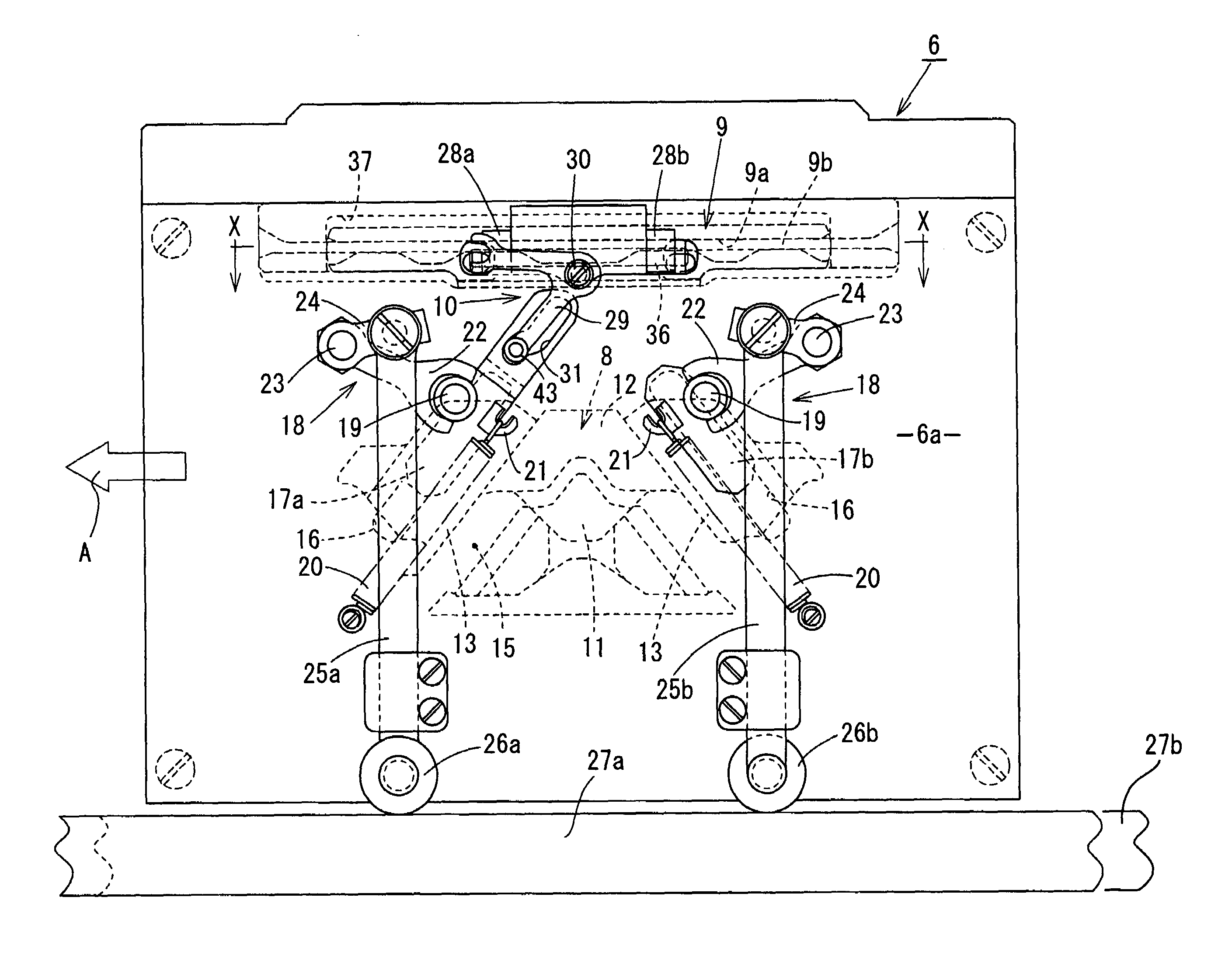

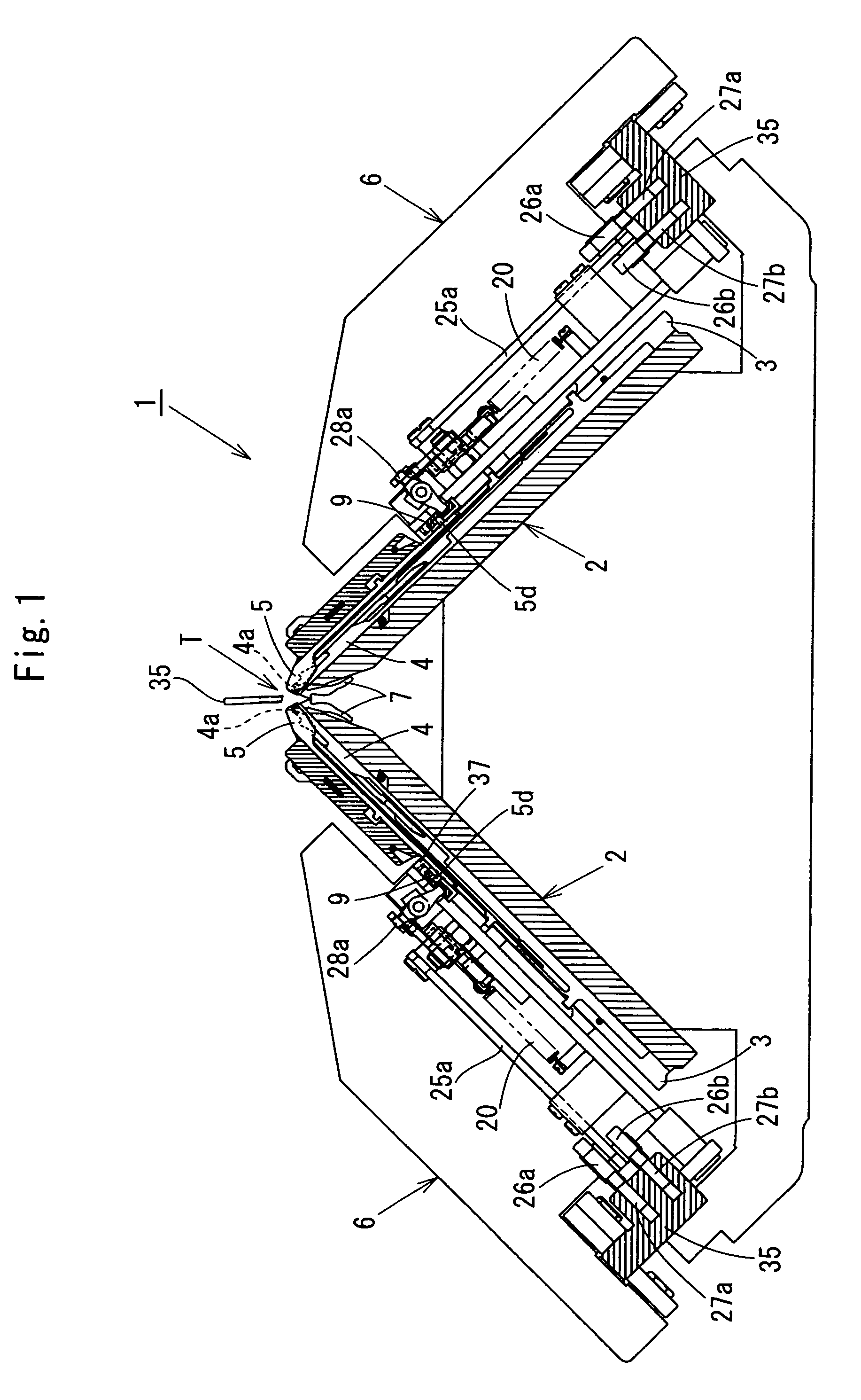

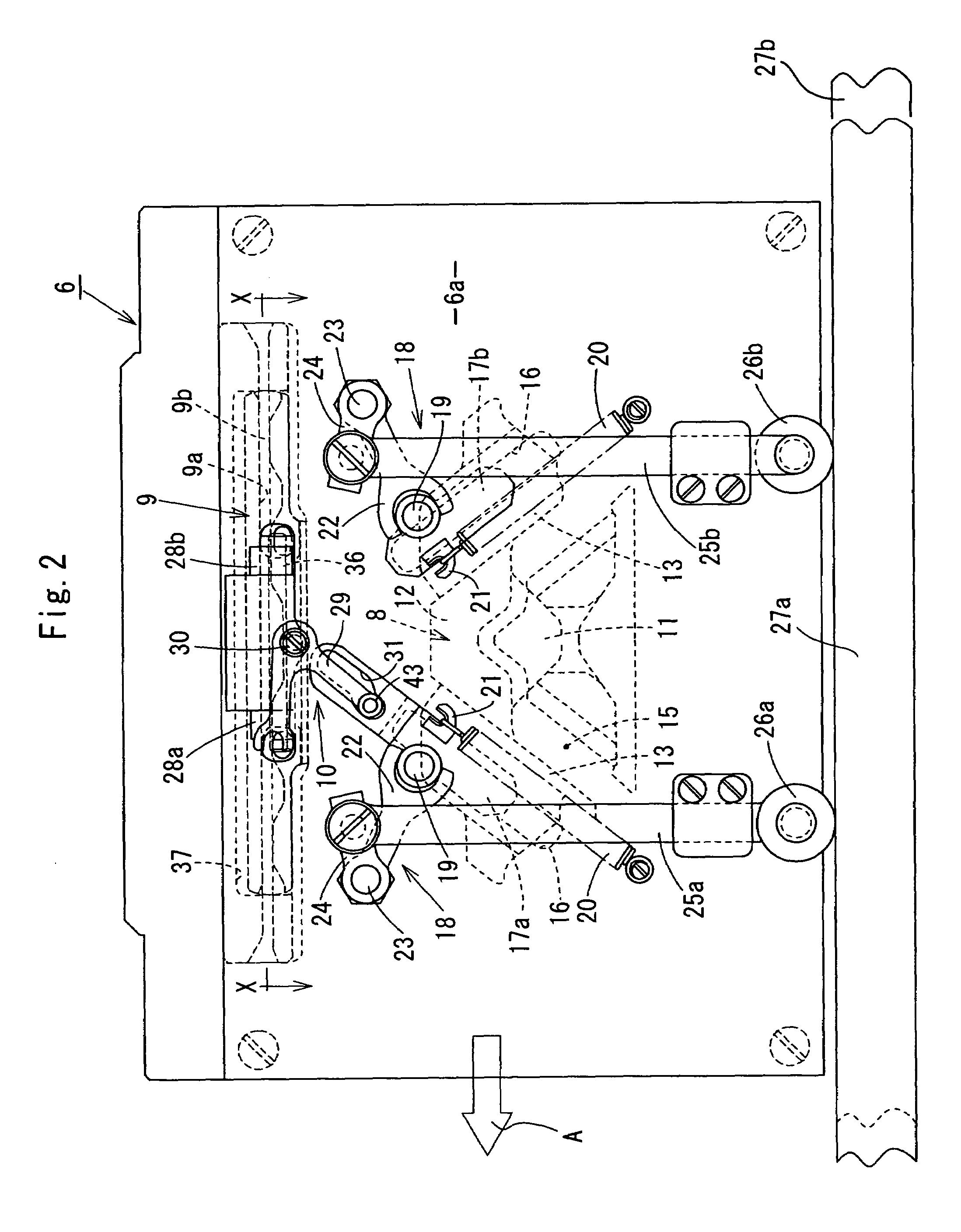

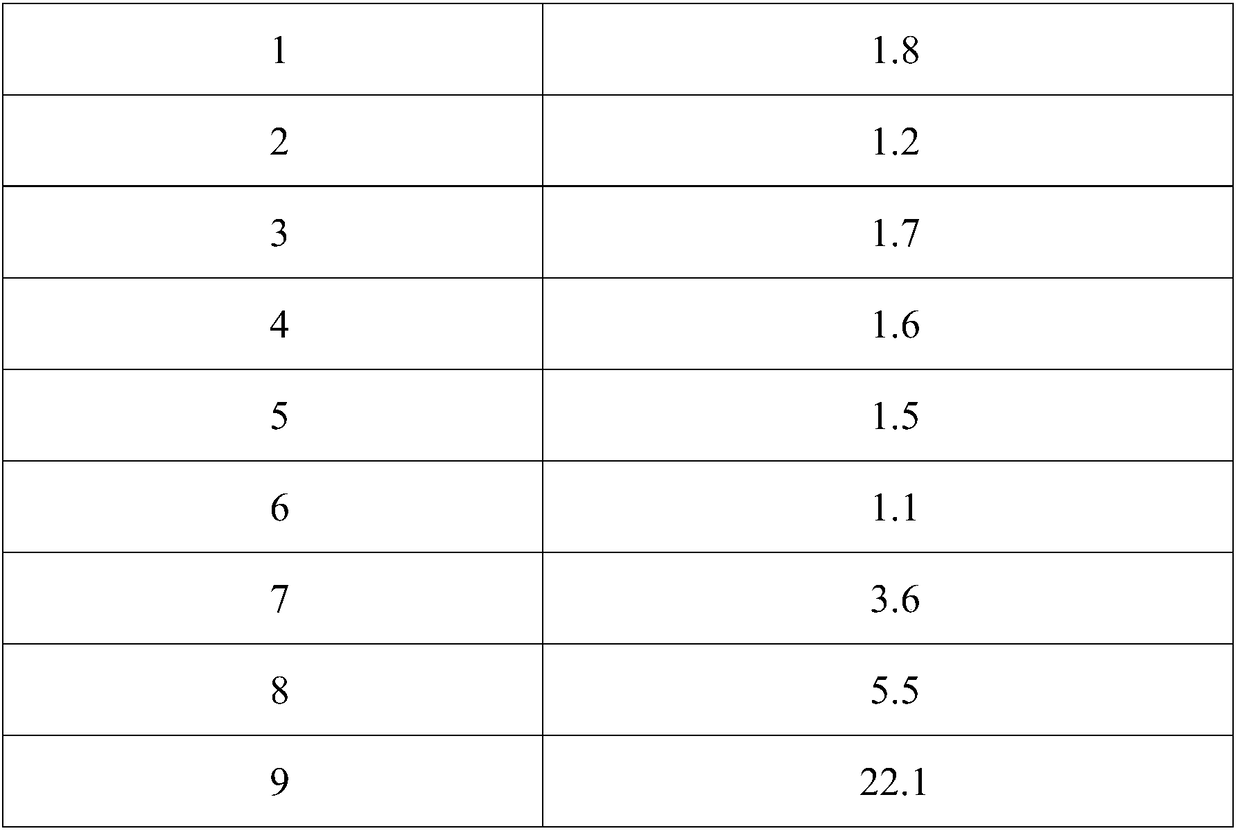

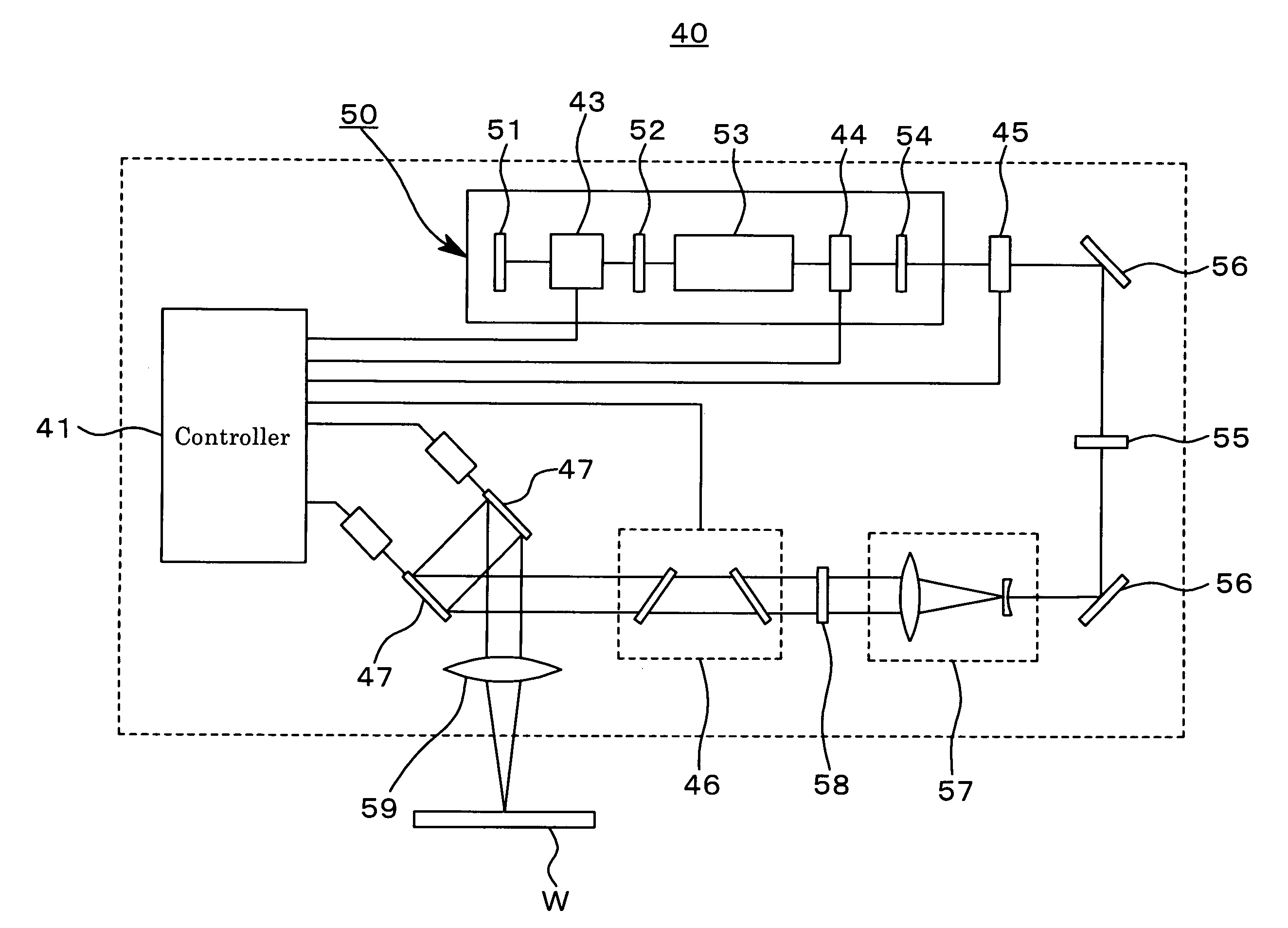

Laser marking device, laser marking method, and object to be marked

InactiveUS20070086822A1Adjustable densityEnhance the imageRecording apparatusDuplicating/marking methodsOptoelectronicsVolumetric Mass Density

The present invention relates to a laser marking device that irradiates a laser beam on a workpiece (W) to transform a portion inside the workpiece at a focal point of the laser beam, thus putting a dot in each predetermined area. The laser marking device includes acquiring means (10, 20) that acquires, as information on the dot, at least two-dimensional position information of an exposed section of the workpiece (W), and density information of the dot, coordinate setting means (30) that calculates, for each dot according to the density information, dot depth information showing the distance from the surface of the workpiece (W) to the dot in the thickness direction of the workpiece (W), and sets three-dimensional coordinates for each dot based on a position specified by the dot depth information and the two-dimensional position information, and laser marking means (40) that performs marking with the three-dimensional coordinates as a laser beam focal point.

Owner:ARAI HELMET LTD

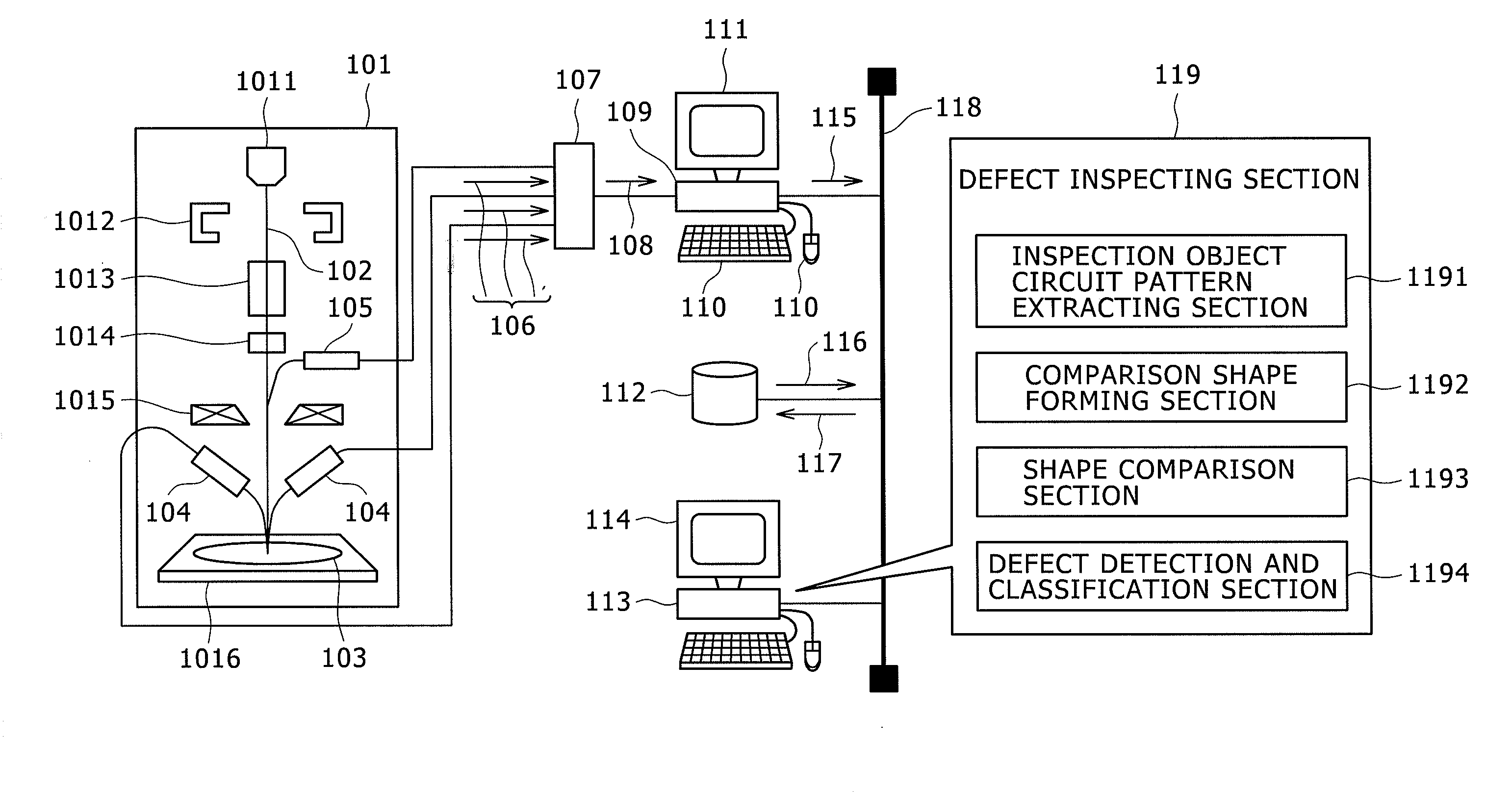

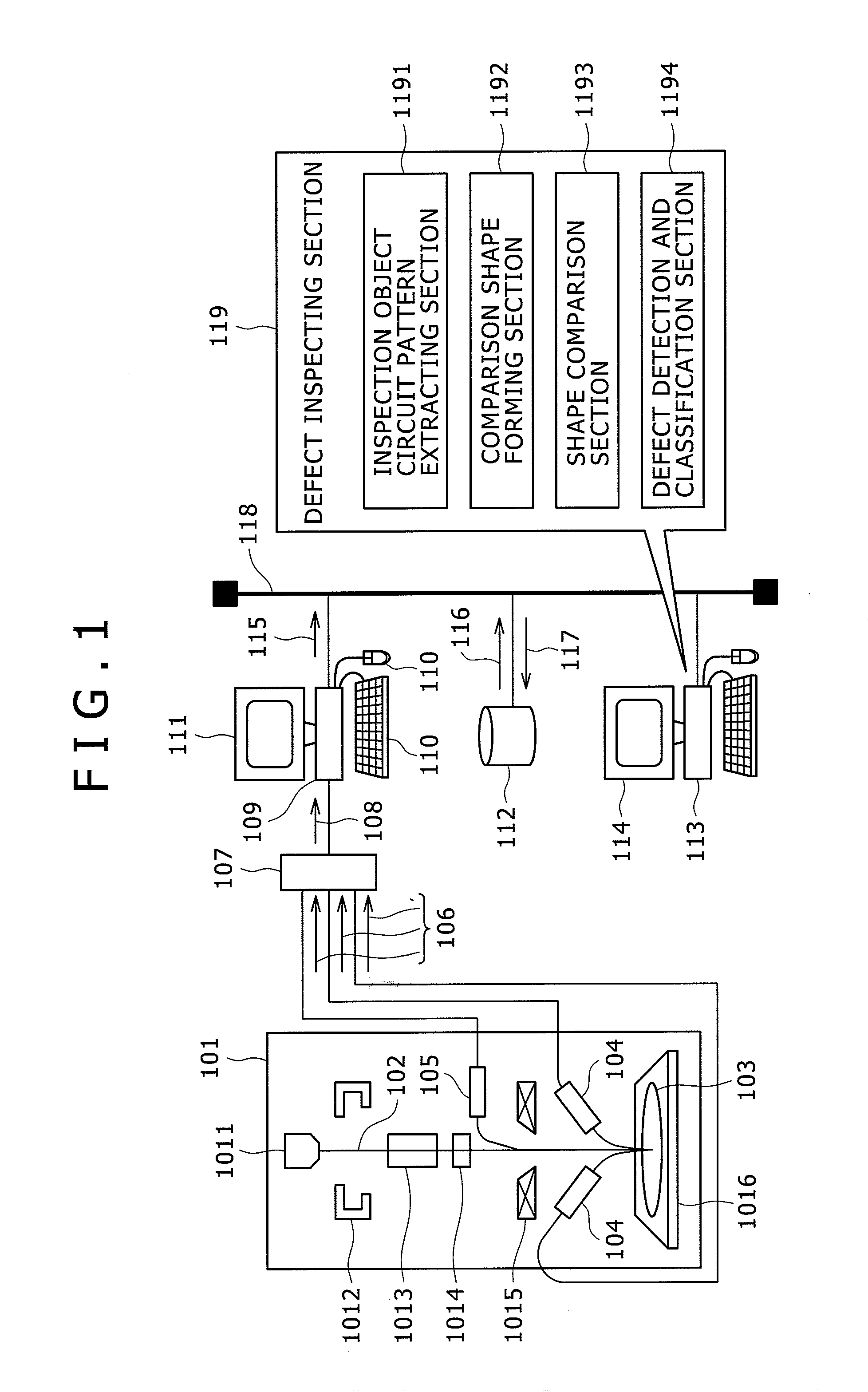

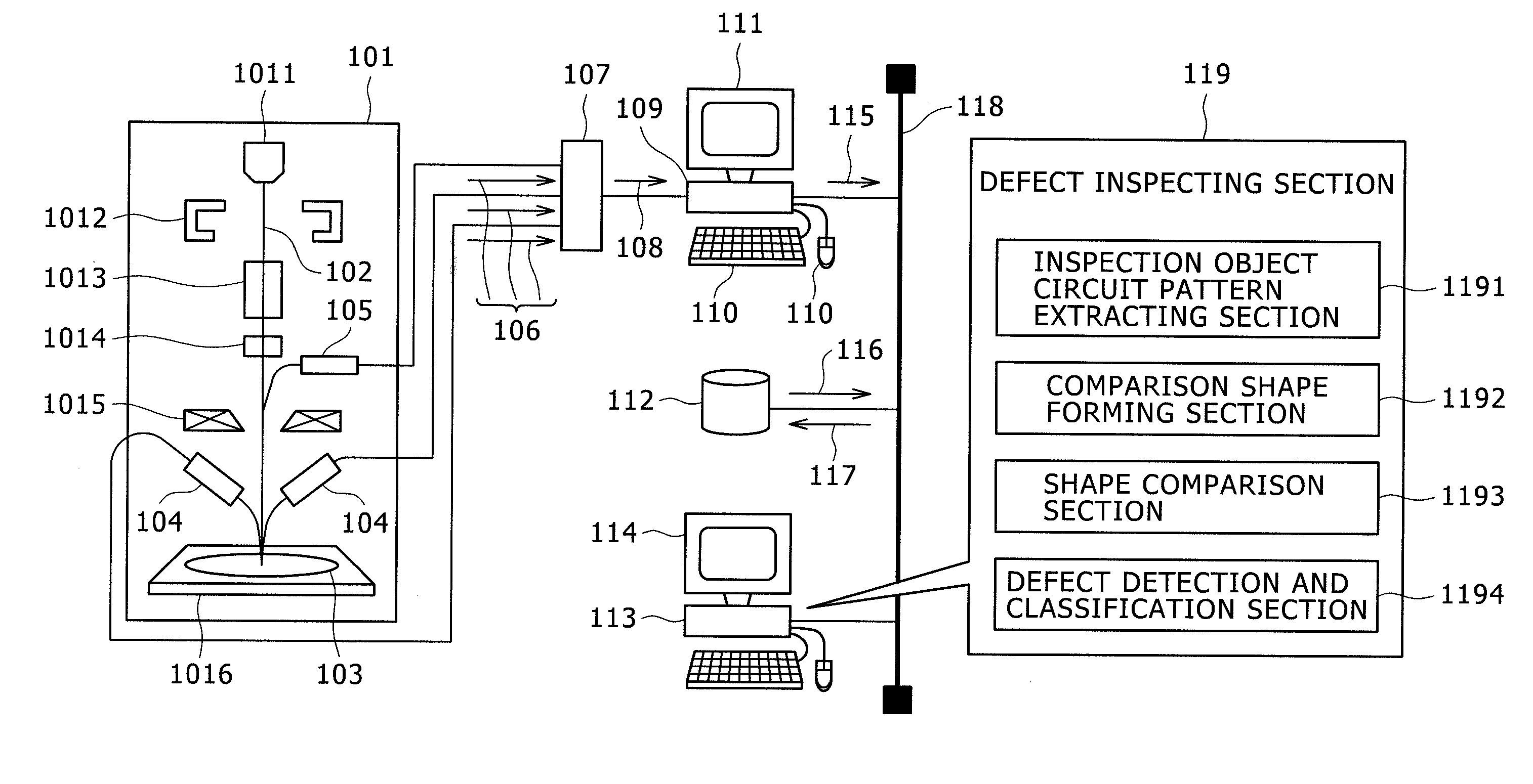

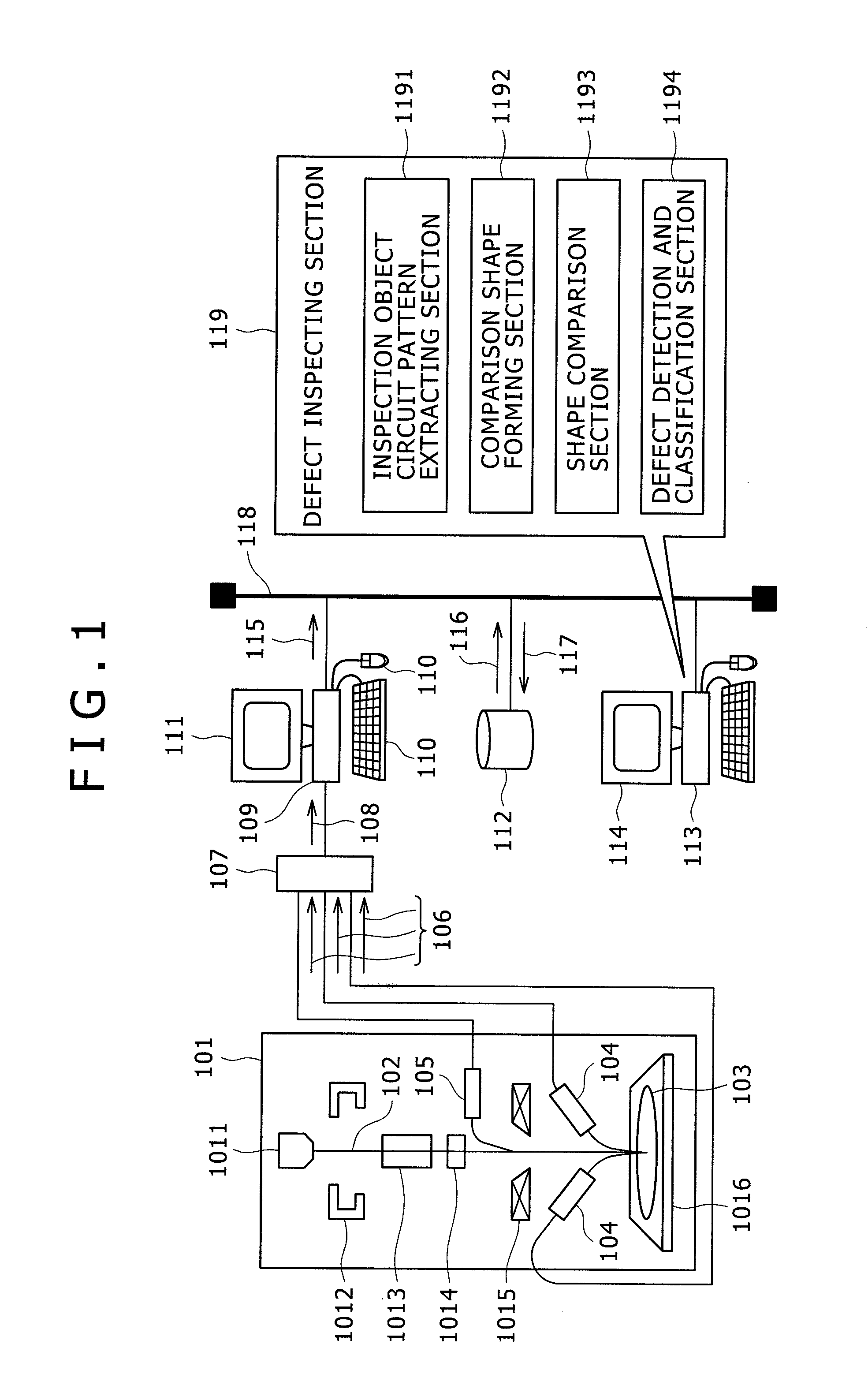

Method and apparatus for inspecting defect of pattern formed on semiconductor device

ActiveUS20090208090A1Improve accuracyAdjustable densityImage enhancementImage analysisEngineeringSemiconductor

In the inspection apparatus for a defect of a semiconductor and the method using it for automatically detecting the defect on a semiconductor wafer and presuming the defect occurrence factor using the circuit design data, a plurality of shapes are formed from the circuit design data by deforming the design data with respect to shape deformation items stipulated for respective defect occurrence factor for comparison with the inspection object circuit pattern. The defect is detected by comparison of the group of shapes formed and the actual pattern. Further, the occurrence factors of these defects are presumed, and the defects are classified according to respective factor.

Owner:HITACHI HIGH-TECH CORP

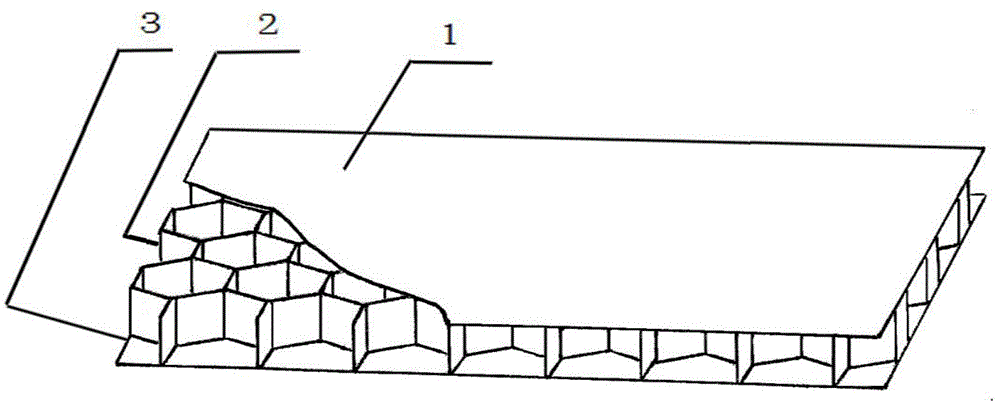

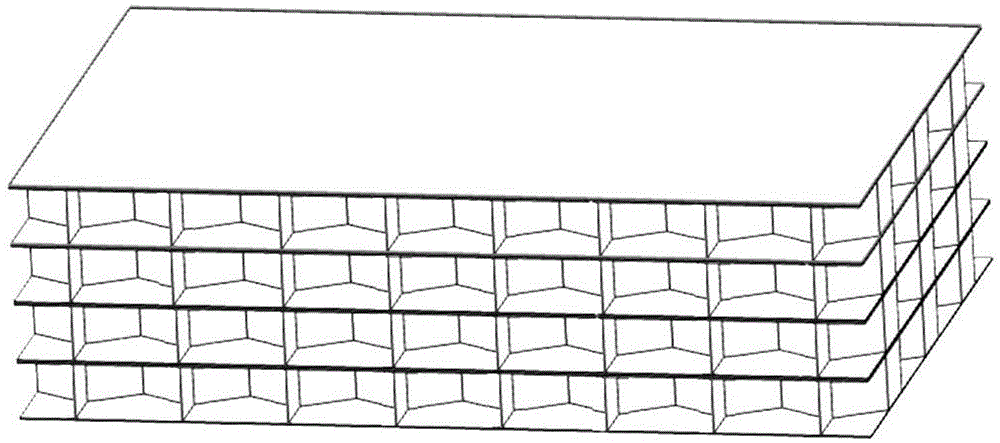

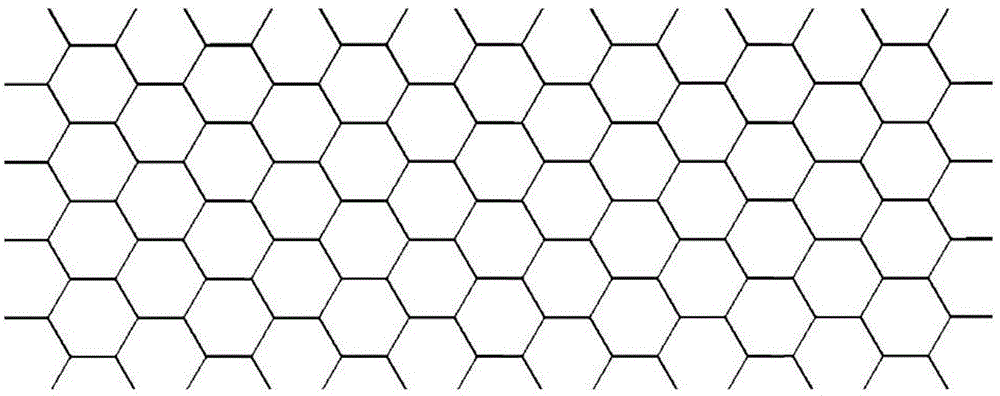

Preparation method for resin honeycomb sandwich structure and composite material structure thereof

InactiveCN105015047AEasy to manufactureProduct quality is stable and reliableSynthetic resin layered productsLaminationHoneycomb structureMaterial structure

The invention discloses a preparation method for a resin honeycomb sandwich structure and a composite material structure thereof, and provides a closed cell honeycomb structure and a honeycomb sandwich composite material structure prepared by the honeycomb structure to mainly solve the technical problems of reduction in mechanical performance of a conventional honeycomb sandwich structure under water erosion, complexity in a forming process and higher manufacturing cost. Specifically for the closed cell honeycomb structure, closed cell honeycomb units are structurally designed, a closed cell resin honeycomb sandwich structure is prepared by a 3D (3-Dimensional) printing technology, and the resin honeycomb sandwich structure is adhered to a composite material panel to form a composite material honeycomb sandwich structure by adopting a vacuum bag or resin transfer molding process. The preparation method has the characteristics of convenience, reliable product quality and reduction in the production cost, and a good foundation is laid for the application of the composite material honeycomb sandwich structure to the high-tech fields of aerospace, vehicles and ships.

Owner:SHENYANG AEROSPACE UNIVERSITY +1

High density fracturing liquid

The invention offers high density fracturing fluid formula used inorganic salt to improve water-base fracturing fluid density. Its feature is that its weight ratio is as follows: weight additive 4-50%, vegetable gum thickener 0.3-1.0%, cross linking agent 0.1-2.0%, pH value regulator 0.5-1.0%, cracking agent 0.002-0.3%, cleanup additive 0.05-0.5%, fungicide 0.03-0.2%, and water 30-73%. The density of the high density fracturing fluid is adjustable and can exceed 1.51g / cm3. It has good high temperature resistant, shearing resistant, and so on. Thus it can supply reliable assurance for abnormal high pressure and ultra-deep well exploration test oil and exploitation.

Owner:PETROCHINA CO LTD

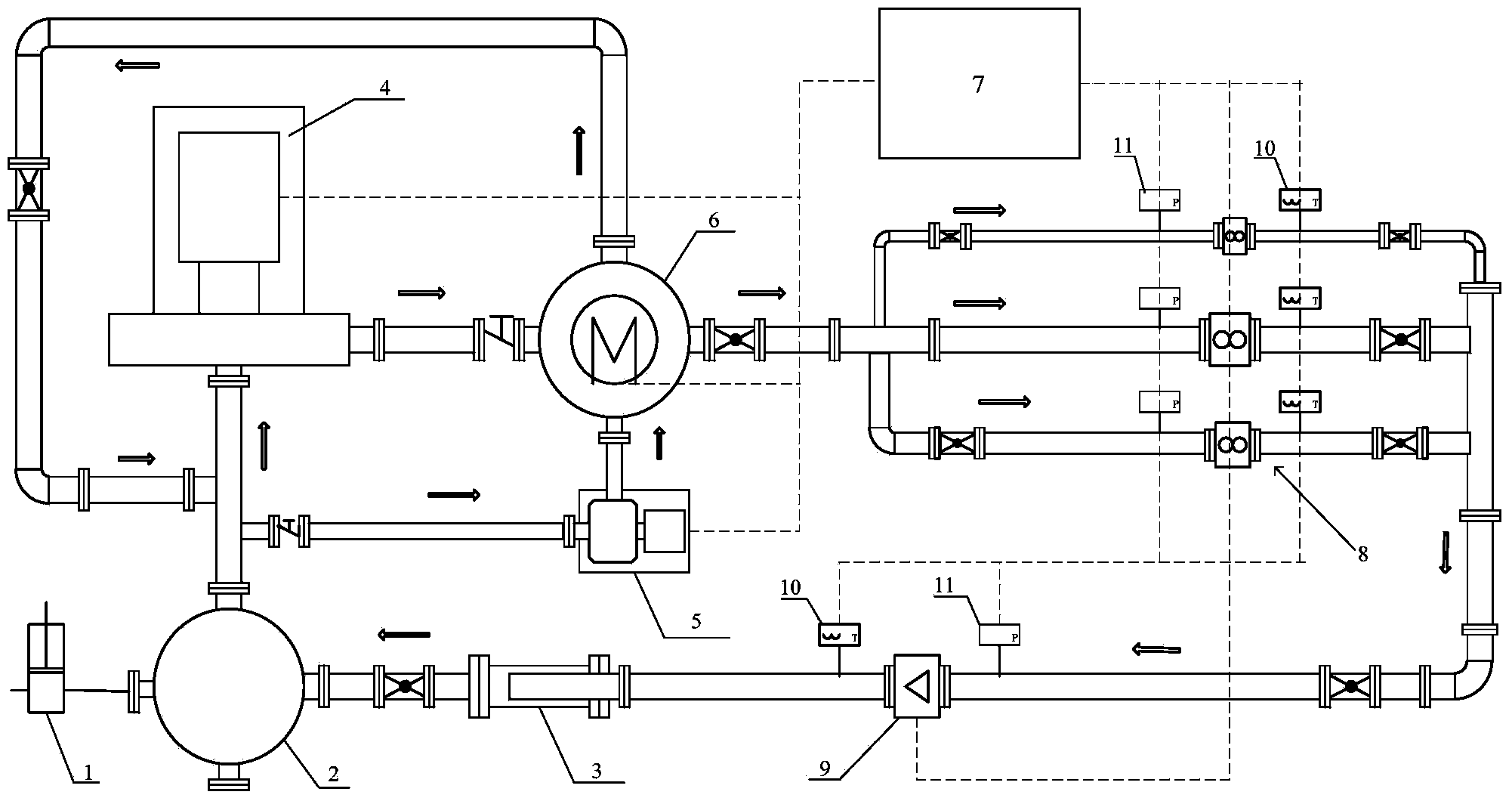

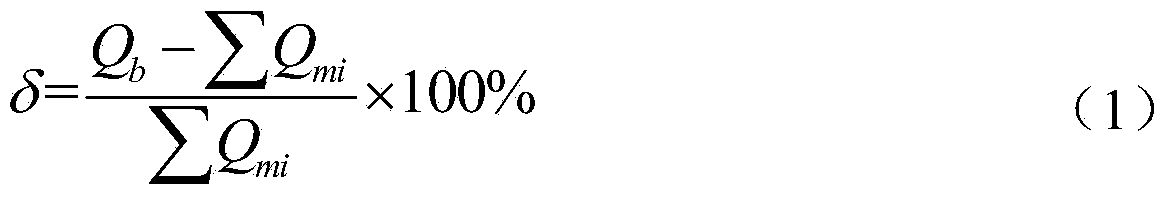

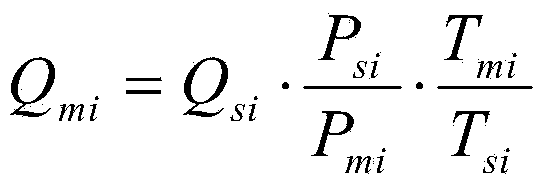

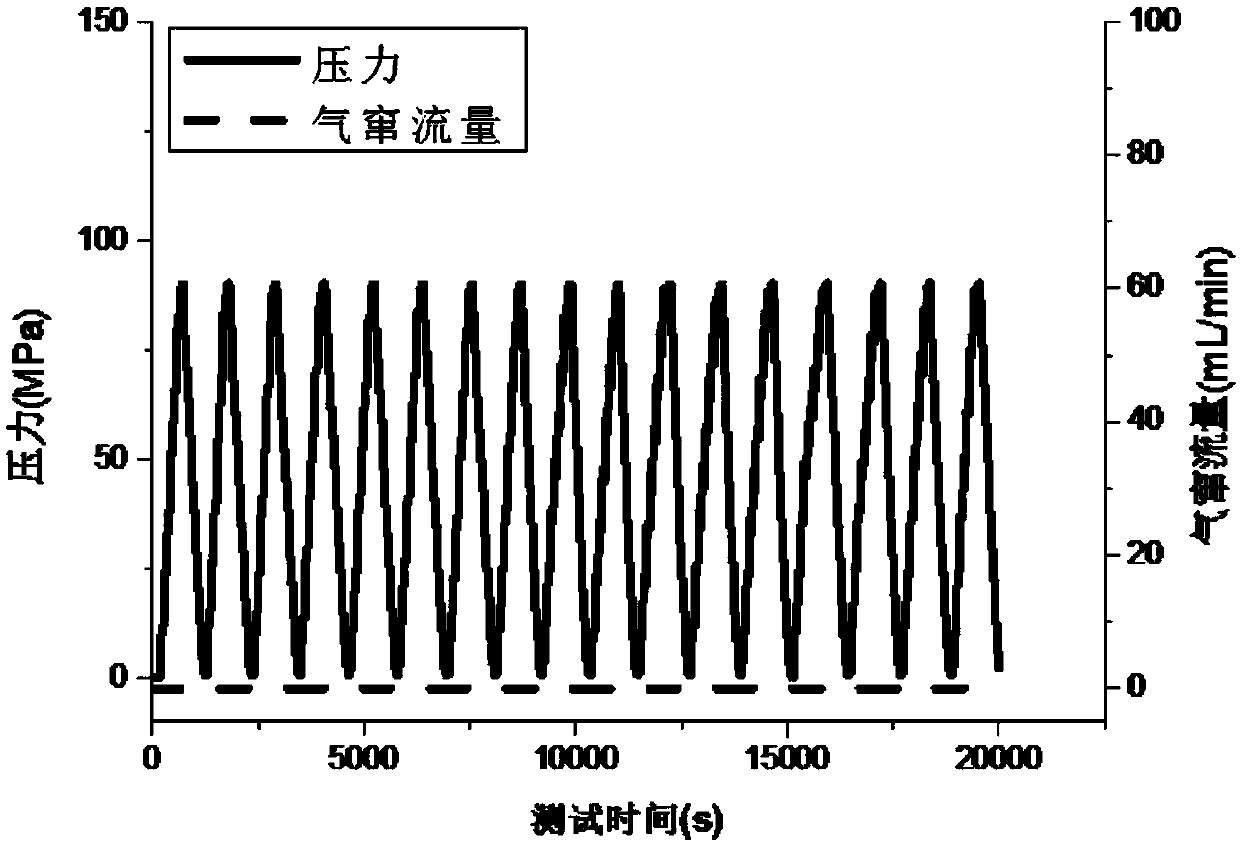

Gas flow standard device and application method thereof

The invention provides a novel gas flow standard device and an application method thereof. The gas flow standard device mainly comprises a standard flow meter set, a test stand for a to-be-tested flow meter, a signal acquisition and control system, a gas circulation power system and a high-pressure gas source, wherein the standard flow meter set, the to-be-tested flow meter and the gas circulation power system are communicated in sequence through a pipeline to construct an enclosed loop; the signal acquisition and control system is provided with a temperature measuring unit and a pressure measuring unit respectively at pipeline sections where the standard flow meter set and the to-be-tested flow meter are positioned, and is used for controlling each flow regulating valve in a high-pressure fan, a heat exchanger and the enclosed loop. The gas flow standard device has the advantages of small floor area, stable and adjustable gas detection pressure, low running noise and low running energy consumption.

Owner:SHAANXI TIANYI INTELLIGENT INSTR

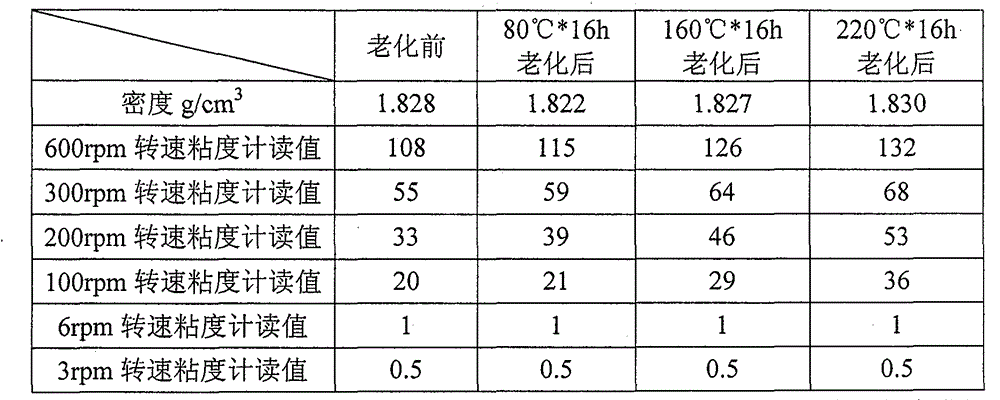

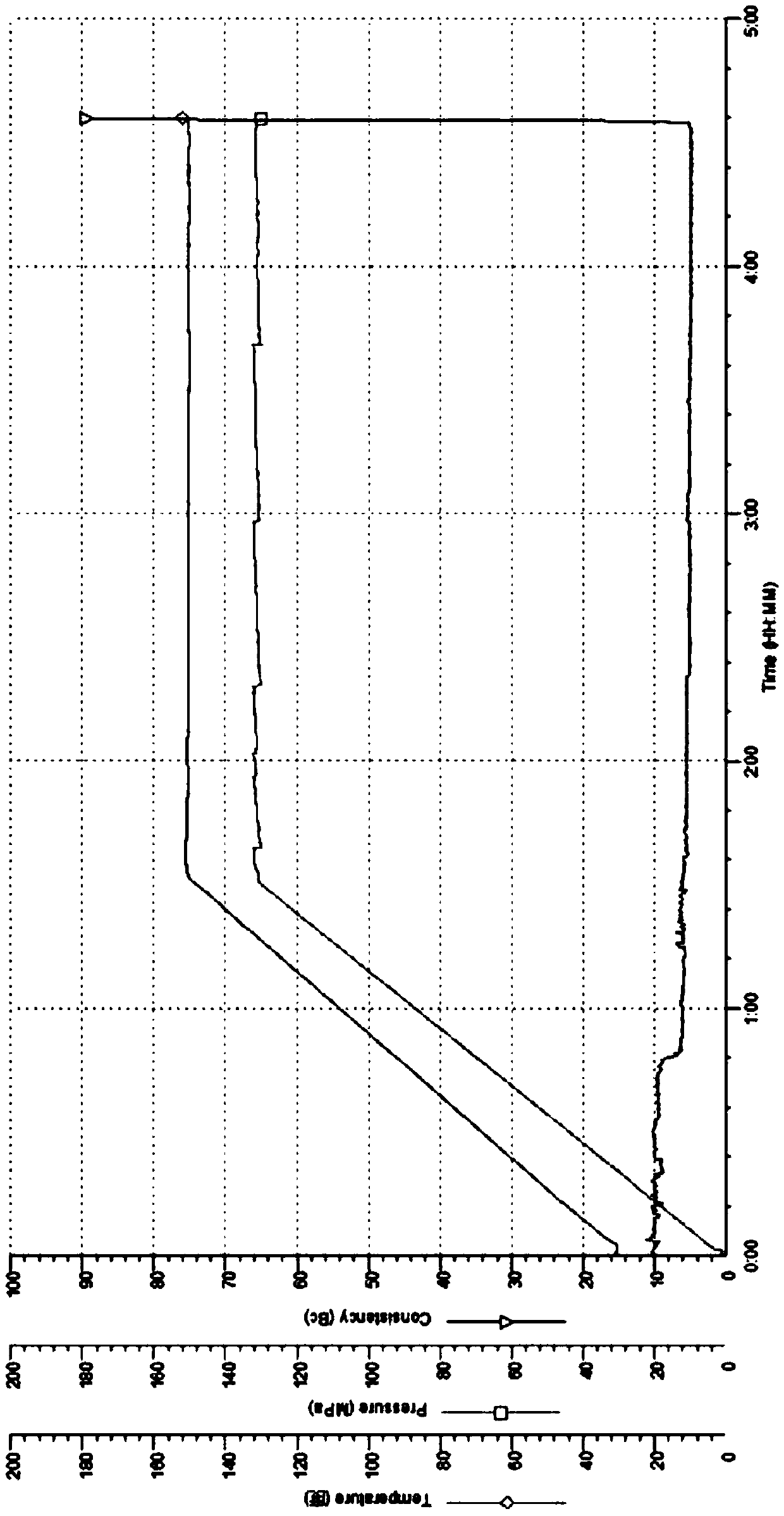

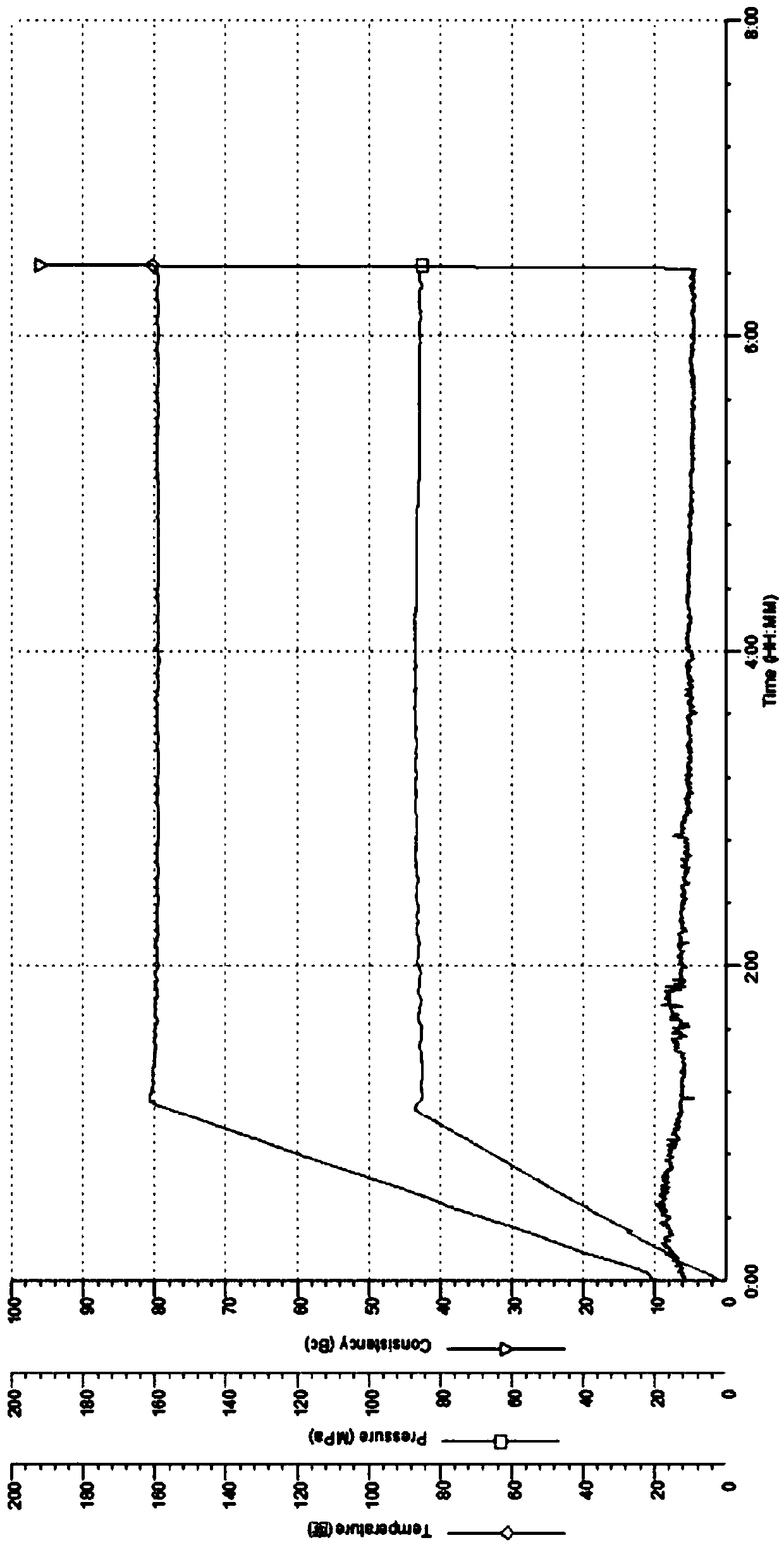

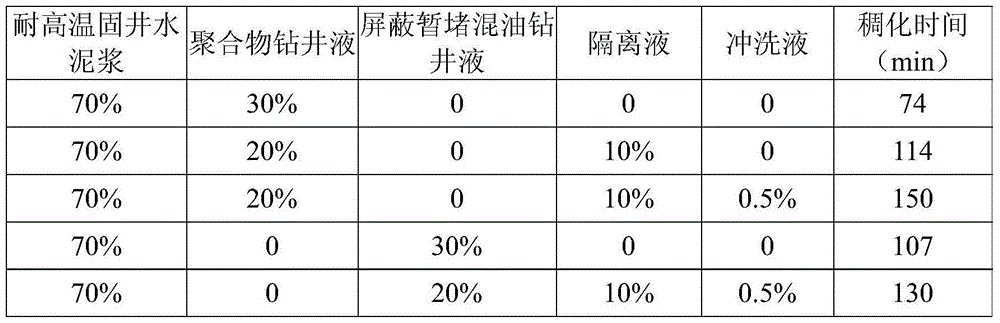

High-temperature-resistant non-silicate cement paste system for cementing thermal production well of thickened oil

ActiveCN102994058AAdjustable density and thickening timeGood liquidityDrilling compositionSilicate CementHeat regulation

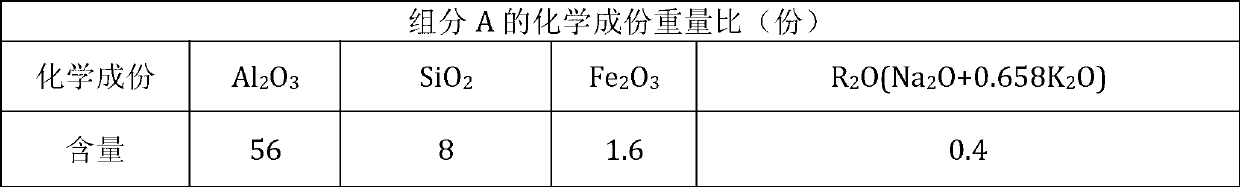

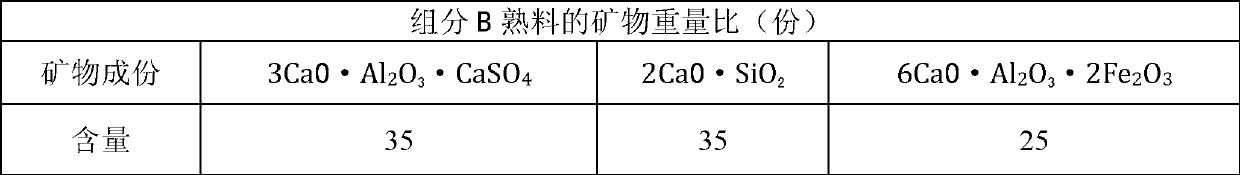

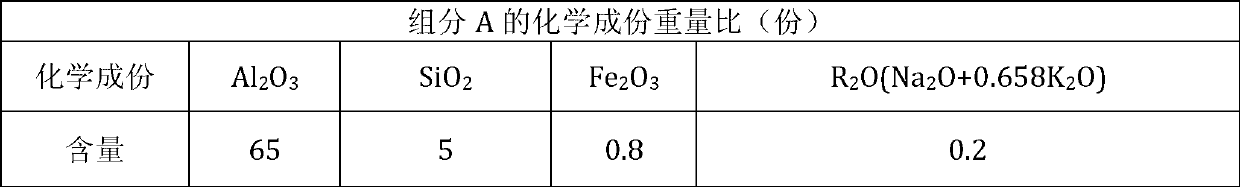

The invention relates to a high-temperature-resistant non-silicate cement paste system for cementing a thermal production well for thickened oil. The high-temperature-resistant non-silicate cement paste system is composed of the following components in parts by weight: 100 parts of high-temperature-resistant cement, 1.0-4.0 part(s) of fluid loss agent, 1.0-4.0 part(s) of dispersant, 0.5-3.0 part(s) of thickening time control agent, 60-120 parts of water and 15-80 parts of heat regulators, wherein the high-temperature-resistant cement is formed by mixing components A and B, the component A comprises 50-77 parts of Al2O3, 0.5-8.0 part(s) of SiO2, 0.5-2.5 part(s) of Fe2O3 and 0-0.4 part of R2O(Na2O+0.658K2O), and the component B comprises 33-63 parts of 3CaO.Al2O3.CaSO4, 14-37 parts of 2CaO.SiO2 and 15-35 parts of 6CaO.Al2O3.2Fe2O3. The high-temperature-resistant non-silicate cement paste system disclosed by the invention has great significance to enhancement of safe and efficient development of the thickened oil and has broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

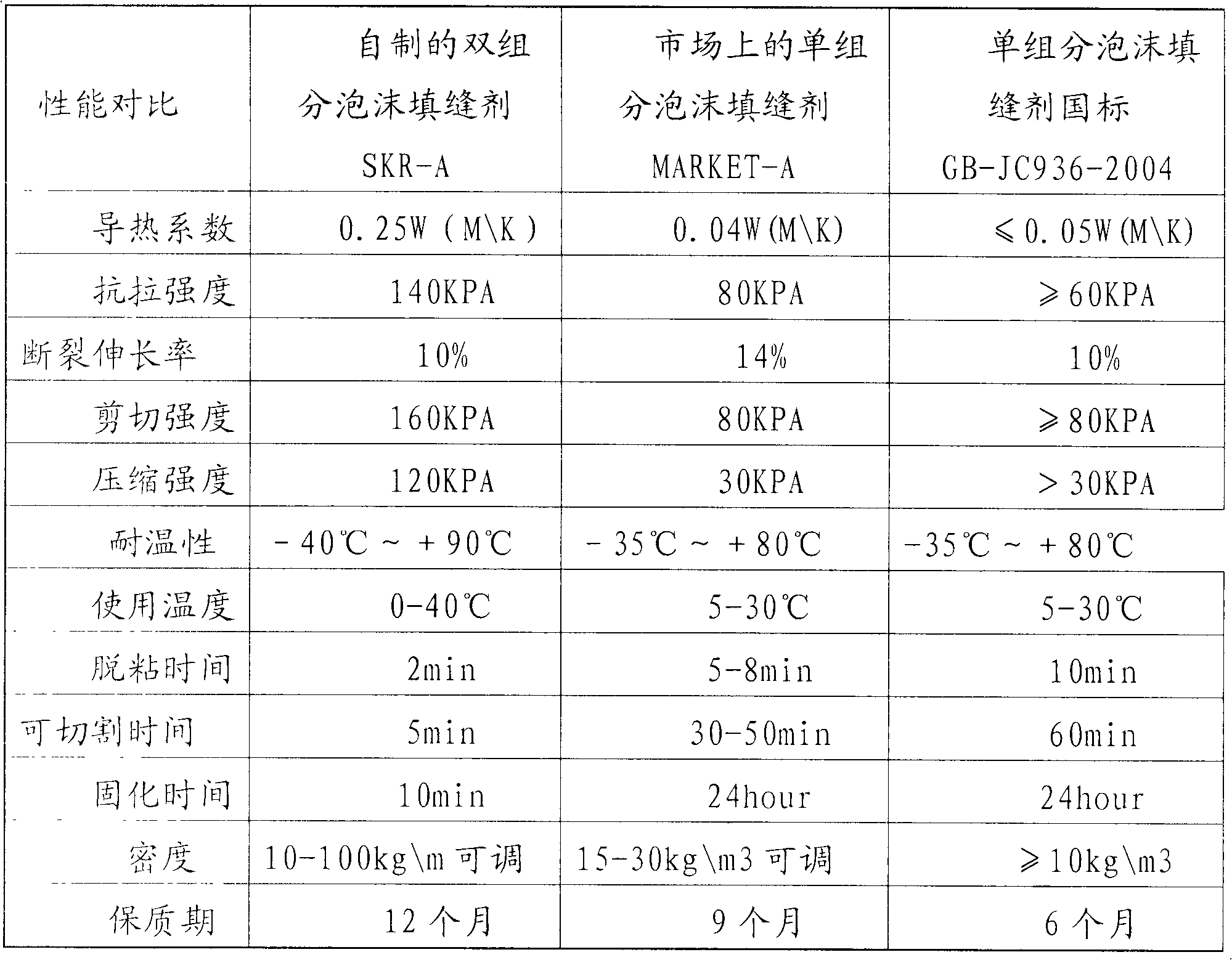

Production method for portable self-spraying bi-component foam caulking agent

InactiveCN103819649AGood yieldSimple production processOther chemical processesPolyesterVegetable oil

The invention discloses a production method for a portable self-spraying bi-component foam caulking agent. Polyols (polyether polyol, polyester polyol and vegetable oil polyol), a catalyst, silicone oil, a foaming agent, other accessories and the like are poured into a special galvanized iron pot, and are injected with a propellant to form a component A; one or more of crude MDI (diphenyl-methane-diisocyanate), liquefied MDI or prepolymers thereof are poured into another special galvanized iron pot, and are injected with the propellant to form a component B. When the portable self-spraying bi-component foam caulking agent is used, pot valves of the components A and B are opened, and the two components are mixed through a mixing gun for foaming formation after being automatically sprayed.

Owner:BEIJING DONGCHEN RUIFENG CHEM

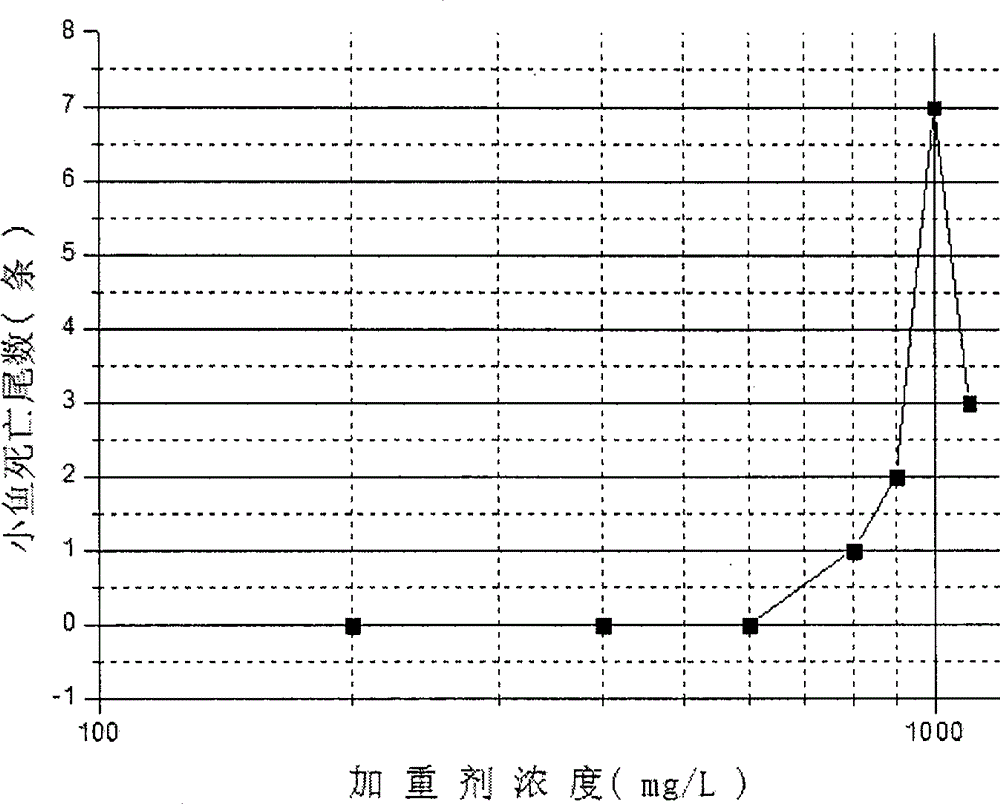

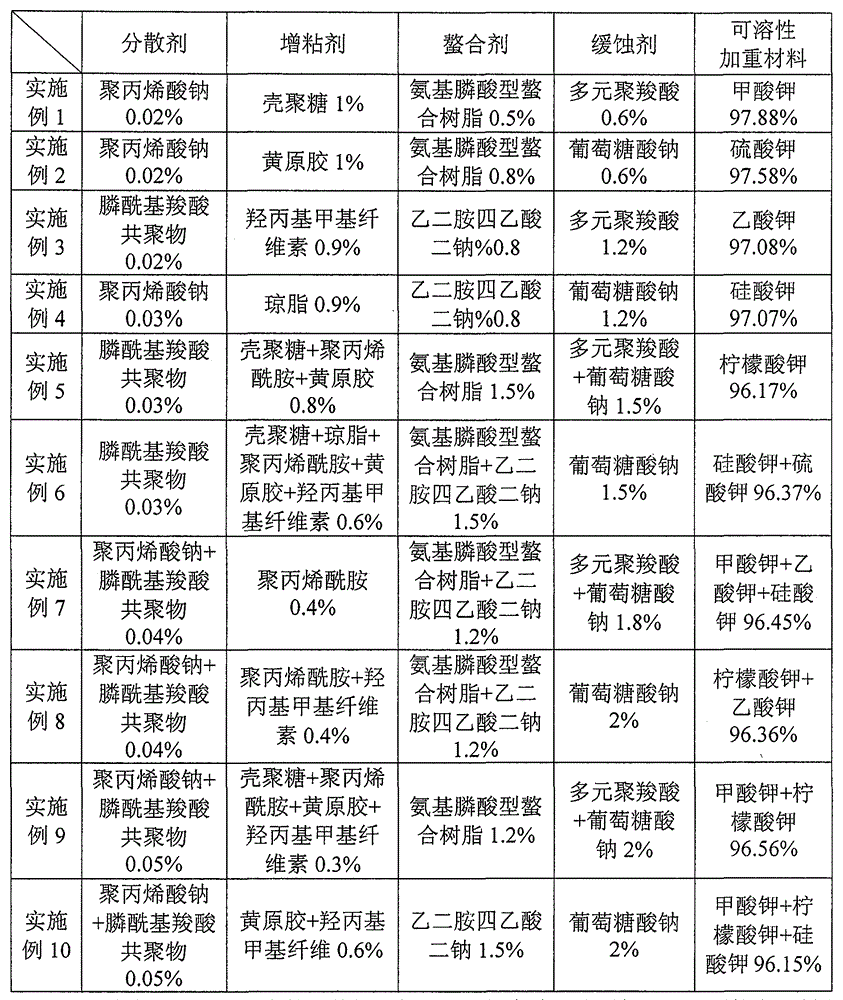

Environment-friendly high-density solid-free weighting agent and preparation method

ActiveCN104610937AWide range of densitiesReduce pollutionDrilling compositionCarboxylic acidPotassium formate

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

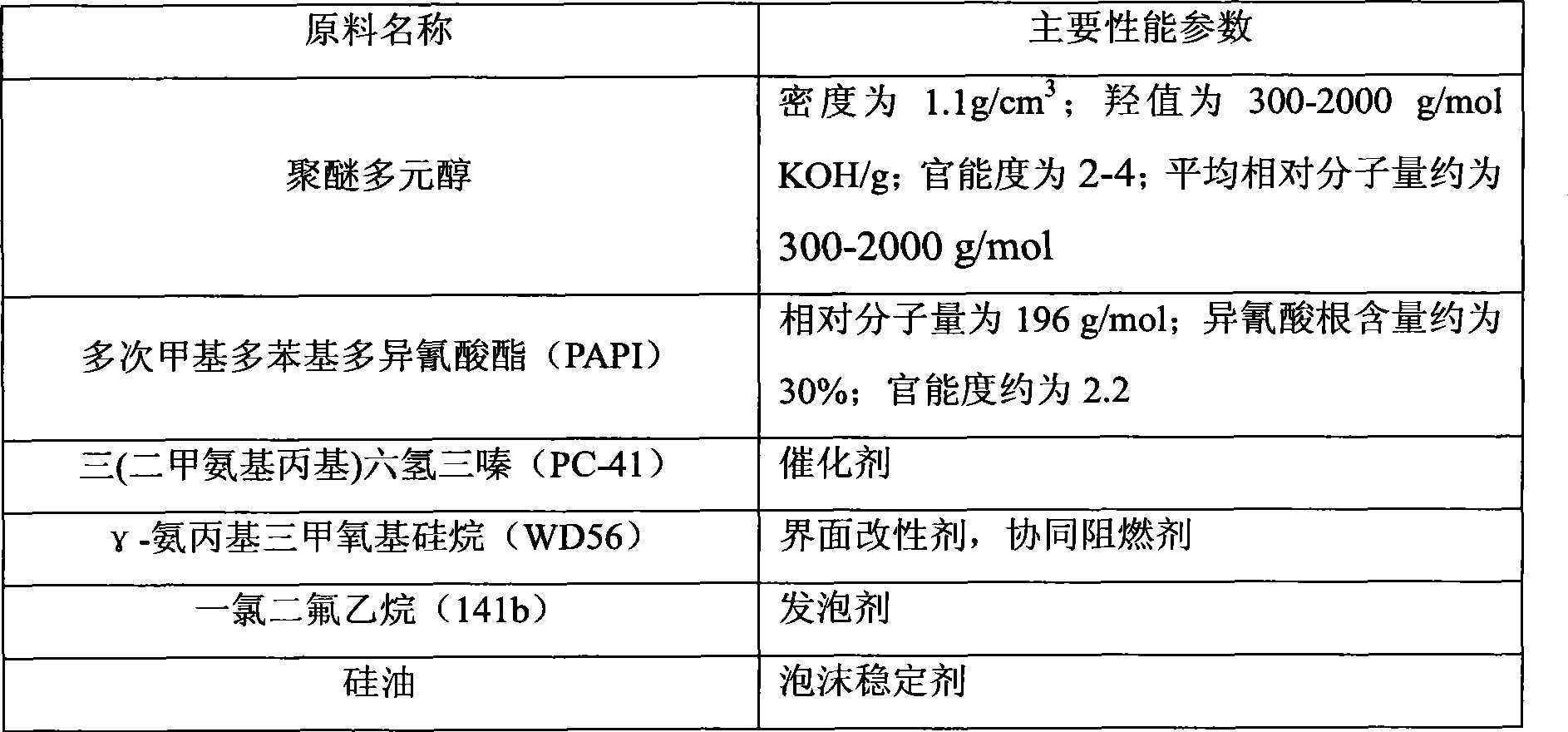

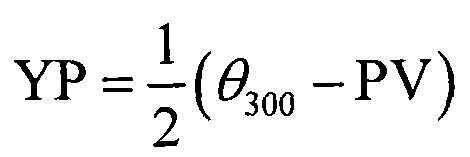

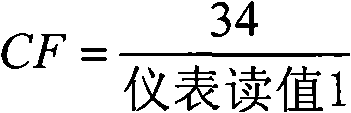

Halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material and preparation method thereof

The invention belongs to the field of high-flame-retardant rigid polyurethane foam insulation materials, which particularly relates to a halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material and a preparation method thereof. The method comprises the following steps: mechanically stirring a mixture formed by polyether (or polyester) polyhydric alcohols, a catalyst, a silicone oil, a silane coupling agent, a foaming agent, expansible graphite and inorganic fillers (one or more than one material selected from magnesium hydrate, kaolin, aluminium hydroxide and calcium carbonate) in certain proportion and evenly mixing; then, fully mixing the mixture with polyisocyanates; pouring into a mould of 50 DEG C to 100 DEG C; closing a mould cover; and finally, foaming and curing, thereby obtaining the halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material. The flame retardation of the insulation material is improved under the synergistic effect of the expansible graphite and the inorganic fillers, so that the limit oxygen index of the insulation material can reach 90; and the vertical combustion performance of the insulation material can reach the level UL94 V0. According to the insulation material provided by the invention, the defect of a flame retardant containing halogen and phosphorus is overcome; and the flame retardation of the insulation material is improved under the synergistic effect of the environment-friendly fillers. Thus, the application requirement of the insulation material in practical engineering can be satisfied.

Owner:BEIJING ACAD OF BUILDING ENG

Drilling fluid for drilling

ActiveCN101974316AImprove pressure bearing capacityOvercome the disadvantage of difficult density controlDrilling compositionFoaming agentWell drilling

The invention discloses a low temperature microbubble drilling fluid for offshore oil drilling. The drilling fluid comprises water, sodium carbonate, sodium hydroxide, a flow type modifier, a foaming agent and a stabilizing agent in a mass part ratio of 100: (0.1-0.3): (0.1-0.2): (0.3-0.4): (0.2-0.3): (0.1-0.4). A perforation fluid also comprises a collapse prevention inhibitor, a clay stabilizer, a temperature stabilizing agent and a bactericide. The low temperature microbubble drilling fluid for offshore oil drilling provided by the invention is the novel drilling fluid. In performance, thelow temperature microbubble drilling fluid for offshore oil drilling has the novel advantages of leakage controlling and leakage stopping and a characteristic of adjustable density besides the characteristics of the common bubble drilling fluid in the prior art.

Owner:CHINA NAT OFFSHORE OIL CORP +1

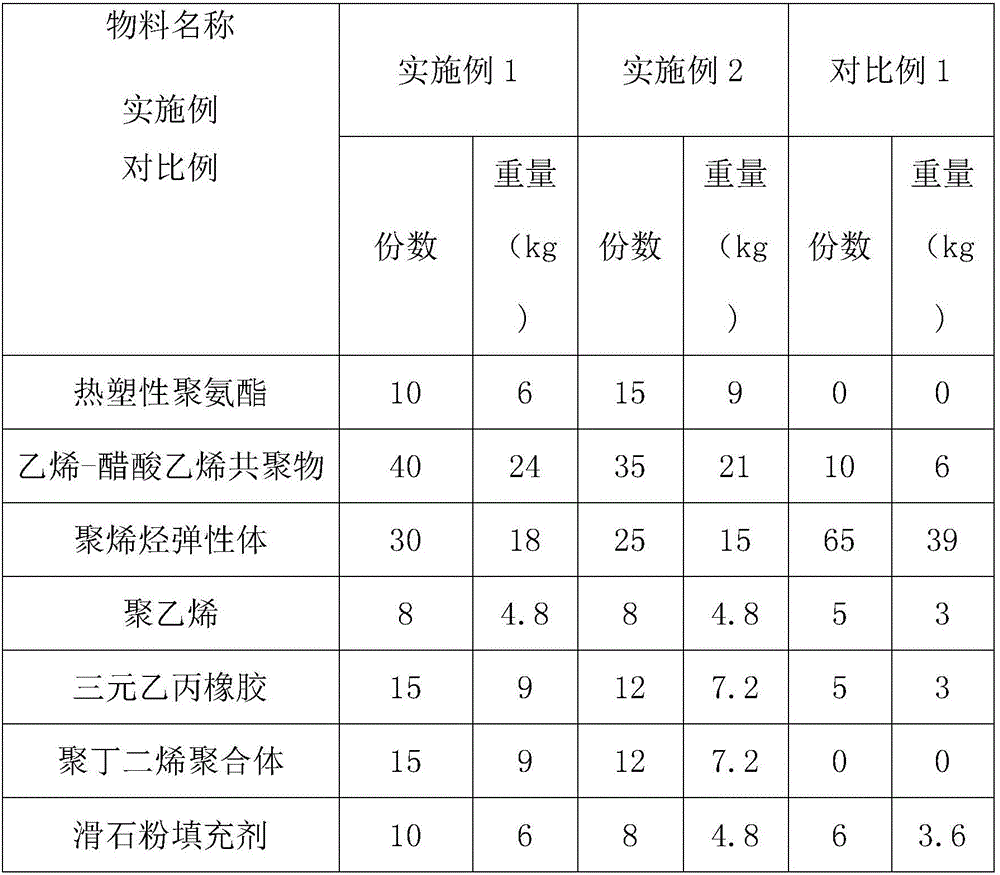

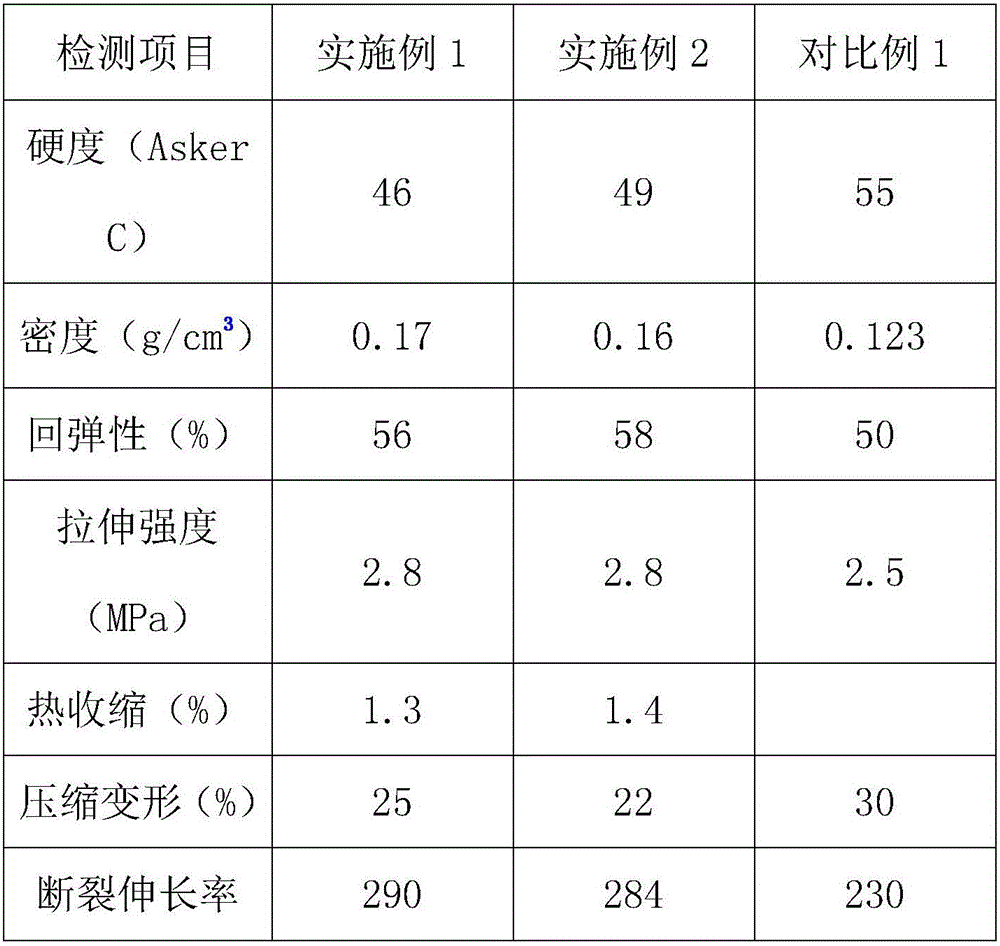

Thermoplastic polyurethane composite foamed material and preparation method thereof

The invention provides a thermoplastic polyurethane composite foamed material and a preparation method thereof. The thermoplastic polyurethane composite foamed material is prepared from 10-25 parts of polyurethane, 35-45 parts of ethylene-vinyl acetate copolymers, 15-30 parts of polyolefin elastomers, 6-10 parts of polyethylene, 6-18 parts of ethylene propylene diene monomers, 6-15 parts of polybutadiene polymers, 3-5 parts of filler, 1.5-2.2 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 0.8-1.4 parts of zinc stearate, 0.1-0.4 parts of a cross-linking agent, 0.7-1.0 part of a bridging agent and 2.5-3.5 parts of a foaming agent. The thermoplastic polyurethane composite foamed material is high in rebound resilience, resistant to compression and good in tear resistance. The preparation method of the thermoplastic polyurethane composite foamed material comprises steps as follows: 1) components except zinc oxide, the cross-linking agent, the bridging agent and the foaming agent are weighed; 2) all the components weighed in the step 1) are mixed; 3) the rest components are weighed; 4) the components weighed in the step 3) are added to a material obtained after mixing in the step 2) for mixing; 5) granulation is performed; 6) foaming is performed.

Owner:ANTA CHINA

Weft knitting machine with movable yarn guide member

A stitch cam for setting the density of a knit by drawing in a knitting needle holding yarn fed from a yarn feeder is adjustably provided on a carriage. The stitch cam and the yarn guide member are connected by a linking device such that when the stitch cam moves to a knit-forming side, the movable yarn guide member moves in a direction to advance to a side of a gap portion between the mouth portions, and when the stitch cam moves to a stitch-cam-intermitting side, the movable yarn guide member moves in a direction to be retreated from the gap portion between the mouth portions to a needle bed side.

Owner:SHIMA SEIKI MFG LTD

High-temperature-resistant anti-channeling emulsion elastic and tough cement paste and preparation method thereof

InactiveCN110937857AImprove performanceImproved high temperature strength stabilityDrilling compositionAntifoam agentPolymer chemistry

The invention relates to high-temperature-resistant anti-channeling emulsion elastic and tough cement paste and a preparation method thereof, and belongs to the field of oil-gas well cementing cementpaste, wherein the high-temperature-resistant anti-channeling emulsion elastic and tough cement paste comprises the following components in parts by weight: 100 parts of G-grade oil well cement, 3-20parts of a high-temperature-resistant organic anti-channeling emulsion, 3-15 parts of a high-temperature-resistant inorganic anti-channeling emulsion, 0.5-5 parts of a high-temperature-resistant toughening material, 20-90 parts of a high-temperature strength stabilizing material, 1-10 parts of a high-temperature expanding agent, 1-12 parts of a high-temperature-resistant fluid loss agent, 0.1-10 parts of a high-temperature retarder, 0.5-3 parts of an antifoaming agent, 0-300 parts of a density adjusting material, and 35-200 parts of water. According to the invention, the cement paste system ismainly applied to the field of high-temperature oil-gas well cementation below 200 DEG C, the gas channeling prevention performance is excellent, caement is high and stable in high-temperature strength and low in elastic modulus, the gas layer can be subjected to effective sealing and annulus sealing in high-temperature and high-pressure gas well cementation, the annulus gas channeling and the wellhead pressure are prevented, the efficient production of an oil-gas well is guaranteed, and good application and popularization value is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

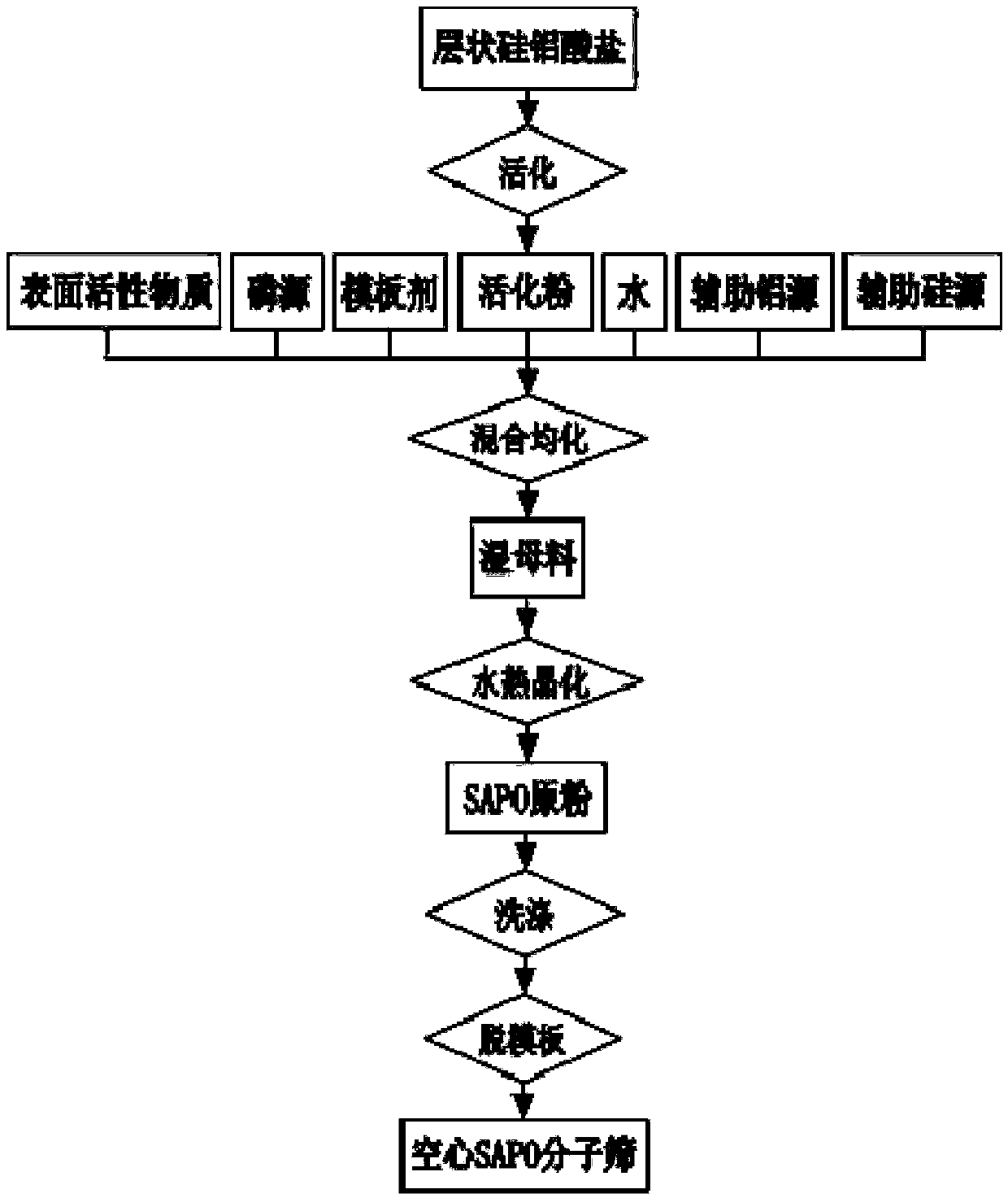

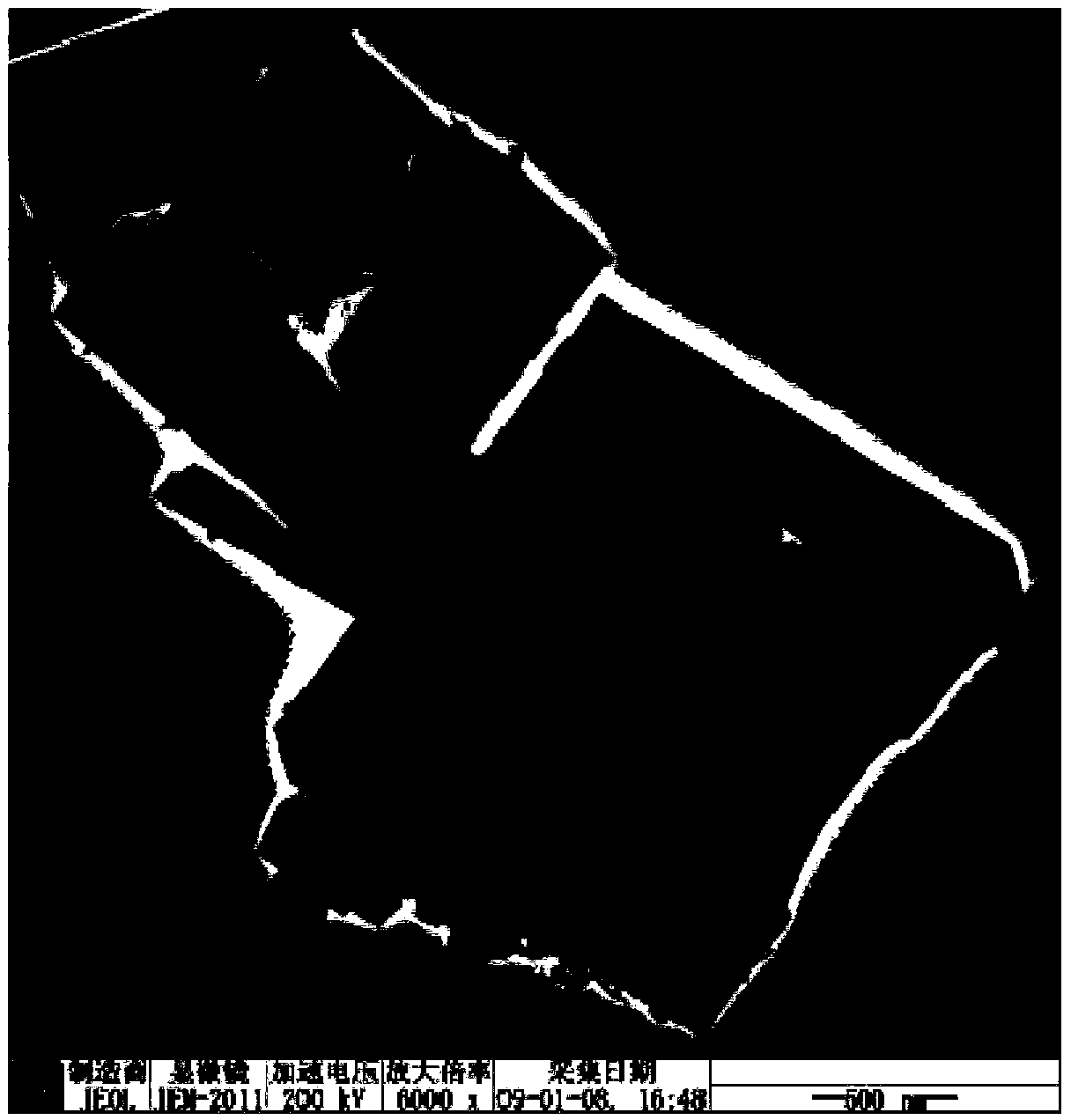

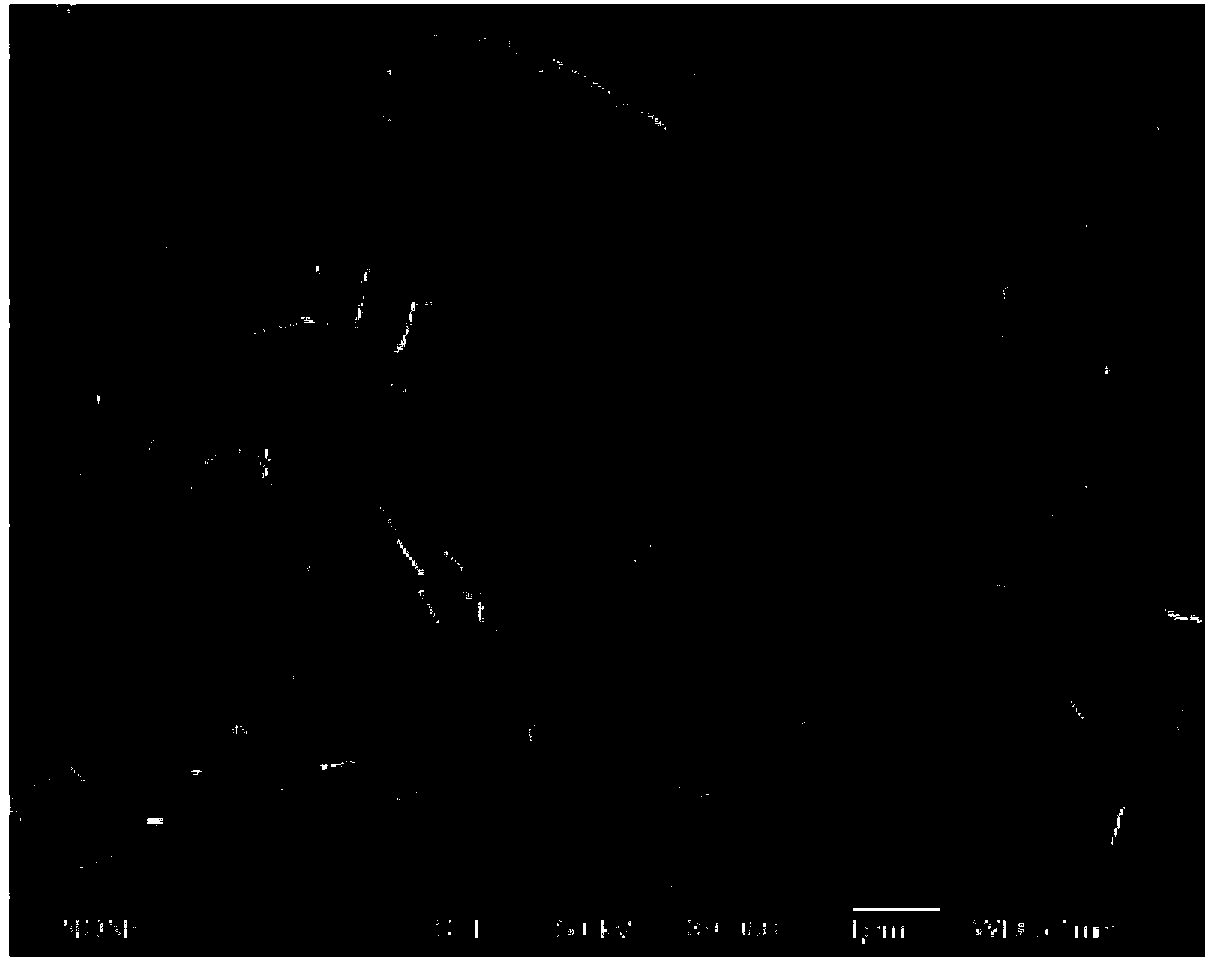

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964456ASuitable for acidityExtend your lifeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveSingle crystal

The invention discloses an SAPO molecular sieve, which has hollow single crystals. The SAPO molecular sieve has optional pore structure, adjustable silicon content and distribution, controllable strength and density of acid site, and long service life of catalyst. The invention also discloses a preparation method of the SAPO molecular sieve. The method uses layered silicate as a raw material, which is subjected to activation, and mixed and homogenized with a phosphorus source, an auxiliary aluminum source and water to obtain a wet masterbatch; and the wet masterbatch is subjected to hydrothermal crystallization to obtain a raw powder of the hollow SAPO molecular sieve, wherein the molar ratio of Al and Si in the wet masterbatch is higher than 1. The method use easily available raw materials, has low cost and can be prepare the SAPO molecular sieve with hollow structure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

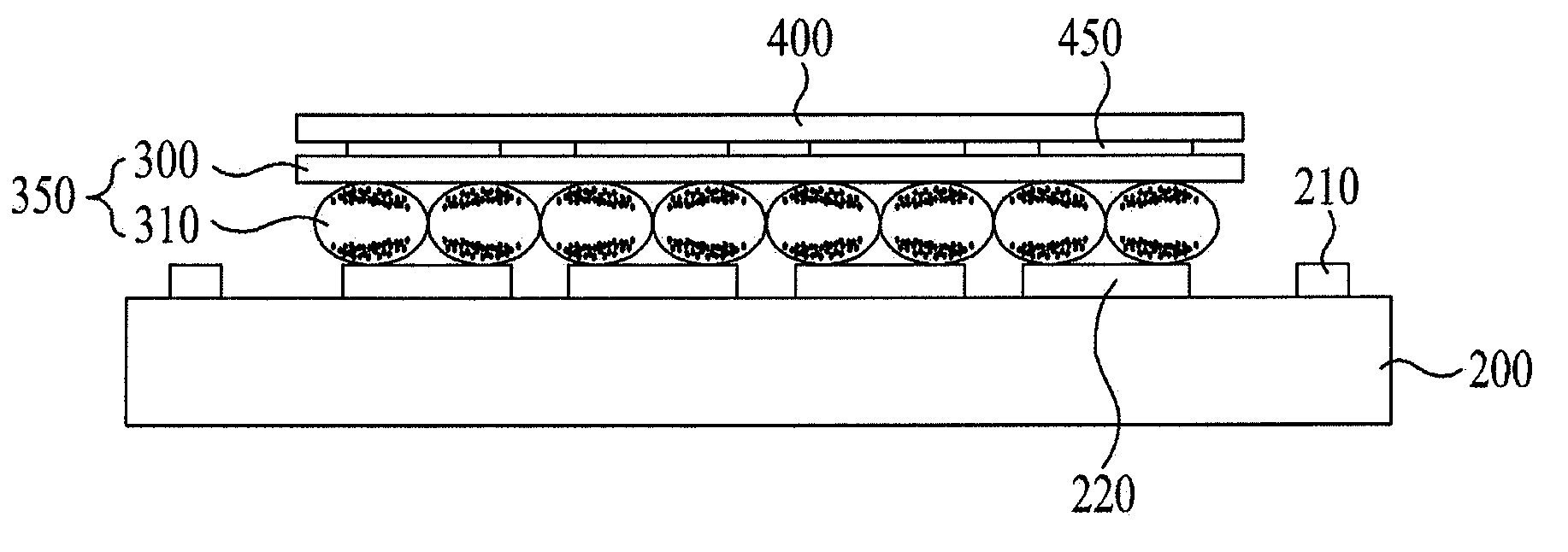

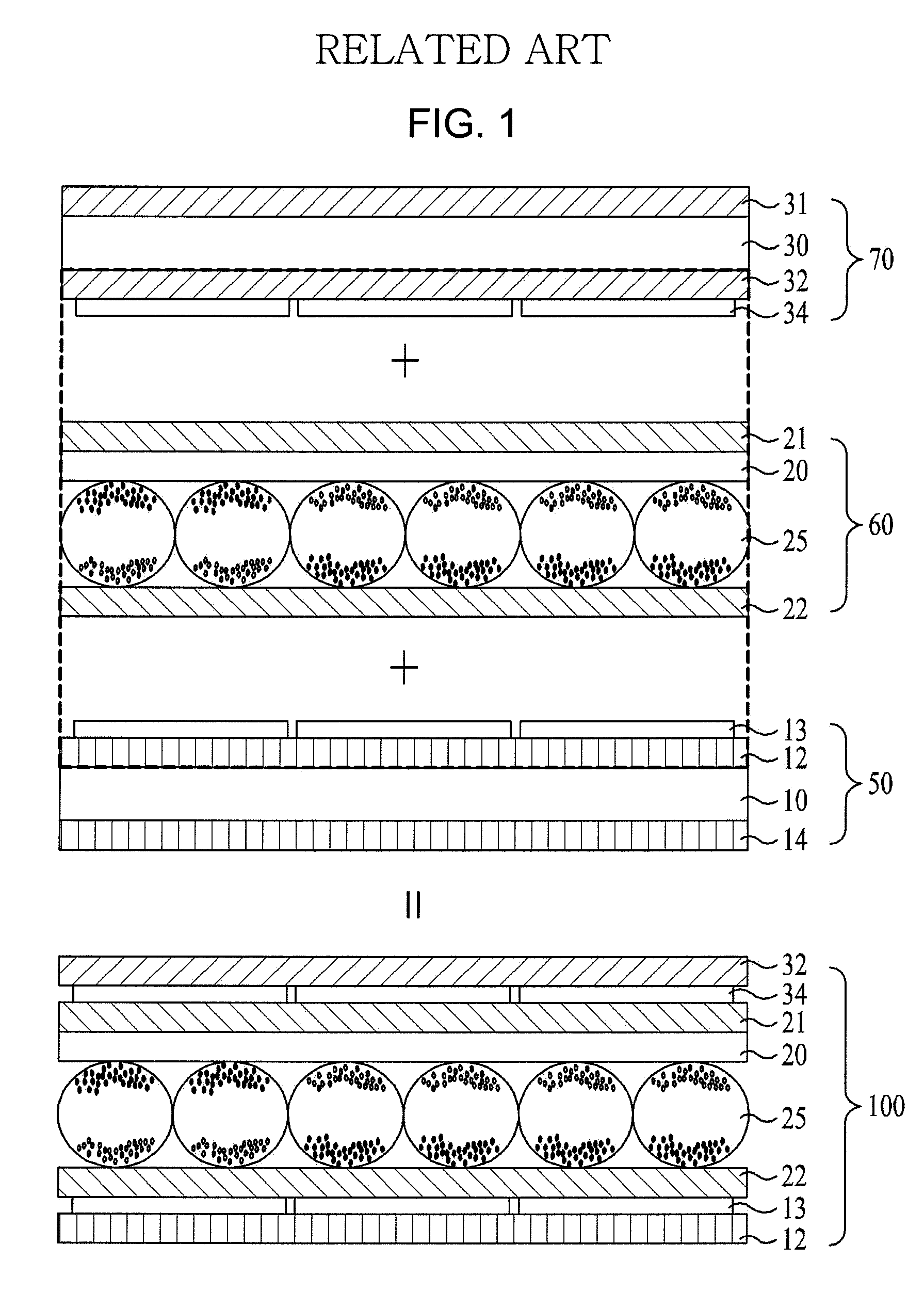

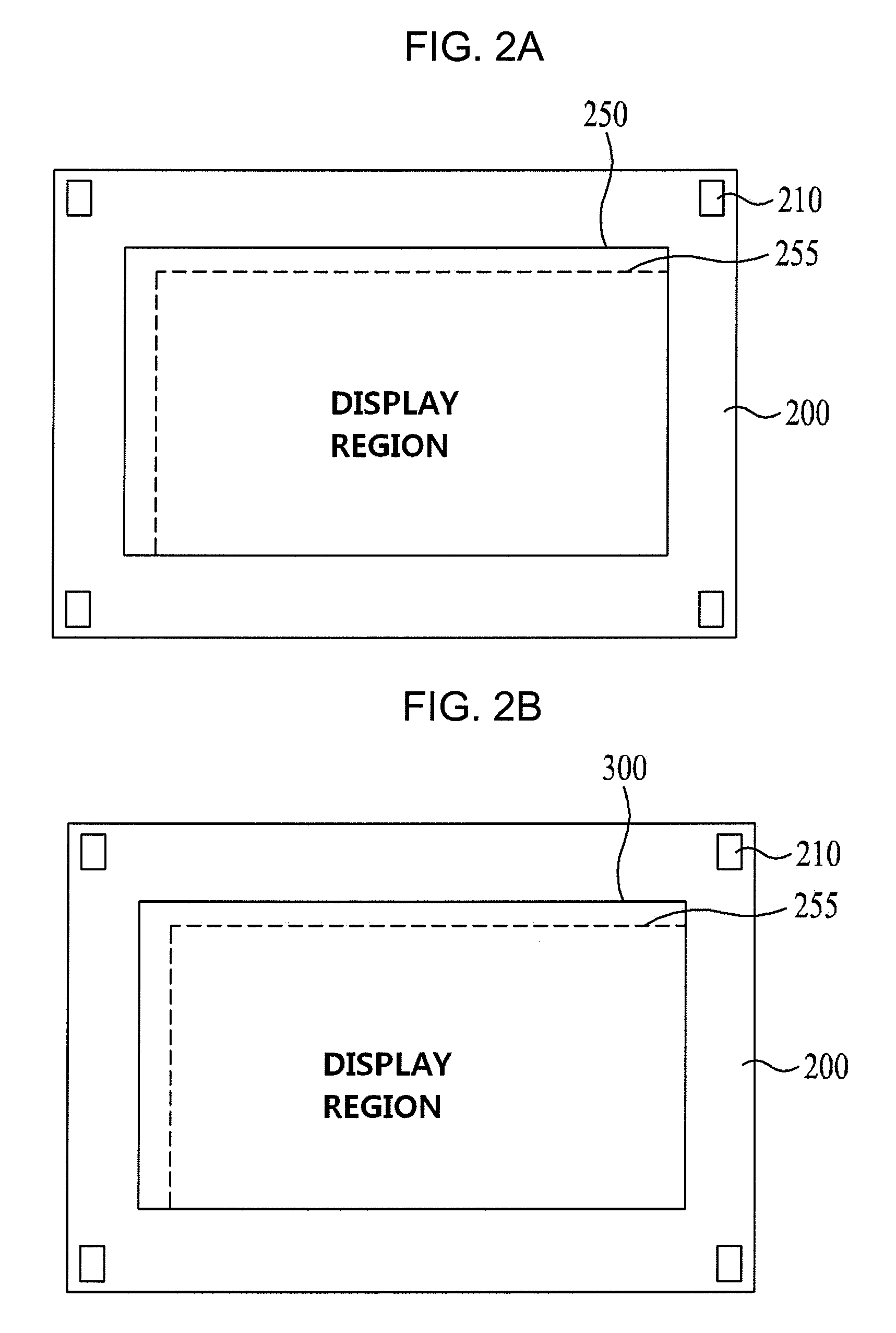

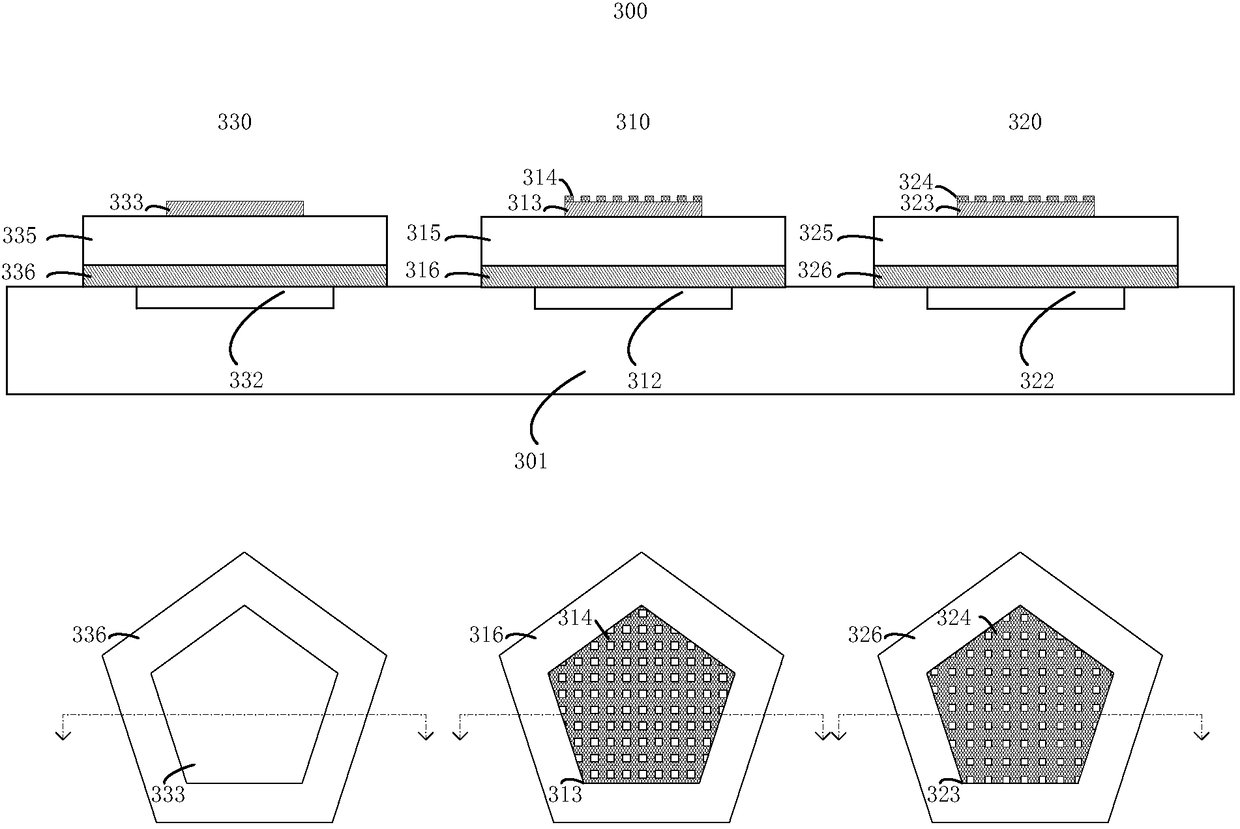

Color electrophoretic display device and method for manufacturing the same

InactiveUS20100157411A1Adjustable densityPrecise alignmentSolid-state devicesSemiconductor/solid-state device manufacturingElectrophoresisDisplay device

Discussed are a color electrophoretic display device with a color filter layer, which is formed in a droplet state on a rear surface of an electronic ink film through surface treatment so as to be capable of adjusting density of droplets in pixels and achieving correct alignment, and a method for manufacturing the same. The method includes forming a thin film transistor (TFT) array substrate including a display region, in which a plurality of pixel regions are defined in a matrix, and alignment keys provided at the outside of the display region, forming an electrophoretic layer including a micro capsule layer formed so as to correspond to the display region of the TFT array substrate, and forming a color filter layer on the electrophoretic layer using the alignment keys so as to correspond to the respective pixel regions of the display region.

Owner:LG DISPLAY CO LTD

Graphene hydrogel, graphene aerogel as well as preparation method and application thereof

ActiveCN106032274AAdjustable densityHigh densityOther chemical processesAlkali metal oxides/hydroxidesHigh energyFreeze-drying

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

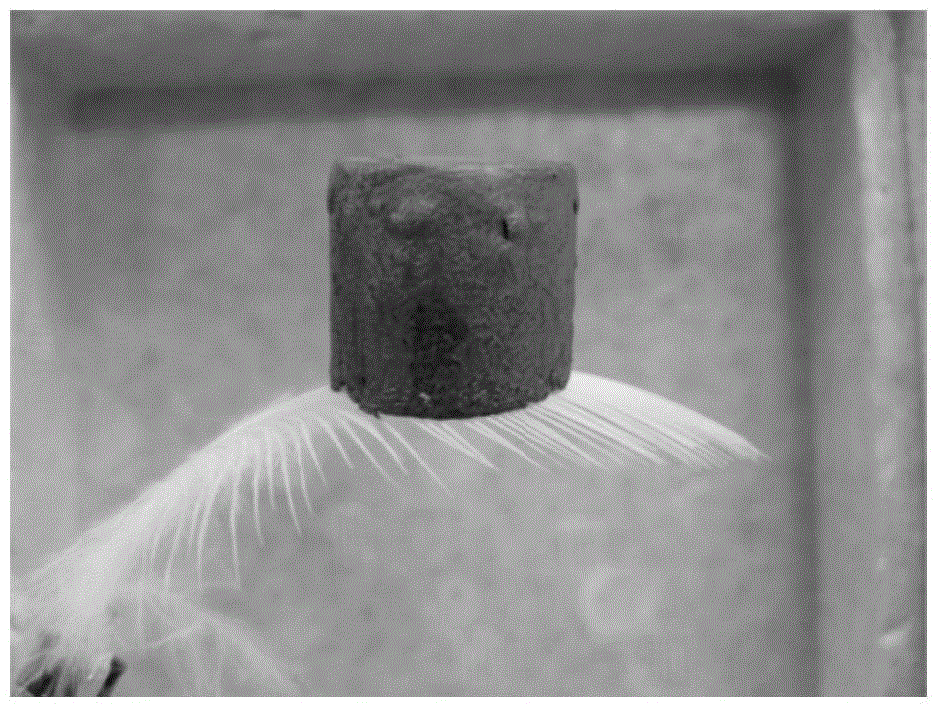

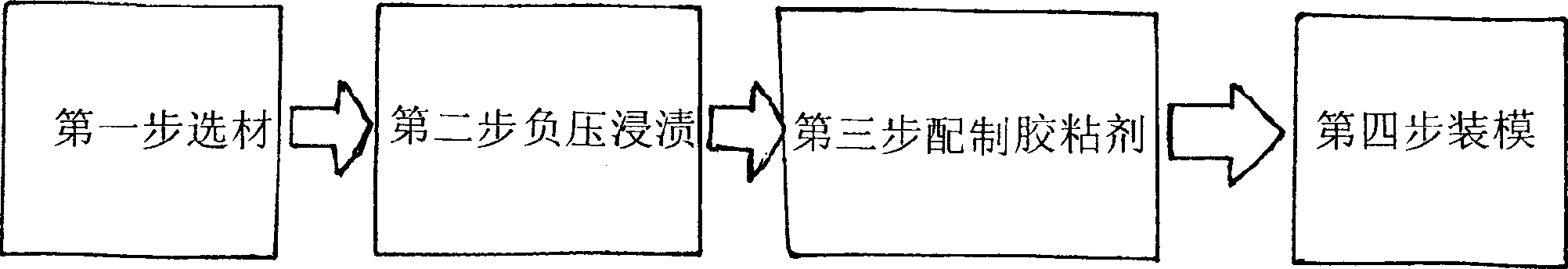

Technique and method for manufacturing technical wood laminted wood

InactiveCN101367226AAdjustable densitySimple production processWood treatment detailsFlat articlesTemperature controlVacuum pumping

The invention relates to a process for producing a technical wood integrated material and a preparation method thereof. The process comprises the following: step one, selecting a material, in which, the water content of the wood material is controlled to lower than 12 percent, dyeing liquor is prepared in a dyeing tank at a temperature of between 85 and 95 DEG C for 1 to 2 hours; step two, pumping imbibition by a vacuum pump with negative pressure of between minus 0.88 and minus 0.95MPa, impregnating the wood material for 2 hours under a pressure of between 0.98 and 1.2MPa after impregnating the wood material under reduced pressure for 1 hour, vacuum pumping for half an hour to control the water content to between 12 and 18 percent; step three, preparing phenolic resin glue, in which, the wood material is placed in a 15 to 20 percent adhesive flume to be impregnated for 20 to 40 minutes, and drying the wood material at low temperature; and step four, placing the wood material in a mould, controlling the density to carry out compression forming, perforating a tip on the mould after forming, placing the mould in a drying kiln at a high temperature of between 60 and 160 DEG C for solidifying for 8 to 20 hours, and discharging the wood material from the kiln. The invention has the advantages of simple production process, convenient operation, various colors and various wood veins, and adjustable density of the wood material.

Owner:高庆国

Leaking stoppage reinforcing agent

InactiveCN103740348APrevent precipitationGood for condensationDrilling compositionSulfite saltSlurry

The invention discloses a leaking stoppage reinforcing agent comprising the following components in parts by weight: 20-30 parts of sodium silicate, 20-30 parts of phenolic resin, 30-50 parts of calcium carbonate, 1-5 parts of potassium silicate, 1-5 parts of sodium sulfite, 0.5-3 parts of polyacrylamide (PAM), 0.5-3 parts of sodium carboxymethylcellulose CMC-LV and 0.5-3 parts of hydroxyethyl cellulose (HEC). According to a conventional preparation method, the materials are added into a kneading machine in sequence in parts by weight at normal temperature and under normal pressure and then are uniformly mixed and stirred, and then the mixture is crushed into granular products, of which the particle size is 0.01mm-0.3mm, after being dried. The leaking stoppage reinforcing agent disclosed by the invention has the characteristics of easily available raw materials, scientific and simple process, safe construction, capability of reinforcing the wall of a leakage stratum well, capability of being added into different types of leaking stoppage slurry when being used together with other materials for reinforcement, capability of improving the reinforcing performance of leaking stoppage slurry and the like, and is widely applied to petroleum and geological drilling engineering.

Owner:DONGYING TAIER GASOLINE TECH

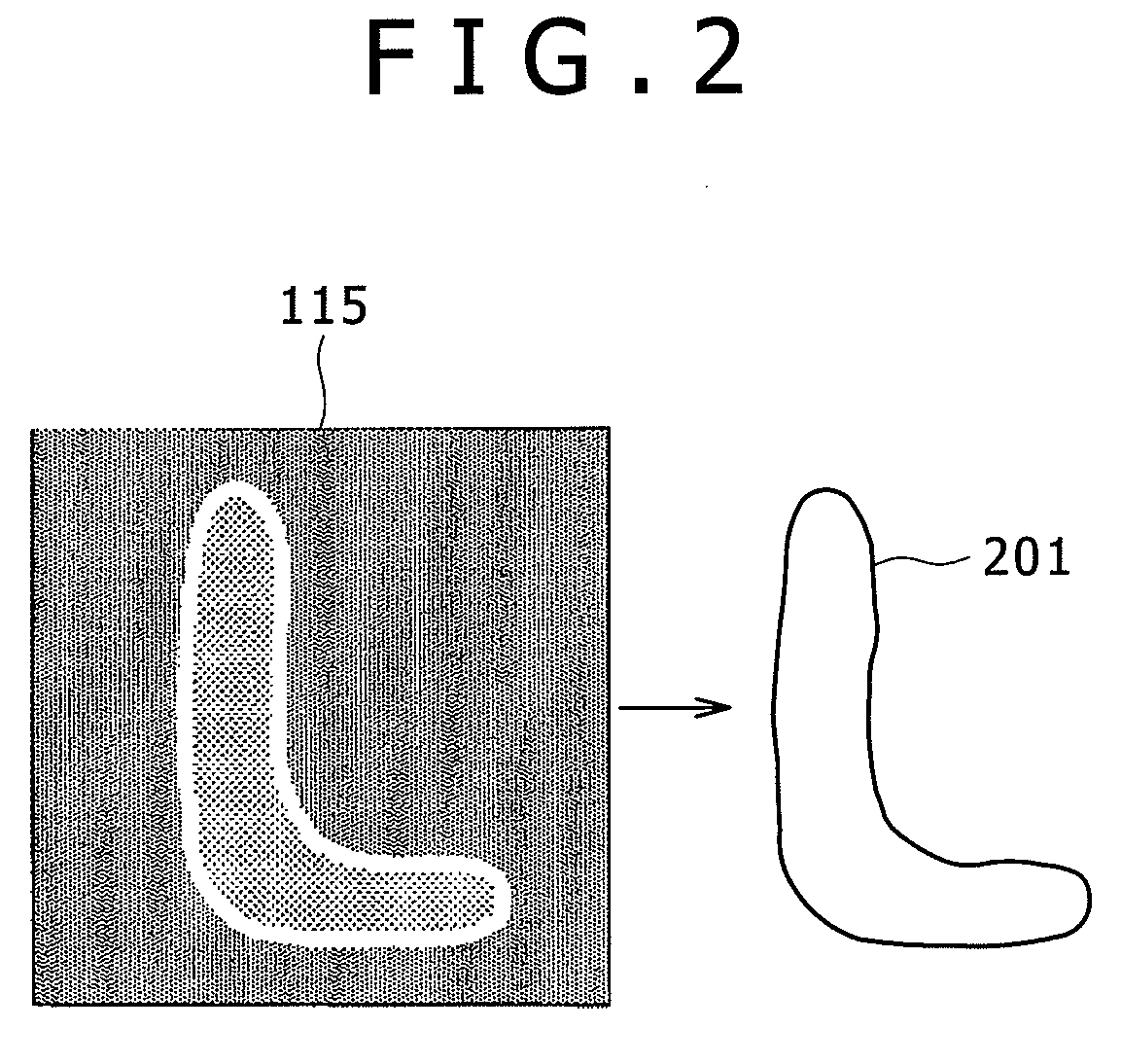

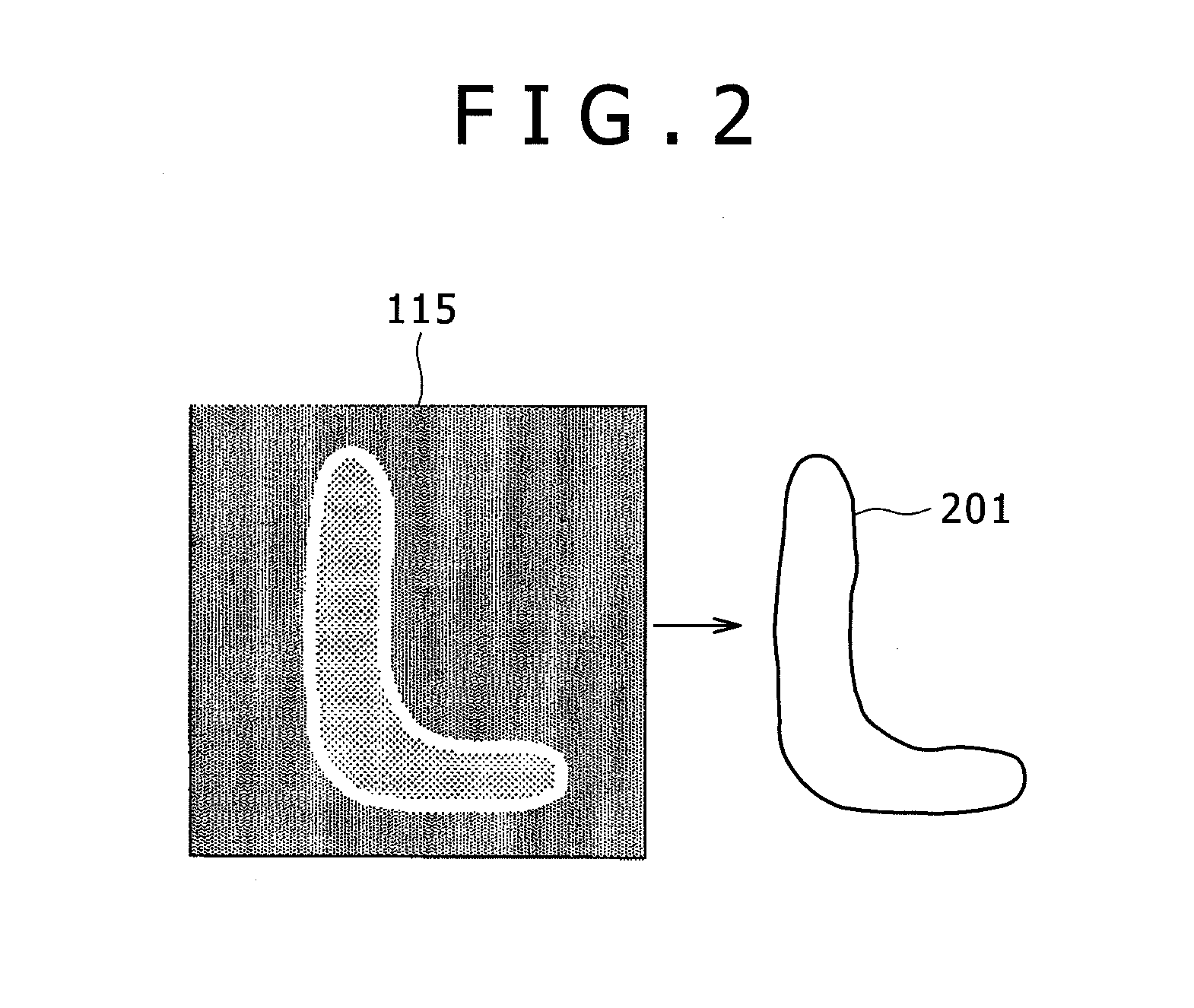

Method and Apparatus For Inspecting Defect Of Pattern Formed On Semiconductor Device

ActiveUS20120002861A1Improve accuracyAdjustable densityImage enhancementImage analysisEngineeringSemiconductor

An apparatus and method for inspecting a defect of a circuit pattern formed on a semiconductor wafer includes a defect classifier have a comparison shape forming section for forming a plurality of comparison shapes corresponding to an SEM image of an inspection region by deforming the shape of the circuit pattern in accordance with a plurality of shape deformation rules using design data corresponding to the circuit pattern within the inspection region and a shape similar to the SEM image of the inspection region out of the plurality of comparison shapes formed and selected as the comparison shape, and a shape comparing and classifying section for classifying the SEM image using information of the comparison shape selected in the comparison shape forming section and the inspection shape of the circuit pattern of the SEM image of the inspection region.

Owner:HITACHI HIGH-TECH CORP

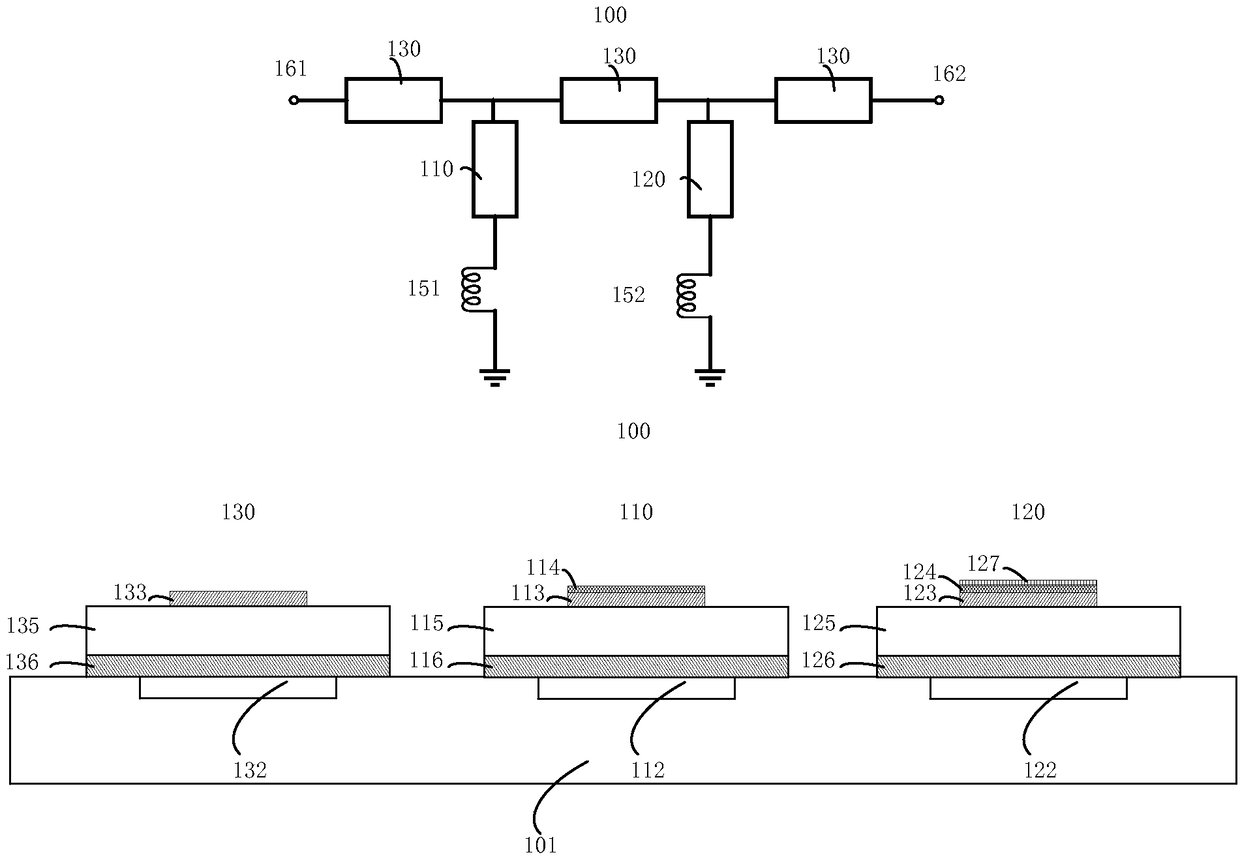

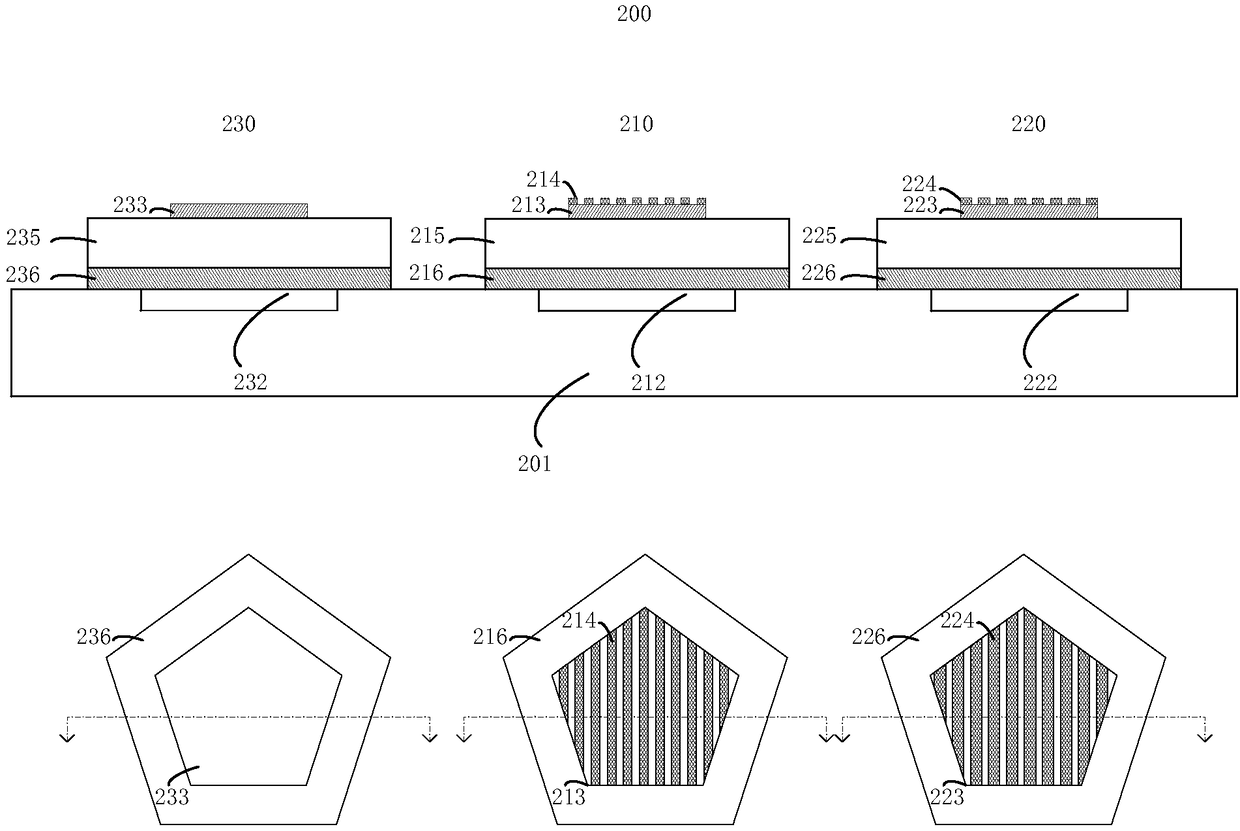

Filter

PendingCN108173528ASolve the problem of increased process stepsAdjustable densityMultiple-port networksResonator

The invention discloses a filter. The filter comprises at least a series resonator and at least two parallel resonators. The parallel resonator or the series resonator comprises a weight load layer, wherein the density of the weight load layer is adjustable. According to the filer provided by the invention, the effect that the parallel resonator can adjust the resonant frequency of the resonator in the filter by only needing one weight load layer is achieved.

Owner:湖北宙讯科技有限公司

Fresh water-based micro bubble drilling fluid for drilling coal bed gas

The invention relates to a fresh water-based micro bubble drilling fluid for drilling coal bed gas. The fresh water-based micro bubble drilling fluid for drilling the coal bed gas is prepared from fresh water, sodium carbonate, sodium hydroxide, basic zinc carbonate, a flow pattern regulator, a foaming agent and a stabilizing agent. The main performance of the fresh water-based micro bubble drilling fluid for drilling the coal bed gas is not lower than that of a drilling fluid used in the conventional coal bed gas drilling process, and the drilling fluid has a good leakage controlling and leakage plugging effect, solves the problem that a low pressure easily-leaked coal bed is easily leaked in the drilling process, and can effectively improve the bearing capacity of a stratum; when the coal bed is not drilled and leaked, the drilling fluid has various engineering properties required by drilling; and when a leaked coal bed is met, the drilling fluid automatically plugs the stratum and drilling is continued; through the proportion of a treatment agent, the poor soil solid-phase contamination resistance and calcium resistance of the drilling fluid are improved; and the properties of the drilling fluid are easy to maintain.

Owner:CHINA UNITED COALBED METHANE +2

Carbon fiber reinforced metal ceramic base composite material

The invention discloses a carbon fiber reinforced metal ceramic base composite material. The carbon fiber reinforced metal ceramic base composite material consists of a carbon fiber prefabricated body, an interface layer, a ceramic basal body and a metal basal body; metal is one of an aluminum alloy, a magnesium alloy, a copper alloy and a tin alloy; ceramic is SiC; the density of the composite material is 1.8-3.8 g / cm3; and the invention further discloses a method for preparing different alloy ceramic composite materials. The composite material has the advantages of short preparation period and adjustable density, overcomes the brittleness and low density of the ceramic, and can meet the demands on the ceramic base composite materials in multiple fields.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

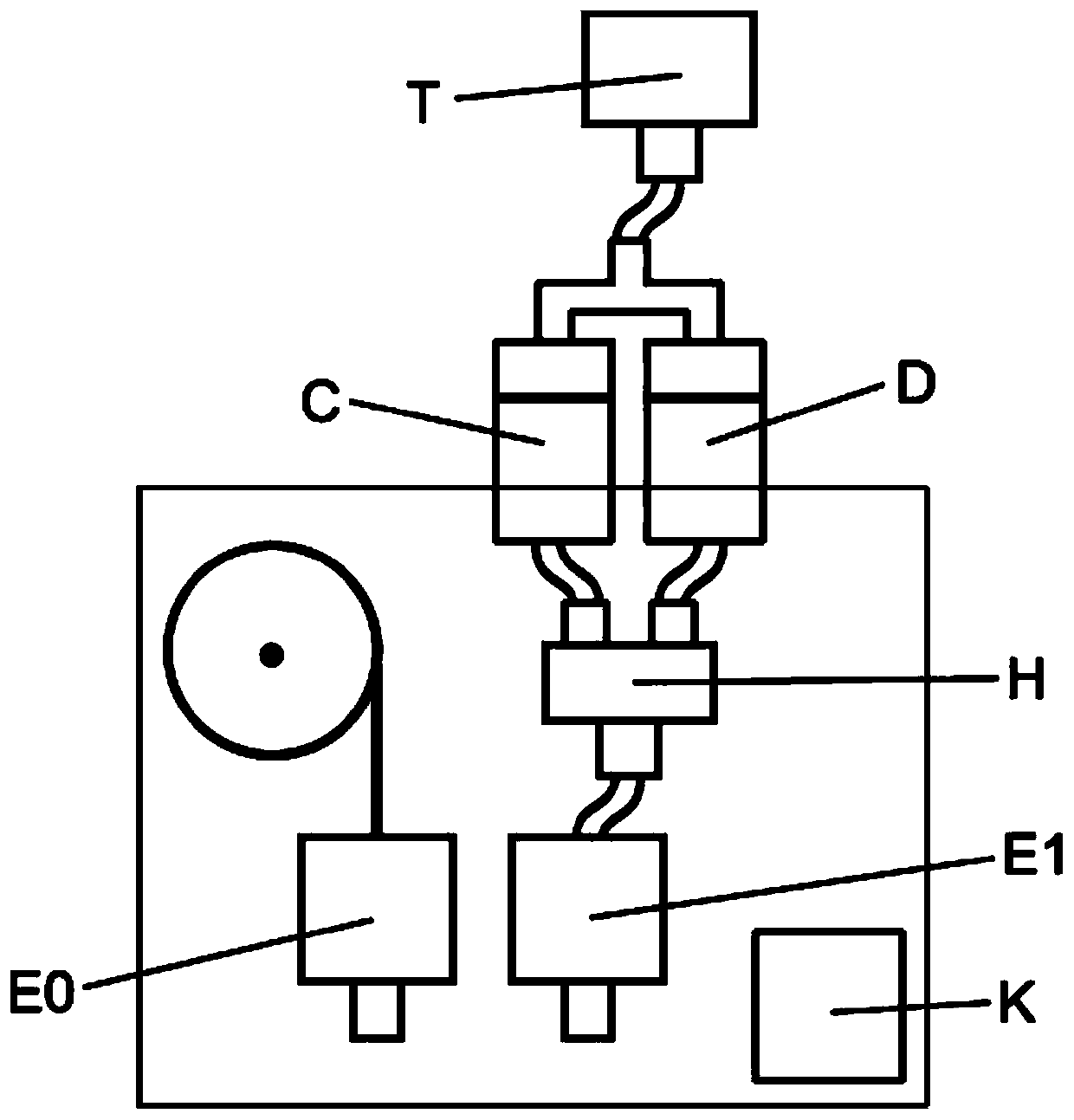

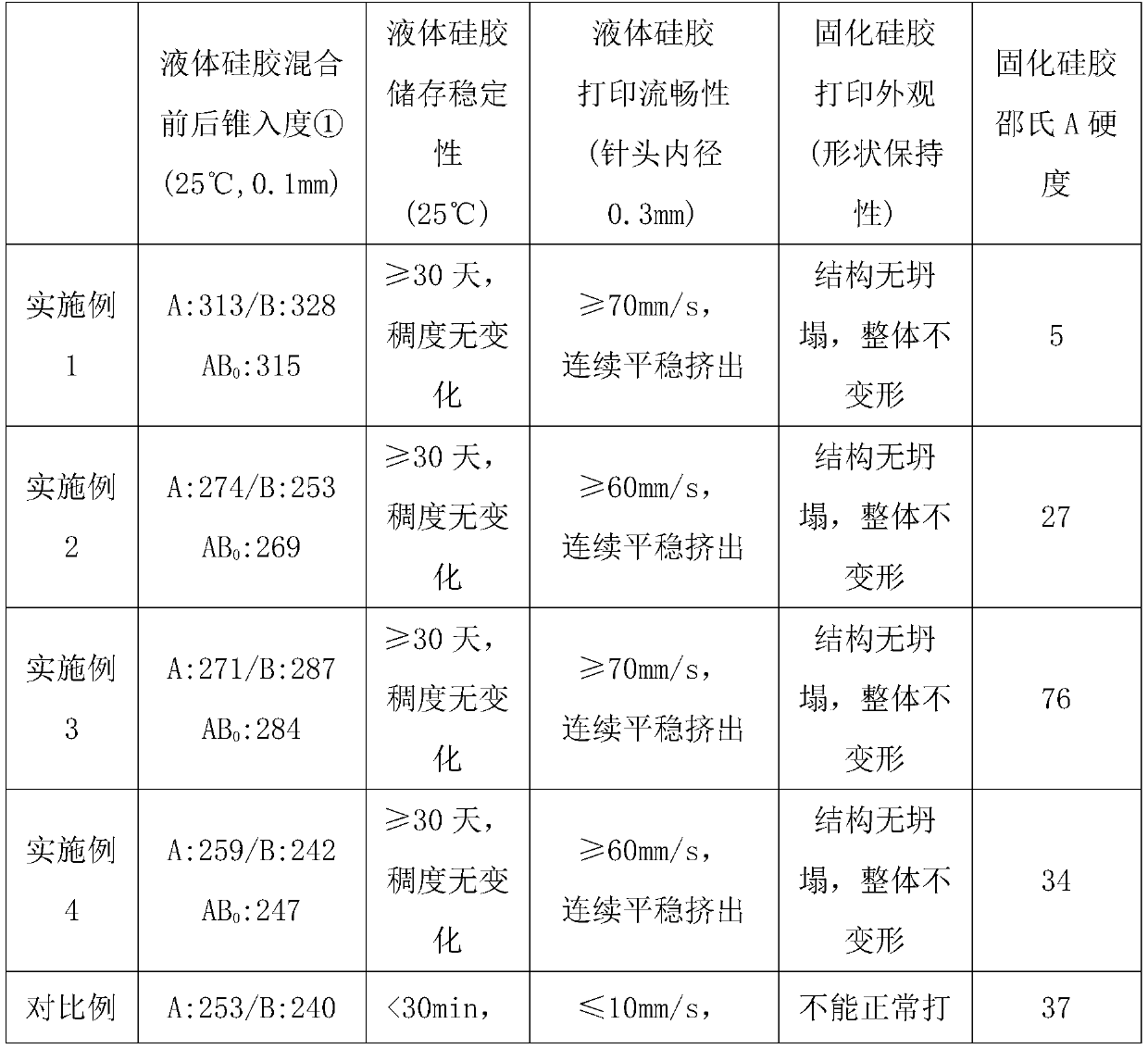

Dual component liquid silica gel for 3D printing and printing method thereof

ActiveCN110128833ASolve problems that are difficult to 3D printIncrease elasticityAdditive manufacturing apparatus3D object support structuresOrganic solventPolyol

The invention discloses a dual component liquid silica gel for 3D printing and a printing method thereof. The liquid silica gel comprises a component A and a component B. The component A comprises following components in parts by weight: 100 parts of vinyl polysiloxane, 0.01 to 5 parts of a hydrosilylation catalyst, 1 to 10 parts of polyether polyol, and 1 to 10 parts of fumed silica. The component B comprises following components in parts by weight: 100 parts of vinyl polysiloxane, 1 to 50 parts of hydrogen containing polysiloxane, 0.01 to 5 parts of a hydrosilylation inhibitor, 1 to 10 partsof polyether polyol, and 1 to 10 parts of fumed silica. During the printing process, the thickness of the liquid silica gel does not change, the structure is not deformed, an onsite heat treatment isnot needed, only post sectioned thermosetting moulding is needed, the printing technology is simplified, and the printing cost is reduced. The liquid silica gel does not contain any organic solvent or photosensitive component, is very safe and nontoxic, and 3D products prepared from the liquid silica gel can be applied to fields, which have high safety requirements, such as children toys, food, medicines, and the like.

Owner:SOUTH CHINA UNIV OF TECH

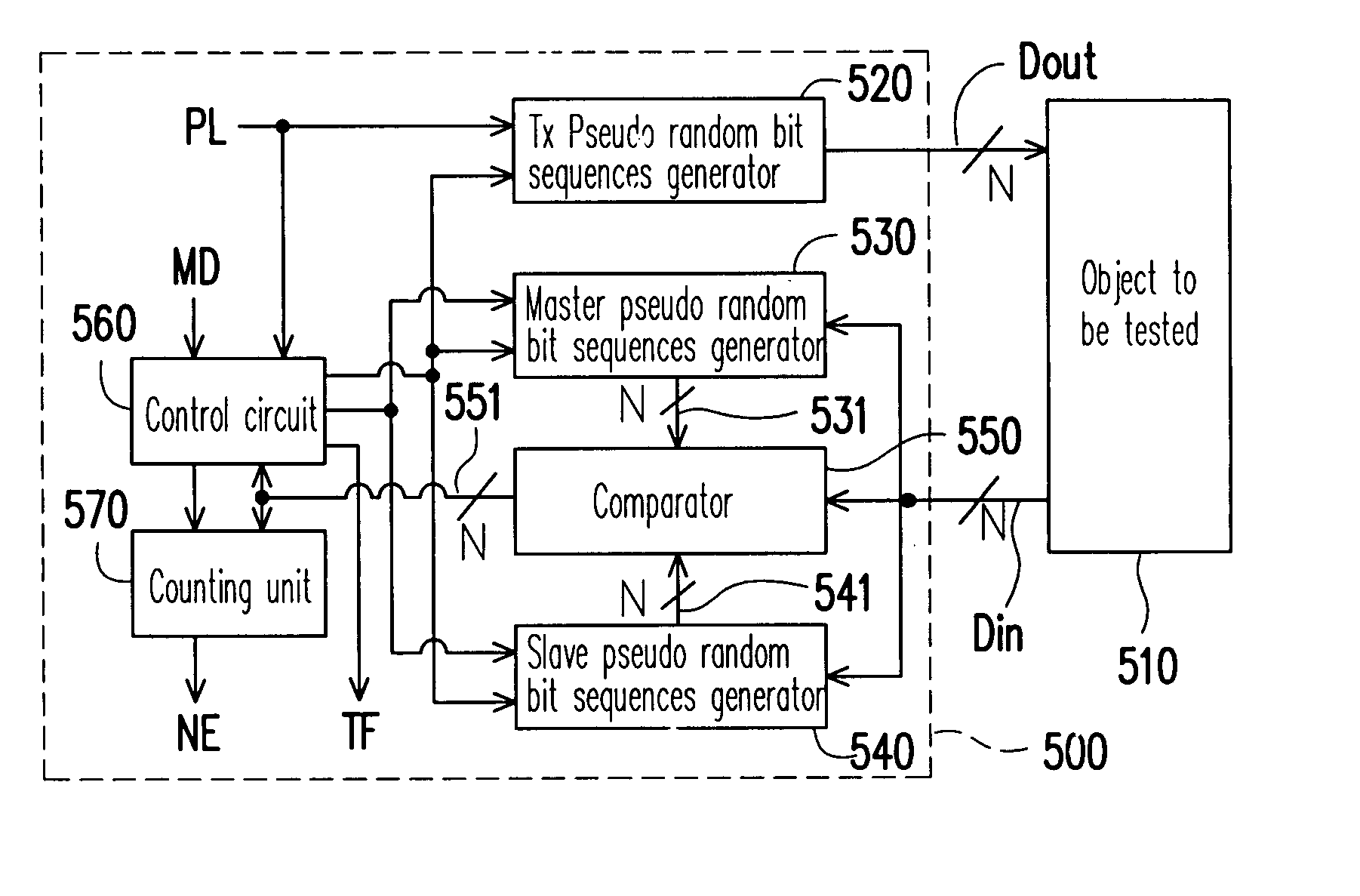

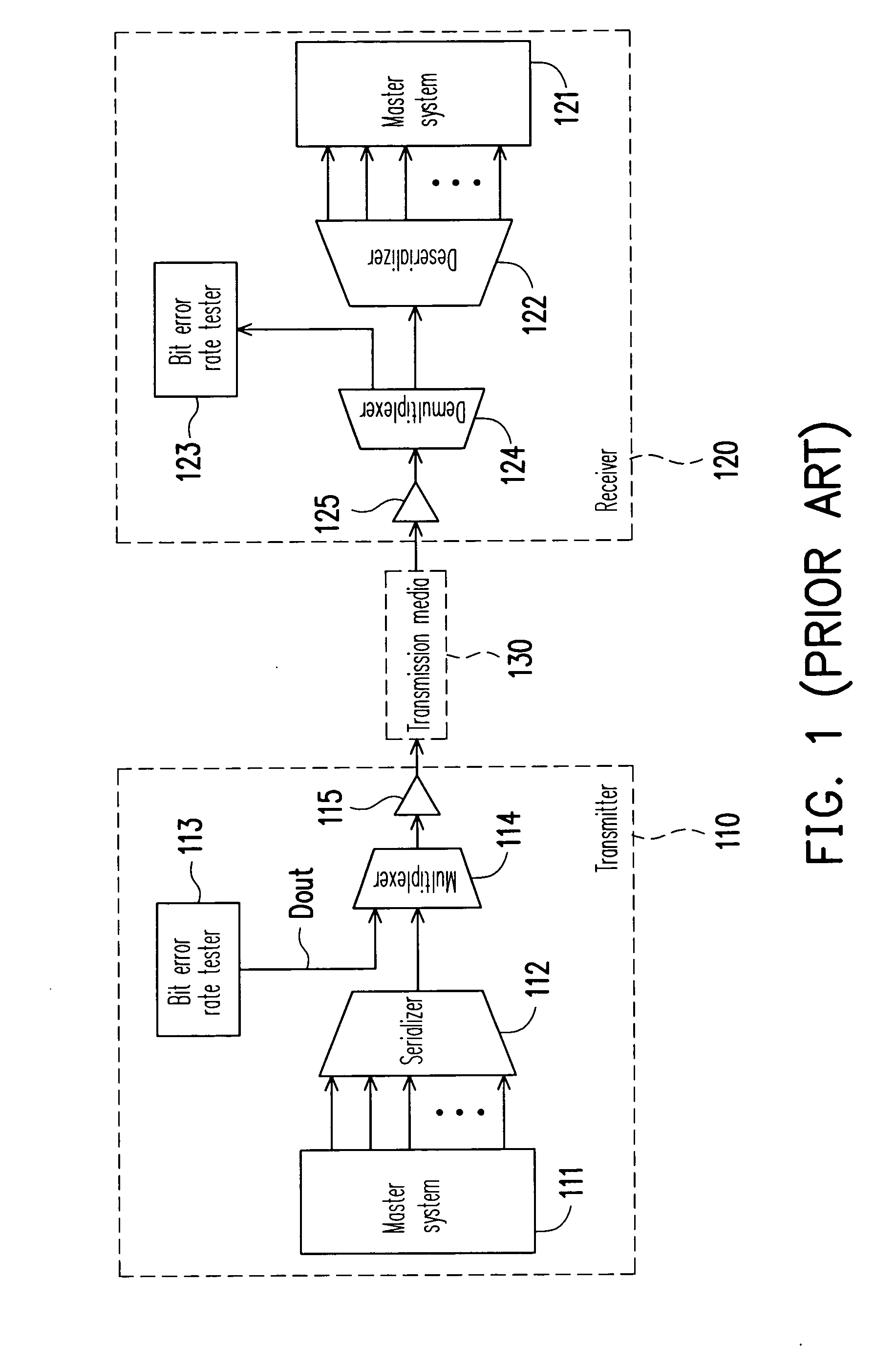

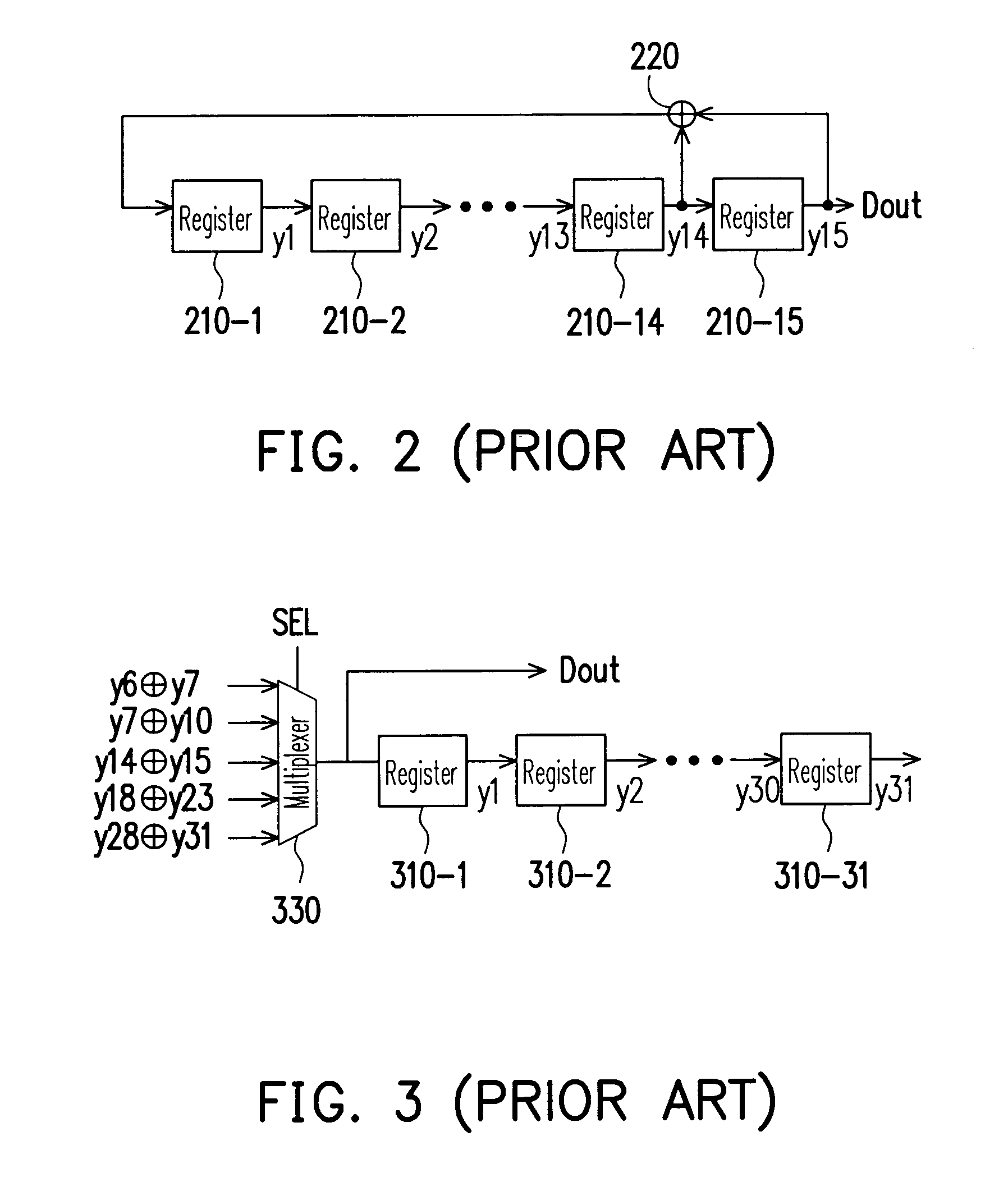

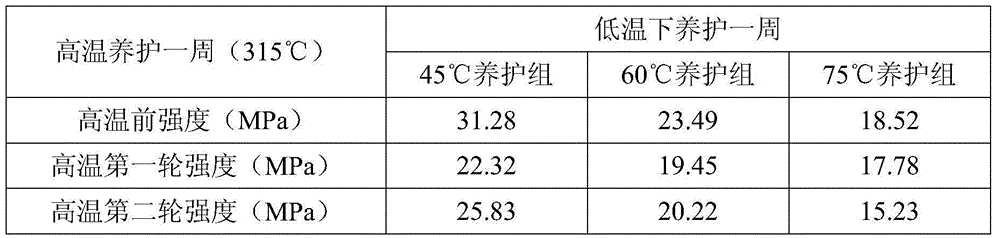

Bit error rate tester and pseudo random bit sequences generator thereof

InactiveUS20060133468A1Improve reliabilityAdjustable densityError preventionElectronic circuit testingOutput compareComputer science

A bit error rate tester and a pseudo random bit sequences (PRBS) generator thereof are provided. The bit error rate tester includes a transmitter PRBS generator, a master PRBS generator, a slave PRBS generator, a comparator, and a counting unit. The transmitter PRBS generator generates a parallel N-bit (N is an integer larger than 1) original PRBS, wherein an object to be tested receives the original PRBS and outputs a parallel N-bit code to be tested. The master and the slave PRBS generators generate a master and a slave parallel N-bit PRBS, respectively. The comparator receives, compares, and determines whether the code to be tested, the master and the slave PRBS are the same or not, and outputs a comparison result. The counting unit coupling to the comparator counts a number of bit errors based on the comparison result.

Owner:NAT CHIAO TUNG UNIV

High temperature resistant well cementation cement paste used for steam injection thermal production well

InactiveCN104059622AMeet the requirements of rapid condensationHigh strengthDrilling compositionTime controlThermal stability

The invention provides high temperature resistant well cementation cement paste used for a steam injection thermal production well, and the cement paste comprises the following components by weight: 100 parts of high temperature resistant cement, 30-40 parts of a high temperature stabilizer, 0.5-1.2 parts of a thickening time control agent, 2.5-4.5 parts of an oilwell cement fluid loss agent, 0.02-0.15 part of an anti sedimentation agent, 0.02-0.15 part of a defoaming agent, and 45-100 parts of water. The high temperature resistant well cementation cement paste can effectively solve the problems of quick reduction in strength, fast rising in permeability and the like of well cementation cement paste systems in the prior art, can improve the thermal stability, reduces the possibility of channeling and casing damage, can make oilwells long-term sealed, improves production efficiency, and reduces production cost.

Owner:PETROCHINA CO LTD

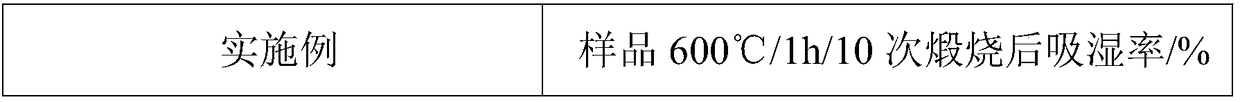

Silicon dioxide aerogel composite material and preparation method and application thereof

ActiveCN109336545AMeet the requirements of reusable and stable performanceAdjustable densityFiberMoisture resistance

The invention relates to a preparation method of a silicon dioxide aerogel composite material. The preparation method of the silicon dioxide aerogel composite material comprises the following steps: (1) carrying out hydrolysis-polycondensation reaction on a fluorine-containing silane coupling reagent under the acidic catalysis condition, and constructing temperature-resistant hydrophobic layer structures on the surfaces of sol particles; (2) dipping the obtained silicon dioxide sol in a fiber-reinforced body under the catalysis condition, and carrying out sol-gel, aging, solvent replacement and drying to obtain a hydrophobic fiber-reinforced aerogel composite material; (3) removing unstable residual active groups and water on the surface of the aerogel composite material at a high temperature to realize surface activation; (4) further carrying out hydrophobic treatment by using a fluorine-containing silane hydrophobization reagent; and (5) drying the fiber-reinforced aerogel compositematerial after the fiber-reinforced aerogel composite material is subjected to hydrophobic treatment. The prepared aerogel composite material can be recycled at a high temperature and a low temperature, is excellent in heat-insulation effect and has moisture resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Laser marking device, laser marking method, and object to be marked

InactiveUS7705870B2Adjustable densityEnhance the imageRecording apparatusDuplicating/marking methodsVolumetric Mass DensityOptoelectronics

A laser marking device that irradiates a laser beam on a workpiece (W) to transform a portion inside the workpiece at a focal point of the laser beam, thus putting a dot in each predetermined area. The laser marking device includes acquiring mechanism (10, 20) that acquires, as information on the dot, at least two-dimensional position information of an exposed section of the workpiece (W), and density information of the dot, coordinate setting mechanism (30) that calculates, for each dot according to the density information, dot depth information showing the distance from the surface of the workpiece (W) to the dot in the thickness direction of the workpiece (W), and sets three-dimensional coordinates for each dot based on a position specified by the dot depth information and the two-dimensional position information, and laser marking mechanism (40) that performs marking with the three-dimensional coordinates as a laser beam focal point.

Owner:ARAI HELMET LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com