Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

346 results about "Opacifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An opacifier is a substance added to a material in order to make the ensuing system opaque. An example of a chemical opacifier is titanium dioxide (TiO₂), which is used as an opacifier in paints, in paper, and in plastics. It has very high refraction index (rutile modification 2.7 and anatase modification 2.55) and optimum refraction is obtained with crystals about 225 nanometers. Impurities in the crystal alter the optical properties. It is also used to opacify ceramic glazes and milk glass; bone ash is also used.

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

Vegetable capsule of starch composition and preparation method

InactiveCN1687203AWide variety of sourcesNo pollution in the processPharmaceutical delivery mechanismFood preparationPreservativePlasticizer

The present invention relates to a starch composite plant capsule and its preparation method. Said method includes the following steps: uniformly mixing starch or starch composite, dispersing it in distilled water, heating for 15-60 min, at 60-95 deg.c to make starch be fully gelatinated, then adding plasticizer, gel, surfactant, opacifier, edible color matter, preservative, ant-oxidant and enhancer, fully and uniformly mixing them, then decompressing and defoaming, and adopting conventional capsule-forming process to make the obtained colloid liquid into the invented starch composite plant hollow capsule, and its capsule-forming temperature is 40-95 deg.C.

Owner:TIANJIN UNIV

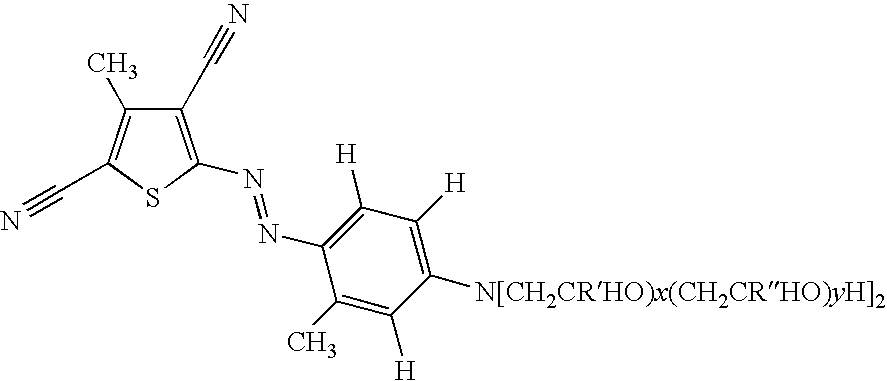

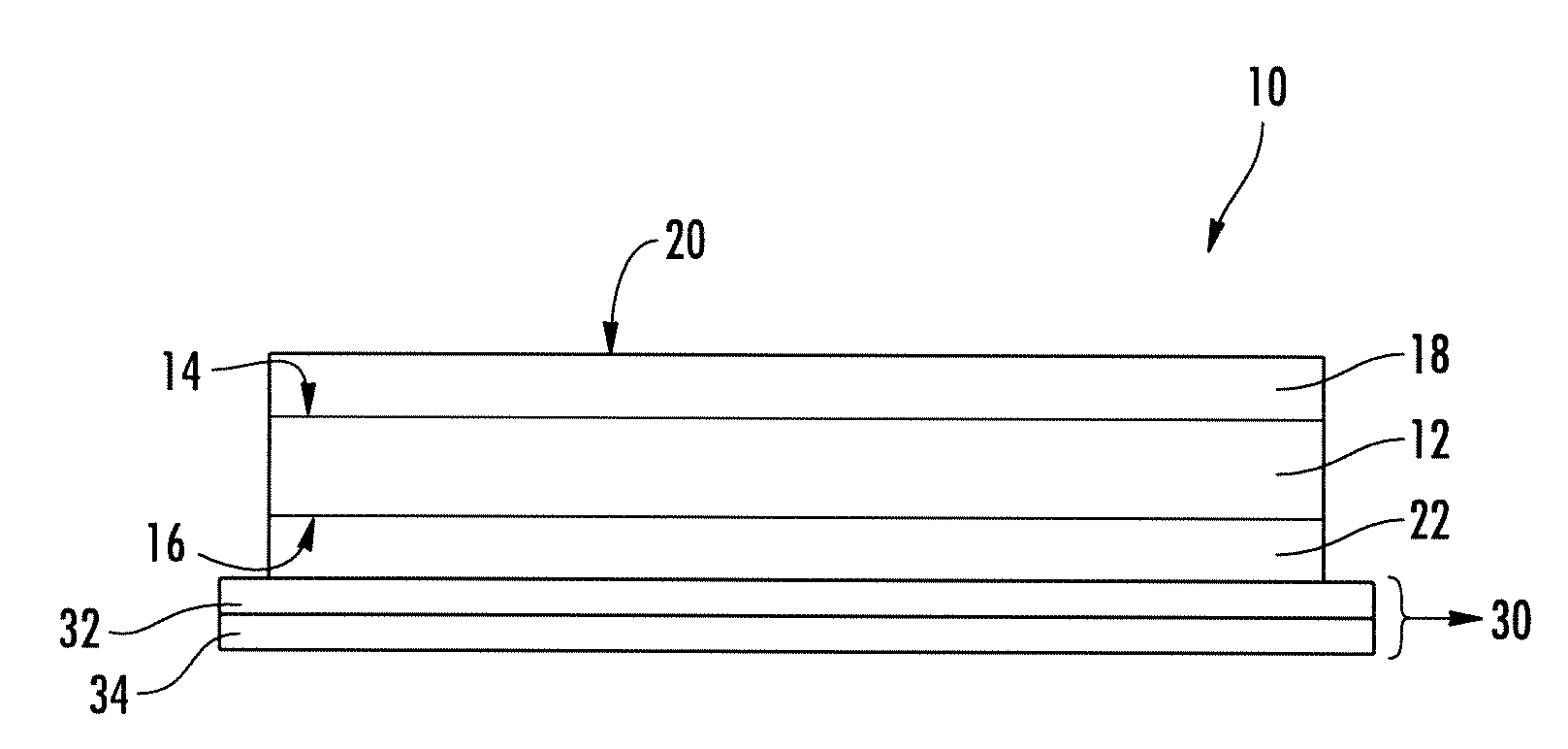

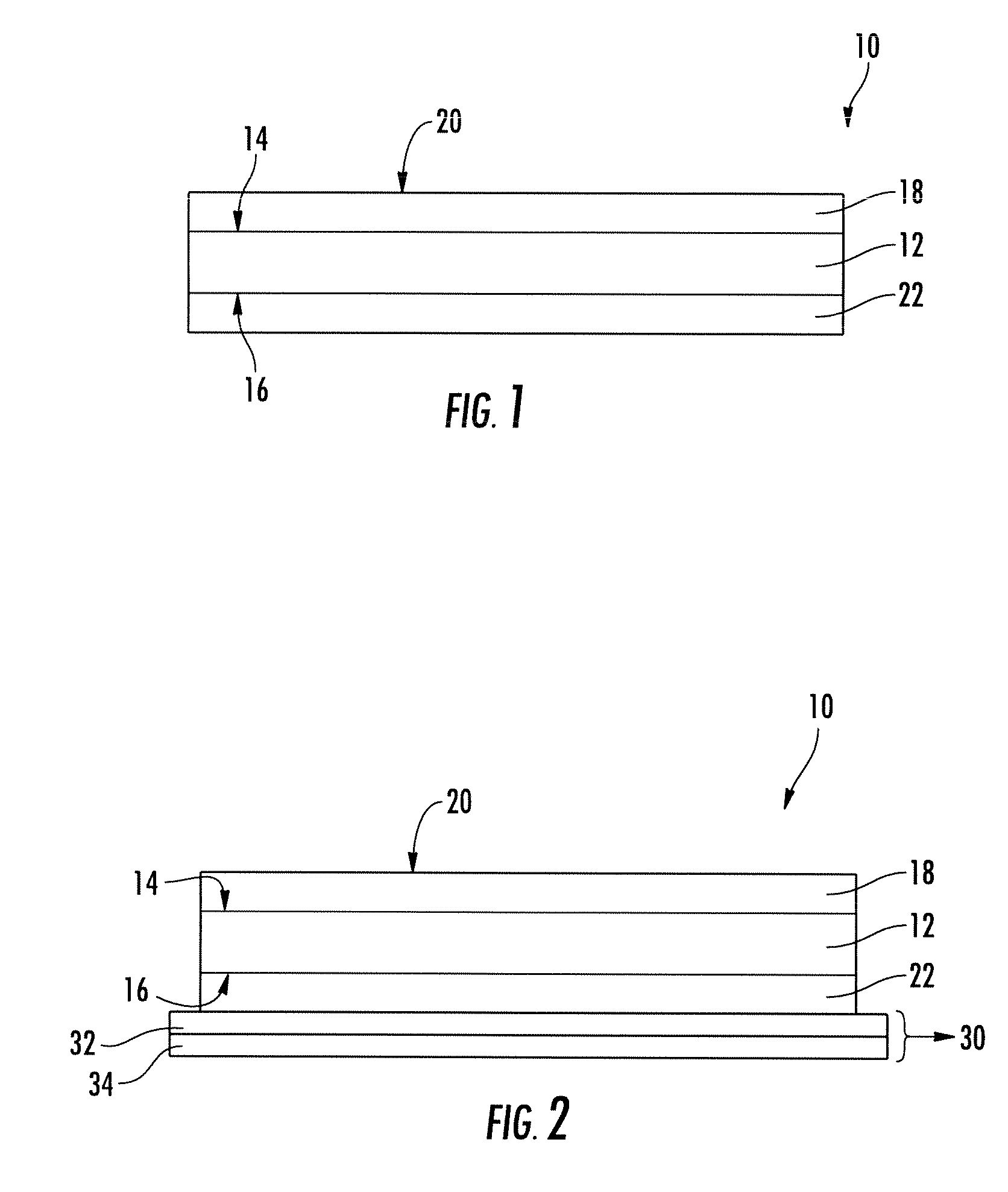

Electrochromic display device and compositions useful in making such devices

InactiveUS6879424B2Easy to manufactureLow powerTenebresent compositionsNon-linear opticsDisplay deviceRedox

The present invention relates to a composition and to a display device having the composition positioned between electrodes. The composition contains: (a) a compound that undergoes a reversible redox reaction to generate a pH gradient between the two electrodes, (b) an indicator dye, (c) a charge transport material, and optionally, (d) a matrix material and (e) an opacifier, and (f) secondary redox couple wherein components (a), (b), and (c) are different from one another and the standard reduction potential of component (a) is less than the standard reduction potential for the other components. Depending on the electric field present between the electrodes, a display image may be generated.

Owner:AVESO INC

Water-soluble pouch

ActiveUS20100305020A1Organic/inorganic per-compounds compounding agentsDetergent materialsAntioxidantWater soluble

The present application relates to a water soluble pouch comprising at least one compartment, wherein said compartment comprises a first liquid composition comprising an opacifier and an antioxidant and has a fresh Hunter L value of greater than 7 and a b value of less than 4.

Owner:THE PROCTER & GAMBLE COMPANY

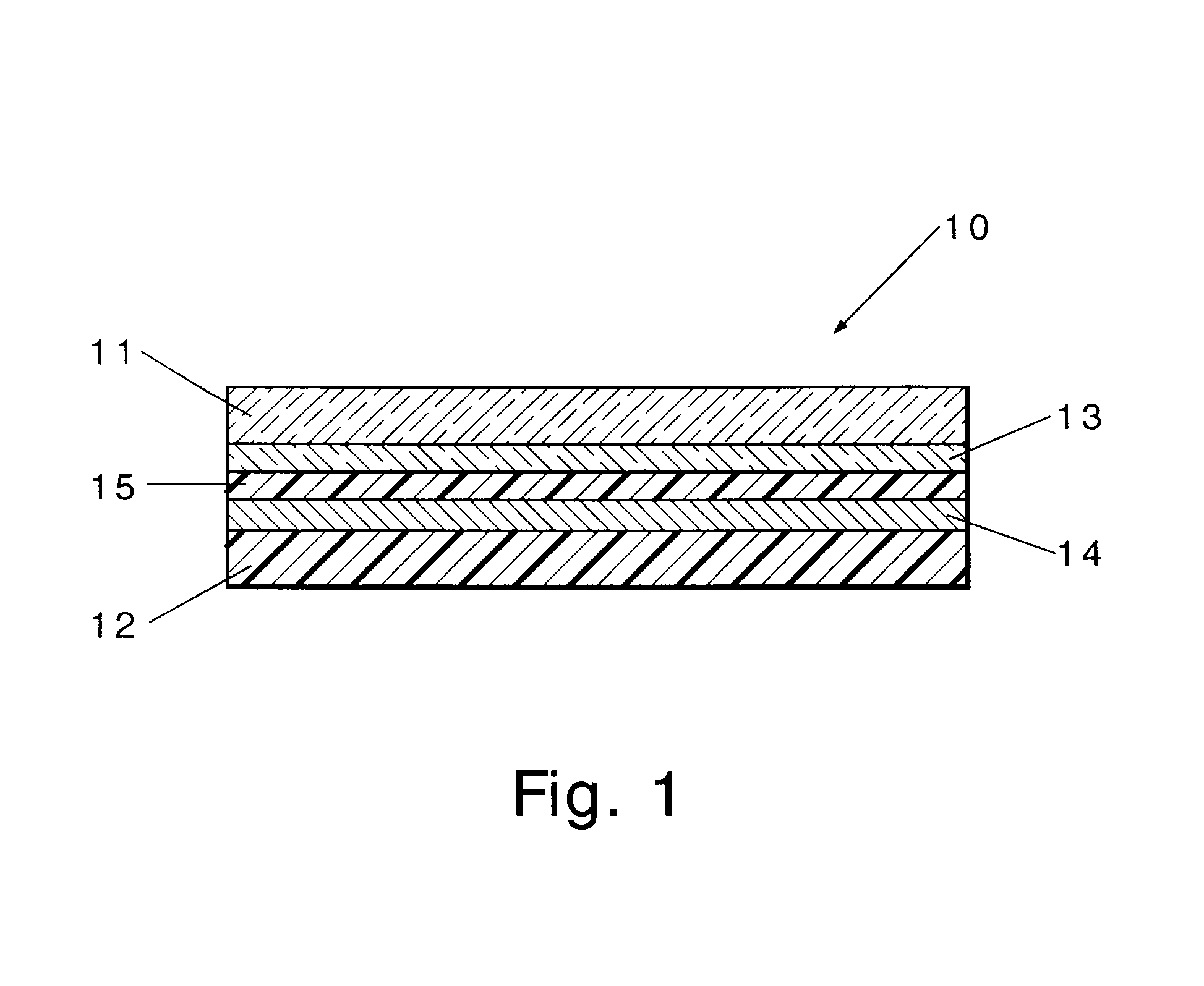

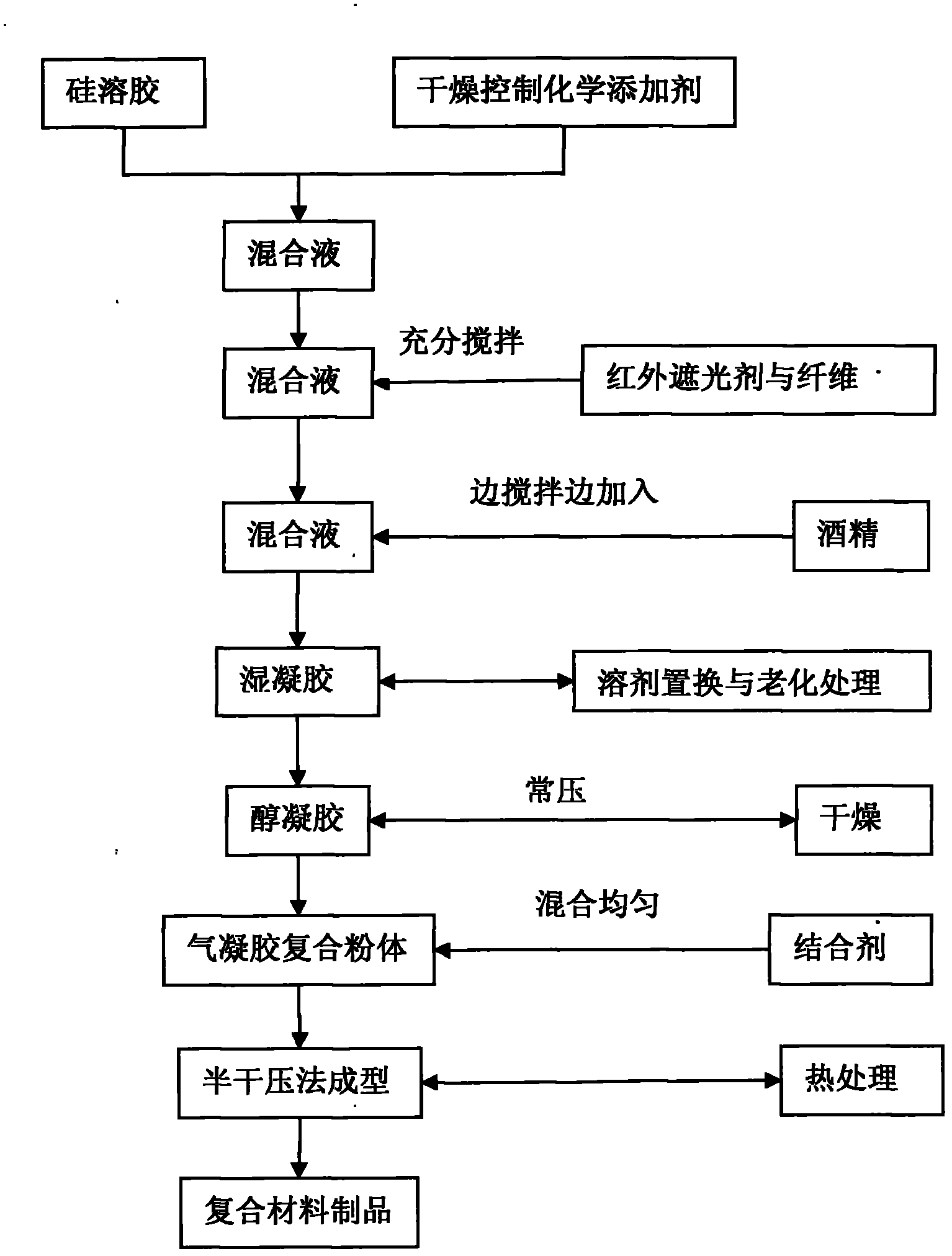

Method for preparing fiber-containing silicon dioxide aerogel composite thermal insulation material

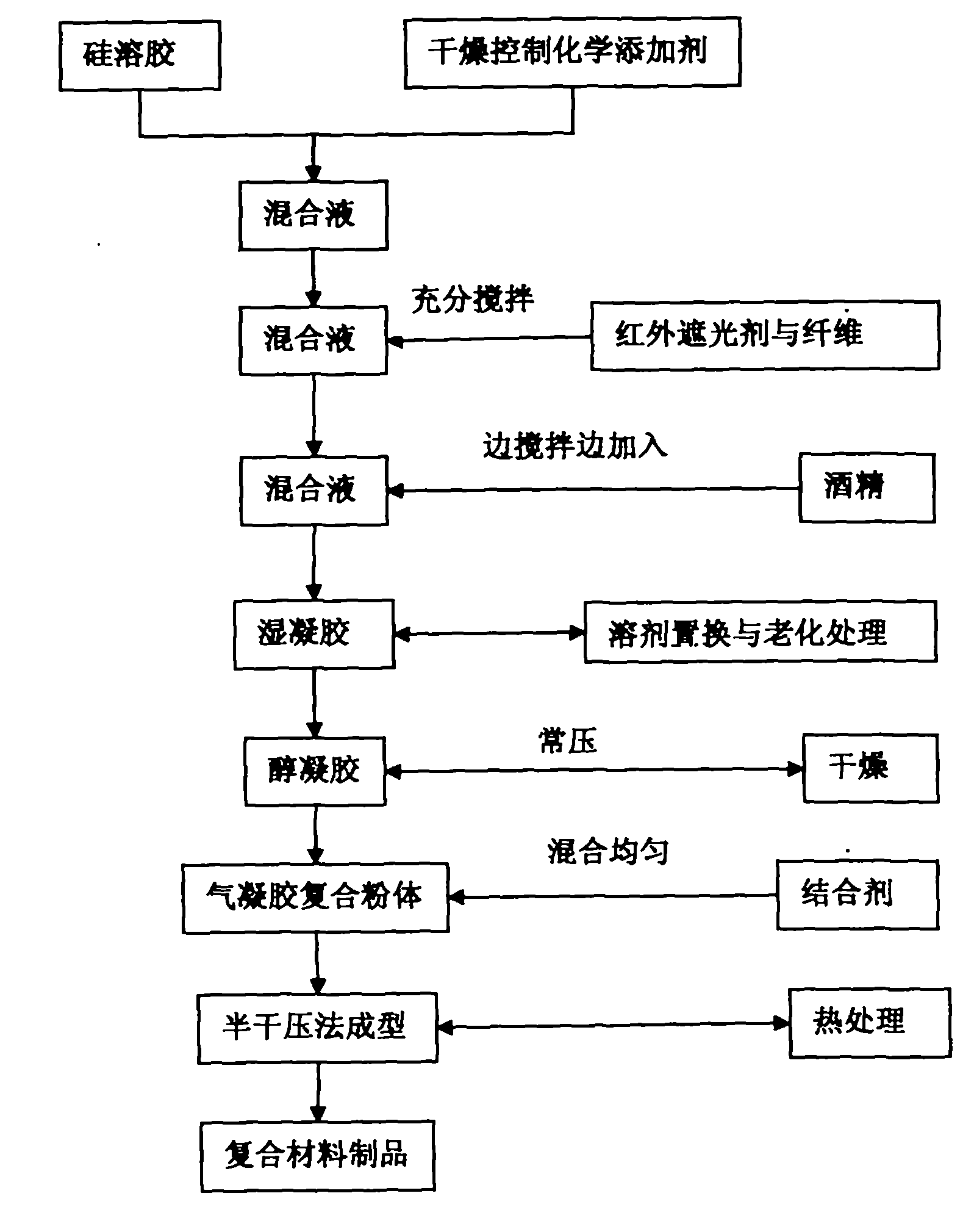

The invention relates to a method for preparing a fiber-containing silicon dioxide aerogel composite thermal insulation material. The method is mainly characterized by comprising the following steps of: adding fiber and an infrared sunscreen agent into aerogel precursor solution to form composite gel, and treating the composite gel to obtain fiber-containing silicon dioxide aerogel composite powder; and adding a little binding agent and performing compression molding by adopting a half-dry pressing method, and performing heat treatment to obtain composite products in various shapes. By adopting a technical route for preparing the composite powder and molding by adopting the half-dry pressing method, products in complex shapes are easy to produce, supercritical drying at high cost and in danger of high pressure is avoided, and the method is easy for mass production. By taking industrial silica sol and industrial spirit as main raw materials for preparing silicon dioxide aerogel, addinga drying controlled chemical additive, the infrared sunscreen agent and the fiber in turn and finally slowly adding the industrial spirit until gelling, the fiber and the infrared sunscreen agent canbe fully and uniformly mixed with the aerogel in the composite powder, the thermal insulation of the materials is improved, and a higher-strength light thermal insulation material is prepared.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Chewable tablet containing montelukast sodium

ActiveCN101773481AImprove stabilityAvoid photolysisInorganic non-active ingredientsPill deliveryMedicineMontelukast Sodium

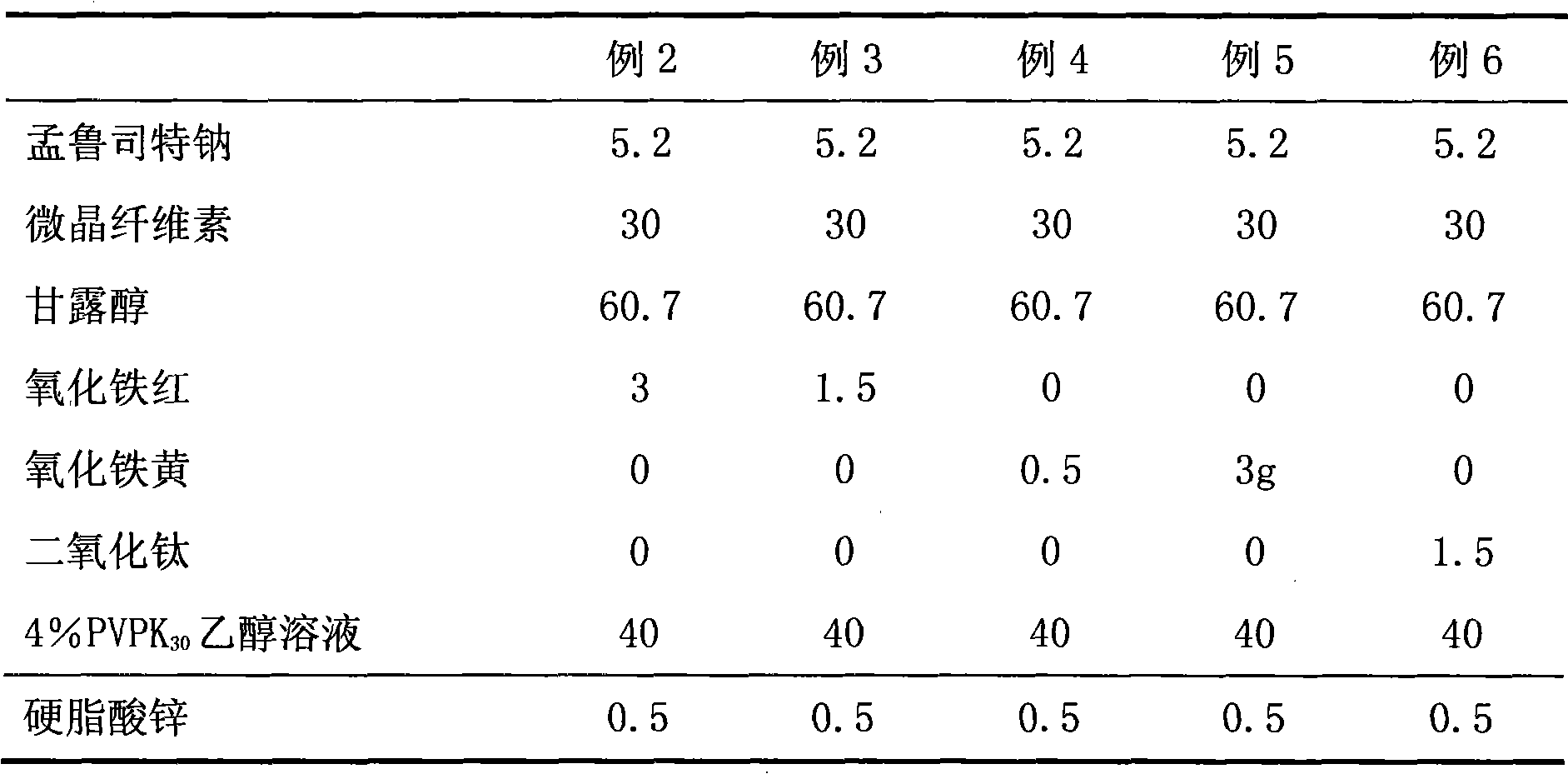

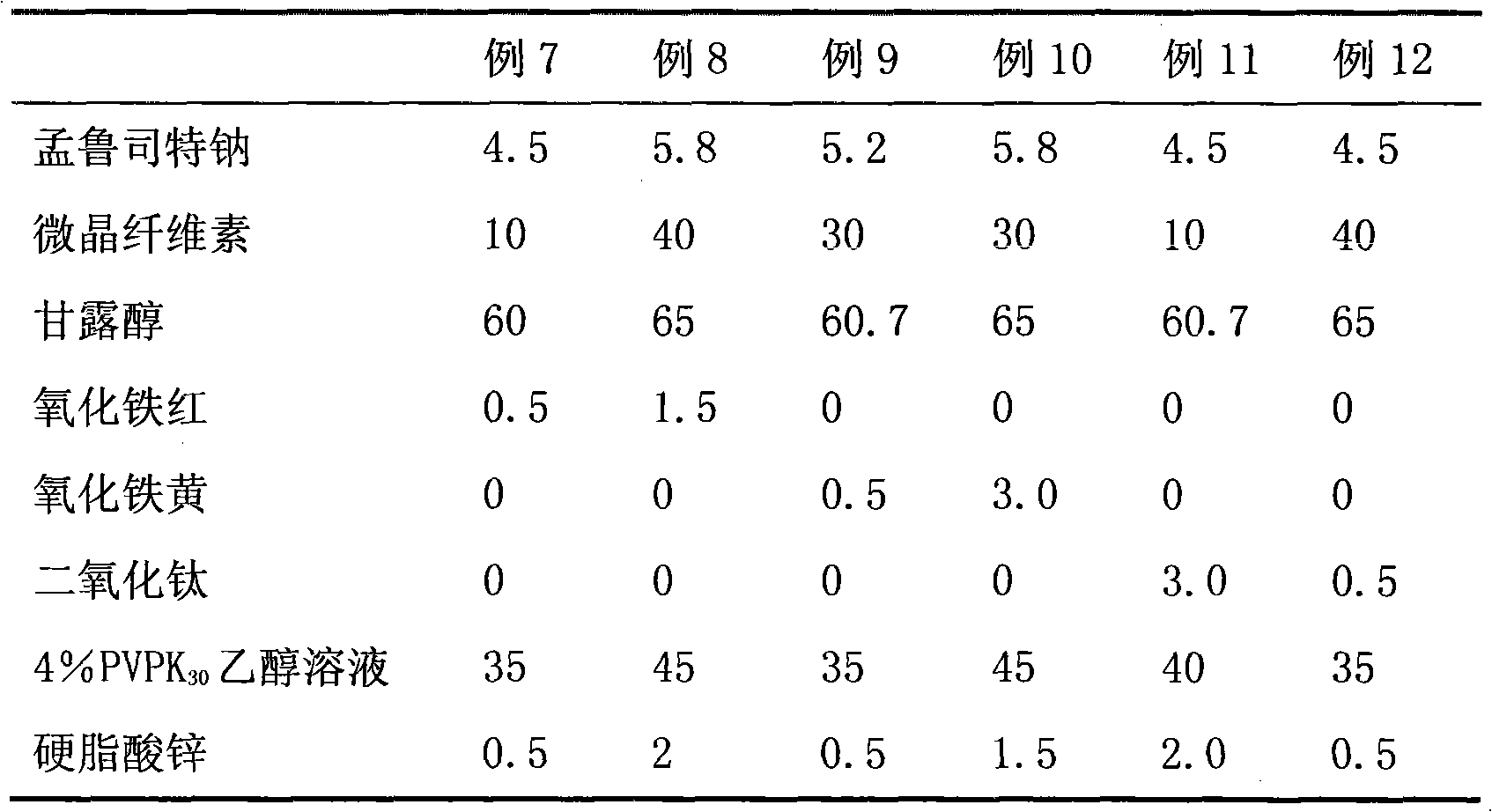

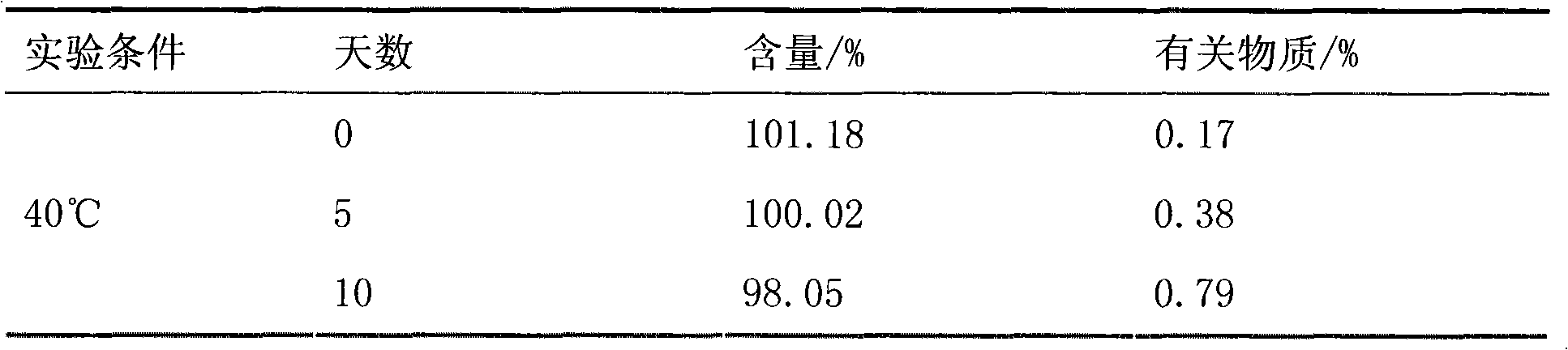

The invention belongs to the field of medicine preparations, which particularly relates to a chewable tablet of montelukast sodium. Because the production process of the chewable tablet of the montelukast sodium needs the light shielding operation at present, the mass production is inconvenient, and the chewable tablet of the montelukast sodium has the defect of poorer stability. In the invention, zinc stearate and an opacifier of iron oxide red, iron oxide yellow and titanium dioxide are added into the auxiliary materials of a chewable tablet of montelukast, so that the content of relevant substances can be lowered, and the stability of the chewable tablet is enhanced.

Owner:LUNAN PHARMA GROUP CORPORATION

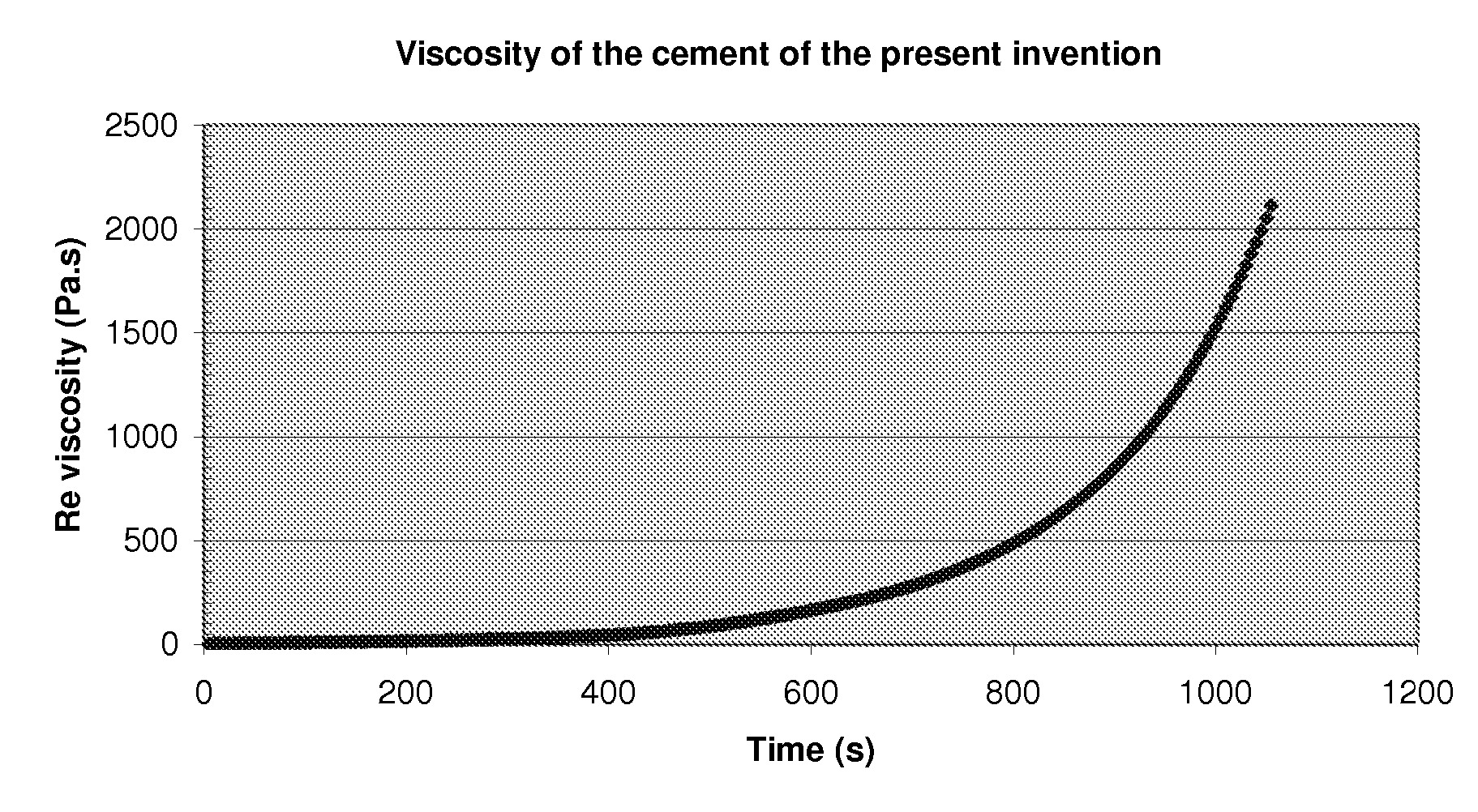

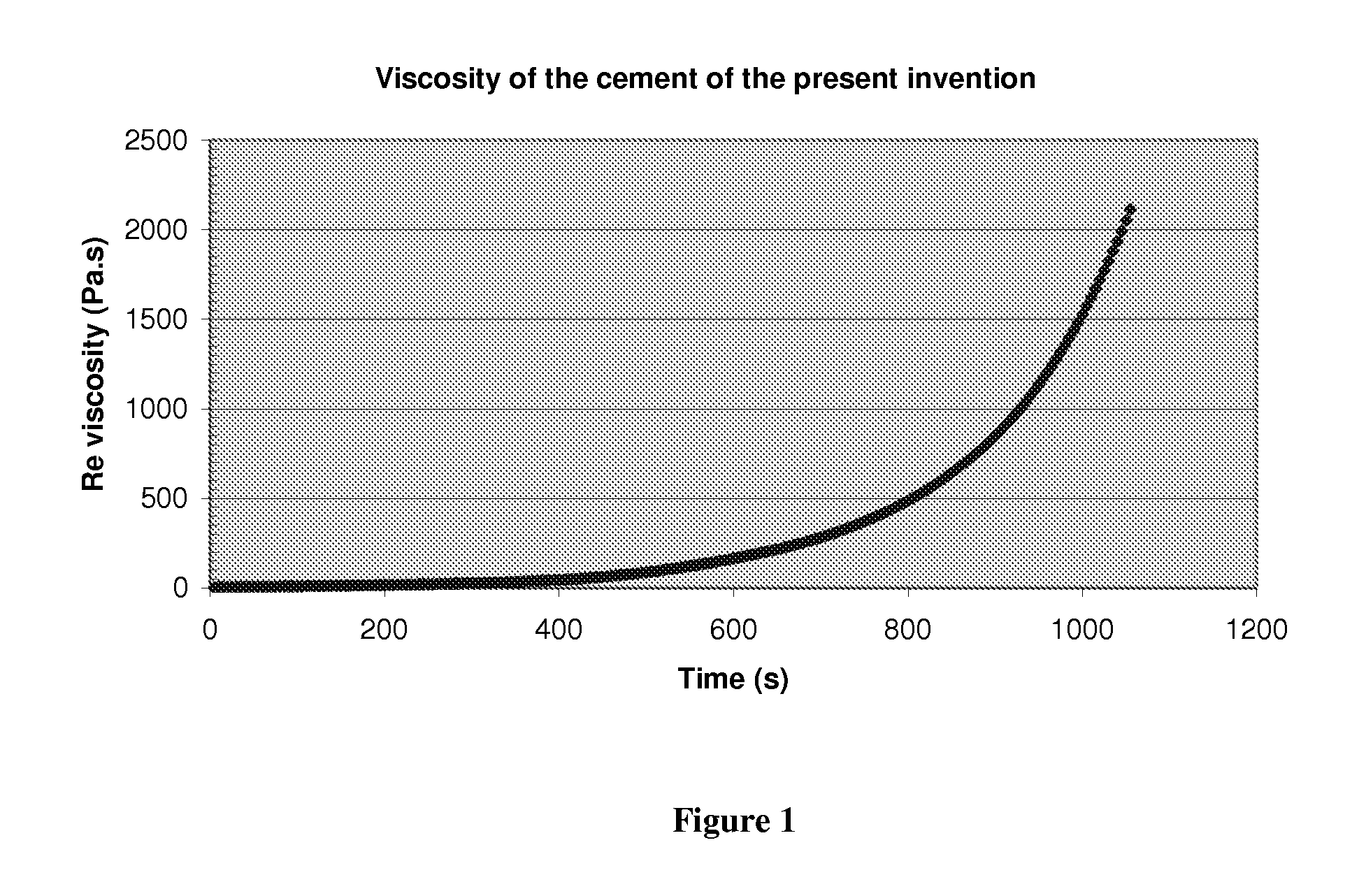

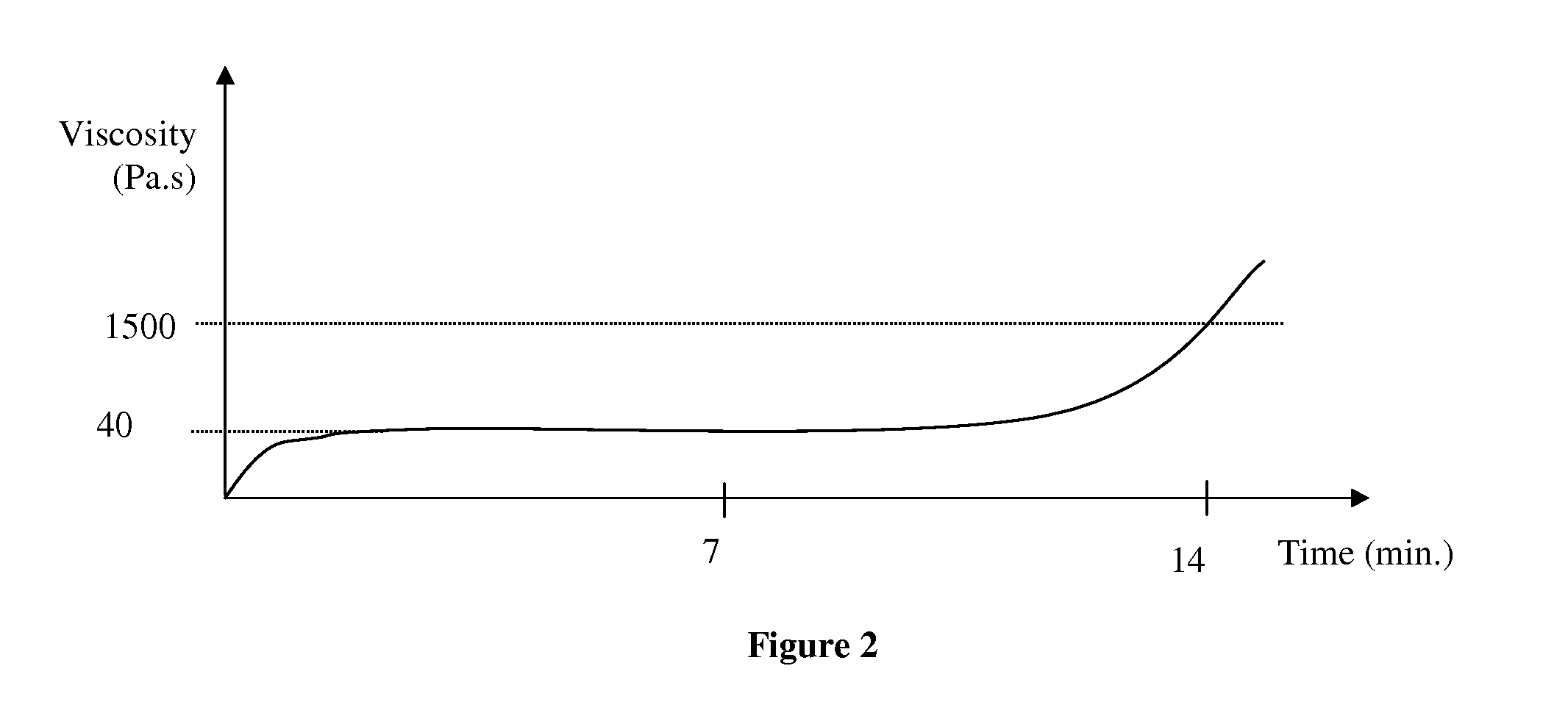

Polymer cement for percutaneous vertebroplasty and methods of using and making same

The invention provides a fluid cement for medical use for bone reconstruction, in particular for filling the vertebral body, and a binary composition which is intended for the preparation of such a cement. The invention also provides a device for conditioning the binary composition, and a method of preparing a bone cement from a binary composition. The fluid cement according to the invention comprises: a) approximately 60% to 85% by weight of a polymer comprising a polymethylmethacrylate and a methylmethacrylate monomer and b) approximately from 15 to 40% by weight of a radio-opaque composition. Preferably, the radio-opaque composition comprises a radio-opacifier, such as barium sulfate and zirconium dioxide, in a mixture with a calcium phosphate, for example apatite hydroxide.

Owner:TEKNIMED SAS

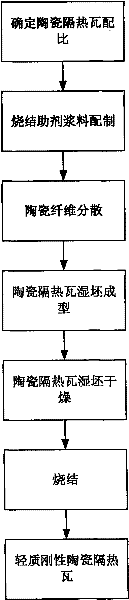

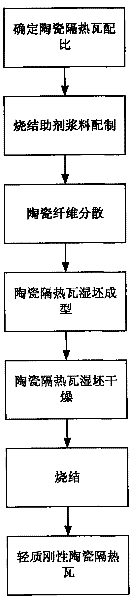

Lightweight rigid ceramic heat-insulation tile and manufacture method thereof

The invention relates to lightweight rigid ceramic heat-insulation tile and a manufacture method thereof. The lightweight rigid ceramic heat-insulation tile comprises the following components: ceramic fibers, starch accounting for 0.05-15wt% of the ceramic fibers, a sintering aid and a sunscreen, wherein the ceramic fibers are composed of 50-100wt% of quartz fibers and 0-50wt% of porzite fibers; the sintering aid is boron nitride accounting for 0.01-15wt% of the ceramic fibers; and the sunscreen is silicon carbide accounting for 0-20wt% of the ceramic fibers. According to the invention, the quartz fibers and porzite fibers are utilized as raw materials to manufacture the ceramic heat-insulation tile with good heat-insulation and mechanical properties through fiber dispersion, wet blank shaping, high-temperature sintering and like. The obtained ceramic heat-insulation tile has the advantages that the density is 0.15-0.80 g / cm<3>, the thermal conductivity at room temperature is 0.045W / m.K, and the plane tensile strength is larger than 0.4 MPa. According to the invention, the porzite fibers are utilized to substitute for aluminum oxide fibers and aluminum borosilicate fibers, and the performance of the ceramic heat-insulation tile is approximate to that of the ceramic heat-insulation tiles used by the space shuttles in America.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Nano-pore SiO2 aerogel thermal insulation composite material and preparation method thereof

The invention discloses a nano-pore SiO2 aerogel heat-insulating composite material and a preparation method thereof. The nano-pore aerogel heat-insulating composite material comprises SiO2 aerogel, an infrared opacifier and reinforced fibers. The preparation method comprises: mixing silicasol and indium-tin oxide ITO nano alcohol slurry or nano composite alcohol slurry of ITO and TiO2 through supersonic wave action, mixing the mixture and the reinforced fibers, directly pouring the mixture into a die to form a wet gel complex, and performing supercutical fluid drying. The material has good heat transfer function and good obstructing function on solid heat conduction, air heat convection and infrared radiation heat conduction, simultaneously has good hydrophobicity, simple technique, low cost and wide application scope, has the mechanical strength reaching more than 1.2 MPa, and can be used in situations with higher heat protection requirement in the fields of avigation, spaceflight, military affairs and domestic use.

Owner:CHANGSHA XINGNA AEROGEL

Method of Preparing Silica Aerogel Granules

ActiveUS20130106008A1Easy to fillEasy to handleGroup 4/14 element organic compoundsOther chemical processesSilane compoundsAmbient pressure

A method of preparing transparent or nontransparent silica aerogel granules. The method includes forming a granular wet gel by spraying a silica sol into alcohol, the silica sol being prepared by mixing a water glass solution or an opacifier-containing water glass solution with an inorganic acid solution, forming a granular alcohol gel through gelation aging and solvent substitution of the granular wet gel in alcohol, hydrophobically modifying the surface of the granular alcohol gel using an organic silane compound, and drying the surface modified gel at ambient pressure or in a vacuum. The method may prepare silica aerogel granules in a short period of time through heat treatment at a relatively low temperature and at ambient pressure or in a vacuum, thereby ensuring excellent economic feasibility, continuity and reliability, suited for mass production.

Owner:DAEHYUP TECH

High-efficiency insulating material used for high-temperature pipeline and preparation method thereof

ActiveCN101671157AReduced heat transfer ratioEnhanced inhibitory effectThermal insulationPipe protection by thermal insulationSupercritical dryingFiber

The invention discloses a high-efficiency insulating material capable of being used for a high-temperature pipeline with insulation requirements. The high-efficiency insulating material comprises thefollowing mixed raw materials by weight percentage: 40 to 80 percent of nano SiO2 powder, 5 to 40 percent of infrared opacifier and 0 to 25 percent of reinforcing fiber. The high-efficiency insulatingmaterial is formed by adopting a drying method and overcomes the defect that the sol-gel method for preparing an aerogel-based material needs supercritical drying. The high-efficiency insulating material is designed by a microstructure, carries out full restriction on heat conduction, convection and radiant heat transfer at high temperature simultaneously and leads the heat-conducting coefficientof material under the use temperature to be lower than that of static air.

Owner:NAVAL UNIV OF ENG PLA

Aerogel heat insulation composite material containing nano semiconductor infrared light screening agent and preparation thereof

The invention discloses an aerogel thermal insulation composite material containing an infrared opacifier of nanometer semiconductor antimony tin oxide (ATO) or aluminum zinc oxide (AZO) and a method for preparing the same. The aerogel thermal insulation composite material comprises the components of SiO2 aerogel, the infrared opacifier which is nanometer ATO or nanometer AZO particles, and reinforcing fiber. Silicasol and ATO or AZO nanometer alcohol slurry can be mixed together through mechanical agitation or ultrasonic action, and the mixture flows to a fiber felt or fiber prefabricated part through a seepage process to form a wet gel complex to further perform supercritical fluid drying. The aerogel thermal insulation composite material has good thermal conductivity and good barrier effect on solid heat conduction, air heat convection and infrared radiation heat transfer, and has good hydrophobicity, simple process and low cost simultaneously; the mechanical strength of the material can reach 0.10 to 2 MPa; besides, the aerogel thermal insulation composite material has wide application range and can meet the applications in occasions with higher thermal protection requirements for aviation, aerospace, military and civil use.

Owner:CHANGSHA XINGNA AEROGEL

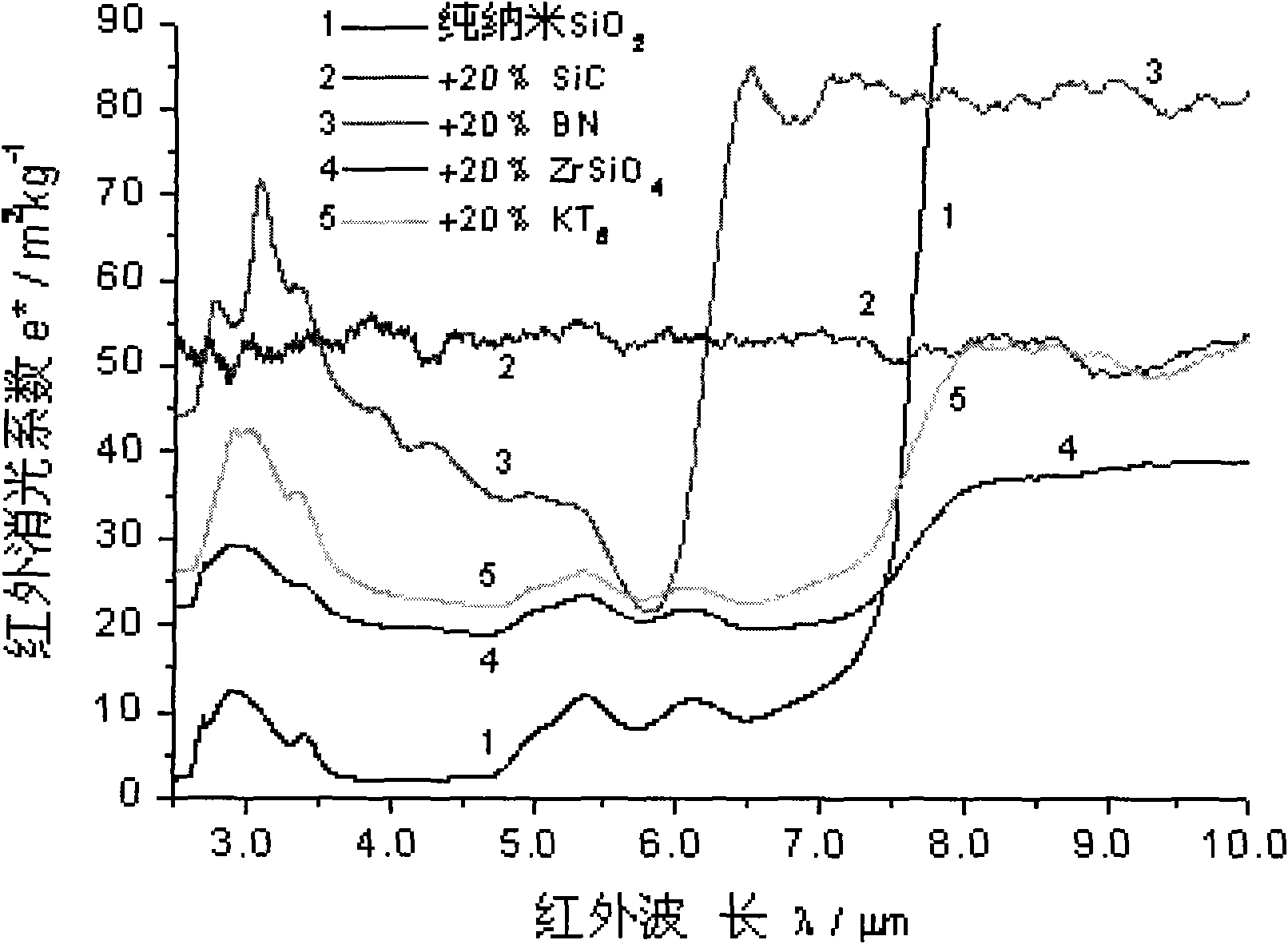

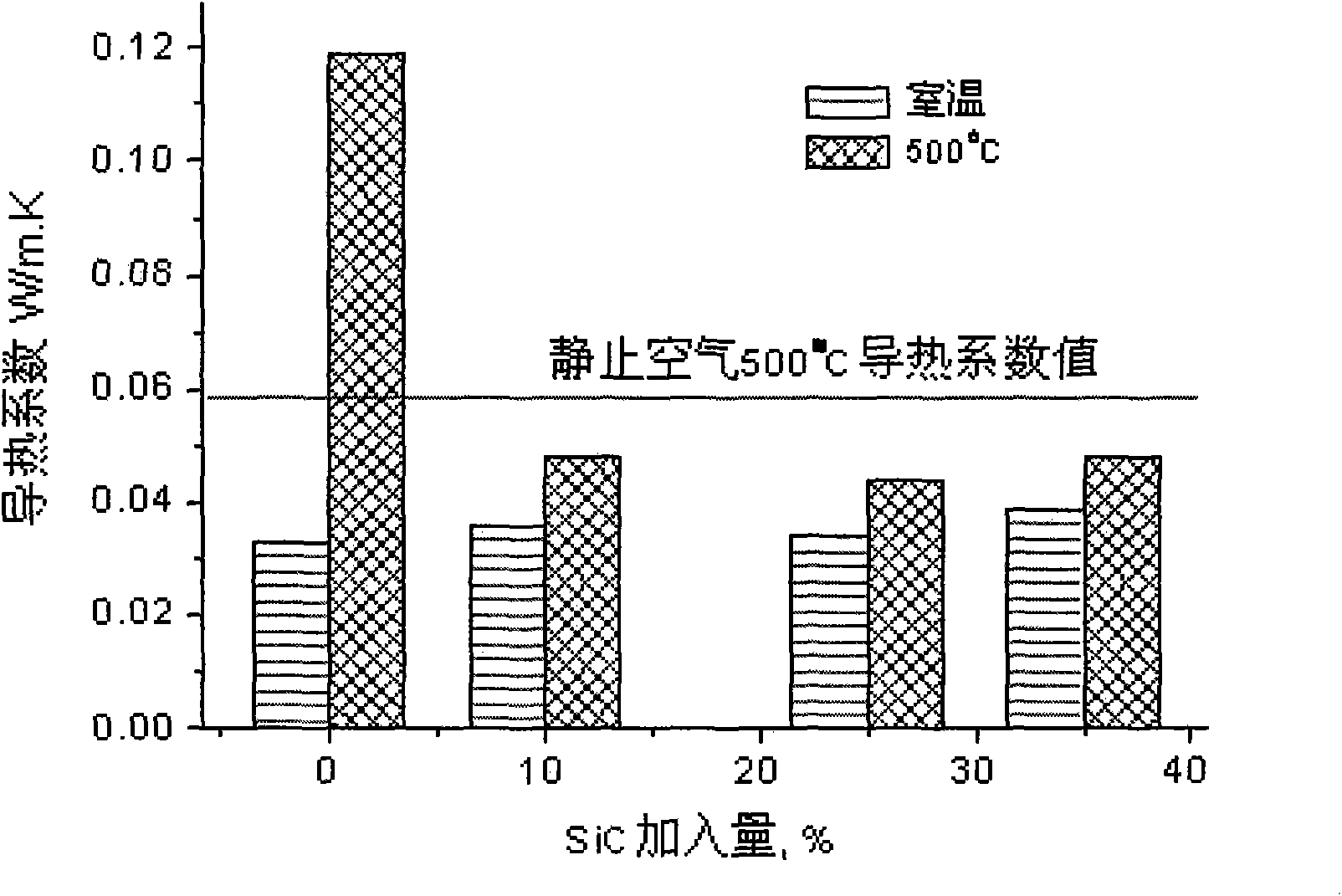

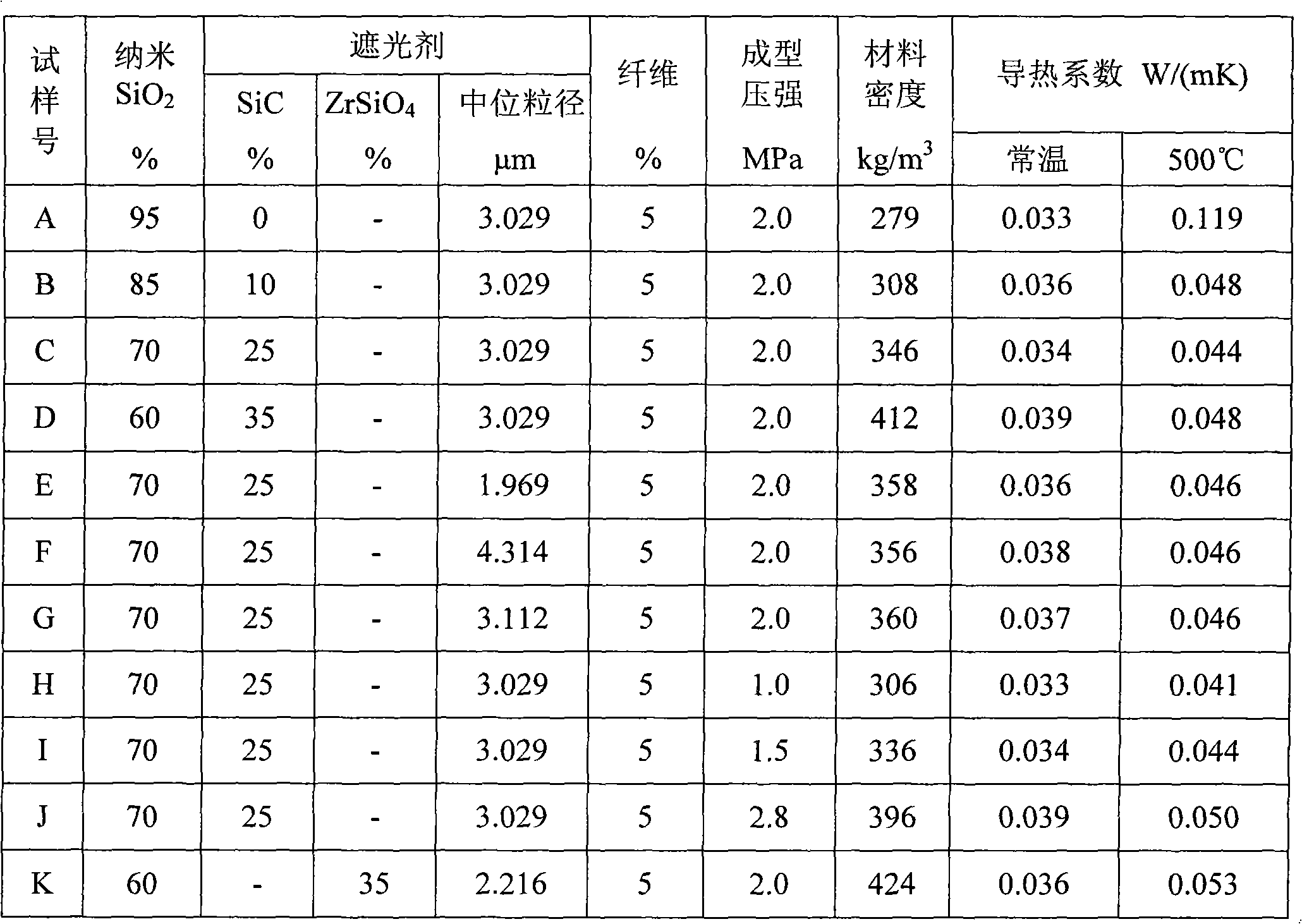

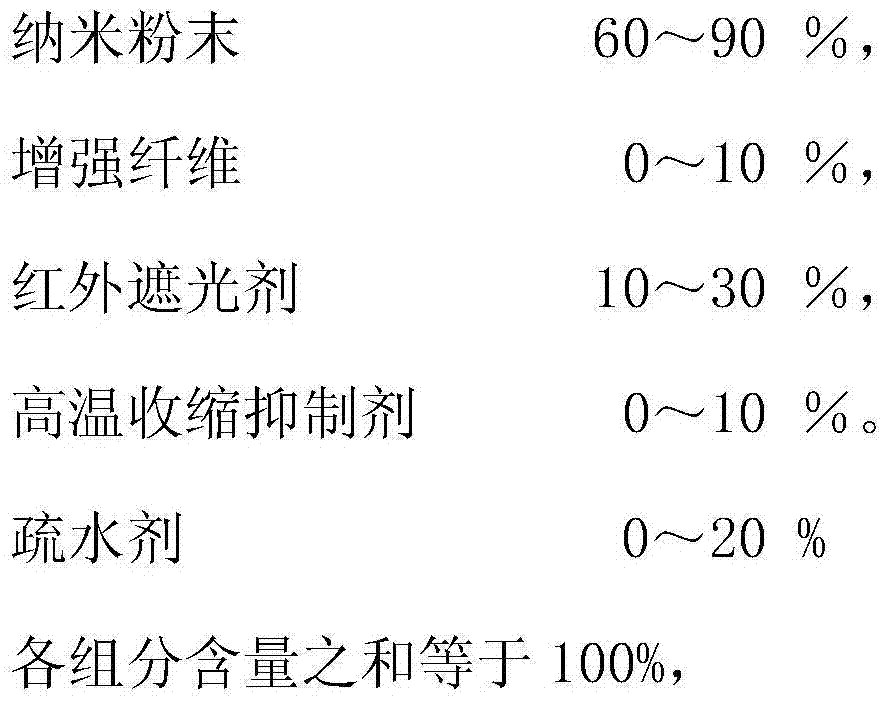

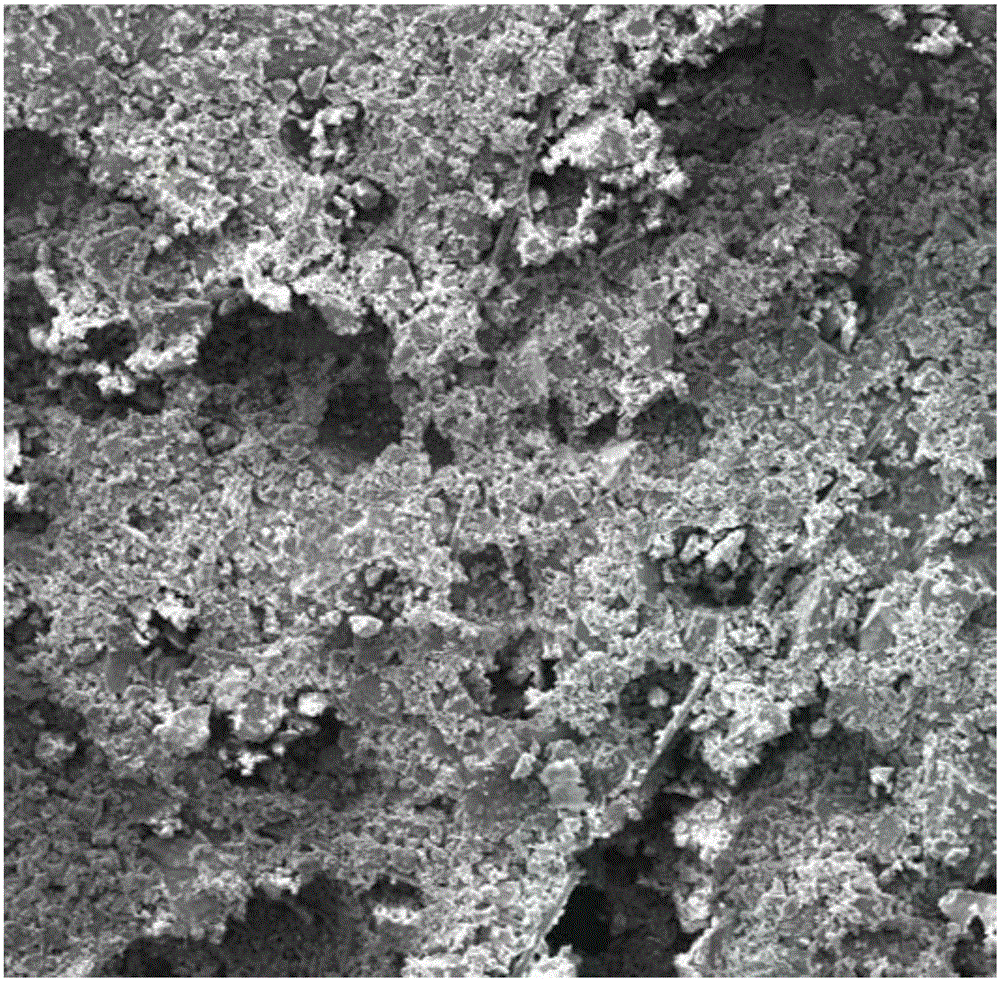

Preparation method of nanopowder-based composite thermal insulation material

The invention provides a preparation method of a nanopowder-based composite thermal insulation material. The preparation method comprises the following steps: by using nanopowder as a base material and alkali-free ultrafine glass fibers, aluminium silicate fibers, zirconia fibers, multicrystal mullite fibers and the like as reinforcing materials, adding infrared opacifiers (potassium hexatitanate whiskers, SiC, ZrSiO4 and rutile or anatase TiO2), adding a high-temperature contraction inhibitor and a hydrophobe as required and carrying out dispersion, blending, compression forming and the like, thus preparing the nanopowder-based composite thermal insulation material. The preparation method belongs to the dry forming preparation process and is simple in preparation process and safe and reliable in operation process. The press-formed thermal insulation material has good mechanical property, thermal insulation property, high-temperature thermal stability and hydrophobicity and can meet the requirements of the fields such as aerospace, the high-temperature industry and the like for efficient thermal insulation materials.

Owner:GUANGXI UNIV

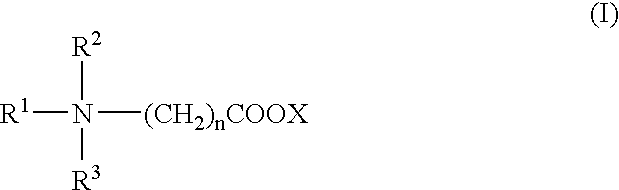

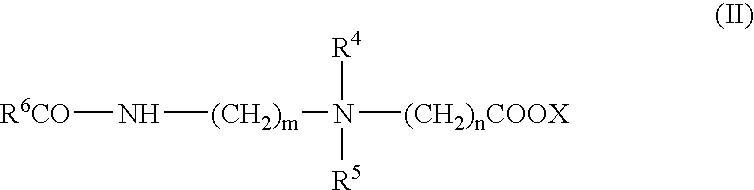

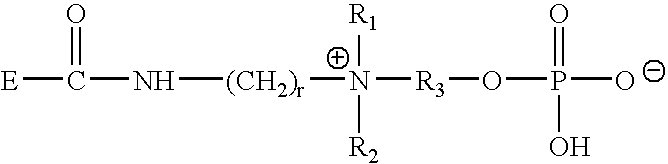

Low-viscosity opacifiers free from anionic surface-active agents

The invention relates to wax-based opacifier preparations containing (a) at least one amphoteric surfactant, (b) at least one fatty acid partial glyceride, (c) at least one fatty acid polyglycol ester and optionally (d) a polyol, with the proviso that the ratio by weight of (a) to (b) is between 10:1 and 4:1 and the ratio by weight of (b) to (c) is between 1:1 and 5:1 and the preparations are free from anionic surfactants.

Owner:COGNIS DEUT GMBH & CO KG

Liquid rinse-off compositions for personal care comprising a trimethyl-silylalkylsilsesquioxane

InactiveUS6489274B1Increase the gloss and sheen of the hairImprove skinCosmetic preparationsHair cosmeticsPersonal careTrimethylsilyl

This invention relates to liquid rinse-off compositions for personal care comprising trimethylsilylalkylsilsesquioxanes, particularly trimethylsilyl-n-octylsilsesquioxanes (Caprylyl Trimethicones). Preferably the rinse-off compositions are shampoos containing pearlescent and / or opacifying agents.

Owner:CLARIANT FIANCE (BVI) LTD

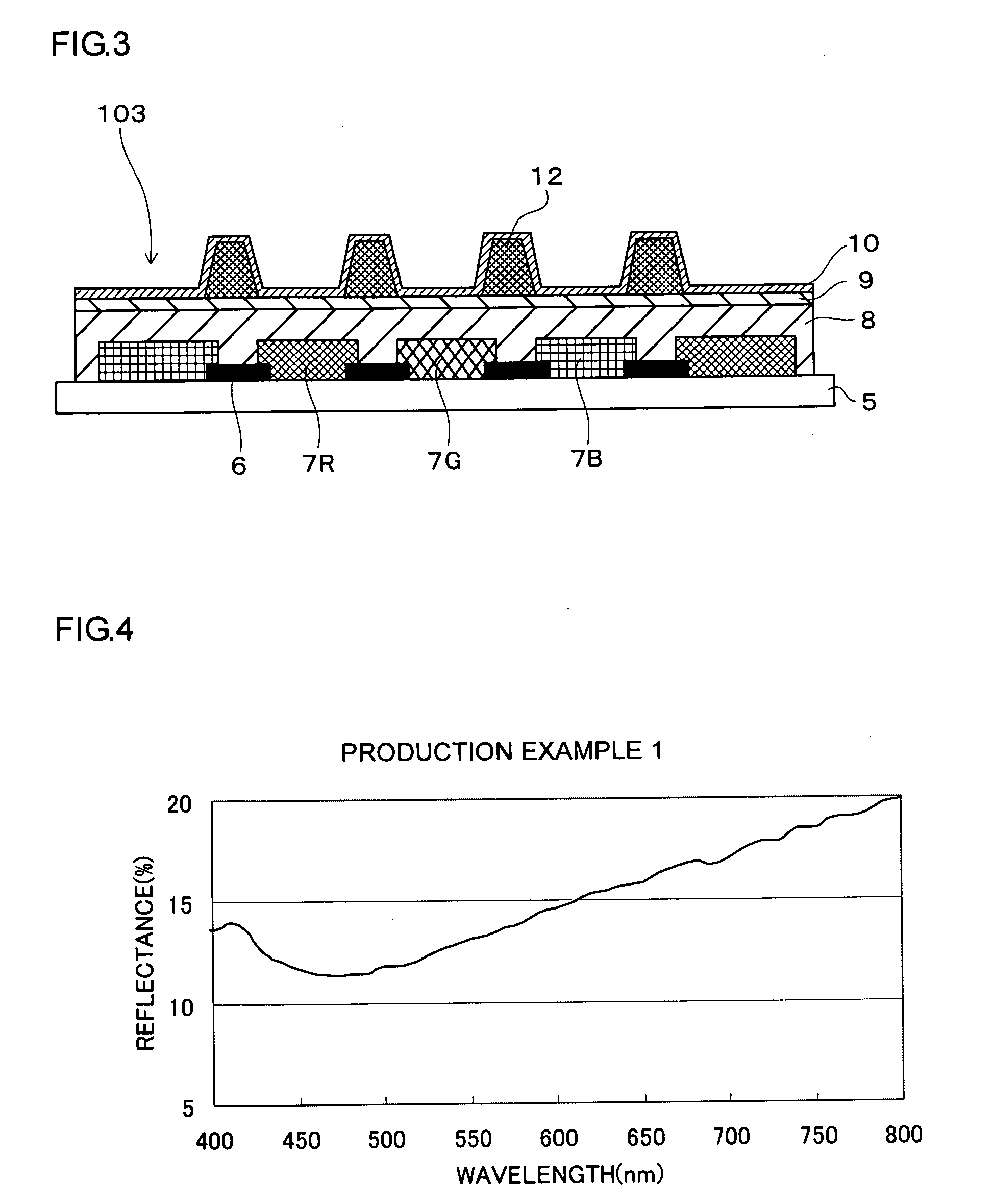

Black Resin Composition for Display Device, and Member for Display Device

InactiveUS20080318018A1High optical densitySufficient optical densitySynthetic resin layered productsConductive materialDisplay deviceX-ray

A black resin composition for a display device, which can achieve a high optical density even when its light-blocking agent content is relatively low and can achieve a high optical density even when it is formed into a thin film, and a member for display device which can reduce unevenness of display caused by a level difference in a pixel part resulting from the film thickness of the black resin composition. The black resin composition for a display device has a black titanium oxynitride represented by composition formula: TiNxOy-nSiO2 (wherein x and y each are a real number of larger than 0 but less than 2, and n is a real number within the range of 0≦n≦0.05), containing a nitrogen atom represented by N in an amount of 17 wt % or more but less than 23 wt %, and having a specific surface area of 5 to 30 m2 / g and a crystalline size as measured with an X-ray diffractometer of 17 to 25 nm, and a curable binder system. Also, a member for display device having a light-blocking layer formed using the said black resin composition for display device.

Owner:ISHIHARA SANGYO KAISHA LTD +1

Conditioning detergent compositions

InactiveUS20050019299A1Easy to adjustLow degreeCosmetic preparationsHair cosmeticsSuspending AgentsOpacifier

A conditioning detergent composition comprised of a surfactant portion comprising at least one of anionic, amphoteric, and nonionic surfactants and a conditioner portion comprising at least one branched cationic polymers and a silicone which is different from said branched cationic polymer and which is matrix soluble. The conditioning detergent composition imparts cleansing, wet detangling, dry detangling and manageability to hair and which is relatively non-irritating and thus suitable for use by young children and adults having sensitive skin and eyes. The conditioning detergent composition is able to provide such benefits in an aesthetically pleasing formulation without the need for suspending agents, opacifiers, or pearlizing agents.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Water-soluble pouch

ActiveUS8835372B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAntioxidantWater soluble

The present application relates to a water soluble pouch comprising at least one compartment, wherein said compartment comprises a first liquid composition comprising an opacifier and an antioxidant and has a fresh Hunter L value of greater than 7 and a b value of less than 4.

Owner:PROCTER & GAMBLE CO

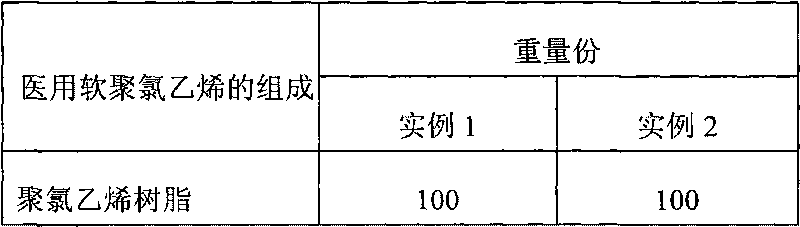

Photophobic medical soft polyvinyl chloride plastic and preparation method thereof

The invention provides a photophobic medical soft polyvinyl chloride plastic and a preparation method thereof. The photophobic medical soft polyvinyl chloride plastic comprises the following compositions in part by weight: 100 parts of polyvinyl chloride resin, 10 to 90 parts of plasticizer, 1 to 10 parts of stabilizer, 1 to 10 parts of auxiliary stabilizer, 0.1 to 2.0 parts of ultraviolet absorber, 0.1 to 0.5 part of auxiliary antioxidant and 0.1 to 6 parts of surfactant. In the photophobic medical soft polyvinyl chloride plastic, a proper opacifier and the surfactant are selected, pohydrophilic and oleophilic property of the surfactant are utilized, the photophobic medical soft polyvinyl chloride plastic is dispersed more evenly and combined more firmly in a system containing a lipoid plasticizer, the use amount of the opacifier is reduced, and a pigment is difficult to separate out; and the photophobic medical soft polyvinyl chloride plastic has good dissolution resistance, and is suitable for producing special liquid bags, conduits, medical accessories, drip chambers and various disposable medical products. Various indexes of a reduction material and the like of a finished product meet the requirement of GB18458.3-2005 standard; and the photophobic range can meet the special requirement and is even expanded to all wave bands.

Owner:上海新上化高分子材料有限公司

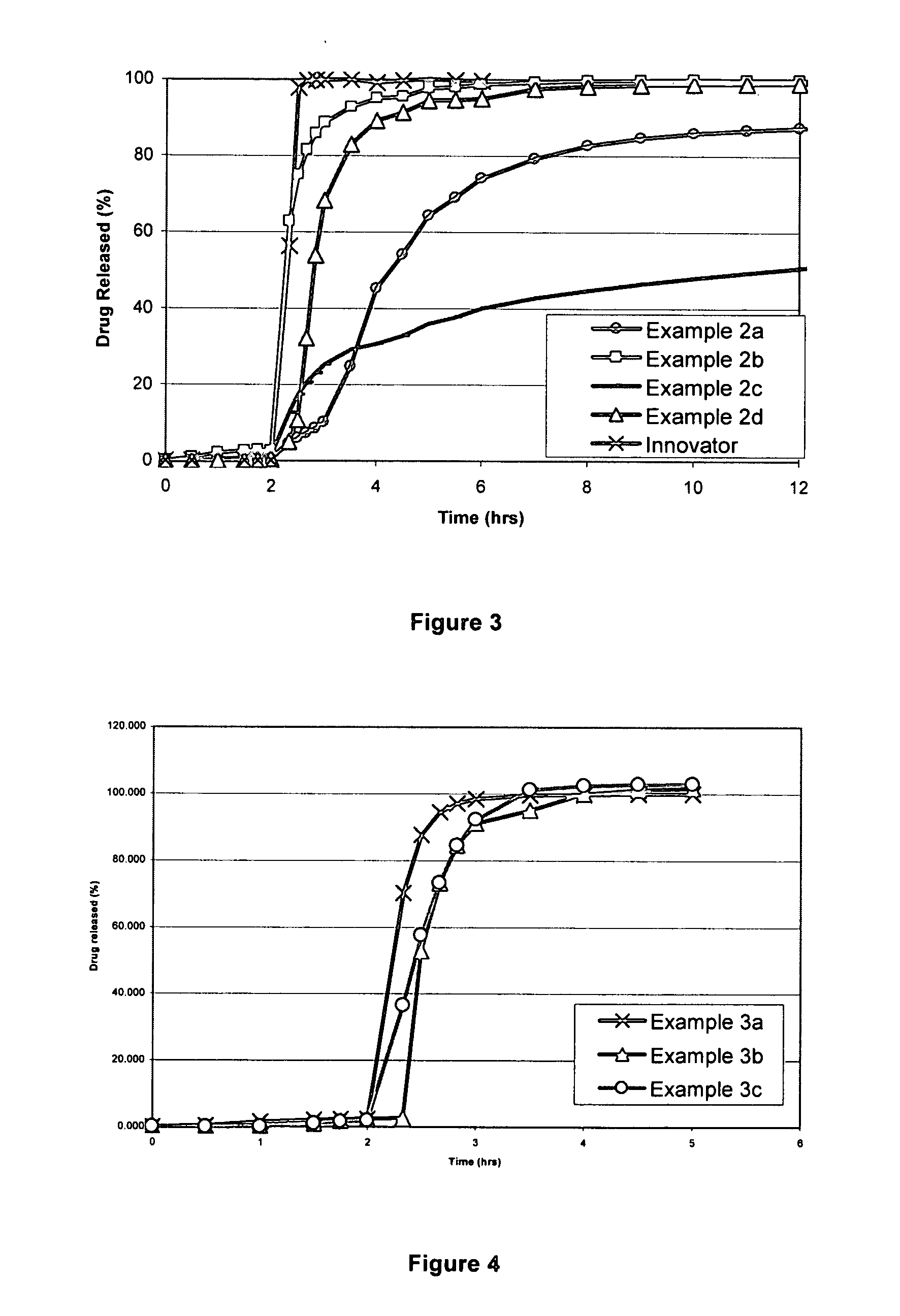

Delayed release pharmaceutical oral dosage form and method of making same

InactiveUS20070190139A1Inhibition of agglomerationBiocideElcosanoid active ingredientsVegetable oilImmediate release

The present invention relates to a multi layer pharmaceutical oral dosage form having delayed release and immediate release properties and method of making same. The delayed release formulation substantially behaves as an enterically coated dosage form but without the formulation and the application of an enteric coating. The delayed release formulation is characterized by a mixture of one or more active ingredients and one or more excipients selected from the group of solid aliphatic alcohols, mixtures of esters of saturated fatty alcohols and saturated fatty acids, natural or synthetic waxes, hydrogenated castor oil, hydrogenated vegetable oil, gums, and mixtures thereof; pH dependent soluble polymers; and optionally an opacifying agent.

Owner:INTELGENX CORP

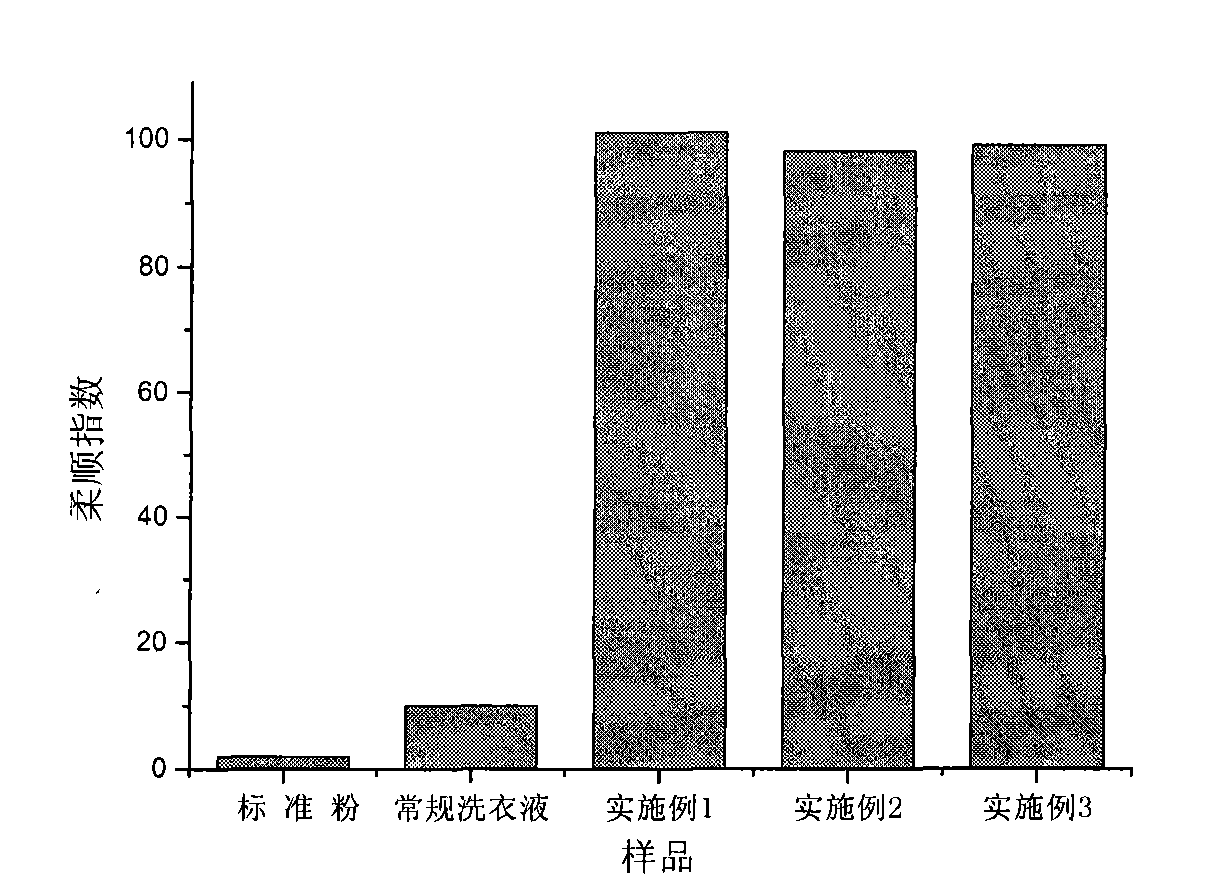

Washing and softening laundry detergent composition

ActiveCN101812381AIncrease the difficulty of washing offTo achieve the effect of decontaminationOrganic detergent compounding agentsNon-ionic surface-active compoundsOpacifierLaundry detergent

The invention discloses a washing and softening laundry detergent composition, which comprises cationic softener, nonionic surfactant, thickener, opacifier and deionized water. The laundry detergent of the invention is convenient to use, low in cost and environmentally-friendly and has the combined functions of washing and softening.

Owner:GUANGZHOU LIBY

Desloratadine grain and preparation method thereof

ActiveCN102038645ADoes not affect releaseEasy to takeOrganic active ingredientsPharmaceutical non-active ingredientsMedicineRoom temperature

The invention relates to a desloratadine grain and a preparation method thereof. The preparation method comprises the steps: fully coating a medicine and proper auxiliary materials (such as a stabilizing agent, a cosolvent, a PH adjusting agent, a filling agent and the like) into a water-soluble high molecular material; and adding a proper opacifier into a coating material, so that the medicine can be isolated from the light and the external moist air when the medicine is stored, and the stability of the medicine can be adequately guaranteed when the medicine is stored under the room temperature; mixing the coated grain with a proper flavoring agent and soluble auxiliary materials to obtain the desloratadine granular formulation; and properly adding a small quantity of edible coloring agent and fruity essence to increase the novelty to the children, and improve the taking compliance.

Owner:HAINAN PULIN PHARMA +1

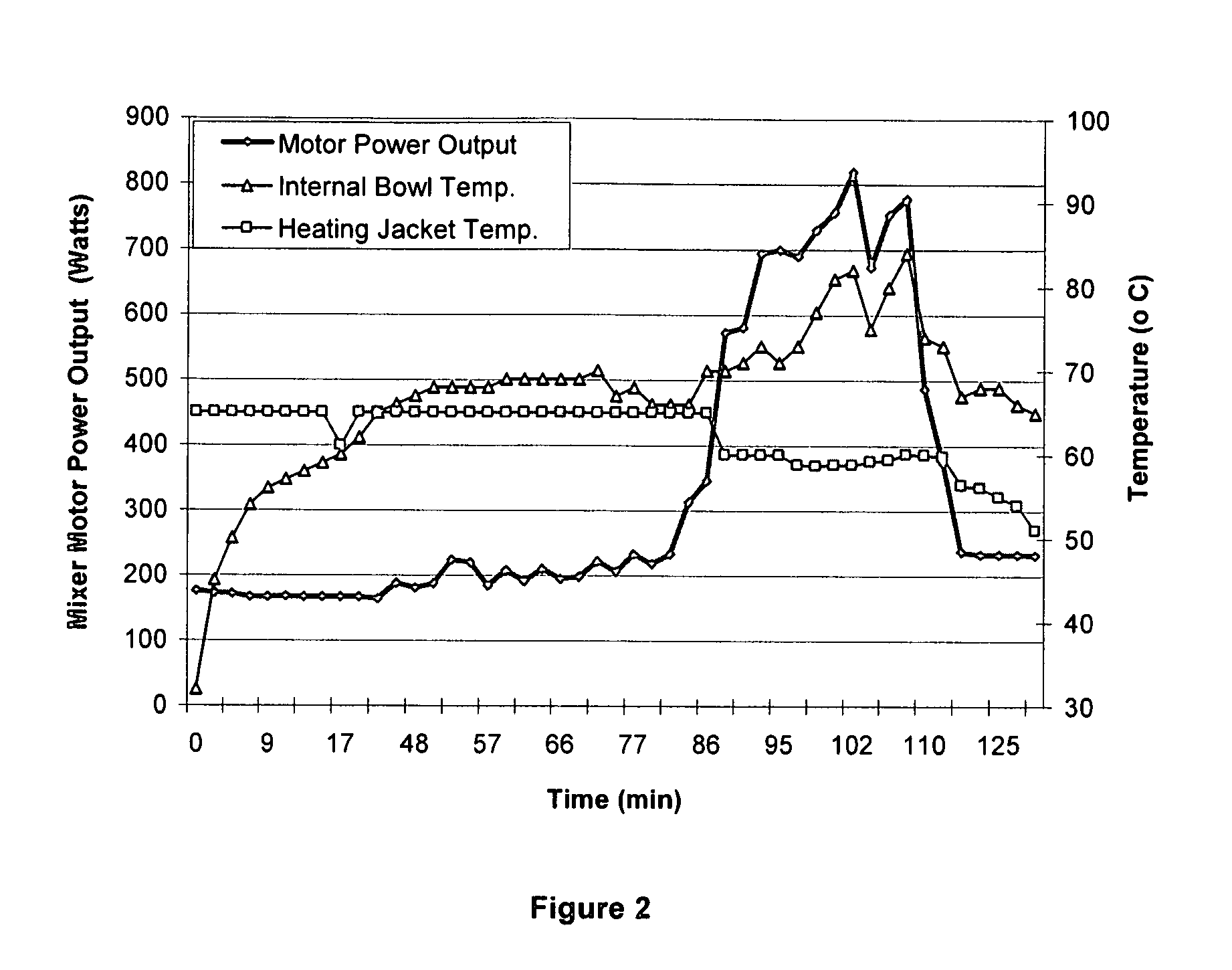

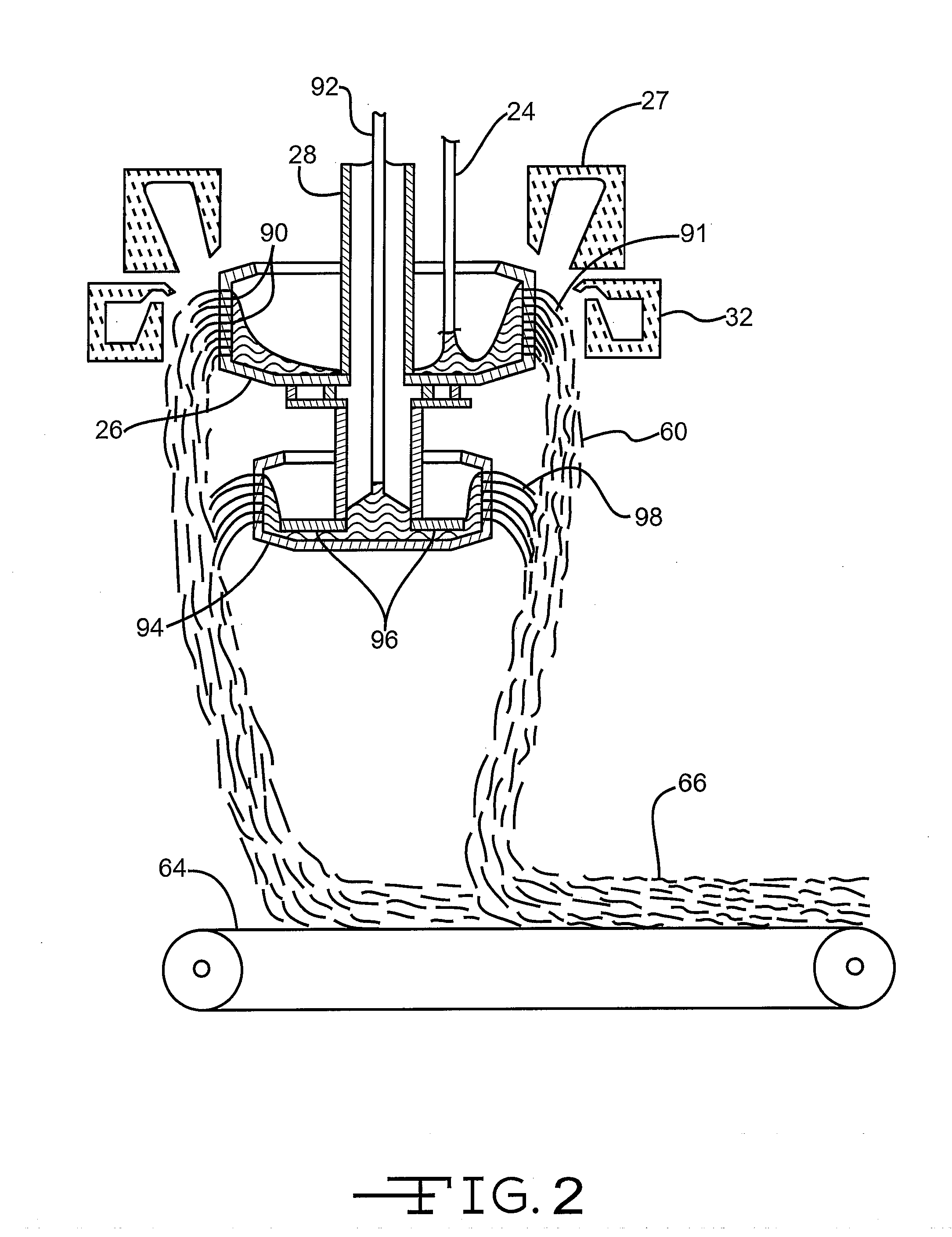

High thermal resistivity insulation material with opacifier uniformly distributed thoughout

A fibrous insulation product with improved thermal resistance and method of making it are provided. A plurality of base fibers (e.g. glass) are formed into an insulation product, which may be bindered or unbonded. At least one infrared opacifying agent, such as soot, carbon black or graphite, is applied to the fibrous insulation product such that the base fibers are substantially uniformly coated with opacifying agent. The opacifying agent may be applied, for example, from a fluid suspension or by pulling the fiber through a sooty flame. When opacifying agent applied via a suspension and a binder is desired, it is preferable to avoid binder dispersions that can dislocate the opacifying agent. Alternative binder applications may include co-mingling of base fibers with binder fibers, or other physical or mechanical distributions.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Liquid-activated formulation with hot melt binding matrix

A liquid-activated formulation is provided, comprising a liquid-activated colorant, a hydrochromic ionic compound, an opacifier, and a hot melt binding matrix.

Owner:THE PROCTER & GAMBLE COMPANY

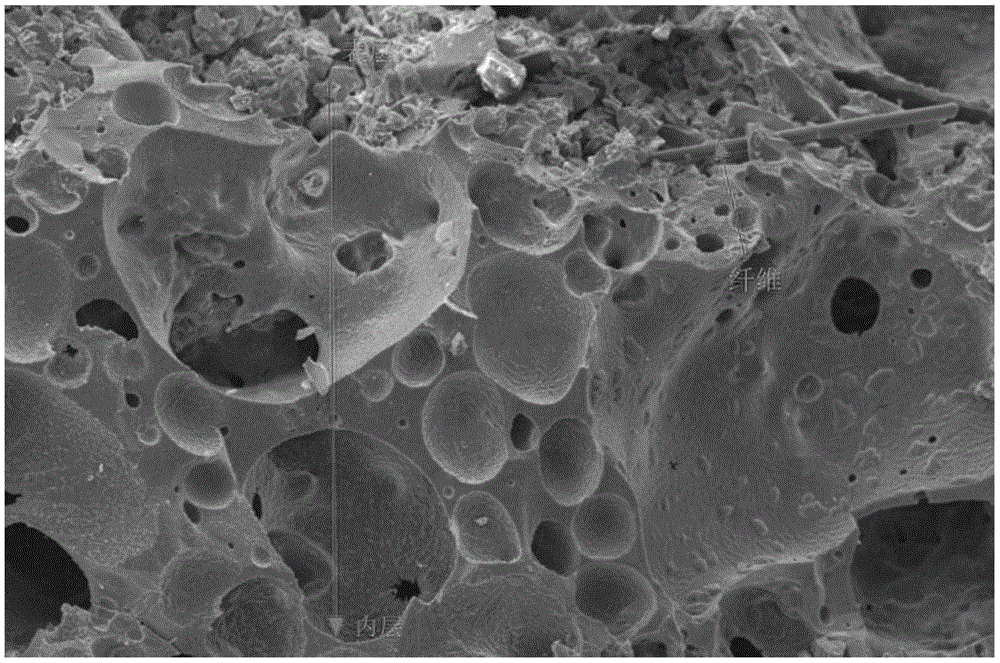

Xonotlite compound super insulating material and preparation method thereof

InactiveCN101671156AImprove thermal conductivityLow thermal conductivityThermal insulationPipe protection by thermal insulationFiberXonotlite

The invention relates to an xonotlite compound super insulating material and a preparation method thereof. The xonotlite compound super insulating material comprises the following mixed raw materialsby weight percentage: 40 to 80 percent of SiO2 aerogel, 5 to 40 percent of infrared opacifier and 0 to 25 percent of reinforcing fiber. The preparation method comprises the following steps: adopting secondary particles which are provided with surface loose structures and are formed by mutual winding of xonotlite fiber with ultrafine diameters and SiO2 aerogel precursor prepared by adopting industrial water glass as silicon source to carry out compounding in advance; filling the SiO2 aerogel precursor in loose accumulation body of secondary particles of vacuum-dehydrated xonotlite, and drying after gelatinization and surface modification; filling the aerogel at the inner parts and the shells of the secondary particles of the xonotlite to form xonotlite-aerogel compound powder; and then mixing the xonotlite-aerogel compound powder with the infrared opacifier and the reinforcing fiber evenly, pressing the mixture in forming equipment with a negative pressure device and forming to obtain the xonotlite compound super insulating material. The invention has simple technique and low cost; and the prepared xonotlite compound super insulating material has excellent performance and can be used for insulation of a heating power device and a high-temperature pipeline.

Owner:NAVAL UNIV OF ENG PLA

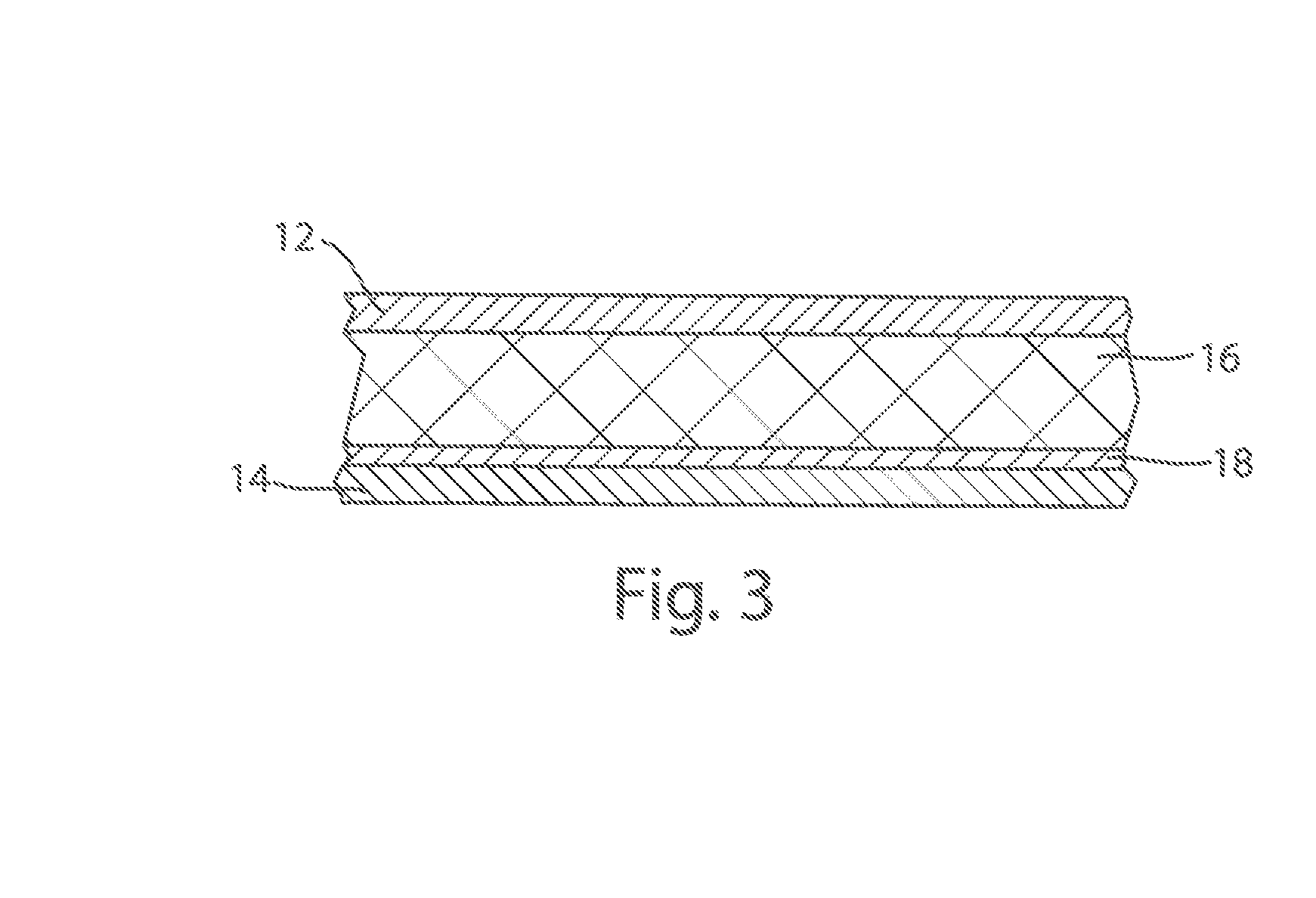

Coated Label Substrates

A coated label substrate including a label substrate, a printable coating, and a connector (e.g., an adhesive layer) is generally provided. The printable coating overlies one surface of the label substrate. The printable coating includes an organic polymer covalently bonded to a plurality of inorganic nanoparticles (e.g., metal oxide nanoparticles such as SiO2), and is configured to not melt during printing at temperatures up to about 350° F. Other materials, such as an opacifier, may also be present in the printable coating. An ink composition (e.g., toner ink, resin ribbon composition, etc.) can be applied an external surface of the coated label substrate formed by the printable coating to defines an image on the external surface

Owner:NEENAH PAPER INC

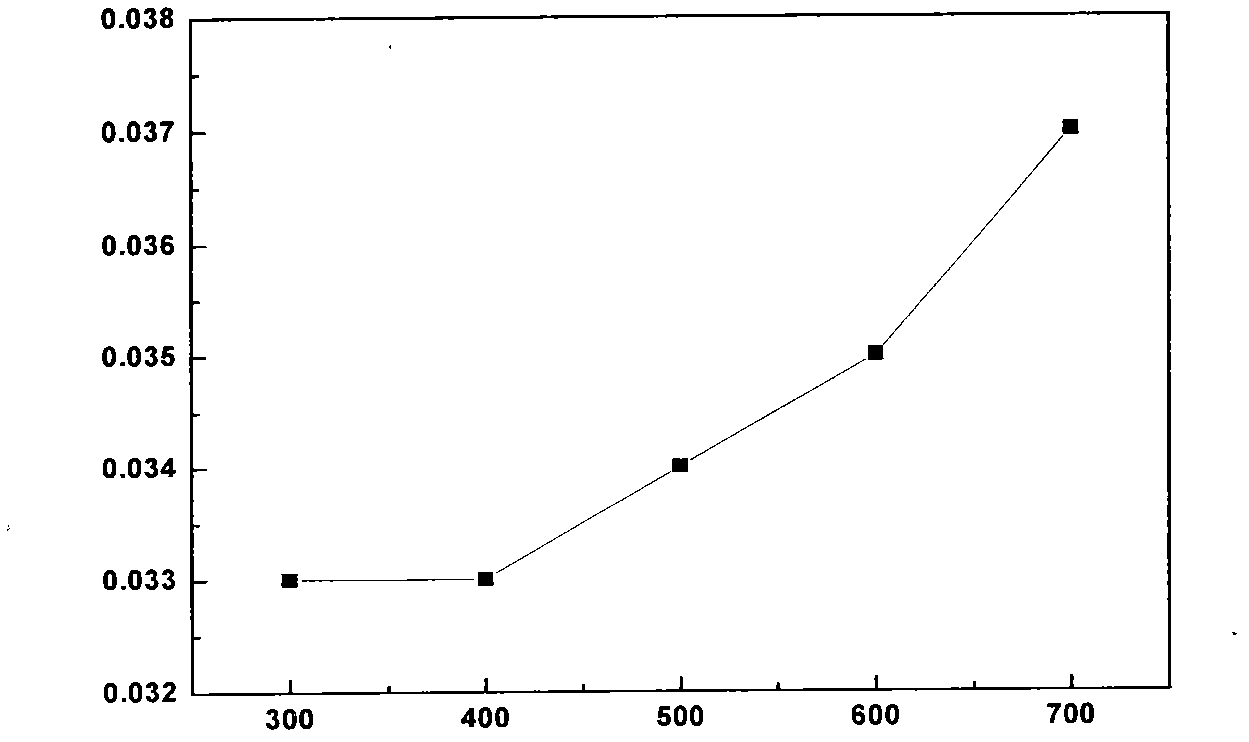

Nanosized silica thermal insulation material and preparation method based on normal-temperature drying wet process thereof

The invention discloses a nanosized silica thermal insulation material and a preparation method based on a normal-temperature drying wet process thereof. The method comprises the following steps: adding nano silica powder, a ceramic powder opacifying agent, a xonotlite whisker or other enhanced fibers or whiskers subjected to hydrophobic treatment to a container with a water solution containing a binder; adding a foaming agent to rapidly agitate into even foam; carrying out suction filtration to obtain concentrated foam slurry; finally, orderly carrying out filter-pressing molding and normal-temperature drying on the concentrated foam slurry, so as to obtain the nanosized silica thermal insulation material. The method disclosed by the invention has the advantages of being short in production cycle (one day in general), simple in process, low in cost, and easy for realization of mechanical large-scale production. The nanosized silica thermal insulation material prepared by using the method has heat preservation and heat insulation performances similar to a monox aerogel thermal insulation material, the heat conductivity coefficient at 100 DEG C is smaller than 0.02W / m.K, and the heat conductivity coefficient below 700 DEG C is smaller than 0.05W / m.K.

Owner:CHINA BUILDING MATERIALS ACAD +1

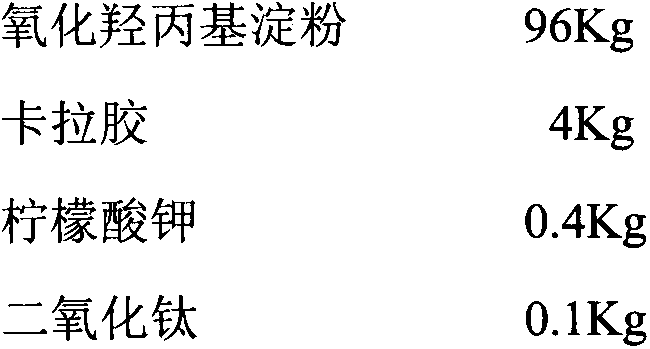

Oxidized hydroxypropyl starch empty capsules and preparation process thereof

InactiveCN105709234AAdapt to a wide rangeWide variety of sourcesPharmaceutical non-active ingredientsCapsule deliveryPlasticizerOpacifier

The invention relates to oxidized hydroxypropyl starch empty capsules and a preparation process thereof. The oxidized hydroxypropyl starch empty capsules are prepared from oxidized hydroxypropyl starch, water, plasticizer, gelatinizer, coagulant aid, opacifier and colorant. The empty capsules are prepared through the procedures of mixing, glue dissolving, blank making, forming and the like. The oxidized hydroxypropyl starch empty capsules and the preparation process have the advantages that the oxidized hydroxypropyl starch is adopted as a main raw material and is a purely-natural and pollution-free material, the source of the raw materials is wide, and production cost is low.

Owner:CHINA PHARM UNIV

Opacifiers

An opacifier concentrate including (a) 5 to 50% by weight of a styrene / acrylate copolymer; (b) 3 to 90% by weight of at least one anionic, nonionic, amphoteric and / or zwitterionic surfactant; and (c) 0 to 10% by weight of an additive, and (d) the remainder up to 100% by weight water. The opacifier concentrate may be incorporated into a cosmetic preparation.

Owner:COGNIS IP MANAGEMENT GMBH

Rebar corrosion resistant coating and coating method therefor

ActiveCN105131660AImprove adhesionIncreased strain valuePretreated surfacesAnti-corrosive paintsRebar corrosionAbsorbed energy

The invention discloses a rebar corrosion resistant coating, and raw material comprises the following components: 45-70 parts of glass powder, 2-8 parts of clay, 26-50 parts of borax, 0.5-3 parts of fiber, 5-15 parts of opacifier, 1-10 parts of adherence agent and 0.25-2.8 parts of electrolyte. The invention further discloses a rebar corrosion resistant coating coating method, comprising the following step of: 1) dry mixing; 2) wet mixing; 3) pre-treating; 4) coating; 5) drying; 6) sintering; and 7) cooling at room temperature. The rebar corrosion resistant coating is high in ductility, high in adhesion performance, high in compactness and excellent in corrosion resistance, the fiber is introduced into the coating so that the corrosion resistant coating, during the breaking process, absorbs energy through mechanisms such as crack deflection, fiber breakage and fiber and removal, so that the coating toughness is improved, the cracking formation is delayed, and the mechanical property of the rebar can be maintained at the same time.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com