Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

276results about How to "The reaction temperature is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

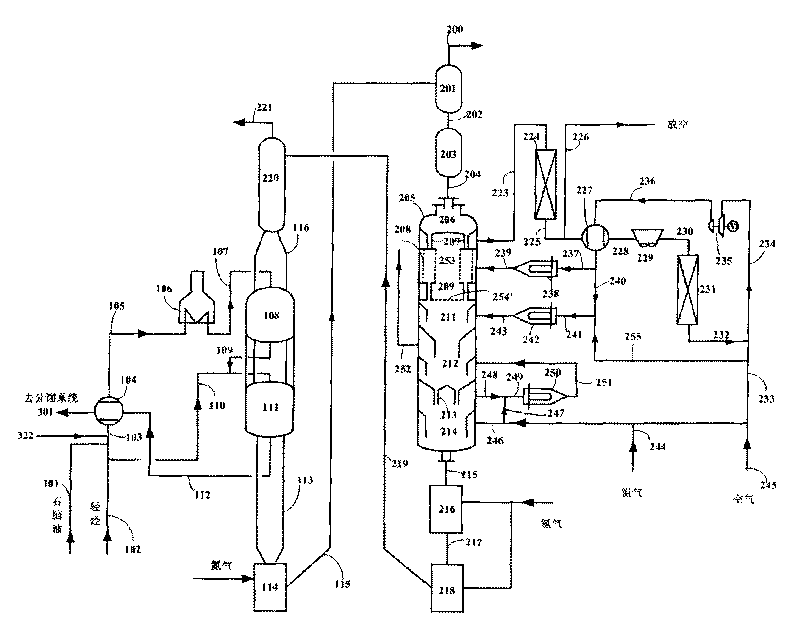

Modifying method for naphtha and light hydrocarbon aromatization

ActiveCN101747933ALower end pointReduce carbon deposition rateCatalytic naphtha reformingLiquid productHydrogen

A modifying method for naphtha and light hydrocarbon aromatization comprises: contacting naphtha and C3-C5 light hydrocarbon with aromatization catalyst in the presence of hydrogen-containing gas to carry out aromatization modifying reaction, wherein the reaction temperature is 250-600 DEG C, and the volume ratio of hydrogen to naphtha is 20-400. The method can convert naphtha with low octane value and low-carbon hydrocarbon into gasoline component with high octane value and excellent liquefied gas, the final distilling point of liquid product and the carbon-accumulating speed of catalyst areobviously reduced, and the service life of catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

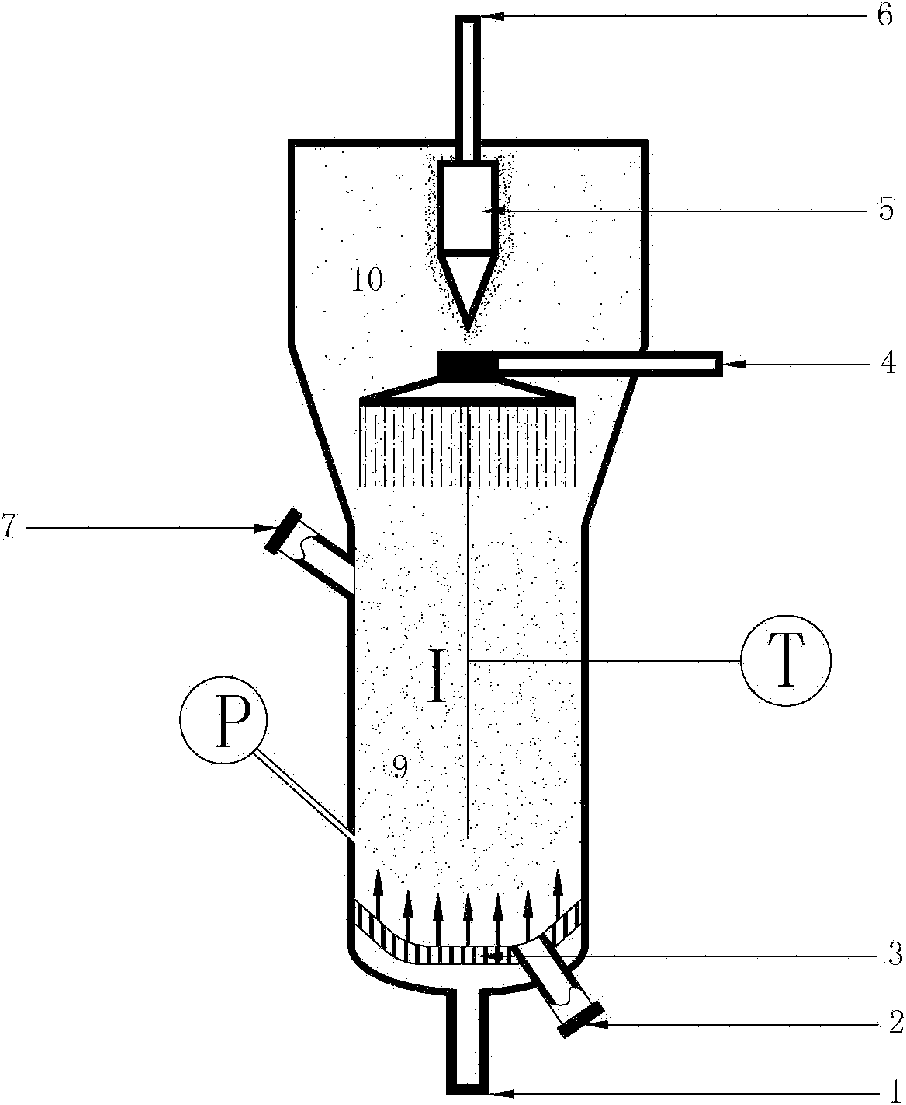

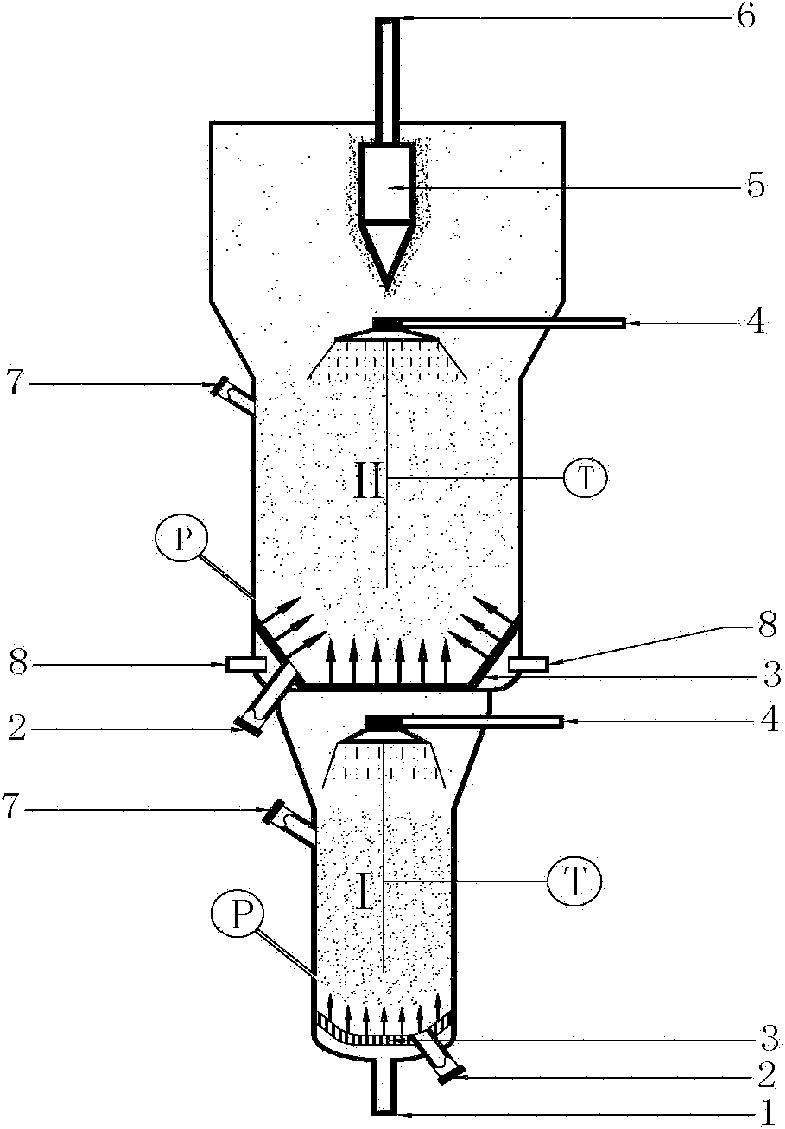

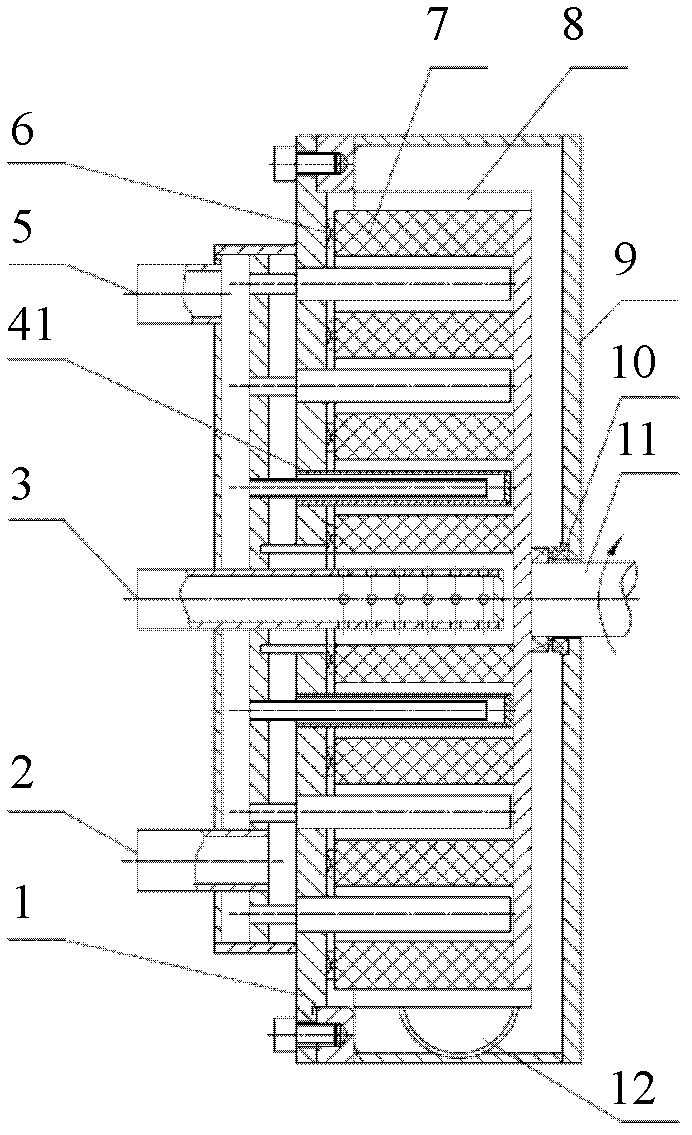

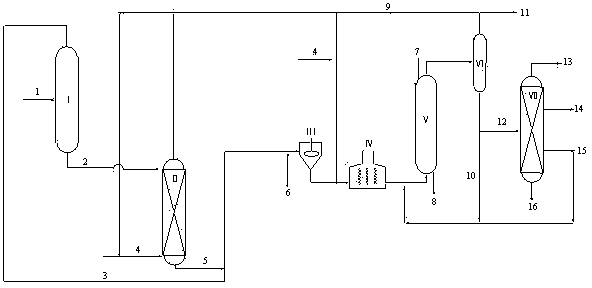

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

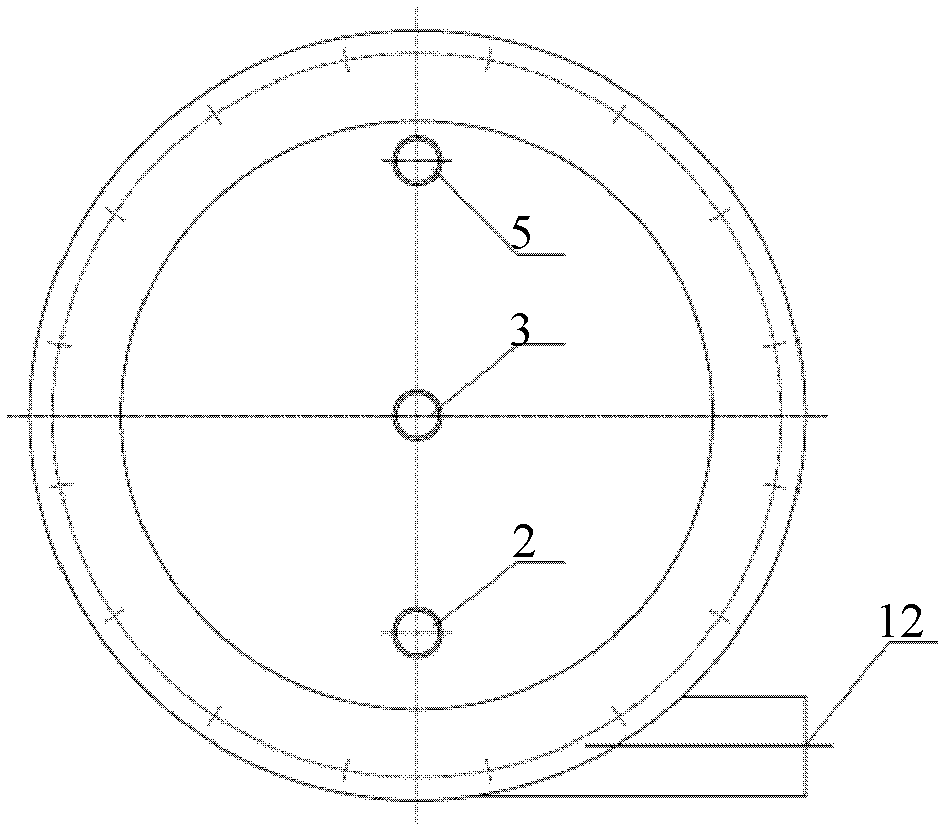

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Titanium oxide - aluminum oxide composite carrier, preparation method and application thereof

ActiveCN1689702AEasy to prepareThe reaction temperature is easy to controlCatalyst carriersCatalyst activation/preparationAluminateTitanium oxide

The present invention discloses one kind of composite titania-alumina carrier and its preparation process and application. The composite carrier contains titania in 10-50 wt% and in anatase and / or rutile form and contains alumina in alpha-Al2O3 form. The composite carrier has acid surface and total acid amount of 0.6-8 A / g / sq cm. The preparation process includes the following steps: mixing titanium tetrachloride solution and AlCl3.6H2O crystal through stirring and diluting, mixing with sodium meta-aluminate solution to obtain aluminum titanium hydroxide precipitate, ageing, filtering, washing, drying, crushing, kneading, and roasting at 800-1200 deg.c to obtain the carrier. The composite carrier is used in selective hydrogenation and is favorable to reducing side product 'green oil' and prolonging the life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

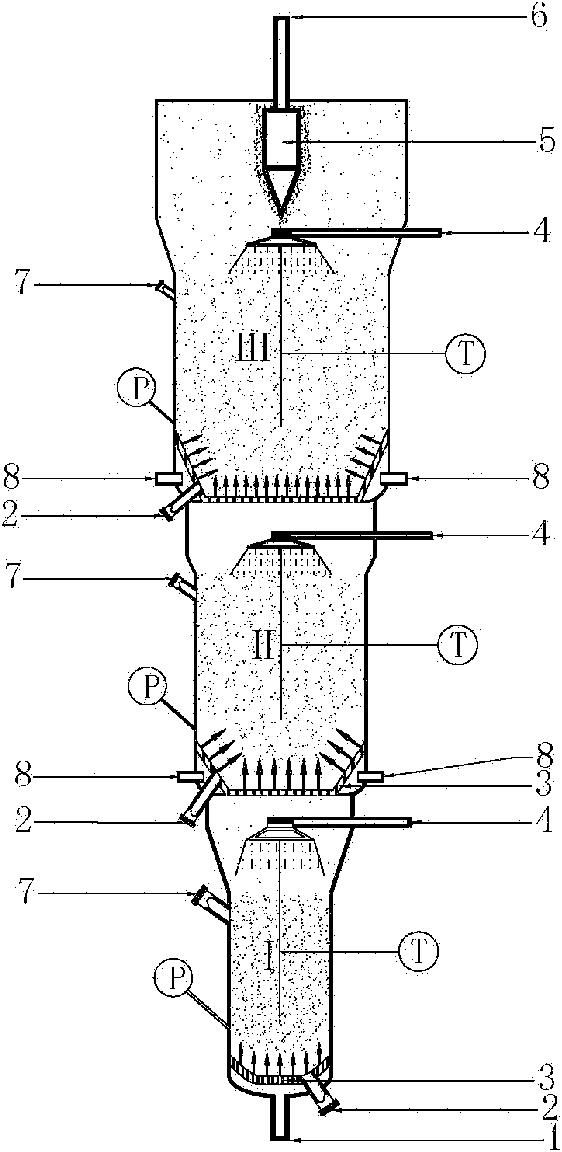

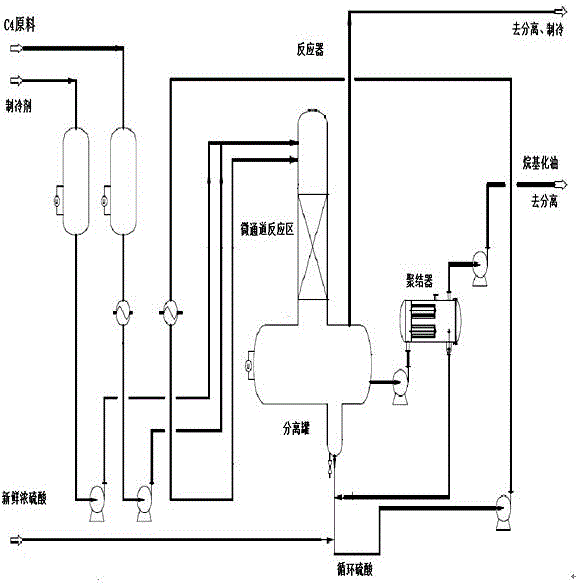

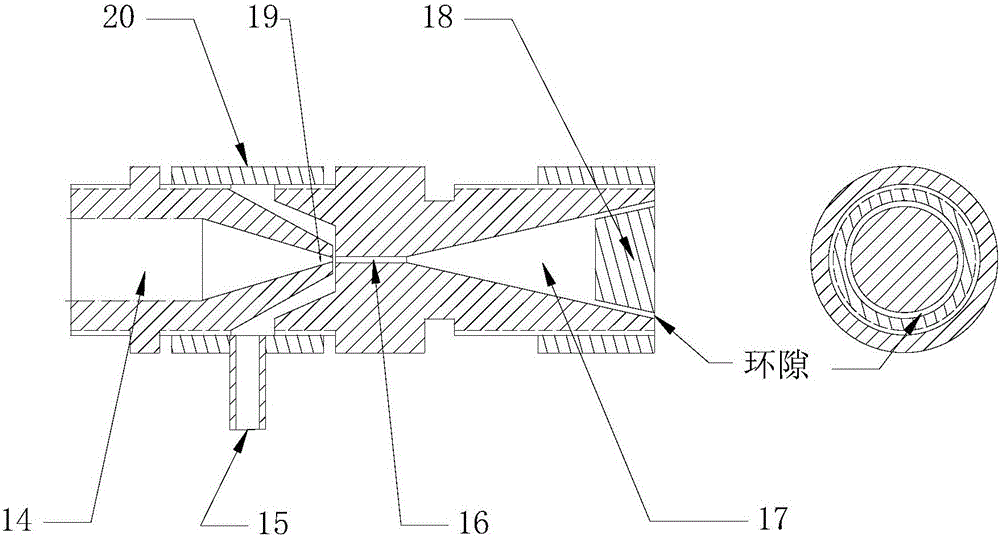

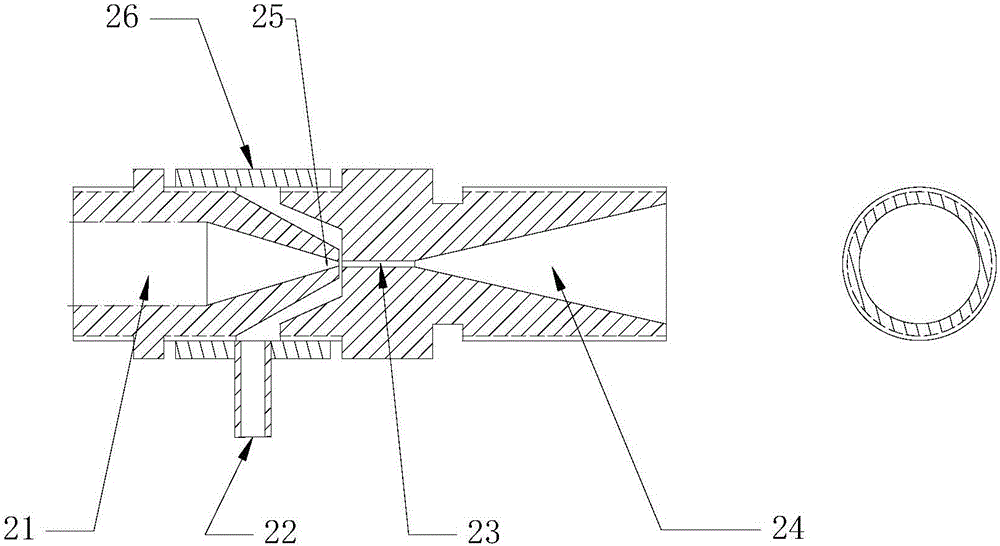

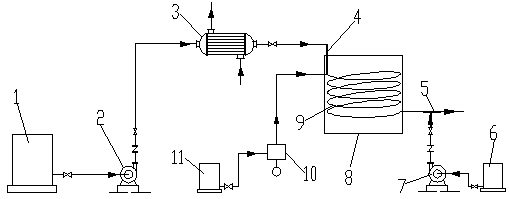

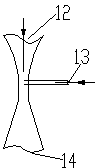

Microreactor and system for liquid-liquid multi-phase reaction and liquid acid alkylation method

ActiveCN107261997AGuaranteed uptimeAchieve microChemical/physical/physico-chemical microreactorsLiquid hydrocarbon mixtures productionMicroreactorAlkyl transfer

The invention relates to the technical field of organic synthesis chemistry and particularly relates to a microreactor and system for a liquid-liquid multi-phase reaction and a liquid acid alkylation method. The microreactor comprises an inner pipe and an outer casing pipe, the inner pipe and the outer casing pipe are coaxial, the inner tube and the outer casing pipe form an annular microchannel, a first diversion pipe, an inner film pipe and a second diversion pipe having the same external diameters are orderly connected to form the inner pipe, the upper side of the outer casing pipe is provided with a heavy phase inlet, an end cap is arranged between one end of the outer casing pipe and the wall of the first diversion pipe, the other end of the outer casing pipe is provided with a product outlet, the heavy phase inlet and the inner pipe are arranged so that a heavy phase flow and a light phase flow contact in a parallel flow way and a distance-determination structure is arranged in the annular microchannel. The system comprises the microreactor, a light phase storage device, a heavy phase storage device and a separation device. The liquid-liquid phase interfaces of the microreactor are increased by 10 times or more than that of the general reactor so that the small size, high efficiency, high selectivity, large treatment amount, small energy consumption and high universality are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

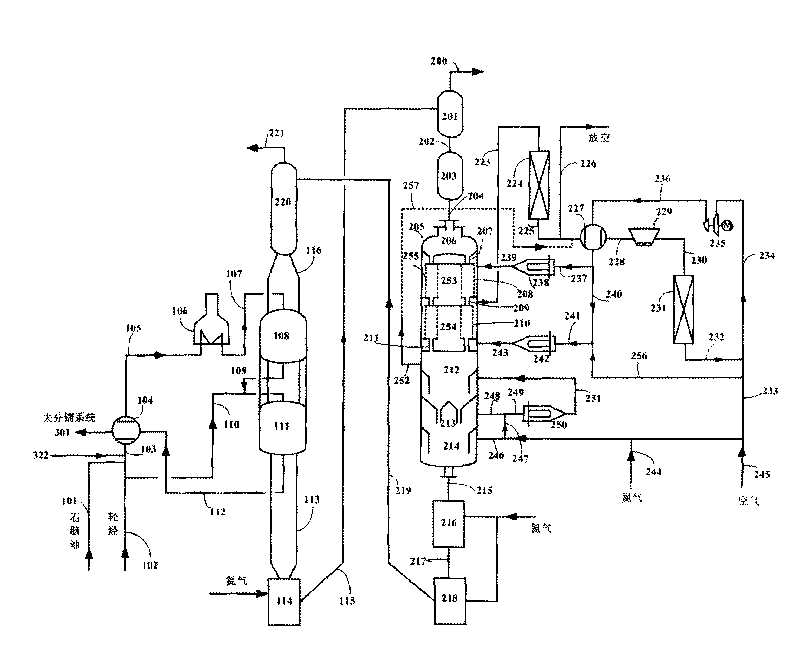

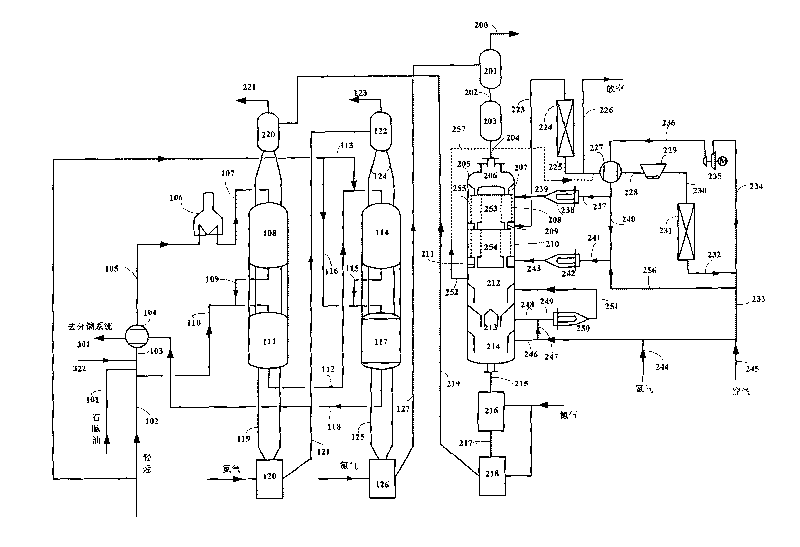

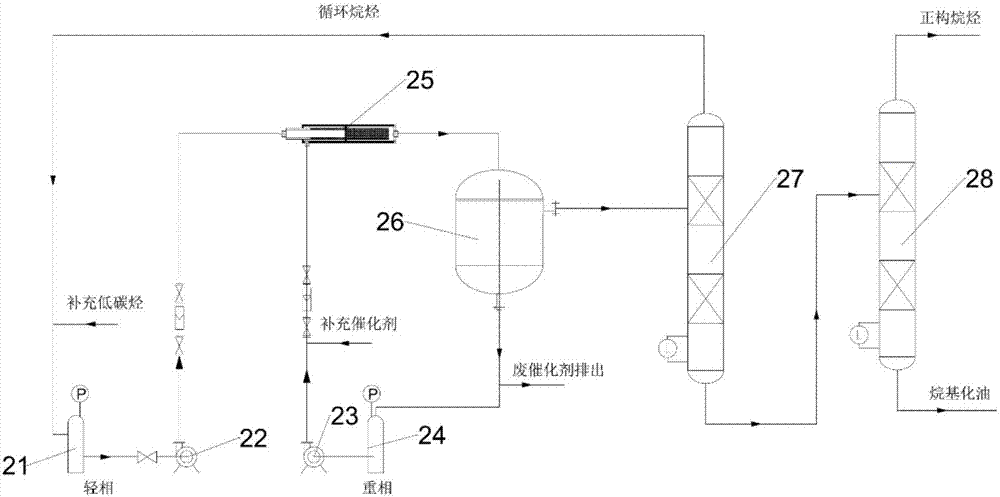

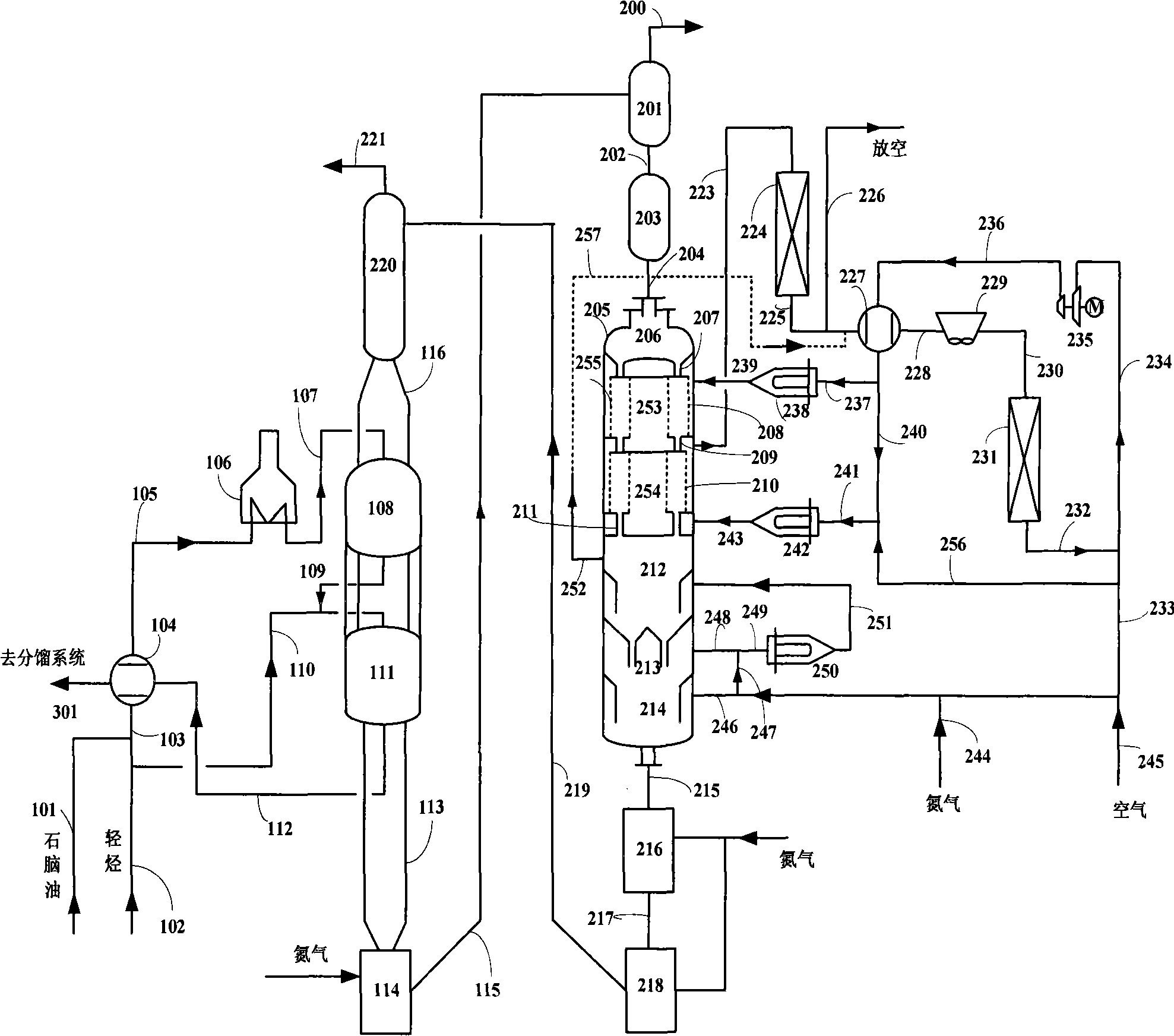

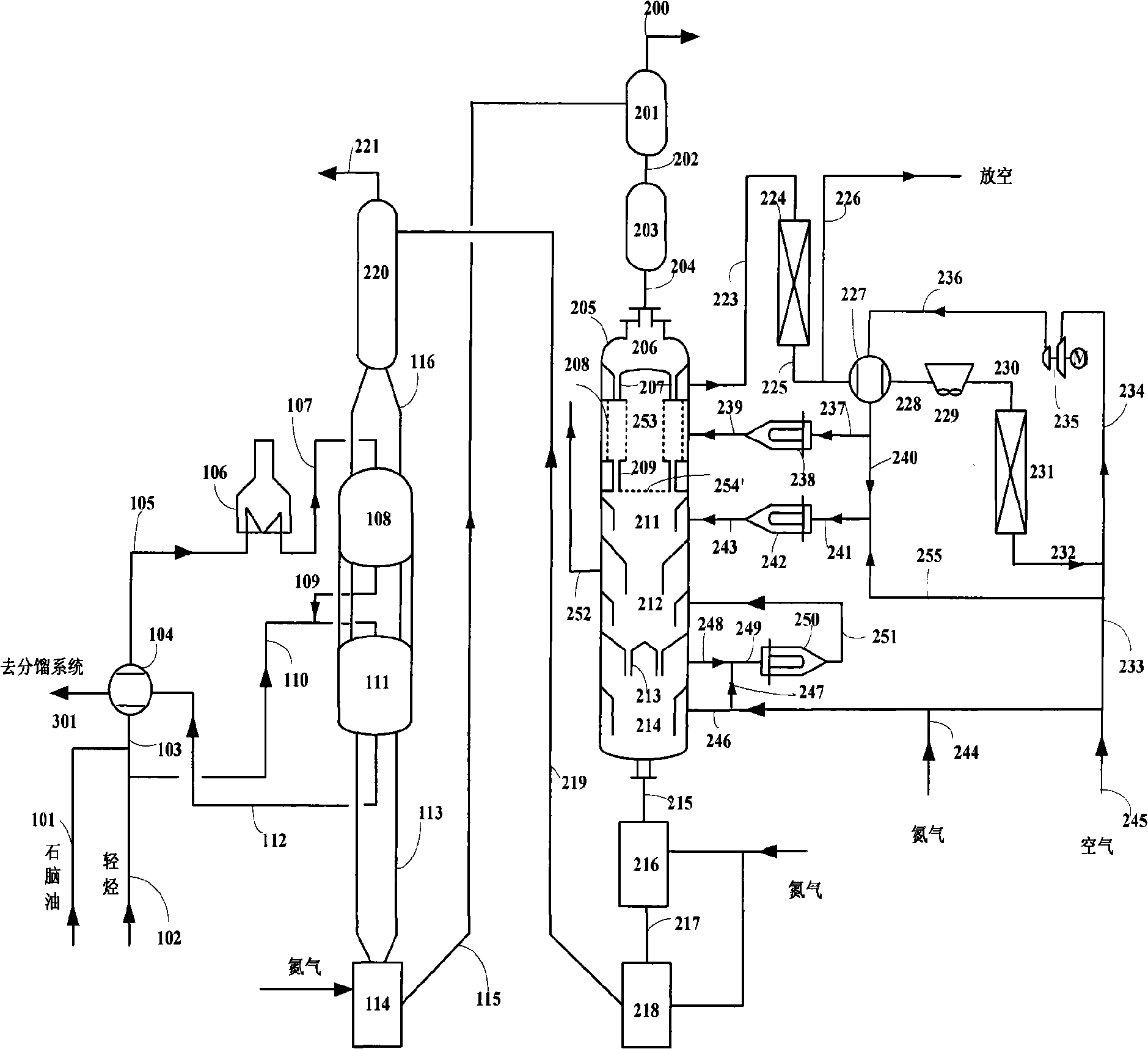

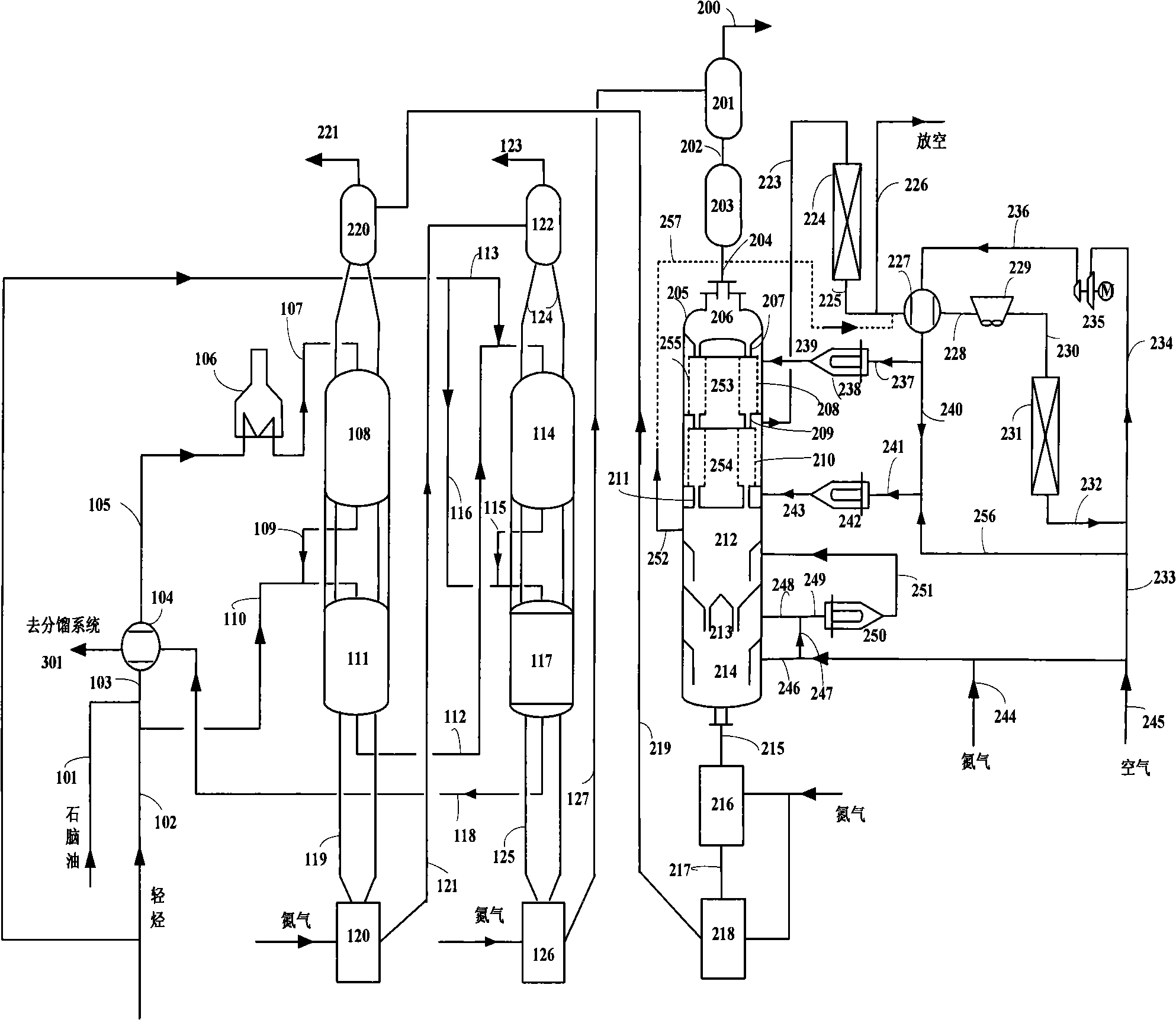

Aromatization method without hydrogen for light hydrocarbon

ActiveCN101314731ARegeneration operation flexibility increasedReduce energy consumptionCatalytic naphtha reformingOxygenMoving bed

A non-hydrogen aromatization method of light hydrocarbons comprises the following steps: (1) mixing naphtha with C3 to C5 light hydrocarbons, adding into a moving bed reaction zone, contacting with aromatization catalyst to carry out aromatization reaction, adding the spent catalyst flowing from the bottom of the moving bed reaction zone into a catalyst regenerator from the top through a spent catalyst elevator, a spent catalyst riser pipe, a spent catalyst separation hopper and a pressure transformation and flow control zone, passing through the buffer zone, a burning zone, a drying zone and a cooling zone in the catalyst regenerator sequentially from top to bottom, introducing oxygen-containing regeneration gas in the burning zone to burn and regenerate the spent catalyst, lifting the regenerated catalyst, and adding into the moving bed reactor from the top. The method can transform low-octane naphtha and low-carbon hydrocarbons into high-octane petrol and high-quality liquefied gas, and has the advantages of large generation operation flexibility, low energy consumption, good catalyst regeneration effect and long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reactor for distribution modulation of Fischer-Tropsch synthesis product and application thereof

ActiveCN102626600APrecise and controllable temperatureControl distributionLiquid hydrocarbon mixture productionChemical/physical/physico-chemical processesHypergravityProcess engineering

A reactor for distribution modulation of Fischer-Tropsch synthesis products and application thereof belong to the technical field of hypergravity reactor. The reactor comprises a sealed reactor shell, a rotor fixed with catalyst bed layers, a rotating shaft, an end cover, a reactant inlet and a reactant outlet. A rotor of a rotating packed bed catalytic reactor is provided with multiple concentric ring-type catalyst bed layers therein; an interlayer heat transfer section is arranged between every two catalyst bed layers, the interlayer heat transfer section is a concentric ring formed by multiple separated casings or heat pipes surronuding the center of the rotor; the end cover is provided with a heat transfer medium inlet and outlet devices; and the outer edge of the rotor is provided with blades. The rotating packed bed catalytic reactor changes the variety and amount of catalyst and inner structure and hypergravity level of the hypergravity reactor to synthesize products with specific component distribution with high selectivity. The hypergravity rotating packed bed catalytic reactor with a novel structure of the invention has advantages of orientated production of the target product, good heat and mass transfer performances and long service life of catalyst, etc.

Owner:BEIJING UNIV OF CHEM TECH +1

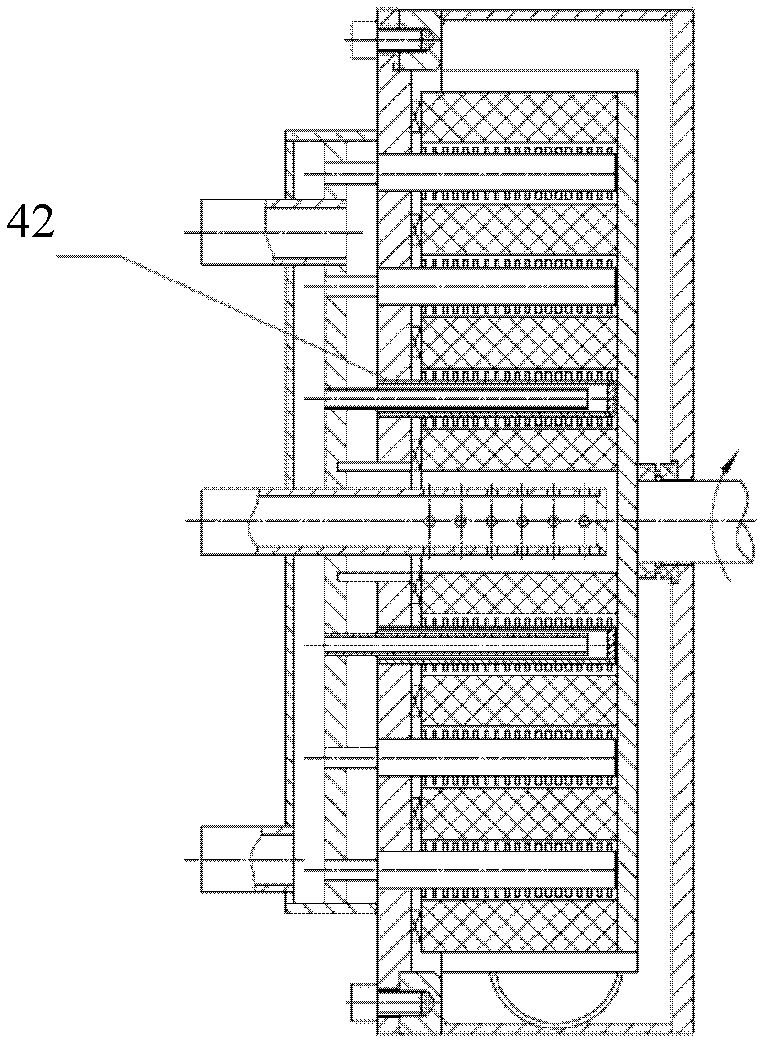

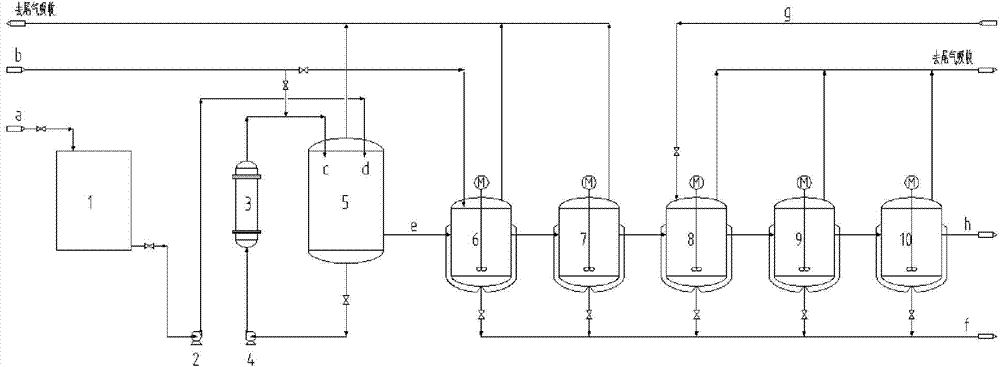

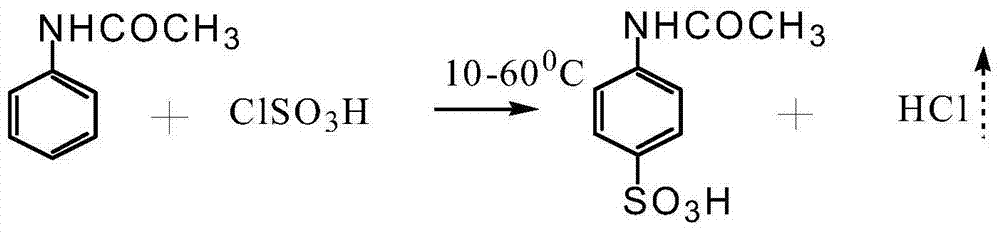

Continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate

ActiveCN104496866AImprove conversion rateThe reaction temperature is easy to controlSulfonic acid preparationMolten stateChlorosulfuric acid

The invention discloses a continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate. The process comprises the steps: performing reaction on chlorosulfonic acid and acetanilide which serve as raw materials; respectively atomizing chlorosulfonic acid and molten-state acetanilide and contacting with each other during feeding to perform reaction. According to the continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate, the molten-state acetanilide is used as a raw material, and the reaction on the acetanilide in an atomizing state and chlorosulfonic acid which is also in an atomizing state are carried out and the reaction temperature is easily controlled, so that the production of byproducts such as parachloroaniline is avoided, and the conversion rate of acetanilide serving as a raw material is high. The process is convenient to operate, short in production period, controllable in reaction process, less in labor demands, low in cost and easy for industrial production.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

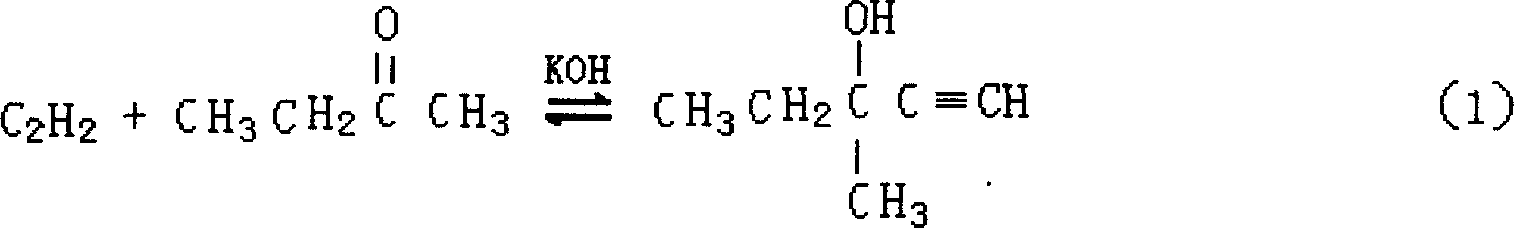

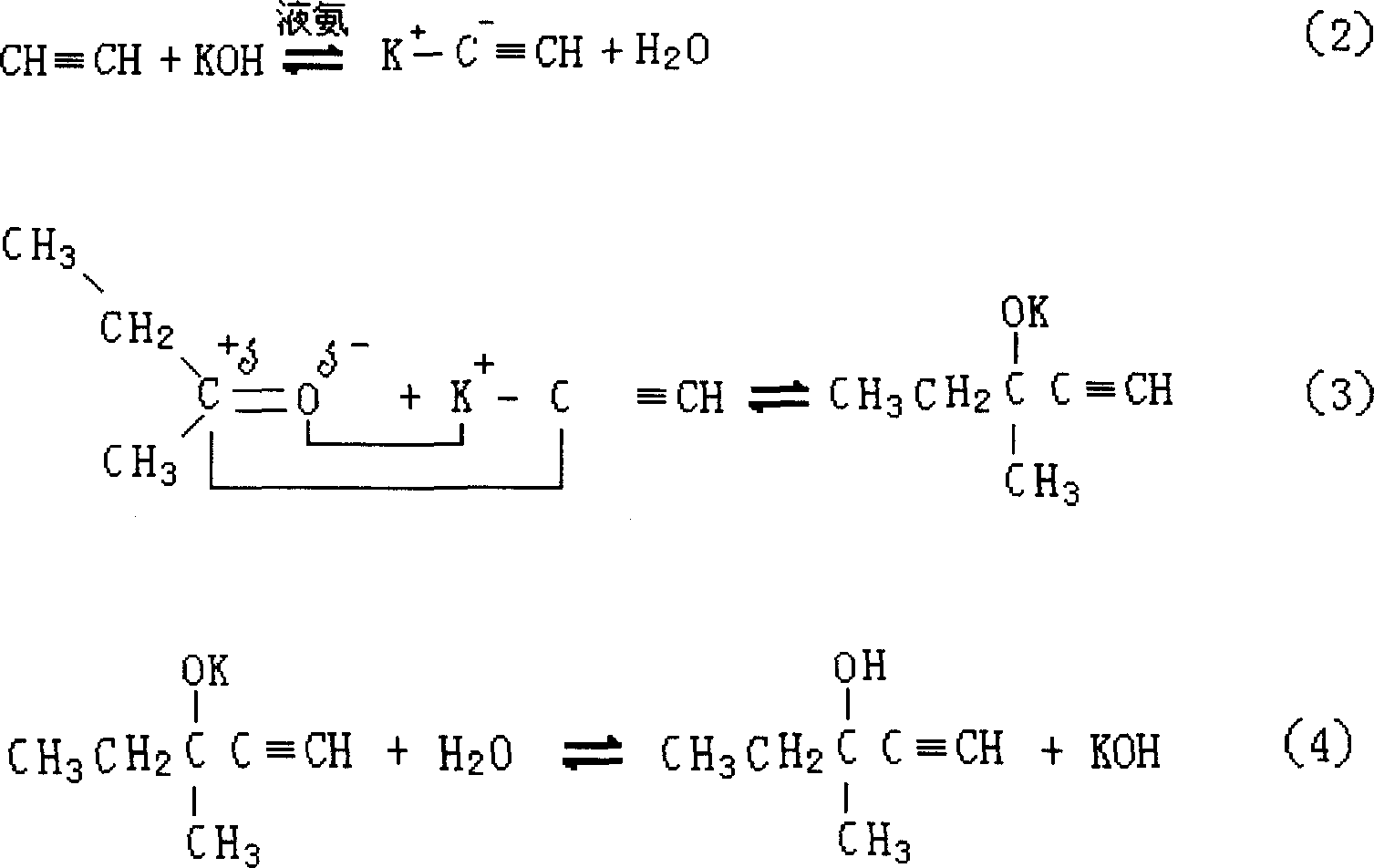

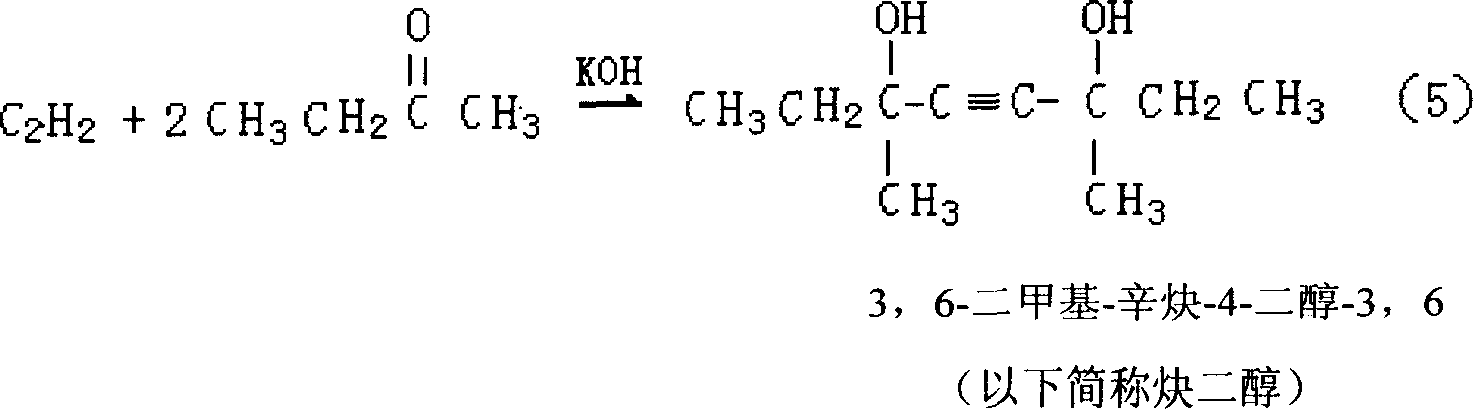

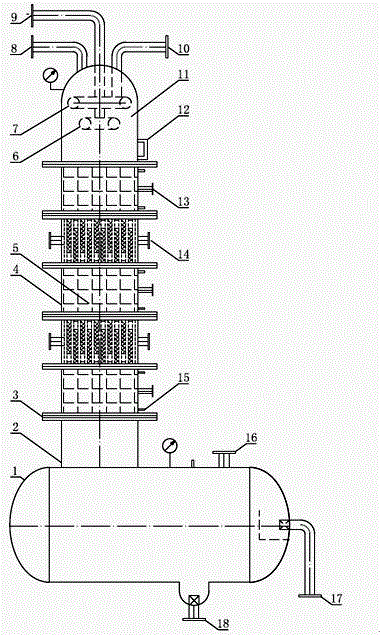

Method for synthesizing alkynol by ketone and acetylene

ActiveCN1765862AGood dispersionImprove efficiencyOrganic compound preparationHydroxy compound preparationDispersityPotassium hydroxide

The invention relates to a method to compose alkynol by ketone and acetylene, which comprises: adding the ketone and catalyst of caustic potash solution into reaction system with mole ratio as 0.15~0.30. The catalyst has well dispersity and high efficient as well as recycle to reduce cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing and purifying watermelon ketone

The invention relates to a method for preparing and purifying watermelon ketone. According to the method, 4-methylcatechol and 1,3-dichloroacetone are used as raw materials to prepare a watermelon ketone rough product, and the watermelon ketoxime with the high purity is obtained by carrying out oximation, crystallization and purification on the watermelon ketone rough product; and then, the watermelon ketone with high purity is obtained by carrying out oxime removing on the watermelon ketone through oxidization or reduction or hydrolysis. The method disclosed by the invention has the advantages of good selectivity, high yield, wide raw material source, low price, and reasonable and feasible process design.

Owner:WUHAN UNIV OF TECH

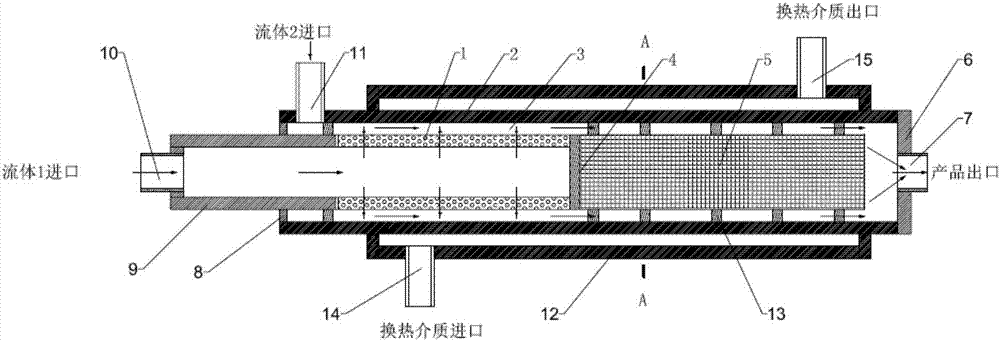

Alkylation method and apparatus using novel microchannel reactor

ActiveCN107519828AWell mixedImprove mass transfer efficiencyChemical/physical/physico-chemical microreactorsLiquid carbonaceous fuelsAlkyl transferReaction temperature

The invention discloses an alkylation method adopting a novel microchannel reactor. A reactor used in the invention is designed to be the microchannel reactor; a microchannel reaction zone is composed of a tubular microchannel reaction zone and a planar microchannel reaction zone, wherein the tubular microchannel reaction zone is composed of an inorganic or organic polymeric material having a fiber-grade dense porous structure and the planar microchannel reaction zone is composed of flaps liable to heat transfer. The alkylation method in the invention uses isobutane and C3-C5 olefins as raw materials and further utilizes a considerable amount of propane as a cooling agent and an entrainer to realize vaporization for heat extraction, so low reaction temperature is ensured; and a knockout drum with a hydrocyclone separation function is arranged on the bottom of the reactor for separation of products. The alkylation method and apparatus provided by the invention have the characteristics that alkylation can be carried out at a low temperature; no pre-mixing is needed for reaction raw materials; bed pressure drop is small; good energy-saving effect is obtained; high product quality is ensured and the like. The alkylation method and apparatus can realize high-efficiency energy-saving safe low-carbon environment-friendly continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

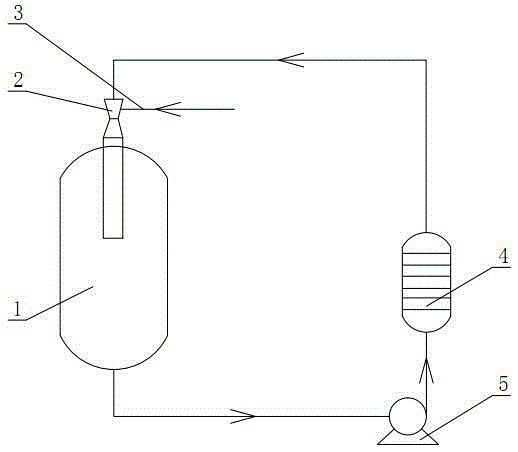

Method for preparing 2-chloro-5-chloromethylthiazole by jet loop reactor

ActiveCN105254583AImprove mixing efficiencyReduce manufacturing costOrganic chemistryOrganic solventBiochemical engineering

The invention discloses a method for preparing 2-chloro-5-chloromethylthiazole by a jet loop reactor, and relates to the technical field of synthesis of the 2-chloro-5-chloromethylthiazole. The jet loop reactor comprises an ejector, wherein the ejector is arranged at the upper part of the reaction kettle; a lower outlet of the reaction kettle is communicated with an inlet of a circulating pump; an outlet of the circulating pump is communicated with the inlet of a heat exchanger; the outlet of the heat exchanger is communicated with the top inlet of the ejector; an air inlet pipe is arranged on the side surface of the ejector; 1-isothiocyano-2-chlorine-2-propylene is dissolved into an inert organic solvent to prepare a liquid-phase material; the liquid-phase material is added to the reaction kettle, and enters from the top inlet of the ejector after passing through the circulating pump and the heat exchanger; chlorine enters the ejector through the air inlet pipe and is mixed with the liquid-phase material; the mixed material passes through the reaction kettle, the circulating pump and the heat exchanger and then returns to the top inlet of the ejector; circular reaction is carried out until the chlorine is introduced; a 2-chloro-5-chloromethylthiazole product is obtained after post-treatment. The method disclosed by the invention is high in yield, few in solid wastes and high in production efficiency; the reaction temperature is easy to control.

Owner:河北德瑞化工有限公司

Method for preparing 3-iodo-2-propynyI butyl carbamate

InactiveCN101337912ASuppress generationThe reaction temperature is easy to controlCarbamic acid derivatives preparationOrganic compound preparationIodine solutionsSolvent

The invention discloses a method for preparing iodopropargyl n-butyl carbamate, which comprises the following steps: a mode 1 reaction kettle, a mode 2 reaction kettle, a mode 3 reaction kettle, a mode 4 reaction kettle and a mode 5 reaction kettle are connected in series, wherein, projecting discs are arranged in the mode 3 reaction kettle and the mode 5 reaction kettle; return tubes and liquid stirrers are arranged in the mode 2 reaction kettle and the mode 4 reaction kettle; the mixed liquid composed of iodine solution and propargyl n-butyl carbamate is continuously charged into the projecting disc of the mode 5 reaction kettle, reaction liquid flows from the bottom of the mode 5 reaction kettle into the mode 4 reaction kettle continuously and flows from the return tube of the mode 4 reaction kettle into the projecting disc of the mode 3 reaction kettle continuously, and chloros water solution is continuously charged into the projecting disc of the mode 3 reaction kettle at the same time; the reaction liquid flows from the bottom of the mode 3 reaction kettle into the mode 2 reaction kettle continuously, and the return tube of the mode 2 reaction kettle into the mode 1 reaction kettle continuously; iodopropargyl n-butyl carbamate, the purity quotient of which is more than 99.0 percent, is obtained through washing, filtering and drying after the solvent is removed from the reaction liquid under the vacuum condition in the mode 1 reaction kettle. The product obtained by adopting the method has high purity quotient, large industrialization production is easy to be realized, the secondary reaction can be effectively reduced, and the utility ratio of iodine can be increased.

Owner:JIANGSU ANPON ELECTROCHEM

Equipment and method for continuously preparing high-purity AKD (Alkyl Ketene Dimer) without solvent

ActiveCN102962026AWell mixedViscosity is easy to controlRotary stirring mixersTransportation and packagingCylindrical channelReaction temperature

The invention provides equipment and method for continuously preparing high-purity AKD (Alkyl Ketene Dimer) without a solvent. The used equipment comprises a reactor for enabling raw materials to be continuously mixed and reacted. The main preparation process comprises the following steps of: at first, continuously adding tertiary amine at a reactor starting end, and continuously adding acyl chloride by dividing into three to ten paths; secondly, in a working state of the reactor, driving an inner cylinder to rotate relative to an outer cylinder by using a main motor, so that the added materials are forced to be transported and stirred by blades on transportation sections of an annular cylindrical channel, and are sufficiently cut and mixed on mixing sections through relative motion of a cutting sheet and a kneading sheet; and alternatively distributing the transportation sections and the mixing sections one by one in the axial direction of the annular cylindrical channel, so that the added materials sufficiently react, and a temperature of the materials can be controlled through an inner-outer heat exchange system until products are continuously discharged from a discharging opening. With the adoption of the equipment and the process of the invention, the reaction heat can be generated in a diffused manner, the materials can be sufficiently mixed, the entire reaction can be realized, a reaction temperature and a material viscosity are easy to control, the generation of side reaction can be reduced, and the high purity of the product can be ensured.

Owner:SUZHOU TIANMA SPECIALTY CHEM

Production technology of boron trifluoride complex

ActiveCN102276638ALow costPollution-freeGroup 3/13 element organic compoundsAqueous solutionBoron trifluoride

The invention relates to a process for producing a boron trifluoride complex. The process comprises the following steps of: a, making gas, namely slowly dripping an organic solvent into a caustic soda flake kettle and absorbing water to generate an organic solvent with vapor, leading the organic solvent with the vapor into a complexing device, leading boron trifluoride gas and performing a complexing reaction, and controlling the temperature to 30 to 50 DEG C and the reaction time to 2 to 5 hours; b, crystallizing, namely after the reaction is finished, stirring for 1 to 2 hours, reducing the temperature to 15 to 20 DEG C, centrifuging, collecting centrifugate and applying; and c, drying under reduced pressure, namely allowing crystals obtained after centrifugation to enter a double cone dryer, controlling the temperature to 35 to 45 DEG C, and drying for 3 to 5 hours to obtain the boron trifluoride complex. The process has the characteristics that: aqueous solution is adopted, the cost is low, liquid caustic soda generated after water is absorbed by using caustic soda flakes can be used for other working sections, and the pollution is avoided; and the reaction temperature is normal temperature or a little higher than the normal temperature and is easy to control, the vacuum drying is adopted, the cost for the application of the centrifugate is low and the like.

Owner:RUNTAI CHEM CO LTD

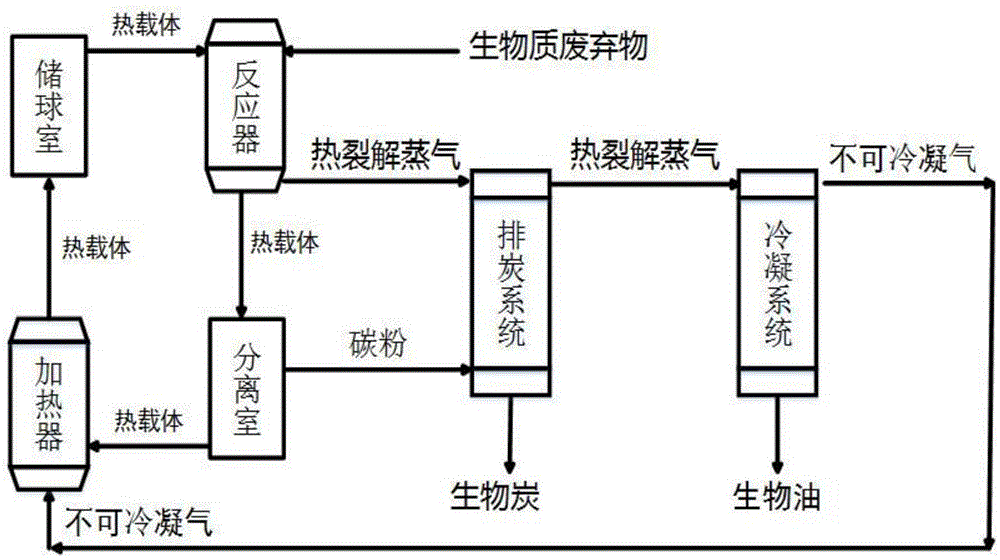

Method for producing liquid fuel from biomass waste

ActiveCN104629786AUniform temperature distributionImprove stabilityDirect heating destructive distillationBiofuelsHeat carrierBiomass

The invention discloses a method for producing a liquid fuel from biomass waste, belonging to the technical field of renewable energy sources. The quick thermal cracking method comprises the following steps: the raw material is delivered into a reactor, heated by a heat carrier, and subjected to thermal cracking in the reactor to generate thermal cracking vapor and biochar; the heat carrier is separated, and delivered into a heater; the biochar is separated by a separator and delivered to a char discharge system via a pipeline; and when the thermal cracking vapor passes through a condensation system, the condensable part is condensed into liquid biological oil, the uncondensable part is delivered to a heat carrier heating system via a pipeline and combusted to heat the heat carrier, and the heat carrier reaching the preset temperature is delivered to a ball storage chamber for cyclic utilization. The device can be used in large-scale industrial production.

Owner:SHANGHAI JIAO TONG UNIV

Novel method for producing nitromethane

ActiveCN102659602AMild distillation conditionsHigh purityOrganic chemistryOrganic compound preparationOrganic synthesisDistillation

The invention relates to a novel method for producing an important organic synthetic intermediate nitromethane. If a substitution reaction between dimethyl sulphate and sodium nitrite is performed to produce nitromethane, there exists factors which damage the environment and safety, such as a lot of harmful gases generated during the reaction and simple distillation processes and spark which is easy to generate during the rectification process. According to the novel method, soda ash is used to adjust pH of the reaction solution, a few organic amine is also added, and simultaneously the reaction temperature is controlled within 30-35 DEG C. Therefore, harmful gases during the reaction process are greatly minimized, spark generated during the rectification process is avoided, and the product having purity of 99.9% can be finally obtained.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

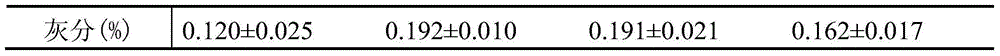

Method and equipment for preparing aromatic sulfonic acid by gas-phase sulphonation of aromatic organic compound

ActiveCN101570500AImprove mass transfer efficiencyQuick contact mixChemical industrySulfonic acid preparationLiquid productSimple Organic Compounds

The invention relates to a method and equipment for preparing aromatic sulfonic acid by the gas-phase sulfuric anhydride sulphonation of aromatic organic compounds with a rotating packed bed. The method solves the problems of the existing method in which the aromatic sulfonic acid is prepared by the sulphonation of aromatic organic compounds using sulfuric anhydride gas as sulphonating agent. The method is as follows: the aromatic organic compounds and the mixed sulfuric anhydride gas enter the started rotating packed bed and come into contact to produce partial sulphonation reaction; the liquid product after reaction enters a tubular heat exchanger and the reaction proceeds; and the aromatic sulfonic acid is obtained. The equipment comprises the rotating packed bed; the liquid inlet of the rotating packed bed is connected with a raw material storage tank; the gas inlet of the rotating packed bed is connected with the mixed sulfuric anhydride gas source; and the liquid outlet of the rotating packed bed is connected with a product storage tank through the tubular heat exchanger. The invention has the advantages of easy control of reaction temperature, reduction of the possibility of subsidiary reaction, enhancement of reactive selectivity, avoidance of environmental pollution, energy saving, small equipment volume, light weight, convenient installation and maintenance, and convenient starting and shutdown.

Owner:ZHONGBEI UNIV

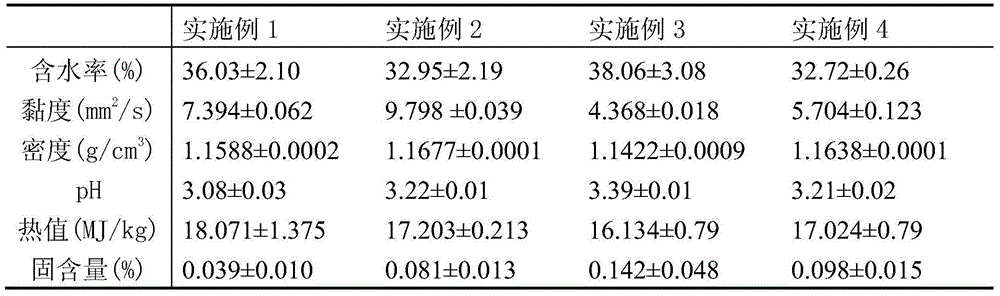

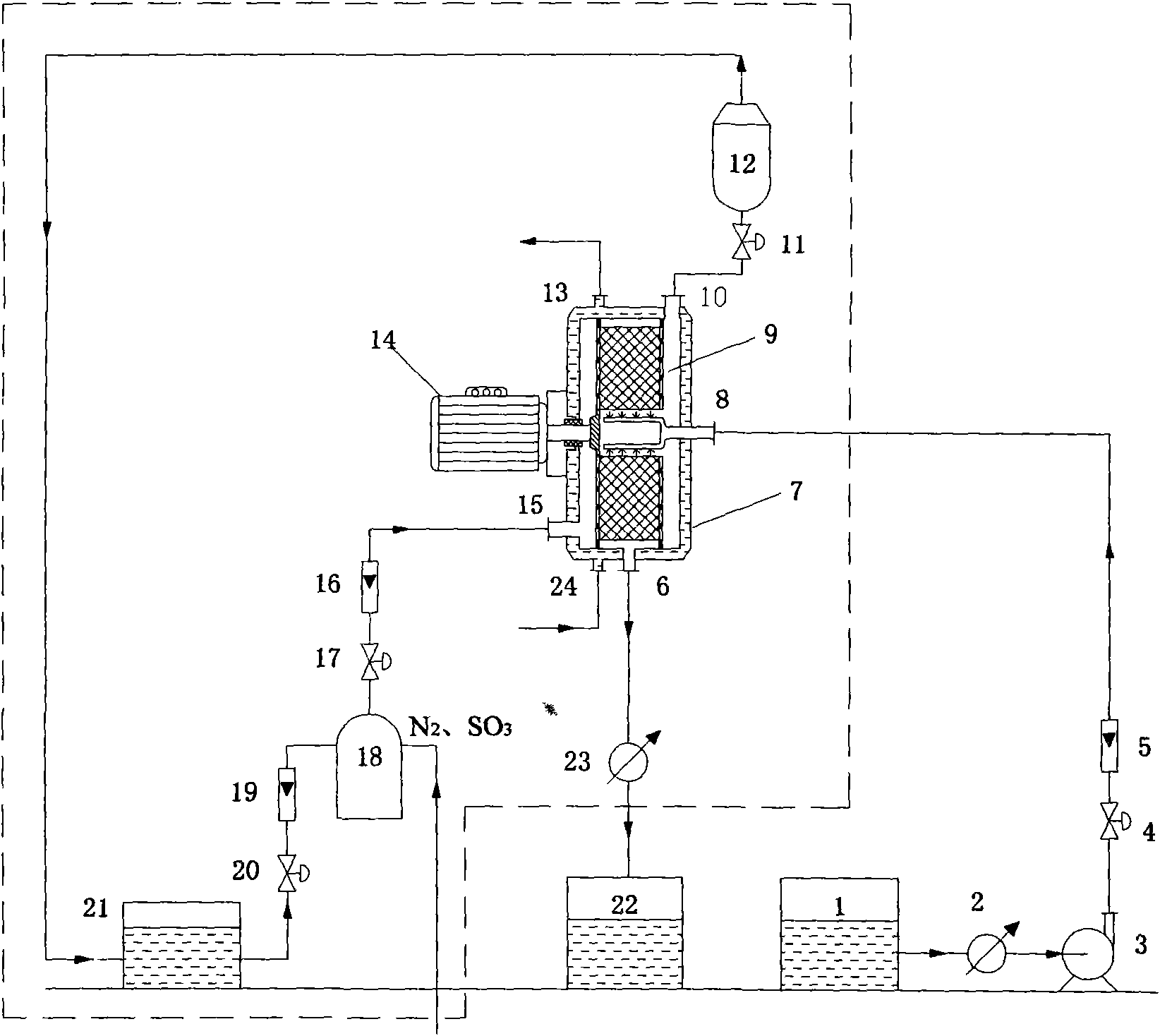

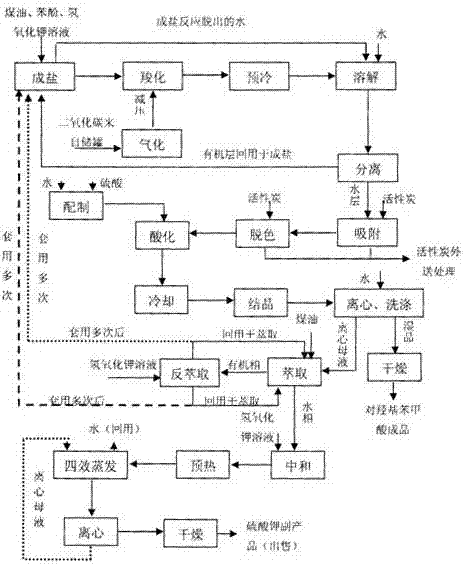

Para-hydroxybenzoic acid continuous production technique by liquid-phase method

InactiveCN102690195AAdvanced production technologyAchieve serializationOrganic compound preparationSulfate/bisulfate preparationPotassium hydroxideSolvent

The invention relates to a para-hydroxybenzoic acid continuous production technique by a liquid-phase method, belonging to para-hydroxybenzoic acid production techniques. According to the invention, phenol and potassium hydroxide are subjected to salification reaction, subjected to carboxylation reaction with carbon dioxide, and acidified with concentrated sulfuric acid to obtain the para-hydroxybenzoic acid product. The technique comprises the following steps: reaction: proportioning a potassium hydroxide solution, phenol and a solvent, and adding into a salification reaction kettle to carry out salification reaction, thereby obtaining potassium phenate; filtering: sending the material containing solid para-hydroxybenzoic acid to a centrifugal machine, separating, washing with water to obtain the solid para-hydroxybenzoic acid, and drying to obtain the para-hydroxybenzoic acid; extraction and recycling: sending the filtrate obtained in the filtering step and a washing solution to an extraction column, and extracting with an extractant in the extraction column; and potassium sulfate preparation: drying the wet material with a continuous evaporator to obtain the potassium sulfate product. The invention has the advantages of high unit volume productivity, easy control on production, less environmental pollution, shorter technical process and low production equipment investment, and can easily implement continuous production.

Owner:JIANGSU TIANXIN BIO ENG

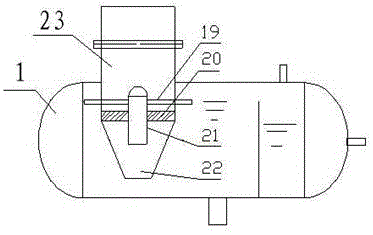

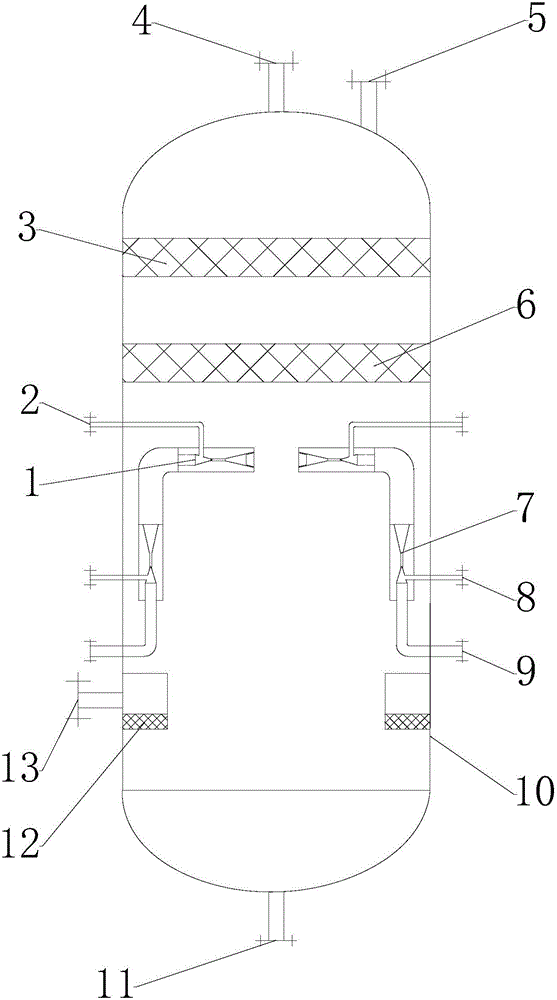

Impinging stream polyphase reactor

ActiveCN106179146ASimple structureAdded convective mixing sectionLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferEmulsion

The invention is an impingement flow multiphase reactor, which relates to liquid-liquid mixed multiphase reaction. The reactor mixes the high-viscosity and low-viscosity fluids uniformly into a low-viscosity emulsion at a lower temperature and in a short period of time through the raw material injection premixer, and then sprays out a ring-shaped liquid film at high speed through multiple jets hitting the nozzles of the reactor The phase impact strengthens the reaction, so that the reaction can be carried out quickly and fully. The impinging flow multiphase reactor introduced by the invention has simple structure, no stirring parts, is not easy to leak, has a large contact area of reaction liquid, can realize rapid and efficient mixed reaction of immiscible fluids in large-scale production, and has high product selectivity. It can be applied to reaction devices with high fluid viscosity, liquid-liquid immiscibility and rapid mixing reaction between liquids in fine chemical industry, petrochemical industry, pharmaceutical industry, biochemical industry and other industrial processes, especially liquid acid catalyzed isobutane alkylation reaction .

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

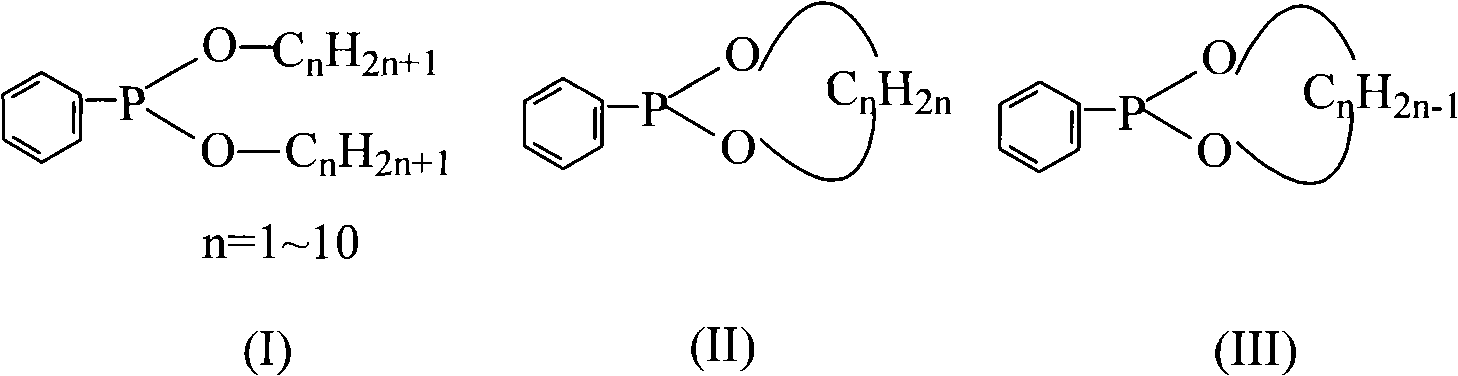

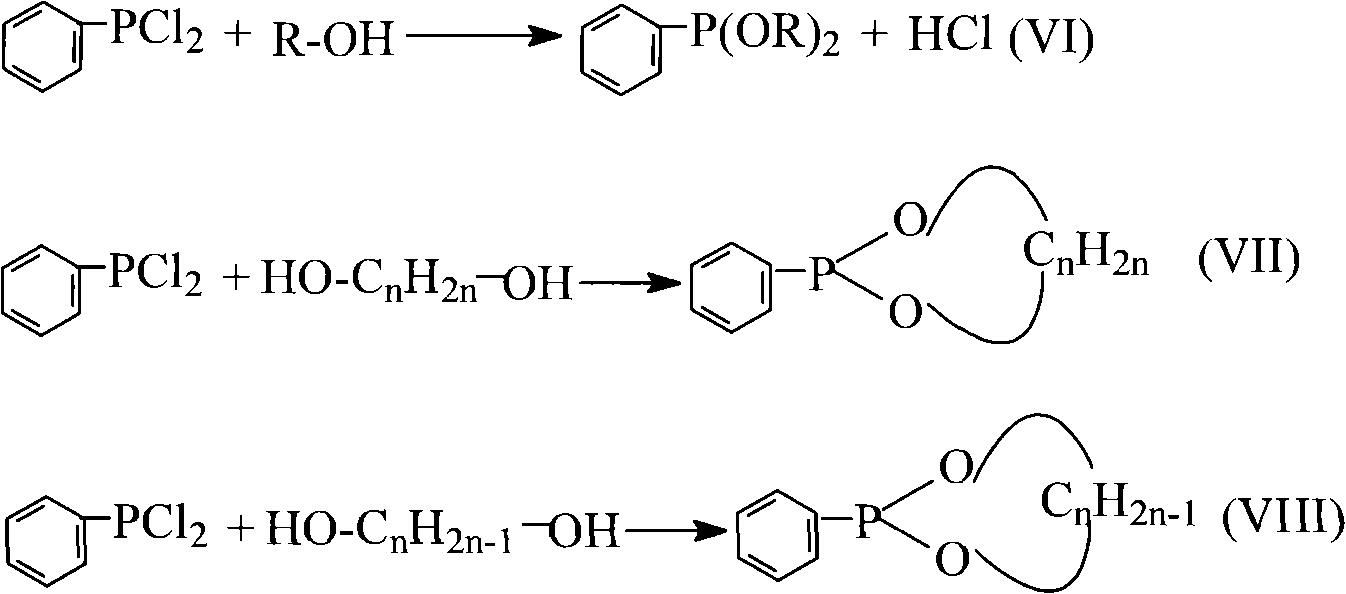

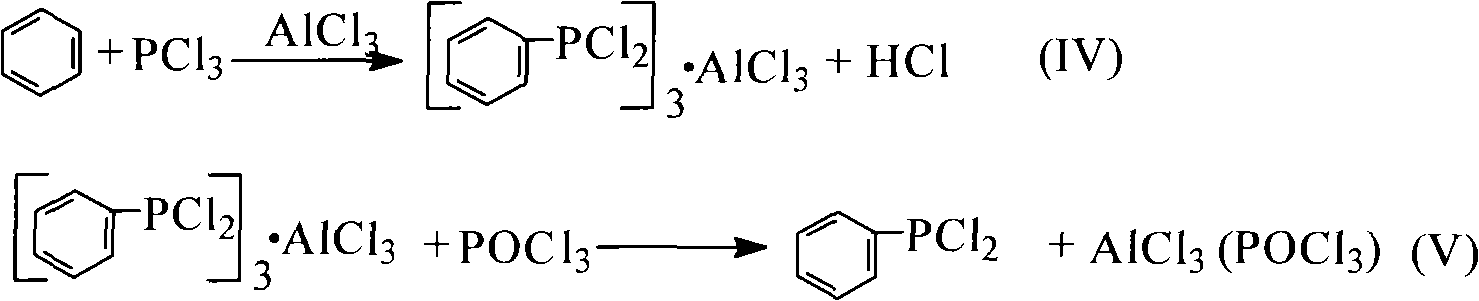

Method for preparing dialkyl phenyl-phosphonite

InactiveCN101538281ALow costReduce manufacturing costGroup 5/15 element organic compoundsAlcoholPhosphate

The invention relates to a method for preparing dialkyl phenyl-phosphonite which is a key intermediate of acyl phosphate photoinitiator. The method takes benzene, phosphorus trichloride and alcohol as main materials and synthesizes dialkyl phenyl-phosphonite through a two-step reaction. The method has the improvements that: in the second step of reaction, phenyldichlorophosphine reacts with the alcohol to synthesize the object under the condition of non-catalyst, the reaction temperature is controlled within 10 DEG C below zero to 10 DEG C, and phenyldichlorophosphine is dropwise added; and then the reaction is carried out under the condition of stirring at the temperature of 30 to 50 DEG C for 0.5 to 7 hours. The invention has the advantages of low cost, easy post treatment, high yield, and the like and is suitable for industrial production.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

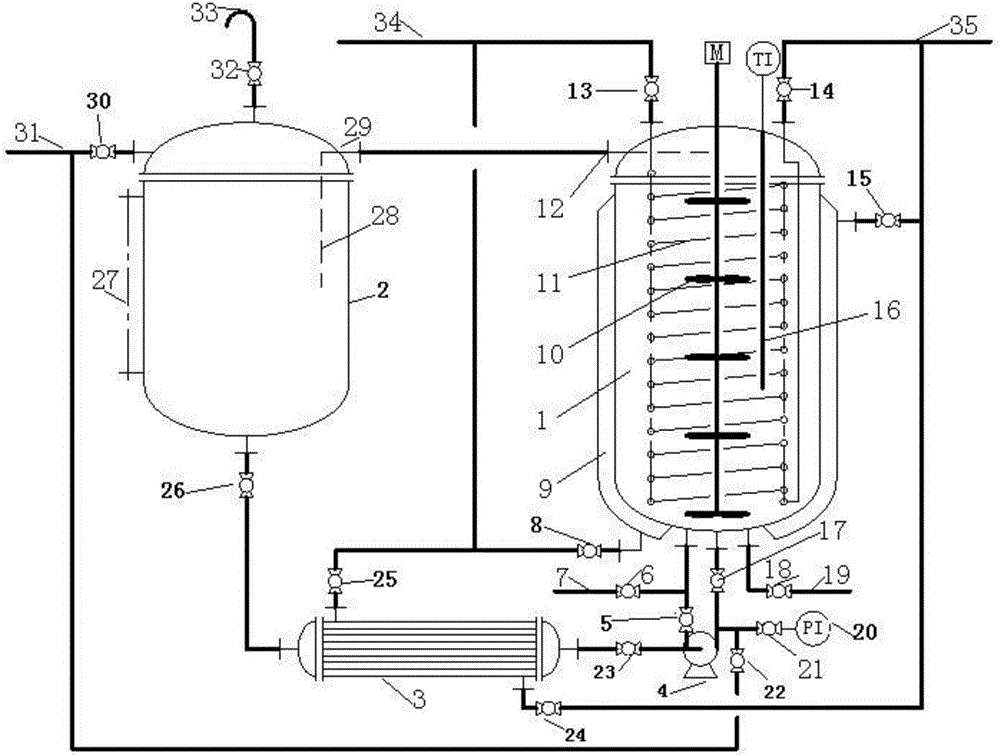

Reaction device for strengthened heat transfer and continuous production method with strong exothermic reaction

ActiveCN106732295AIncrease the areaImprove heat transfer efficiencyGroup 5/15 element organic compoundsChemical industryReaction temperatureProcess safety

The invention relates to the technical field of chemical engineering equipment, and in particular to an exothermic reaction device. The exothermic reaction device comprises a reaction kettle, a crude product tank, a cooler and a circulating pump, wherein a material outlet formed in the top part of the reaction kettle is connected with a crude product inlet formed in the crude product tank; a material outlet formed in the bottom part of the crude product tank is connected with an inlet of a circulating material passage of the cooler; an outlet of the circulating material passage is connected with an inlet of the circulating pump; an outlet of the circulating pump is connected with a circulating inlet in the bottom part of the reaction kettle; an after-pump circulating valve is arranged between the circulating pump and the circulating inlet, and a crude product external circulating passage is formed. A part of a crude product is utilized for carrying out external circulation strengthened heat transfer, the external circulation strengthened heat transfer is not limited by a space of the reaction kettle, the heat exchange area of the cooler can be increased at will, the heat transfer efficiency is increased, a reaction temperature can be easily controlled, and the process safety and the production capacity are increased; circulating water is used as a refrigerant for replacing traditional calcium chloride brine, so that the corrosivity is greatly reduced, common carbon steel processing and manufacturing equipment can be used, the investment cost is reduced, reaction heat is transferred by using circulation of the crude product, and impurities cannot be introduced in.

Owner:青岛长荣化工科技有限公司

Erlotinib preparation method suitable for industrial production

The invention relates to a preparation method of erlotinib and hydrochloride thereof. The preparation method comprises the following steps: 1, reacting 4,5-di(2-methoxyethoxy)-2-nitrophenylacetonitrile with sodium hydrosulfite to obtain 4,5-di(2-methoxyethoxy)-2-aminophenylacetonitrile: controlling the reaction temperature to 45-55DEG C, adding sodium hydrosulfite in batches, adjusting the pH value to 8-9 by using ammonia water after the reaction ends, and directly filtering to obtain 4,5-di(2-methoxyethoxy)-2-aminophenylacetonitrile; and 2, reacting 4,5-di(2-methoxyethoxy)-2-aminophenylacetonitrile with N,N-dimethylformamide dimethyl acetal to obtain a product, and directly reacting the product with m-aminophenylacetylene without purification to obtain erlotinib; and also comprises: carrying out re-crystallization purification treatment on crude erlotinib obtained in step 2 in order to obtain finished erlotinib with the single impurity content being smaller than 0.1%.

Owner:海南卓泰制药有限公司

Equipment and process for extracting helium from BOG gas with high hydrogen content

InactiveCN111547691AThe reaction temperature is easy to controlIncrease the permeability coefficientGas treatmentDispersed particle separationGas compressorDehydrogenation

The invention discloses equipment for extracting helium from BOG gas with high hydrogen content and a process thereof, and relates to the field of equipment and process for extracting helium from BOGgas. The equipment comprises a catalytic dehydrogenation reactor, a cooler, a molecular sieve dryer, a feed gas compressor, a heat exchanger, a membrane separator, a vacuum pump, a buffer tank, a crude helium compressor, a helium purifier, a helium supercharger, a digital display type gas supply busbar device and a helium bottle; according to the invention, the permeability coefficient of gas molecules is increased in a manner of before- membrane pressurization and after- membrane vacuumizing; relatively high yield and purity of helium are achieved by using a relatively small membrane area; ina membrane separation process for extracting concentrated crude helium from BOG feed gas, Non-phase change is realized, and the equipment investment and the operation cost are reduced; the recovery rate of helium is increased before desorbed gas of the helium purifier returns to the feed gas compressor, and the helium yield of the whole device is as high as 99%; an interface is additionally arranged on an original BOG fuel gas pipeline to concentrate helium in BOG feed gas, and the loss of impermeable gas passing through a membrane separator is lower than 5%.

Owner:DALIAN HAIAO MEMBRANE TECH

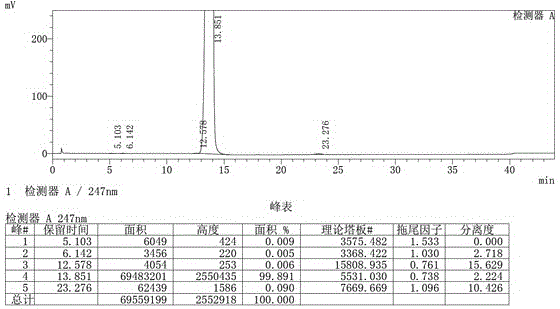

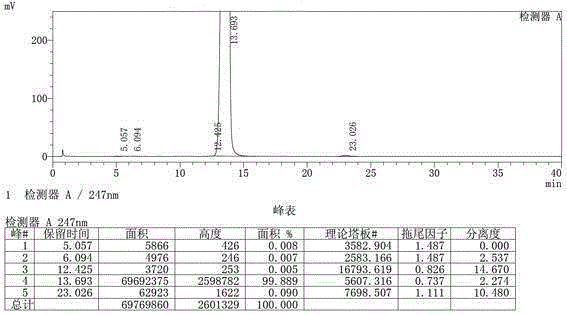

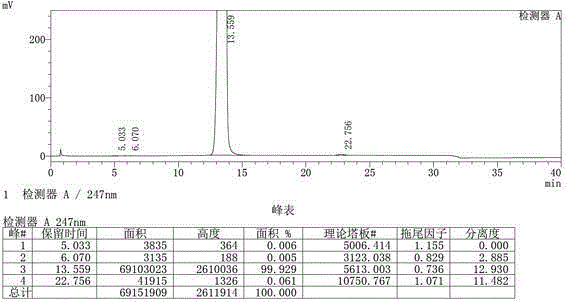

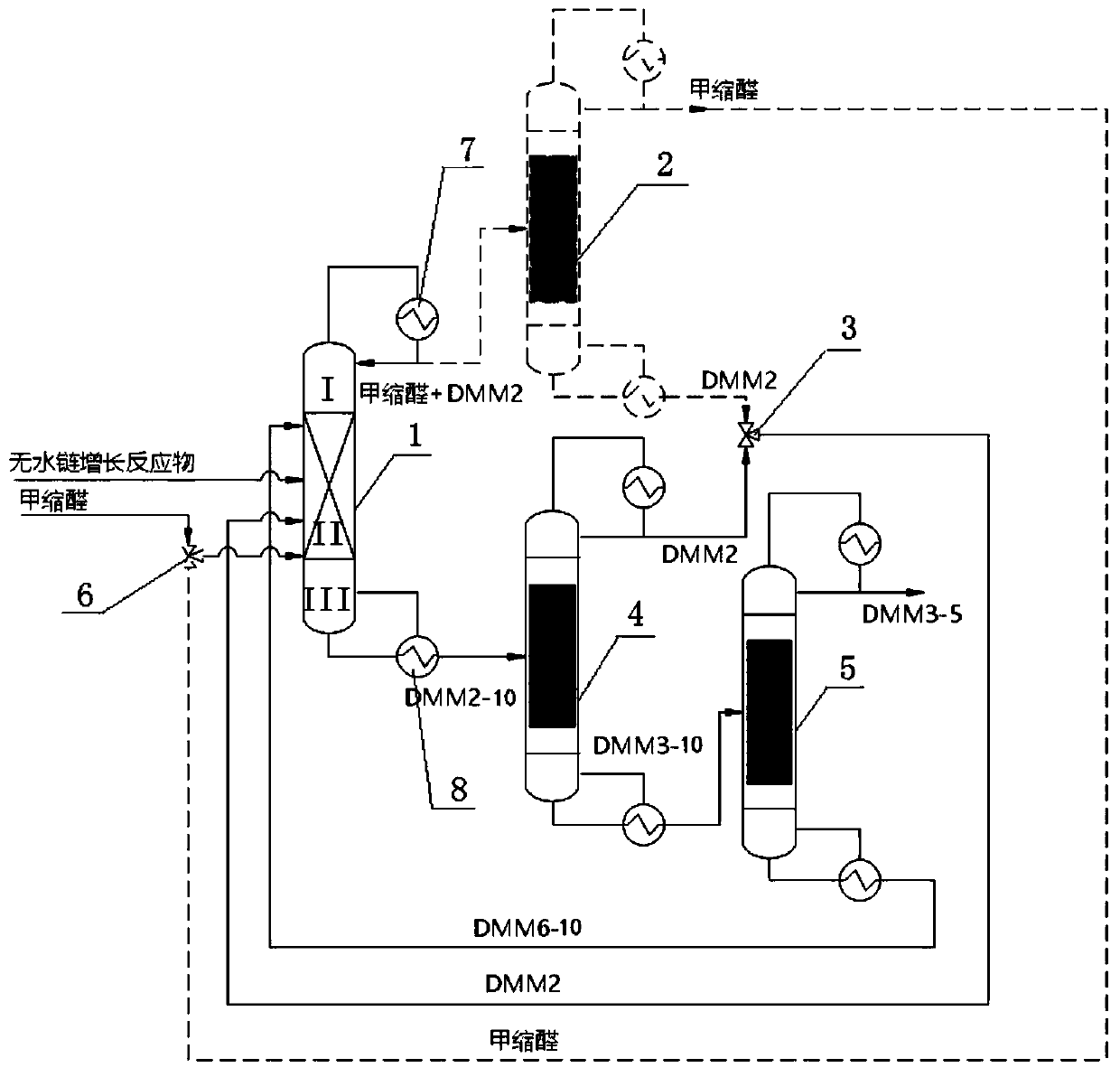

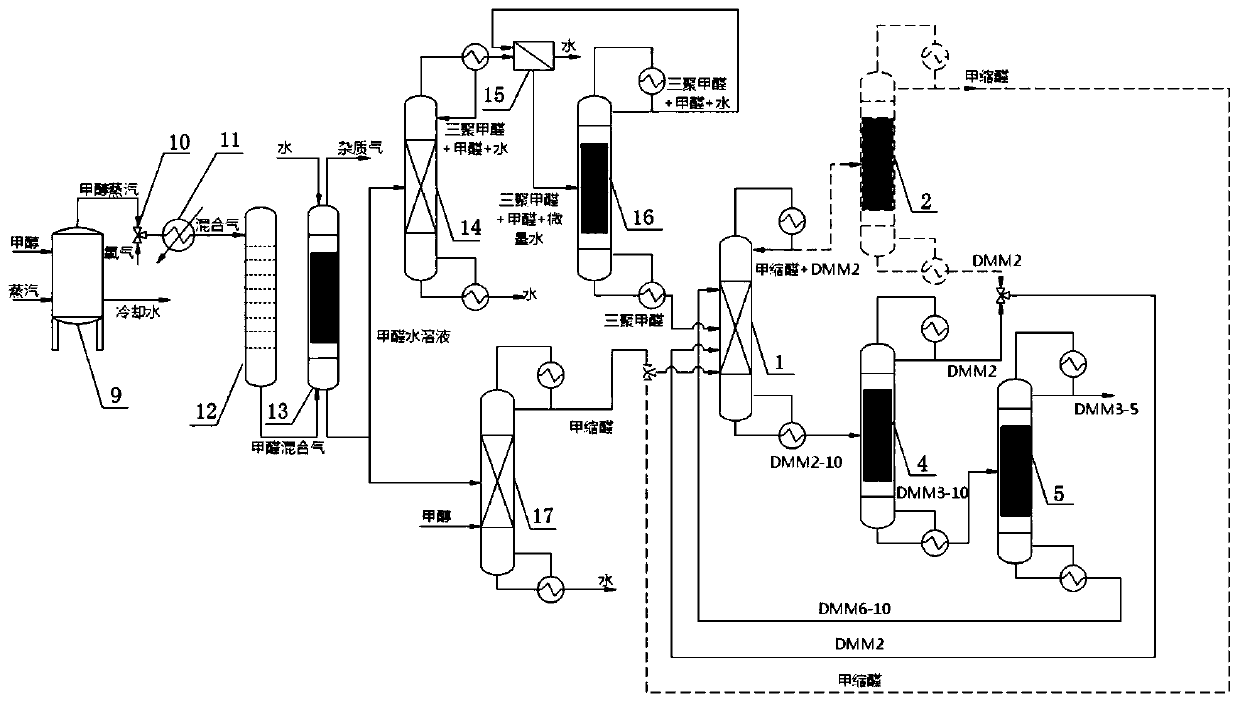

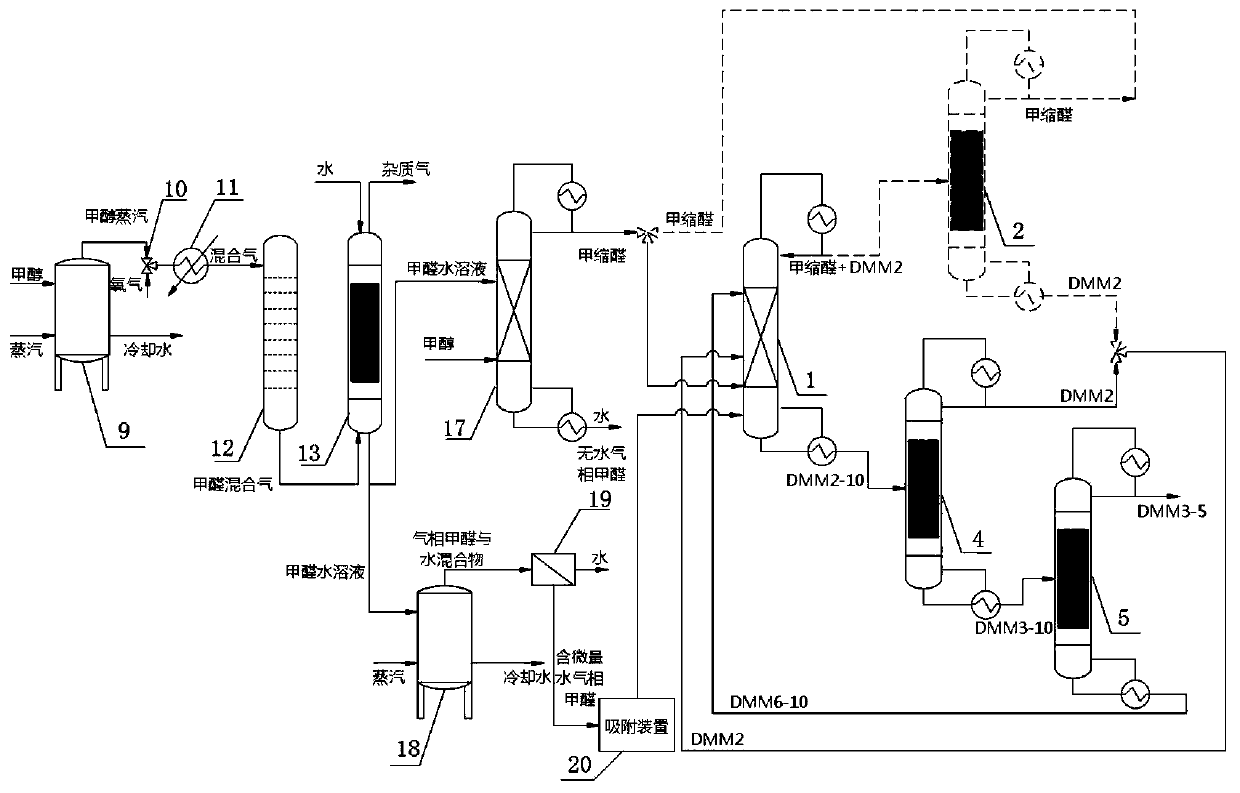

Reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers)

ActiveCN110078600AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationGas phaseParaformaldehyde

The invention provides a reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers). According to the method, industrial methylal for product chain termination and one or a mixture of two or more of trioxymethylene, paraformaldehyde and gas-phase formaldehyde for product chain propagation are taken as raw materials, no water exits in a reaction system, a PODEn mixed product with multiple degrees of polymerization is obtained through a reaction under the action of an acidic catalyst, a reaction product with the degree of polymerization higher than2 is recovered from the column bottom under the separation action of a PODEn reactive distillation reaction column, and DMM2 with low degree of polymerization and incompletely reacted methylal are recovered from the column top; a product recovered from the column bottom is separated by a production refinery column, a target product DMM3-5 is obtained, DMM2 with low degree of polymerization and DMM6-10 with high degree of polymerization are returned to the PODEn reactive distillation reaction column; incompletely reacted methylal is recycled as a raw material. By use of the characteristic of reactive distillation, excessive methylal is adopted in the reaction process, the conversion rate of formaldehyde substances is substantially increased, and the selectivity and the yield of DMM3-5 are increased.

Owner:TIANJIN UNIV

Preparation system and preparation method for polyisobutylene

The invention discloses a preparation system and a preparation method for polyisobutylene. The system comprises an isobutylene storage tank, a catalyst storage tank, a termination agent storage tank, a rapid mixer, a static mixing tube type polymerization reactor and a rapid reaction termination mixer. The isobutylene storage tank is connected to an isobutylene cooler through a pipeline and a raw material delivery pump. The isobutylene cooler is in pipeline connection with a raw material inlet of the rapid mixer. The catalyst storage tank is connected to the catalyst inlet of the rapid mixer through a pipeline and a catalyst metering pump. The outlet of the rapid mixer is communicated with the inlet of the static mixing tube type polymerization reactor, the outlet of which is communicated with the reaction feed inlet of the rapid reaction termination mixer. The termination agent storage tank is connected to the termination agent inlet of the rapid reaction termination mixer through a pipeline and a termination agent delivery pump. The static mixing tube type polymerization reactor is located in a constant temperature brine bath groove. The system provided by the invention has the advantages of uniform reaction temperature, narrow molecular weight distribution of polyisobutylene, and controllable molecular weight, etc.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

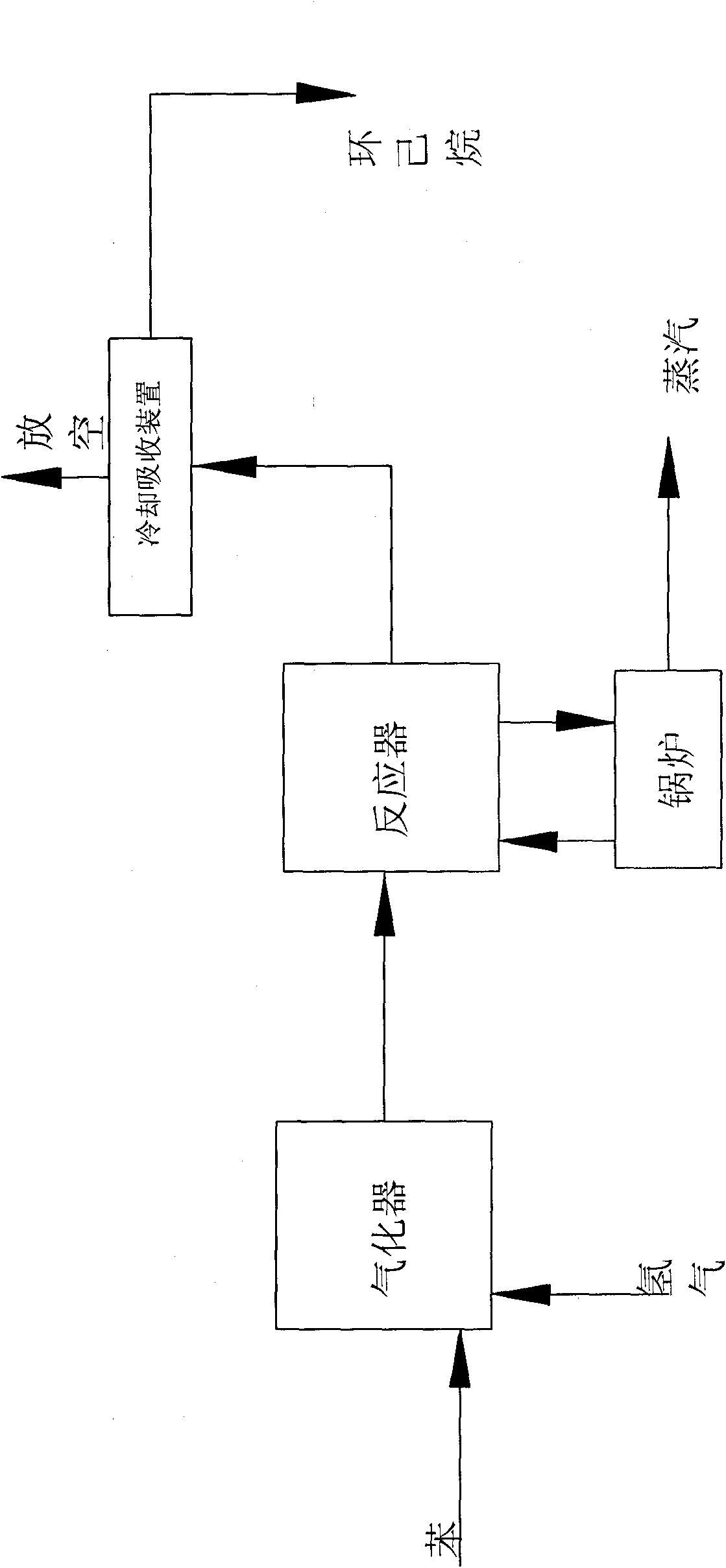

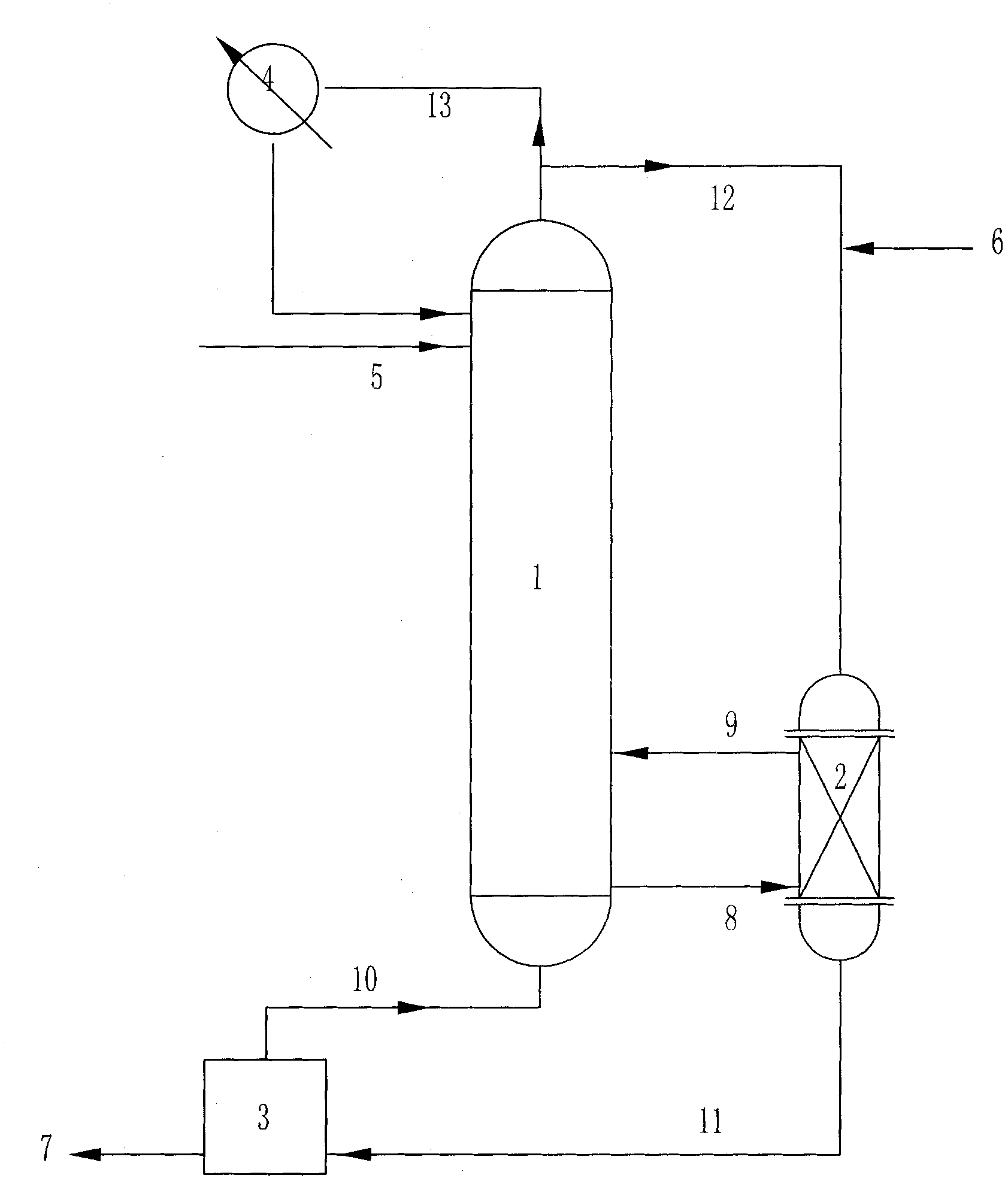

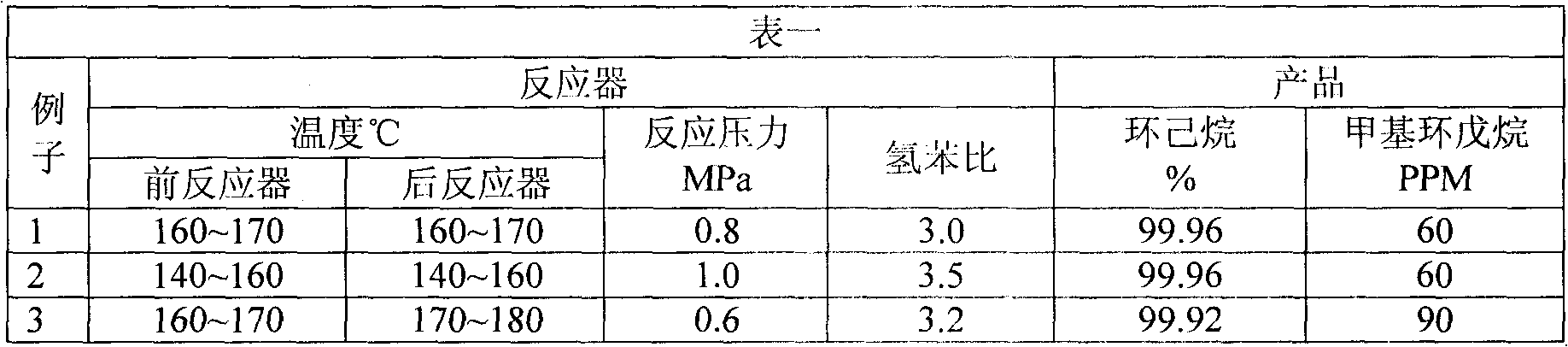

Device for producing cyclohexane by adding hydrogen in benzene and synthesis process

ActiveCN101898930ARemove in timeThe reaction temperature is easy to controlHydrocarbon by hydrogenationBenzeneHydrogen

The invention discloses a device for producing cyclohexane by adding hydrogen in benzene and a synthesis process. The device mainly comprises a gasification tower (1) and a reactor (2), wherein a liquid phase benzene inlet (5) is arranged at the upper part of the gasification tower (1), a liquid phase benzene outlet is arranged at the lower part of the gasification tower (1), the liquid phase benzene outlet is connected with a shell pass inlet of the reactor (2) through a pipeline (8), a shell pass outlet of the reactor (2) is connected to the gasification tower (1) through a pipeline (9), a gas phase outlet is arranged at the top of the gasification tower (1) and connected to a pipe pass of the reactor (2) through a pipe pass feed pipeline (12), a hydrogen material pipeline (6) is connected to the pipe pass feed pipeline (12), and a pipe pass discharge pipeline (11) is arranged at the bottom of the reactor (2). In the device, heat discharged from the intermediate reaction in the cyclohexane synthesis process is directly used for gasification of reaction material benzene so as to release the reaction heat without secondary heat exchange, therefore, the stable reaction conversion ratio is achieved, and the production capacity is improved.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

Coal liquefied oil boiling bed hydrogenation technique

ActiveCN103773483AThe reaction temperature is easy to controlRaw material can be adjustedTreatment with hydrotreatment processesHydrogenation reactionEconomic benefits

The invention discloses a boiling bed hydrogenation technique for improving the coal liquefied oil light oil yield; catalytic cracking oil slurry clarified oil is distilled to obtian a light fraction and a heavy fraction, the heavy fraction is countercurrent mixed with hydrogen for hydro-upgrading reaction, the upgraded heavy fraction and the light fraction are mixed, and enter, together with coal liquefied oil and cycled liquid production oil, into a boiling bed reactor for hydrogenation reaction; a reaction effluent is separated to obtain liquid production oil, part of the liquid production oil returns back to the boiling bed reactor, and the rest of the liquid production oil is fractionally distillated to obtain various products. After upgrading of oil slurry, the content of mononuclear aromatics and polyaromatic hydrocarbons is greatly increased, the upgraded oil slurry is used as a hydrogen donor for the coal liquefaction oil boiling bed hydrogenation process, by the synergy of the coal liquefied oil and the hydrogen donor, the coal liquefied oil conversion rate can be significantly improved, the yield of light oil can be increased, at the same time, catalytic cracking slurry oil being difficult to process can be well utilized, and the economic benefit is very good.

Owner:CHINA PETROLEUM & CHEM CORP +1

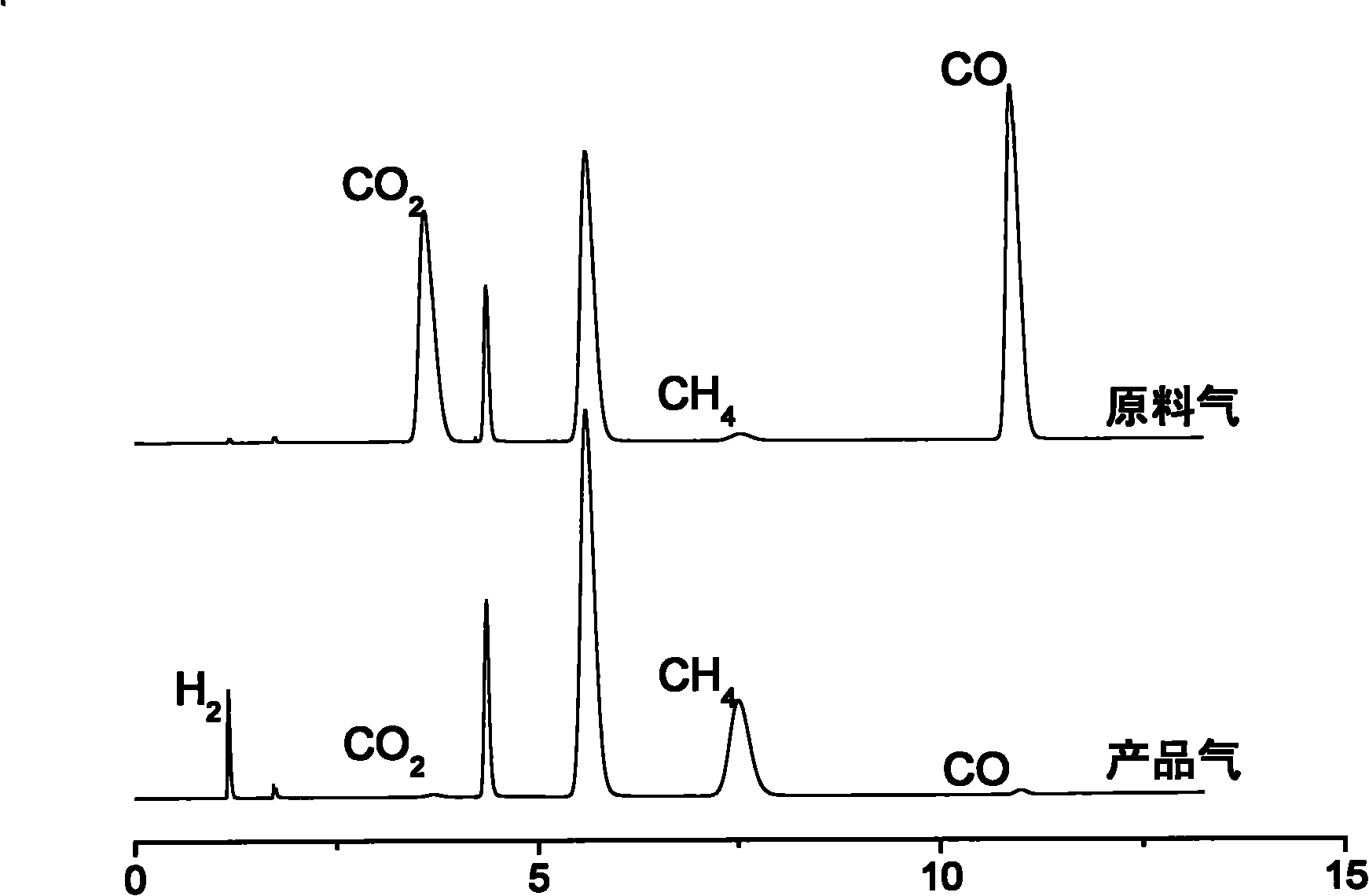

Method for hydrothermally reducing CO2 or CO into methane by using porous nickel catalyst

InactiveCN102464544AOvercoming the problem of temperature instabilitySolve the problem of easy carbon deposition and deactivationHydrocarbon from carbon oxidesDispersed particle separationNickel catalystHydrogen

The invention relates to a method for hydrothermally reducing CO2 or CO into methane by using a porous nickel catalyst. The method comprises the following steps of: placing the porous nickel catalyst into a hydrothermal reactor, mixing hydrogen and CO2 or CO according to the molar ratio of 1:(1-10) in the hydrothermal reactor, controlling the temperature of the reactor to 200 to 400 DEG C, and adjusting the pressure of the reactor to 6 to 20MPa and the reaction time to 5 to 180 minutes to obtain the reaction product, namely methane. When the method is compared with the prior art, the highest conversion rate of CO2 and CO is 99 percent, the whole reaction is performed under a hydrothermal condition, the defect that the catalyst is inactivated because carbon is easy to accumulate on the surface of the catalyst in a gas-phase reduction process is overcome, and the used catalyst has the characteristics of high strength, good activity, good thermal stability, excellent low-temperature activity and the like.

Owner:TONGJI UNIV

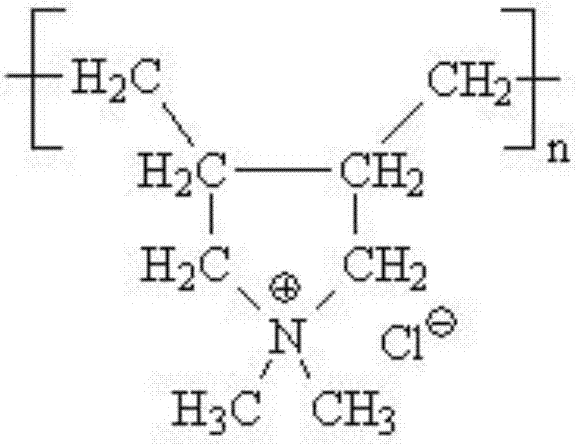

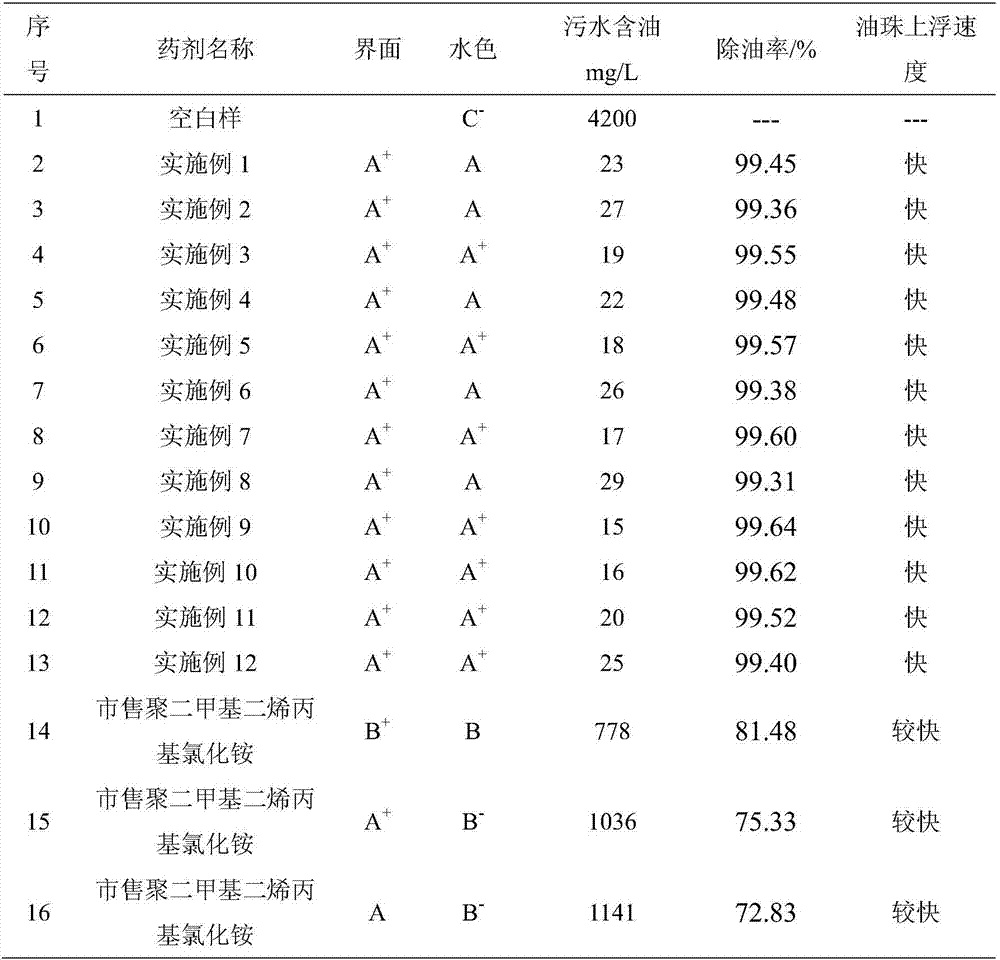

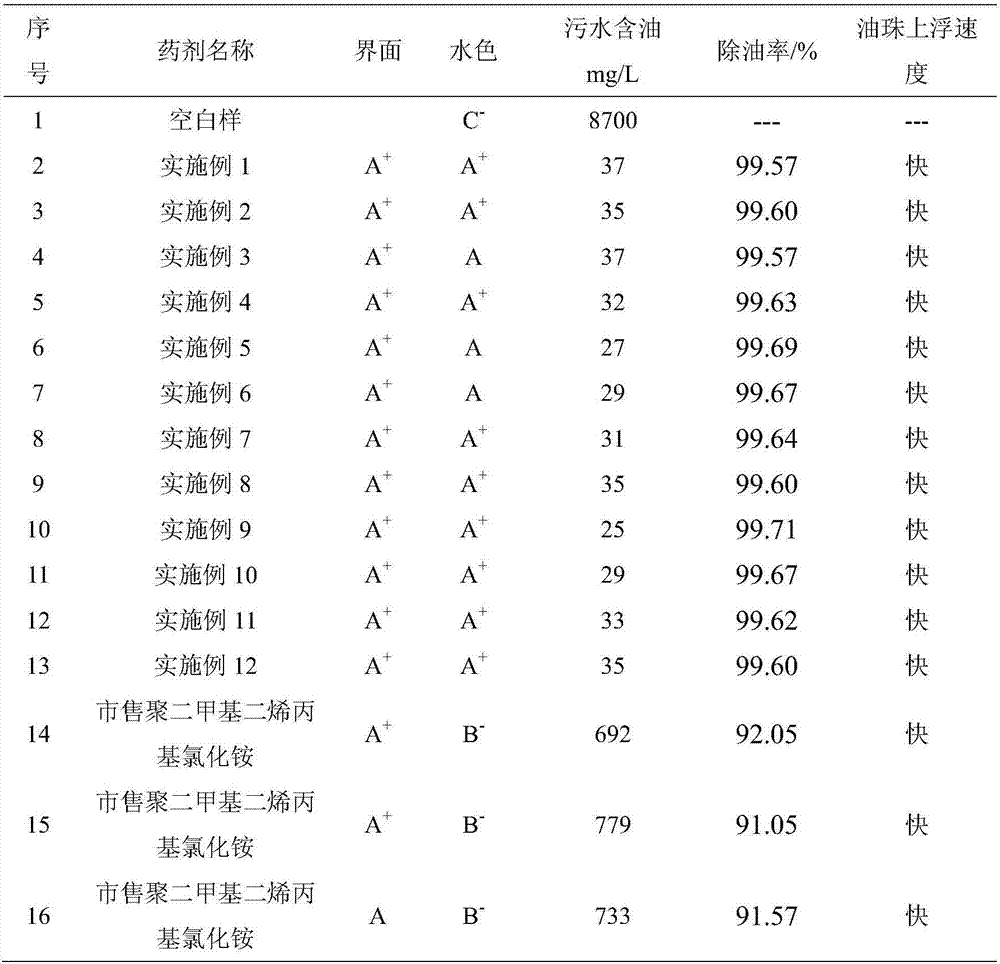

Preparation method of poly (diallyldimethylammonium chloride) as flocculating agent for treating sewage

ActiveCN106986959ALow oil removal rateLow monomer conversionWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationLow speedReaction temperature

The invention discloses a preparation method of poly (diallyldimethylammonium chloride) as flocculating agent for treating sewage. The preparation method comprises the following steps: (1) adding an initiator, a complexing agent and ethylene glycol as a chain transfer agent in an aqueous solution of diallyldimethylammonium chloride, stirring uniformly, and feeding nitrogen to remove air in a reaction container; (2) heating reaction liquid obtained from the step (1) while stirring, and carrying out polymerization reaction; (3) heating to the temperature of 65-85 DEG C, adding the initiator in the reaction liquid again, and adding water in the reaction liquid for reaction; and (4) under protection of the nitrogen, carrying out insulation and curing to obtain the poly (diallyldimethylammonium chloride). The method is simple in process and easy to operate, the reaction temperature is convenient to control, polymerization reaction is stably carried out at low speed, products with medium and low relative molecular mass are easily obtained, and the preparation method is suitable for treatment of oilfield chemical flooding output liquid. The prepared flocculating agent for treating the sewage is high in oil removal rate, high in monomer conversion rate, good in water purification effect, low in viscosity of products and convenient to inject, and has universal applicability.

Owner:中海油(天津)油田化工有限公司 +2

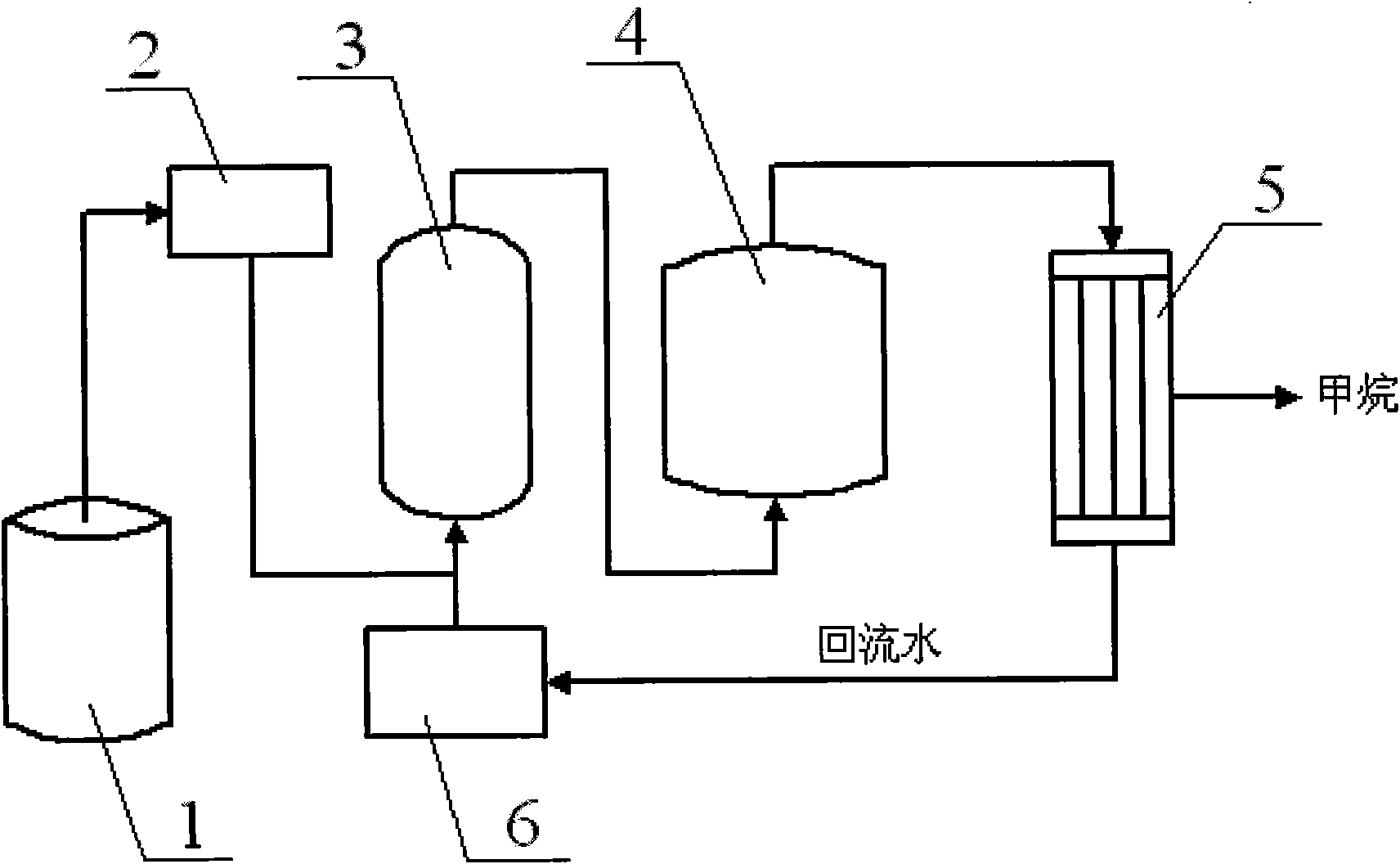

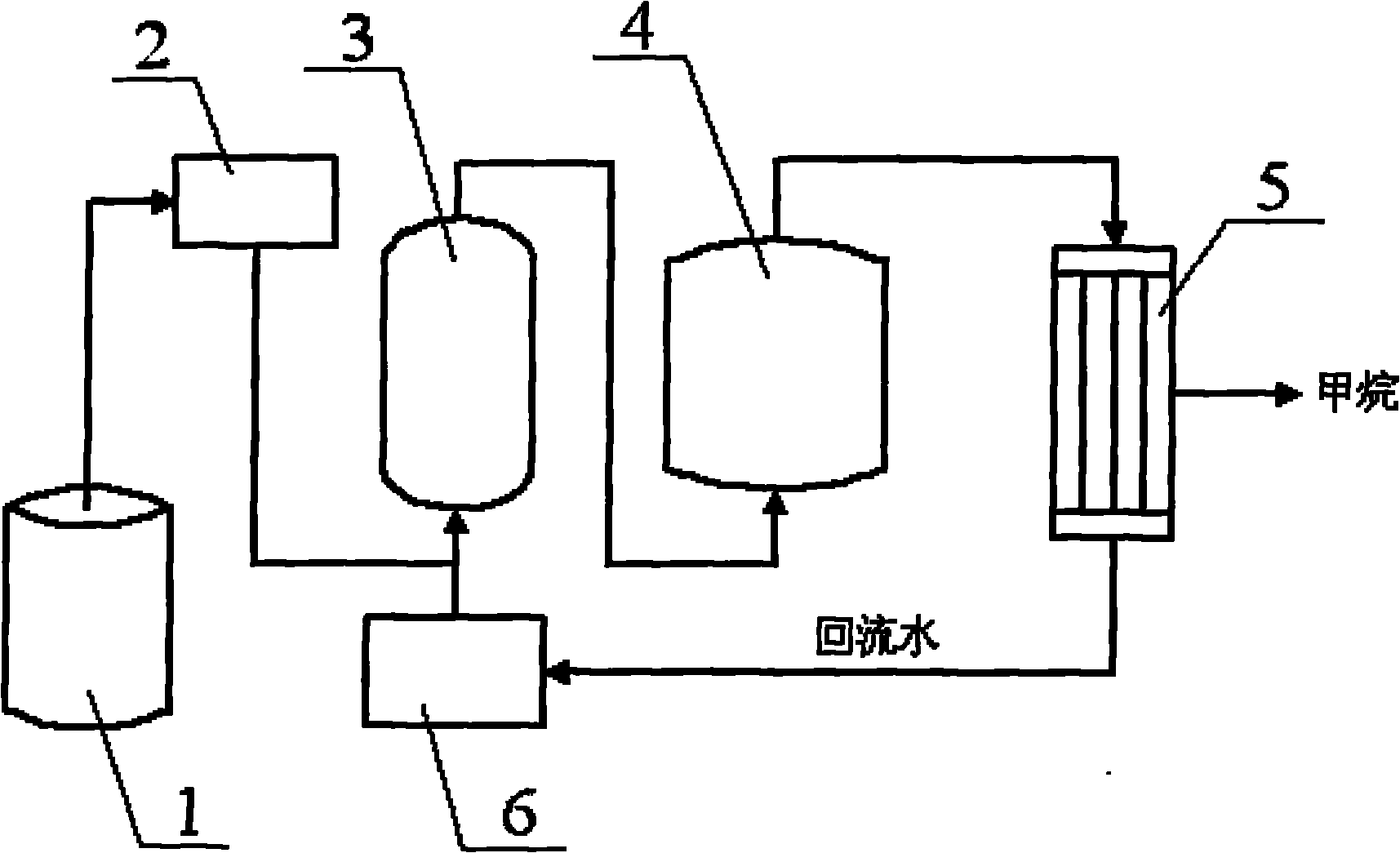

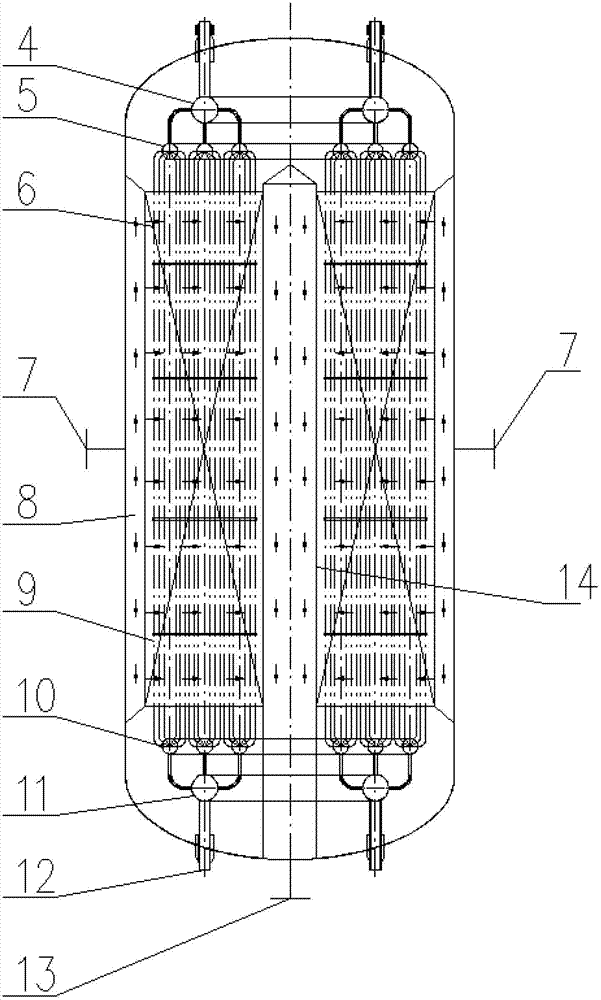

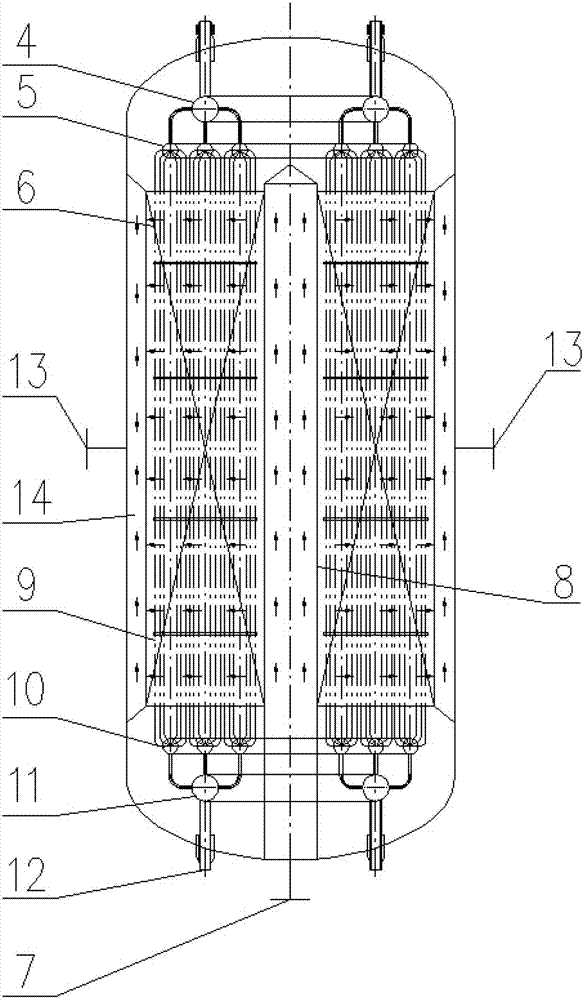

Methanation furnace for producing methane from coal synthesis gas and production method of methanation furnace

InactiveCN102814149ASimple internal structureHigh industrial application valueHydrocarbon from carbon oxidesGaseous fuelsSyngasMethanation

The invention relates to the technical field of chemical equipment, in particular to a methanation furnace for producing methane from coal synthesis gas and a production method of the methanation furnace. The method is characterized in that the synthesis gas passes through catalyst beds in the radial direction after entering gas distributors from synthesis gas inlets on the side wall of the methanation furnace to be distributed; methane gas synthetized by reaction flows out from a methane gas outlet at the lower part of the methanation furnace after being collected by a central tube of a central gas collector; longitudinal tube nests are arranged in each catalyst bed; and boiler water enters from water inlets at the lower part, enters the longitudinal tube nests through lower water collecting looping pipes and flows out from upper water collecting looping pipes after absorption reaction heat is vaporized. According to the methanation furnace for producing the methane from the coal synthesis gas, the flowing direction of the synthesis gas flowing through the catalyst beds is changed, so that the catalytic reaction is more completely performed; secondly, the tube nest intensively arranged pass through the horizontal catalyst beds arranged at equal interval, so that a cooling effect is obvious, and the reaction temperature can be easily controlled; and the gas collector is also arranged to collect the methane gas in the manner of unification. The methanation furnace for producing the methane from the coal synthesis gas is higher in industrial application value.

Owner:SHANGHAI MENFLOWTECH CHEM ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com