Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238results about How to "Viscosity is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

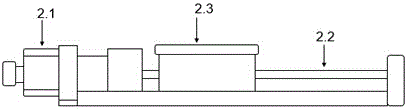

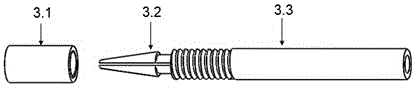

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Method for preparing high boiling silicone oil by using organic silicon high boiling substances

The invention relates to a method for preparing high boiling silicone oil by using organic silicon high boiling substances, comprising hydrolyzation of alcohol and neutralization, wherein the organic silicon high boiling substances are hydrolyzed in the mixed liquid of alcohol and water and refluxed for 1-4 hours; nitrogen purging is carried out on the reactant, and then the reactant is added with hydrogen chloride dissolved in urea, zinc oxide and ammonium bicarbonate and in the system thereof. The invention integrally uses the organic silicon high boiling substances and lowers the chlorine content in silicon oil products, ensures the molecular weight and viscosity to be controllable and mass to be more stable; the usage of the neutralizing agent and latent solvent is reduced greatly, thus reducing the production cost; the process is simple and the industrial production is easy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

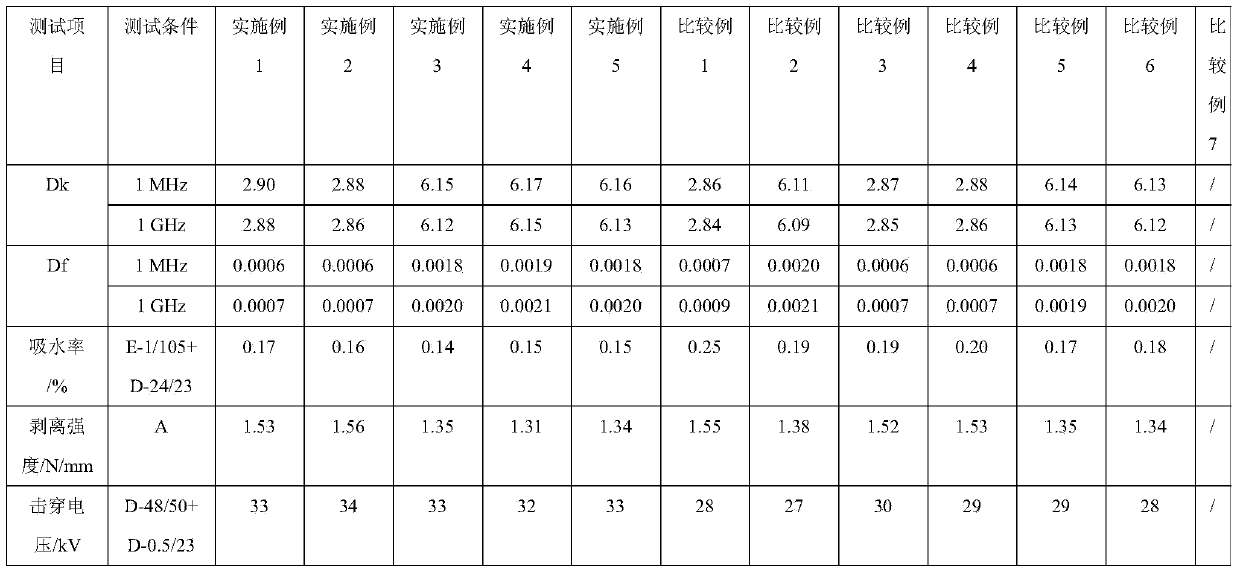

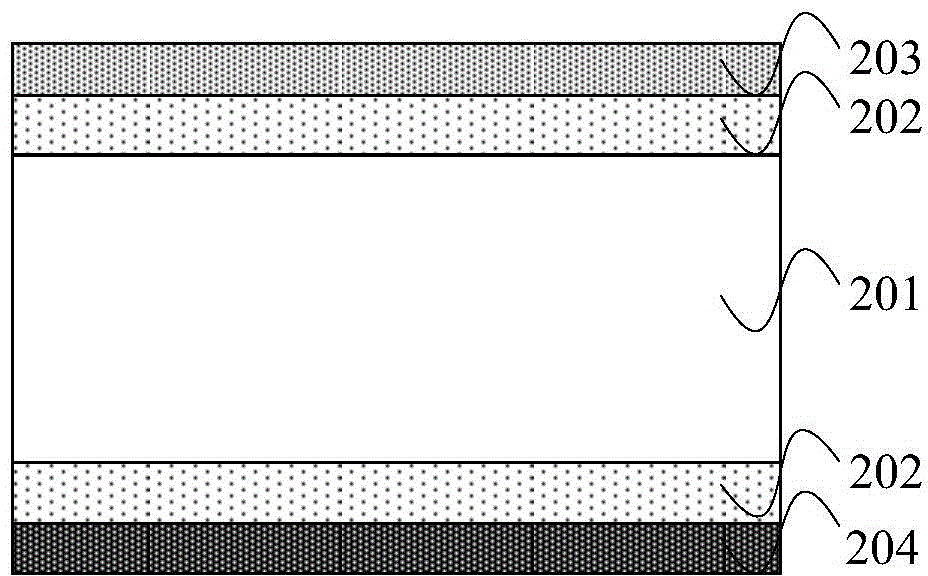

Preparation method of polytetrafluoroethylene (PTFE) composite dielectric substrate

ActiveCN104175686AViscosity is easy to controlEasy to coat and moldSynthetic resin layered productsLaminationEmulsionMicrowave

The invention relates to the field of a high-frequency copper-clad plate of a polytetrafluoroethylene (PTFE) dielectric substrate, and in particular relates to a preparation method of a polytetrafluoroethylene (PTFE) composite dielectric substrate used for a microwave circuit. The method comprises the steps of firstly, mixing fluororesin emulsion, inorganic filler and a thickening agent to prepare stable and uniform dispersion liquid; after that, enabling a release type base material to be coated with the dispersion liquid, and then baking; after baking, carrying out release type separation on a resin layer and the base material; cutting and overlapping the separated resin layer according to the thickness and the size of the substrate; covering the two sides of the resin layer with copper foils, and carrying out high-temperature lamination sintering to obtain the PTFE composite dielectric substrate covered by the copper foils at the double sides. After the preparation method is used, the formation of a hole in the composite dielectric substrate and the residue of an organic auxiliary agent are effectively reduced; the preparation method has the advantages of being simple and convenient in technology, beneficial to large scale production, etc.

Owner:GUANGDONG SHENGYI SCI TECH

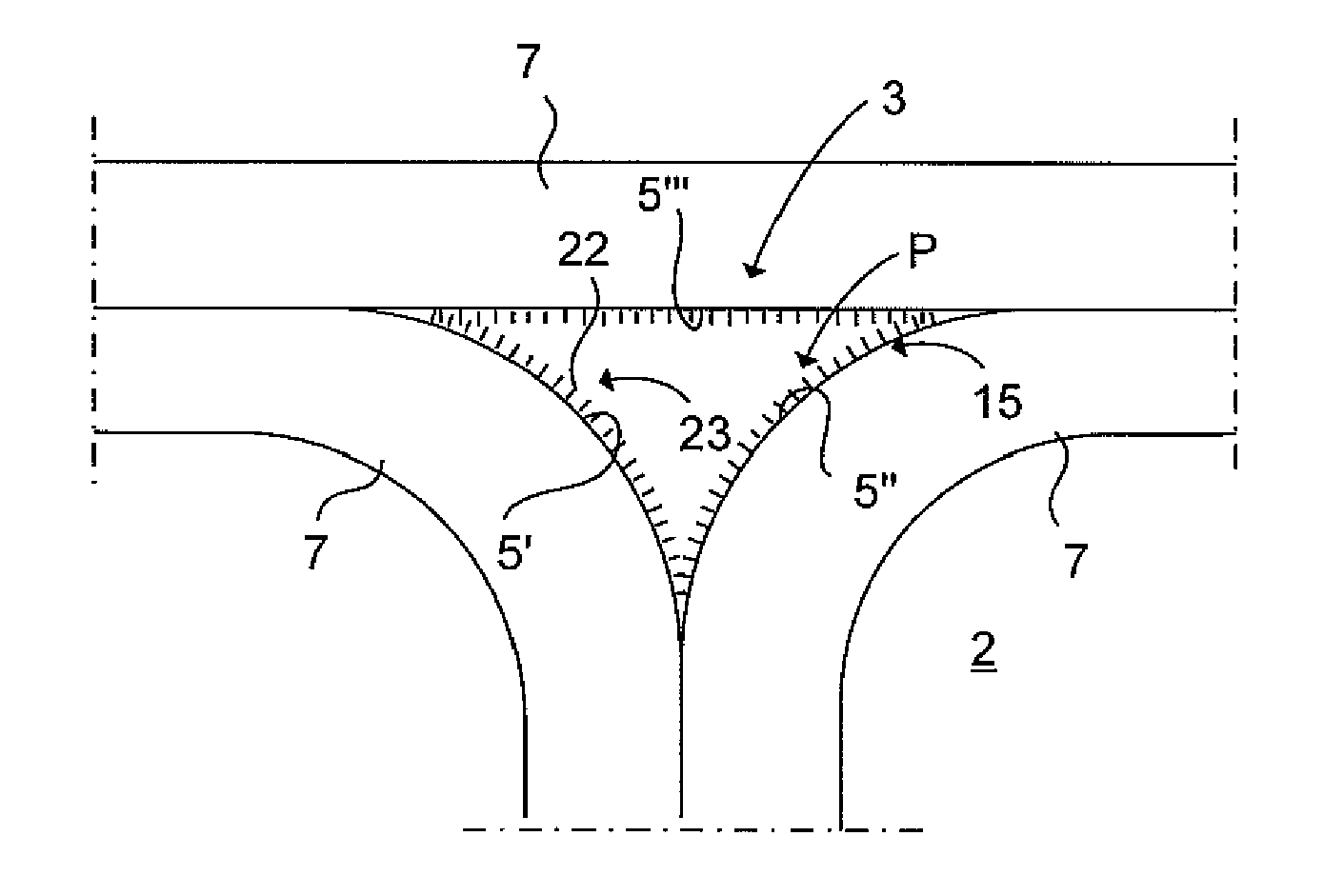

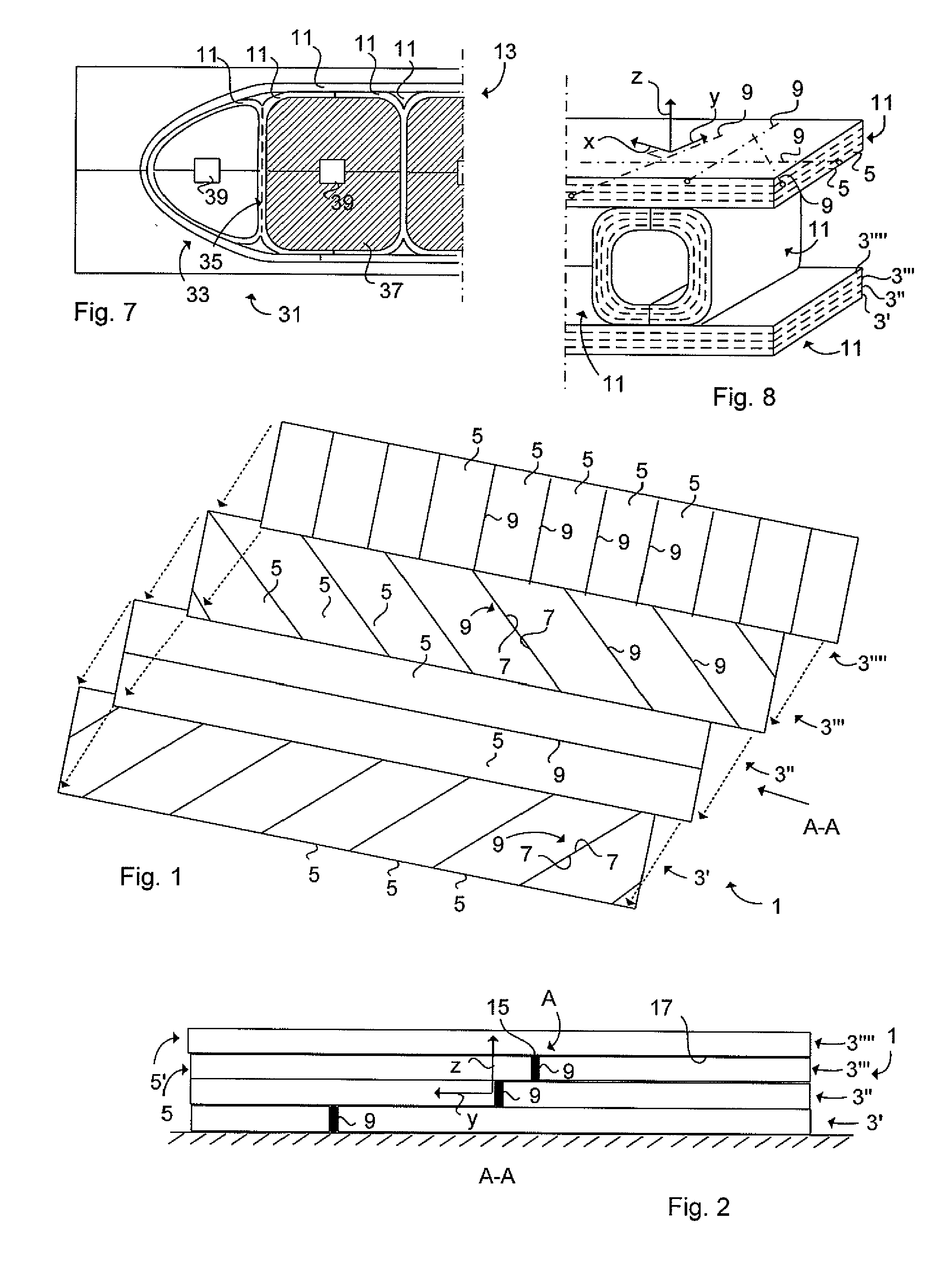

Nano-reinforced radius filler for an aircraft structure and a method of producing an aircraft structure comprising such filler

InactiveUS20120074265A1Easy to handleCost effective productionFuselage framesMaterial nanotechnologyNanostructureMaterials science

A composite radius filler for use in an aircraft structure. The aircraft structure includes structural composite parts assembled together to form the aircraft structure. The composite radius filler is arranged between rounded sections of the structural composite parts for filling a gap formed between the structural composite parts. The composite radius filler is made structural by a nanostructure arranged within the composite radius filler for the reinforcement of the interface between the radius filler and the structural composite part. A method for producing an aircraft structure including a nano-reinforced radius filler.

Owner:SAAB AB

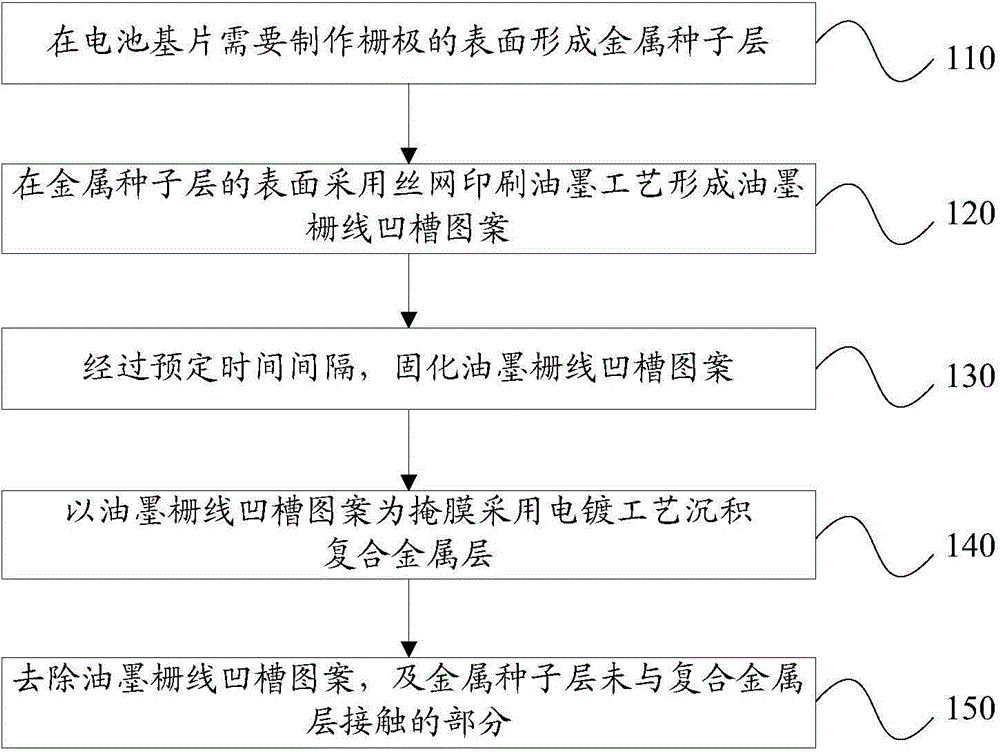

Silicon heterojunction solar cell with electroplating electrode and manufacturing method thereof

InactiveCN104538495AGood removal effectUniform expansion deformationPhotovoltaic energy generationSemiconductor devicesScreen printingManufacturing technology

The embodiment of the invention discloses a silicon heterojunction solar cell with an electroplating electrode and a manufacturing method thereof. The method comprises the steps that a metal seed layer is formed on the surface, where a grid needs to be manufactured, of a cell substrate; a silk-screen printing ink process is used for forming an ink grid line groove pattern on the surface of the metal seed layer; after a preset time interval, the ink grid line groove pattern is cured; the ink grid line groove pattern is used as a mask film, an electroplating process is used for depositing a composite metal layer; the ink grid line groove pattern and the part, which is not in contact with the composite metal layer, of the metal seed layer is removed. The implementation mode for forming the ink grid line groove pattern by the silk-screen printing ink process is simple and controllable, moreover, ink can be removed easily, and the manufacturing technology is simple. In the curing process, the ink can be evenly expanded and deformed, the width of an opening of the obtained ink grid line groove pattern is small, the depth-width ratio of a formed metal grid line is large, the light shading area is small, and the efficiency of the silicon heterojunction solar cell with the electroplating electrode is improved.

Owner:ENN SOLAR ENERGY

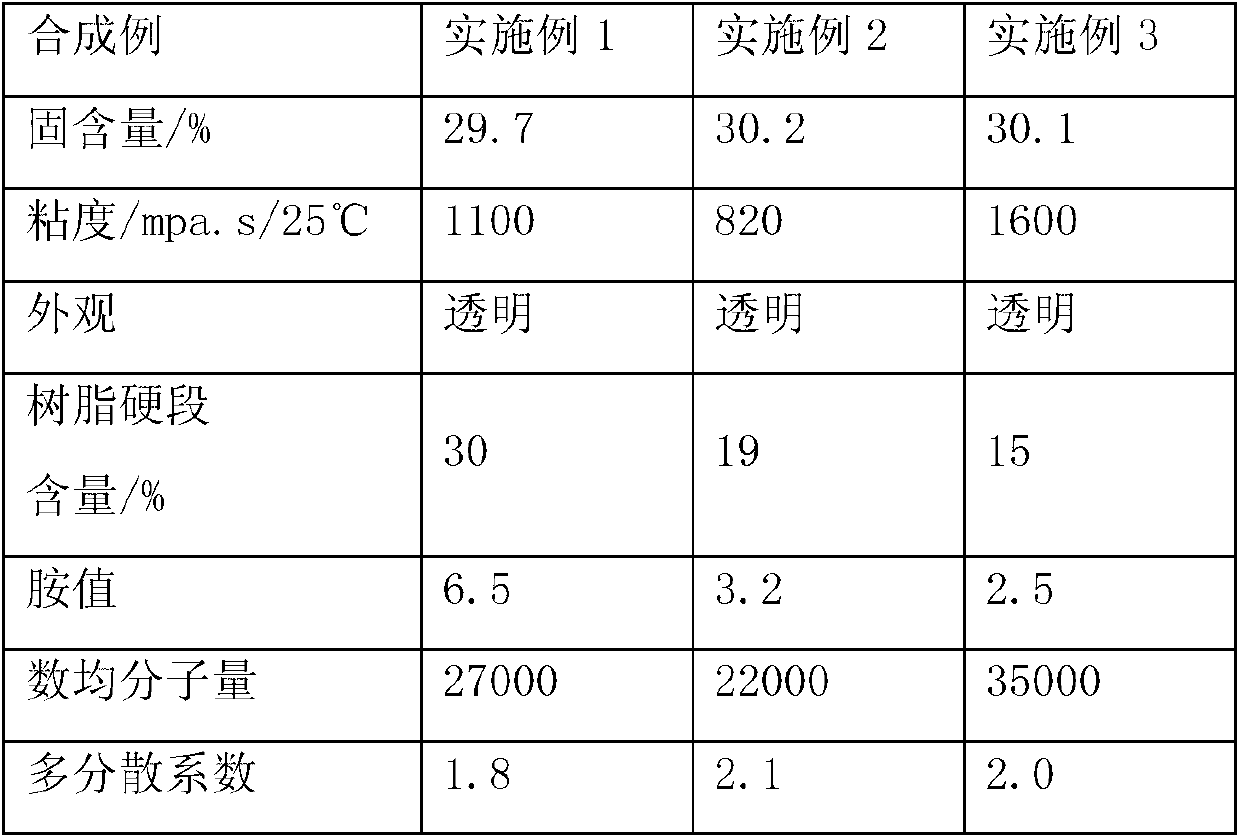

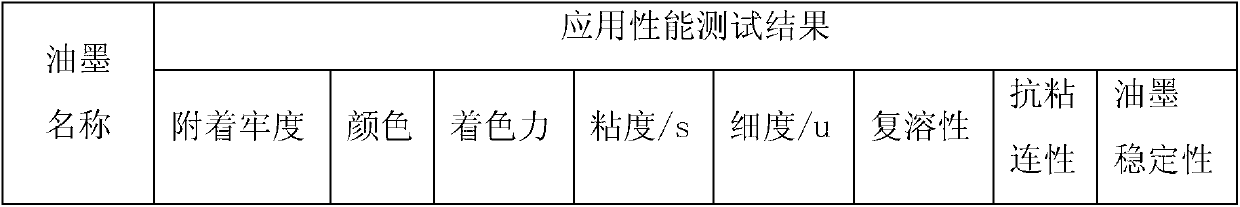

Preparation method of polyurethane resin for gravure composite ink

ActiveCN103012724AMild responseThe chain extension process is stable and controllableInksEnd-groupPolyethylene glycol

The invention discloses a preparation method of polyurethane resin for gravure composite ink, wherein the polyurethane resin is alcohol ester-soluble polyurethane resin not containing free cyanate ester radicals. Large amounts of allophanate radicals are introduced into the resin so that the ink prepared from the resin has excellent adhesion fastness to substrates such as PET (Polyethylene Glycol Terephthalate), NY (Nylon) and PP (Polypropylene) and the like. The preparation method is characterized in that diisocyanate is reacted with high-molecular polyol to generate NCO-terminated prepolymers, and then the prepolymers are added into a solvent containing an amine chain extender to achieve the polyurethane resin for the ink. The soft and hard segment of the resin has the advantages of wide adjustable range, large cohesive energy, good anti-aftertack property and good heat resistance; and the prepared ink has high binding strength to various printing substrates and has high composite strength. The preparation method provided by the invention has obvious characteristics of stable reaction in the synthesis process of the resin, easiness in control of the preparation process, narrow distribution of the molecular weight and good dissolubility of the resin.

Owner:NANTONG GAOMENG NEW MATERIAL

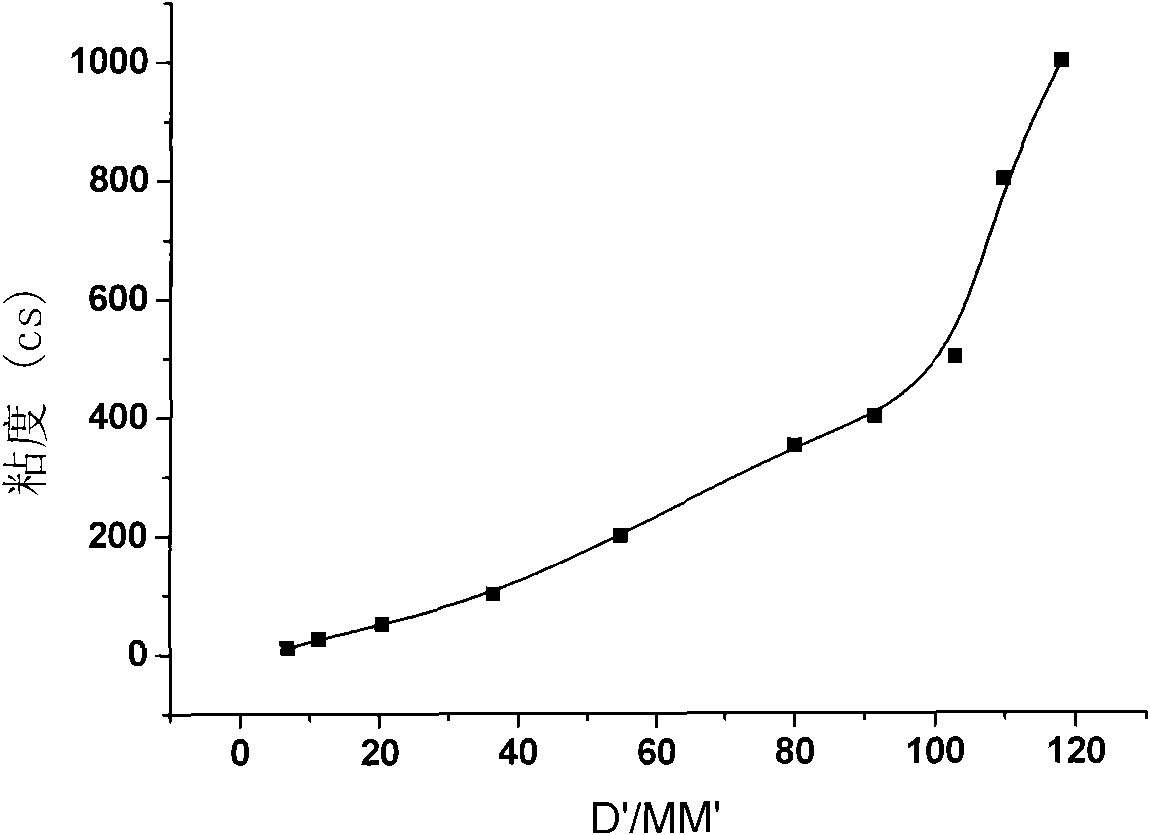

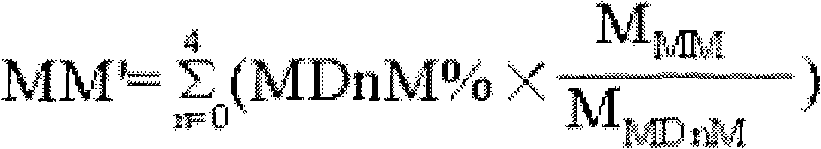

Method for preparation of silicon oil by silicon oil byproduct

The invention relates to a method for the preparation of silicon oil by silicon oil byproduct, in which dimethyl silicon oil byproduct in acid method production is used as raw material to prepare low-viscosity dimethyl silicone coil under the catalysis of solid acid catalyst. The method comprises the steps: calculating the constitution of raw materials in the silicon oil byproduct and drawing a proportion-viscosity relationship curve of the raw materials to set a feeding ratio, controlling reaction temperature between 50 and 110 DEG C under the catalyst of 3%-15% of solid catalyst, and implementing telomerization for 2 to 6 hours. By reutilizing the silicon oil byproduct, the method solves the problem of warehouse occupation of the silicon oil byproduct and lowers production cost. Using the solid acid catalyst can directly prepare neutral equilibration reaction product without neutralization and water washing procedures, the reaction process is simple, the viscosity of the product is easy to control and the regenerated byproduct can still be used repeatedly.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

High-performance viscosity-controllable silicon-based heat conducting paste and preparation method thereof

InactiveCN102382631AEasy to manufactureImprove stabilityHeat-exchange elementsHeat conductingDesign control

The invention provides a high-performance silicon-based heat conducting paste, which comprises, by weight, 5%-20% of substrate, more than 1%-10% of viscosity modifier and the balance being heat conducting filler. By means of adding viscosity modifier, the designed controlling requirements on viscosity of heat conducting paste can be met, stability of the powdered heat conducting filler in a heat conducting paste system is improved, and the obtained heat conducting paste is excellent in performance.

Owner:TIANJIN LAIRD TECH LTD

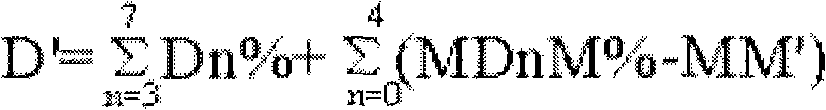

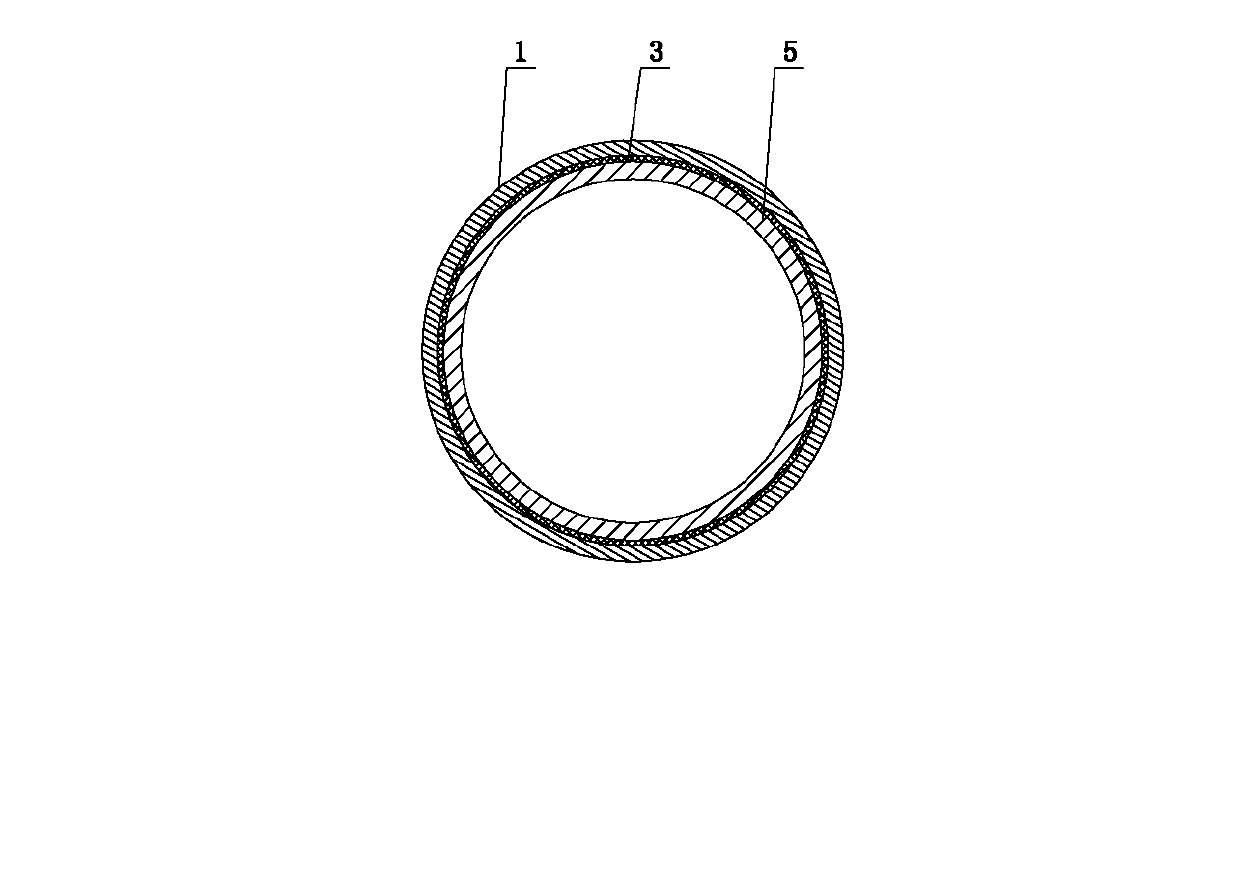

Novel high-strength HDPE (High-Density Polyethylene) composite tube and production method thereof

ActiveCN102996913AExtended service lifeInhibition of oxidative degradationRigid pipesCorrosion resistantOxidative degradation

The invention discloses a novel high-strength HDPE (High-Density Polyethylene) composite tube, which is obtained by composting an HDPE core tube, and a modified PE (Poly Ethylene) layer, wherein the innermost layer is the HDPE core tube which is enwrapped by a PE bonding layer, and the modified PE layer enwraps the PE bonding layer. The composite tube disclosed by the invention has the characteristics of good shock resistance, high compression strength, high wear resistance and the like. The HDPE core tube is corrosion resistant so that the composite tube is long in service life and capable of resisting the invasion by various corrosive media, such as an acid, an alkali and a salt, the modified PE layer is adopted so that plastic oxidative degradation is inhibited, tube ultra-violet resistance performance is improved, and tube service life is prolonged, and the PE bonding layer adopts a thermoplastic elastic body so that material performance is greatly improved, bonding capacity between the core tube and the modified PE layer is improved, and service life can reach 60 years.

Owner:HUBEI HUIFENG PLASTIC PIPE

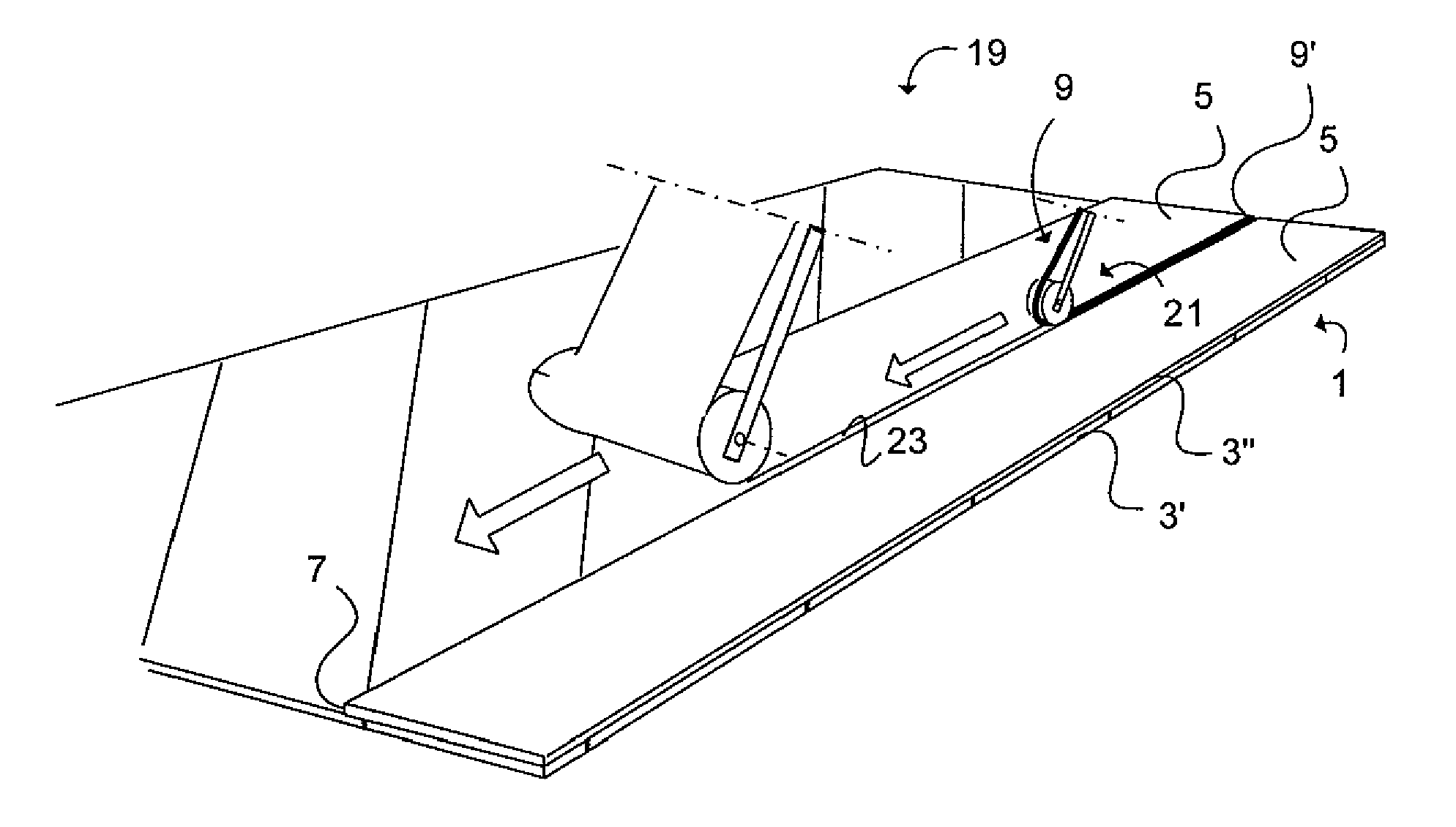

Structural longitudinal composite joint for aircraft structure

InactiveUS20120088056A1Reduced thermal linear expansionEasy to handleMaterial nanotechnologyLayered productsFiberNanostructure

A structural composite part made of pre-impregnated fiber plies. The edges of two adjacent fiber plies are connected via a longitudinal composite joint made structural by a nanostructure arranged within the composite joint. A method of producing a structural composite part made of pre-impregnated fiber plies. The edges of two adjacent fiber plies are connected via a longitudinal composite joint made structural by a nanostructure and an aircraft structure comprising such structural composite parts.

Owner:SAAB AB

Preparation of rosen modified mixed alkyl phenolic resin

The present invention belongs to the field of resin preparation technology that is a kind of connecting material to printing ink. It is obtained with processed by the following steps: arbitrarily mixing p-methyl hydroxybenzene, p-tert-butylphenol, p-tex-octylphenol and p-nonylphenol, making them produce reaction with formaldehyde to synthesize A-stage mixed alkyl phenolic resin, then using rosin to make modification and using polyhydric alcohol to make esterification. Said invention is easy to operate, safe, and its resin oil-solubility and fatty hydrocarbon solubility are good. Its colour islight and softening point is high. The printing ink made up by using said invented product does not skin, and possesses good printing property.

Owner:山西省应用化学研究所

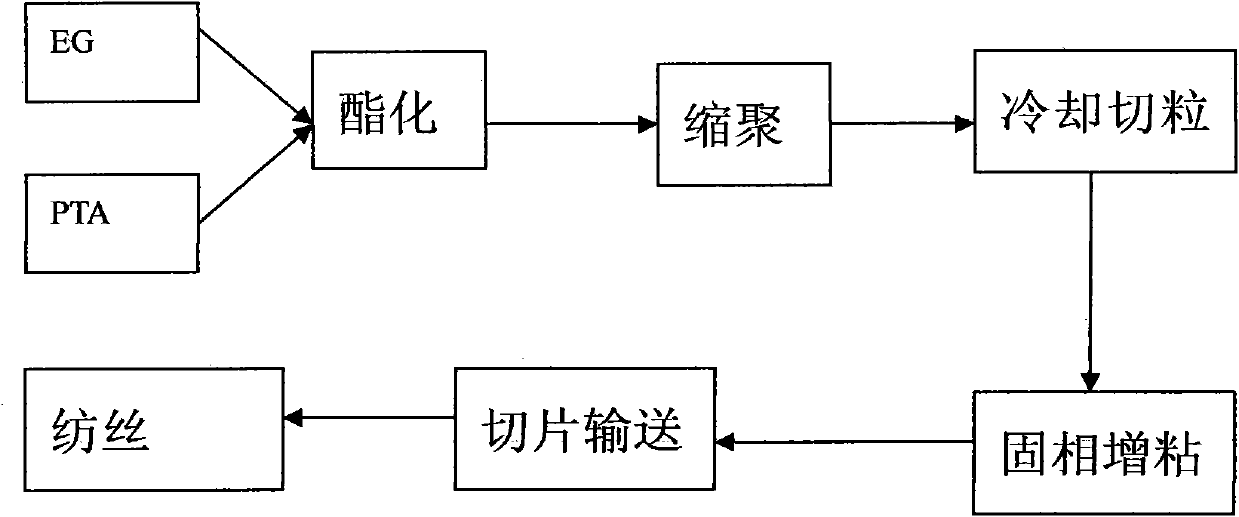

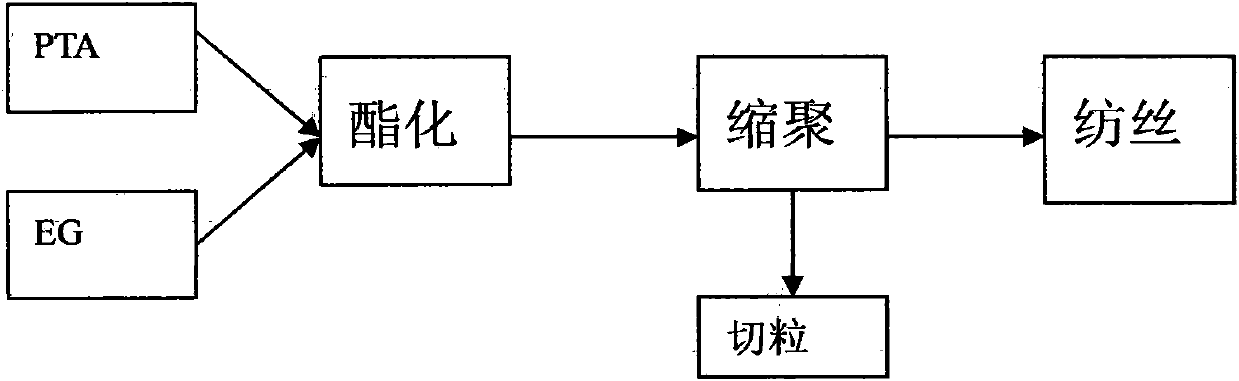

Production process for directly-spun terylene industrial filament of liquid-phase tackifying fusant

ActiveCN101768788AEasy to degradeReduce manufacturing costFilament forming substance formingMelt spinning methodsChemistryPolyester

The invention discloses a production process for a directly-spun terylene industrial filament of a liquid-phase tackifying fusant, belonging to the technical field of spinning. The production process includes the following steps: esterification, polycondensation, liquid-phase tackification and spinning. The production process is characterized in that: in a vertical reaction kettle, liquid-phase tackfication is carried out on the fusant obtained through esterification and polycondensation of glycol and phthalic acid; the vertical reaction kettle adopts a tower type film forming structure; the fusant enters the vertical reaction kettle from the top part for distribution, and the film forming is naturally finished under the action of gravity; a backflow pipeline is provided for the discharging of the reaction kettle, the viscosity and flow rate of the fusant are controlled by the backflow adjusting, the intrinsic viscosity of the polyester fusant after being tackified in a liquid-phase manner is within 0.85 to 1.0dl / g, and the fusant is conveyed to a spinning box body by a gear pump for spinning. By reasonably designing the reaction kettle and allocating the process, the invention effectively solves the consistency between the fusant reacting condition and the staying time; meanwhile, the consumption of a public medium is reduced, and the cost is lowered; by optimizing the process, the invention increases the production efficiency of a system and improves the product quality.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

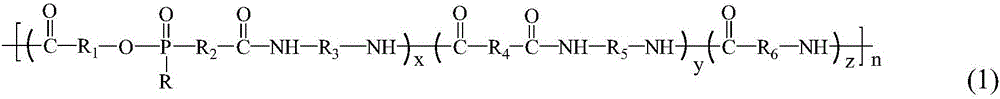

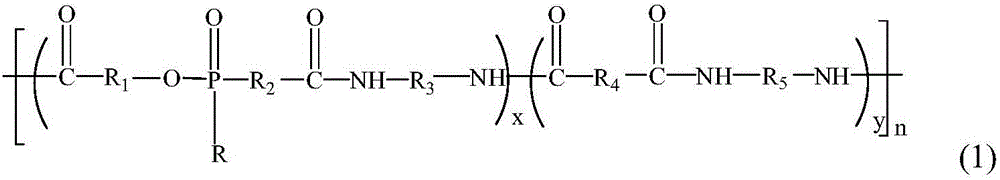

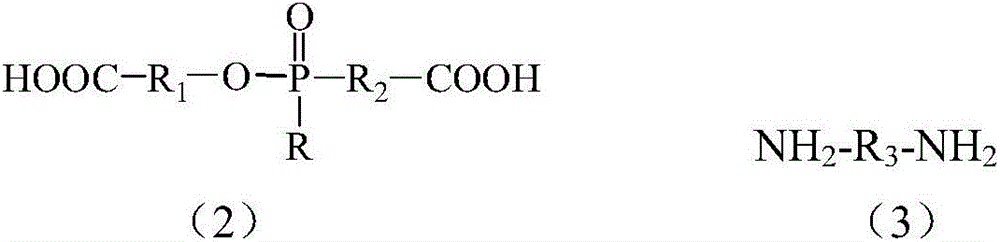

Organophosphorus copolymeric flame-retarded polyamide and preparation method thereof

InactiveCN106496548AViscosity is easy to controlSolve the problem of not being able to achieve a higher degree of aggregationDiamineIon

The invention discloses organophosphorus copolymeric flame-retarded polyamide and a preparation method thereof. The preparation method particularly comprises the following steps that 1 an organophosphorus flame-retarded monomer reacts with a diamine monomer, and salt is prepared; 2, diacid, diamine and / or binary amide salt, lactam, the salt prepared in the step 1, an antioxidant, a catalyst and deionized water are added into a reaction kettle, and the needed organophosphorus copolymeric flame-retarded polyamide material is prepared in situ in a nitrogen atmosphere by regulating and controlling the reaction temperature and pressure. According to the organophosphorus polyamide material prepared through the method, a little amount of reaction flame retardant is added, a synergistic flame retardant does not need to be added, the viscosity is controllable in the preparation process, and the obtained product is excellent in mechanical property and outstanding in flame retardance. Meanwhile, the preparation method has the advantages that the technology is environmentally friendly and simple, the cost is low, and operation is easy to learn.

Owner:CHENGDU TALY TECH CO LTD +1

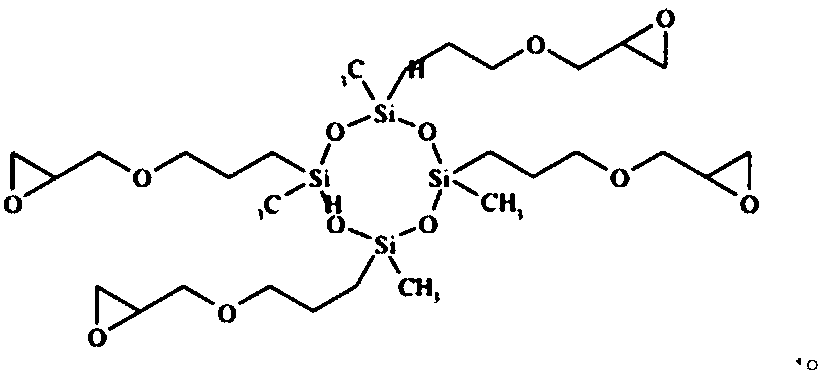

Nanometer single-component flexible epoxy compound for magnetic core adhesion, and preparation method thereof

ActiveCN107652933AViscosity is easy to controlReduce gapNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAccelerant

The invention discloses a nanometer single-component flexible epoxy compound for magnetic core adhesion. The nanometer single-component flexible epoxy compound for magnetic core adhesion comprises thefollowing components in parts by mass: 100 parts of epoxy resin, 4 to 30 parts of a curing agent, 4 to 20 parts of an accelerant, 0 to 5 parts of color paste, 3 to 60 parts of tetrafunctional organosilicon modified epoxy resin, 1 to 20 parts of nanometer rubber core-shell, 0.05 to 0.2 part of a defoaming agent, 0 to 0.2 part of a coupling agent, 0 to 0.2 part of a dispersing agent, 1 to 30 partsof a thixotropic agent and 10 to 300 parts of fillers. The invention also provides a preparation method of the single-component epoxy resin compound. The nanometer single-component flexible epoxy compound for magnetic core adhesion has the following advantages: the viscosity is low and the adding amount is small; the functionality degree is high, the adhesion can be improved and the linear expansion coefficient can be reduced; the brittleness of a Si-O bond in the curing process is lower than that of a C-C bond multifunctional diluent.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Ground substance and plaster of Chinese traditional medicine as well as its preparing method

InactiveCN1480129AOvercoming irritationLow allergy rateAerosol deliveryOintment deliveryMedicineIrritation

A matrix for Chinese-medicinal plaster is prepared from polyisobutylene, viscosity increaser, softening agent, filler, percutaneous absorption promoter, and solvent. Its advantages are low hypersensitivity and irritation to skin, and controllable viscosity. Its Chinese-medicinal plaster is prepared through proportionally mixing said matrix with the Chinese-medicinal extract.

Owner:桂林华润天和药业有限公司

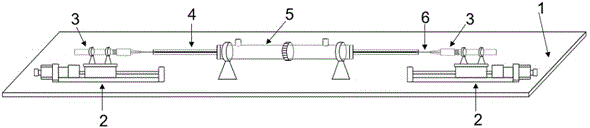

Atmosphere protection type chalcogenide glass optical fiber tapering device and use method

ActiveCN105731785APrevent surface oxidationGood temperature control effectGlass fibre drawing apparatusElectrical resistance and conductanceTemperature control

The invention discloses an atmosphere protection type chalcogenide glass optical fiber tapering device and a use method.The device comprises an optical platform, two electric displacement platforms, two optical fiber clamps, a seamed quartz tube and an atmosphere protection tube type resistance furnace.Firstly, the seamed quartz tube filled with a chalcogenide glass optical fiber penetrates through the atmosphere protection tube type resistance furnace and is clamped and fixed through a diaphragm; then the two ends of the optical fiber are fixed to the electric displacement platforms through the optical fiber clamps, inert gas is introduced into the furnace, the optical fiber is softened after being heated, and the electric displacement platforms are started for two-way traction tapering; finally ultraviolet curing glue is injected into the two ends of the seamed quartz tube for fixing the tapered optical fiber in situ.The device can taper the optical fiber under inert atmosphere protection, and oxidation of the surface of the optical fiber is effectively avoided; the temperature control effect on the periphery of the optical fiber is good, and the tapering success rate is high; in-situ fixing or packaging of the tapered optical fiber can be achieved; operation is simple, cost is low, and efficiency is high.

Owner:XUZHOU NORMAL UNIVERSITY

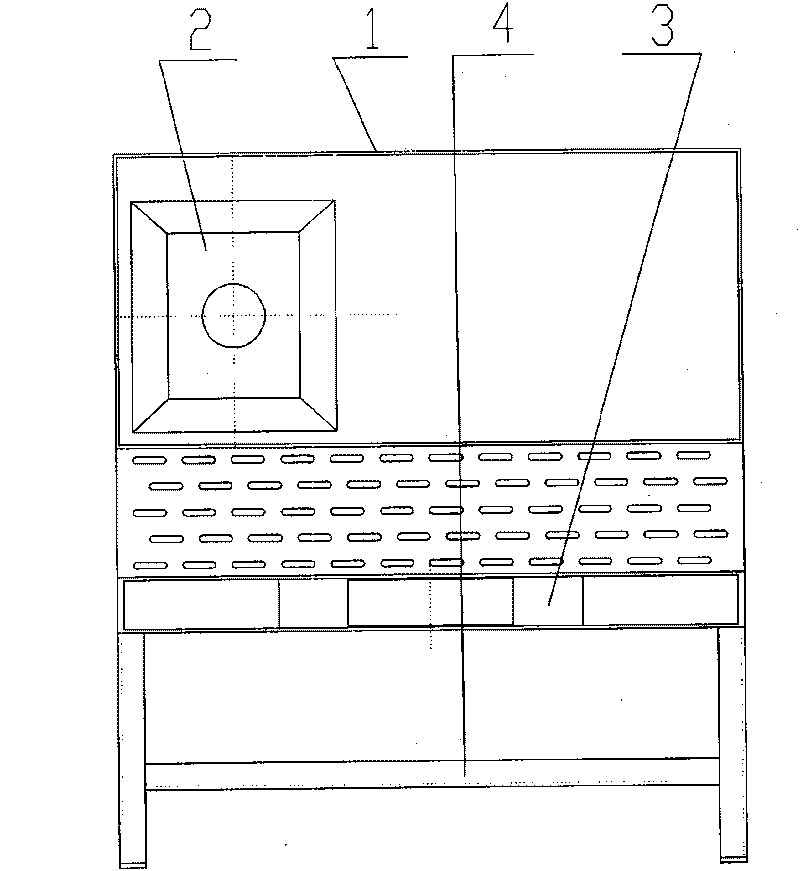

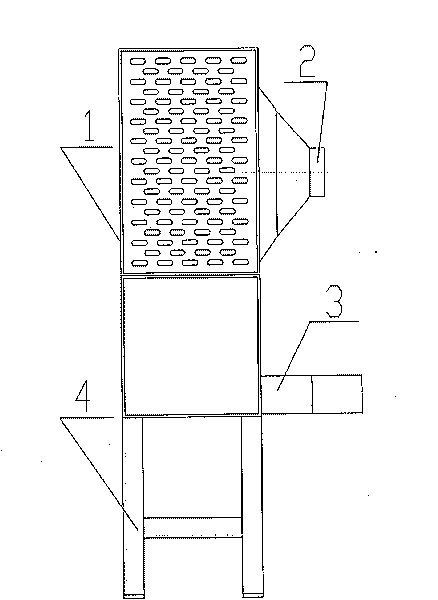

Equipment and method for continuously preparing high-purity AKD (Alkyl Ketene Dimer) without solvent

ActiveCN102962026AWell mixedViscosity is easy to controlRotary stirring mixersTransportation and packagingCylindrical channelReaction temperature

The invention provides equipment and method for continuously preparing high-purity AKD (Alkyl Ketene Dimer) without a solvent. The used equipment comprises a reactor for enabling raw materials to be continuously mixed and reacted. The main preparation process comprises the following steps of: at first, continuously adding tertiary amine at a reactor starting end, and continuously adding acyl chloride by dividing into three to ten paths; secondly, in a working state of the reactor, driving an inner cylinder to rotate relative to an outer cylinder by using a main motor, so that the added materials are forced to be transported and stirred by blades on transportation sections of an annular cylindrical channel, and are sufficiently cut and mixed on mixing sections through relative motion of a cutting sheet and a kneading sheet; and alternatively distributing the transportation sections and the mixing sections one by one in the axial direction of the annular cylindrical channel, so that the added materials sufficiently react, and a temperature of the materials can be controlled through an inner-outer heat exchange system until products are continuously discharged from a discharging opening. With the adoption of the equipment and the process of the invention, the reaction heat can be generated in a diffused manner, the materials can be sufficiently mixed, the entire reaction can be realized, a reaction temperature and a material viscosity are easy to control, the generation of side reaction can be reduced, and the high purity of the product can be ensured.

Owner:SUZHOU TIANMA SPECIALTY CHEM

High solidness low viscosity nano composite polyester resin and method of preparation

InactiveCN1635025AImprove performanceHigh silica concentrationPolyurea/polyurethane coatingsIn situ polymerizationCarboxylic acid

The invention relates to a high solidness low viscosity nano composite polyester resin and method of preparation, wherein silicon dioxide colloidal having a grain diameter of 10-150 with hydroxyl on the surface is mixed with polyhydric alcohols and dicarboxylic acids to synthesize nano silica dioxide composite polyester resin with a molecular weight of 1000-5000, hydroxyl value 80-200mgKOH / g, solid content greater than 95wt%, viscosity being 800-2000mPs.s through molten in-situ polymerization method, the content of the nano silicon dioxide is 1-15wt% of the nano silicon dioxide composite polyester resin.

Owner:FUDAN UNIV

In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

InactiveCN106497027ASolve the problem of not being able to achieve a higher degree of aggregationViscosity is easy to controlAntioxidantIn situ polymerization

The invention discloses in-situ polymerization type N-P synergistic flame-retardant nylon and a preparation method thereof. The preparation method provided by the invention particularly comprises the following steps: (A) carrying out a reaction between organic phosphorus flame-retardant monomers and diamine monomers to form salt; (B) emulsifying a nitrogen flame retardant and dispersing to obtain nitrogen flame retardant emulsion; (C) adding diacid and diamine or binary amide salt or a solution thereof, the prepared salt or a solution thereof, the nitrogen flame retardant emulsion, an antioxidant and a catalyst into a reaction kettle, and performing in-situ polymerization under the inert atmosphere by regulating and controlling reaction temperature and pressure intensity to prepare the required N-P synergistic flame-retardant nylon. The N-P synergistic flame-retardant nylon prepared by the method reduces the total amount of the required added flame retardant due to the synergistic effect. The viscosity can be controlled in the whole preparation process, a product with excellent mechanical property and flame retardance can be obtained, the vertical combustion test can reach UL-94 V-0 level, and the limit oxygen index is 28 percent or higher.

Owner:CHENGDU TALY TECH CO LTD +1

Water-based aluminium foil glue composition with high peel strength and controllable viscosity and preparation method

ActiveCN103849331AProcess production is clean and simpleNo three wastes pollutionEster polymer adhesivesUnsaturated alcohol polymer adhesivesWater basedFunctional monomer

The invention discloses a water-based aluminium foil glue composition with high peel strength and controllable viscosity and a preparation method. The water-based aluminium foil glue is formed by compounding water-based styrene-acrylic emulsion and dispersion liquid of polyvinyl alcohol. The peel strength can be as high as 12N / (25mm), and the viscosity (100-30000mpa.s) is controllable. The water-based aluminium foil glue comprises the following components: 15-25% of soft monomers, 10-20% of hard monomers, 1-5% of functional monomers, 0.2-0.8% of initiator, 1-4% of emulsifiers, 0.2-1% of PH buffer agent, 1-4% of PH agent, 50-80% of softened water and 5-30% of polyvinyl alcohol dispersion. The glue has strong blue light, excellent bonding capacity and controllable viscosity, is environment-friendly, is relatively low in cost, is easy to dry, has freezing resistance and does not contain plasticizers or harmful substances.

Owner:CHANGZHOU INST OF CHEM

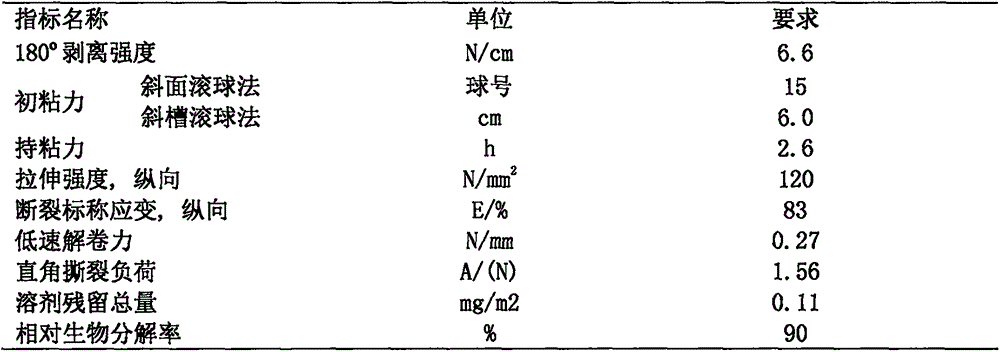

Biodegradable LA (lactide) oligomer bonding agent, and preparation method and purpose thereof

The invention relates to a biodegradable bonding agent material prepared from LA (lactide) chemical synthesis products. The LA materials are poured into a reaction container containing solvents according to the proportion of 5 to 50 percent of the mass of the solvents; a reactor has a stirring and control function; the reactor is controlled under the nitrogen gas protection condition; a certain reaction temperature is controlled; meanwhile, the stirring is performed; after the LA is completely fused, catalysts are added; after reacting for a period of time, stirring is stopped; after the materials are taken out, extraction and centrifugation are performed, so that the LA chemical synthesis products are obtained; then, the LA chemical synthesis products are dissolved by acetic ester, so that the biodegradable bonding agent is obtained. The bonding agent has the characteristics that the preparation is simple; the relative molecular weight and the viscosity are controllable; the biodegradable performance is realized. The biodegradable bonding agent material can be used in the fields of adhesive tapes, leather, sticking paper, stationery, office, electronics, automobile edge trimming fixation, shoe industry, handwork ornament pasting and fixation and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

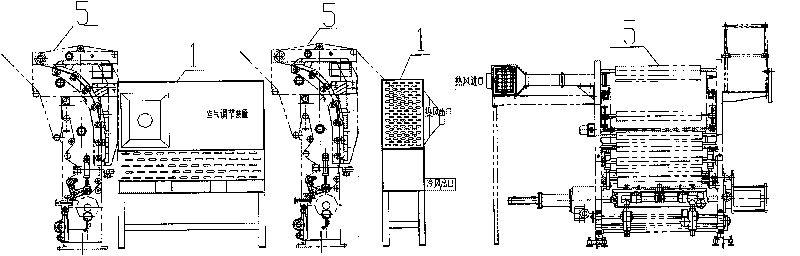

Efficient energy-saving environmental-friendly unit type photogravure press and energy-saving environmental-friendly method

InactiveCN101734002ASimple structureUse to achieveRotary intaglio printing pressPrinting press partsEnvironmental resistancePhotogravure

The invention relates to an efficient energy-saving environmental-friendly unit type photogravure press used for air temperature adjustment of the unit type photogravure press self as well as an energy-saving environmental-friendly method. The photogravure press comprises a unit type photogravure press, an air conditioning plant is arranged between units requiring constant temperature of the unit type photogravure press, a hot wind outlet arranged on the upper part of the air conditioning plant is communicated with an inlet of a drying box body in the unit type photogravure press, a cold wind outlet on the lower part is positioned below the unit in the unit type photogravure press. The invention has the advantages of high cost performance, can realize seamless butt joint with the traditional technology and saves electricity for 56% if compared with products with the same grade on the basis of satisfying the normal function of printing machinery and national environmental protection requirement and has obvious energy saving effect; the environmental impact assessment index is obviously lowered; the efficient energy-saving environmental-friendly unit type photogravure press can realize seamless butt joint with the technology and craft of the existing printing mechanical products under the condition that performance is greatly improved, and also can be used for energy saving modification of printing machinery with low energy efficiency ratio.

Owner:HANGZHOU YUEHUA PRINTING & PACKAGING MACHINERY

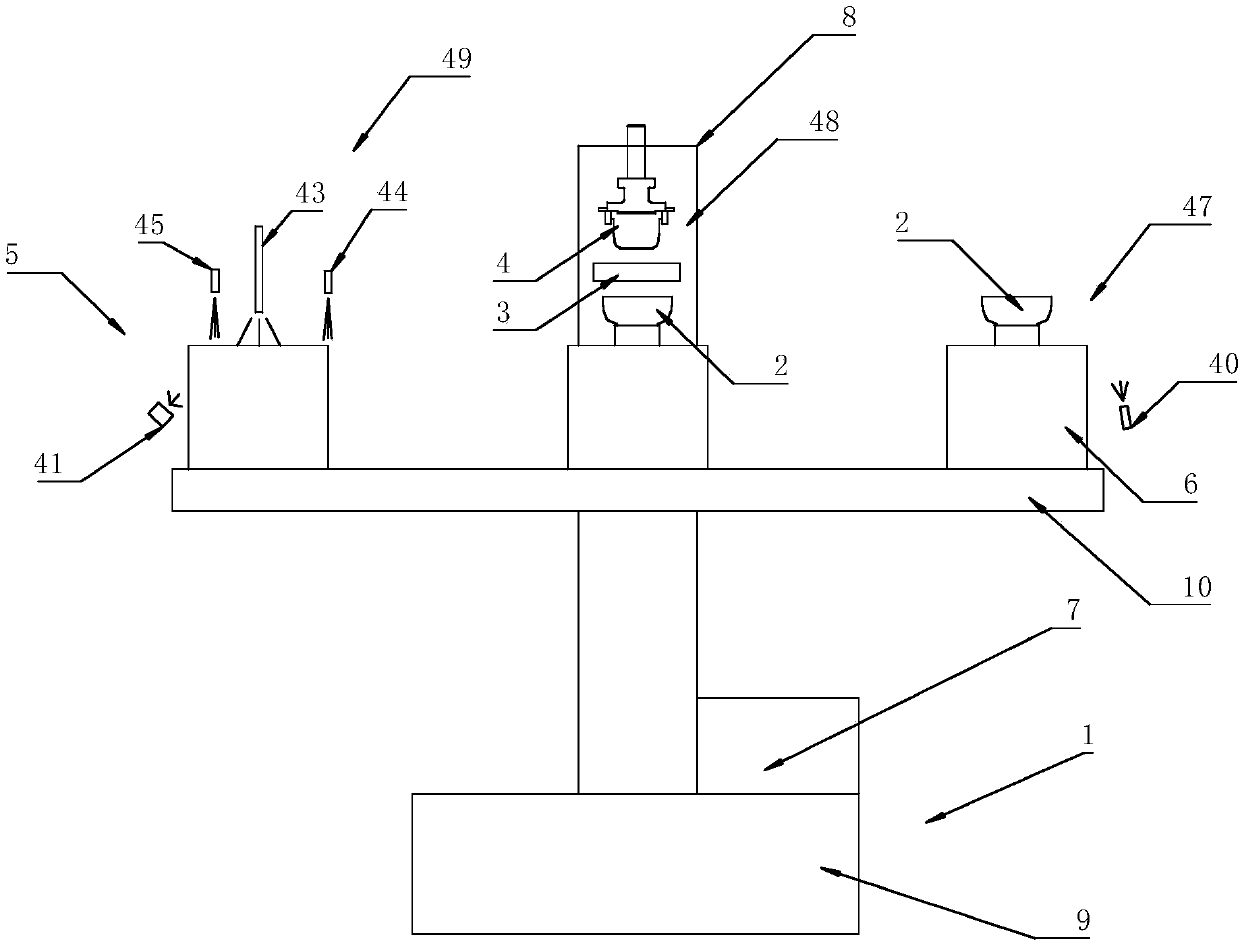

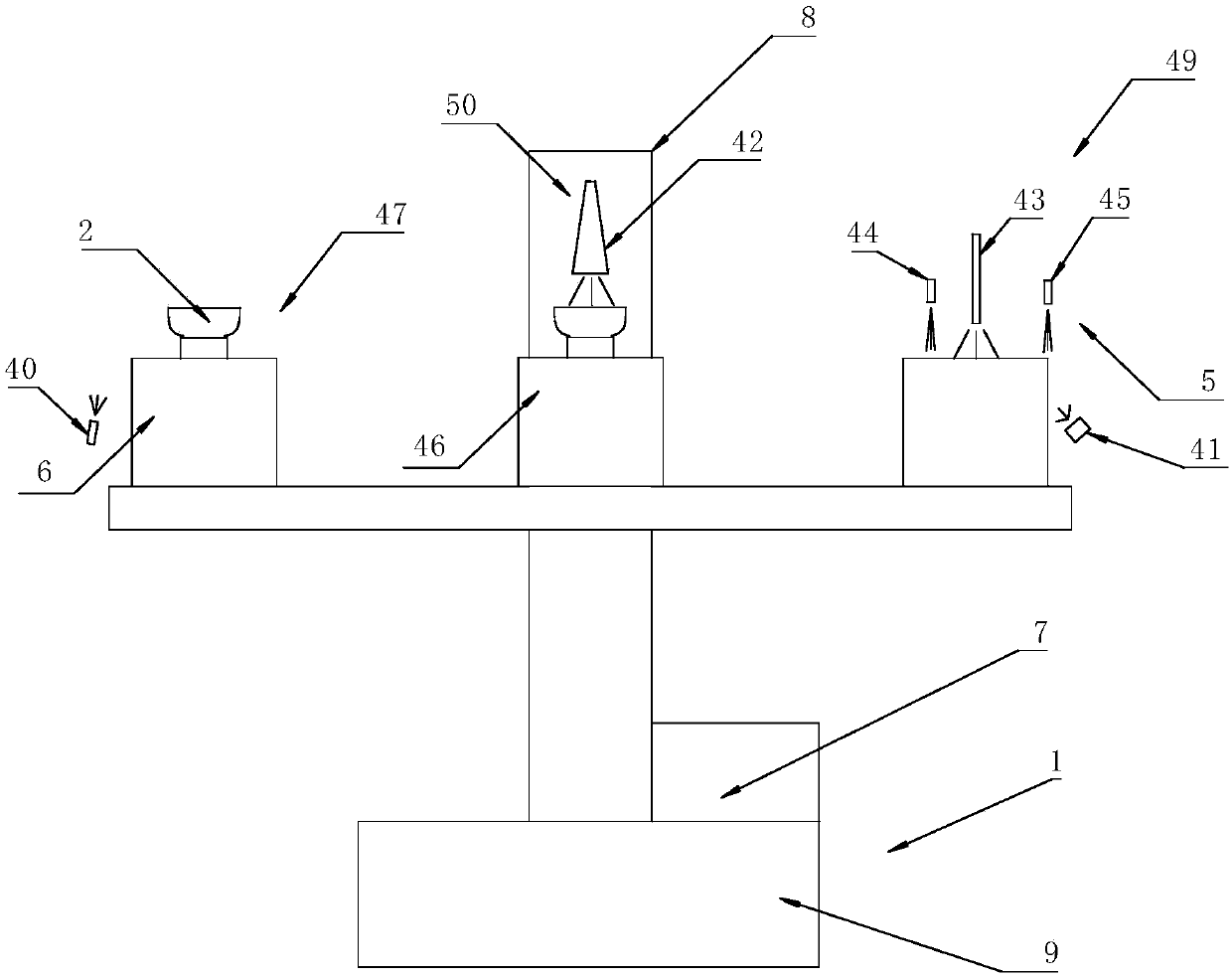

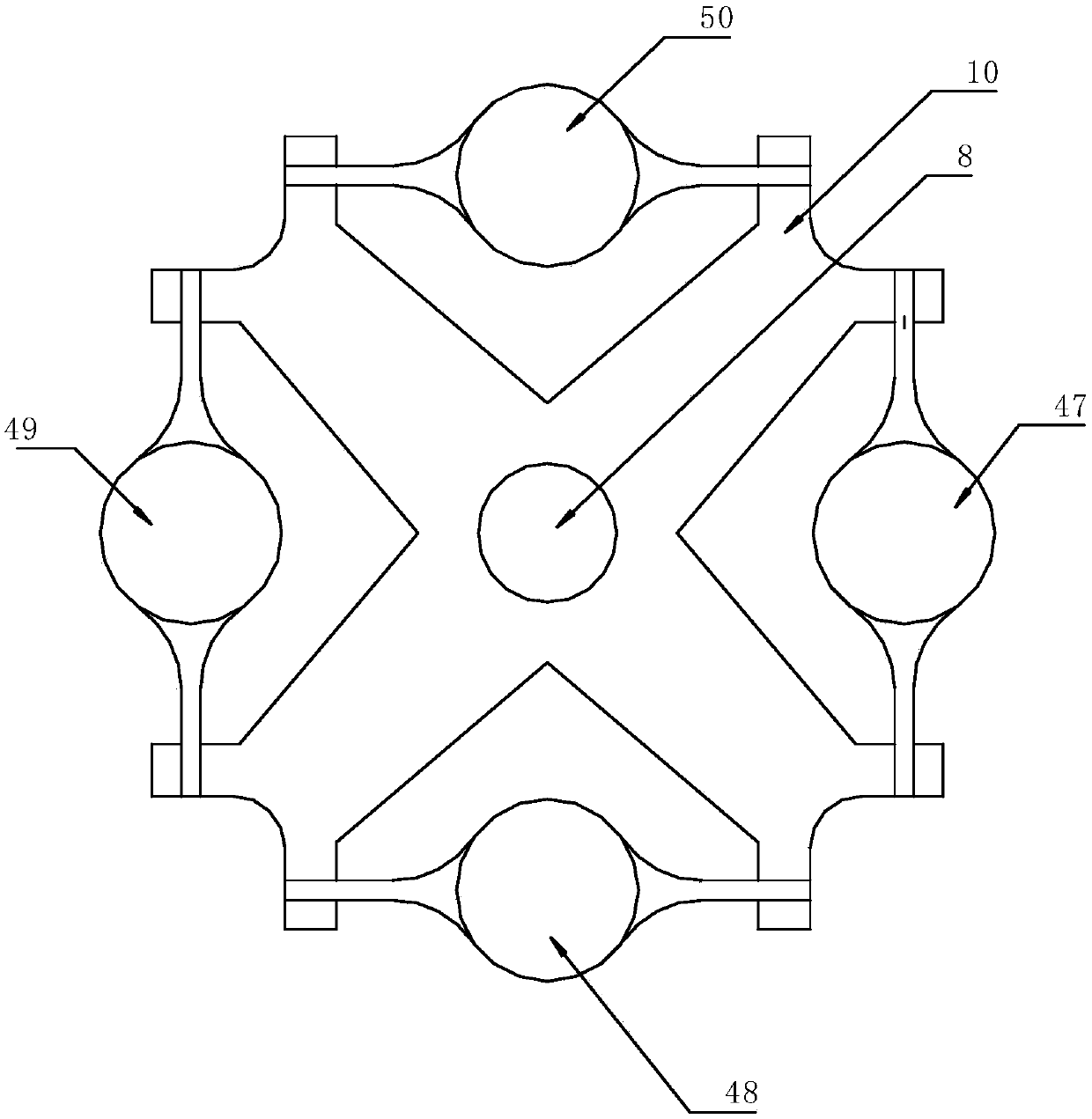

Glass profiling device and glass profiling method

ActiveCN107739145AStable processingImprove qualityGlass pressing apparatusGlass press-moulding apparatusMaterials science

The invention belongs to the technical field of glass profiling, particularly discloses a glass profiling device and a glass profiling method, and aims at solving the problem how to improve the continuity of linking of various procedures in the glass profiling process. The glass profiling device comprises a rotation mechanism, a lower die component, an upper die component, a receiving work station, a profiling work station, a cooling work station and a removing work station; the rotation mechanism comprises a rotation large disc and a turntable drive device; the lower die component is arrangedon the upper surface of the rotation large disc and can rotate to the receiving work station, the profiling work station, the cooling work station and the removing work station respectively along with the rotation large disc; the upper die component is arranged at the profiling work station and on the upper side of the lower die component. The glass profiling method adopts the glass profiling device to profile glasses. The lower die component enters various work stations respectively under the driven of the rotation mechanism to sequentially finish various procedures required for glass profiling, so that the continuity of linking of various procedures is better, and improvement on the quality and the yield of a glass product is facilitated.

Owner:CDGM OPTICAL GLASS

Soybean-based protein adhesive and preparation method thereof

ActiveCN108570305AHigh solid contentViscosity is easy to controlNon-macromolecular adhesive additivesProtein adhesivesAdhesiveMedium density

The invention discloses a soybean-based protein adhesive and a preparation method thereof. The invention first discloses the soybean-based protein adhesive which is prepared from the following raw materials in parts by weight: 50 to 100 parts of soybean meal, 5 to 15 parts of alkali, 5 to 30 parts of urea, 20 to 100 parts of cross-linking agent and 50 to 300 parts of water. The invention further discloses the preparation method for the soybean-based protein adhesive. Since defatted soybean meal sold in the market is adopted as the main raw material of the soybean-based protein adhesive disclosed by the invention, the cost is far lower than the cost of soybean protein isolate. Because the content of soybean-based protein solid in the soybean-based protein adhesive is high, reaching 40 to 55percent, the energy consumption of drying in the process of artificial board production can be reduced, and cost can be reduced. Moreover, the viscosity of the soybean-based protein adhesive disclosed by the invention is controllable, the bonding strength is high, and the soybean-based protein adhesive can be used in the production of artificial boards, such as plywoods, shaving boards, medium density fiberboards and blockboards.

Owner:北京盛大华源科技有限公司

In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

InactiveCN106433103ASolve the problem of not being able to achieve a higher degree of aggregationViscosity is easy to controlIn situ polymerizationAntioxidant

The invention discloses an in-situ polymerization type N-P synergistic flame-retardant nylon and a preparation method thereof. The preparation method comprises the following steps: (1) reacting an organophosphorus flame-retardant monomer with a diamine monomer to form salt; (2) emulsifying and dispersing a nitrogen flame retardant, so as to obtain a nitrogen flame retardant emulsion; and (3) adding a lactam monomer, the salt prepared in the step (1), an antioxidant, the nitrogen flame retardant, a catalyst and a molecular weight adjusting agent into a reaction kettle, and performing in-situ polymerization by regulating reaction temperature and pressure under inert atmosphere, so as to obtain the needed N-P synergistic flame-retardant nylon material. According to the prepared in-situ polymerization type flame-retardant nylon, the content of the flame retardant needing to be added is reduced due to the synergistic effect, the viscosity during the whole preparation process is controllable, the product with both excellent mechanical performance and flame-retardant performance can be obtained, the vertical burning test can achieve the UL94 V-0 grade, and the limiting oxygen index is more than 28%.

Owner:CHENGDU TALY TECH CO LTD +1

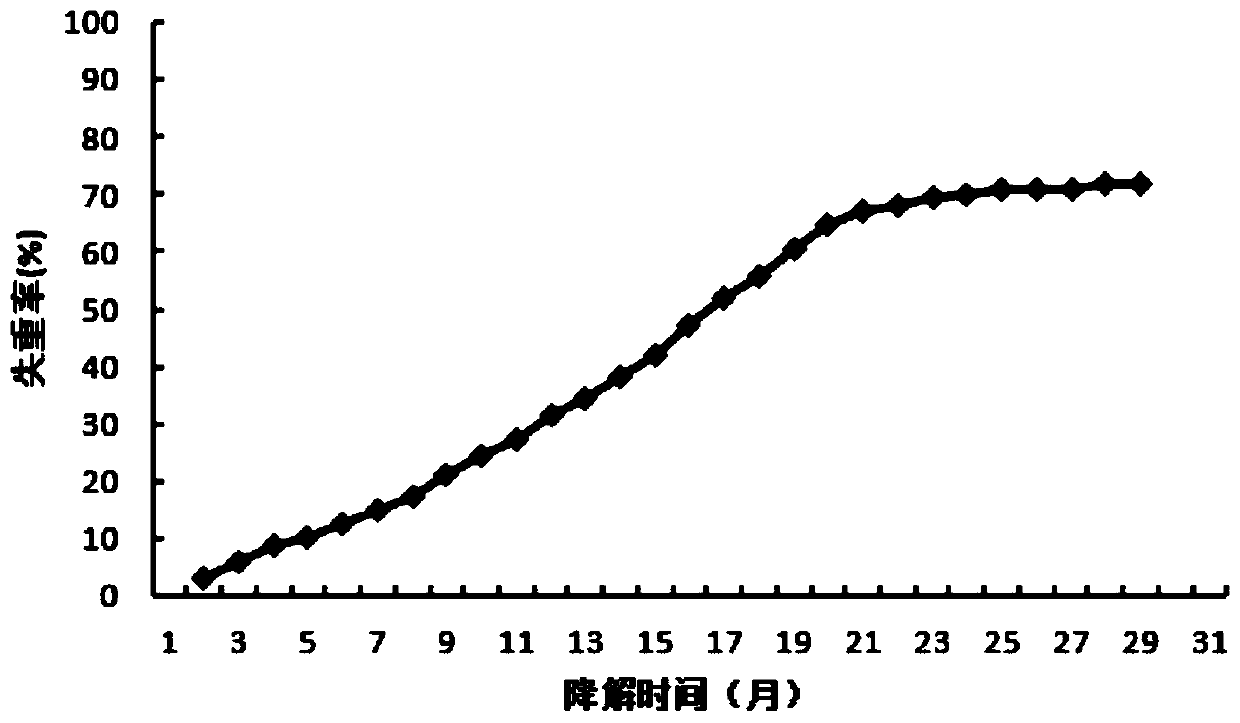

Photocurable polyester oligomer for 3D printing as well as preparation method and application thereof

PendingCN111171300AHigh purityGood mechanical properties and biocompatibilityAdditive manufacturing apparatusSurgeryPrepolymerOligoester

The invention provides a photocurable polyester oligomer for 3D printing as well as a preparation method and application thereof. The preparation method comprises the following steps of: carrying outvacuum heating dehydration on an aliphatic hydroxyl acid monomer to prepare a polyester prepolymer, adding an initiator in the presence of polyol to prepare a hydroxyl-terminated prepolymer by a meltcopolymerization method, and finally adding acrylic acid anhydride to prepare the photocurable aliphatic polyester oligomer. The prepared photocurable aliphatic polyester oligomer can be directly combined with a photoinitiator, and is suitable for DLP type 3D printing. The photocurable aliphatic polyester resin material prepared by the method is high in purity, relatively low and adjustable in viscosity, can be used in the biomedical field, especially in the fields of drug sustained release, tissue engineering, bone fixation, repair materials and the like, a photocuring polyester degradation material is combined with a 3D printing technology, the printed material is non-toxic and has excellent biocompatibility and mechanical properties, the degradation rate is between 6 months and 36 months, and a new direction is provided for application of 3D printing.

Owner:BMF NANO MATERIAL TECH CO LTD

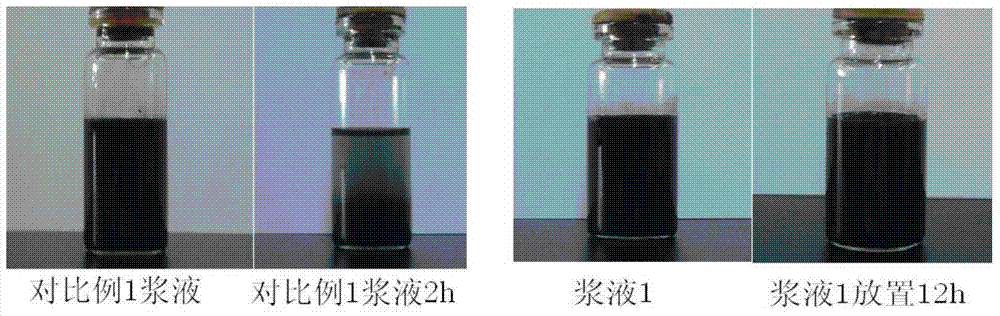

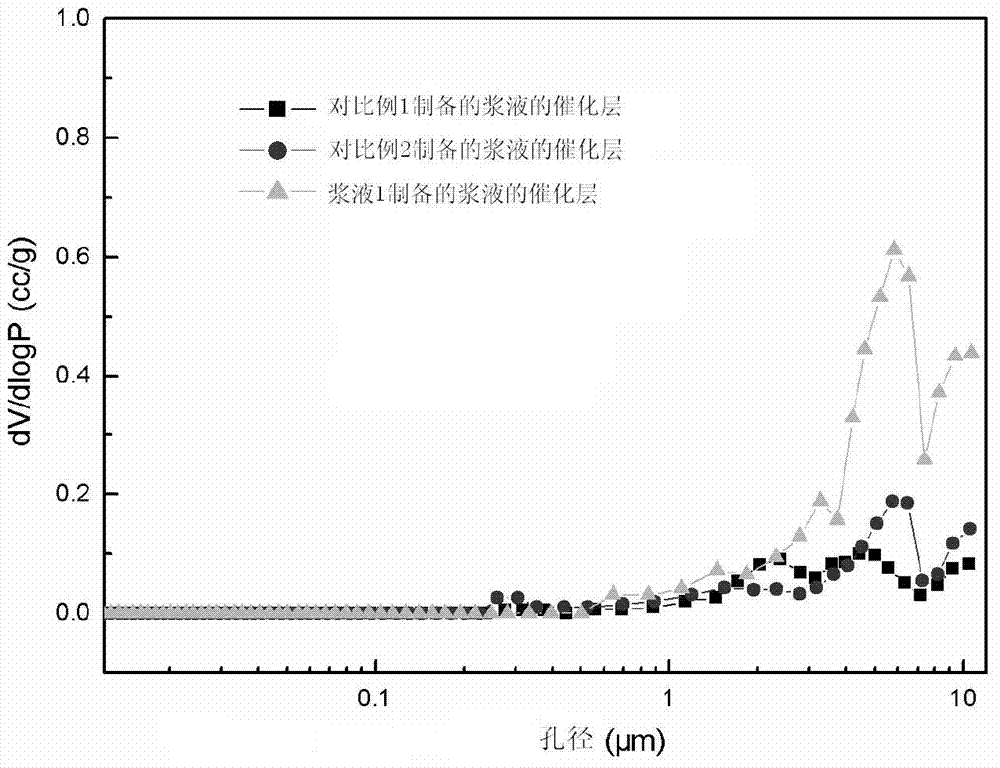

Fuel cell catalyst slurry and application thereof

InactiveCN104716342AViscosity is easy to controlControllable solid contentCell electrodesHigh current densityConductive polymer

The invention discloses a preparation method of proton exchange membrane fuel cell catalyst layer slurry, the catalyst slurry components include a catalyst, a conductive polymer and a solvent, the catalyst slurry viscosity is 100-1000 mPa.s, and the solid content is 10 to 50 wt%. By controlling the final viscosity and the solid content of the slurry, the slurry form and catalyst layer preparation efficiency and effect can be ensured. A catalytic layer electrode prepared from the slurry can be used for assembly of a proton exchange membrane fuel cell membrane electrode (MEA Membrane Electrode Assemble) and the pore size distribution is more conducive to the gas-liquid mass transfer, and is conducive to the improvement of the performance and stability of the battery in a high current density range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polyolefin lithium battery diaphragm coating slurry and application thereof

InactiveCN110148697AEasy to makeLow costSecondary cellsCell component detailsPolyolefinCarbon nanotube

The invention discloses polyolefin lithium battery diaphragm coating slurry, which is prepared by a coating material, a binder and deionized water, wherein the coating material is composed of one or more of graphene coated Al2O3 powder, carbon nanotubes, graphene and graphite according to any proportion; the binder is composed of one or two of sodium alginate, carboxymethylcellulose sodium, styrene butadiene rubber and polyvinylidene fluoride according to any proportion; the mass ratio of the coating material and the binder is 10:(0.01-1), the balance is the deionized water, and the mass fraction of the coating material in the polyolefin lithium battery diaphragm coating slurry is 0.1-30%. The invention further discloses a method of coating a polyolefin lithium battery diaphragm by using the polyolefin lithium battery diaphragm coating slurry. The coating slurry takes water as a solvent, and has the advantages of low cost, environment friendliness, controllable viscosity of the coatingslurry and good wettability and dispersion of the coating slurry. The method of the invention is simple in preparation process, low in cost and suitable for large-scale production.

Owner:SHENZHEN EIGEN EQUATION GRAPHENE TECH CO LTD +1

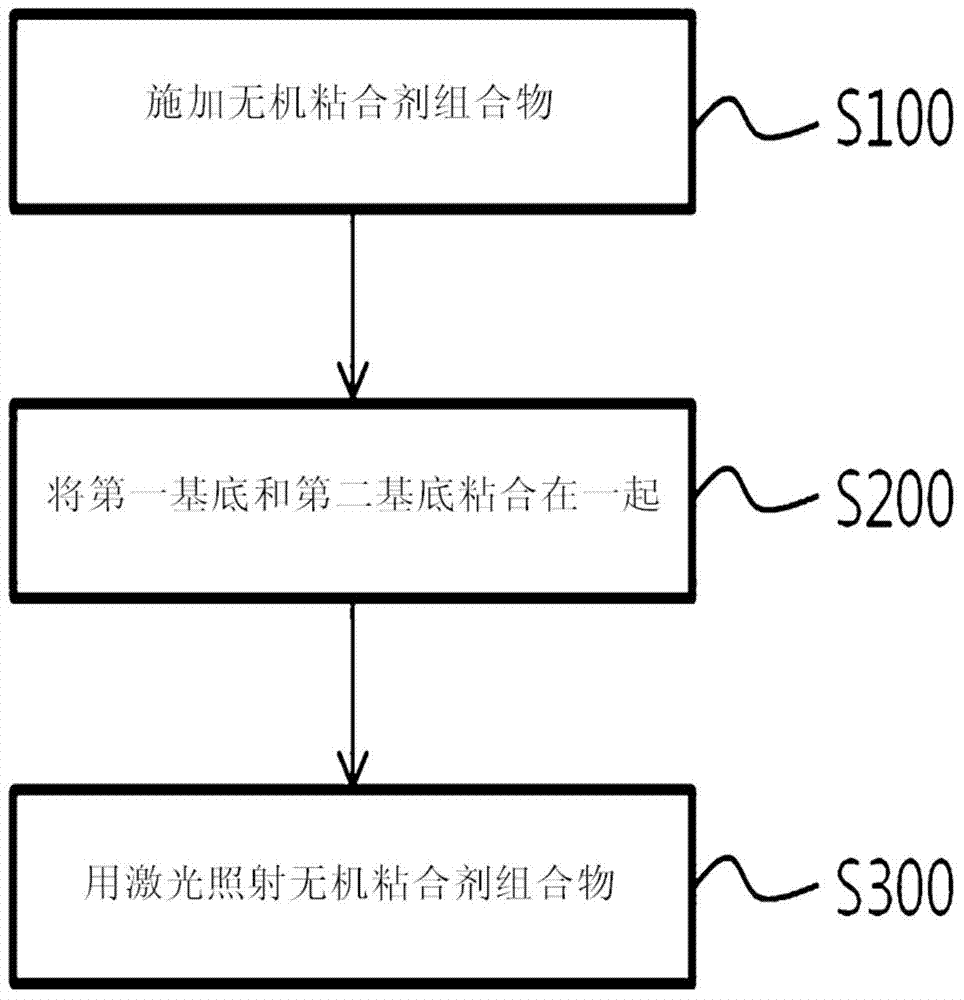

Inorganic adhesive composition and hermetic sealing method using same

ActiveCN104508061AImprove adhesion strengthViscosity is easy to controlNon-macromolecular adhesive additivesOther chemical processesOrganic solventHermetic seal

The present invention relates to an inorganic adhesive composition and to a hermetic sealing method, and more specifically relates to an inorganic adhesive composition with which an organic solvent is not used and to a hermetic sealing method using same. To this end, the present invention provides an inorganic adhesive composition comprising: between 20 and 80 parts by weight of a water glass diluted solution containing between 60 and 90 parts by weight of water glass (Na2SiO2); between 20 and 80 parts by weight of a refractory inorganic filler; and a black pigment.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

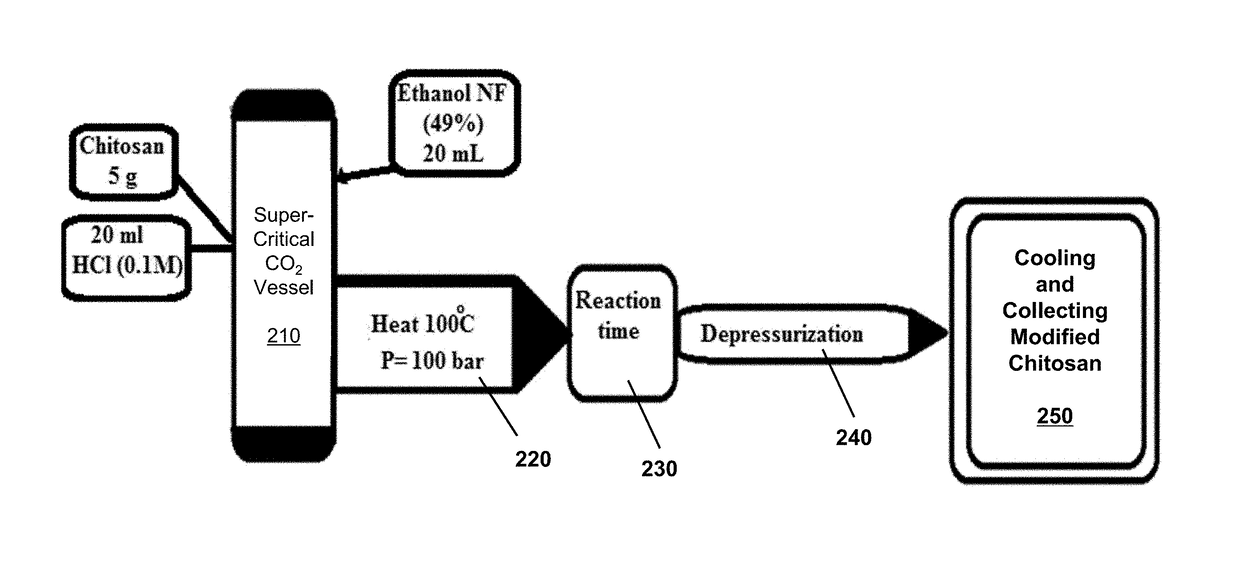

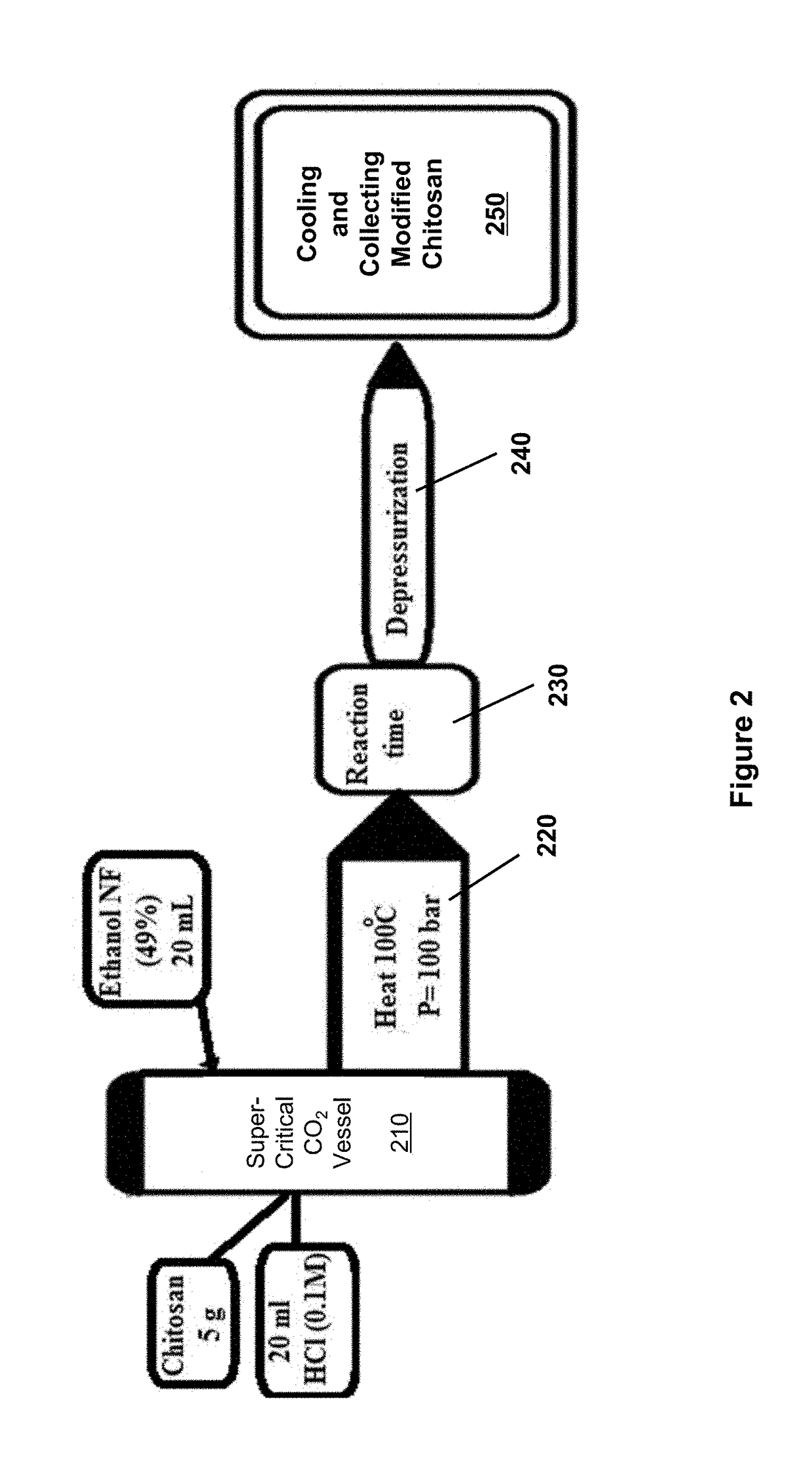

Process of producing and method of using soluble high molecular-weight chitosan

ActiveUS9862780B1Low production costViscosity is easy to controlBiocideFood coatingAlcoholWater soluble

A process for preparing a soluble high molecular-weight chitosan which comprises treating chitosan, water, alcohol, acid mixture with supercritical fluid to prepare a modified chitosan with high aqueous solubility.

Owner:JORDAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com