Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195 results about "Photogravure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photogravure is an intaglio printmaking or photo-mechanical process whereby a copper plate is grained (adding a pattern to the plate) and then coated with a light-sensitive gelatin tissue which had been exposed to a film positive, and then etched, resulting in a high quality intaglio plate that can reproduce detailed continuous tones of a photograph.

Water-based intaglio ink equal to plate engraving ink and uses thereof

ActiveCN101284965AOptimizing physical fastnessNo pollutionInksOther printing apparatusScreen printingSolubility

The invention is equivalent to water soluble intaglio ink of plate engraving ink and / or equivalent to water-soluble screen printing ink of the ink, suitable for a gravure printing machine. The ink has the advantages of nontoxicity, tastelessness, nonflammable property, water solubility, non-environmental pollution and rapid drying; the printing effect of the obtained presswork is the same as or equivalent to the printing effect of the plate engraving presswork; the materialized firmness of the presswork is superior to the materialized firmness of the plate engraving presswork; the ink is low in printing cost and suitable for printing secure and confidential documents with deep printing lines, such as bank notes, securities, stamps, food packing, etc.

Owner:北京万垟防伪技术有限责任公司 +2

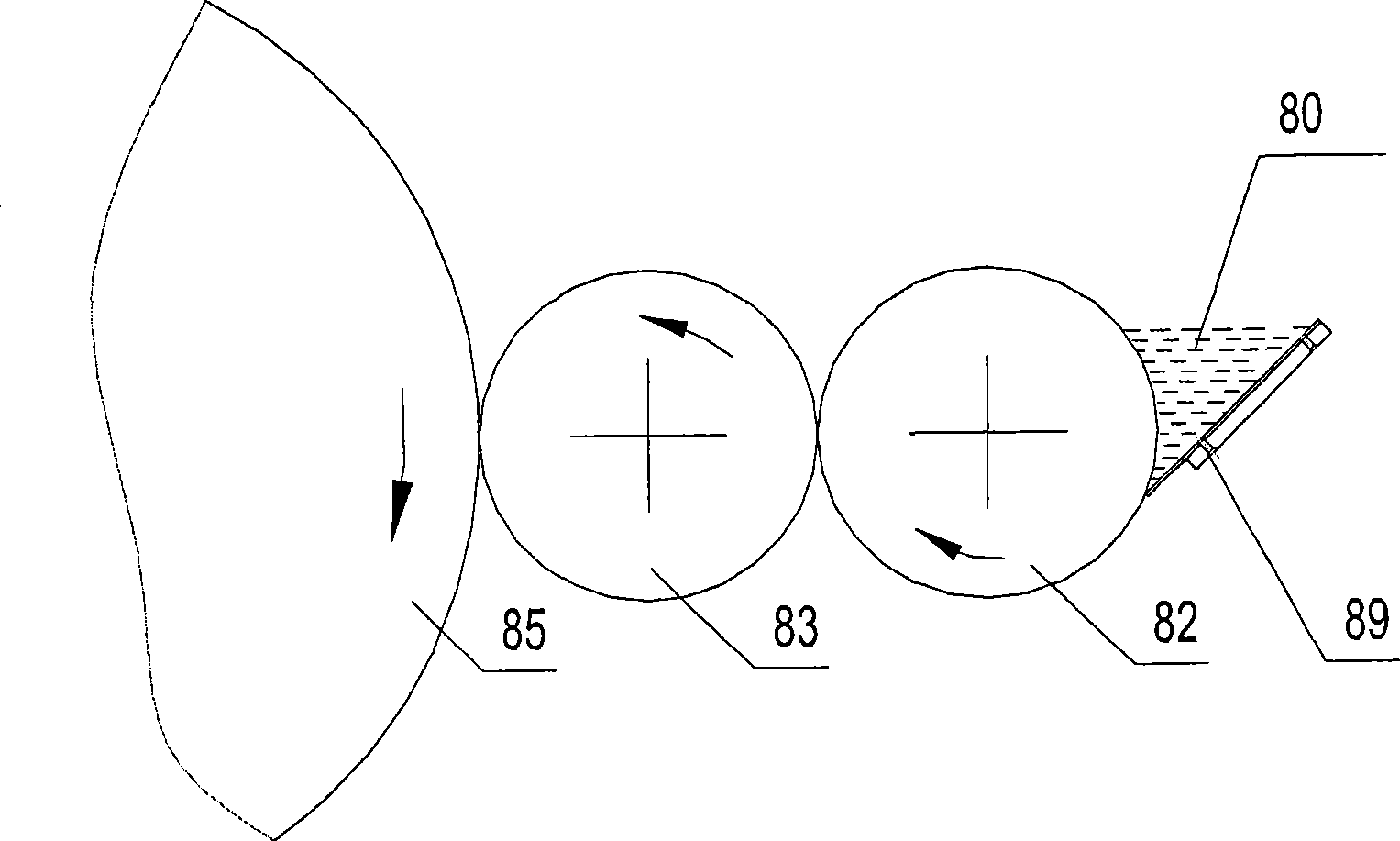

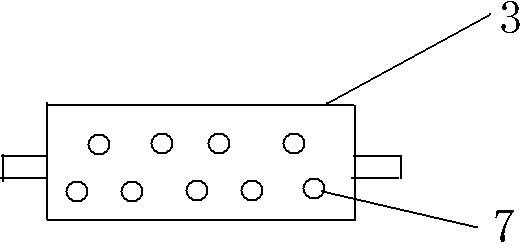

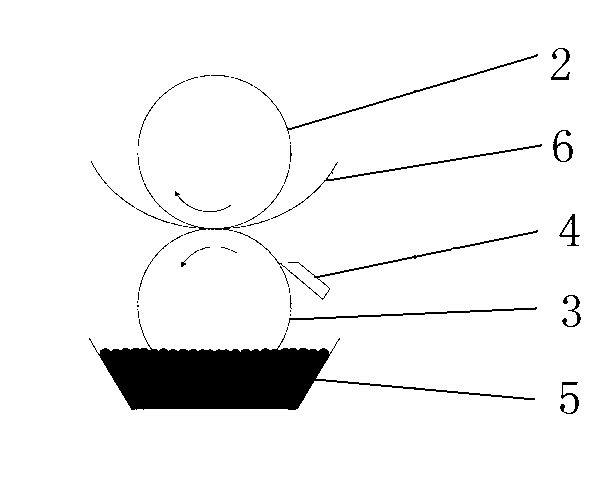

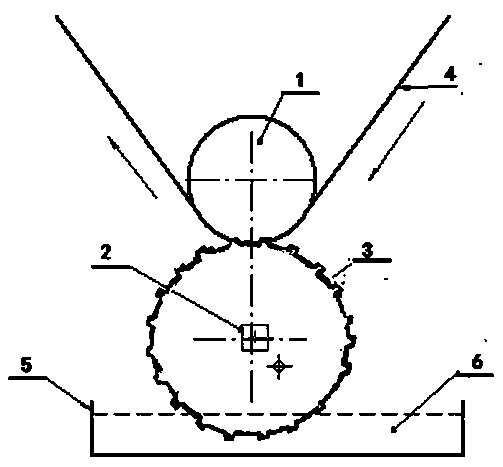

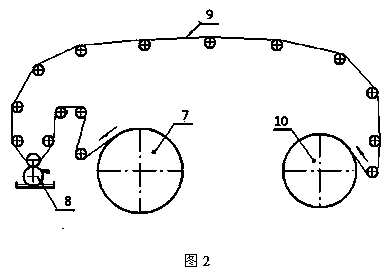

Ink fountain roller, ink distributing unit and ink distributing system of carving photogravure press

ActiveCN101544098AMolushortNot easy to jamRotary intaglio printing pressPrinting press partsPhotogravurePrinting press

The invention provides an ink fountain roller, an ink distributing unit and an ink distributing system of a carving photogravure press. The ink duct roller is a cavity-die inking roller with quasi-grains at the surface, and the quasi-grains correspond to forme grains; the ink distributing unit comprises an ink fountain, the ink fountain roller, a hook type scraper and an elastic color model roller, wherein the ink fountain roller contacts with ink in the ink fountain, the scraper is arranged at one side of the ink fountain roller, the elastic color model roller is arranged at the other side of the ink fountain roller and is in rolling transmission with the ink fountain roller; and the ink distributing system also comprises a gravure roller and an impression roller. The ink fountain roller of the ink distributing unit transmits ink grains which correspond to the gravure grains and have different thicknesses to the color model roller to form basso-relievo-shaped quasi-grain ink; the basso-relievo-shaped quasi-grain ink is transmitted into the gravure grains on the gravure roller; and the gravure roller and the impression roller mutually press to carry out printing. The invention has short ink path, easily ensures the accuracy of ink distribution and easily maintains the printing adaptability without ineffective circulation for the ink.

Owner:CHINA BANKNOTE PRINTING & MINTING

Photogravure ink equal to cut ink and its application

This invention relates to a photograghic intaglio printing ink which equals to carving intaglio printing ink. It can be used in photographic intaglio printer, and its outstanding feature is that the price of the printer is cheap, lithographic cost is low, and the post-treatment step of sewage during printing process is unneeded, so the sewage from carving intaglio printing ink printing process is eradicated completely and with no environmental pollution, and the printing ink is no waste and its non-offset performance is very good. It dries quickly, so it shortens the production cycle and saves the production buildings and land. The color of ink of its printing is of distinct hierachical structure and strong stereoscopic feeling. Its printing effect is the same as that of carving intaglio printings. The physicochemical fastness of its printing is superior to that of carving intaglio printings. Its printing cost is low.

Owner:北京万防伪技术有限责任

Method for transferring patterns on fiber fabric

InactiveCN102797172AReduce investment riskLess investmentTransfer printing processDyeing processTextile printerFiber

The invention relates to a printing method of fabrics, and in particular relates to a method for transferring patterns on a fiber fabric. The method comprises the steps of (1) coating a transfer layer: coating a prepared coating adhesive on a film or paper by a photogravure press or a coating machine so as to form the transfer layer on the surface of the film or the paper, drying, and then printing the surface of the transfer layer by utilizing dye base ink to prepare a transfer printing film or transfer printing paper; (2) starching the fiber fabric: coating fixation slurry for transfer printing on the surface of the fiber fabric; (3) transferring the patterns; and (4) evaporating and fixing: after the transfer, stripping the transfer printing film or the transfer printing paper, drying, evaporating and fixing the fiber fabric. According to the method, the difficulties that the dye base ink can not be directly printed on the film, and the transfer rate of the dye on the paper is not high can be solved, and also the transfer layer, the dye, the film and the paper with an isolation layer are not compatible, so that more than 98% of dye can be transferred, and the transfer rate and the color rate of the printing are improved greatly.

Owner:沈翰宇

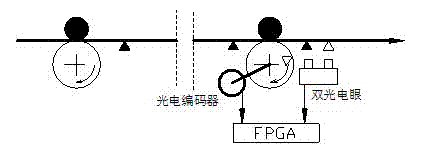

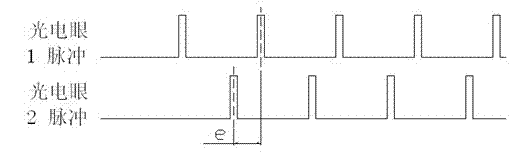

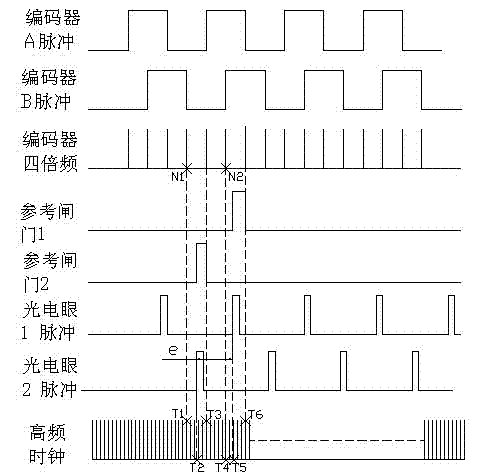

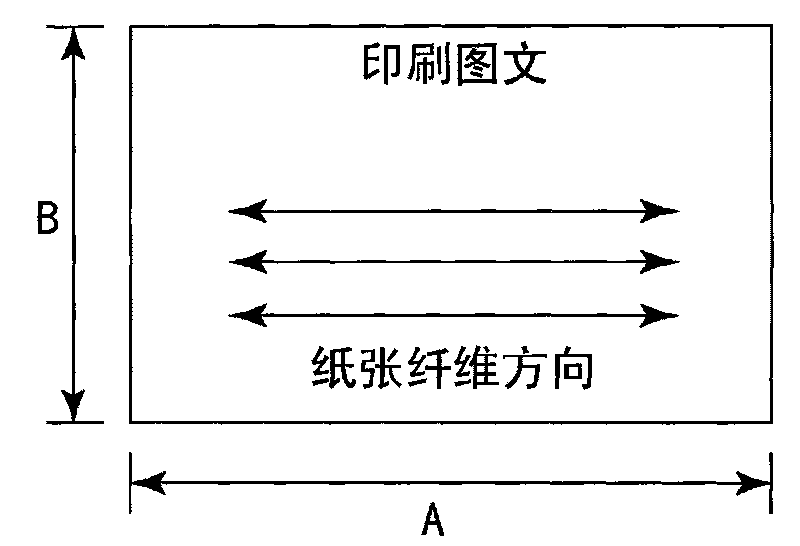

Method for detecting overprint errors of photogravure press on the basis of field programmable gate array (FPGA)

ActiveCN102218900AHigh-resolutionImprove detection accuracyRotary pressesPrinting press partsTaking pulseImage resolution

The invention discloses a method for detecting overprint errors of a photogravure press on the basis of a field programmable gate array (FPGA). The method comprises the following steps of: (1) taking a pulse signal after detecting a color code by two photoelectric eyes as a detecting pulse; (2) taking pulses A and B of an encoder as reference pulses and clock signals of an encoder pulse counter, taking a high-frequency clock in the FPGA as a clock signal of a system clock counter, and determining actual position values of the two photoelectric eyes according to an encoder pulse counter value corresponding to the detecting pulse, a system clock counter value, and system clock count value respectively corresponding to two pulses adjacent to the reference pulses respectively corresponding to two detecting pulses; and (3) determining the pulse count of the two photoelectric eyes within a time interval, wherein the arithmetic product of the pulse count and a pulse equivalent weight is an overprint deviation value. In the method, the high-frequency clock of the FPGA is used for subdividing the encoder to improve the resolution of the encoder so that the detection accuracy of the overprint errors is greatly improved and can meet photogravure registering requirements.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

Ink fountain roller, ink distributing unit and ink distributing system of carving photogravure press

ActiveCN101544098BMolushortNot easy to jamRotary intaglio printing pressPrinting press partsPhotogravurePrinting press

The invention provides an ink fountain roller, an ink distributing unit and an ink distributing system of a carving photogravure press. The ink duct roller is a cavity-die inking roller with quasi-grains at the surface, and the quasi-grains correspond to forme grains; the ink distributing unit comprises an ink fountain, the ink fountain roller, a hook type scraper and an elastic color model roller, wherein the ink fountain roller contacts with ink in the ink fountain, the scraper is arranged at one side of the ink fountain roller, the elastic color model roller is arranged at the other side of the ink fountain roller and is in rolling transmission with the ink fountain roller; and the ink distributing system also comprises a gravure roller and an impression roller. The ink fountain rollerof the ink distributing unit transmits ink grains which correspond to the gravure grains and have different thicknesses to the color model roller to form basso-relievo-shaped quasi-grain ink; the basso-relievo-shaped quasi-grain ink is transmitted into the gravure grains on the gravure roller; and the gravure roller and the impression roller mutually press to carry out printing. The invention hasshort ink path, easily ensures the accuracy of ink distribution and easily maintains the printing adaptability without ineffective circulation for the ink.

Owner:CHINA BANKNOTE PRINTING & MINTING

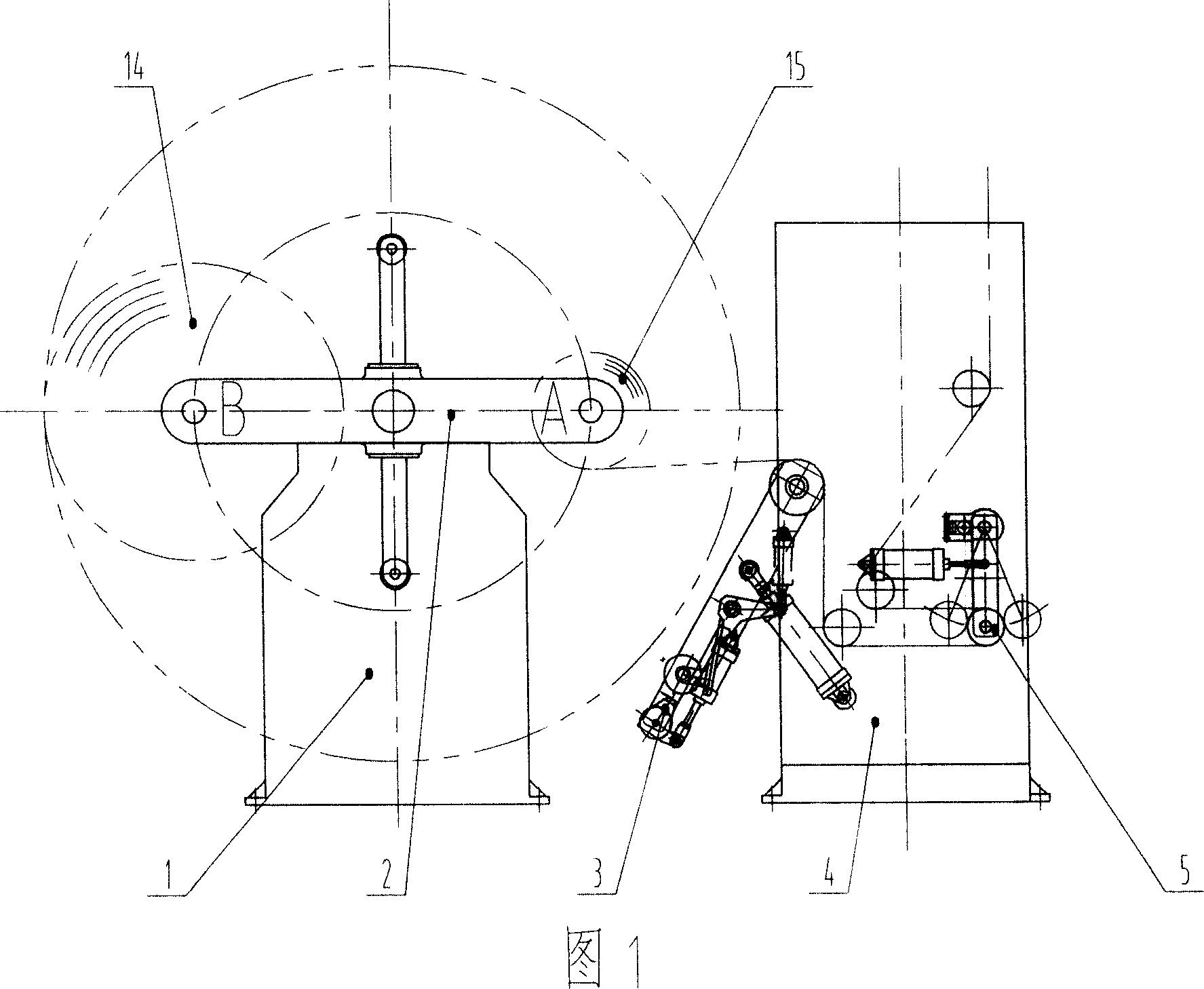

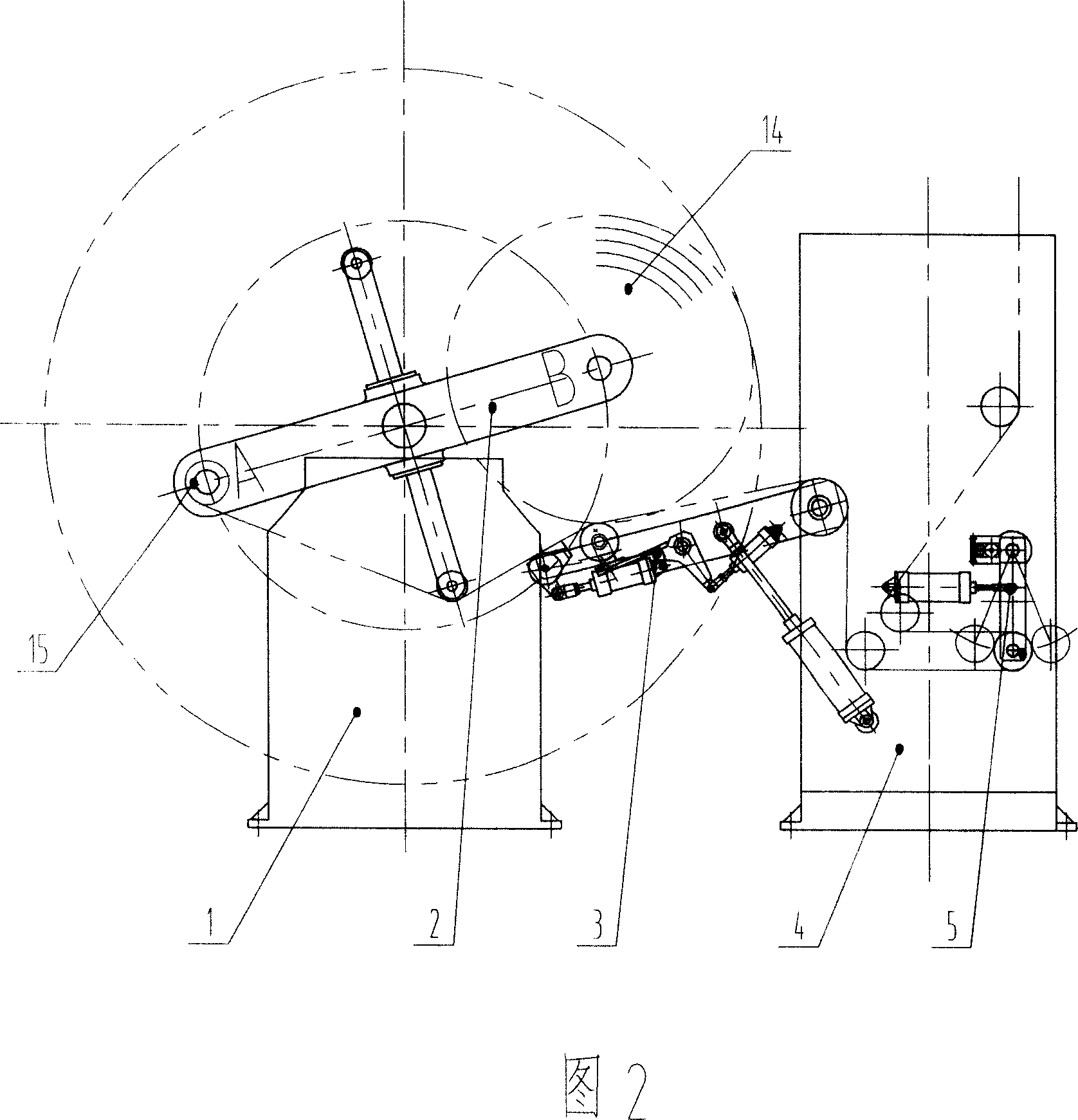

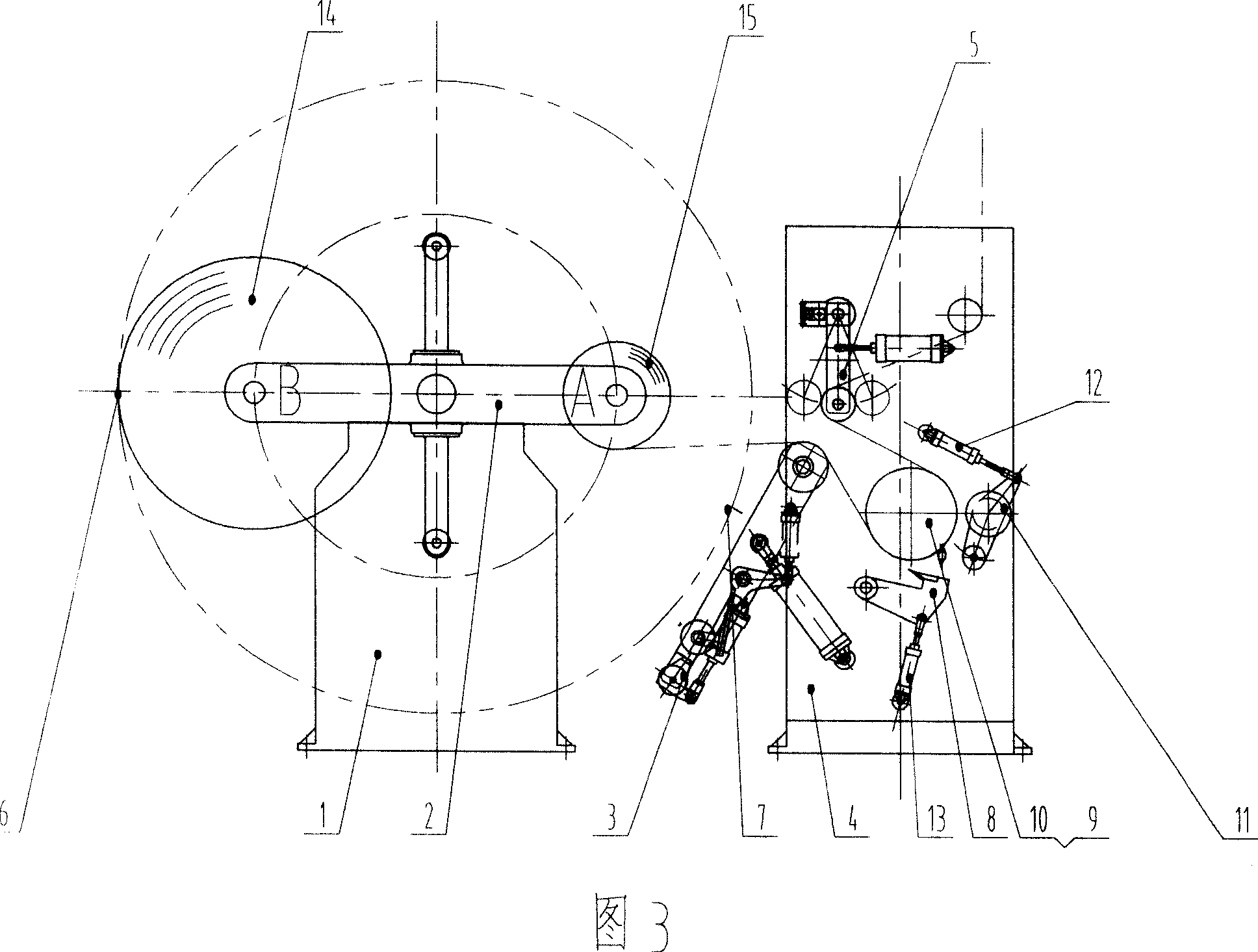

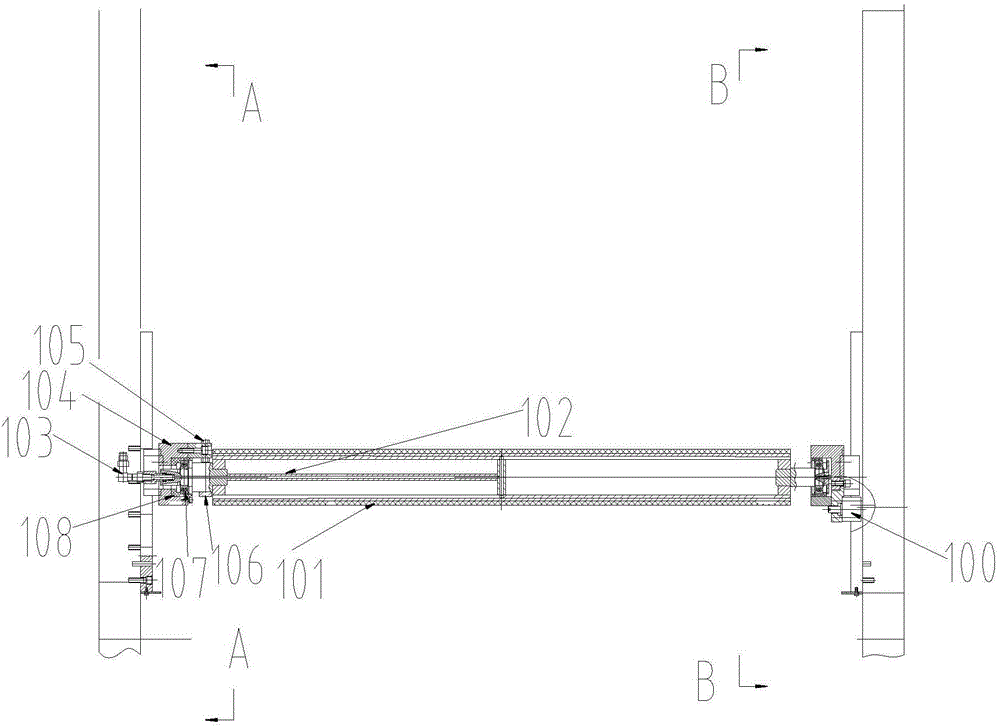

Paper high speed synchronization butt joint device for photogravure press units

InactiveCN101033044AAchieve connectionGuaranteed reliabilityRotary pressesWebs handlingButt jointAdhesive

This invention provides a high speed synchronous paper but-joint device of an unit gravure machine including a turning frame, a turning big arm, a cutting unit, a frame, a swing-roller, a paper-end cutter fixed on the frame, a large roller and a paper roller with back-adhered glue, in which, the paper-end cutter is under the large roller driven by an executing cylinder, a test photoelectric eye is set on the cutter, a steel strip is set on the head of a paper roll, a coder is set on the big roller and the back-adhered paper roll is driven by the executing cylinder and the steel strip is adhered on the head of a new material with a double-side adhesive tape.

Owner:SHAANXI BEIREN PRINTING MACHINERY

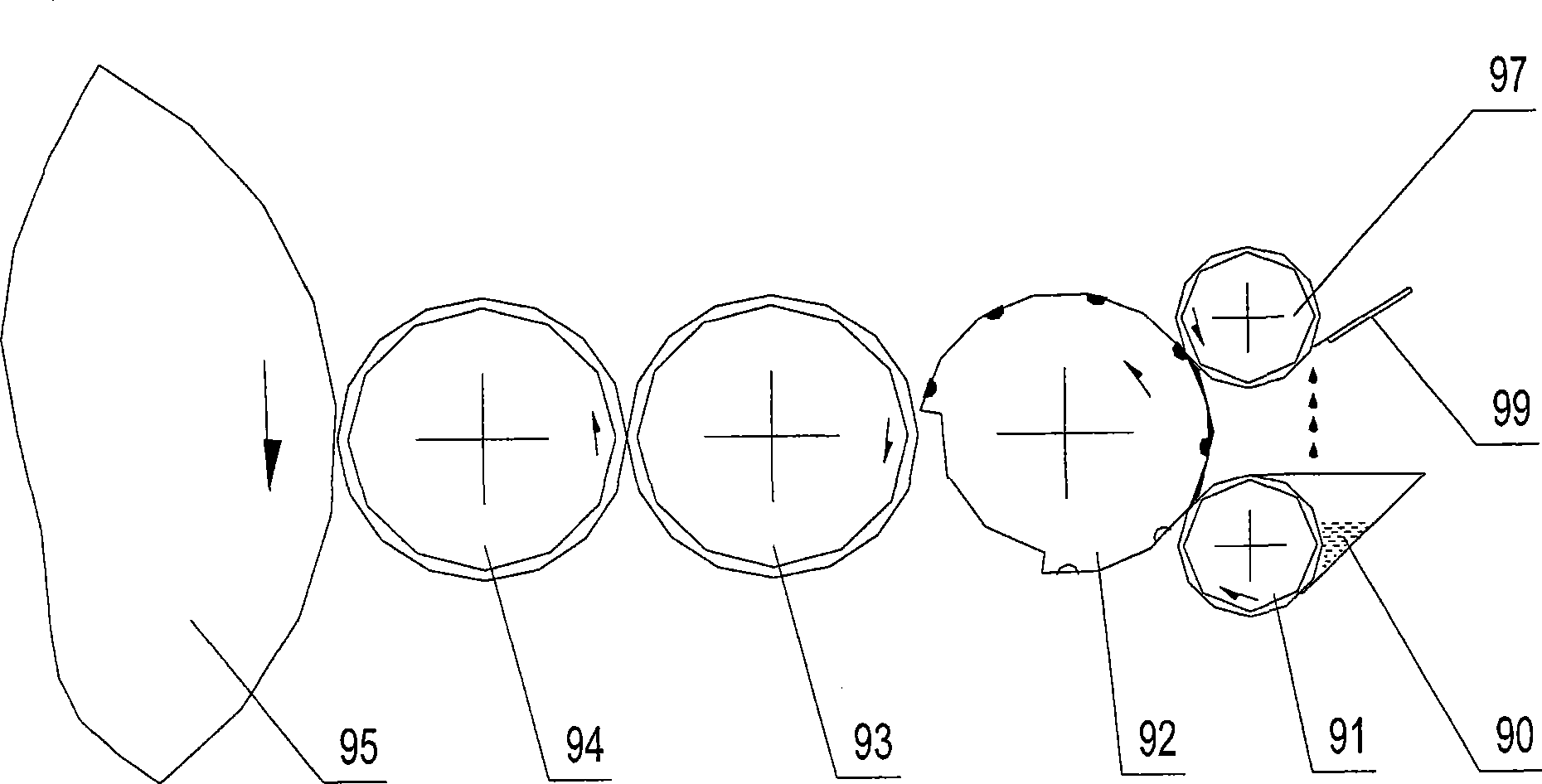

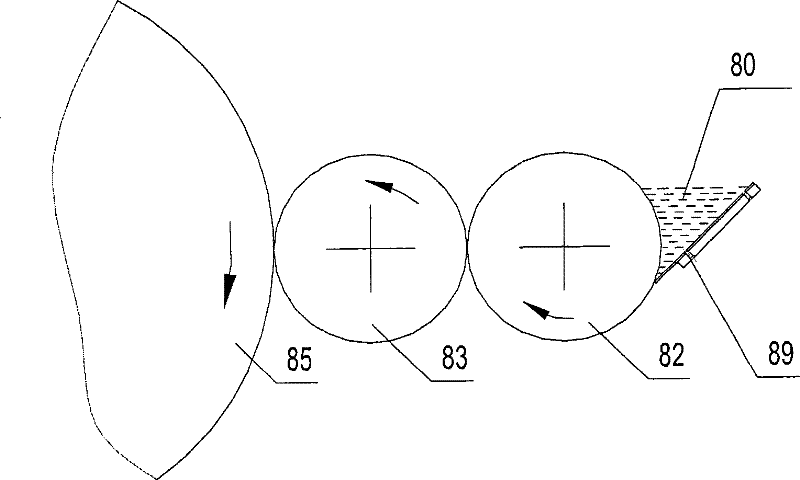

Photogravure press

InactiveCN102991097AExtended service lifeAvoid the defects of low labor efficiencyRotary intaglio printing pressPrinting press partsPhotogravureEngineering

The invention provides a photogravure press, a coating roller of which is made of rubber to ensure that the coating roller is respectively in flexible contact with an absorbing roller and a to-be-printed steel plate, and thus the tightness of the contact is ensured, a pattern region on the absorbing roller can be completely transferred on the coating roller, and a pattern region on the coating roller also can be completely transferred to the to-be-printed steel plate, therefore a complete pattern region is formed. In addition, the photogravure press provided by the invention comprises a first scraper and a second scraper, wherein the first scraper is used for scraping a coating on the absorbing roller, except for a pit for forming an image region, the second scraper is used for removing residual coating on a rubber roller after transferring, therefore, the defects of lower labor efficiency and poor control precision caused by manual removal of the coating are avoided, and thus the labor productivity is increased and the product quality is ensured. In addition, the first scraper and the second scraper are respectively in contact with the absorbing roller and the coating roller by a specific angle, and thus a better scraping effect can be ensured.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Decorative film and manufacturing method thereof

InactiveCN101670744ASimple processing technologyReduce manufacturing costSpecial ornamental structuresOther printing apparatusPhotogravureUltraviolet lights

The invention relates to the technical fields of decorative materials and manufacturing methods thereof, in particular to a decorative film and a manufacturing method thereof. The decorative film comprises a substrate layer, a printing layer and a protective layer positioned on the surface of the printing layer from bottom to top, wherein the printing layer is printed on the surface of the substrate layer through a photogravure press; and the protective layer is a layer of UV paint. The printing layer in the decorative film is directly printed by a printer, and has vivid color. The surface of the decorative film is provided with the protective layer formed by the layer of UV paint, and the protective layer is automatically painted to the surface of the printing layer in a rolling way through machinery equipment, and promotes the decomposition of an initiator under the radiation of ultraviolet light to generate free radicals to initiate resin reaction for instant curing. The UV paint can well protect the printing layer, and improves the wear resistance and acid and alkali resistance of products; and glue-water adhesion or multi-layer attachment by heating is not used, so the environment is protected. The decorative film has simple process, and stable physical and chemical performance of the products.

Owner:莫金发

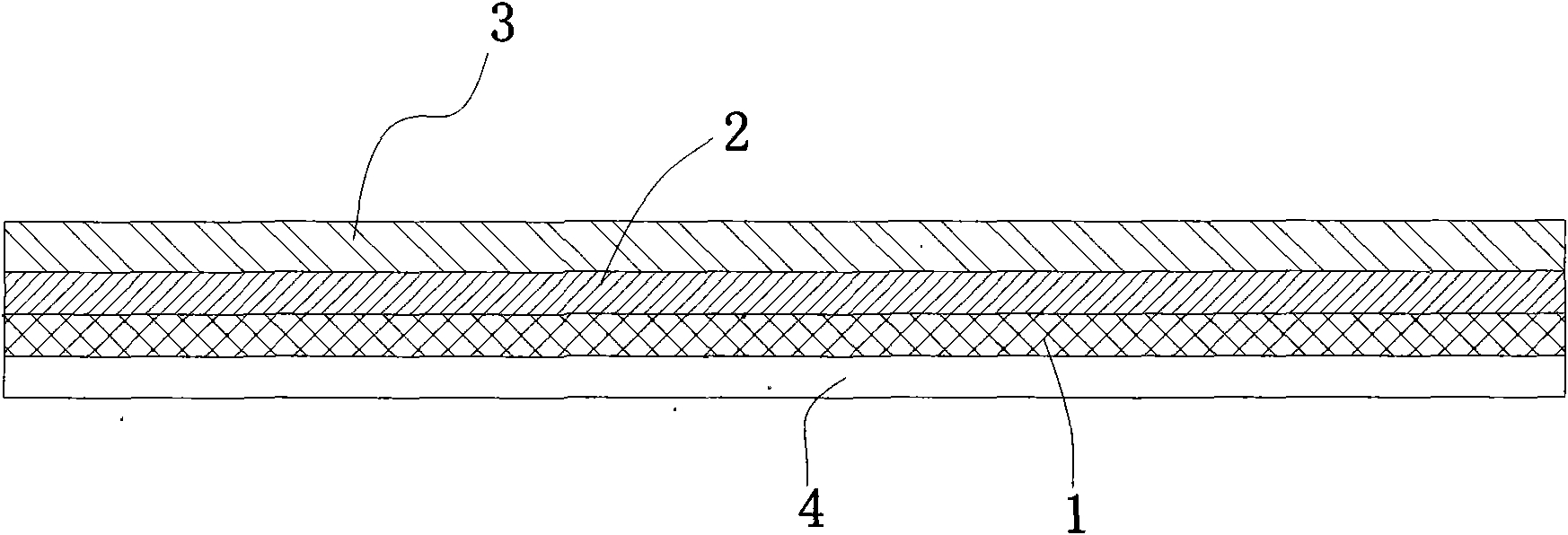

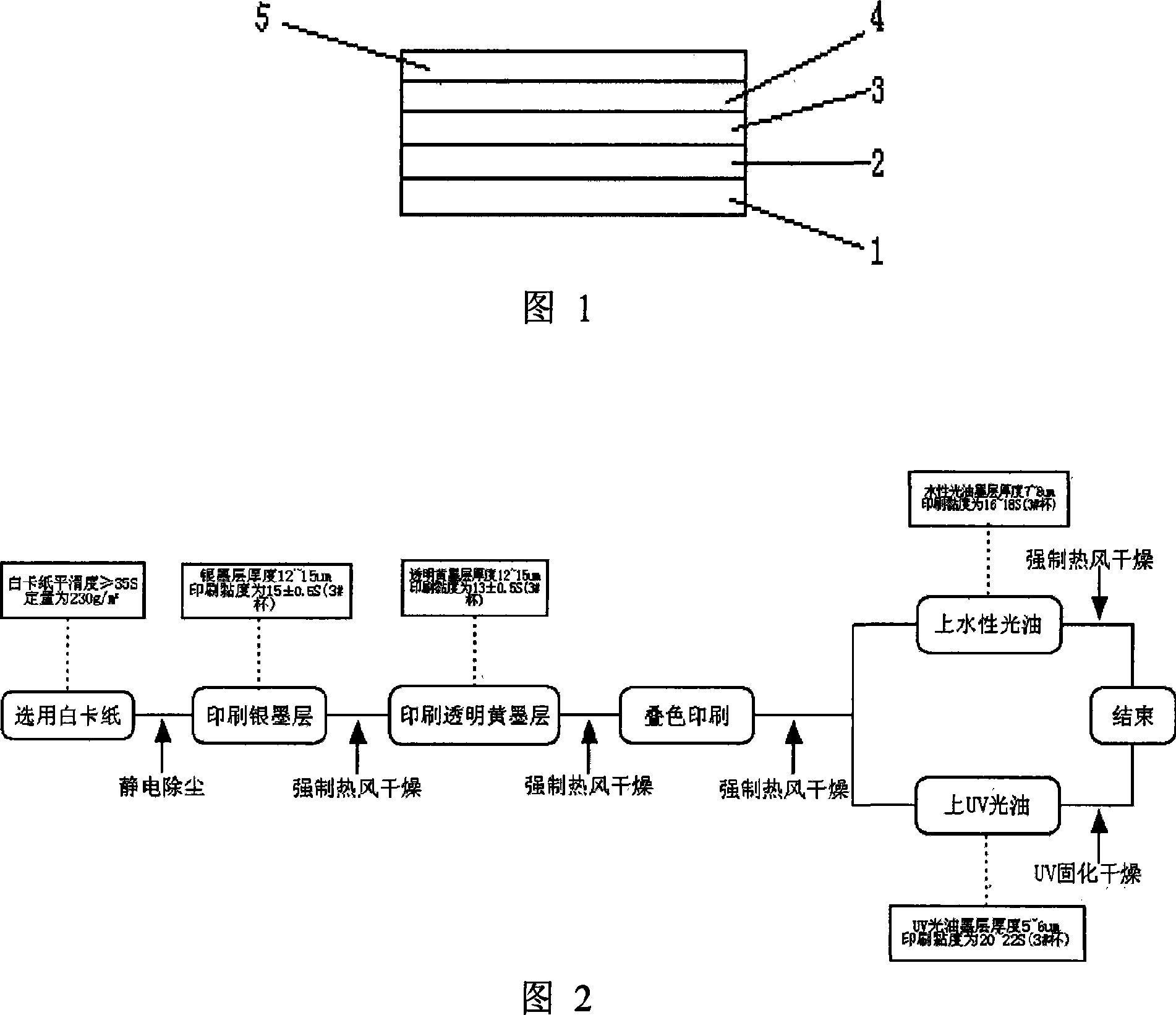

Gravure technique for making white cardboard having same surface effect as gold cardboard

InactiveCN101122105AIncrease flexibilityImprove efficiencyCoatings with pigmentsSpecial paperSilver inkCardboard

The invention relates to the printing technical field, in particular to a photogravure technology providing the white card paper with surface effect of the cold card paper. The printing chromatology principle is applied, so as to print a silver ink layer and transparent yellow ink layer on the white card paper so that the white card paper can have the surface effect of the gold card paper. The invention can not only easily realize the surface effect of the gold card paper wholly or partially on the white card paper, but also can be directly inserted on the normal product printing color class without any extra special treatment, which is highly flexible, high-efficiency, low cost and environment protective.

Owner:HENAN JINMANGGUO PRINTING

Anti-corrosion water-based laser glue capable of being removed easily and ablated by laser

The invention relates to environmental-friendly laser glue needed by a laser ablation method for photogravure. The laser glue is anti-corrosion and can be removed easily and ablated by laser. The laser glue comprises the following components in percentage by weight: 5 to 40 percent of water-based resin, 0 to 10 percent of cross-linking degree controlling agent, 0.2 to 40 percent of laser absorbent, 0 to 5 percent of laser sensitizer, 2 to 10 percent of antifreeze, 0 to 10 percent of quick-drying agent, 0 to 5 percent of pH regulator, 0 to 1 percent of flatting agent, 0 to 1 percent of defoaming agent, 0 to 1 percent of preservative, 0 to 5 percent of thickening agent, 0 to 5 percent of dispersing agent and the balance of deionized water. The water-based laser glue has the advantages of no environmental pollution, no harm to human body and no combustion explosion. The laser glue can also be used for manufacturing precision dials, brass plates, crafts and the like by a corrosion method.

Owner:潘治平

Waterborne over-printing varnish for environment-friendly paper

The invention provides a waterborne over-printing varnish for environment-friendly paper. The waterborne over-printing varnish comprises raw material components: self-crosslinking type acrylic polymer emulsion (A), non-film-forming acrylic polymer emulsion (B), styrene-acrylate copolymer emulsion (C), a waterborne nano organic silica waterproof agent (D) and other commonly-used auxiliaries. The waterborne over-printing varnish for environment-friendly paper emphasizes the environment-friendliness characteristics, can be used for a flexographic plate printing press, a photogravure plate printing press, and a roller coating machine to print or coat paper products with the over-printing varnish. After being printed on the paper, the over-printing varnish can be naturally dried, the dried coating is both bright and waterproof, and the moisture friction resistance can achieve the satisfying effect.

Owner:福建省利得彩环保科技有限公司

Once-through method of aluminum-plating film resin transfer printing

The invention relates to a once-through method of aluminizer resin transfer printing, which is used in the thermal transfer printing technology and comprises the following steps: A. after hot melting resin is hot-melted into liquid, a photogravure press is used for printing a pattern on the aluminium layer of the aluminizer under the condition of keeping the melting state of the resin, and after being cooled to room temperature, the aluminizer is rolled up for standby; and B. when printing is needed, the surface of the aluminizer with the hot melting resin pattern is adhered on a printing stock, treated with impressing at the temperature of between 85 DEG C to 120 DEG C, and the thin film is stripped away after cooling, thus forming the finished product. The method combines the traditional transfer printing of two times, i.e., the pattern thermal transfer printing and the transfer printing of a metallic film layer plated with a metallic film, into the transfer printing of one time, the transfer printing pattern is distinct and smooth, the luster is strong, the color is abundant, and stereoscopic impression can be given.

Owner:邹恒余

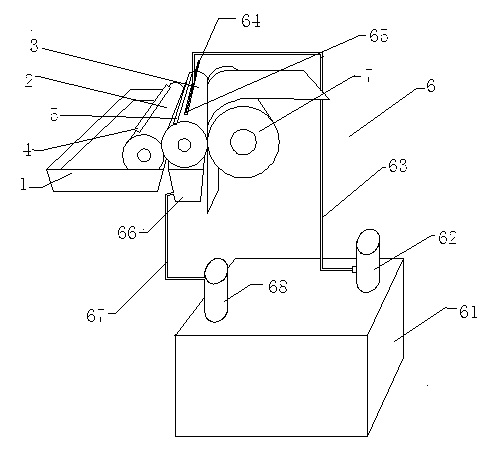

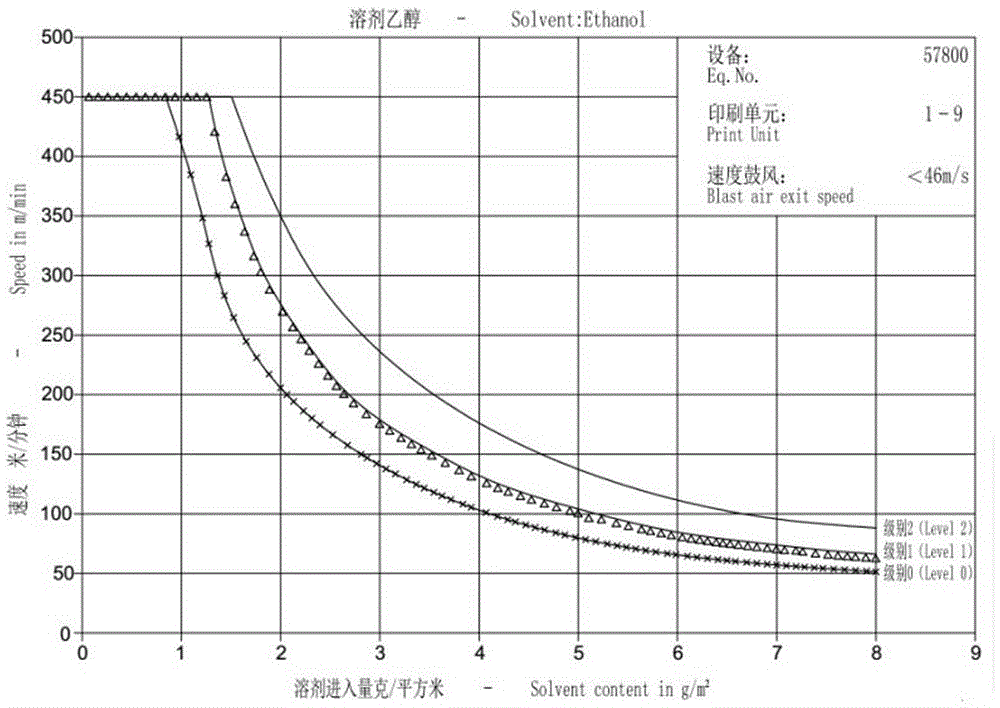

Efficient energy-saving environmental-friendly unit type photogravure press and energy-saving environmental-friendly method

InactiveCN101734002ASimple structureUse to achieveRotary intaglio printing pressPrinting press partsEnvironmental resistancePhotogravure

The invention relates to an efficient energy-saving environmental-friendly unit type photogravure press used for air temperature adjustment of the unit type photogravure press self as well as an energy-saving environmental-friendly method. The photogravure press comprises a unit type photogravure press, an air conditioning plant is arranged between units requiring constant temperature of the unit type photogravure press, a hot wind outlet arranged on the upper part of the air conditioning plant is communicated with an inlet of a drying box body in the unit type photogravure press, a cold wind outlet on the lower part is positioned below the unit in the unit type photogravure press. The invention has the advantages of high cost performance, can realize seamless butt joint with the traditional technology and saves electricity for 56% if compared with products with the same grade on the basis of satisfying the normal function of printing machinery and national environmental protection requirement and has obvious energy saving effect; the environmental impact assessment index is obviously lowered; the efficient energy-saving environmental-friendly unit type photogravure press can realize seamless butt joint with the technology and craft of the existing printing mechanical products under the condition that performance is greatly improved, and also can be used for energy saving modification of printing machinery with low energy efficiency ratio.

Owner:HANGZHOU YUEHUA PRINTING & PACKAGING MACHINERY

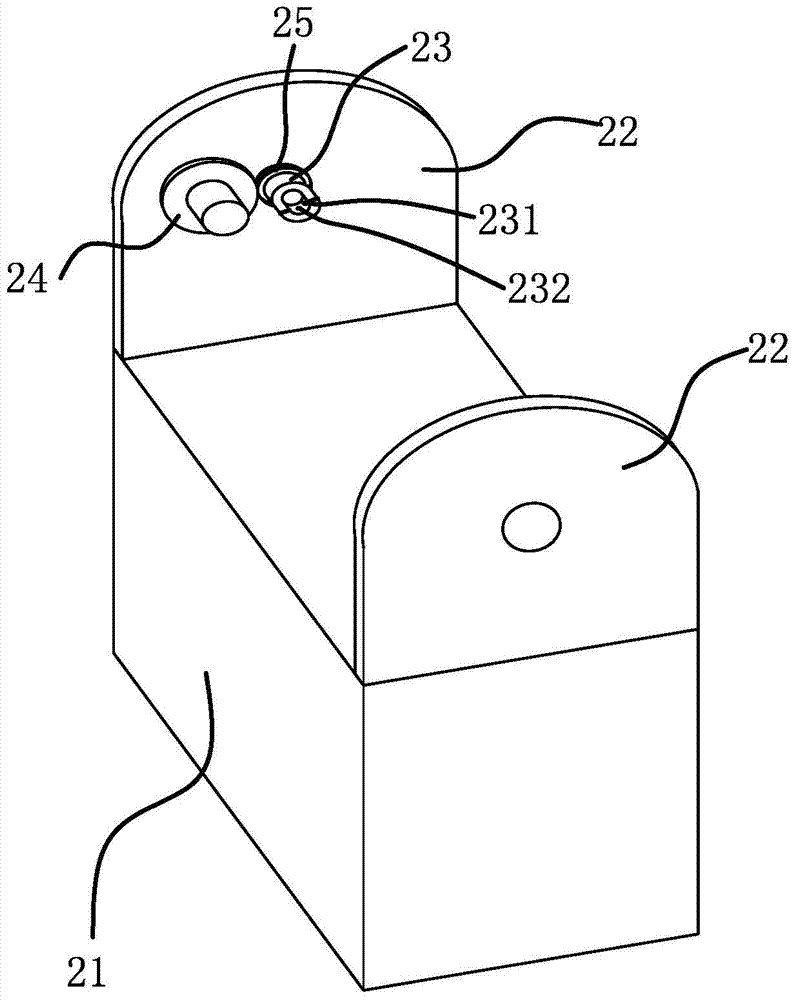

Two-dimensional code spraying device applied to photogravure press

InactiveCN104210224AIncrease productivityRotary intaglio printing pressTypewritersFixed framePhotogravure

The invention discloses a two-dimensional code spraying device applied to a photogravure press. The two-dimensional code spraying device comprises a fixed frame, and guide-in rollers, a photogravure assembly, an oven and guide-out rollers, which are arranged on the fixed frame; a printing substrate is guided by the guide-in rollers, is subjected to gravure on the photogravure assembly, and then is guided out by the guide-out rollers; the oven used for drying printing ink is arranged outside the guide-out rollers; a printing substrate turn-over device and a two-dimensional code sprayer are arranged between the guide-out rollers and the guide-in rollers. According to the reasonable design, the two-dimensional code sprayer can be reasonably arranged in photogravure equipment, two-dimensional code spraying becomes one part of automatic printing, and the production efficiency is improved greatly.

Owner:江苏中印印务集团有限公司

Preparation method of aluminum-free transparent laser environmental-protection inner liner for cigarette

ActiveCN104354484AHigh degree of moldingGuaranteed physical propertiesDuplicating/marking methodsPaper coatingPhotogravureAdhesive

The invention discloses a manufacturing method of an aluminum-free transparent laser environmental-protection inner liner for cigarette. The aluminum-free transparent laser environmental-protection inner liner for cigarette comprises paper, a PET film and a waterborne transfer adhesive. According to the manufacturing method, the PET film is molded through a molding press to form a laser pattern with various patterns, and then is combined with paper by the use of the waterborne transfer adhesive; after the PET film is peeled, the laser pattern is transferred to the paper; a layer of transparent medium is plated on the PET film-peeled paper with the laser pattern by the use of a vacuum aluminum plating machine; the transparent medium-plated paper with the laser pattern undergoes water supplement treatment; and a cigarette logo pattern is printed by the use of a photogravure press. By reasonable proportioning and a new technology, the prominent problem that embossing of paper is fuzzy, is easy to bounce back and is not resistant to folding is solved. In comparison with the prior art, the method provided by the invention is environmentally friendly and can be used to maintain original physical properties of paper. By the method, aluminum-free transparent laser environmental-protection inner liner for cigarette has advantages of good flexibility and molding degree, no bouncing-back, folding resistance, clear and accurate printed typeface and the like.

Owner:汕尾高峰科特纸业股份有限公司

Digital color-spray color matching technique used for intaglio printing

InactiveCN105437806AReduce wasteShorten development timeDuplicating/marking methodsPhotogravurePrinting press

The invention discloses a digital color-spray color matching technique used for intaglio printing. A color manuscript is provided for intaglio printing through digital color-spray printing. Color pre-matching is conducted on a digital printer and a photogravure press before the color manuscript is printed through digital color-spray. By means of the digital color-spray color matching technique used for intaglio printing, the time for developing a new color can be greatly shortened, the success rate of new color designing and platemaking is increased, the printing effect is guaranteed, the waste of printing rollers is reduced, and the development cost is substantially reduced.

Owner:ZHEJIANG DILONG NEW MATERIAL

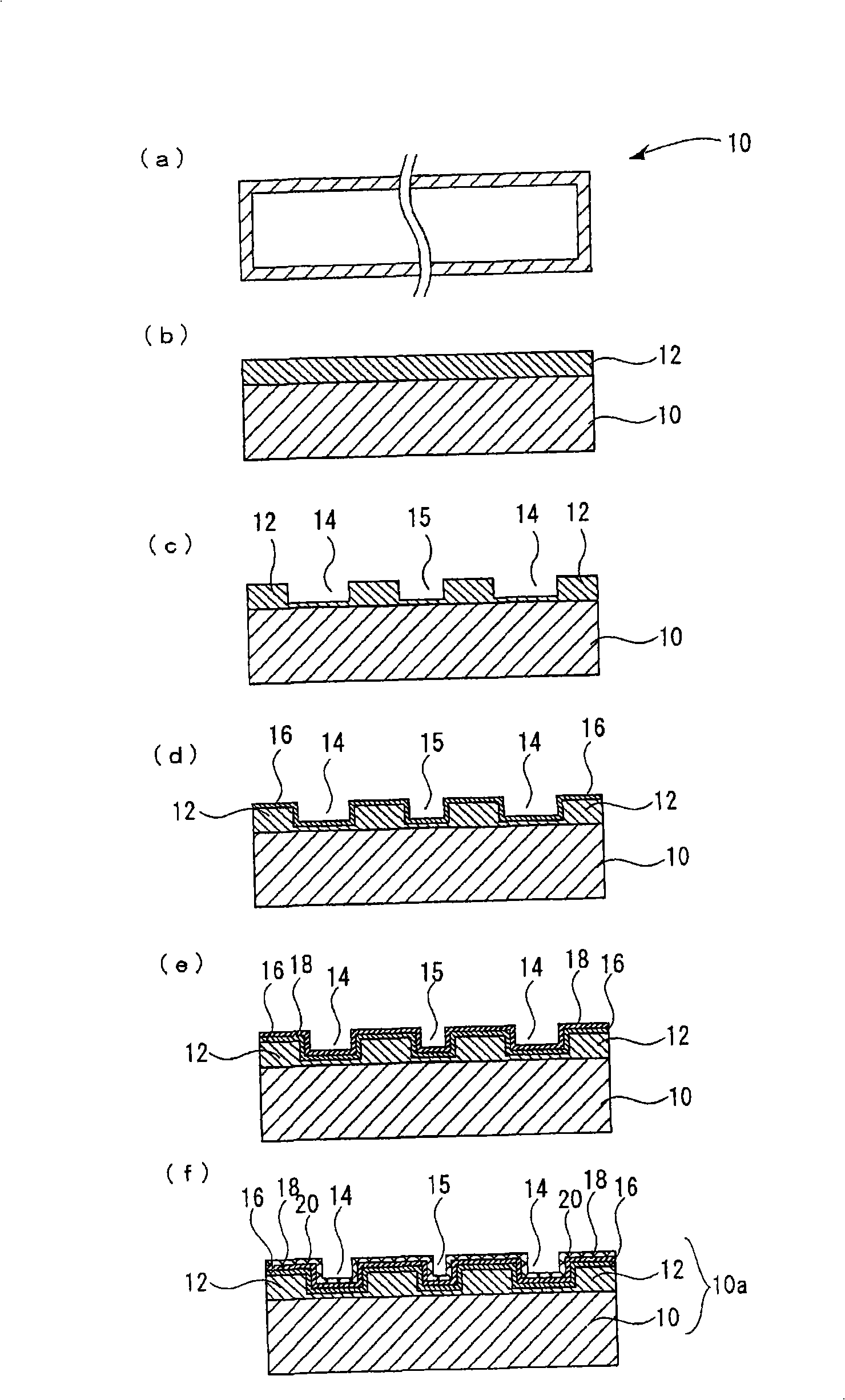

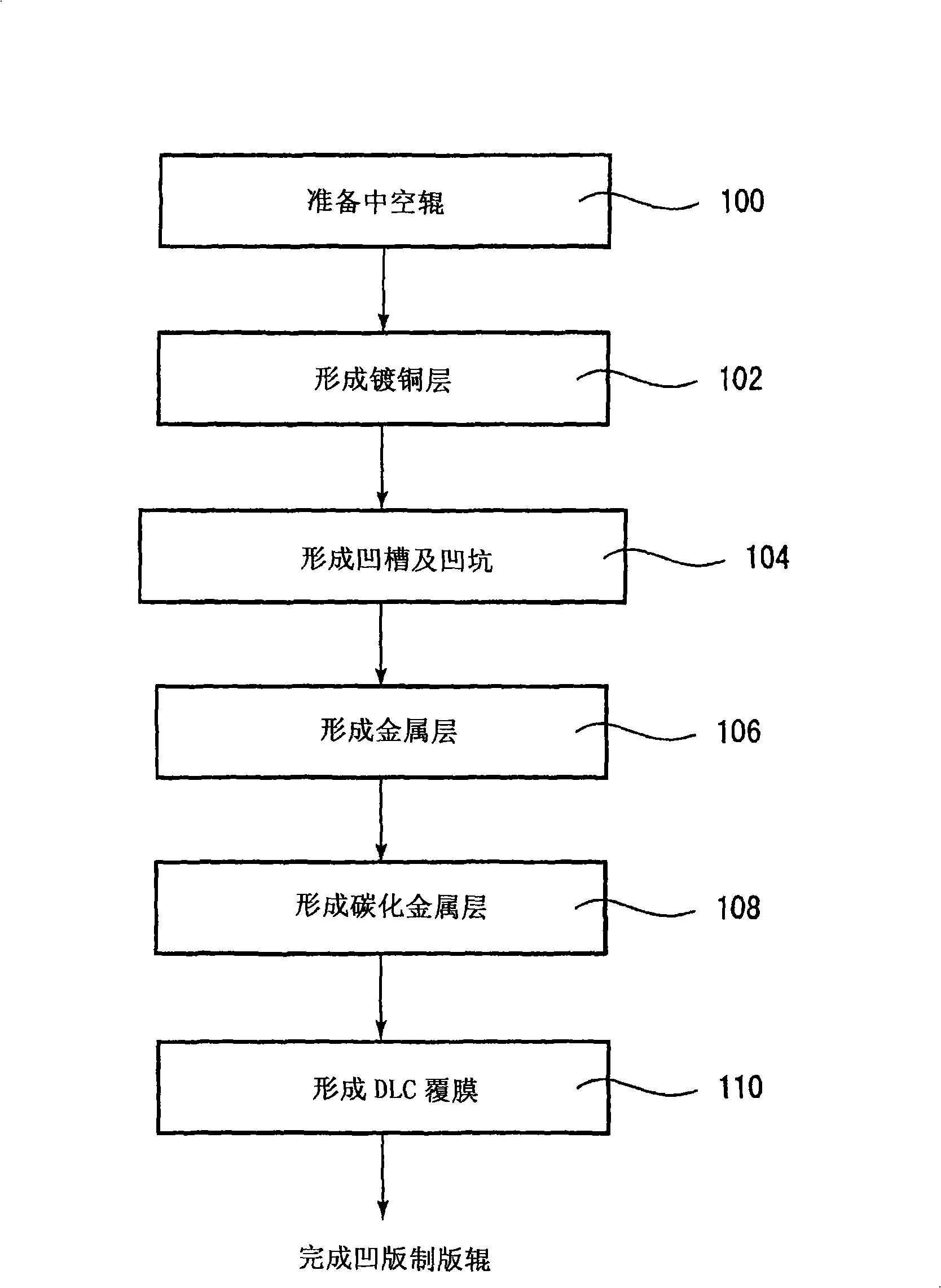

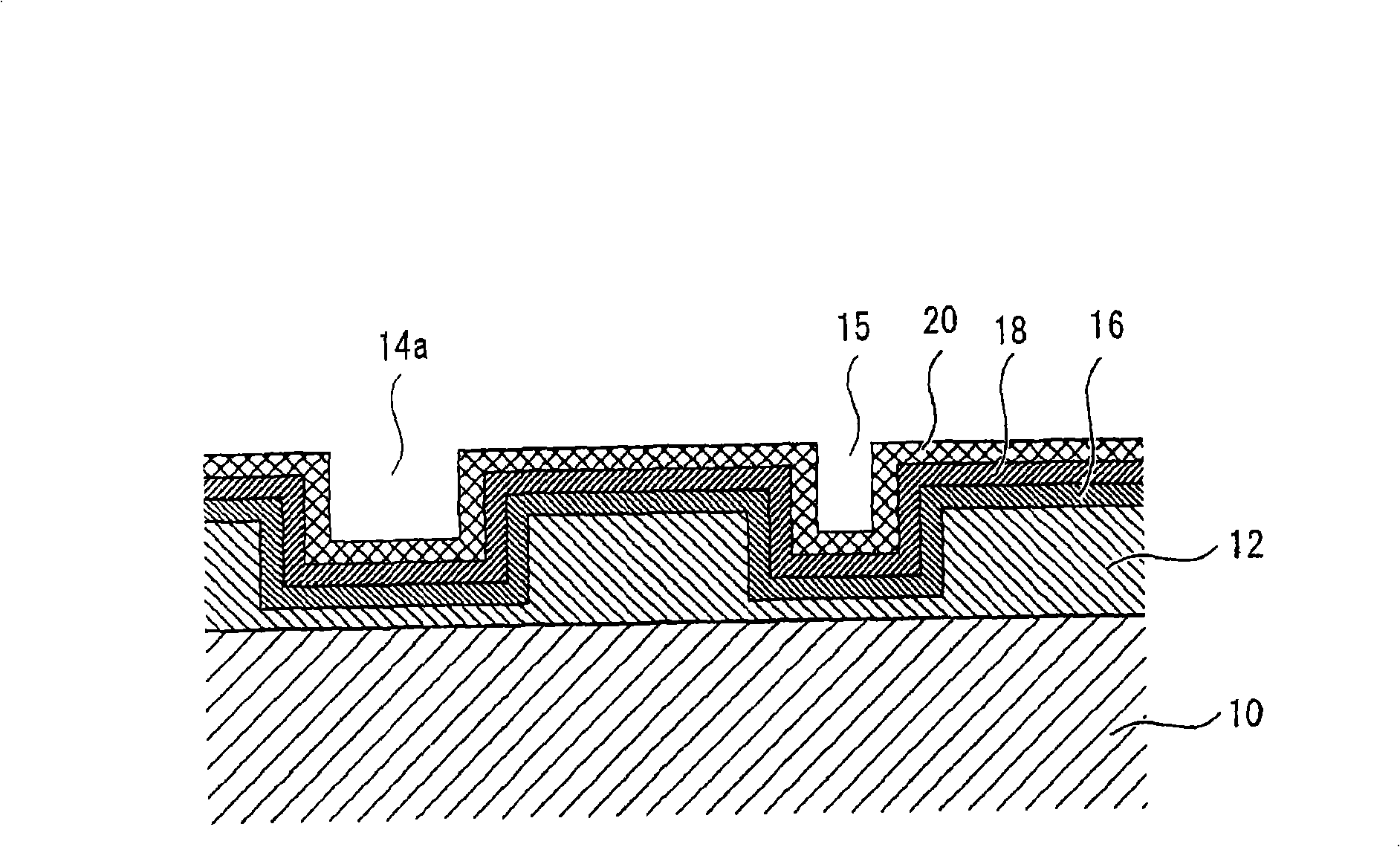

Gravure platemaking roll and its manufacturing method

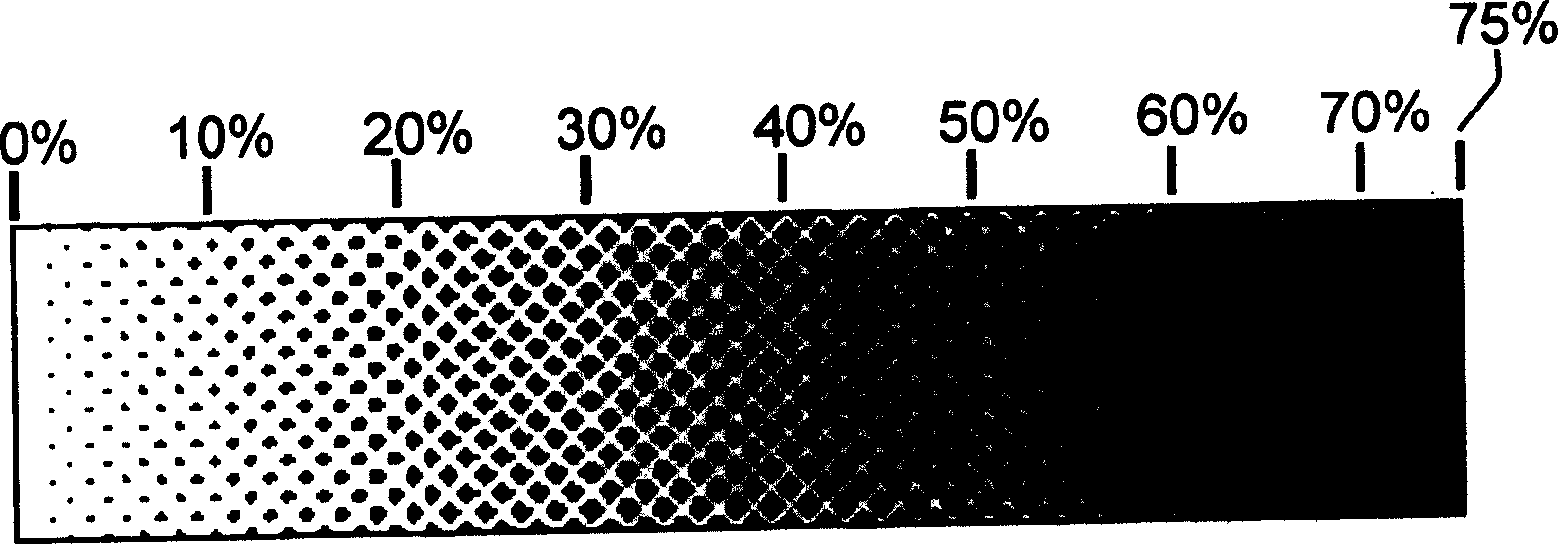

InactiveCN101272913AFog EliminationHigh strengthVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

A novel photogravure engraving roll capable of improving plate fog, being provided with a surface reinforcing film layer completely free from toxicity and the possibility of pollution, and being excellent in plate wear; and a production method of the roll. The photogravure engraving roll comprises a metal hollow roll, a copper-plated layer provided on the surface of the hollow roll and formed with many gravure cells on the surface thereof, a metal layer provided on the surface of the copper-plated layer, a metal carbide gradient layer of the metal provided on the surface of the metal layer, and a diamond-like carbon film covering the surface of the metal carbide gradient layer, wherein a pit being smaller than the minimum gravure cell in the highlighted portion of the copper-plated layer and having a size not permitting ink transfer is arranged so that at least one pit exists in the one-pitch area of a screen line in a non-printing image.

Owner:THINK LABORATORY CO LTD

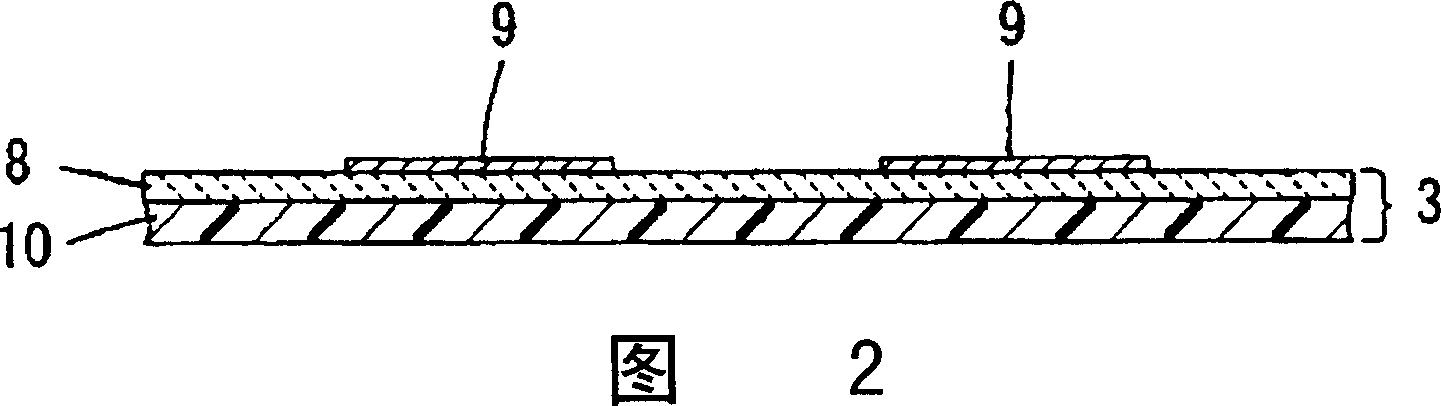

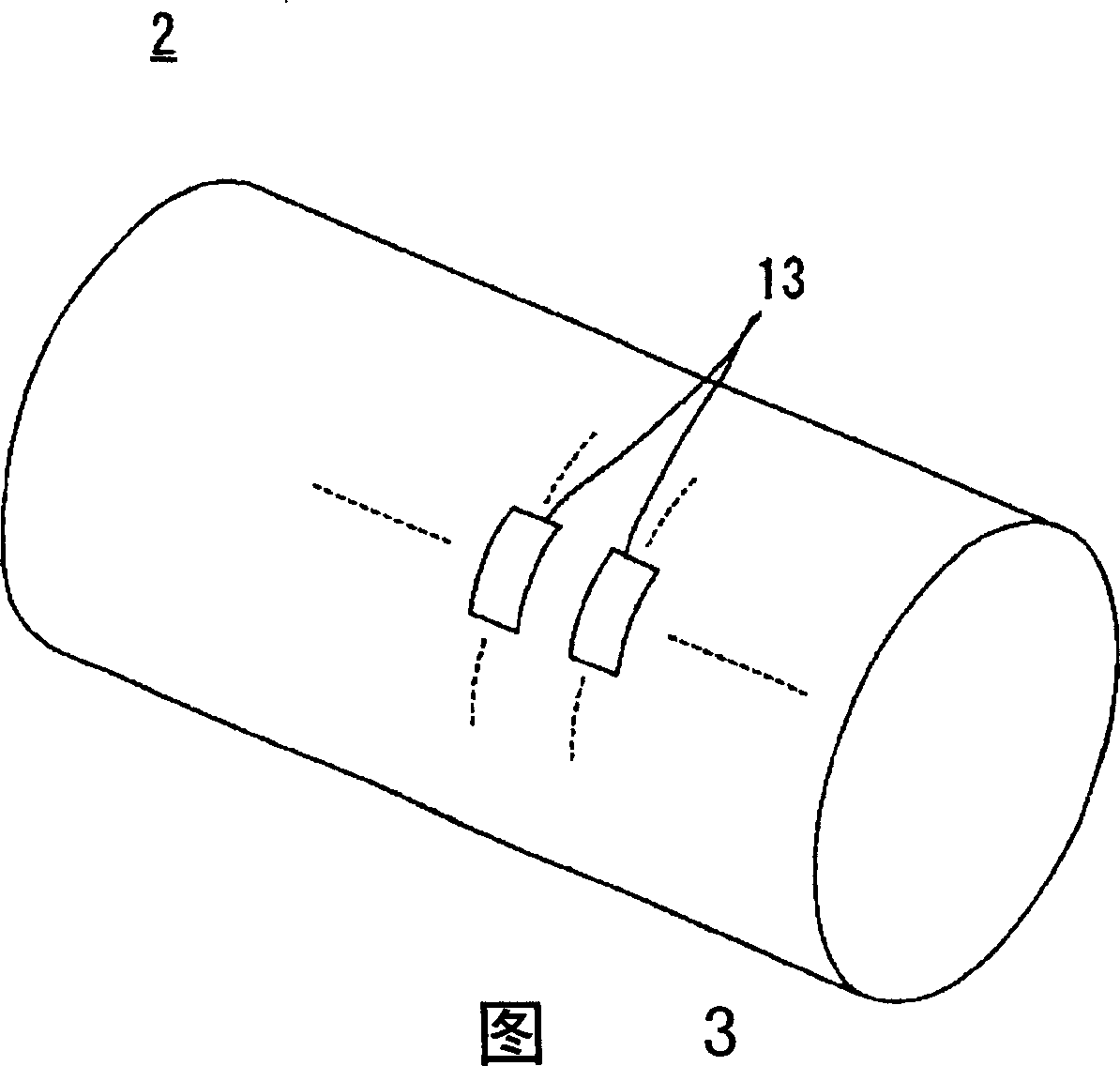

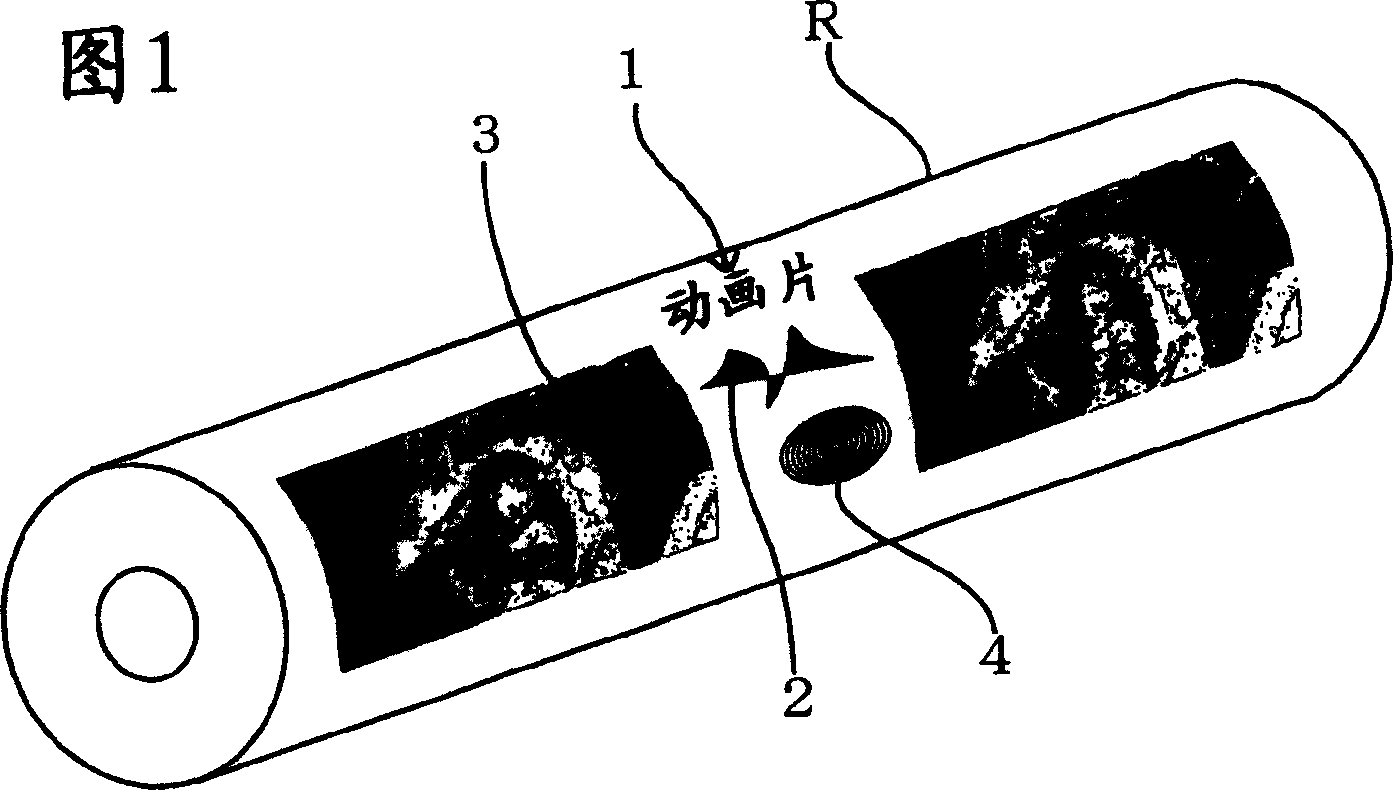

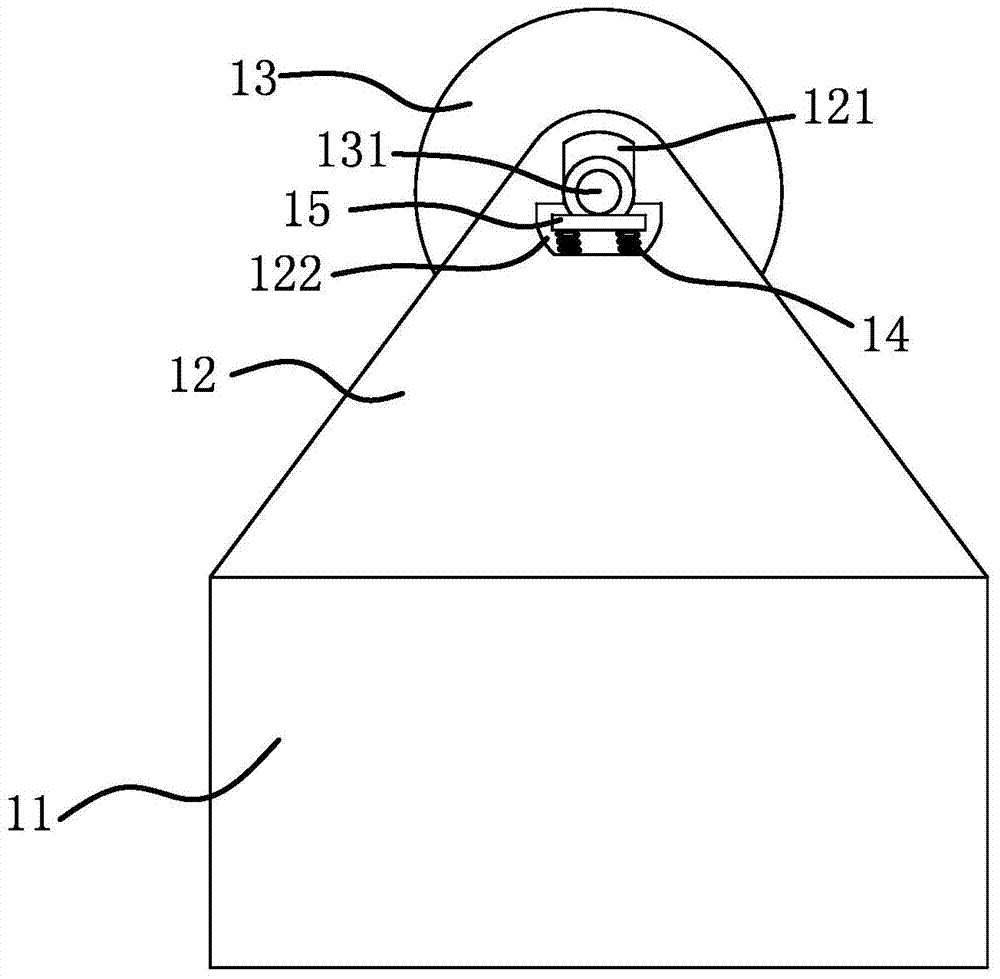

Photogravure roller

Disclosed is a gravure rolling drum of the photogravure printing press capable of forming a coating membrane on the substrate using photogravure by the printing press. The gravure rolling drum is provided with: an image area forming on the circumferential surface of the gravure rolling drum on which the coating pulp forms a coating membrane, and printing-direction walls substantially extending in printing-direction and perpendicular walls extending substantially in direction perpendicular to the printing-direction walls formed in the image areas, and a plurality of cells defined by the printing-direction walls and substantially perpendicular walls. Each perpendicular wall has a cut opening formed therein to communicate the adjacent cells.

Owner:MURATA MFG CO LTD

Method for preparing water-based ink tipping paper with anti-bacterial and anti-virus function

A method for preparing water-based ink tipping paper with anti-bacterial and anti-virus function comprises the following steps: (1) dissolving the water-based ink by mixture of alcohol and water, adding 10 to 1,000 PPM Ganoderma applanatum solid powder or extractive powder of fermented Ganoderma applanatum mycelium; (2) sending the original tipping paper with vertical tensile strength greater than 2.0 KN / m and fixed quantity of 34-40 g / m2 in a drying zone of printing machine before printing, and pre-heating at the temperature of 110-120 DEG C; and (3) printing the pre-heated original tipping paper by a photogravure press with curving resolving capability of 60-120 lines per centimeter and glue rollers with shore harness of 45-80HS at the printing zone of the printing machine, heating at the temperature of 150-180 EDG C at the drying zone of the printing machine, repeating the steps for 2-4 times, and finally loading the printed tipping paper in the drying zone to heat at the temperature of 110-120 DEG C.

Owner:何金星 +1

Multicolour photogravure method

InactiveCN101722749AStrong adhesionImprove adhesionOther printing apparatusPrinting after-treatmentEmulsionPhotogravure

The invention discloses a multicolour photogravure method which uses spray Al paper as printing paper and waterborne ink as printing ink. During the printing process, firstly a layer of polyacrylate emulsion coating is printed on the spray Al paper, and after the polyacrylate emulsion coating is dried and cured, the waterborne ink is used for printing. By adopting the scheme for printing, the polyacrylate emulsion coating has good adhesive force with the metal layer such as the surface of the spray Al paper and the waterborne ink also has high coating ability with the polyacrylate emulsion coating so that the ink and papers can be well combined by using the polyacrylate emulsion coating, thus achieving the aim of increasing the adhesive force of ink. The method of the invention realizes that the waterborne ink can be printed on the spray Al paper by adopting the photogravure method, and ensures that the spray Al paper and the waterborne ink which are two kinds of environmental protection type printing materials can be widely applied in the photogravure method field and the photogravure tends to develop in the green and environmental protection direction.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

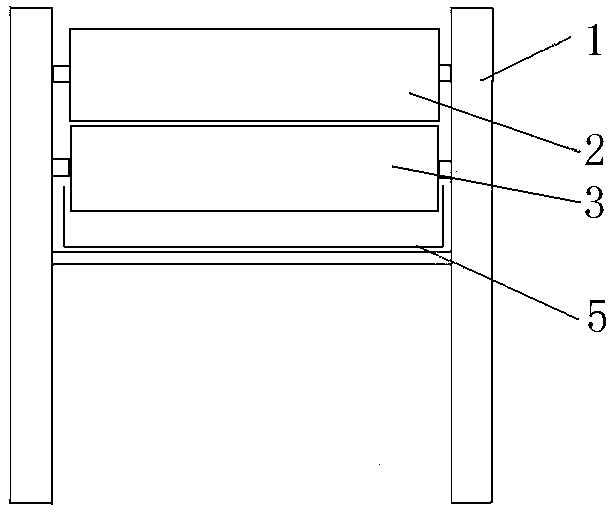

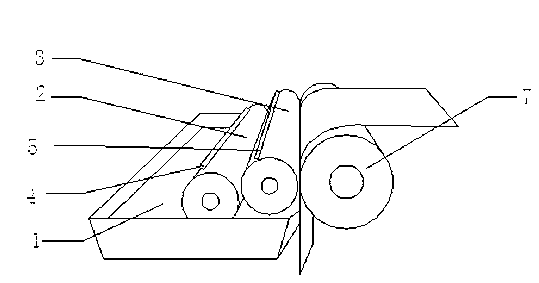

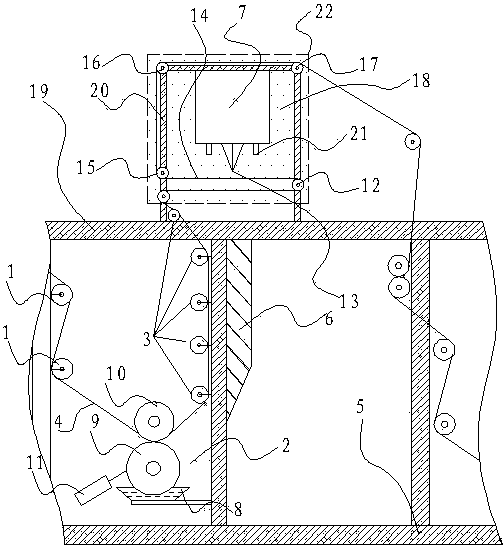

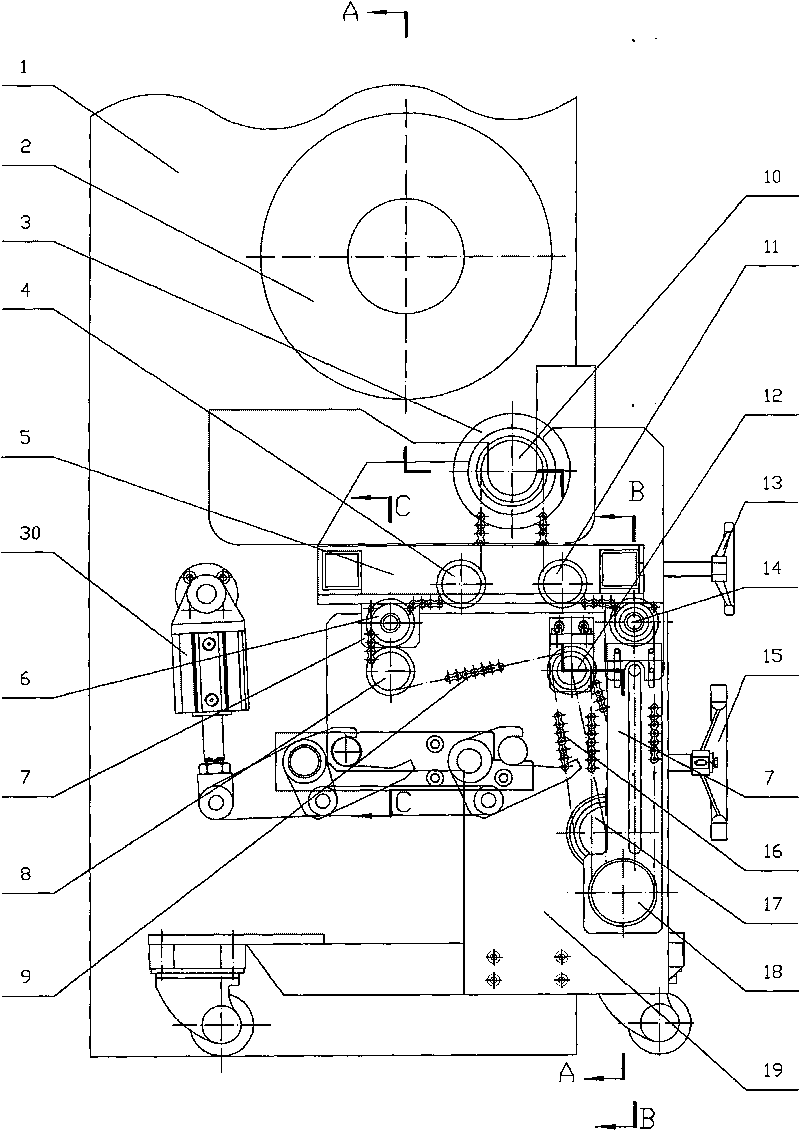

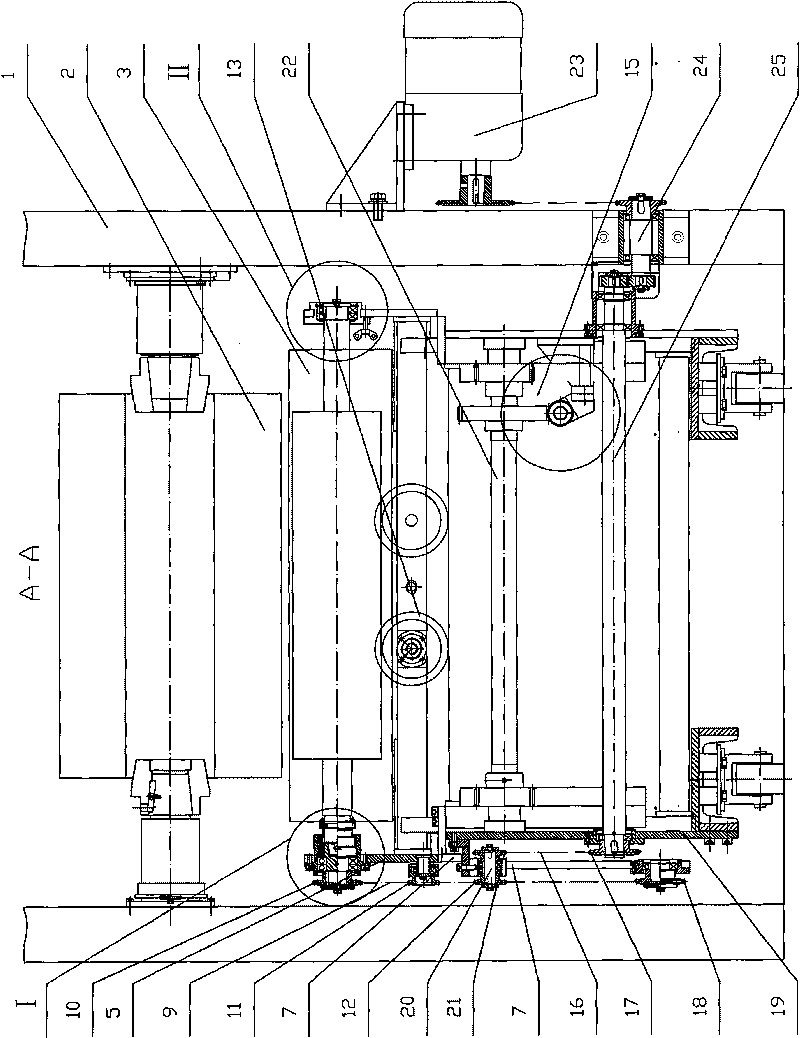

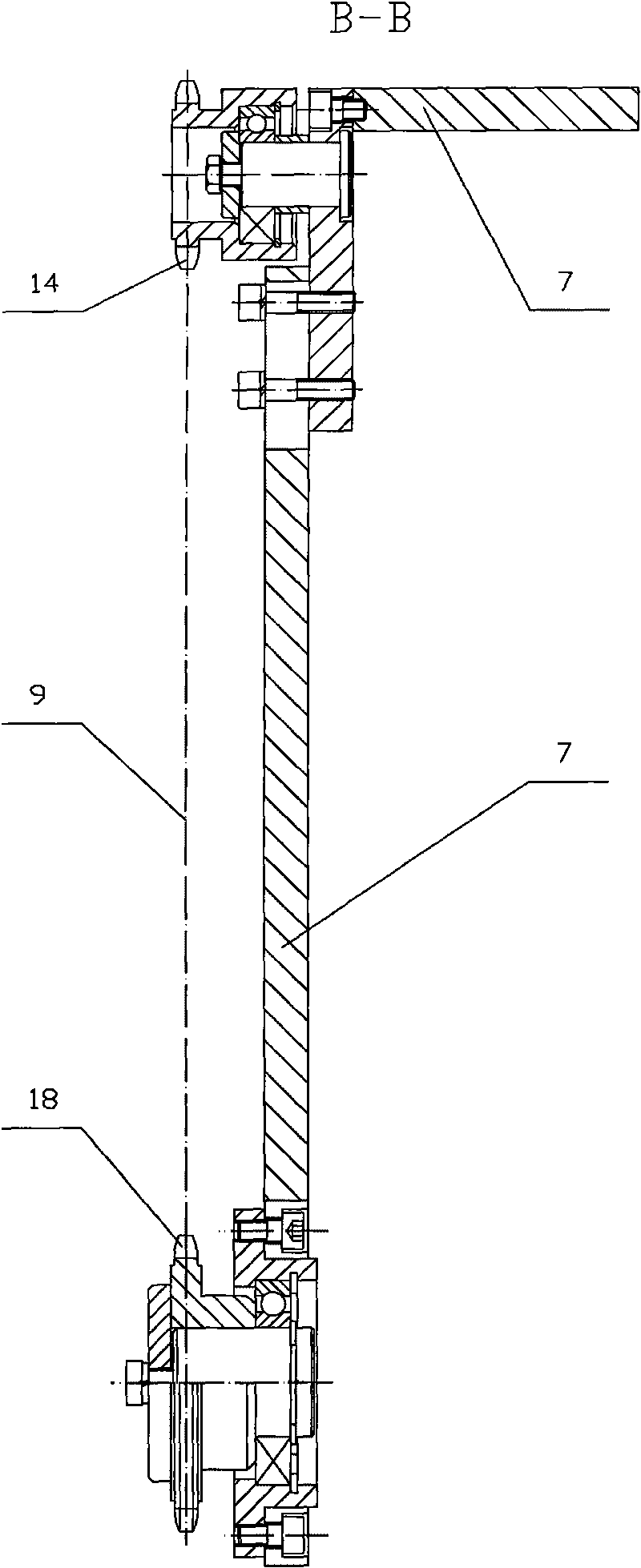

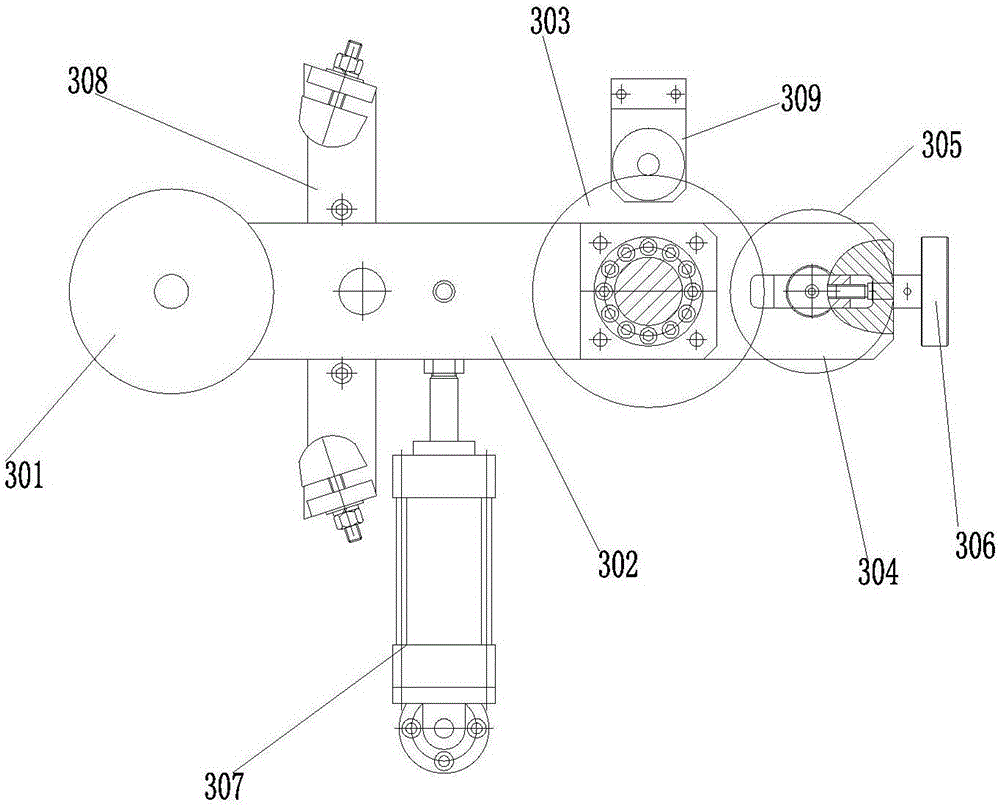

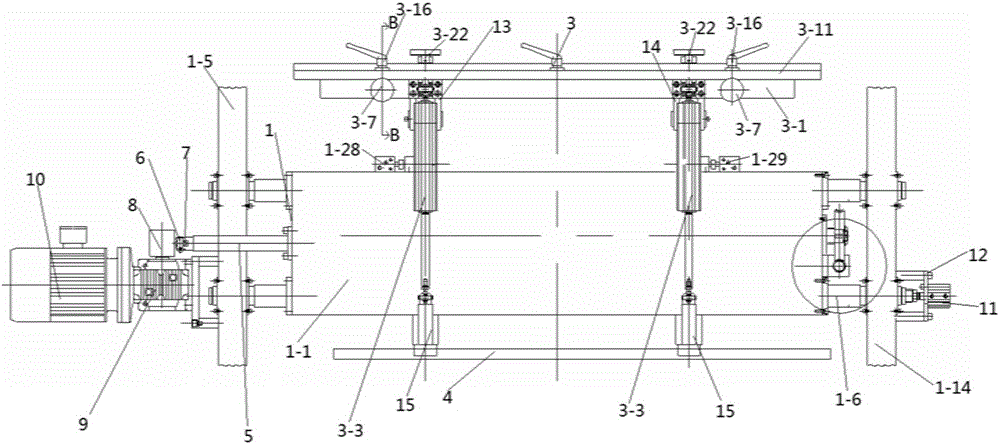

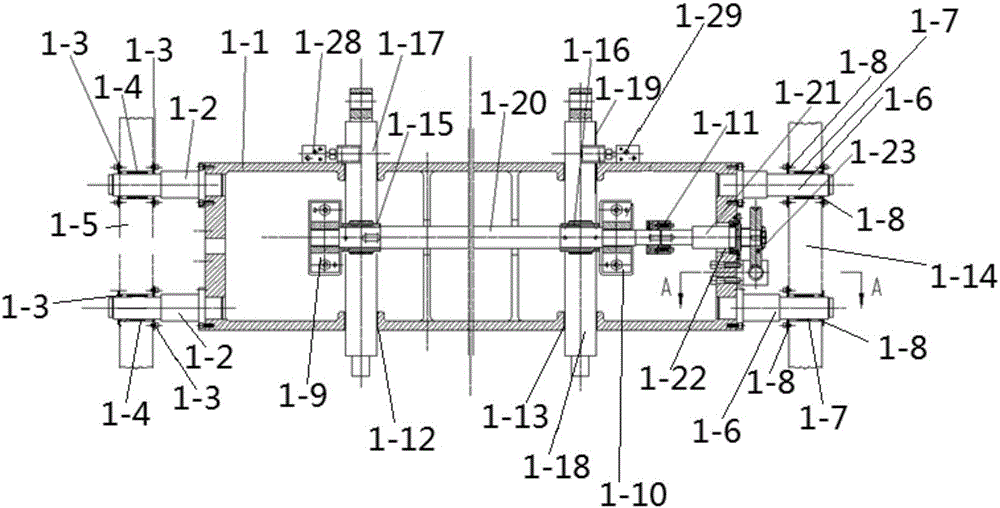

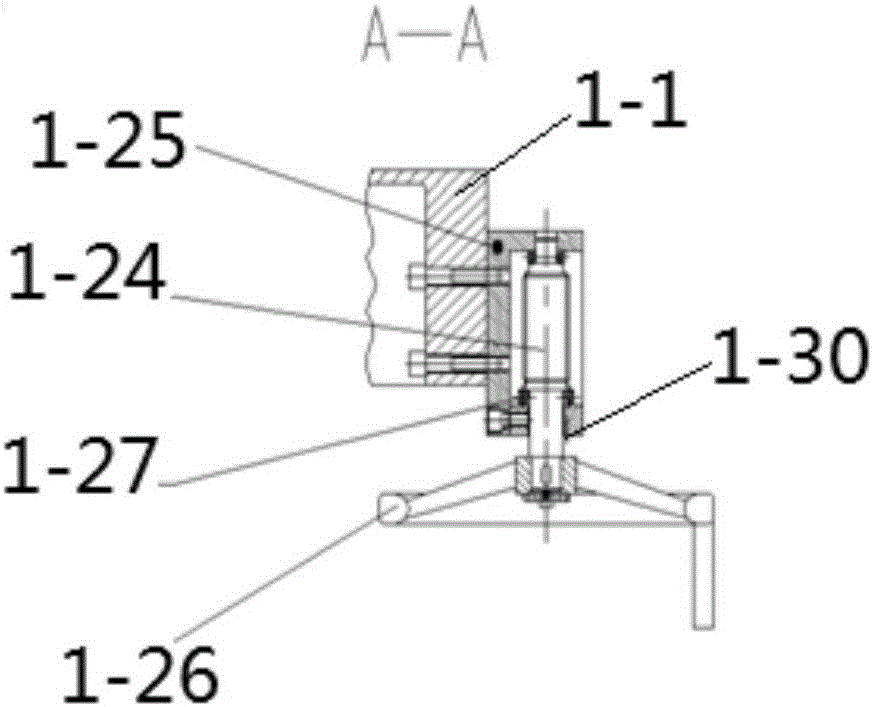

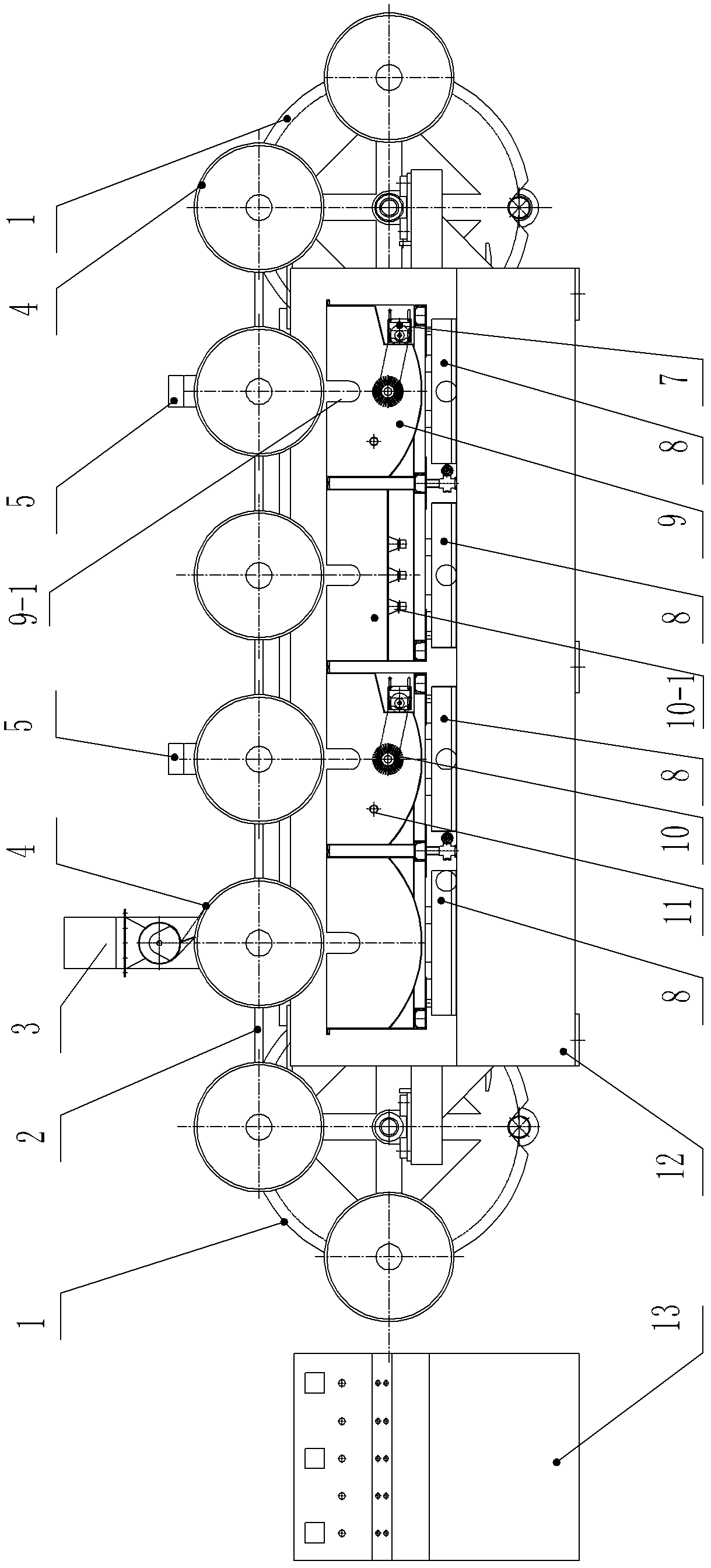

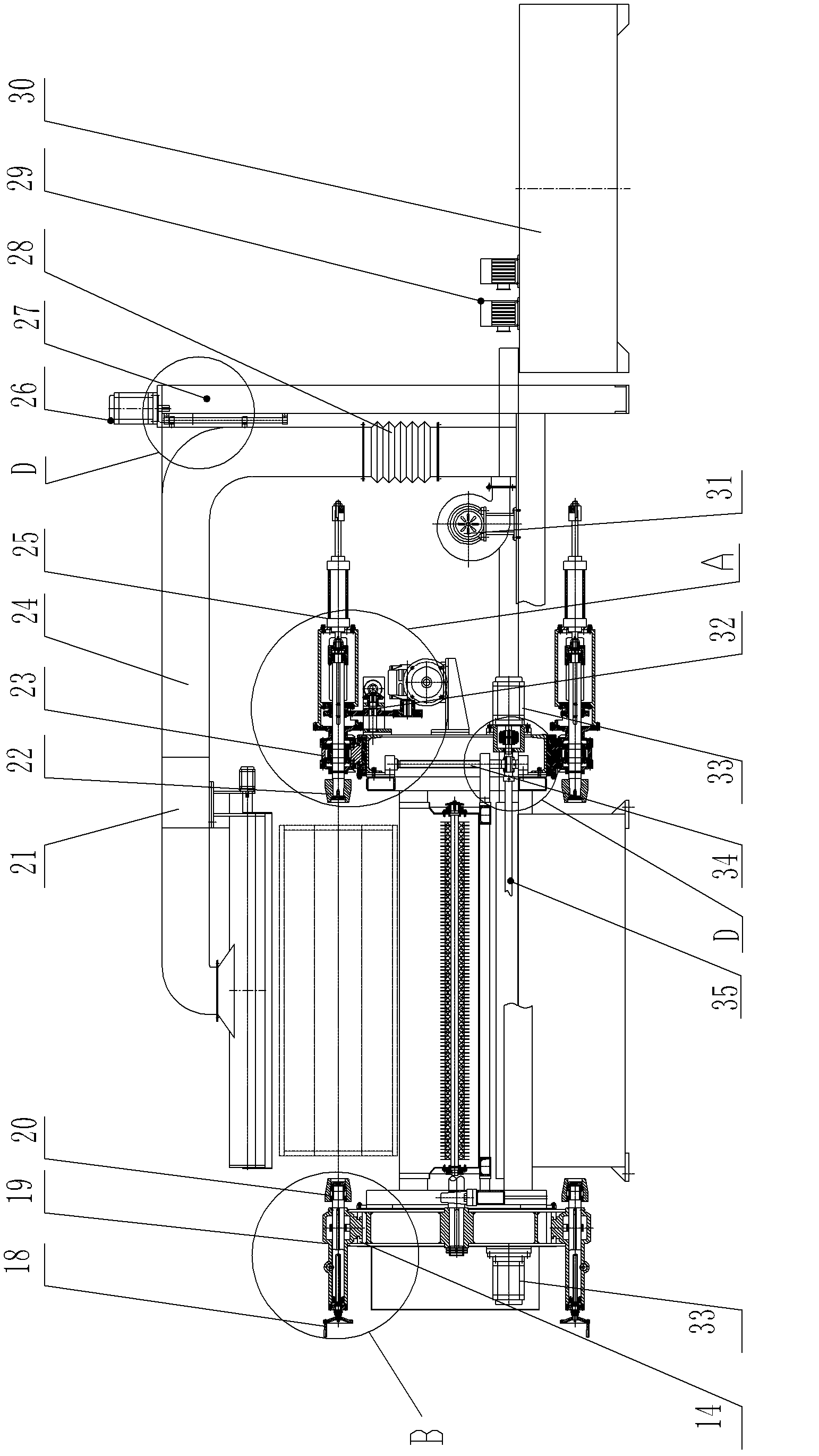

Ink-conveying trolley of photogravure press

ActiveCN101716849AGuaranteed printing qualityEasy to usePrinting press partsLocking mechanismPhotogravure

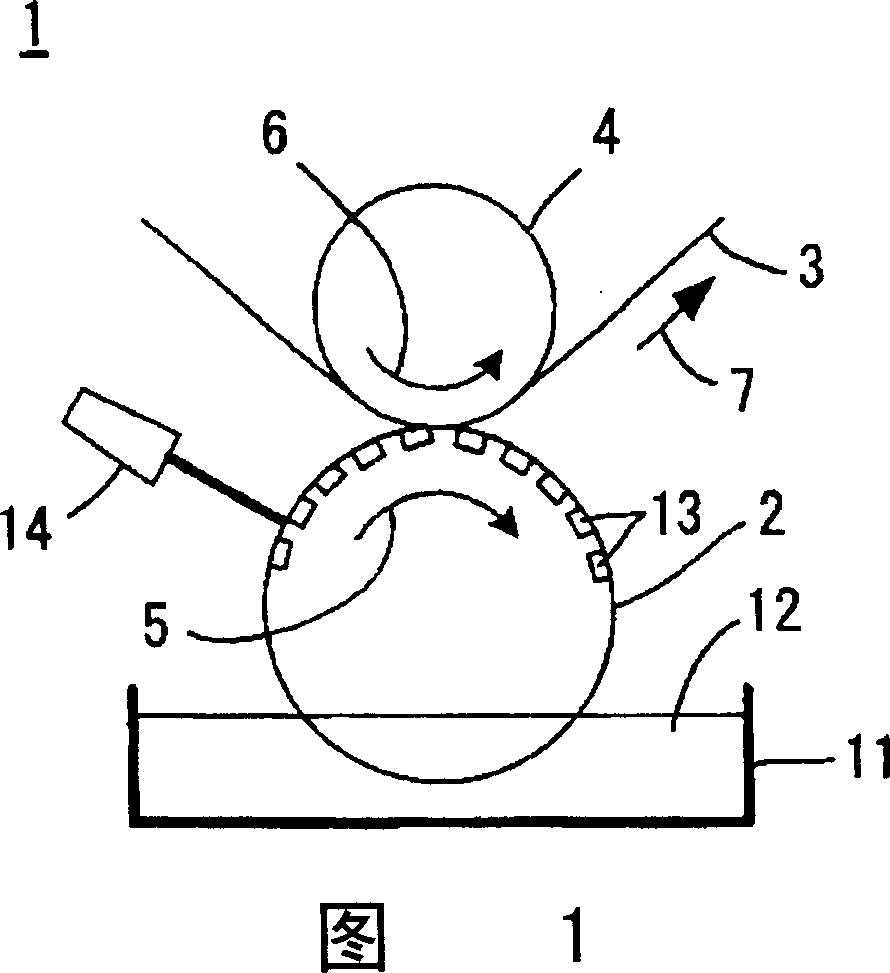

The invention discloses an ink-conveying trolley of a photogravure press, comprising a printing roller (2), an ink-conveying roller (3), an ink-conveying roller up-and-down moving device, an ink-conveying roller fore-and-after moving device and a locking mechanism (30); the printing roller (2) is rotatably connected to a printing frame (1); and the ink-conveying roller (3) is rotatably connected to a frame (19) of the ink-conveying trolley. The transmission mechanism also comprises a power device which is connected to the printing frame (1) and respectively connected with the ink-conveying roller fore-and-after moving device and the ink-conveying roller up-and-down moving device by a transmission gear and a sprocket chain; the ink-conveying roller fore-and-after moving device and the ink-conveying roller up-and-down moving device are connected to the frame (19) of the ink-conveying trolley; and the locking mechanism (30) is connected with the printing frame (1). The invention adopting the structure can freely realize the fore-and-after and the up-and-down motion tracks of the ink-conveying roller and can be accurately locked on the printing frame so as to ensure favorable printing quality.

Owner:NINGBO XINDA PRINTING MACHINERY

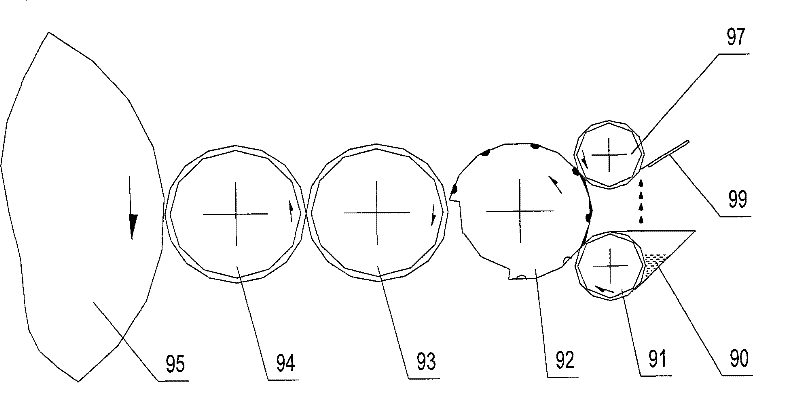

High-speed photogravure press

ActiveCN106274030AConsistent contact areaConsistent timeRotary intaglio printing pressPrinting press partsPhotogravureEngineering

The invention provides a high-speed photogravure press which comprises a winding device, an unwinding device, and at least one set of embossing device positioned between the winding device and the unwinding device, wherein each set of the embossing device is composed of a printing device and a drying oven heating device; all sets of the embossing devices are connected through driving guide rollers. The high-speed photogravure press is characterized in that an emptying traction part connected though a driving guide roller is mounted between the embossing devices and the unwinding device; a receiving traction part connected though a driving guide roller is mounted between the embossing devices and the winding device; at least one roller swinging device used for controlling tension of a printing base material is arranged on the emptying traction part and the receiving traction part; each printing device comprises a backpressure roller device, a rubber roller device and a photogravure stick device which are sequentially arranged from top to bottom; and at least one drying oven heating device is provided with an adjusting device capable of driving gravure transfer speed to be the same. The equipment is consistent in speed, uniform in printing and good in effect, and balance weight adjustable hand wheel is arranged.

Owner:ZHEJIANG MEIGE MACHINERY

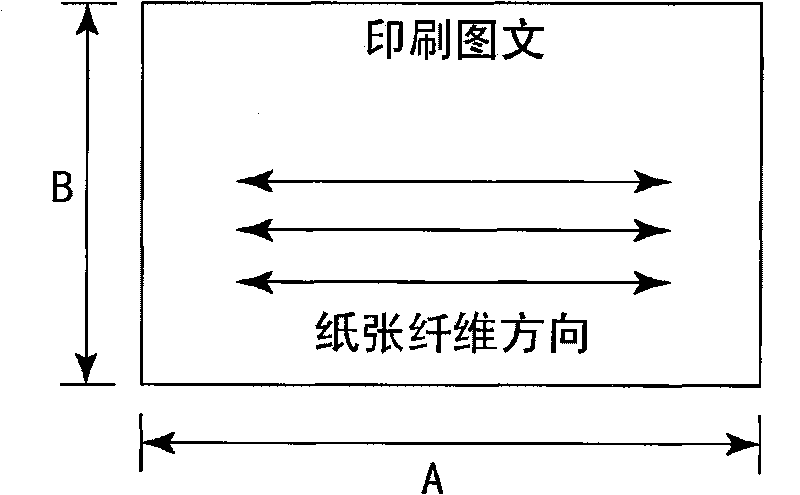

Gravure printing method and gravure printing article

InactiveCN1648769AGuaranteed concentrationAvoid rippleRotary intaglio printing pressScreening processesFine linePhotogravure

The photogravure printing is completed with photogravure comprising AM screen and FM screen. The text and reproduced image needing dense ink are formed with the meshes of corresponding AM screen, while the picture and fine lines with dark and light ink for representing are formed with the meshes of corresponding FM screen.

Owner:THINK LABORATORY CO LTD

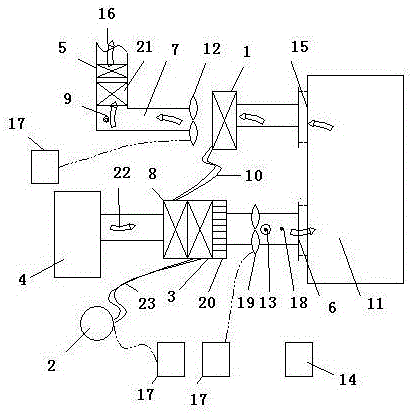

Waste heat recovery and hot air type energy-saving drying control system

InactiveCN105835525AIncrease lossIncrease the difficultyPrinting press partsWaste heat recovery unitPhotogravure

The invention discloses a waste heat recovery and hot air type energy-saving drying control system. The waste heat recovery and hot air type energy-saving drying control system comprises a drying oven exhaust fan (12), an exhaust air valve (21), an axial flow fan (19), a compressor (2), a heat exchanger A (1), a heat exchanger C (3) and a computer control center (14); the heat exchanger A (1) absorbs the heat energy (10) of harmful waste gas (16) exhausted by an air outlet (15) of a drying oven (11), and the heat energy (10) and the heat Z (23) generated by the compressor (2) act on the heat exchanger C (3) and then are conveyed into an air inlet (6) of the drying oven (11). According to the system, the basic heat is provided according to the Carnot principle, the COP is higher than 3.0, the heat recovered from the harmful waste gas is accumulated, the heating efficiency is greatly improved, and the energy is saved; according to the technological conditions of photogravure presses, compound machines and coating machines, the speed of an air inlet fan, the speed of the exhaust fan, the speed of the compressor for heat exchange and the angle of the exhaust air valve are adjusted in a stepless speed adjsutment mode for reducing unnecessary loss of hot air, and the harmful gas is compressed for preparing for harmful gas recovery in the second step.

Owner:DALIAN ALTMA IND CO LTD

Doctor blade device of photogravure press

ActiveCN106079852ASolve the noiseHigh reuse rateRotary intaglio printing pressPhotogravureEngineering

The invention discloses a doctor blade device of a photogravure press. The doctor blade device comprises a doctor blade angle adjusting device, a doctor blade lifting device is arranged on one side of the doctor blade angle adjusting device and connected with a doctor blade shifting device, and a doctor blade clamping plate device is arranged above the doctor blade angle adjusting device. The problems that an existing doctor blade device is complex in structure and high in noise during low-speed printing are solved.

Owner:SHAANXI BEIREN PRINTING MACHINERY

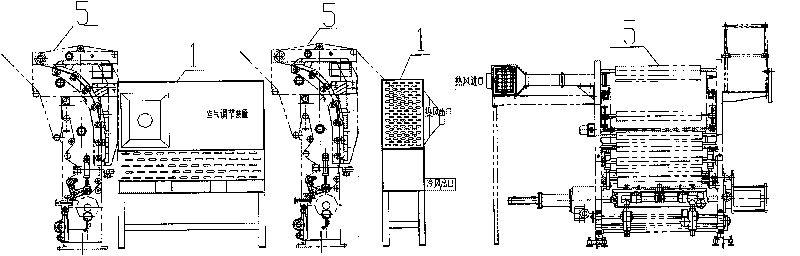

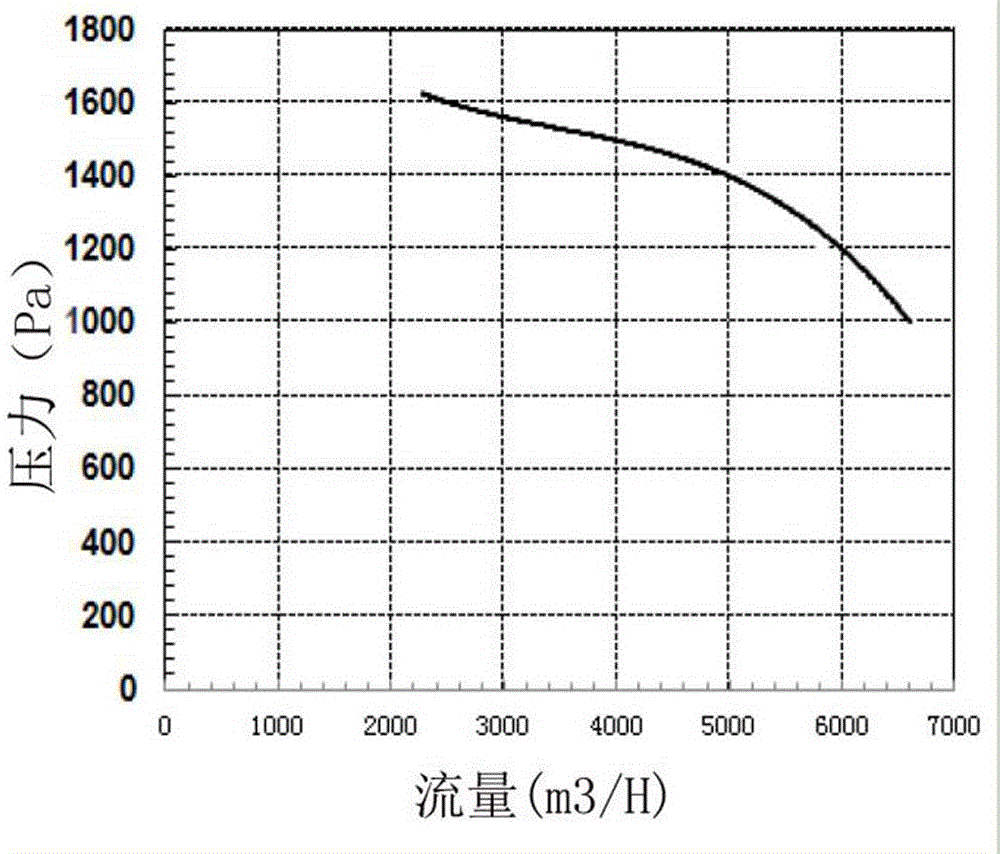

Air conditioning apparatus special for unit-type photogravure press

InactiveCN101737866AMeet the working temperatureNovel structural designEnergy recovery in ventilation and heatingLighting and heating apparatusCold airPhotogravure

The invention relates to an air conditioning apparatus special for a unit-type photogravure press. The upper part of the air conditioning apparatus is provided with a hot air outlet, and the lower part of the air conditioning apparatus is provided with a cold air outlet. The apparatus has the advantages that: firstly, a precedent for the air conditioning apparatus special for the unit-type photogravure press is created; and the apparatus not only has a novel, unique, simple and practical structural design, but also can form cyclic utilization of energy sources together with the unit-type photogravure press, so the apparatus makes use of a heat source, simplifies the structure of a drying roller of the unit-type photogravure press and is beneficial to environment protection; and secondly, the apparatus not only meets the working temperature needed by the unit-type photogravure press, but also avoid constant-temperature design for a workshop of the entire unit-type photogravure press, thereby achieving the purposes of saving energy and saving expense.

Owner:杭州吴泰印刷包装机械有限公司

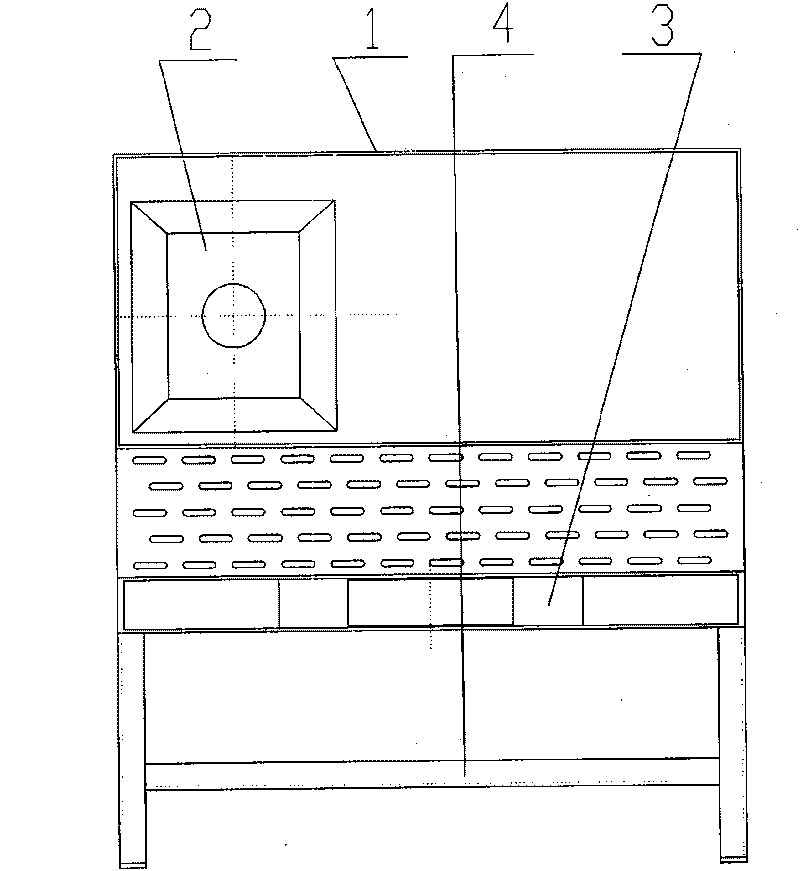

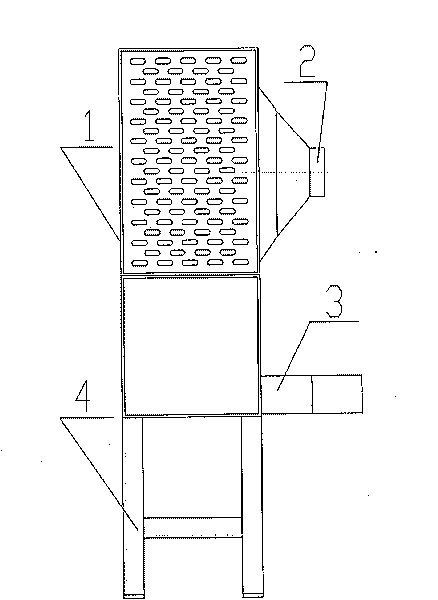

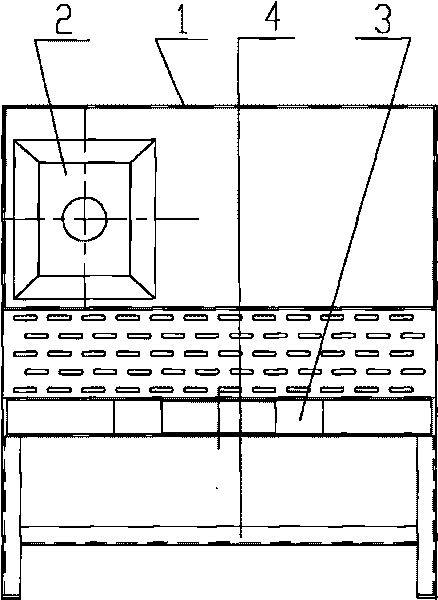

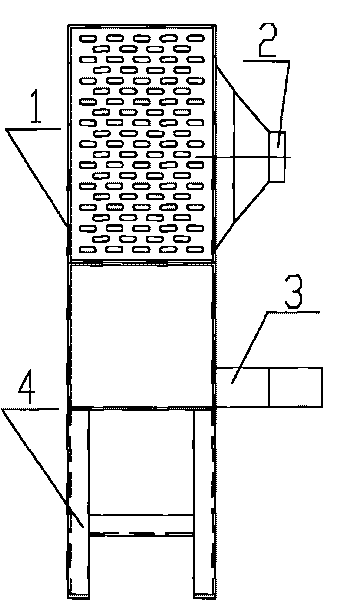

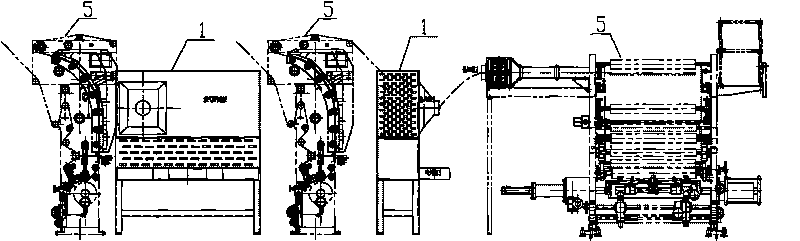

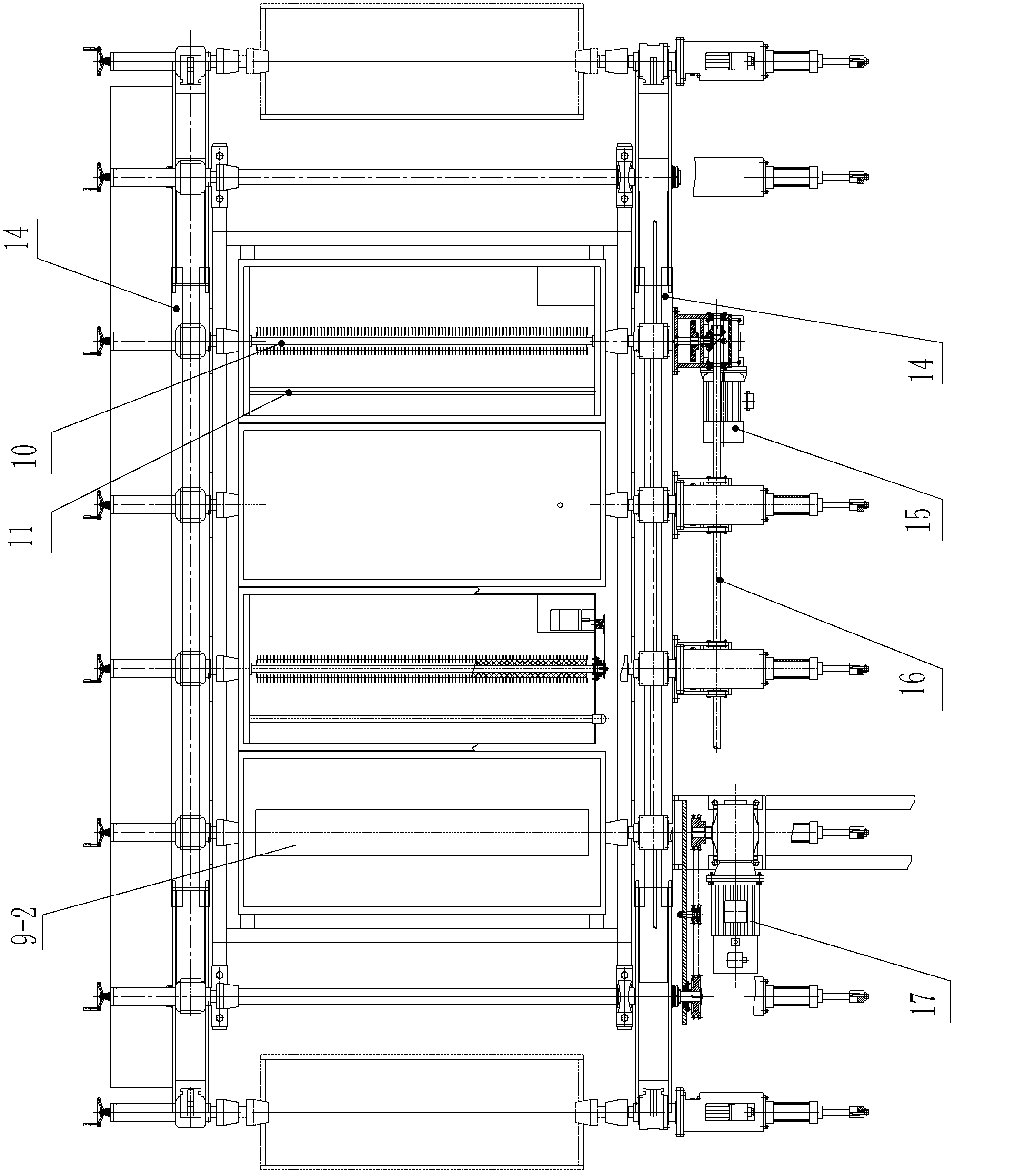

Top-installed type automatic photogravure roller cleaning machine

ActiveCN102500584AHigh speedReduce production capacityDrying gas arrangementsCleaning using toolsWater savingPhotogravure

The invention relates to equipment for automatically cleaning and drying a photogravure roller after printing. The technical problem to be solved is that the provided automatic cleaning machine is capable of rapidly cleaning and drying the photogravure roller and has the characteristics of high automation degree, convenience for use and environment friendlessness. The technical scheme provided bythe invention is as follows: the top-installed type automatic photogravure roller cleaning machine is characterized by comprising a box body type machine frame, a photogravure roller cleaning system,a water-saving circulation system, a photogravure roller transmission system and a host machine, wherein the box body type machine frame is provided with an empty cavity; the photogravure roller cleaning system is installed in the empty cavity; the photogravure roller transmission system is installed on the machine frame; the host machine is used for controlling the photogravure roller cleaning system, the photogravure roller transmission system and the water-saving circulation system; and the empty cavity is upwardly opened.

Owner:杭州临安通达装饰材料有限公司

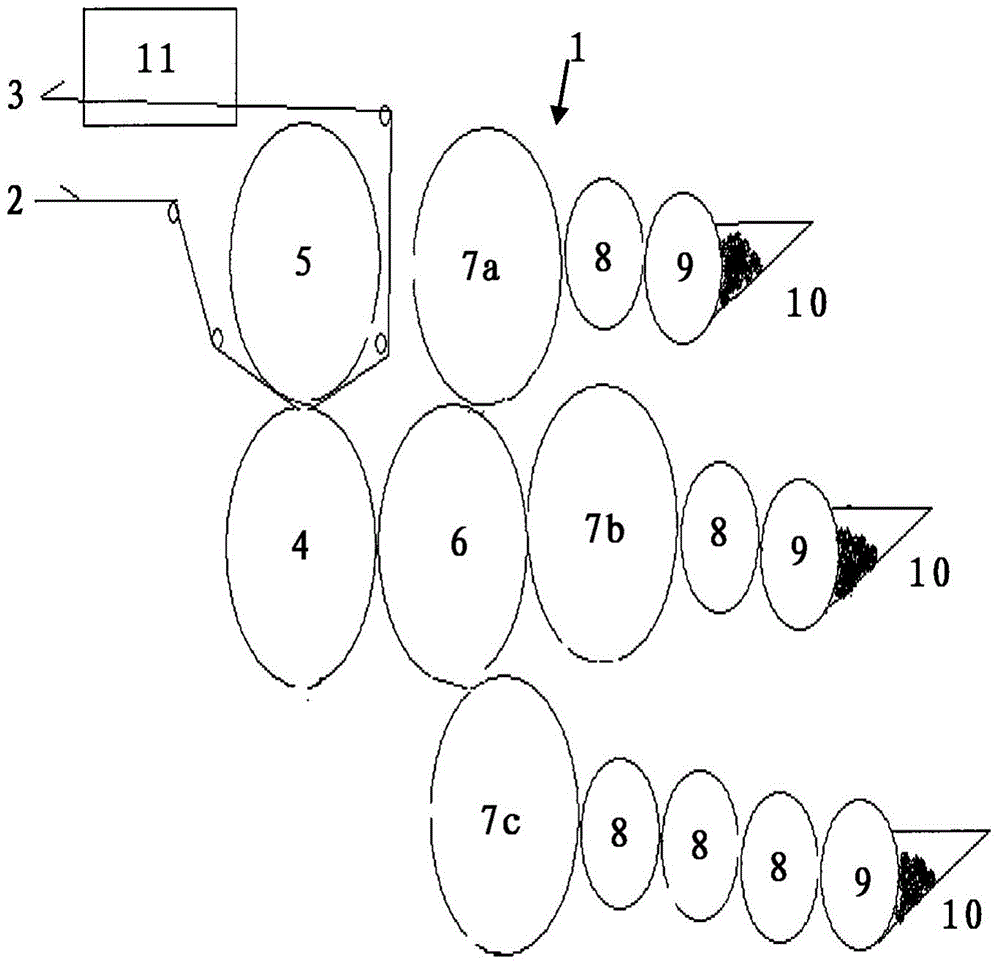

Gravure wiring printing machine and printing method

The invention provides a gravure wiring printing machine (1) and a printing method thereof. The gravure wiring printing machine (1) comprises a paper-feeding mechanism (2), a paper-collecting mechanism (3), a plate cylinder (4) and an impression cylinder (5) which are used for gravure printing. The gravure wiring printing machine (1) further comprises a gravure ink-transferring system. The gravure ink-transferring system is provided with a color-collecting cylinder (6) and represents a plurality of colors in one plate. The color-collecting cylinder (6) is used for converging printing ink in different colors two or more single-color cylinders (7a, 7b, 7c) and then transferring the printing ink to the plate cylinder (4), so that at least one line in a pattern on the plate cylinder is filled with two or more kinds of gravure printing ink in different colors. The gravure wiring printing machine (1) further comprises an ink-scraping system or a plate-wiping system used for scraping off or wiping off unnecessary printing ink in portions without images and texts. The impression cylinder (5) and the plate cylinder (4) with the unnecessary printing ink being scrapped off or wiped off can be operated in a matched mode to complete the gravure wiring printing process.

Owner:北京万垟防伪技术有限责任公司 +2

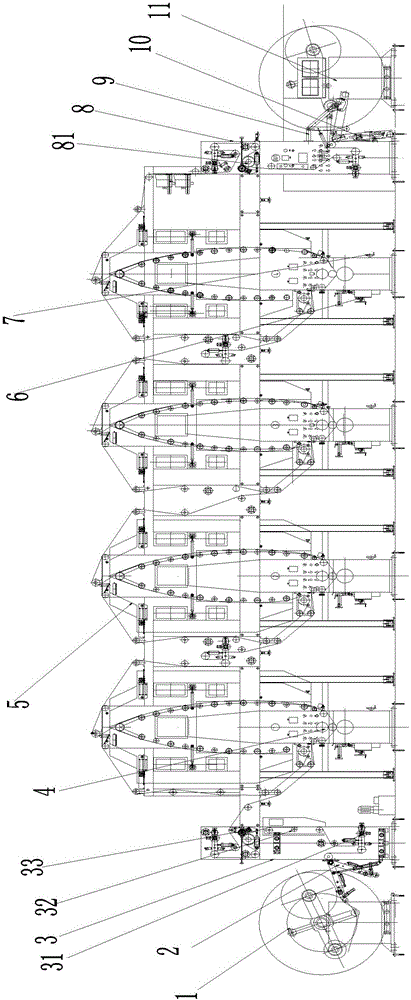

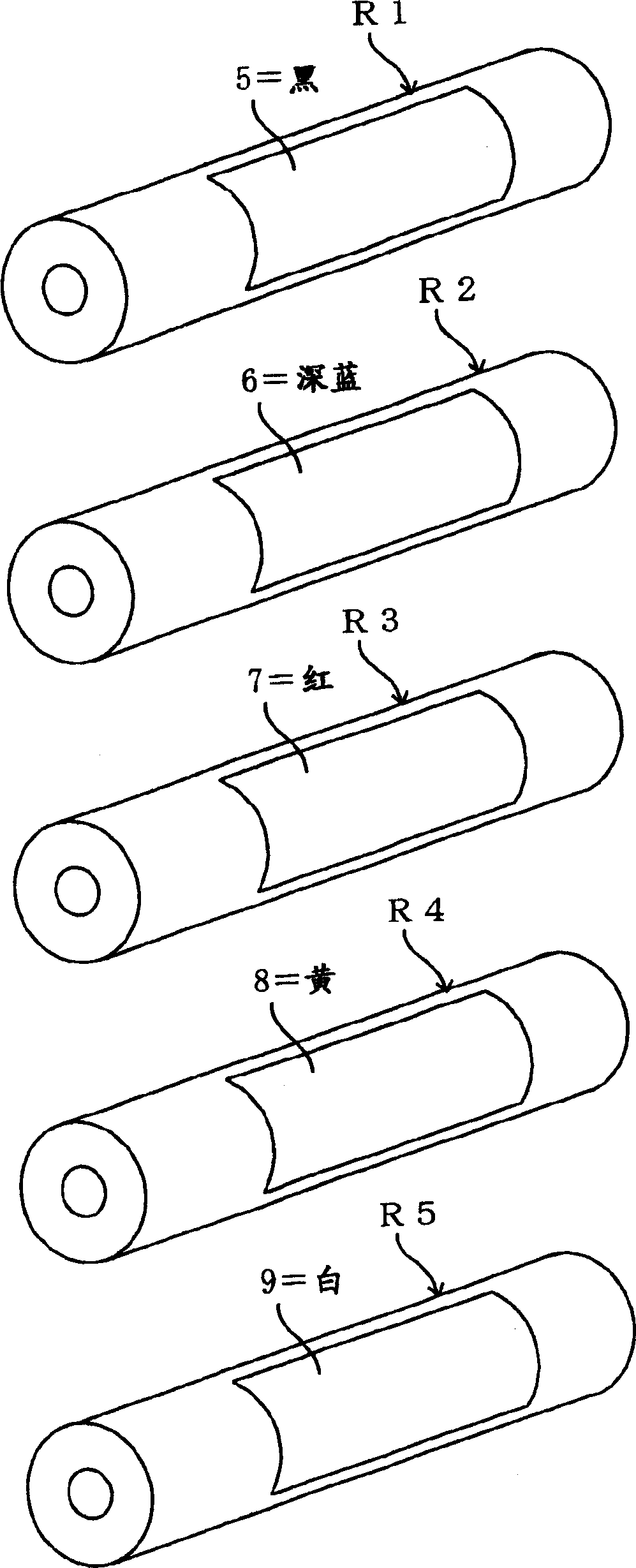

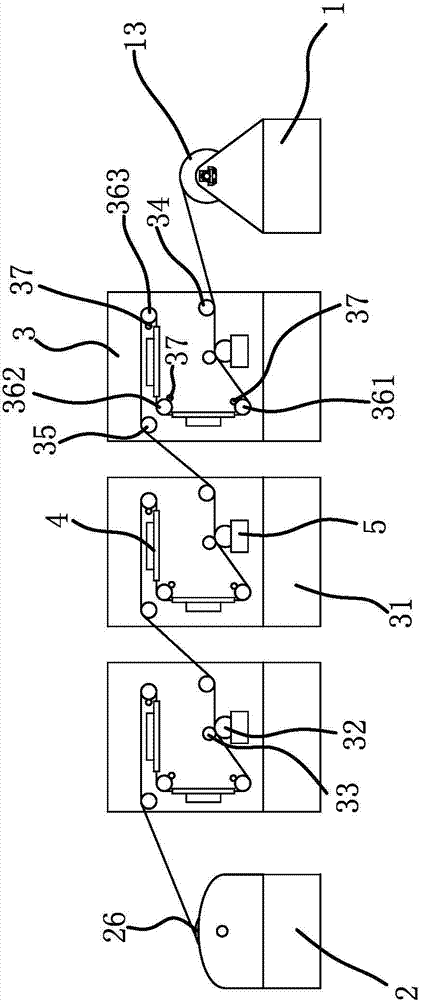

Unit type photogravure press

The invention provides a unit type photogravure press, and belongs to the technical field of machines. The unit type photogravure press solves the technical problem that the tensity of printing paper changes when the printing paper of an existing unit type photogravure press enters the photogravure press, and printing quality is influenced. The unit type photogravure press comprises an unwinding frame and a winding frame, a plurality of printers which are arranged in sequence and can print different colors on the printing paper in sequence are arranged between the unwinding frame and the winding frame, an unwinding roller is rotatably connected with the unwinding frame, an adjusting mechanism which can adjust the height of the unwinding roller according to the amount of the printing paper on the unwinding roller is arranged between the unwinding roller and the unwinding frame, a winding roller is rotatably connected with the winding frame, and a driving mechanism which can drive the winding roller to rotate to wind the printing paper on the unwinding roller through the printers to the winding roller is arranged on the winding frame. The unit type photogravure press has the advantage of being stable in printing quality.

Owner:ZHEJIANG CHANGHAI PACKAGE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com