Two-dimensional code spraying device applied to photogravure press

A technology of a gravure printing machine and a spraying device, which is applied in the directions of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of cumbersome production process, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

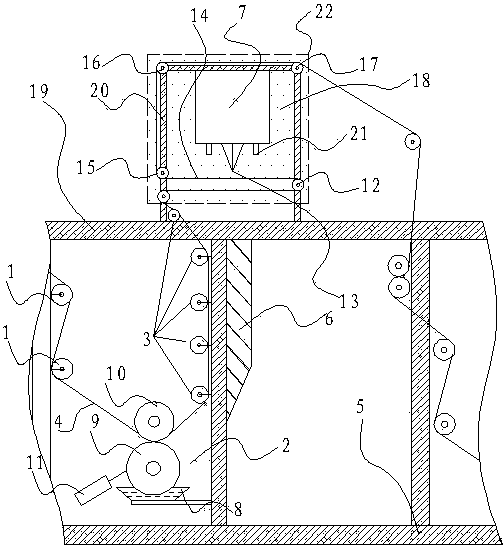

[0020] Such as figure 1 As shown, a two-dimensional code spraying device applied to a gravure printing machine includes a fixed frame 5 and a lead-in roller 1 arranged on the fixed frame 5, a gravure printing assembly 2, an oven 6 and a lead-out roller 3, and the printing substrate 4 is passed through After the lead-in roller 1 is guided, gravure printing is carried out on the gravure printing assembly 2, and then it is led out by the lead-out roller 3. An oven 6 for drying ink is arranged outside the lead-out roller 3, and an oven 6 is provided between the lead-out roller 3 and the lead-in roller 1. Printing substrate turning device and two-dimensional co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com