Decorative film and manufacturing method thereof

A production method and decorative film technology, which are applied to special decorative structures, decorative arts, printing devices, etc., can solve problems such as environmental pollution, scratches on hard objects, and environmental pollution, and achieve the effects of reduced production costs and simple processing techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

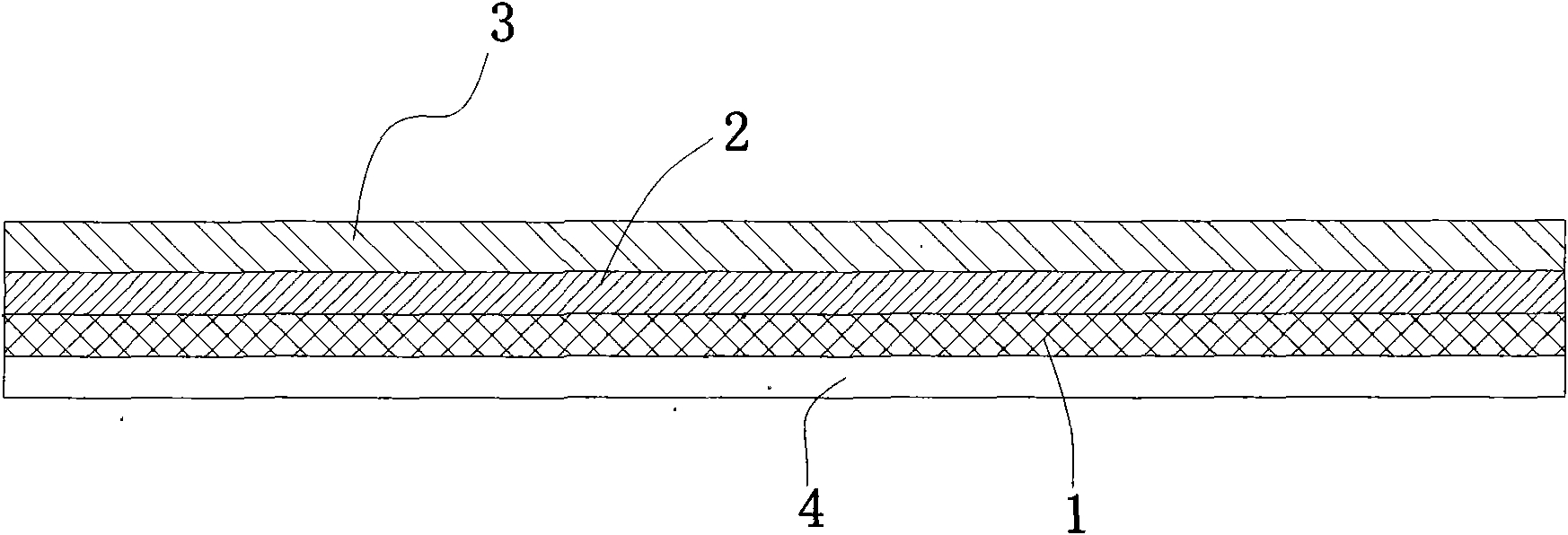

[0020] As shown in Figure 1, the decorative film of the present invention includes from bottom to top: a primer 4, a substrate layer 1, a printing layer 2, a protective layer 3 on the surface of the printing layer 2, wherein the printing layer 2 is printed on the substrate by an oil color printer On the surface of layer 1, the protective layer 3 is UV paint.

[0021] Generally, the substrate layer 1 is a PVC film, of course, PET material or other similar materials can also be used. For example: PP film, PVC film, PET film, BOPP film, PE film.

[0022] The production method of the present invention is as follows:

[0023] The manufacturing method of the decorative film includes the following steps:

[0024] 1. The material roller for preparing the PVC base material is placed on the material rack, and passed through the printing machine to print a layer of oil color image on the base material layer 1 through the printing machine to form the printing layer 2.

[0025] 2. Place the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com