Glass Bottle and can detecting method and detecting device

A technology for glass bottles and jars and a detection method, which is applied to measurement devices, optical devices, optical testing for flaws/defects, etc. It is easy to promote and apply, increase contrast, and ensure the effect of no missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

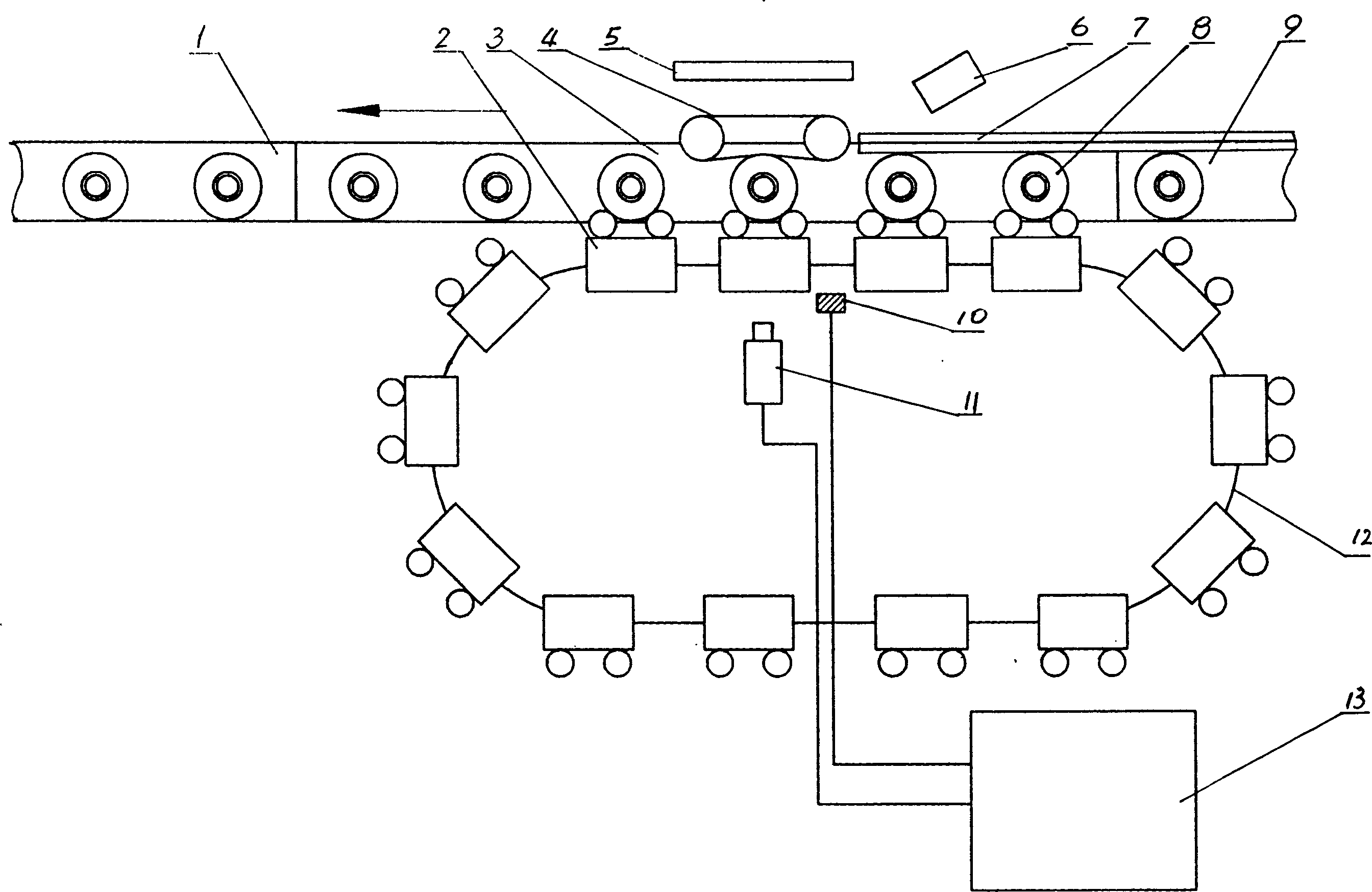

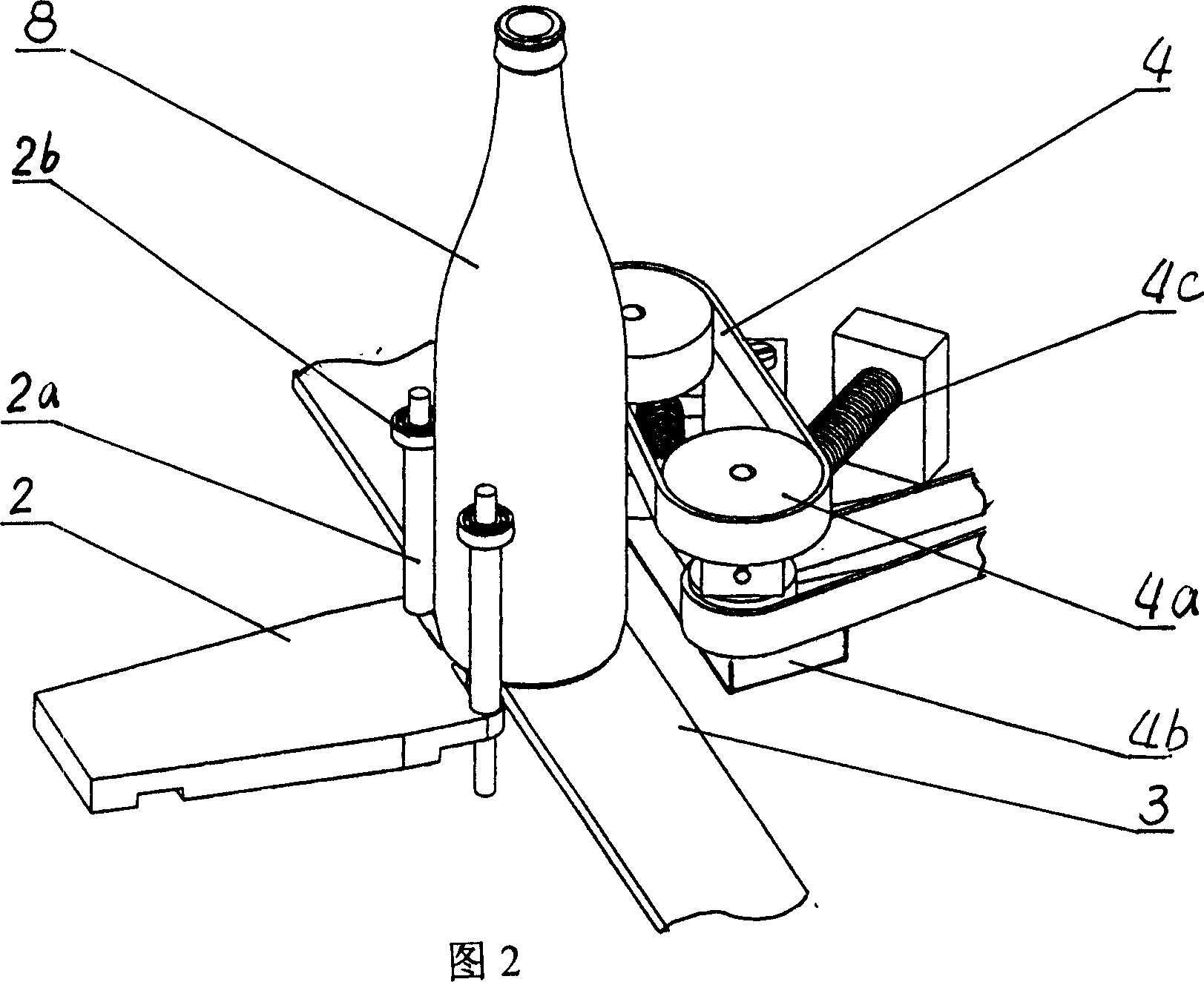

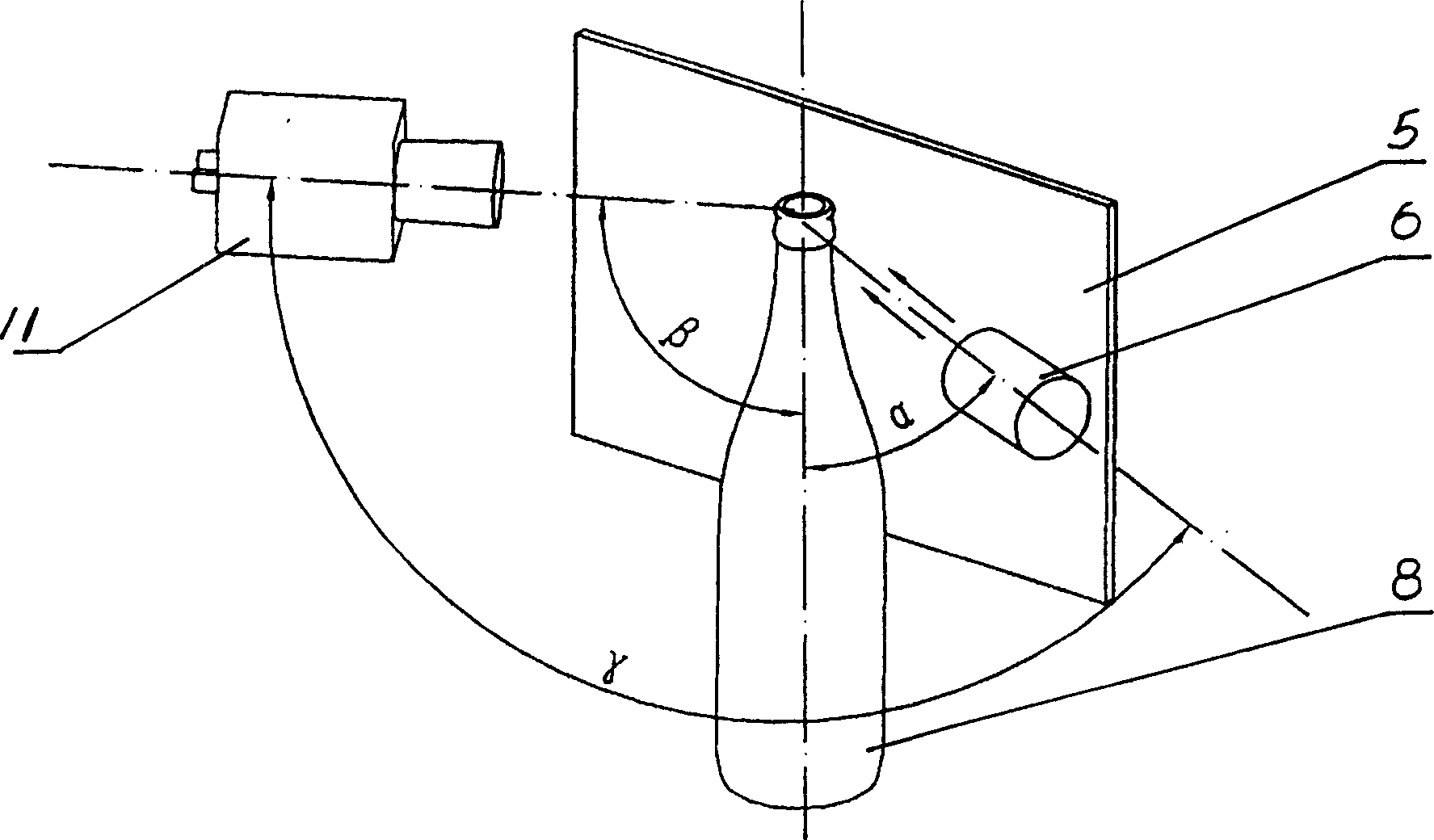

[0017] The detection method for glass bottles and jars of the present invention includes computer image processing and various calculation methods. The light source is projected on the mouth of the glass bottle, and the light screen is used as the background of the glass bottle to be inspected. The glass bottle is rotated 360 degrees, and 15 to 35 images of the bottle mouth are taken during the rotation process. The sequence captured by the computer for the same bottle The images are processed and calculated one by one. As long as a bright spot reflected by the crack of the bottle mouth is found in one of them, it can be determined that there is a crack defect in the bottle mouth.

[0018] When the inspected bottle rotates a circle, the images of multiple series of bottles captured show the state of the entire bottle mouth. When the computer processes the image, the image segmentation algorithm is used to cut out part of the image of the bottle mouth in each picture as the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com