Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3139 results about "Acrylic polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic Polymers. Acrylic polymer emulsions are water based polymers that can be produced from methyl methacrylate, butyl acrylate, 2-ethylhexyl acrylate, acrylic acid, methyl acrylate, etc.

Controlled release formulations coated with aqueous dispersions of acrylic polymers

InactiveUS6143353ADissolution stabilityIncrease weight gainPretreated surfacesMedical devicesWater insolubleActive agent

A stable solid controlled release formulation having a coating derived from an aqueous dispersion of a hydrophobic acrylic polymer includes a substrate including an active agent selected from the group consisting of a systemically active therapeutic agent, a locally active therapeutic agent, a disinfecting and sanitizing agent, a cleansing agent, a fragrance agent and a fertilizing agent, overcoated with an aqueous dispersion of the plasticized water-insoluble acrylic polymer. The formulation provides a stable dissolution of the active agent which is unchanged after exposure to accelerated storage conditions.

Owner:PURDUE PHARMA LP

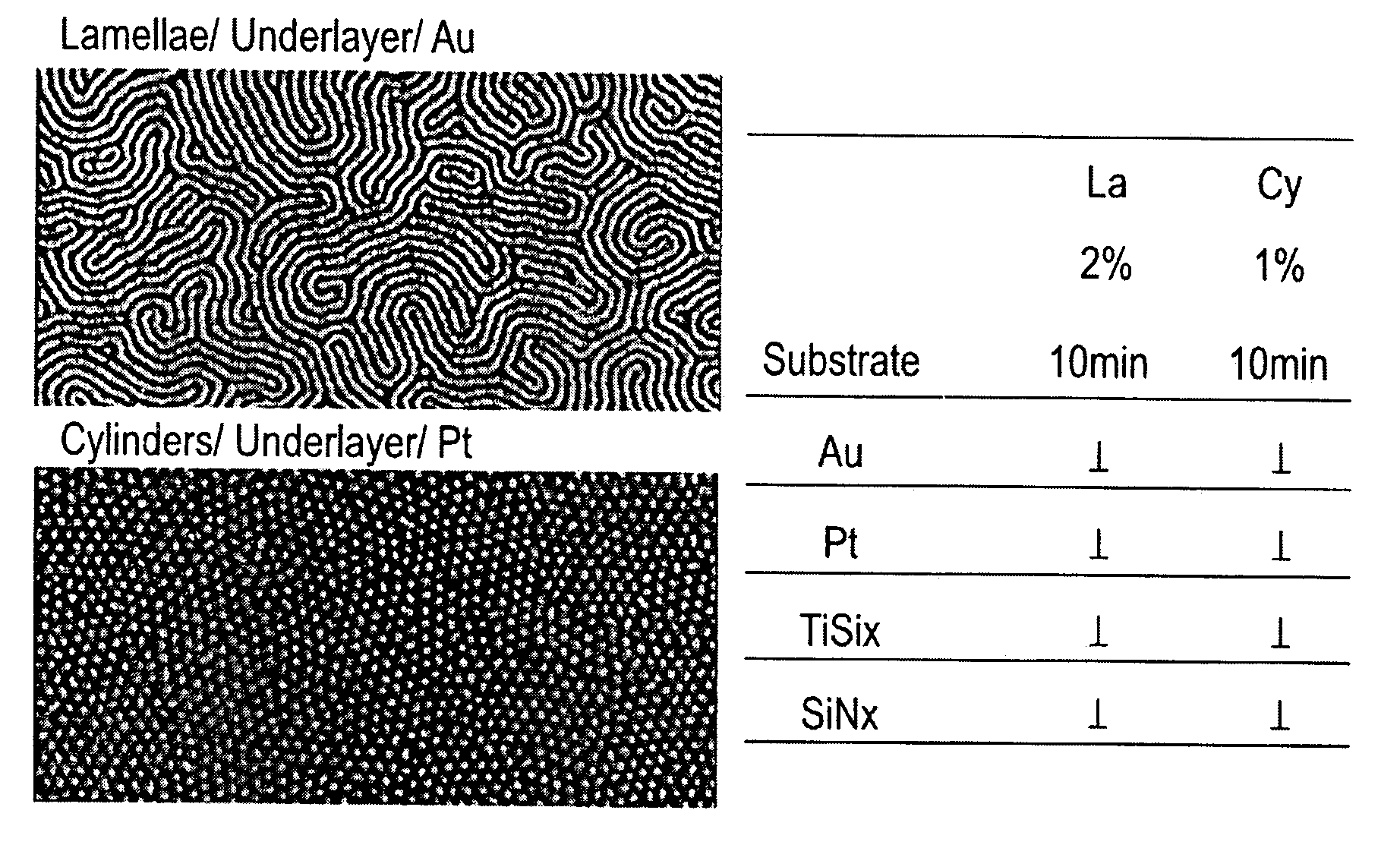

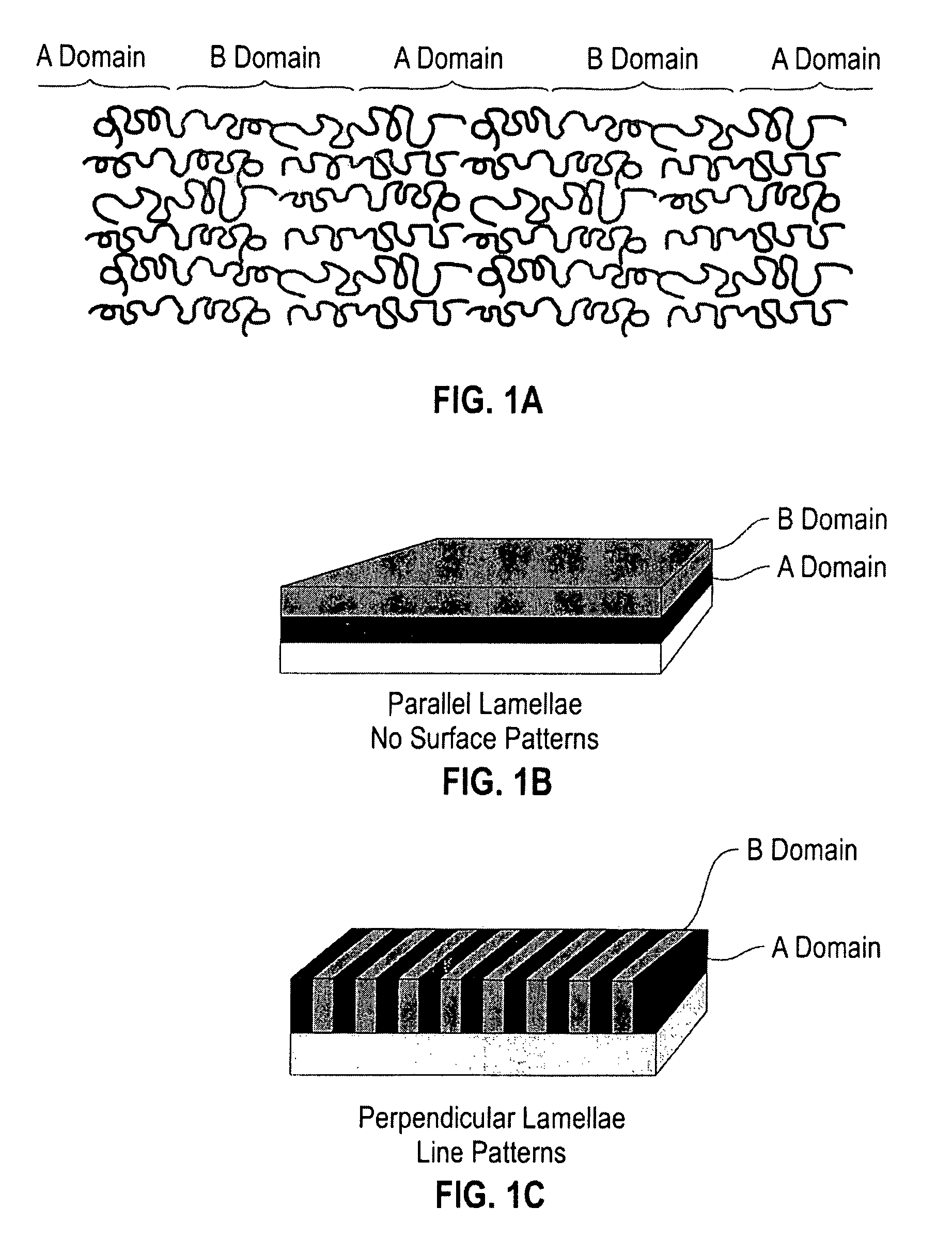

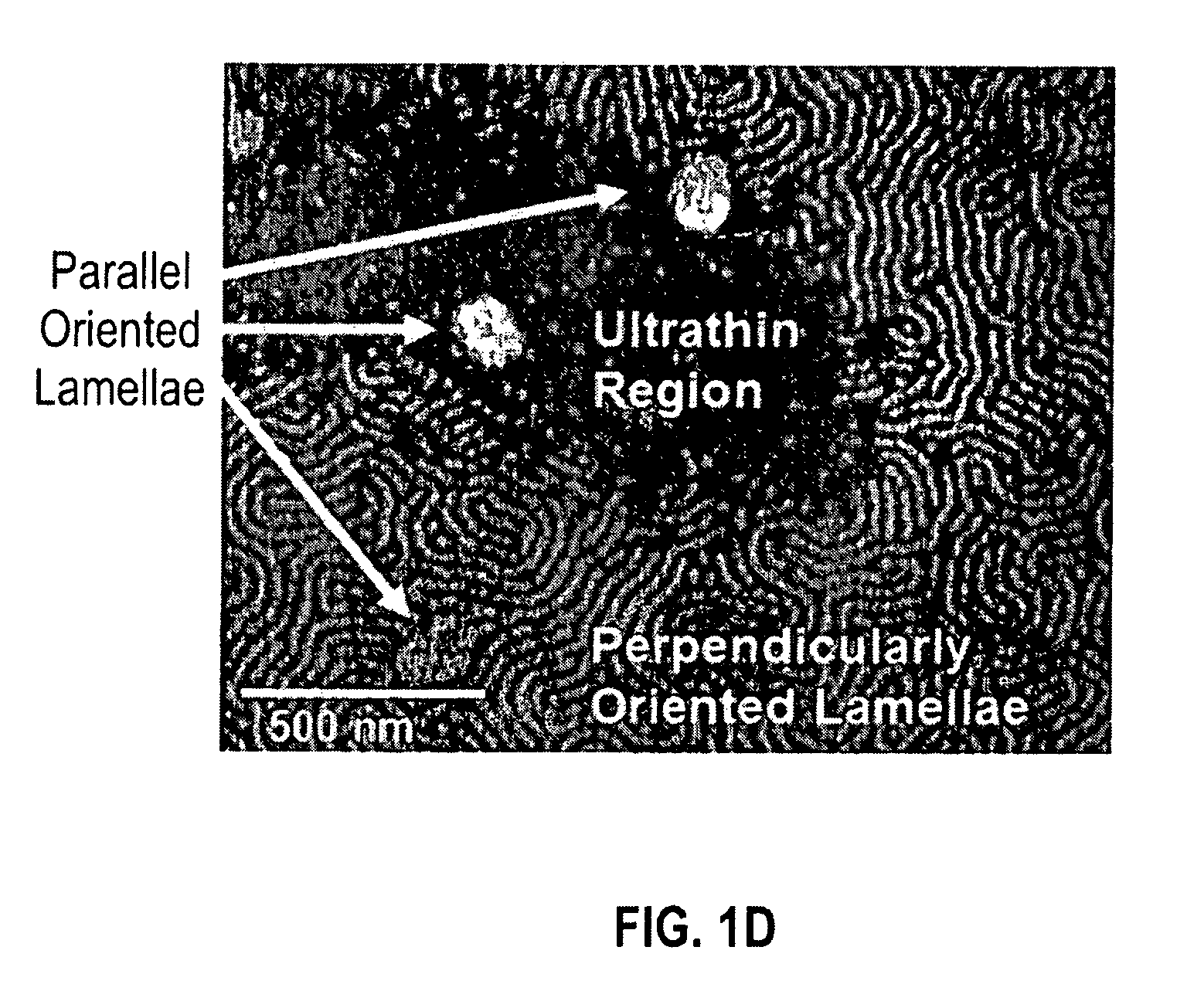

Method of use of epoxy-containing cycloaliphatic acrylic polymers as orientation control layers for block copolymer thin films

ActiveUS7521090B1Easy to controlShorten cycle timePhotosensitive materialsPhotomechanical apparatusOptoelectronicsAcrylic polymer

Disclosed herein is a method of controlling the orientation of microphase-separated domains in a block copolymer film, comprising forming an orientation control layer comprising an epoxy-containing cycloaliphatic acrylic polymer on a surface of a substrate, irradiating and / or heating the substrate to crosslink the orientation control layer, and forming a block copolymer assembly layer comprising block copolymers which form microphase-separated domains, on a surface of the orientation control layer opposite the substrate. The orientation control layer can be selectively cross-linked to expose regions of the substrate, or the orientation control layer can be patterned without removing the layer, to provide selective patterning on the orientation control layer. In further embodiments, bilayer and trilayer imaging schemes are disclosed.

Owner:GLOBALFOUNDRIES US INC

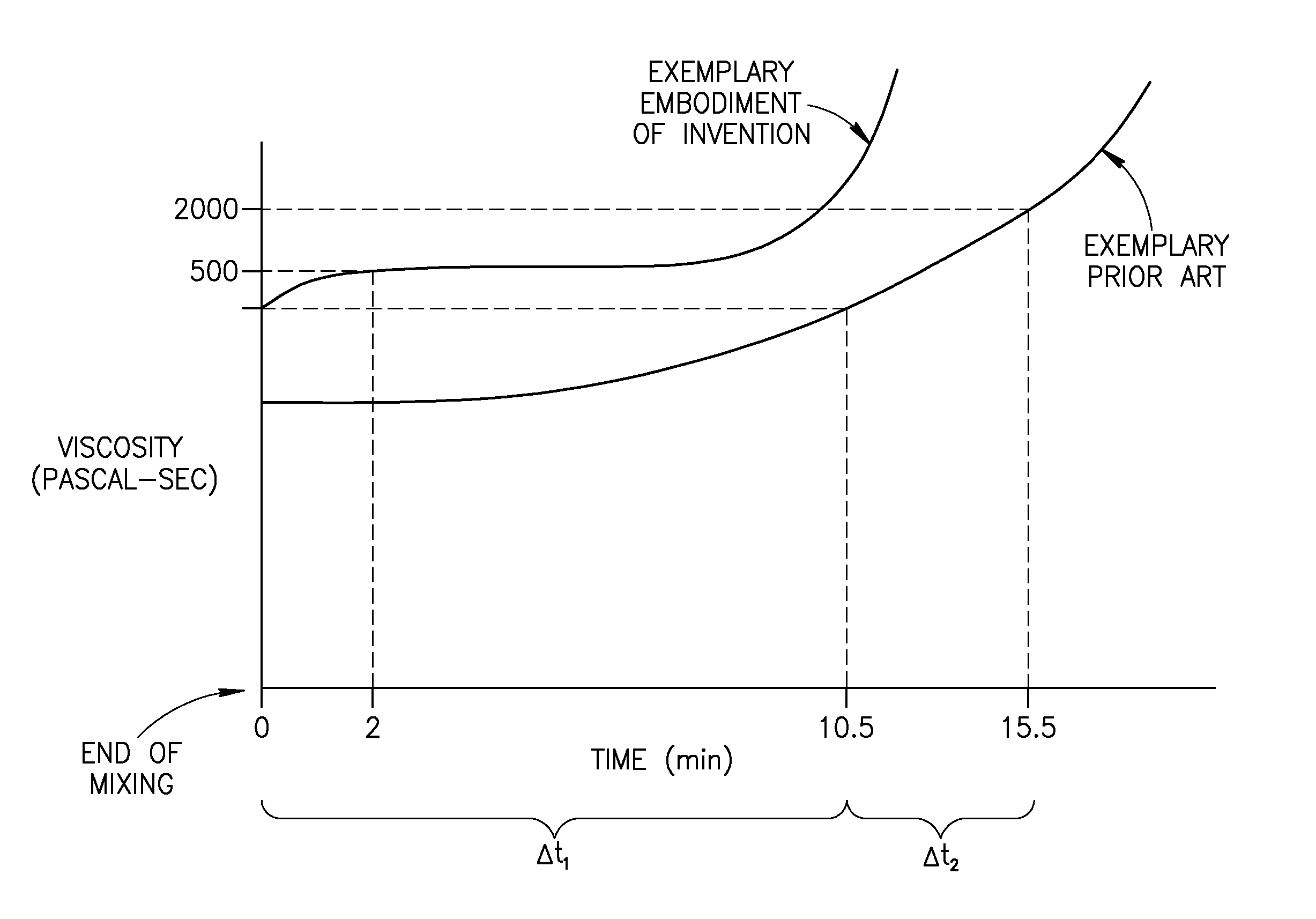

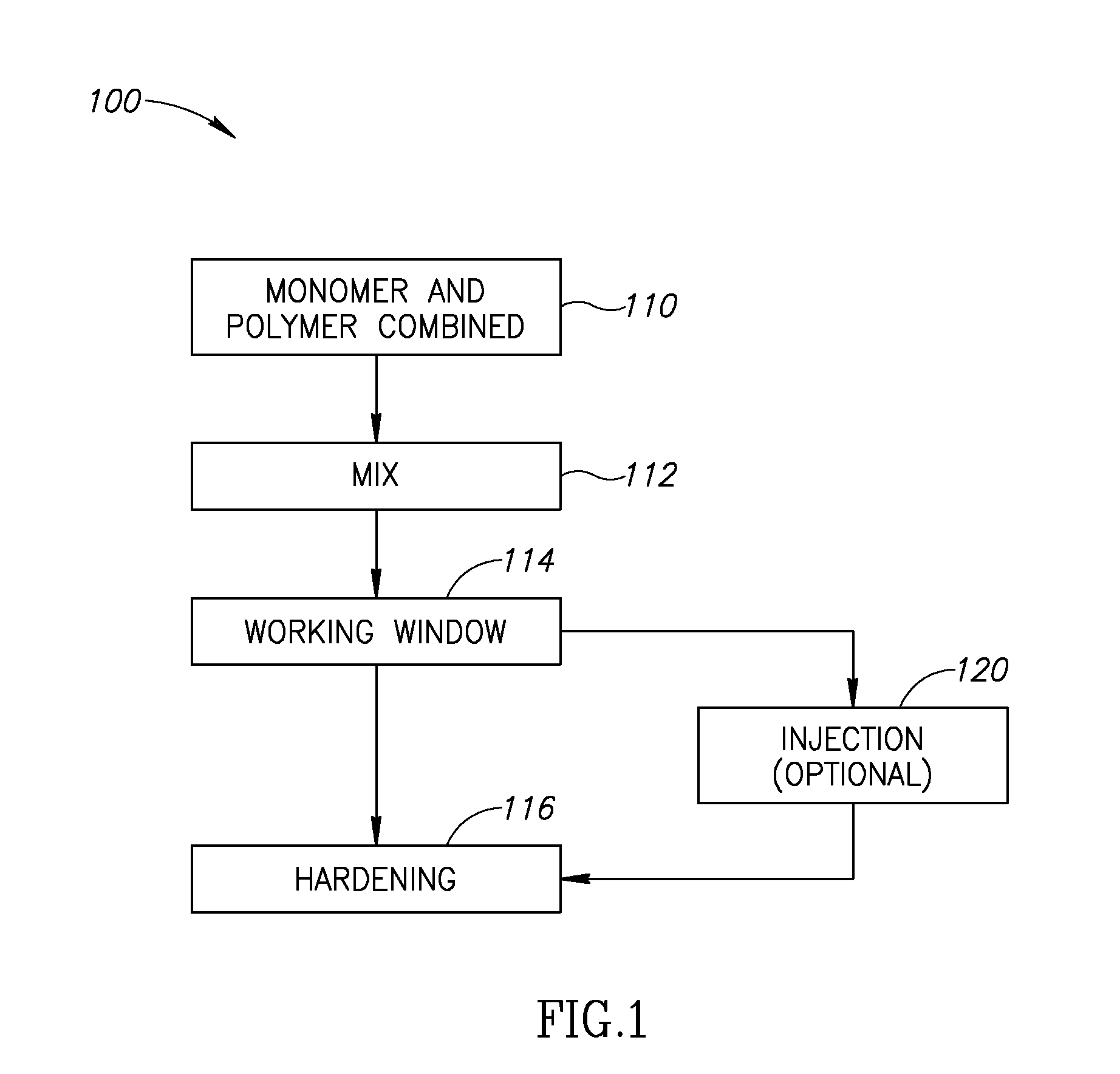

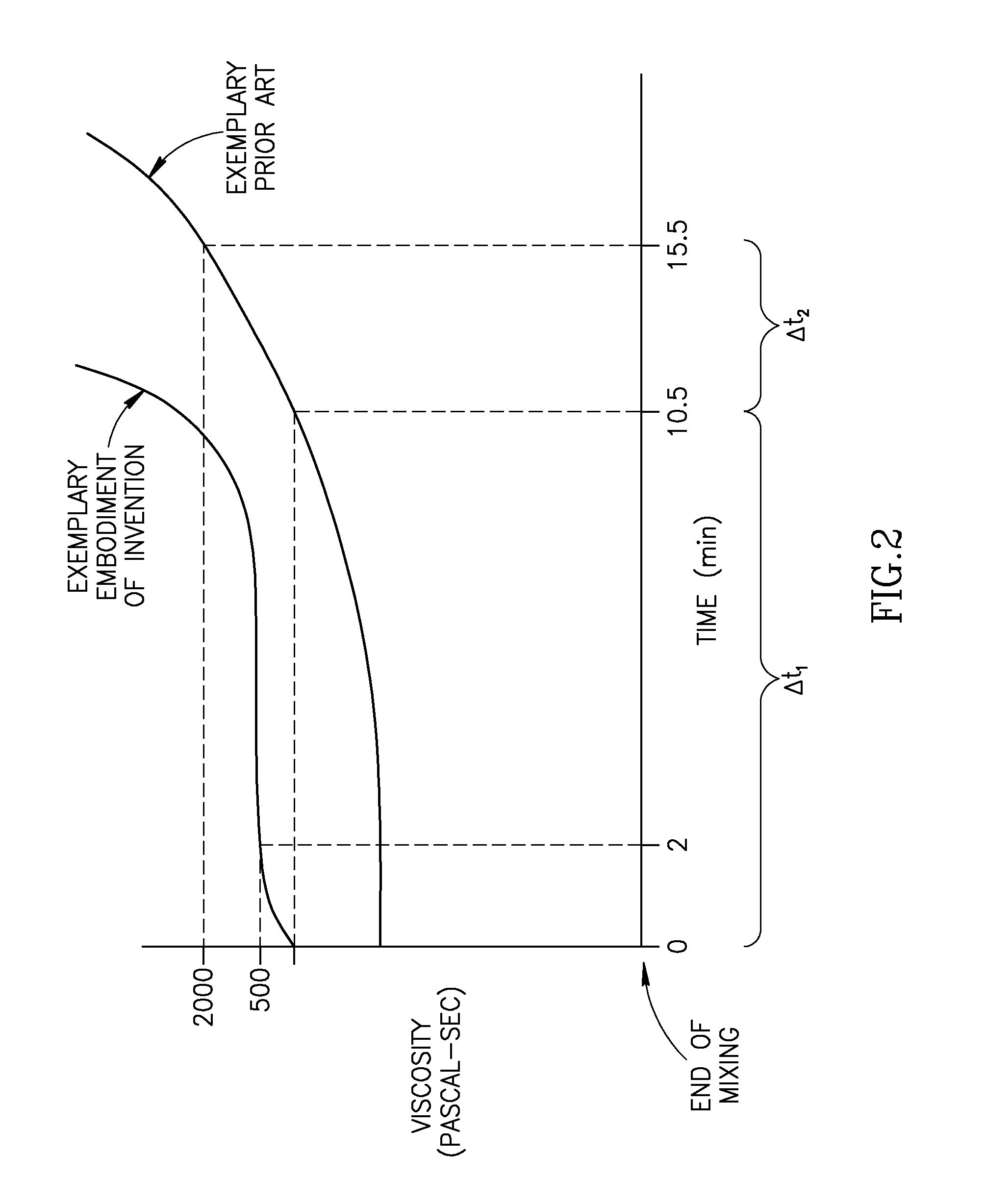

Bone Cement And Methods Of Use Thereof

InactiveUS20070032567A1High unit weightImprove wettabilityImpression capsSurgical adhesivesPolymer scienceBiocompatibility Testing

A bone cement comprising an acrylic polymer mixture. The cement is characterized in that it achieves a viscosity of at least 500 Pascal-second within 180 seconds following initiation of mixing of a monomer component and a polymer component and characterized by sufficient biocompatibility to permit in-vivo use.

Owner:DEPUY SYNTHES PROD INC

Thermosetting anti-refective coatings

Anti-reflective coating compositions having improved etch rate, inter alia, are prepared from certain acrylic polymers and copolymers, such as, glycidyl methacrylate reacted with non-polycyclic carboxylic acid dyes and non-polycyclic phenolic dyes, all light absorbing at a wavelength of 193 nm.

Owner:BREWER SCI

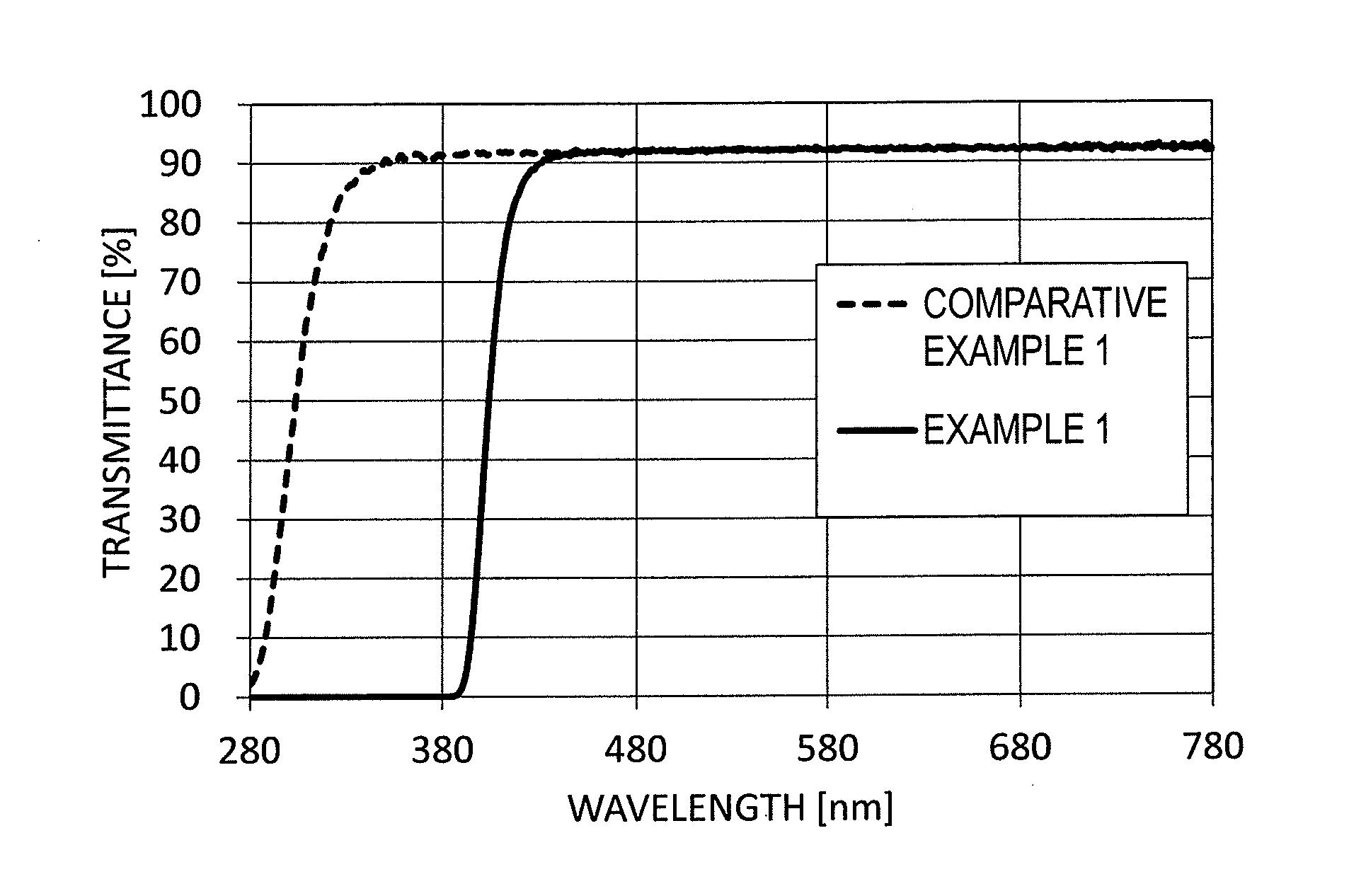

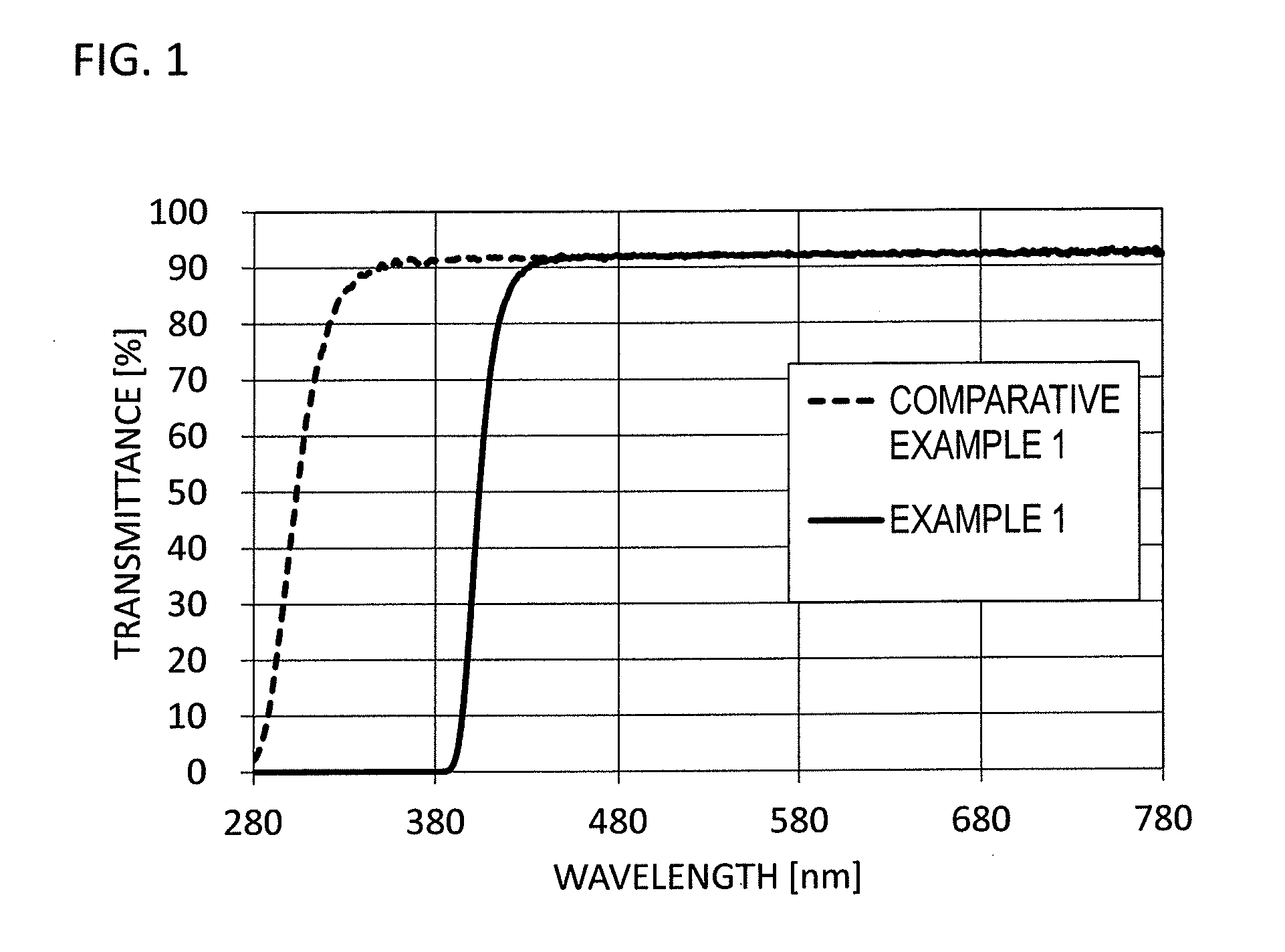

Pressure-sensitive adhesive sheet

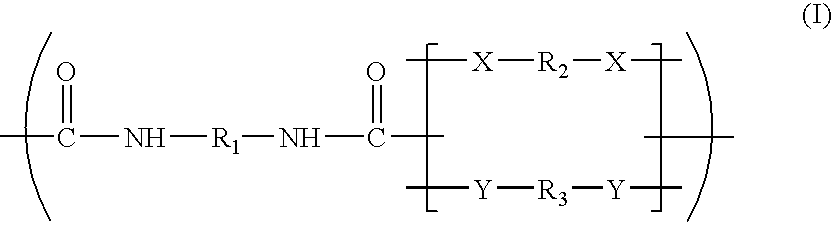

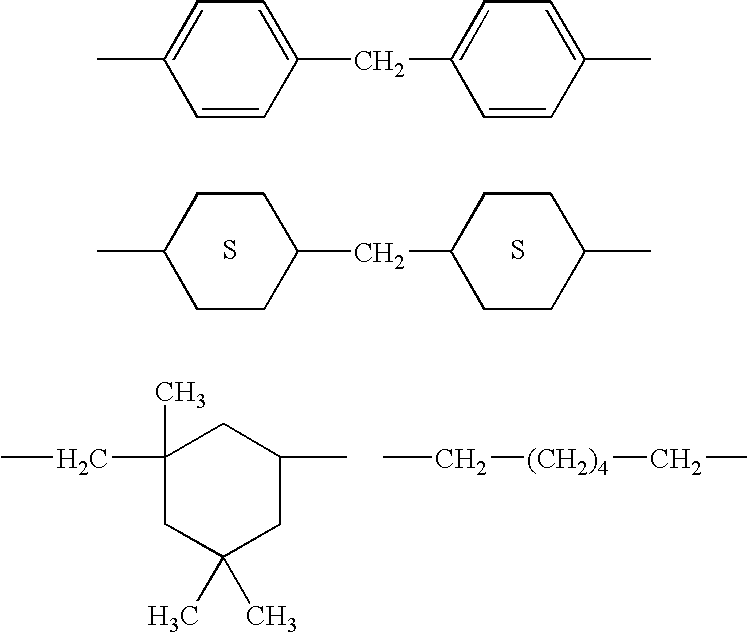

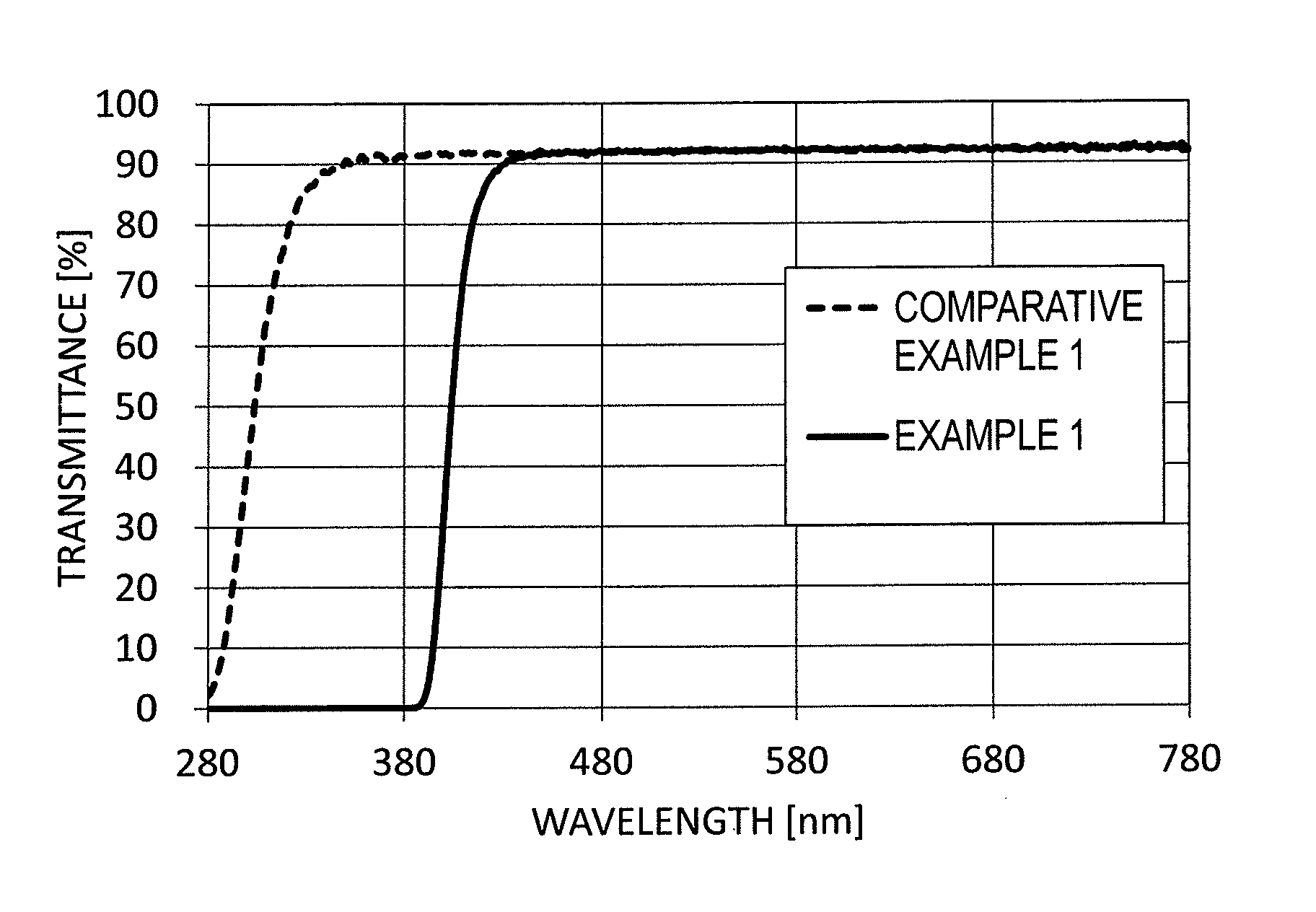

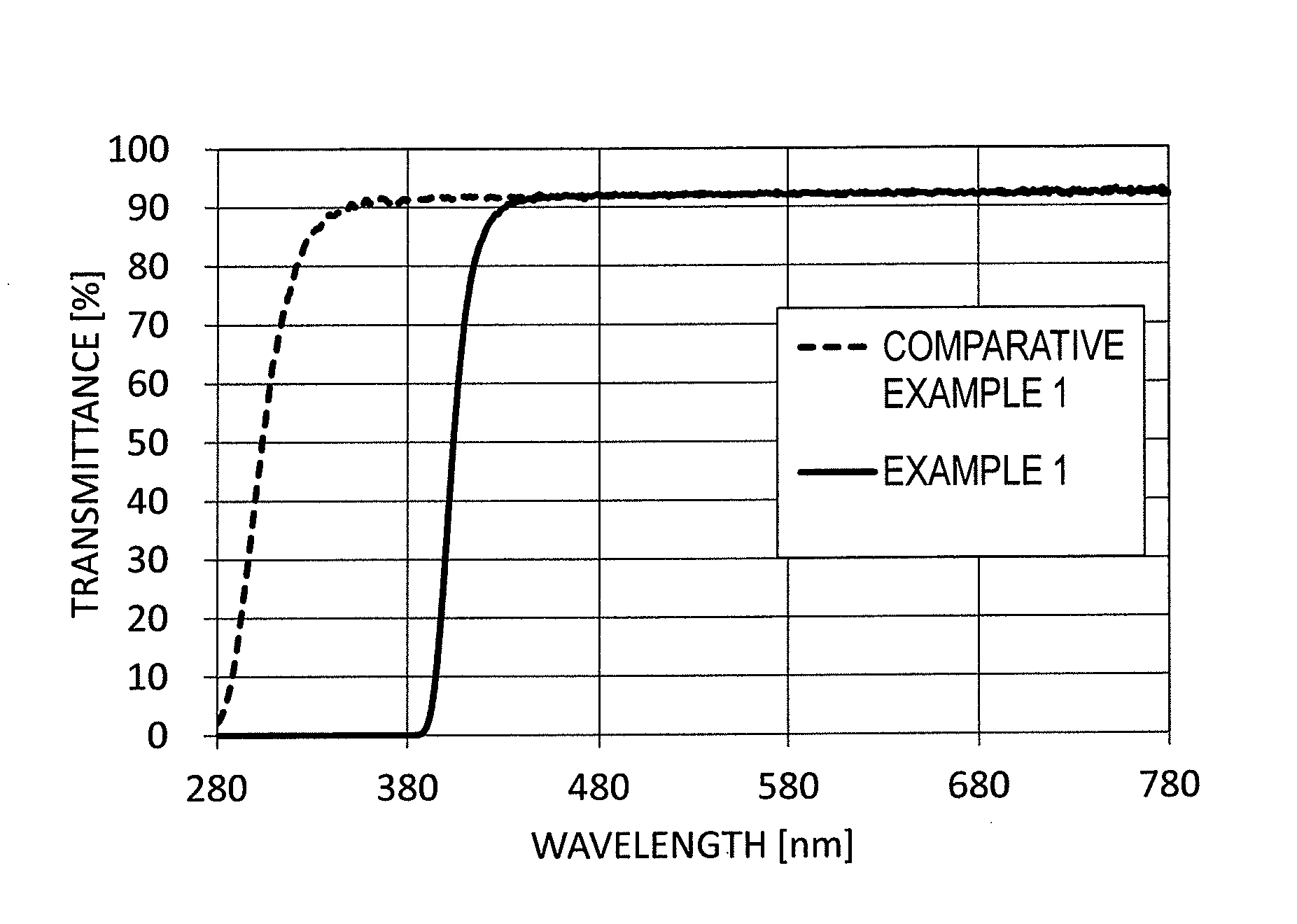

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

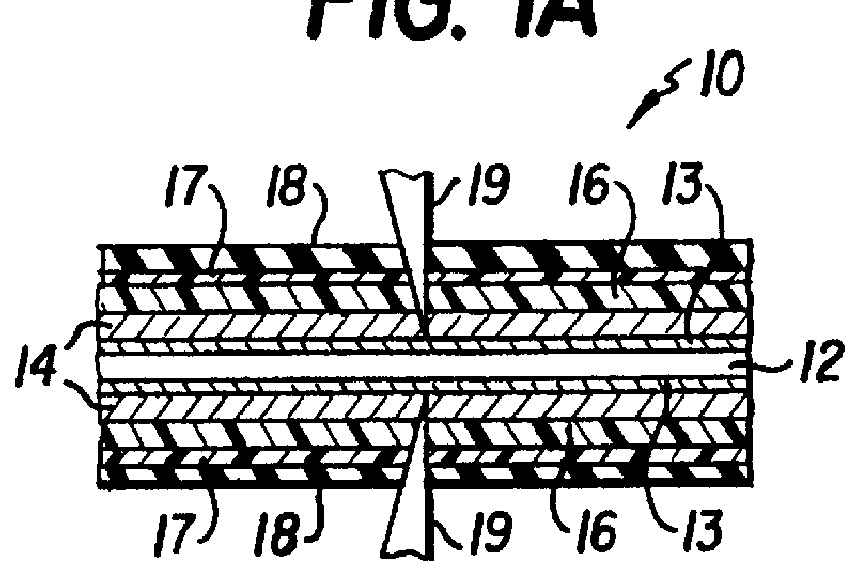

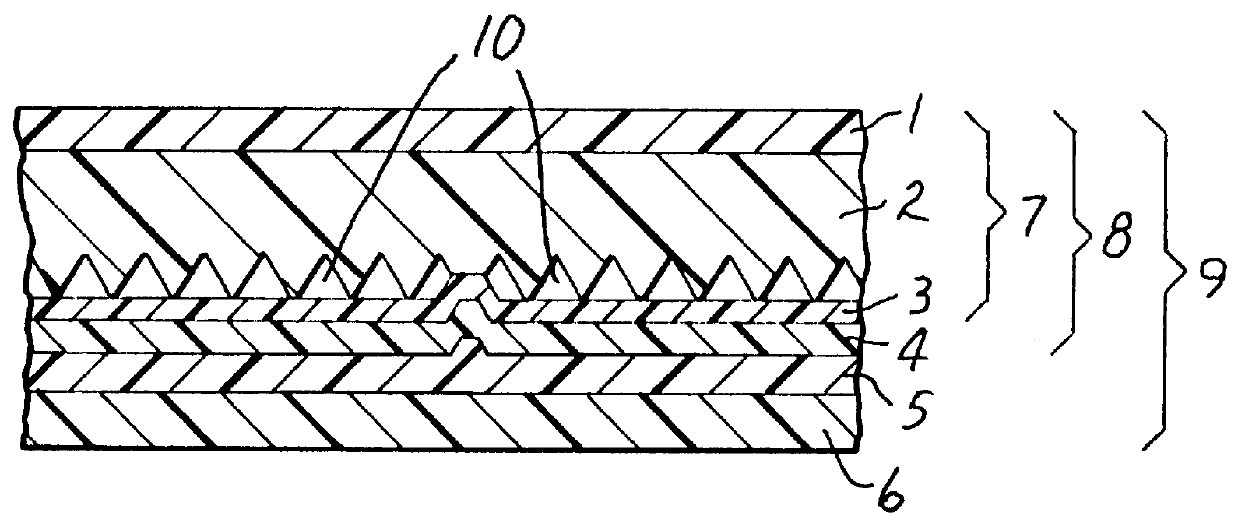

Coated optical fibers having strippable primary coatings and processes for making and using same

InactiveUS6014488ACleanly strippableHigh modulusGlass optical fibreGlass making apparatusFiberSilicon dioxide

PCT No. PCT / US98 / 01289 Sec. 371 Date Sep. 1, 1998 Sec. 102(e) Date Sep. 1, 1998 PCT Filed Jan. 23, 1998 PCT Pub. No. WO98 / 33081 PCT Pub. Date Jul. 30, 1998The invention relates to coated optical fibers which are coated with a particular radiation-cured primary coating layer composition. The fibers which are coated comprises a glass core and a glass cladding layer. The core, for example may comprises silica doped with oxides of germanium or phosphorous and the cladding, a pure or doped silicate such as fluorosilicate. Alternatively, the fibers may comprises a polymerclad silica glass core. Examples of such claddings include organosiloxanes such as polydimethylsiloxane or a fluorinated acrylic polymer.

Owner:HEXION INC

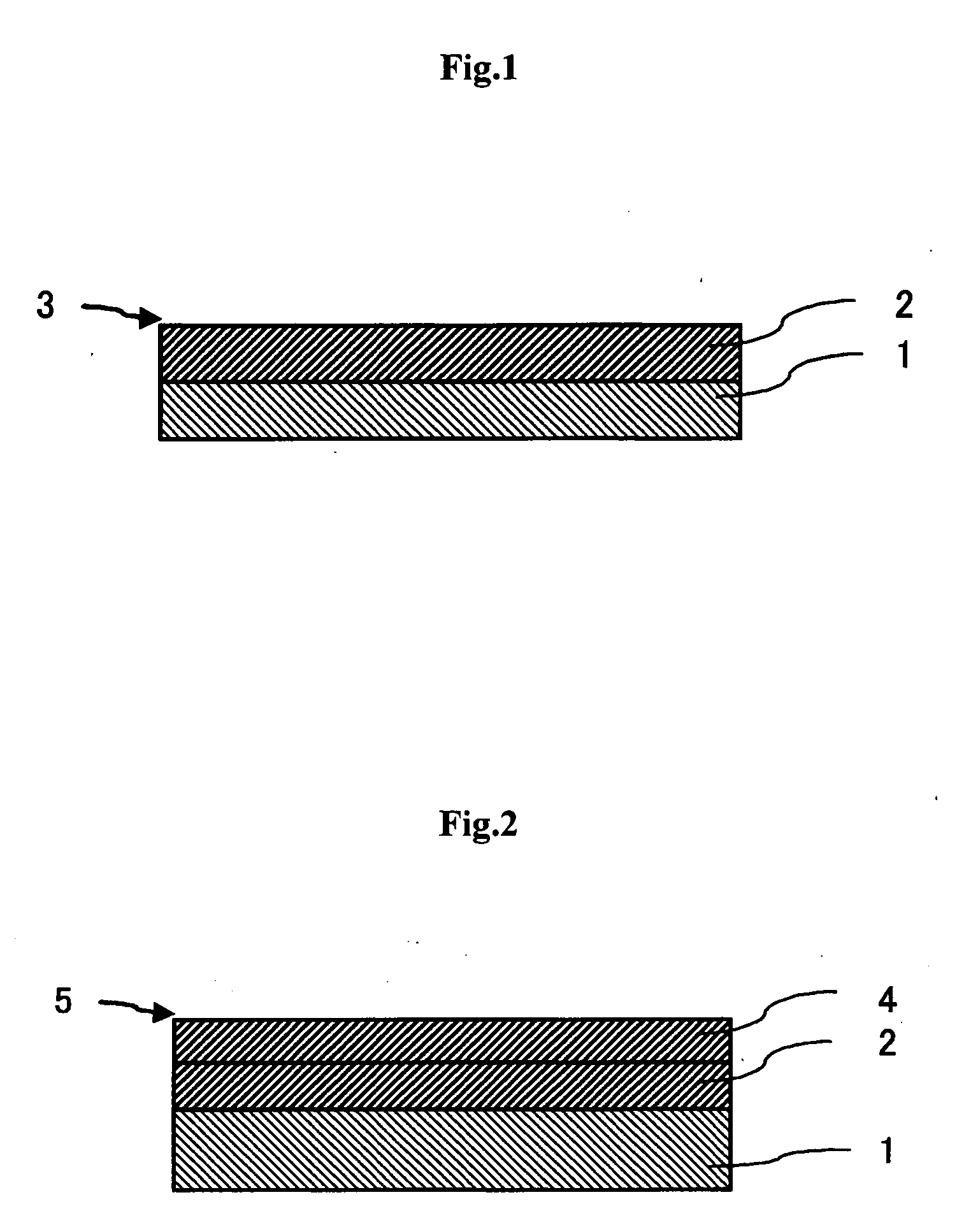

Hard-coated film and method of manufacturing the same

InactiveUS20060134400A1Increase elasticityIncrease flexibilitySynthetic resin layered productsPretreated surfacesMeth-Polyol

The invention is directed to a hard-coated film, comprising: a transparent film substrate; and a hard-coating layer formed on at least one side of the transparent film substrate, wherein the hard-coating layer is made from a material containing a urethane acrylate, a polyol (meth)acrylate and a (meth)acrylic polymer having an alkyl group containing at least two hydroxyl groups. There can be provided a hard-coated film that has high hardness and good flexibility and is resistant to curling due to hardening and shrinking and a method of manufacturing a hard-coated film in which a reduction in production efficiency associated with an increase in the number of manufacturing steps is prevented.

Owner:NITTO DENKO CORP

Film coating

InactiveUS6827947B2Negates needEliminate the problemOrganic active ingredientsNervous disorderPharmaceutical formulationAcrylic polymer

Owner:ASTRAZENECA AB

Water vapor permeable, pressure sensitive adhesive composition

InactiveUS6262329B1Improved pressure sensitive adhesive compositionSimple compositionAdhesive dressingsEster polymer adhesivesWater vaporPolymer chemistry

A water vapor permeable, pressure sensitive adhesive composition comprising a hydrophilic, all acrylic polymer system, free of additives and having enhanced water vapor transmission which contains a significant high amount of hydroxyalkyl acrylate / methacrylate. This adhesive composition is particularly useful in surgical or medical dressing applications.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Clear coating composition having improved early hardness and water resistance

InactiveUS6472493B1Improve efficiencyRemove blemishesLiquid surface applicatorsPolyurea/polyurethane coatingsPolyesterOrganic fluid

A fast hardening clear coating composition for repairing a clearcoat / colorcoat finish of a vehicle, which composition is capable of being wet sanded, buffed or polished to a high gloss finish on the same day of application, comprising a film forming binder and an organic liquid carrier, where the binder contains a hydroxyl component comprising a hydroxyl-containing acrylic polymer and a hydroxyl-terminated polyester oligomer, and an organic polyisocyanate crosslinking component, at least portion of which comprises a trimer of isophorone diisocyanate, where the composition further contains, as a combined curing catalyst, at least one dialkyl tin aliphatic carboxylate, at least one tertiary aliphatic mono or diamine, and at least one aliphatic carboxylic acid, in an effective amount such that the clear coating composition on curing at ambient temperatures is in a water spot free and sufficiently hard state for sanding or buffing within about 4 hours after application or on cool down when baked under normal conditions.

Owner:AXALTA COATING SYST IP CO LLC

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

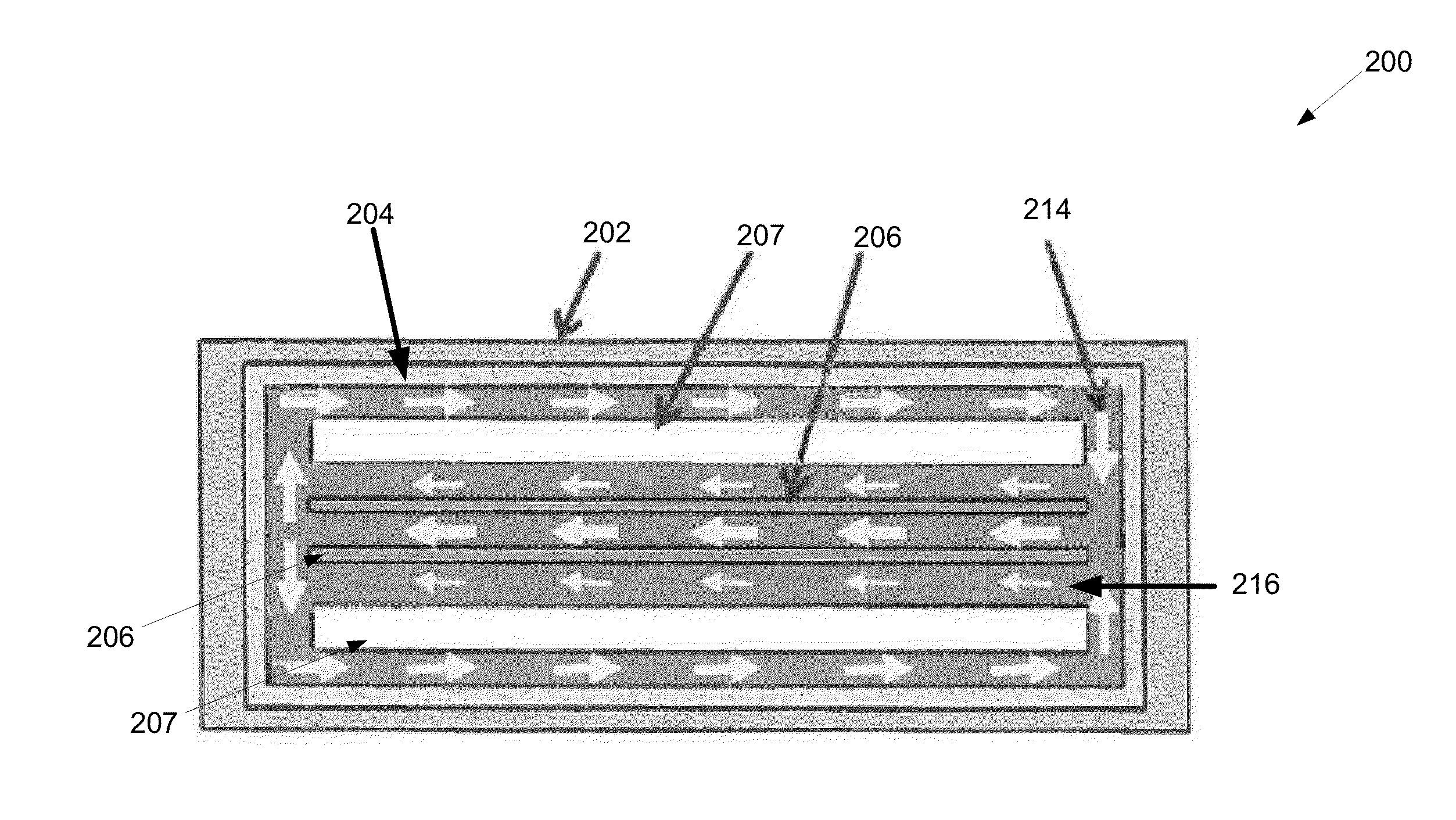

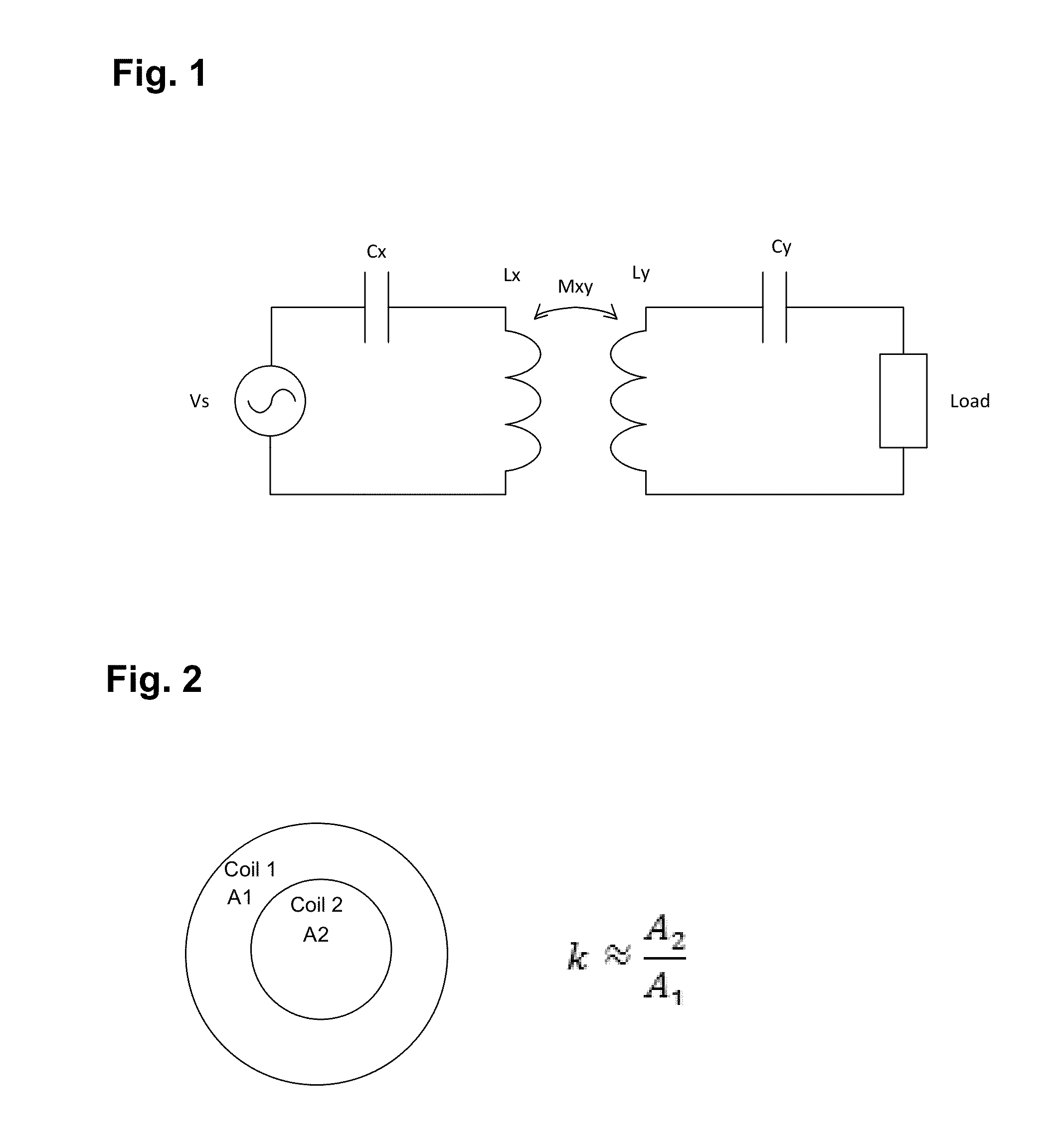

Thermal Management for Implantable Wireless Power Transfer Systems

ActiveUS20140031606A1Reduce heat transferTransformersCircuit arrangementsElectric power transmissionTelecommunications

Thermal management solutions for wireless power transfer systems are provided, which may include any number of features. In one embodiment, an implantable wireless power receiver includes at least one thermal layer disposed on an interior surface of the receiver configured to conduct heat from a central portion of the receiver towards edges of the receiver. The thermal layer can comprise, for example, a copper layer or a ceramic layer embedded in an acrylic polymer matrix. In some embodiments, a plurality of thermal channels can be formed within the receiver to transport heat from central regions of the receiver towards edges of the receiver via free convection. In yet another embodiment, a fluid pipe can be connected to the receiver and be configured to carry heat from the receiver to a location remote from the receiver. Methods of use are also provided.

Owner:TC1 LLC

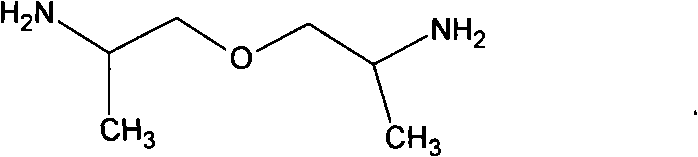

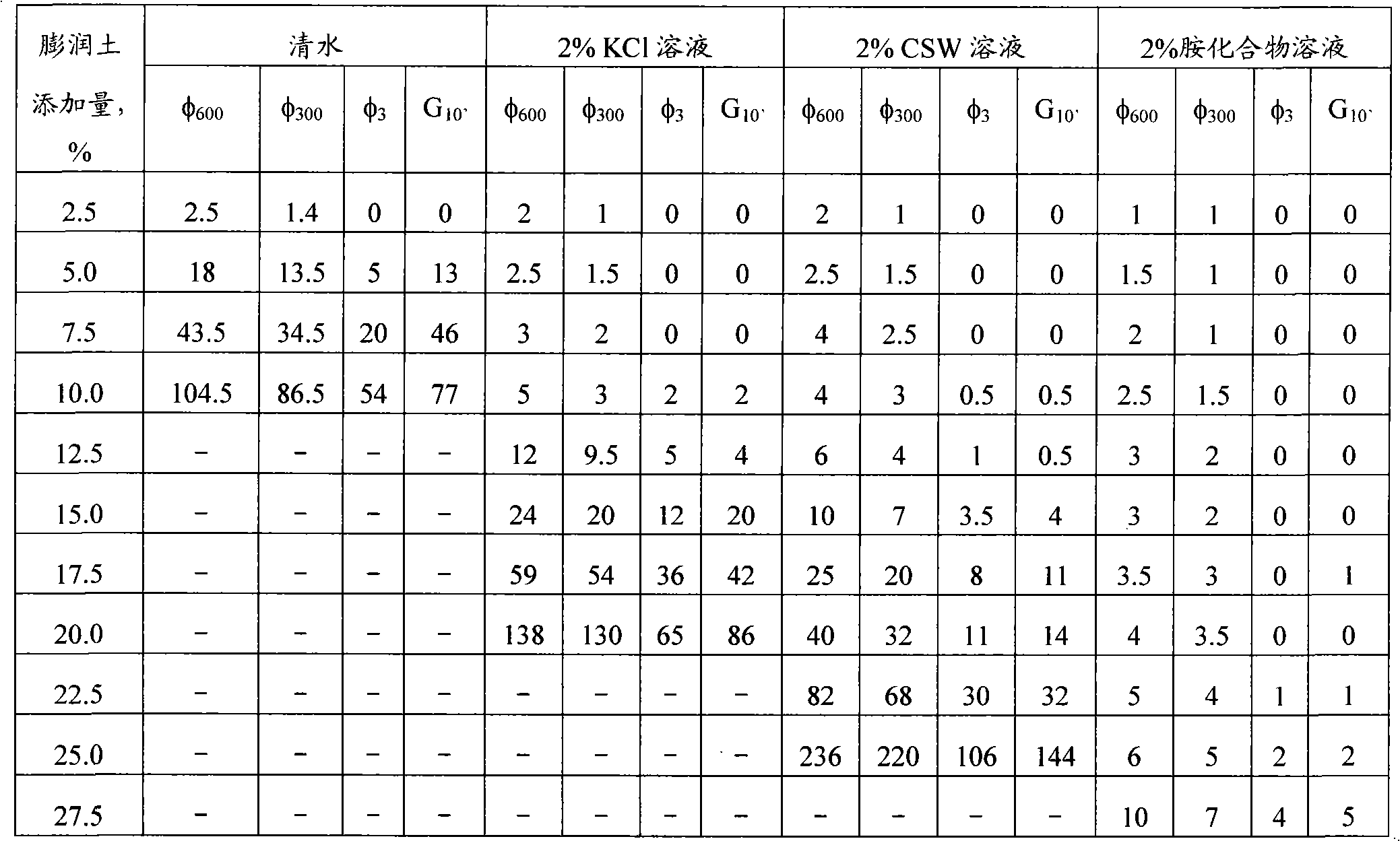

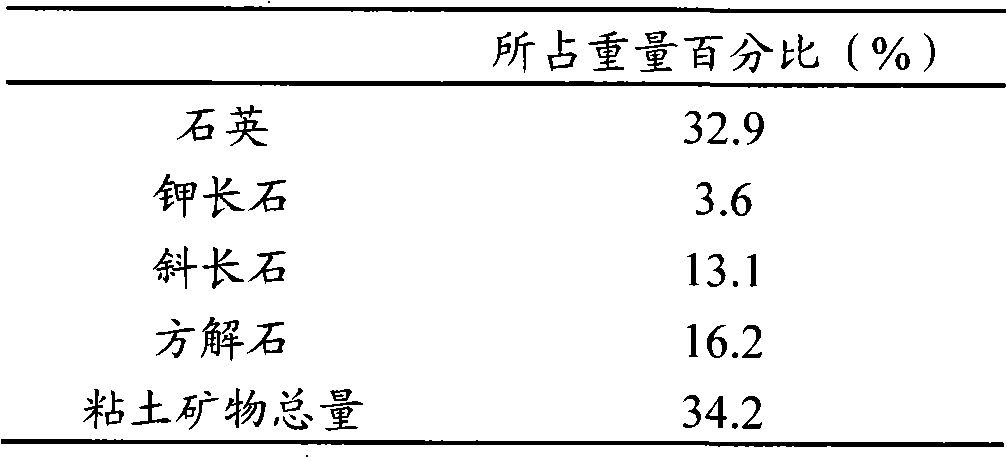

Water-based drilling fluid composition containing amine compound

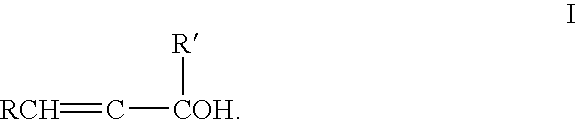

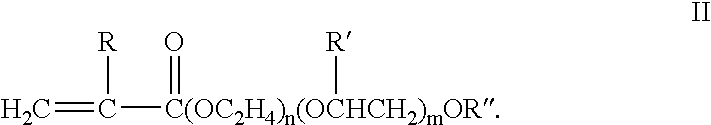

The invention provides a water-based drilling fluid composition containing an amine compound, which comprises the following components: a 0.5 to 5 weight percent of water-based amine compound as shown in formula I: RHN-Y-[OY']X-NHR', wherein Y, Y',x, R and R' are as defined in a manual; 0.1 to 1.0 weight percent of water-based tackifier which is selected from one or more types of xanthan gum, acrylamide-acrylic copolymer and hydroxyl ethyl cellulose; 0.5 to 5 weight percent of water-based fluid loss agent which is selected from one or more types of modified lignite, acrylic polymer, modified starch and modified cellulose; 2 to 12 weight percent of water-based inhibitor which is selected from one or more types of potassium chloride, potassium sulfate, formic acid, formic acid sodium, potassium chloride and epoxypropyltrimethylammonium chloride; and the composition can also further comprises coating agent, weighting agent, lubricant, borehole stabilizer and the like. The water-based drilling fluid composition has good inhibiting performance to clay shale drilling cuttings.

Owner:CNPC DRILLING RES INST

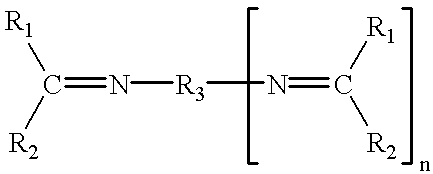

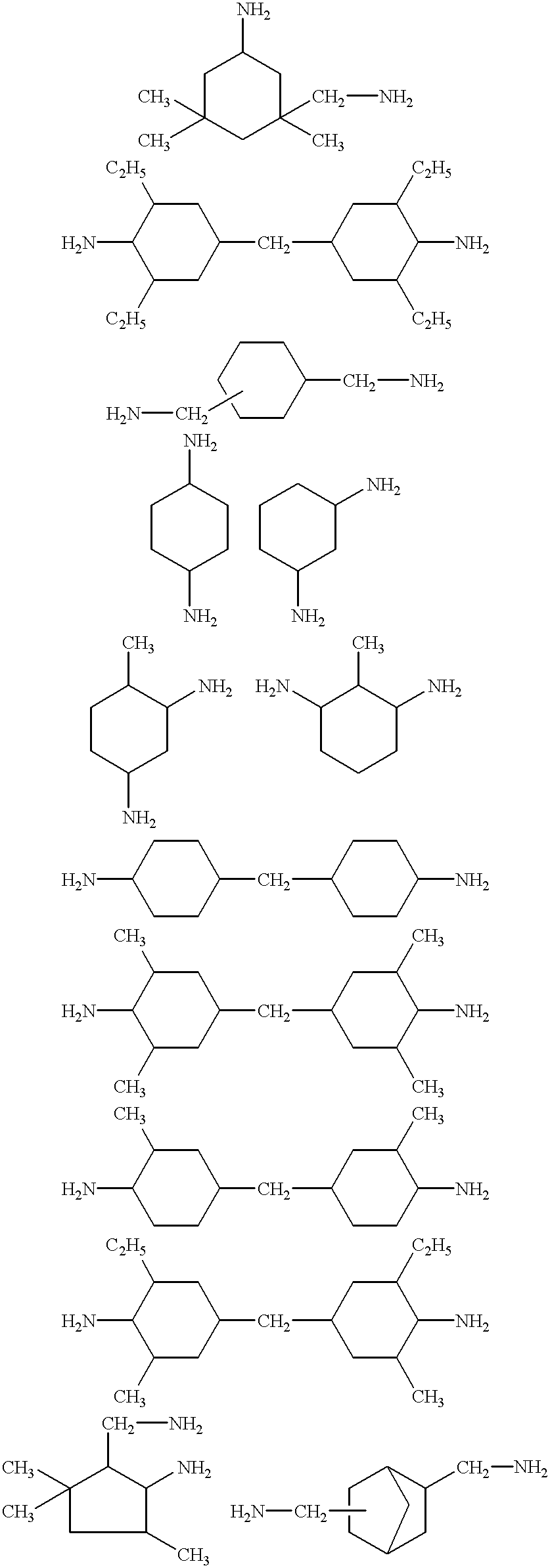

Curable compositions comprising acetoacetoxy and imine functionality

A multi-component curable composition which is reactive upon admixing of the components and which comprises:(i) an acrylic polymer having acetoacetoxy functionality; and(ii) an acetoacetoxy functional derivative of a low molecular weight polyol; and(iii) a crosslinking component comprising at least one imine functional compound having an average of at least two imine groups per molecule which are reactive with acetoacetoxy functionality.

Owner:THE SHERWIN-WILLIAMS CO

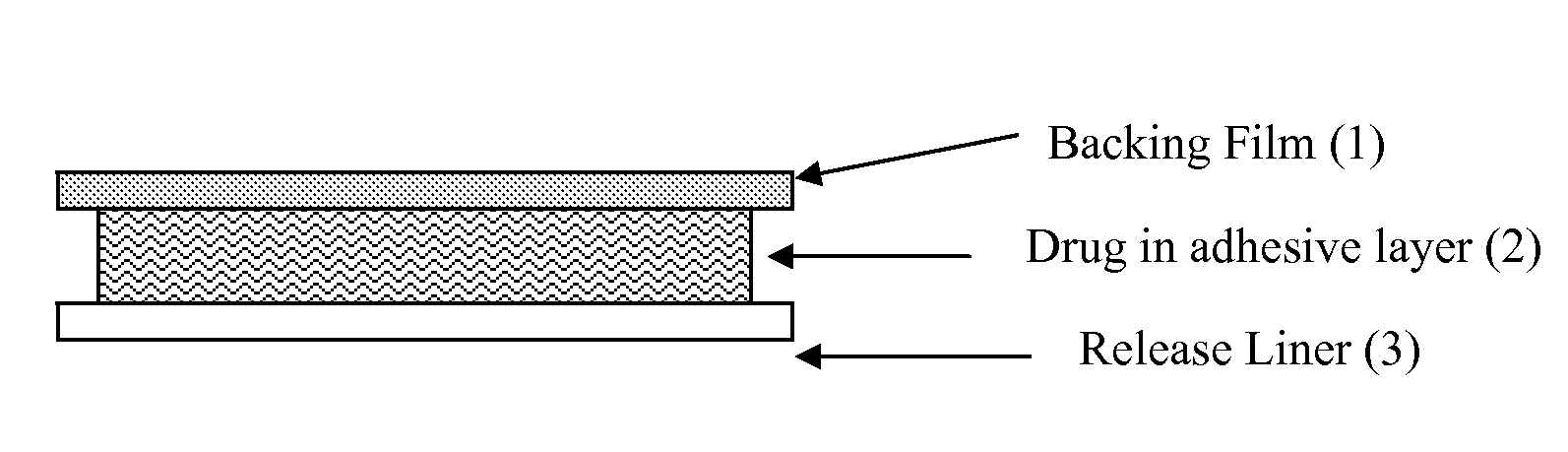

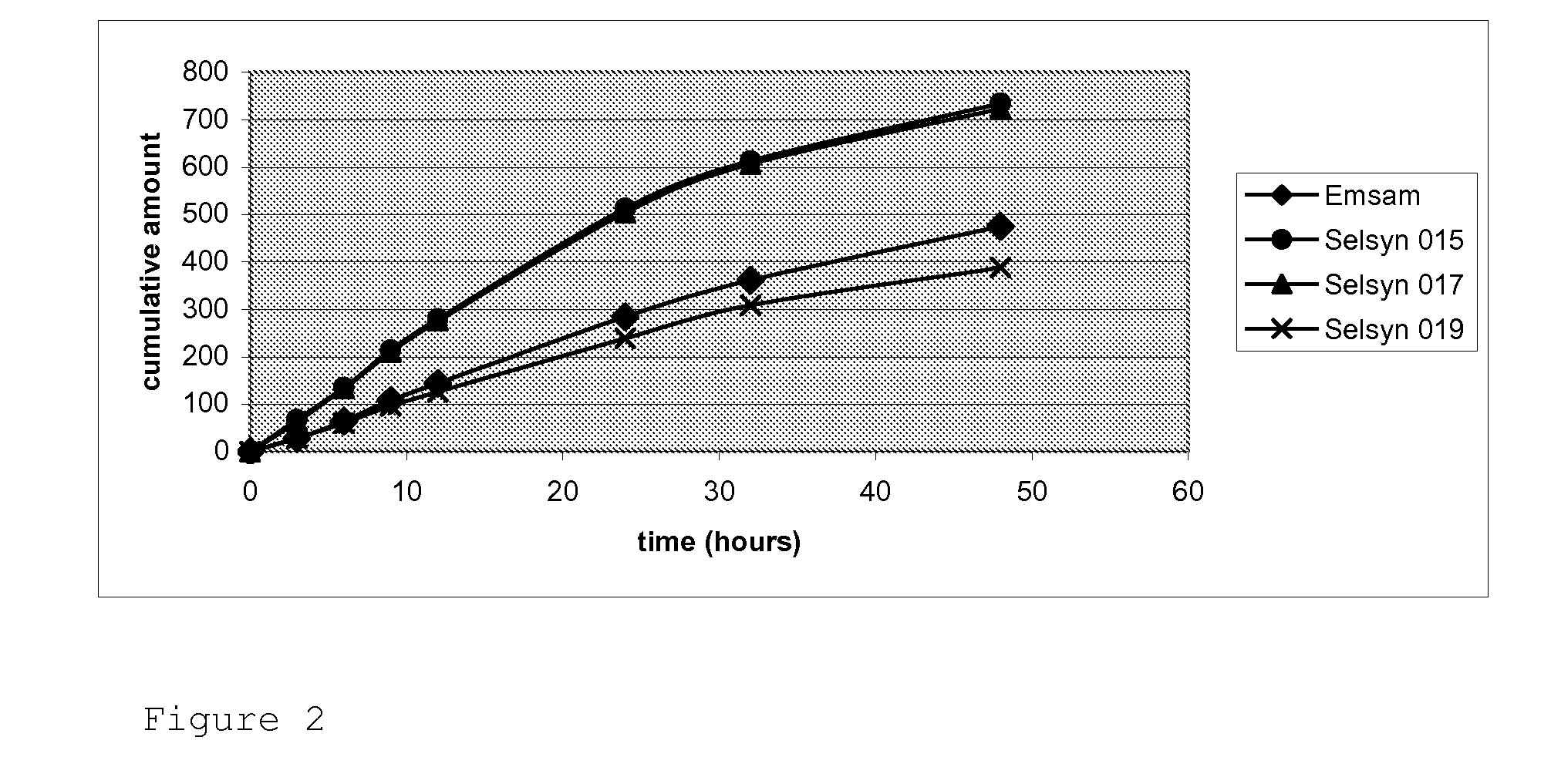

Transdermal drug delivery system for liquid active ingredient

InactiveUS20100087768A1Reduce lossesModerate shearPowder deliveryBiocideAdditive ingredientCross linker

A monolithic device for transdermal administration of an active pharmaceutical ingredient which is selected from propargylamines and rivastigmine and is liquid at 25° C., has an adhesive matrix layer which includes the active ingredient in an acrylic polymer pressure sensitive adhesive without cross-linker agent containing a metal atom, the adhesive having a shear value of between 1.5 and 15 hours, and further includes a non-volatile coadjuvant selected from squalene and triethylcitrate present in the layer in an amount of 1 to 15 wt %. The combination provides good release of the drug in use, reduces loss of the drug during a drying step in manufacture, reduces chemical interaction of the layer with the drug and achieves low level of skin irritation.

Owner:AMARIN TECH

Double-faced pressure-sensitive adhesive tape or sheet, and liquid crystal display apparatus

InactiveUS20070218276A1Improve the immunityIncrease crosslink densityFilm/foil adhesivesEster polymer adhesivesPolymer scienceLiquid-crystal display

The present invention relates to a double-faced pressure-sensitive adhesive tape or sheet, which comprises: a base material; a pressure-sensitive adhesive layer disposed on one surface of the base material, which is a pressure-sensitive adhesive layer (A) including a pressure-sensitive adhesive composition containing an acrylic polymer (A1), and a silicone rubber fine particle (A2) in a proportion of from 3 to 50 parts by weight with respect to 100 parts by weight of the acrylic polymer (A1), the layer (A) being used so as to adhere to the liquid crystal display module unit; and another pressure-sensitive adhesive layer disposed on the other surface of the base material, which is a pressure-sensitive adhesive layer (B) including a pressure-sensitive adhesive composition containing an acrylic polymer (B1), and a low-molecular weight polymer component (B2), which contains, as a principal monomer component, an ethylenic unsaturated monomer having a glass transition temperature of from 60 to 190° C. when it is formed into a homopolymer and having a cyclic structure within the molecule thereof, and which has a weight-average molecular weight equal to or higher than 3,000 but lower than 20,000, in a proportion of from 5 to 35 parts by weight with respect to 100 parts by weight of the acrylic polymer (B1), the layer (B) being used so as to adhere to the backlight, in which the pressure-sensitive adhesive tape or sheet is for use in fixing a liquid crystal display module unit and a backlight unit.

Owner:NITTO DENKO CORP

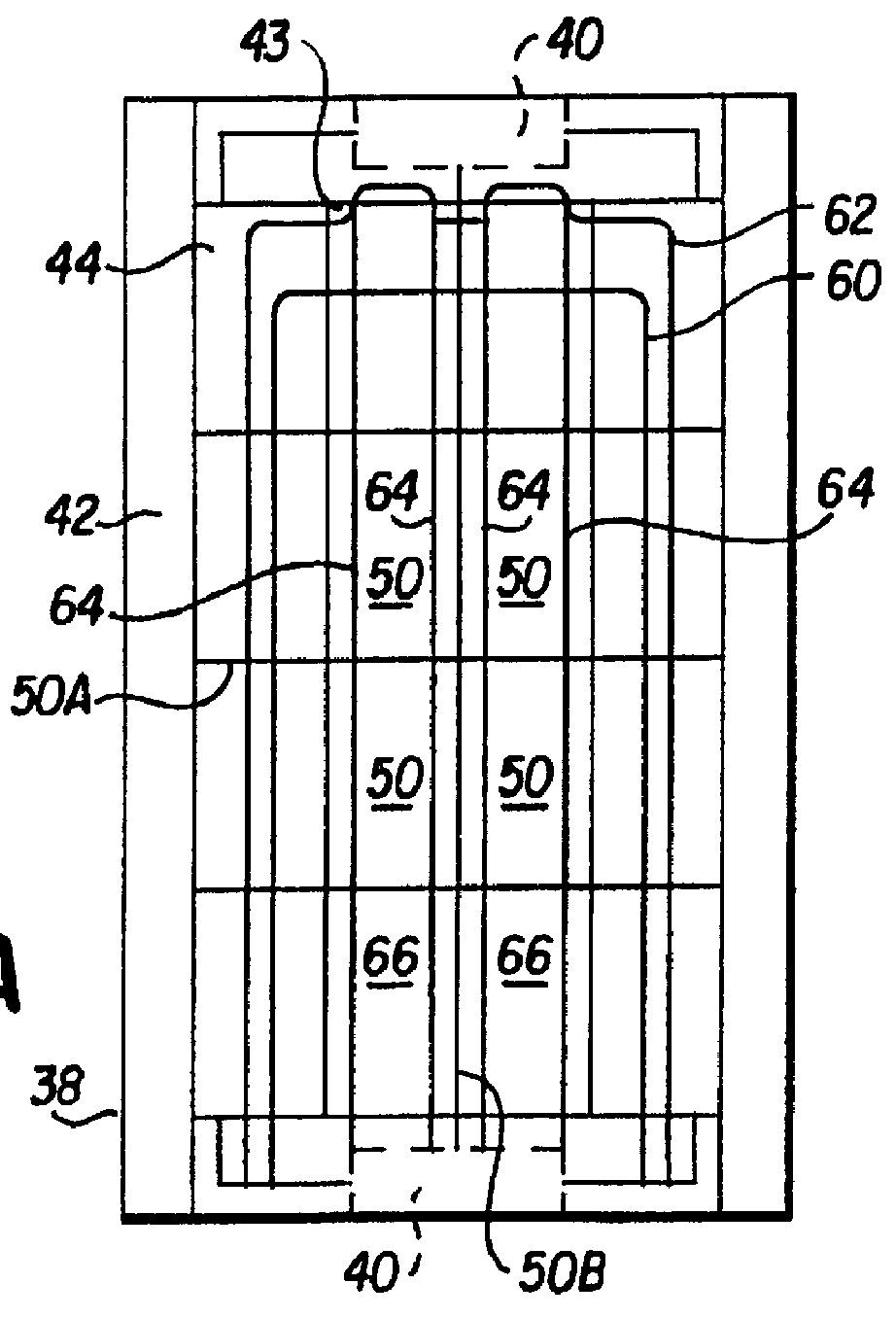

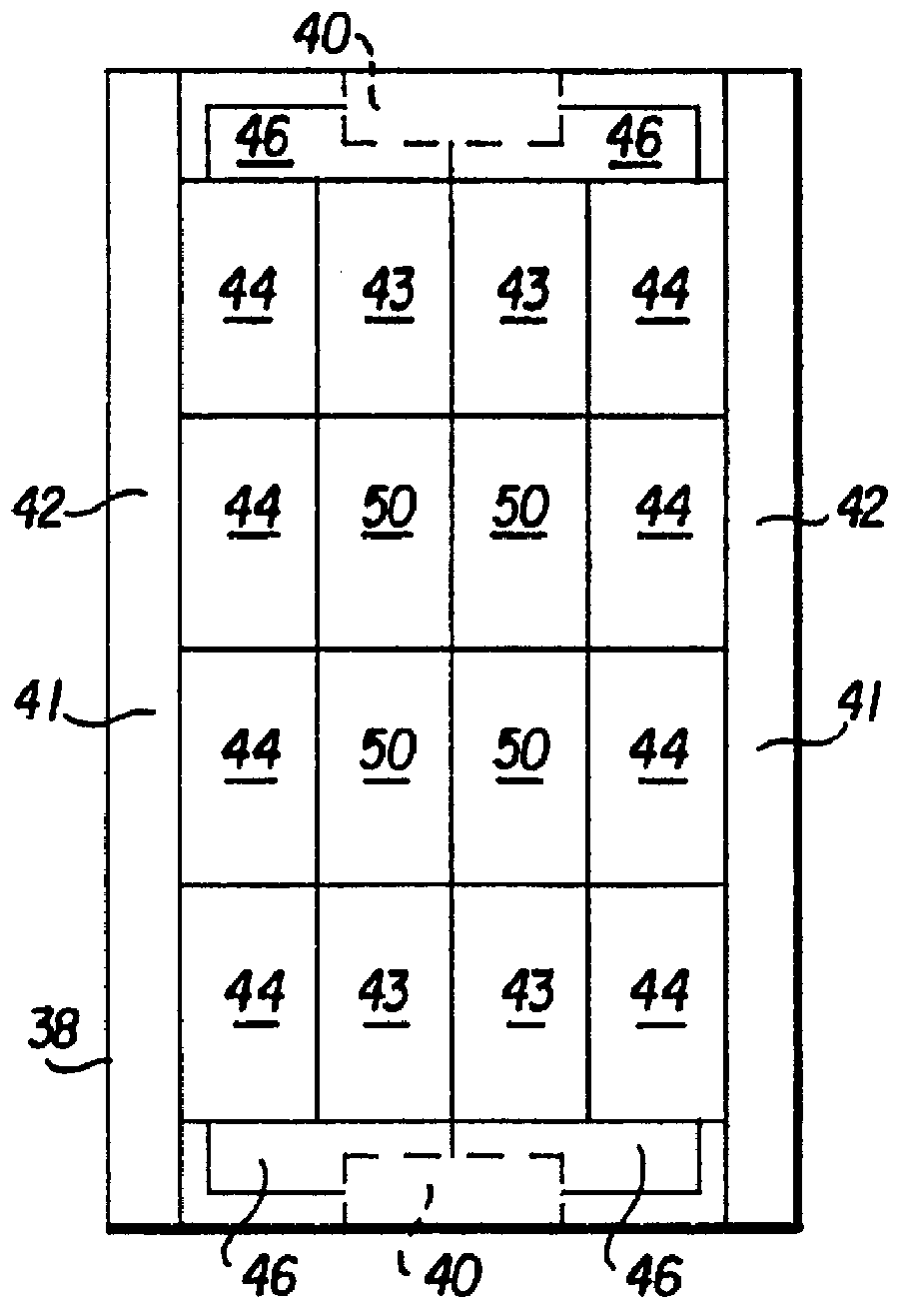

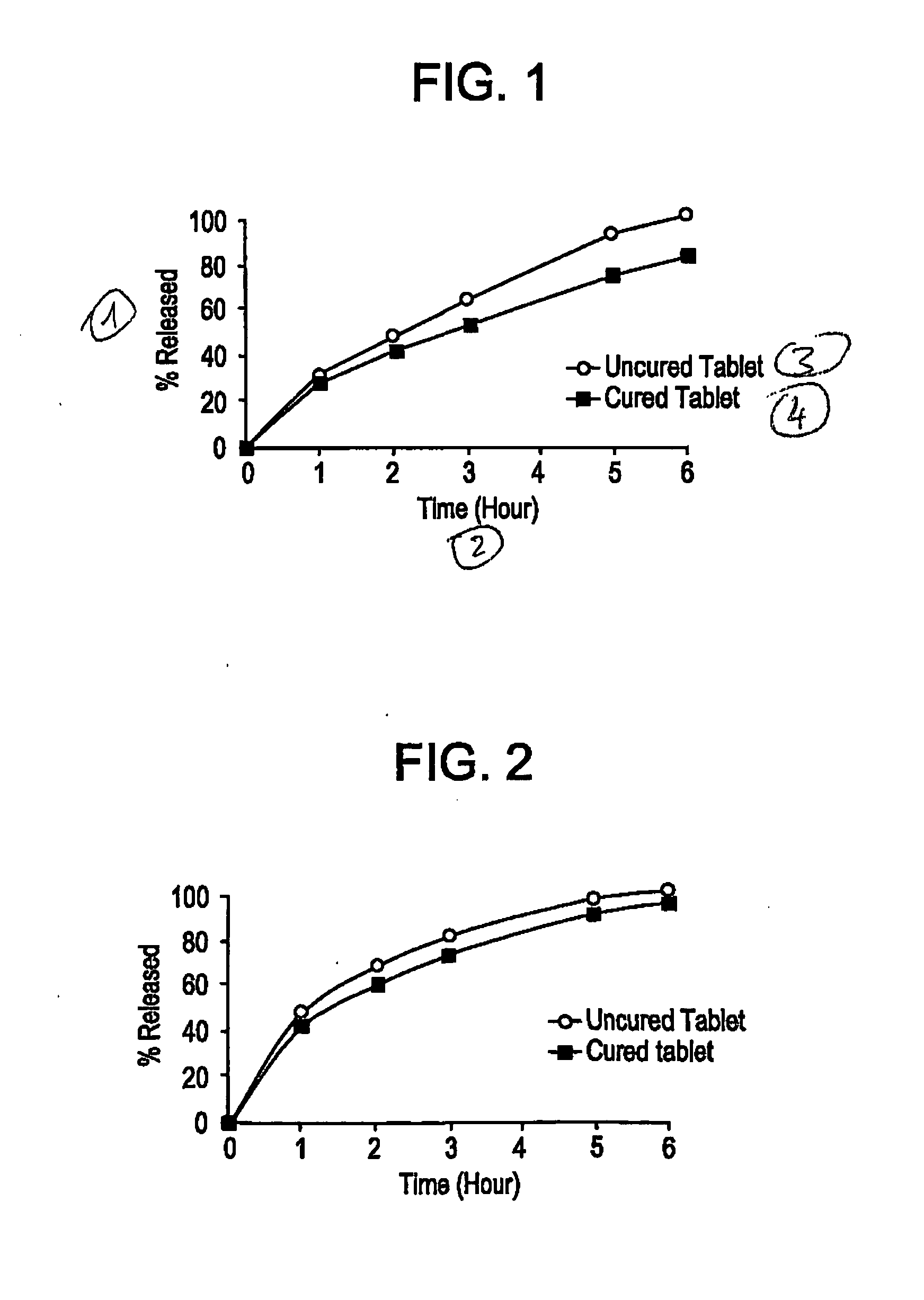

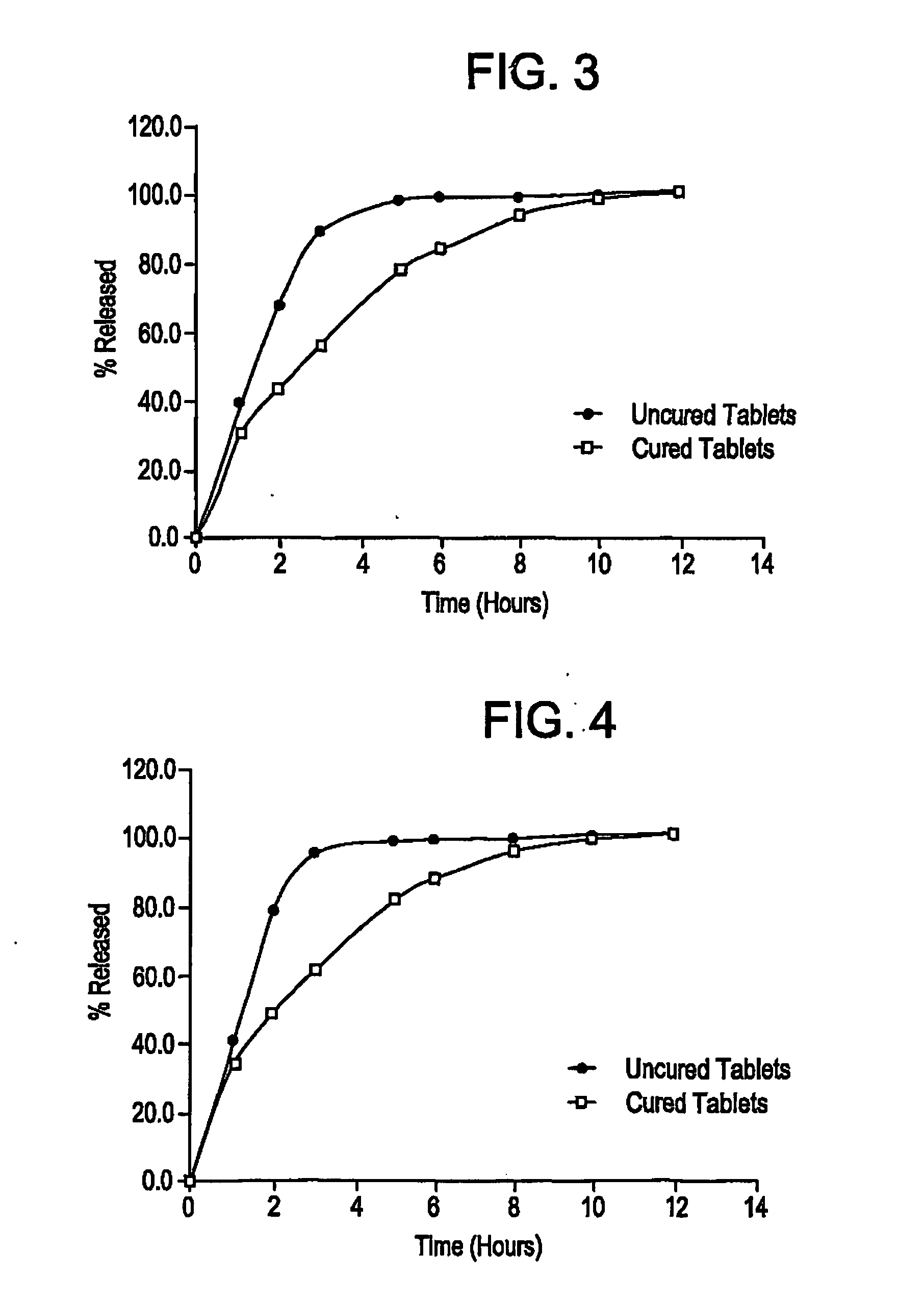

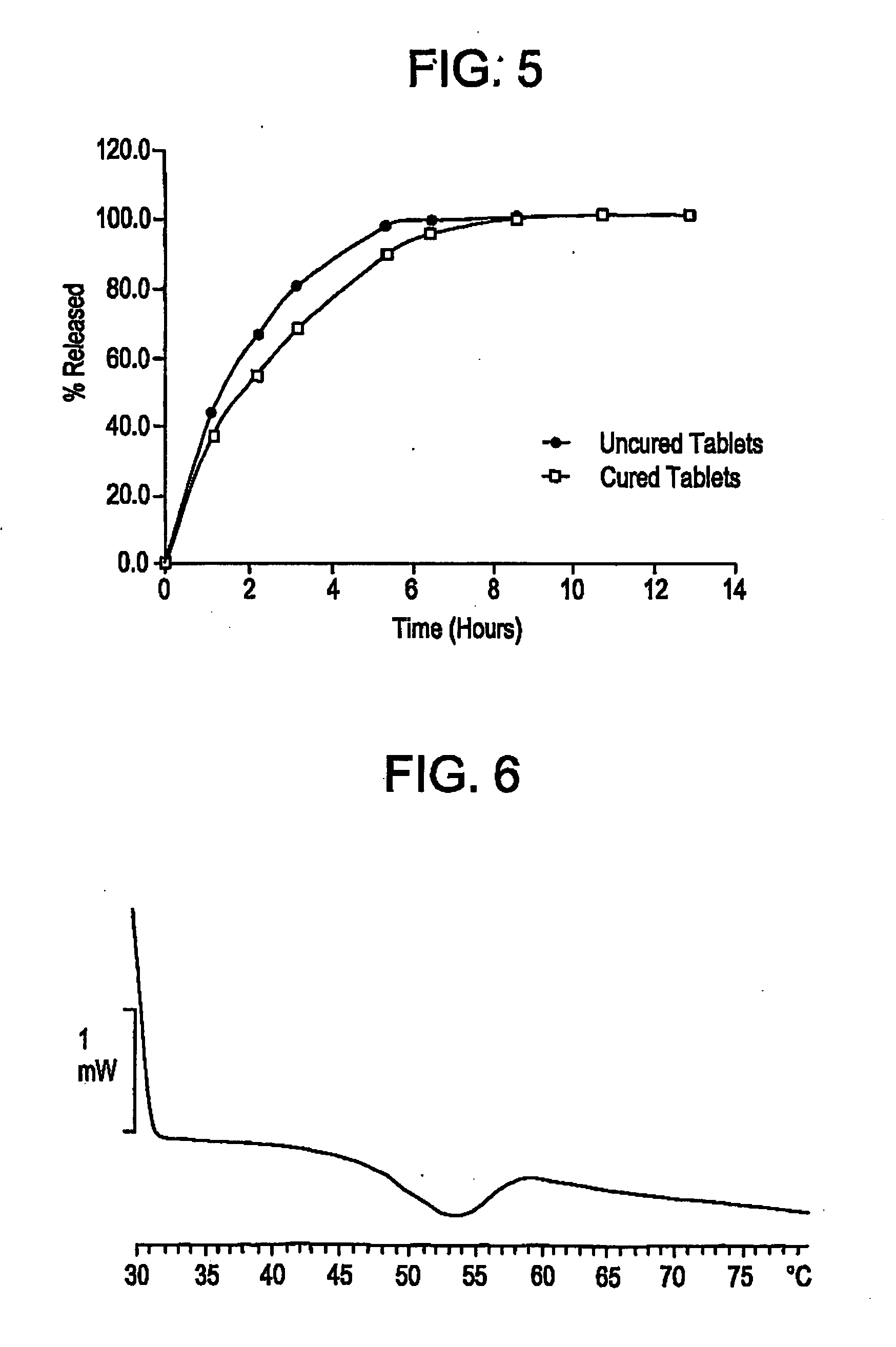

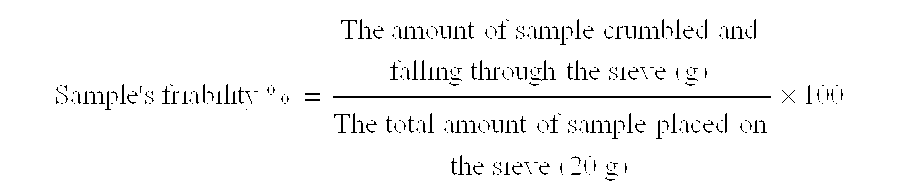

Controlled release dosage forms using acrylic polymer, and process for making

Process for dry mixing a controlled release oral dosage form are provided. The dosage form is produced by mixing, tableting, and curing dosage forms. The cured dosage forms exhibit controlled release properties superior to those of uncured tablets.

Owner:ENDO PHARMA INC

Liquid soap with vitamin beads and method for making same

InactiveUS6846785B2Reduce breakageAppropriate amount of clarityCosmetic preparationsOrganic detergent compounding agentsCross-linkSuspending Agents

A liquid soap having vitamin-containing microcapsules including a base having an anionic surfactant and a chelating agent, a cross-linked acrylic polymer suspending agent, and multiple vitamin-containing microcapsules uniformly suspended in the liquid soap. The liquid soap is formulated at an elevated temperature which is maintained throughout the formulation process.

Owner:DIAL CORPORATION

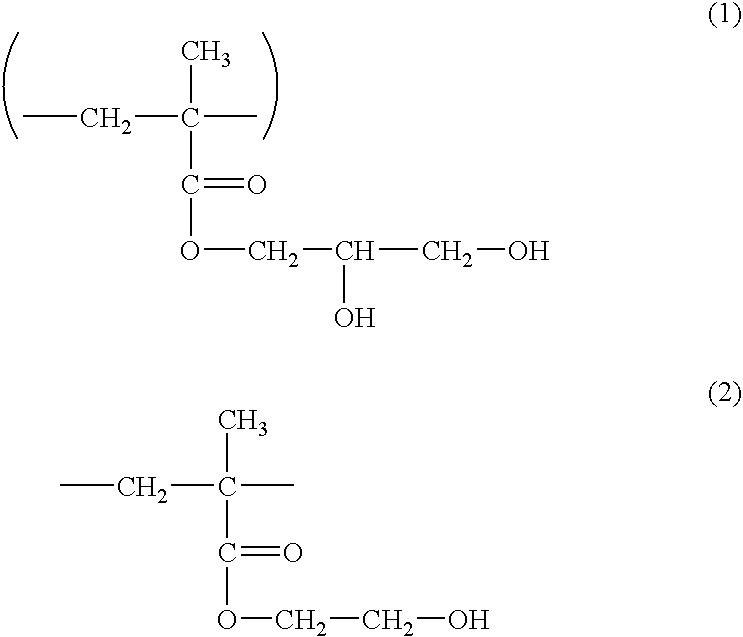

Acrylic polymer for use in pressure-sensitive adhesive composition for touch screen panel

InactiveUS20130211028A1High dielectric constantHigh transparencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAcid value

An object of the invention is to provide a pressure-sensitive adhesive sheet. Provided is an acrylic polymer for use in a pressure-sensitive adhesive composition for a touch screen panel, the acrylic polymer being obtained by copolymerizing monomer components comprising (a) a (meth)acrylic acid ester monomer having a C1-12 hydrocarbon group, (b) a hydroxy group-containing (meth)acrylic acid ester monomer, (c) an amide group-containing monomer, and (d) a vinyl ester monomer. The acrylic polymer has an acid value of 0.1 mg KOH / g or less, a weight-average molecular weight of 400,000 to 2,000,000, a Tg of −80 to 0° C., and a permittivity of 3 to 6.

Owner:DAIDOU KASEI KOGYO KK

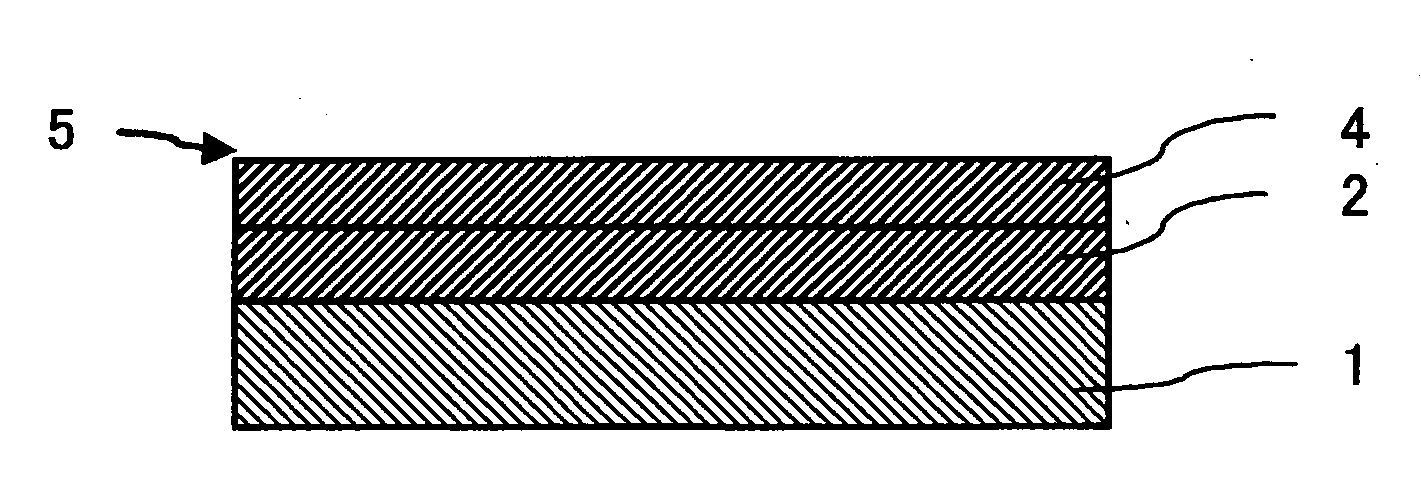

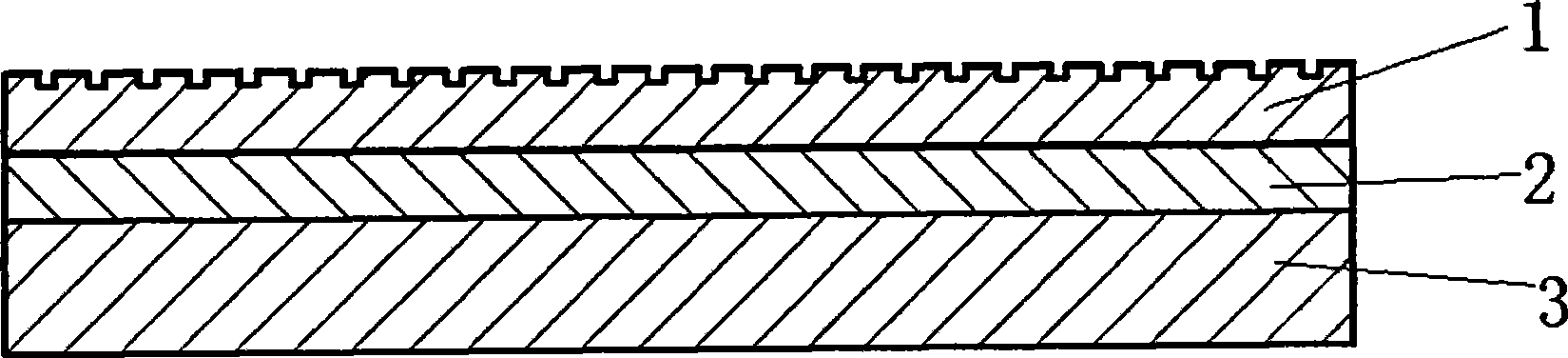

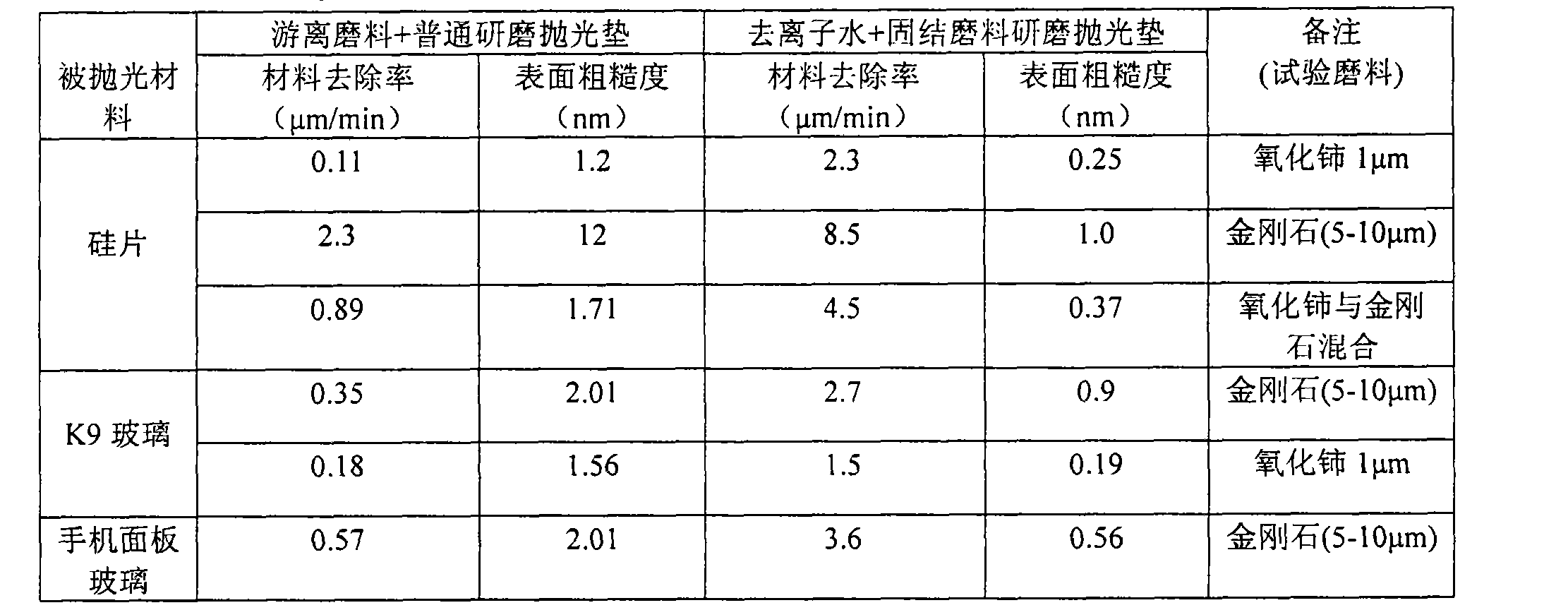

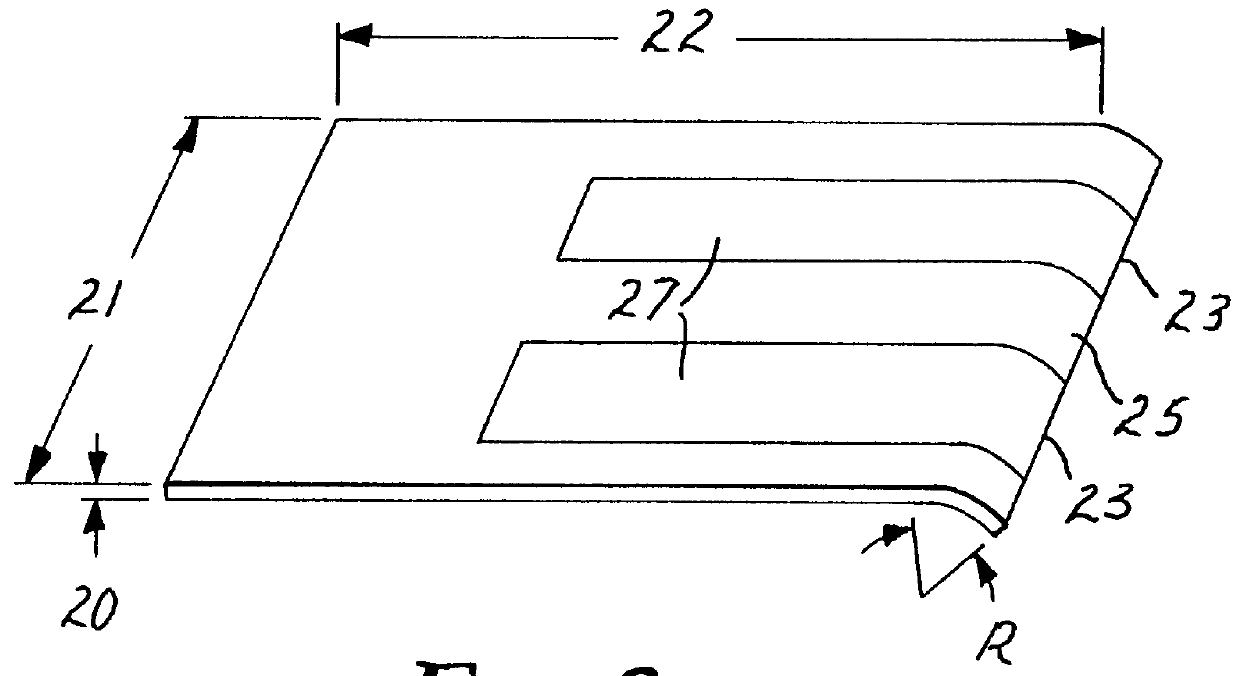

Fixed abrasive grinding polishing pad and method of manufacturing the same

InactiveCN101428404AImprove flatnessPlay a cutting roleAbrasion apparatusGrinding devicesReactive diluentEngineering

The invention provides a solidified abrading agent polishing pad and the preparation method thereof. The solidified abrading agent polishing pad comprises at least three layers, including an elastic layer (3), a rigid layer (2) and an abrading agent layer (1) sequentially arranged from the bottom layer to the top layer. The solidified abrading agent polishing pad is characterized in that the abrading agent layer (1) comprises the following components by the weight percentage: 1% to 40% of an abrading agent with the particle size being 1 nm to 40 Mum, 20% to 80% of polyacrylate prepolymer, 0.05% to 3% of free radical photoinitiator, 0% to 2% of poly-dimethylsiloxane / acrylic polymer, 0% to 20% of a performance adjusting addition agent, and 5% to 40% of esterified acrylic acid reactive diluent. The solidified abrading agent polishing pad which is prepared by the figure-transfer method has a series of advantages of stable grinding and polishing performance, high polishing efficiency, high surface texture of processed workpieces, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pigment based inks for high speed durable inkjet printing

ActiveUS20080207820A1Low velocity variationNon-fibrous pulp additionInksWater solubleCarboxylic acid

An ink composition comprising (a) water, (b) pigment particles, (c) at least one humectant, (d) at least one polyurethane having an average molecular weight of at least about 10,000 and a sufficient number of acid groups to provide an acid number from 60 to about 130, and being present at a weight concentration of greater than 0.7%, and (e) at least one water soluble acrylic polyiner comprising carboxylic acid groups, present at a weight concentration of greater than 0.6%, wherein the acid groups on the polyurethane and acrylic polymers are at least partially neutralized only with a monovalent inorganic base.

Owner:EASTMAN KODAK CO

Process for making an ink jet ink

A process for making an ink jet ink comprising: a) providing a dispersion containing a pigment, a hydrocarbon carrier, and a polyamine / fatty acid condensation polymer dispersant; b) mixing the pigment dispersion with rigid milling media less than 100 mu m; c) introducing the mixture of step (b) into a mill; d) milling the mixture from step (c) until the pigment particle size is below about 100 nanometers (nm); e) adding to the mixture during or after step d) or f) (below) a stabilizer selected from the group consisting of a polyether polyol; a modified polyester resin; an acrylic polymer; an alkylol ammonium salt of a block copolymer having acidic groups; ethoxylated triethanolamine; a high molecular weight block copolymer having an amine functionality; sorbitan sesquioleate; polyhydroxy stearic acid; butylated polyvinyl pyrrolidone; poly(vinylpyrrolidone / 1-hexadecene); and poly(p-tert-butylstyrene-co-styrene-co-2-sulfoethyl-lithium methacrylate); f) separating the milling media from the mixture milled in step (d); and g) diluting the mixture to obtain an ink jet ink having a pigment concentration suitable for ink jet printers.

Owner:EASTMAN KODAK CO

Pressure-sensitive adhesive sheet

ActiveUS9045670B2Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesSynthetic resin layered productsDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Clear cleansing detergent systems

InactiveUS6642198B2Good spreadabilityMild to skin and eyePowder deliveryCosmetic preparationsPolymer sciencePolyol

The present invention is directed to detergent compositions that not only have superior viscosity, spreadability, and clarity properties but also do not cause significant irritation to the skin and eyes. More specifically, acrylic polymeric thickeners are combined with polyol glycol thickeners in order to achieve such properties in detergent compositions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Powdery material and modifier for cementitious material

An acrylic polymer powdery material, which is a particularly useful powdery material as a modifier for cementitious material, comprising fine particles of a core-shell structure comprising a core polymer being comprised of an acrylic polymer having a glass transition temperature (Tg) of -20-+15° C., a weight average molecular weight of 100000-2000000, an acid value of 25 mg KOH / g or less and a shell polymer being comprised of an acrylic polymer having a Tg of 50-90° C., a weight average molecular weight of 100000-2000000, an acid value of 30-130 mg KOH / g, wherein the weight ratio of the core polymer and shell polymer is 30 / 70-80 / 20 (% by weight).

Owner:MITSUBISHI RAYON CO LTD

Polymerizable composition and method for producing (METH) acrylic thermally conductive sheet

InactiveUS20070261785A1Good flexibilityExcellent in bleed resistanceLamination ancillary operationsLaminationPolymer scienceMeth-

A polymerizable composition which contains a component (A): a (meth)acrylic monomer, a component (B): a (meth)acrylic polymer having at least one functional group capable of undergoing a cross-linking reaction in its molecule, a component (C): a (meth)acrylic oligomer having at one terminal of its molecule a functional group capable of undergoing a cross-linking reaction, a component (D): a cross-linking agent having a functional group capable of undergoing a cross-linking reaction, a compound (E): a photopolymerization initiator and / or a thermal polymerization initiator, and a component (F): a thermally conductive filler, is disclosed. Further, a (meth)acrylic thermally conductive sheet having a pressure-sensitive adhesive layer prepared by polymerizing and cross-linking the polymerizable composition on a support is disclosed. The thermally conductive sheet prepared by using the polymerizable composition according to the invention is excellent in flexibility, adhesiveness and bleed resistance and can dissipate heat generated from a heat-generating body such as an electronic device with good efficiency.

Owner:SOKEN CHEM & ENG CO LTD

Retroreflective sheeting articles

InactiveUS6012818ASuitable flexibility and transparencyReduce cohesionLayered productsAldehyde/ketone condensation polymer adhesivesDynamic viscoelasticityAdhesive

A retroreflective sheet comprises a film having a substantially flat surface and a large number of pyramidal projections having retroreflectivity on the opposite surface, and a colored layer and an adhesive layer disposed on the surface of the film having the projections. The adhesive layer comprises a heat-sensitive adhesive containing an acrylic polymer and a phenolic resin, and exhibits an elastic modulus (by dynamic viscoelasticity measurement, compression mode) at 30 DEG C. ranging from about 1x106 to 1x108 dyn / cm2.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure-sensitive adhesive composition and pressure-sensitive adhesive product

A pressure-sensitive adhesive composition contains (a) an acrylic polymer containing an alkyl (meth)acrylate whose alkyl group has from 4 to 12 carbon atoms, as a monomer major component and from 1 to 10 parts by weight, based on 100 parts by weight of the whole of the monomer components, of a carboxyl group-containing monomer as a monomer component and having a weight average molecular weight of from 500,000 to 900,000; and (b) an oligomer containing an ethylenically unsaturated monomer, in which a homopolymer formed therefrom has a glass transition temperature of from 60 to 190° C. and which has a cyclic structure, as a monomer major component and from 1 to 10 parts by weight, based on 100 parts by weight of the whole of the monomer components, of a carboxyl group-containing monomer as a monomer component and having a weight average molecular weight of from 3,000 to 6,000.

Owner:NITTO DENKO CORP

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS7470736B2Improve adhesionImprove coating adhesionSpecial tyresInksWater basedPolyvinyl chloride

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

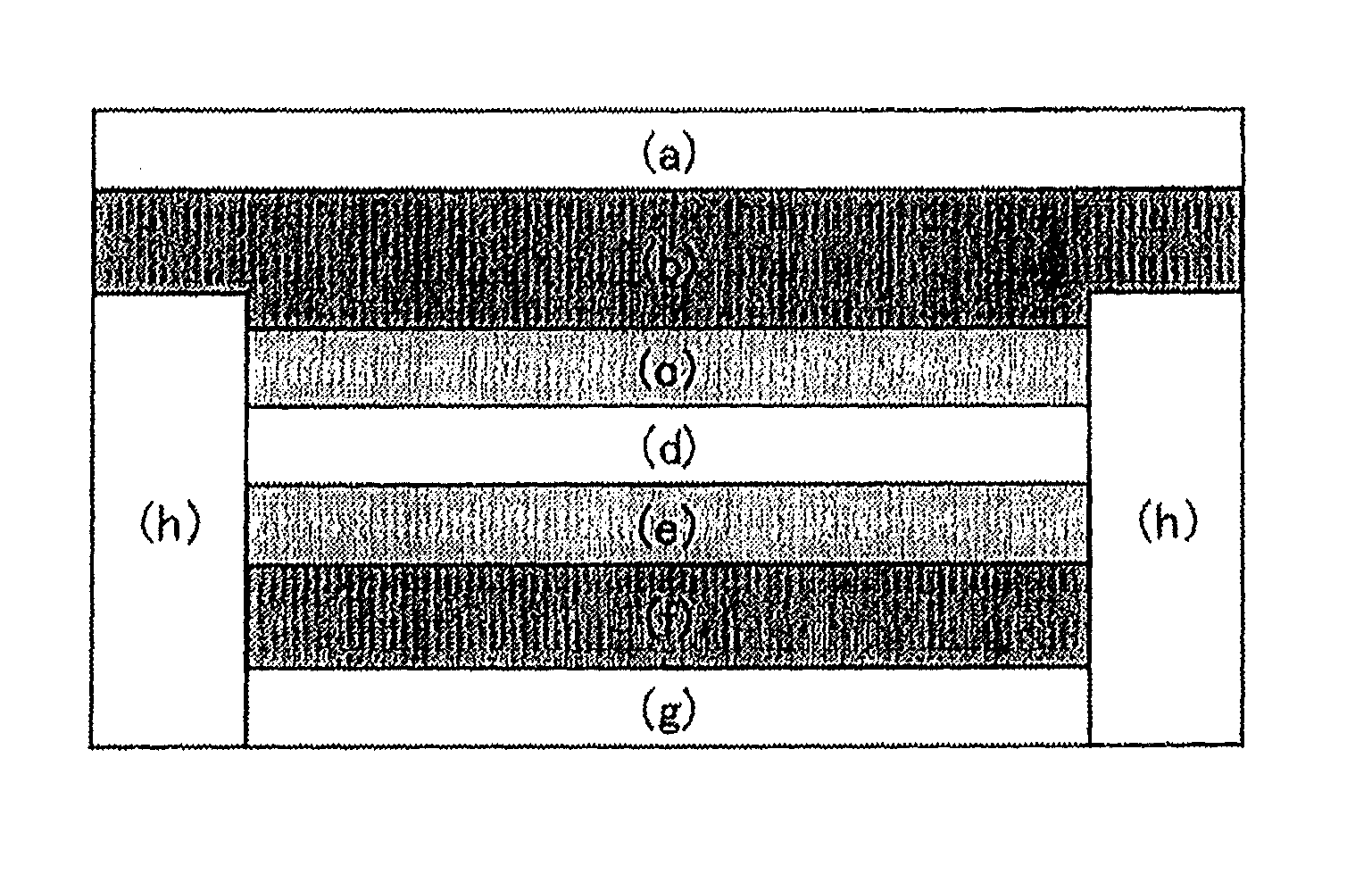

Controlled extended drug release technology

ActiveUS20060003007A1Longer resident timeEasy to controlCapsule deliveryCoatingsActive agentWater insoluble

A controlled extended drug release technology for the controlled extended release of hydrophobic or hydrophilic drugs or therapeutically active agents consisting of a homogeneous blend of one or more therapeutic agents, gas generators and surrounded by one or more layers of coat made of thermoplastic water insoluble cellulose derivatives, acrylic polymers, superdisintegrants and optionally an oil, antioxidants and electrolytes. The technology platform is capable of releasing therapeutic agents via zero, first or pseudo first order release.

Owner:INTELLIPHARMACEUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com