Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1422 results about "Modified cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Some types of modified cellulose are soluble and some insoluble . Cellulose can be also produced from corn cobs or stalks, soybean hulls, sugar cane stalks, oat hulls, rice hulls, wheat straw, sugar beet pulp, bamboo, jute, flax and ramie. Modified cellulose is also used as a filler in tablets and as a laxative.

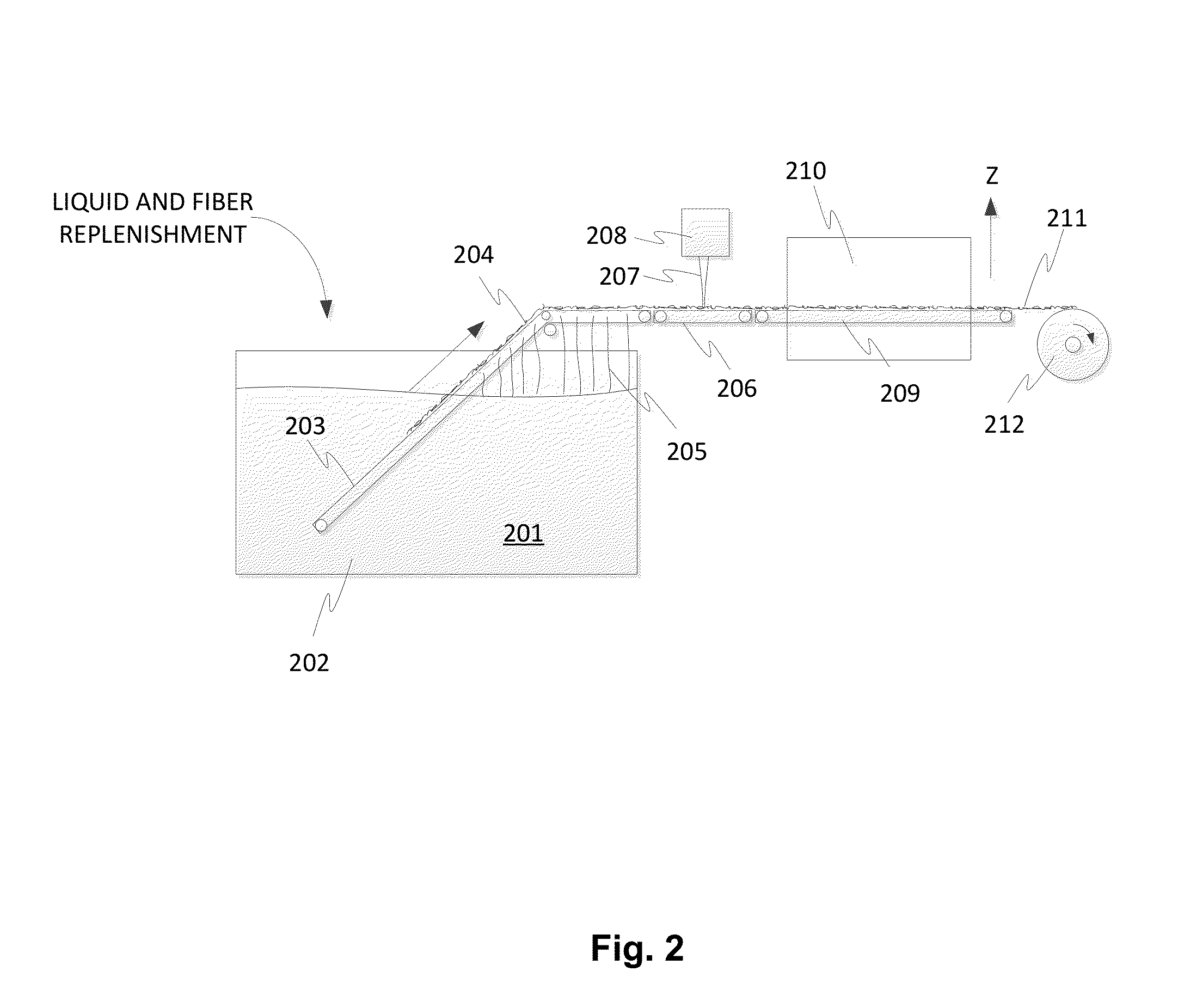

Method of producing and the use of microfibrillated paper

InactiveUS20100065236A1Non-fibrous pulp additionPulp properties modificationChemical structureEngineering

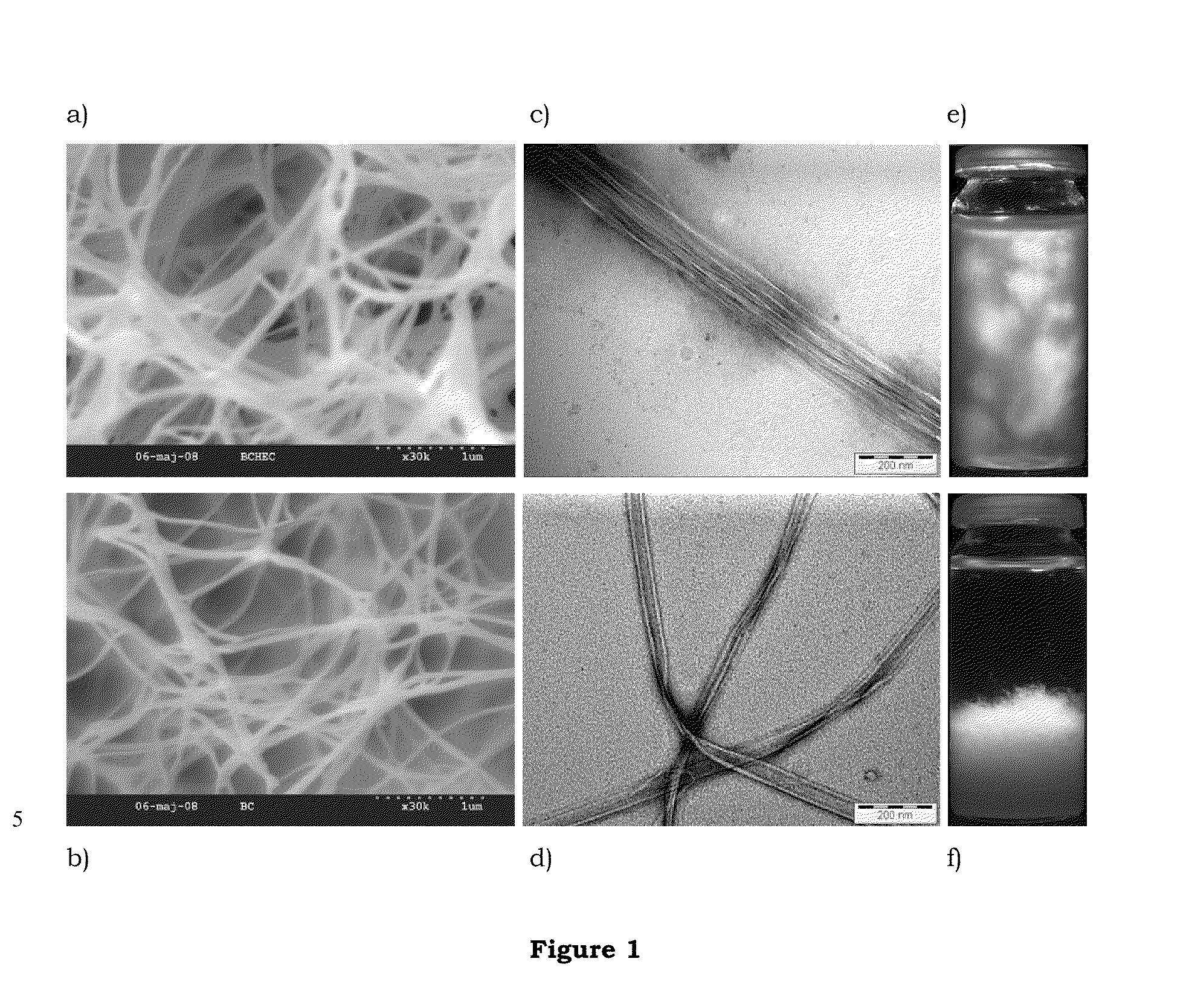

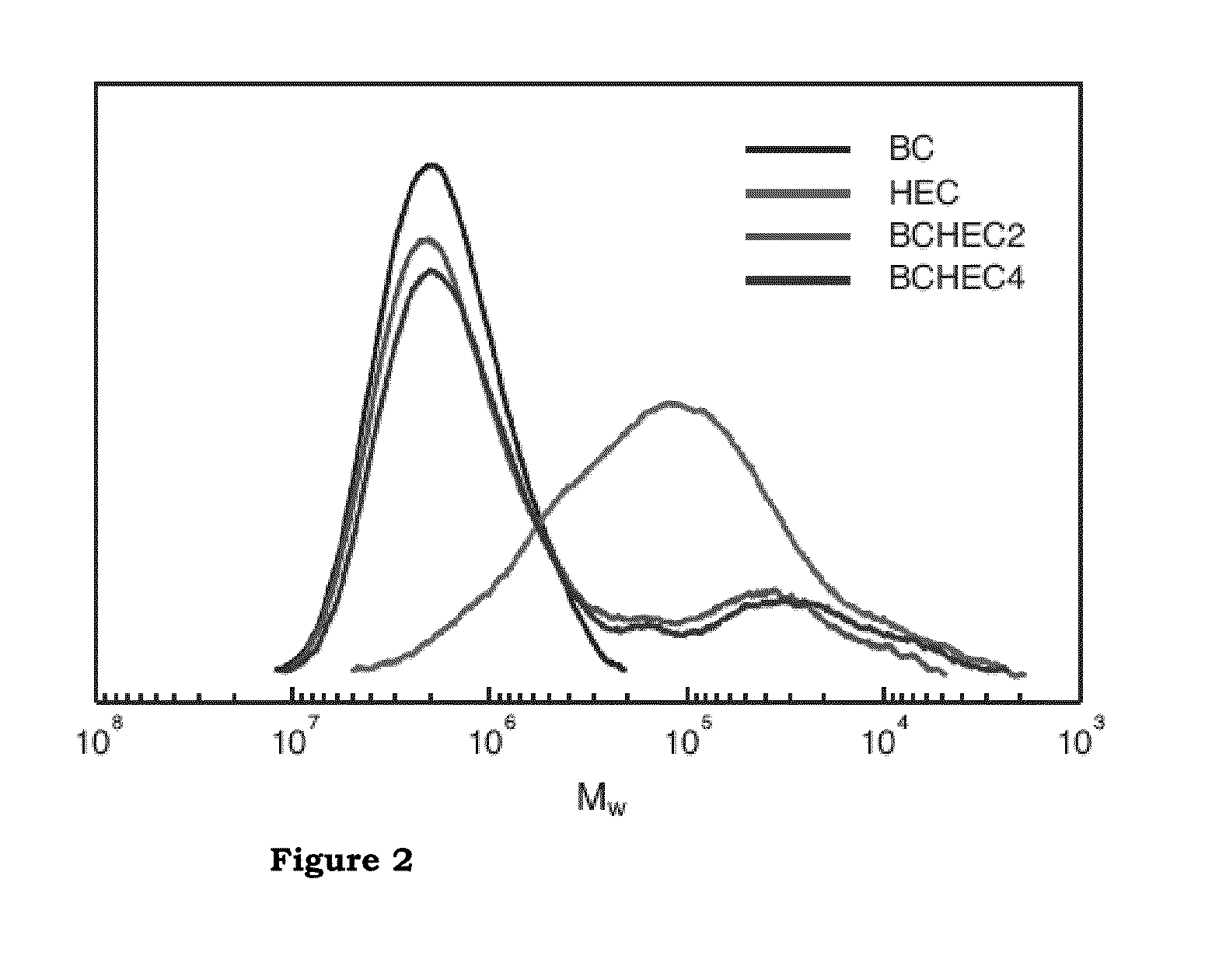

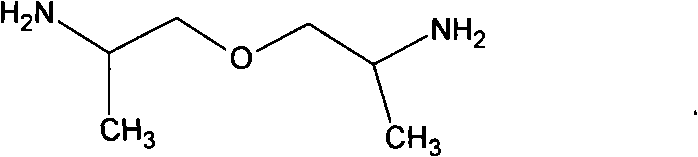

The present invention relates to a method of producing a cellulose based paper, the paper itself and the use thereof where the paper exhibits enhanced mechanical properties. The method involves providing a suspension of well dispersed modified cellulose at a low concentration. The properties and the chemical structure of the paper make it suitable for in vivo applications such as implant material.

Owner:SWETREE TECHOLOGIES AB

Water-based drilling fluid composition containing amine compound

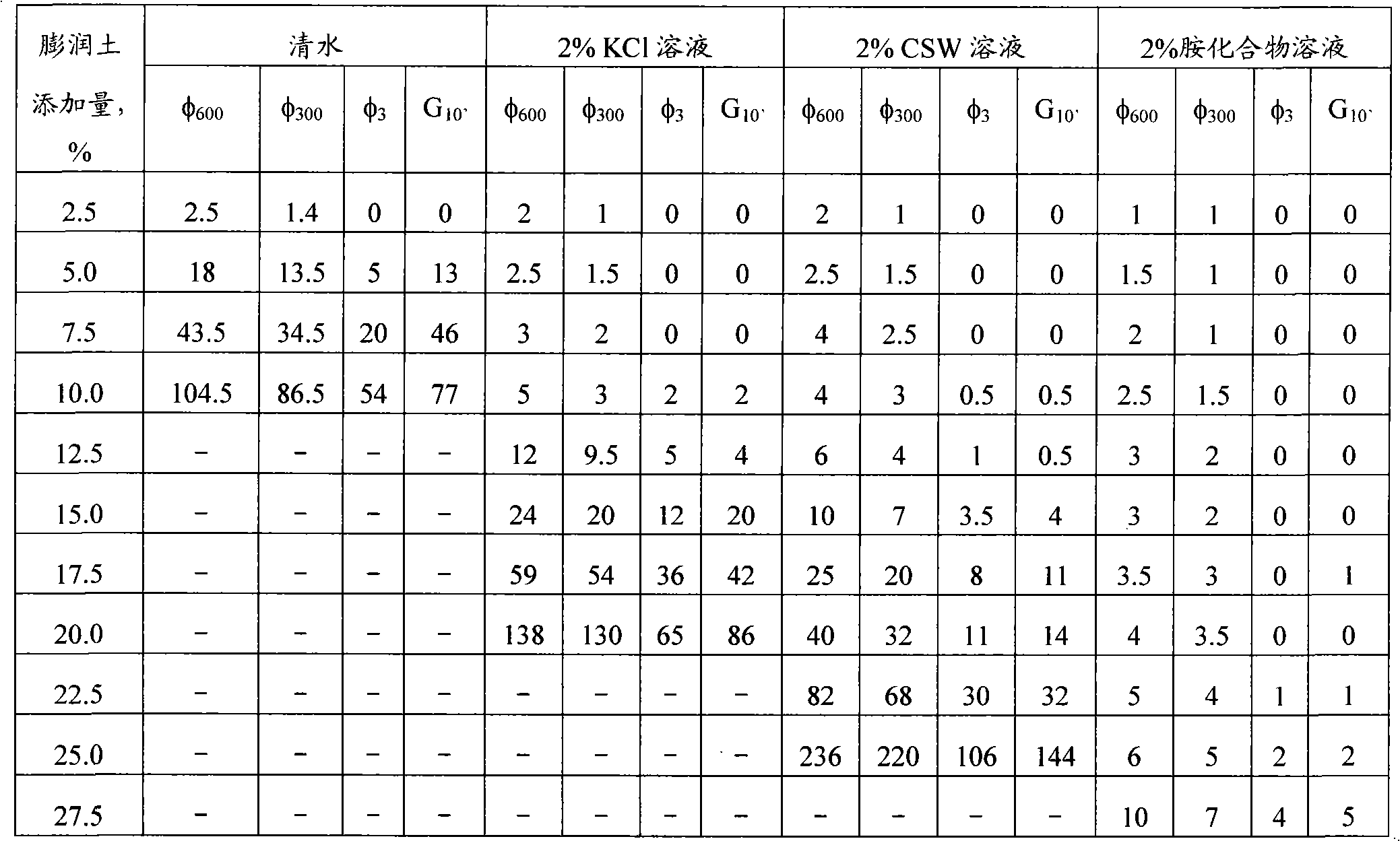

The invention provides a water-based drilling fluid composition containing an amine compound, which comprises the following components: a 0.5 to 5 weight percent of water-based amine compound as shown in formula I: RHN-Y-[OY']X-NHR', wherein Y, Y',x, R and R' are as defined in a manual; 0.1 to 1.0 weight percent of water-based tackifier which is selected from one or more types of xanthan gum, acrylamide-acrylic copolymer and hydroxyl ethyl cellulose; 0.5 to 5 weight percent of water-based fluid loss agent which is selected from one or more types of modified lignite, acrylic polymer, modified starch and modified cellulose; 2 to 12 weight percent of water-based inhibitor which is selected from one or more types of potassium chloride, potassium sulfate, formic acid, formic acid sodium, potassium chloride and epoxypropyltrimethylammonium chloride; and the composition can also further comprises coating agent, weighting agent, lubricant, borehole stabilizer and the like. The water-based drilling fluid composition has good inhibiting performance to clay shale drilling cuttings.

Owner:CNPC DRILLING RES INST

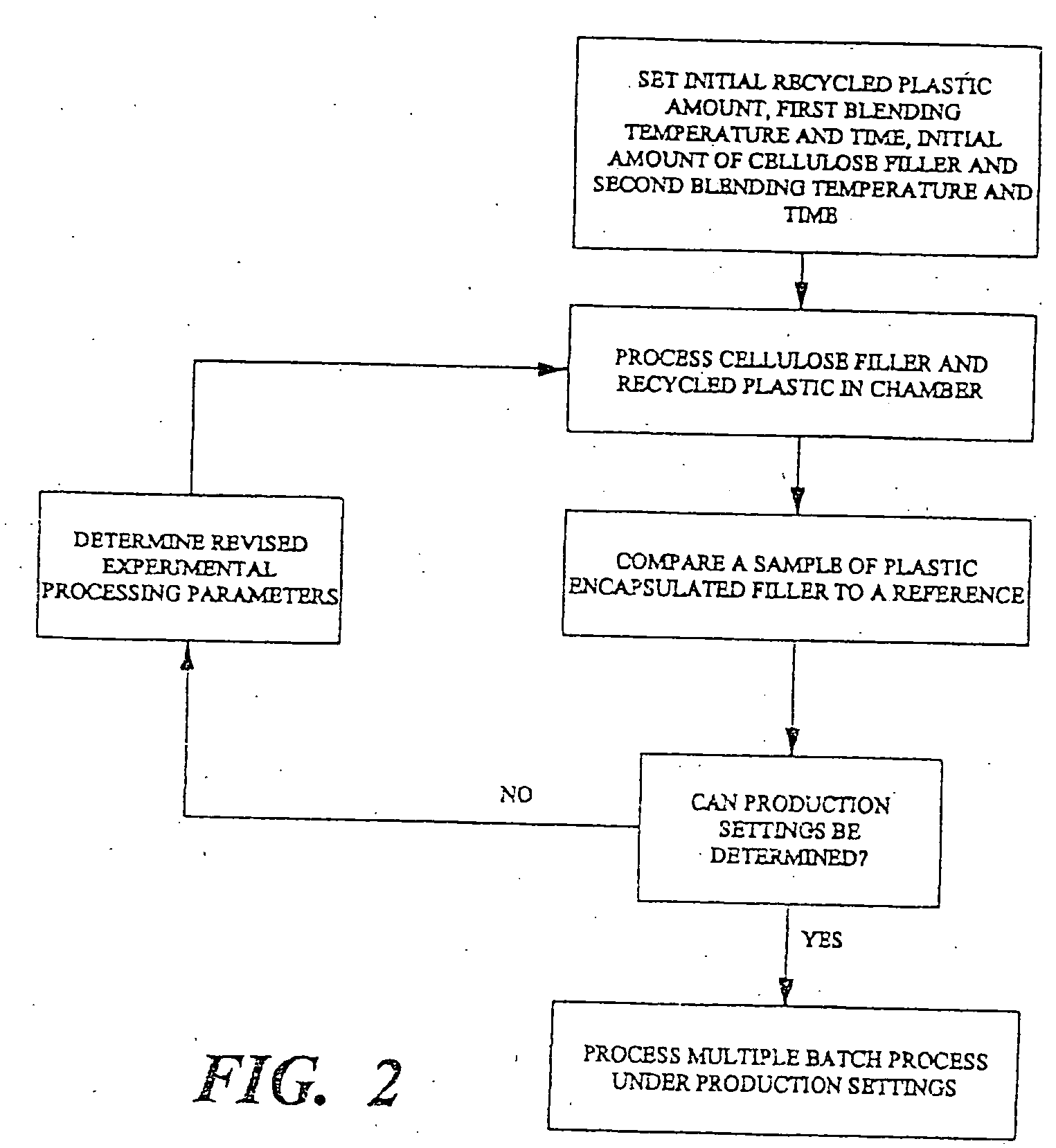

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20060006564A1Reduce the possibilityLower melting and softening temperaturePlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

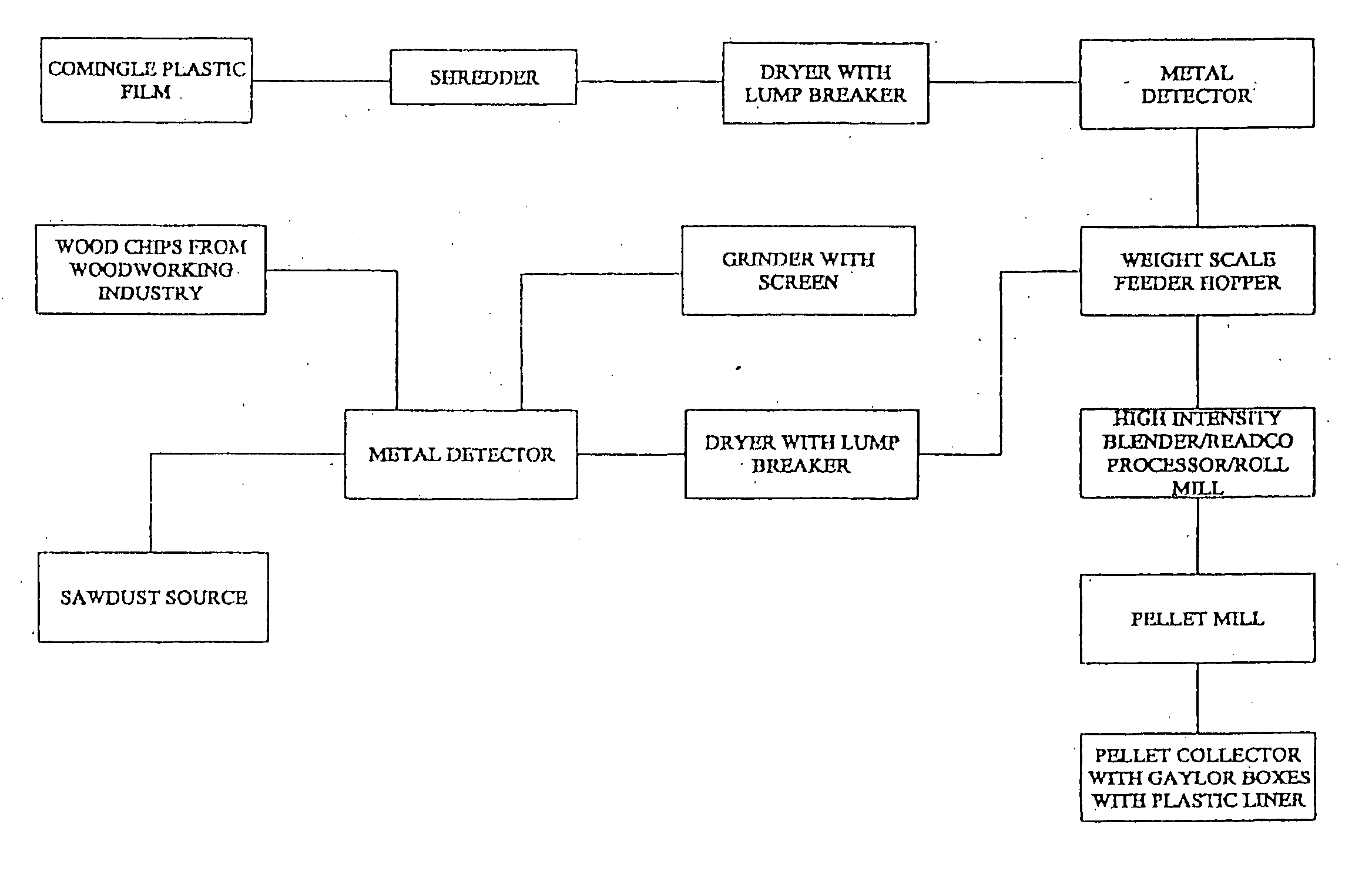

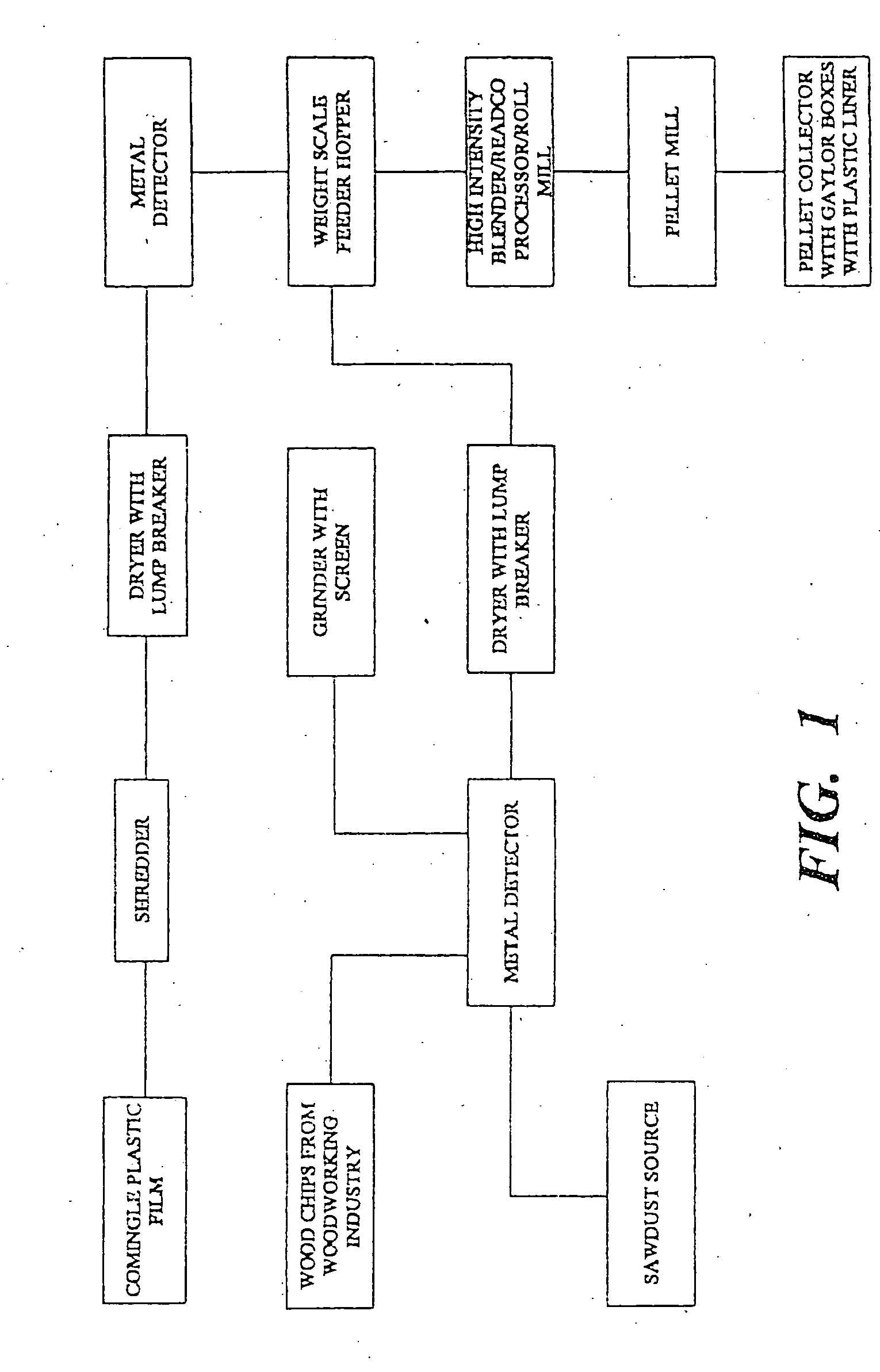

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

Preparation method of modified cellulose adsorbents

InactiveCN103480348AWide variety of sourcesLow priceOther chemical processesWater/sewage treatment by sorptionEpoxyPolymer science

The invention discloses a preparation method of modified cellulose adsorbents. The preparation method comprises the following steps: (1) activating cellulose in alkaline aqueous solution to obtain activated cellulose; (2) reacting the activated cellulose with epoxy chloropropane to obtain epoxy cellulose; (3) reacting the epoxy cellulose with an oxidizing agent to obtain epoxy dialdehyde oxidized cellulose; (4) reacting cyclodextrin with epoxy dialdehyde oxidized cellulose to obtain cyclodextrin grafted modified cellulose; and (5) reacting the cyclodextrin grafted modified cellulose with amino-terminated hyperbranched polymer to obtain the modified cellulose adsorbents. The raw material source is wide, the price is low, and the environment-friendly effect is achieved; the preparation method is simple, the reaction condition is mild, the equipment requirement is low and scale production is facilitated; and the prepared adsorbent has stable performance and broad-spectrum adsorption capacity for heavy metal ions, dyes and other organic matters and is environment-friendly, the cellulose additional value is remarkably promoted, and good economic and social benefits are achieved.

Owner:SUZHOU UNIV

Method for producing modified cellulose

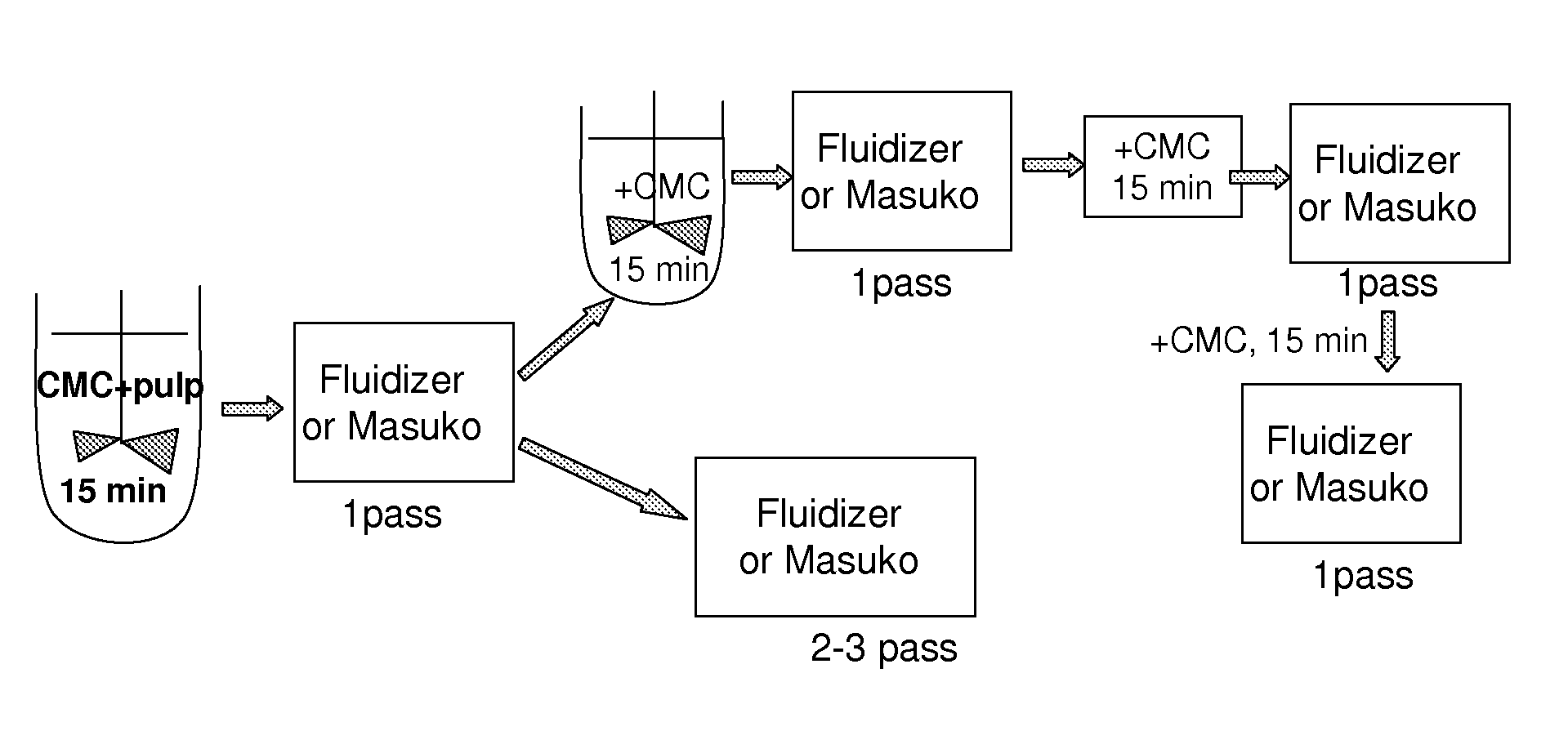

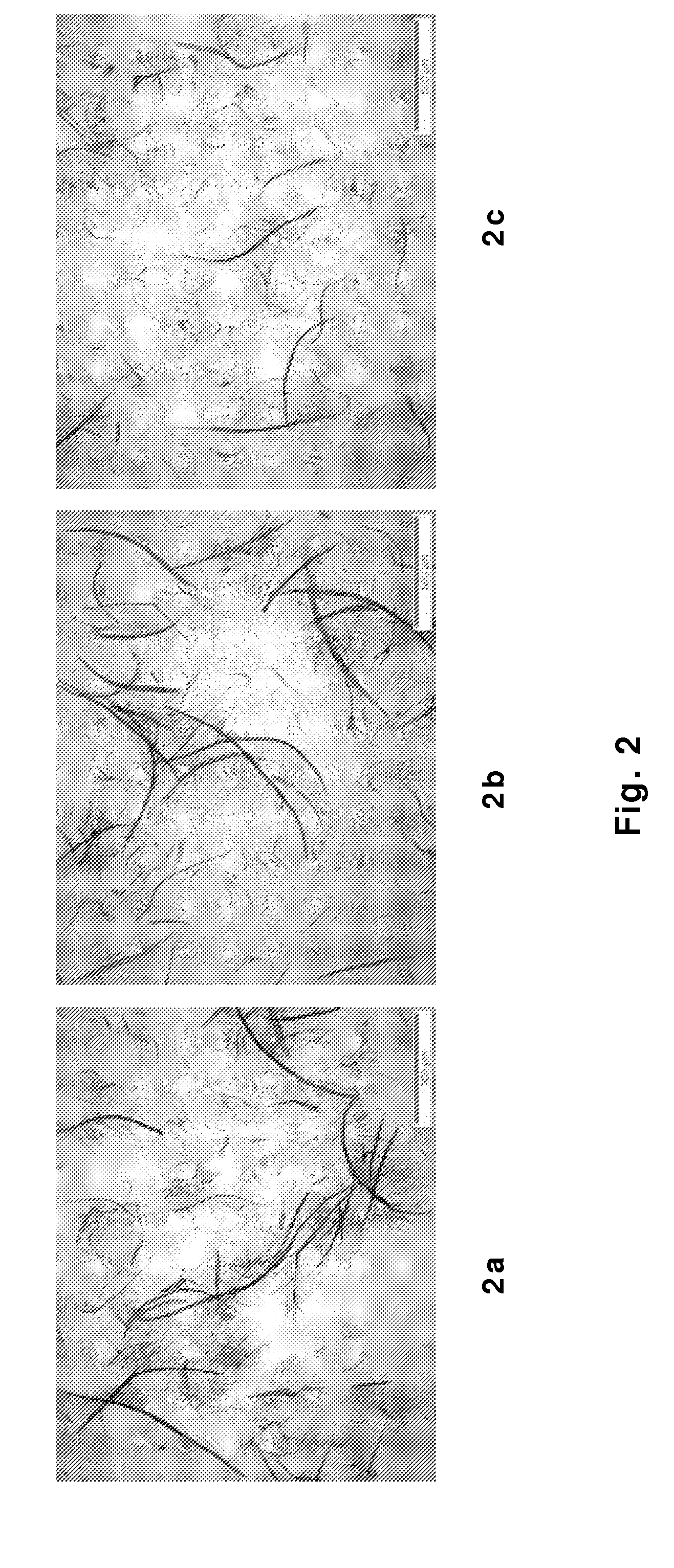

InactiveUS20120043039A1Improve propertiesEfficient productionSpecial paperPaper after-treatmentFiberFiber suspension

The present invention provides a method for producing modified nanofibrillated cellulose characterized by bringing cellulosic material into a fiber suspension, adsorbing a cellulose derivative or polysaccharide or polysaccharide derivative onto fibers in said fiber suspension under special conditions and subjecting the obtained fiber suspension derivative to mechanical disintegration. A modified nanofibrillated cellulose obtainable by a method of the present invention is provided. Furthermore, the invention relates to the use of said modified nanotibrillated cellulose.

Owner:UPM-KYMMENE OYJ

Chemical mechanical polishing compositions and methods relating thereto

ActiveUS20060000151A1Inorganic/elemental detergent compounding agentsPigmenting treatmentNonferrous metalCompound (substance)

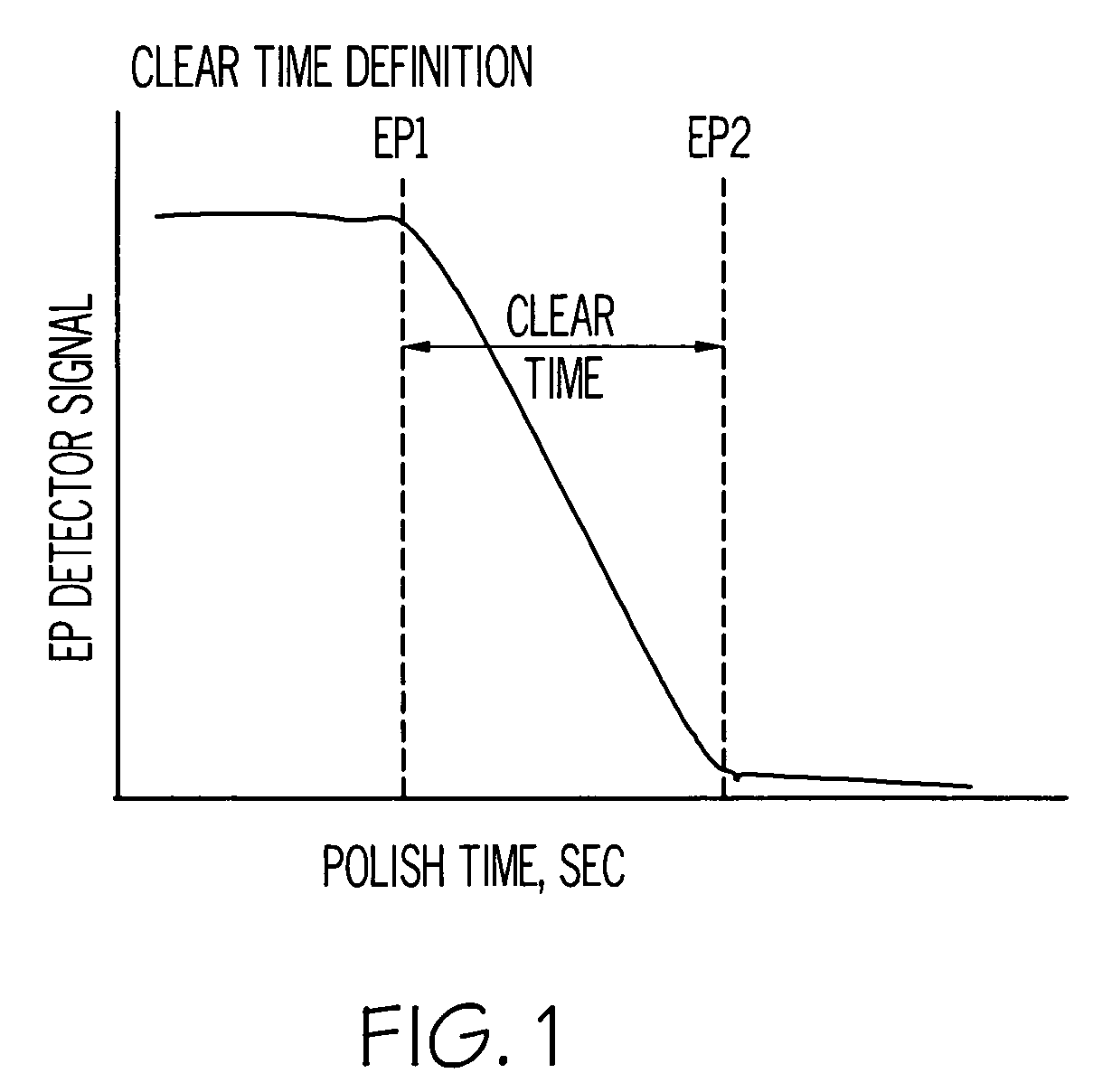

The present invention provides an aqueous composition useful for CMP of a semiconductor wafer containing a metal comprising oxidizer, inhibitor for a nonferrous metal, complexing agent for the nonferrous metal, modified cellulose, 0.001 to 10% by weight copolymer blends of a first copolymer and a second copolymer and balance water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Cellulose-containing polishing compositions and methods relating thereto

An aqueous composition is useful for chemical mechanical polishing of a patterned semiconductor wafer containing a nonferrous metal. The composition comprises an oxidizer, an inhibitor for the nonferrous metal, 0.001 to 15 weight percent of a water soluble modified cellulose, non-saccaride water soluble polymer, 0 to 15 weight percent phosphorus compound, 0.005 to 10 weight percent of a water miscible organic solvent, and water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

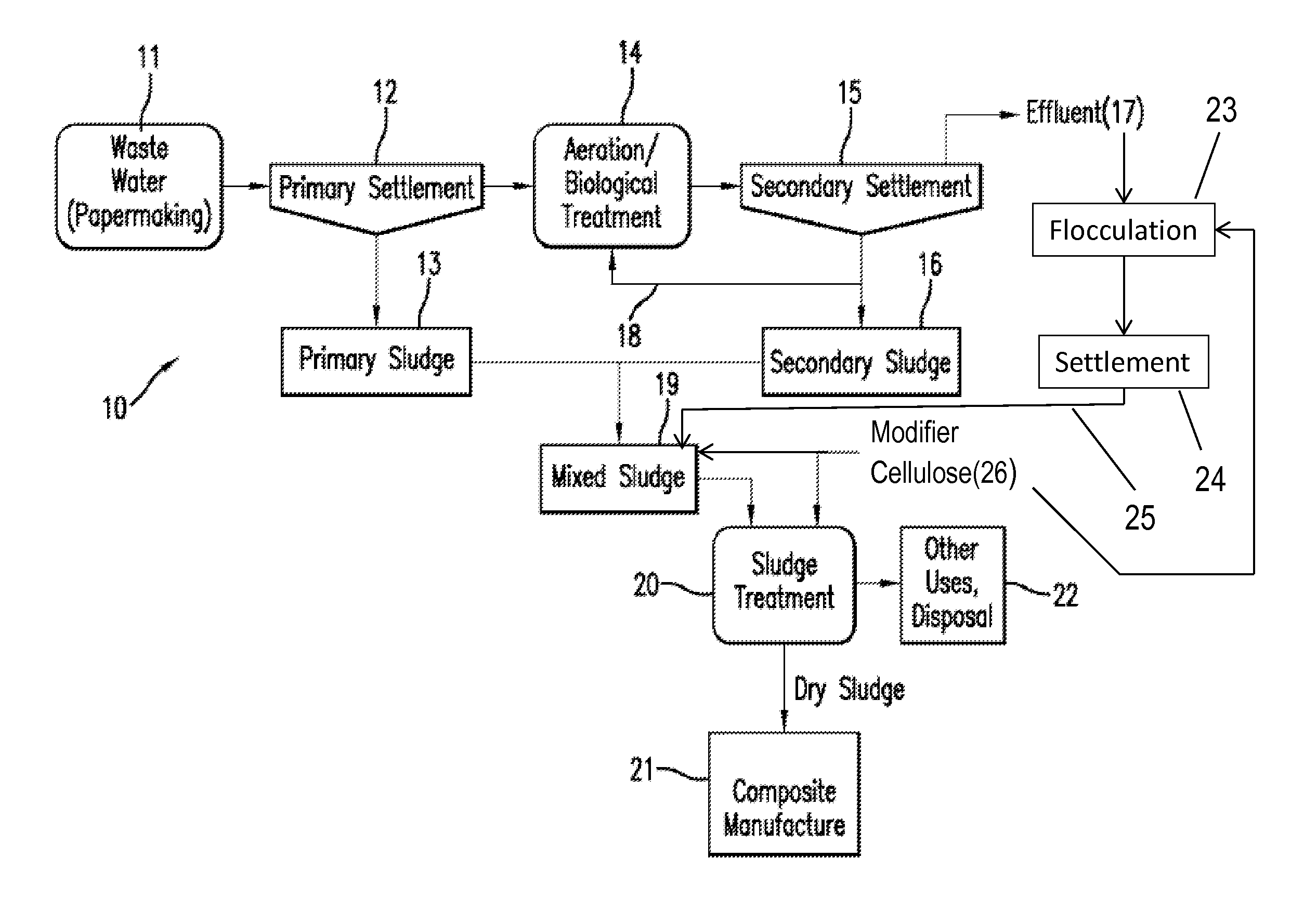

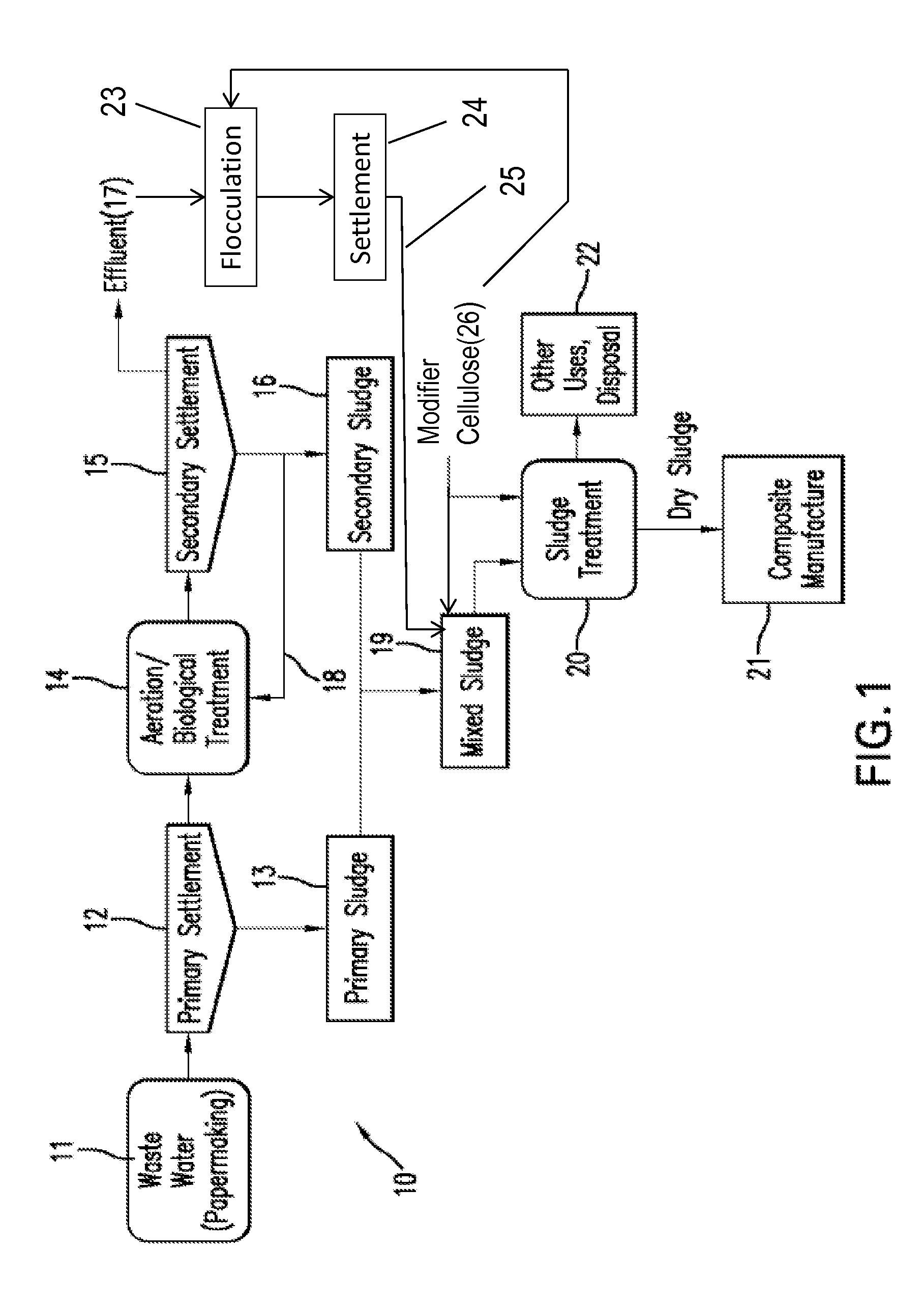

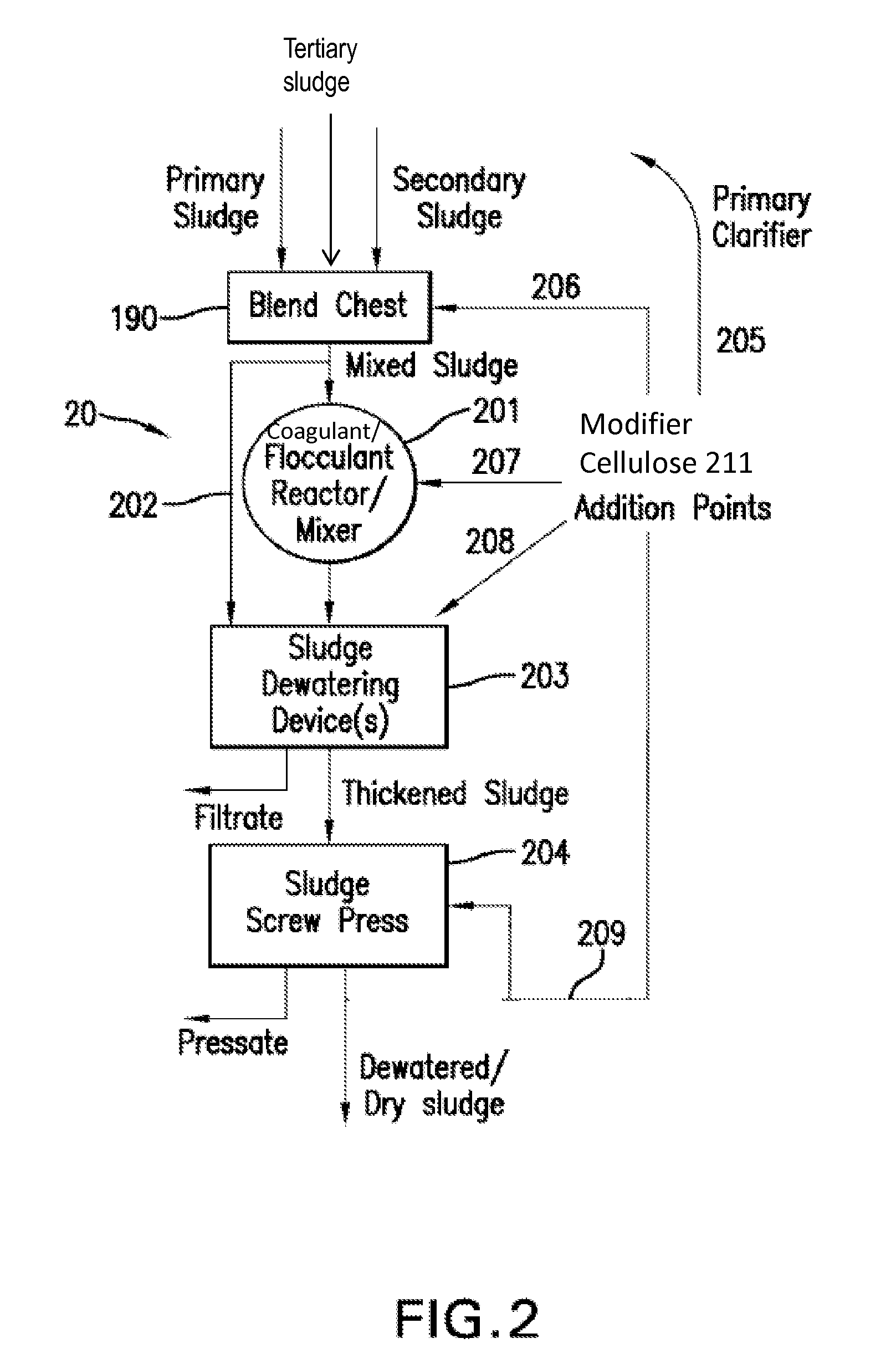

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

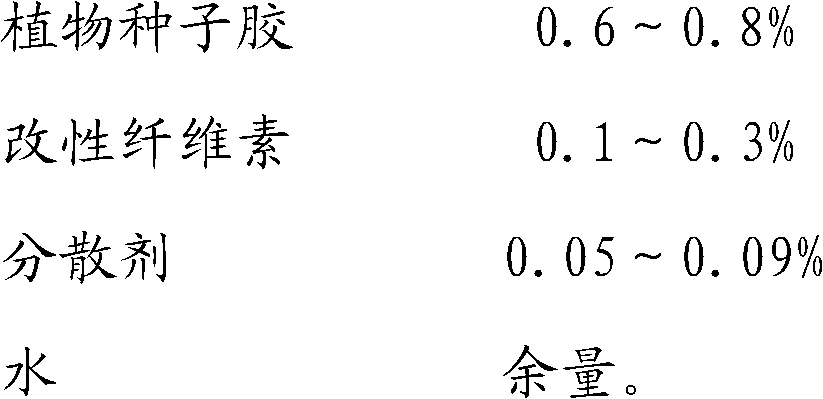

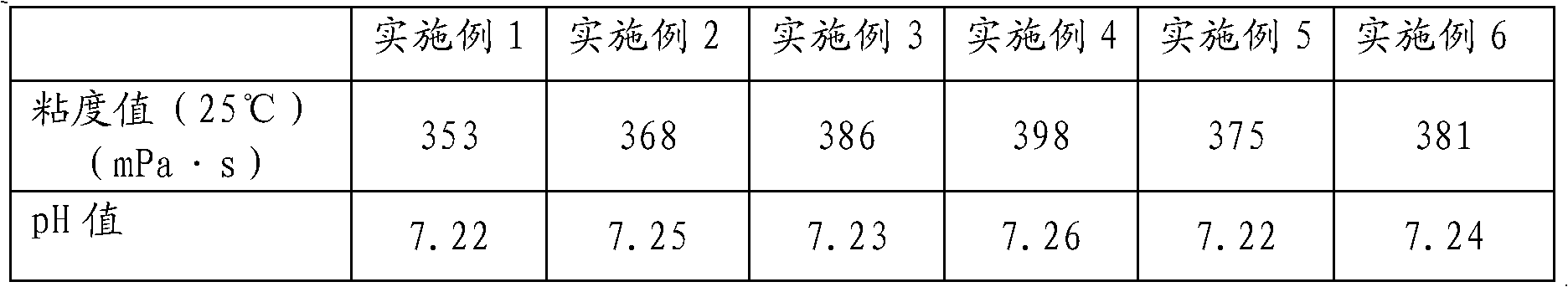

dust suppressant

The invention discloses a dust inhibitor, which comprises the following raw material in percentage by weight: 0.6 to 0.8 percent of plant seed colloid, 0.1 to 0.3 percent of modified cellulose, 0.05 to 0.09 percent of dispersant and the balance of water. The dust inhibitor can be prepared at normal temperature in a common mixing equipment from mixed aqueous solution of plant seed colloid, modified cellulose, crosslinking agent, dispersant and reinforcing agent; and after being prepared, the dust inhibitor can be sprayed onto the surface of coal in carriages to allow the coal to form a layer of cured film on the surface, the viscosity of the film is high, the wind corrosion rate of the film is low, so that the dust pollution along railways in railway transportation of the coal and the dust loss of the coal are avoided. Besides, dust inhibition in railway coal transportation, the dust inhibitor can be used for dust inhibition on roads in mining areas, urban roads, constructions sites, stations, ports and the like so that the dust inhibitor can be used almost without being limited by fields, and the dust inhibitor can be widely used.

Owner:北京中盛益世环保科技有限公司

Method for preparing waterproof moisture-permeable coated fabric

InactiveCN101736595ASimple manufacturing methodScalable productionFibre treatmentMoisture permeabilityPolyurethane coating

The invention discloses a method for preparing a waterproof moisture-permeable coated fabric. The moisture permeability of a polyurethane coated fabric is improved by adding modified cellulose powder which accounts for 5 to 50 percent of the weight of polyurethane and is modified by a silane coupling agent into a polyurethane coating agent, and the waterproof property of the polyurethane is improved by adding inorganic powder which accounts for 0.5 to 5 percent of the weight of the polyurethane and is modified by the silane coupling agent, wherein the silane coupling agent accounts for 0.5 to 1 percent of the weight of the modified cellulose powder; and the silane coupling agent accounts for 0.5 to 1 percent of the weight of the inorganic powder. The modified polyurethane which accounts for 15 to 50 percent of the weight of a base fabric is coated on the base fabric of a knitted fabric, a woven fabric or a non-woven fabric to prepare the waterproof moisture-permeable coated fabric with good performance. The method is simple and easy, and can perform mass production; and the prepared fabric has excellent waterproof and moisture-permeable abilities, solves the contradiction between the waterproof capacity and the moisture-permeable capacity of the fabrics, and can be applied to coated fabrics for functional clothing, shoes, tents and buildings in a large quantity.

Owner:ZHEJIANG SCI-TECH UNIV

Viscosity modified formaldehyde-free binder compositions

ActiveUS20140134909A1High viscosityLaminate strength deterioratesNon-fibrous pulp additionNon-macromolecular adhesive additivesGuar gumHydroxyethyl cellulose

Viscosity-modified carbohydrate binder compositions are described. The binder compositions may include a carbohydrate, a nitrogen-containing compound, and a thickening agent. The binder compositions may have a Brookfield viscosity of 7 to 50 centipoise at 20° C. The thickening agents may include modified celluloses such as hydroxyethyl cellulose (HEC) and carboxymethyl cellulose (CMC), and polysaccharides such as xanthan gum, guar gum, and starches.

Owner:JOHNS MANVILLE CORP

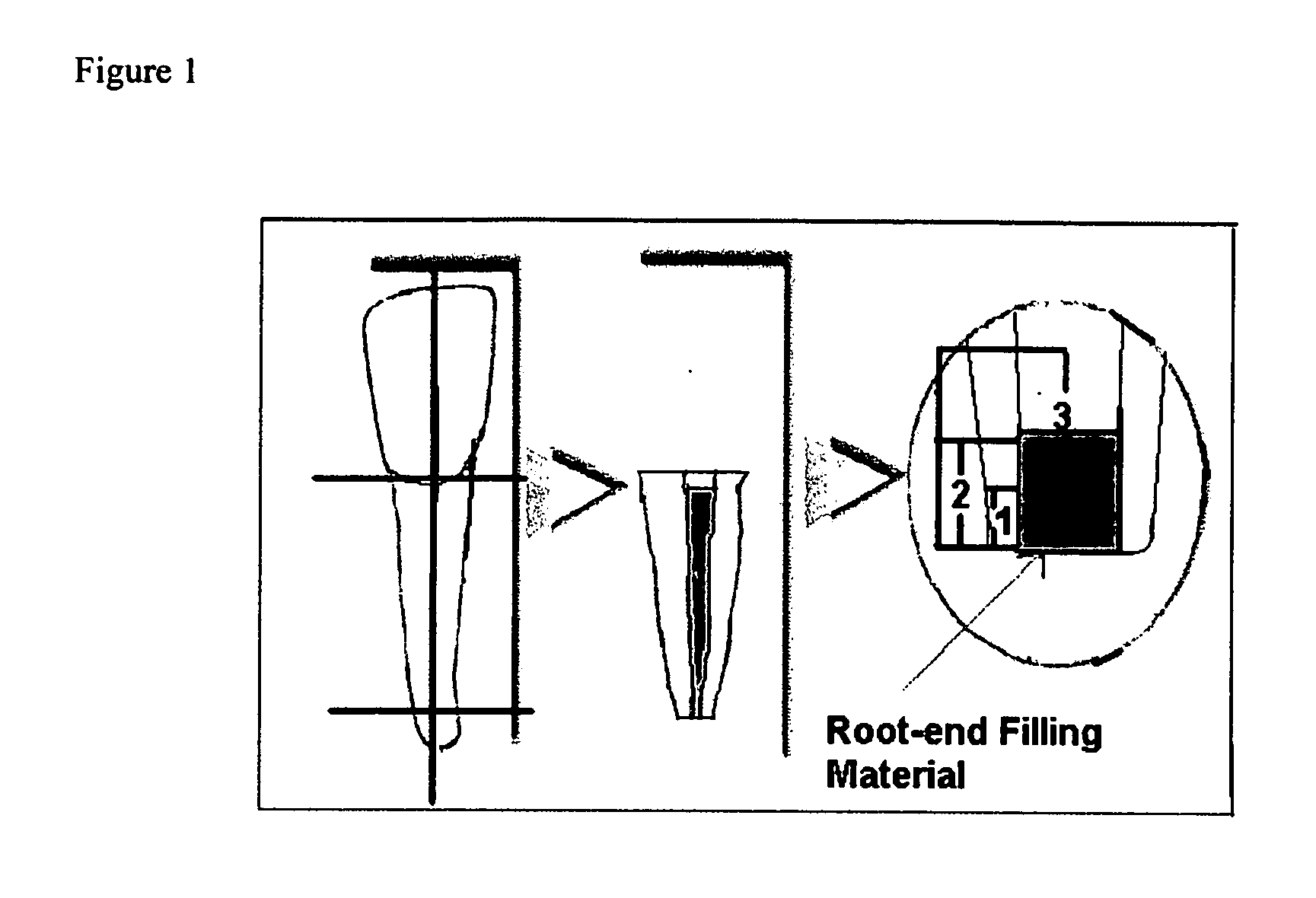

Dental repair material

InactiveUS20070009858A1Easy to operateEffective treatmentImpression capsDentistry preparationsRepair materialChloride

The invention is directed to an improved dental composition useful in the repair of cavities, apex repairs, root perforations and root canals. Disclosed is a dental composition and dental composition additive which have improved handling characteristics, for example improved viscosity and setting time. The addition of effective amounts of a modified cellulose and calcium chloride to available dental repair compounds, such as mineral trioxide compound, results in the improved dental composition without affecting the other characteristics of the dental repair compound.

Owner:SAINT LOUIS UNIVERSITY

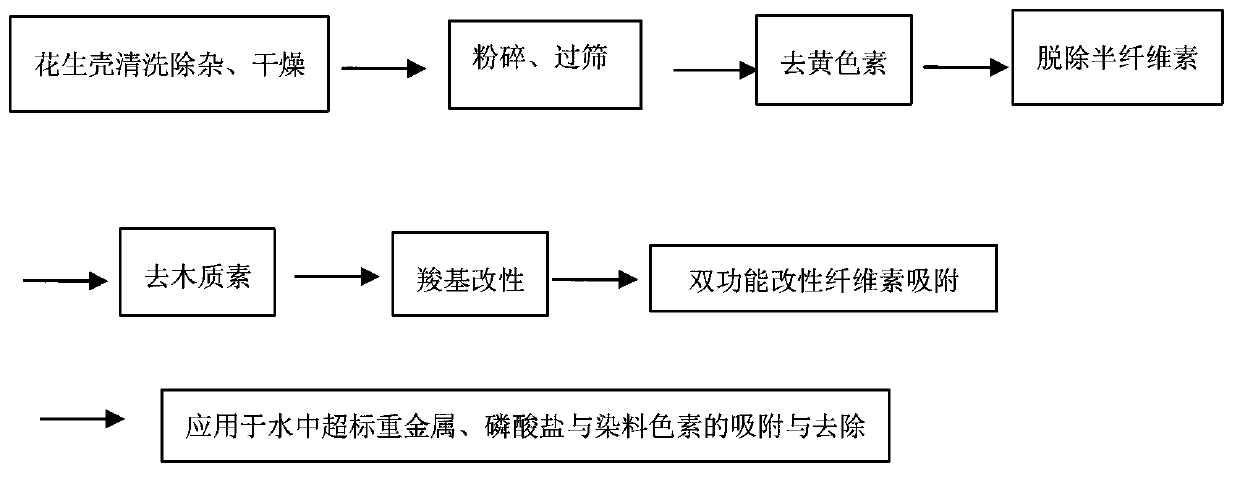

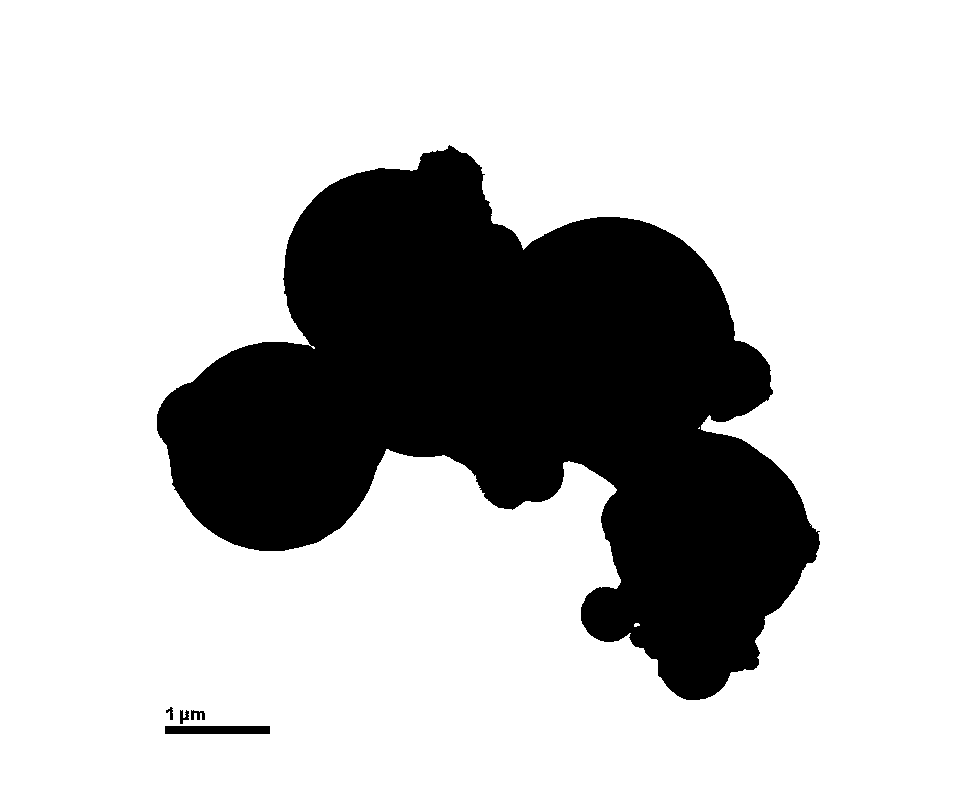

Method for preparing bifunctional modified cellulose adsorbing agent from peanut shells and application of method

InactiveCN103272568AGood biocompatibilityAchieve adsorptionOther chemical processesWater/sewage treatment by sorptionPhosphateSorbent

The invention discloses a method for preparing a bifunctional modified cellulose adsorbing agent from peanut shells and application of the method. The method comprises the following preparation steps of: washing, drying and crushing waste peanut shells, which are taken as raw materials, and removing flavochrome, hemicellulose and xylogen from the crushed peanut shells so as to obtain peanut shell cellulose; and performing surface functional modification on the materials through substitution and amidation further so as to finally obtain the amino and carboxy bifunctional modified peanut shell cellulose adsorbing material. The product is powdery and light brownish yellow, and the particle size of the product is 1.5-2.5 microns. The bifunctional modified peanut shell cellulose adsorbing material has a good adsorption effect for excessive heavy metals such as copper, chrome and mercury, phosphate, methylthionine chloride dye, and the like in water. The adsorbing agent is simple in preparation method, low in cost, cheap, easily available, good in biological compatibility and environment-friendly, contains a great deal of functional chelation groups, can realize simultaneous adsorption and removal of negative ions and positive ions, and has the advantages of being recyclable and the like.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

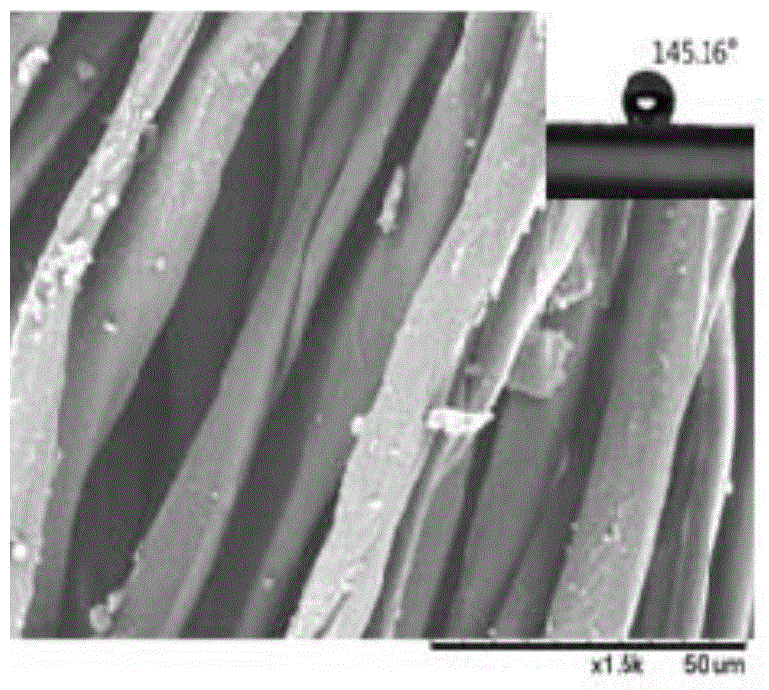

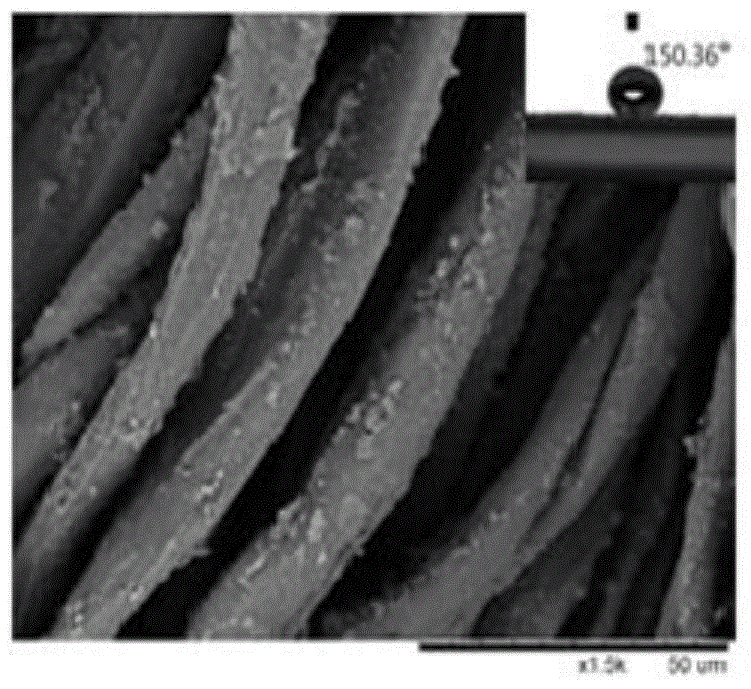

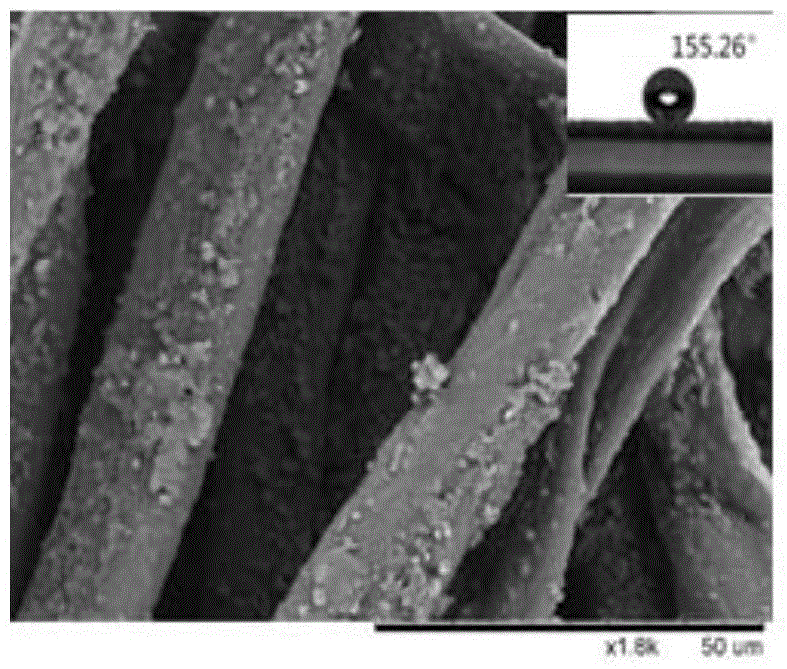

Method for preparing durable cellulose fiber fabric with super-hydrophobic surface

InactiveCN104594028AExcellent Durability Super Hydrophobic PropertiesMeet functional requirementsVegetal fibresCross-linkState of art

The invention relates to a method for preparing a durable cellulose fiber fabric with a super-hydrophobic surface. The method comprises the following three steps: preparing modified SiO2 composite sol, preparing a modified fabric and performing super-hydrophobic finishing on the fabric. The active groups are introduced into nanometer SiO2 and fiber surface, the fabric is finished by adopting a simple one-step method, the binding force between the fabric and the inorganic nanometer SiO2 is enhanced by virtue of the active groups on the fiber surface and the cross-linking effect on the modified SiO2 surface, the covalent bonding firmness between the modified sol and the surface of the modified cellulose fiber fabric is improved, and the super-hydrophobic interface of a fluoride-free cellulose fiber fabric with certain washing fastness is finally obtained. Compared with the prior art, the preparation method disclosed by the invention is economical and environmentally friendly, and the industrial production is promoted.

Owner:SHANGHAI UNIV OF ENG SCI

Combination of Inorganic Hemostatic Agents with Other Hemostatic Agents

InactiveUS20080145455A1Low costStanching flowBiocideOrganic active ingredientsBiopolymerChitin formation

Several hemostatic bandages that are commercially available function by tightly sealing a wound so that hemostasis can occur before excessive blood loss takes place. Hemostatic bandages which seal a wound but which do not actually speed the coagulation mechanism include chitosan and chitin-based bandages. Hemostatic gauzes based on chemically modified cellulose are also commercially available. These bandages and gauzes, used in combination with various inorganic materials such as zeolite, silica, and / or diatomaceous earth powder show a synergistic effect. It has been found that the inorganic material activates the contact coagulation mechanism while the biopolymer component binds the wound and prevents excessive blood loss.

Owner:HONEYWELL INT INC

Railway coal transportation dust-depressor and manufacturing method thereof

ActiveCN101348706AAvoid dustEasy to manufacture and implementOther chemical processesLoading/unloadingPolymer scienceCoal dust

The invention discloses a coal railway transportation dust depressor, which is invented for solving the problems of high cost, poor depression effect and so on in the prior art. The raw materials by weight percent for preparing effective compositions in the coal railway transportation dust depressor are: 2 to 7 percent of synthesized water-soluble polymer, 0.1 to 5 percent of modified cellulose water-soluble polymer, 85 to 95 percent of water and 0 to 2 percent of bluestone, wherein the synthesized water-soluble polymer is prepared by complexing at least two water-soluble polymers. The coal railway transportation dust depressor consists of more than two synthesized water-soluble polymers and a small amount of auxiliary agent, and has the advantages of high viscosity and low cost. When used, the coal railway transportation dust depressor is uniformly sprayed on particles on the surface of a coal bed to form a curing layer with certain strength, thereby the coal-dust particles of various grain sizes are bonded together and have certain toughness, and the aim of preventing flying dust on the surface of the coal bed is achieved.

Owner:随州市荷叶精细化工有限公司 +2

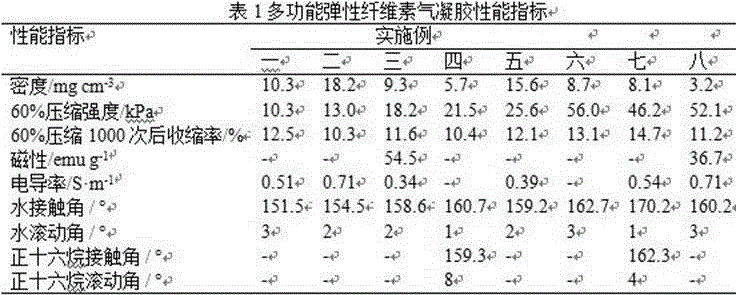

Preparation method of multifunctional cellulose elastic aerogel

The invention discloses a preparation method of a multifunctional cellulose elastic aerogel, belonging to the field of aerogel materials. The preparation method comprises the following steps: dispersing cellulose in water, carrying out pretreatment by adding sodium chlorite or / and in a solvothermal way, and cleaning with deionized water to obtain a purified cellulose dispersion solution; adding a modifier to perform chemical modification, thereby obtaining a modified cellulose suspension; dispersing the modified cellulose suspension in an organic solvent, forming, drying to form a modified cellulose gel, and finally, carrying out heat treatment on the modified cellulose gel to obtain the multifunctional cellulose elastic aerogel. The cellulose is subjected to pretreatment and chemical modification, thereby lowering the density of the aerogel, greatly enhancing the elasticity and mechanical strength of the aerogel, endowing the aerogel with excellent magnetism, electric conductivity, superhydrophobicity, superoleophobicity and many other functions, and widening the application range of the traditional cellulose aerogel.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

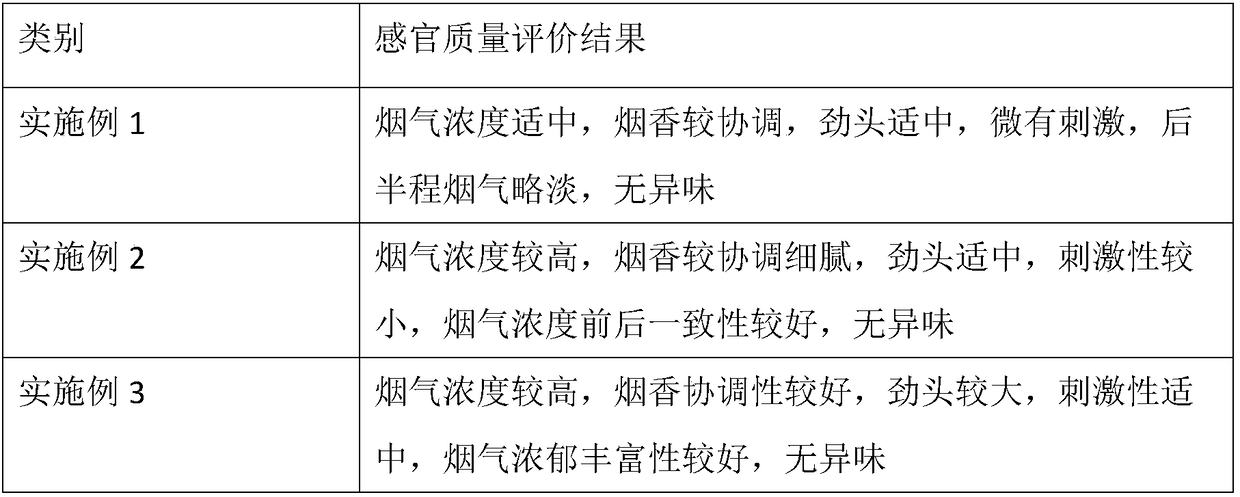

Cigarette core material for heating incombustible cigarettes and preparation method thereof

The invention provides a cigarette core material for heating incombustible cigarettes. The cigarette core material is prepared from the following components in percentage by weight: 10-50% of tobaccofiber and tobacco powder, 5-30% of wood pulp fibers, 5-30% of one or more of hemp fibers, bamboo fibers, soybean fibers, cocoon fibers, cotton fibers, polylactic acid fibers and modified cellulose fibers, 10-50% of tobacco essence, 10-30% of smoke producing agent, 1-10% of heat conduction material, 1-10% of phase change absorption material and 1-20% of paper coating component which is selected from one or more of a hydrophobic material, a microcapsule suspension and an essence suspension containing the tobacco powder. According to the cigarette core material, the heat conduction material is added, so that the heat can be uniformly conducted; the cigarette core paper is uniformly heated in the heating process; in addition, the phase change absorption material is used and is capable of achieving phase change and absorbing heat under the heated condition so as to prevent the cigarette core material paper from being locally overheated in the heating process.

Owner:NANTONG JIN YUAN NEW MATERIALS CO LTD

Personal care and household compositions of hydrophobically-modified polysaccharides

A conditioning composition is used in functional systems (personal care and household care compositions) that has a nonionic hydrophobically modified cellulose ether (HMCE) having a weight average molecular weight (Mw) with a lower limit of 400,000 and an upper limit of 2,000,000 and a hydrophobic substitution lower limit of 0.6 wt % and an upper limit amount which renders said cellulose ether insoluble in a 5 wt % solution of surfactant and less than 0.05% by weight soluble in water and wherein the cellulose ether provides conditioning benefit to the functional system substrate. This composition has at least one active functional system ingredient.

Owner:HERCULES INC

Sizing of paper

InactiveUS6306255B1High cationic demandExcellent characteristicsNatural cellulose pulp/paperSpecial paperCellulose fiberSizing

The invention relates to an aqueous disperion containing a cellulose-reactive sizing agent and an anionic hydrophobicailly modified cellulose-derivative, its preparation and use in the production of paper. The invention also relates to a substantially water-free composition containing a cellulose-reactive sizing agent and an anionic hydrophobicailly modified cellulose-derivative, its preparation and use in the preparation of an aqueous dispersion of cellulose-reactive sizing agent. The invention further relates to a process for sizing cellulosic fibers by addition of an aqueous sizing dispersion containing a cellulose-reactive sizing agent and a hydroically modified dispersing agent to a stock containing cellulosic fibers, and optional fillers, and dewatering the stock on a wire to obtain a web containing cellulosic fibers.

Owner:AKZO NOBEL NV

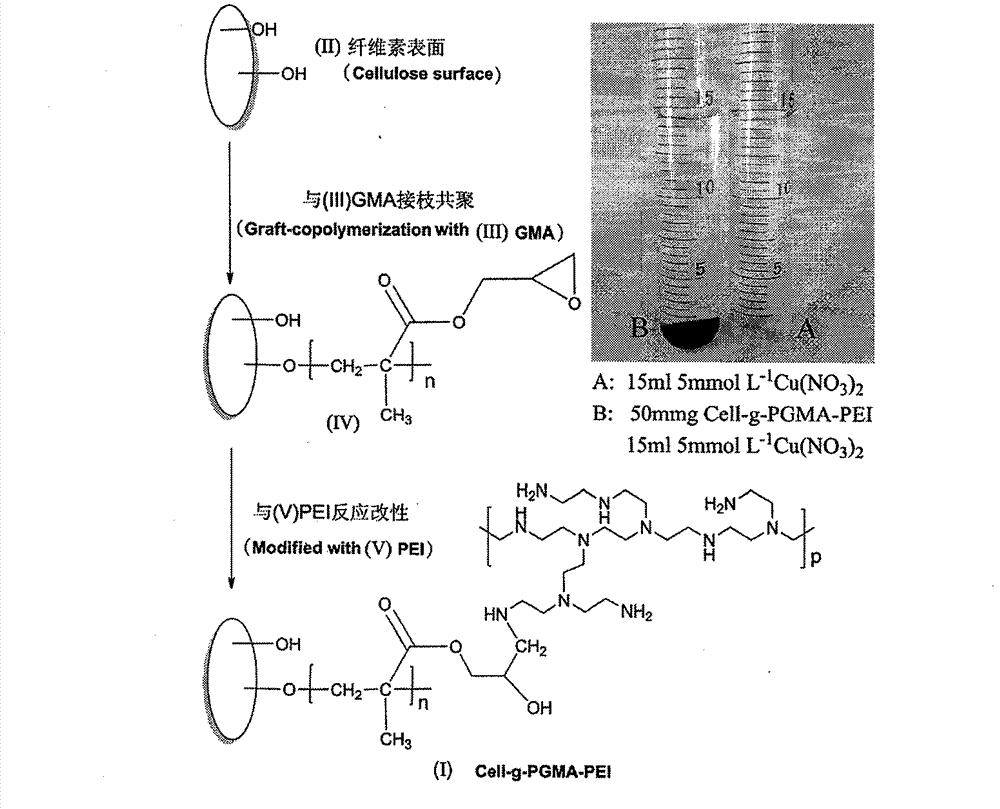

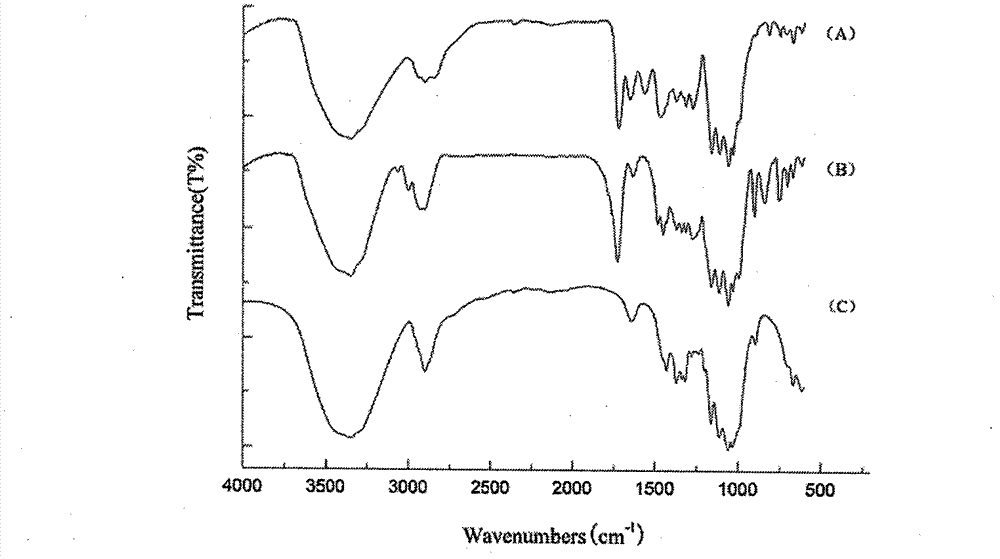

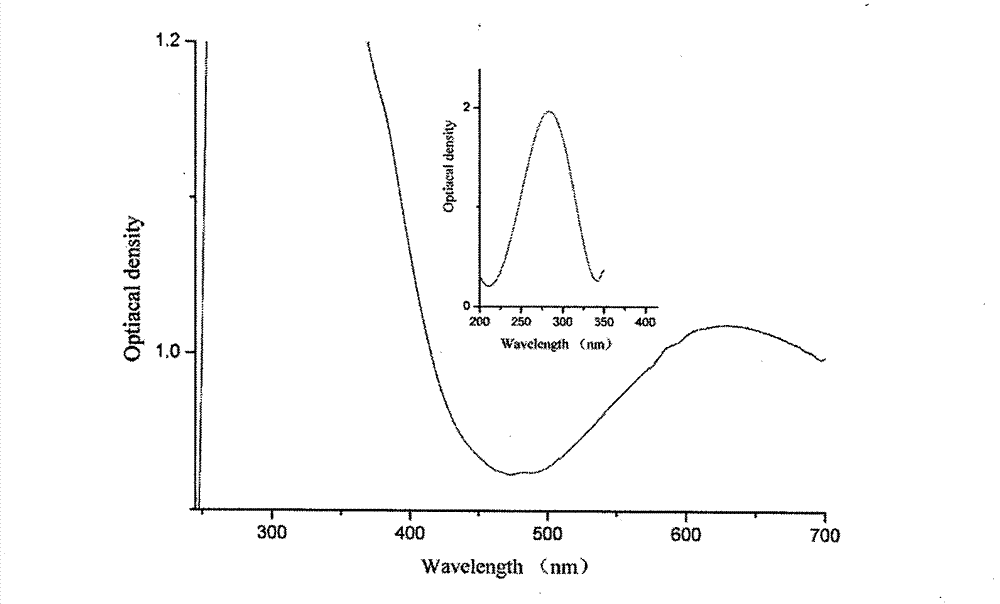

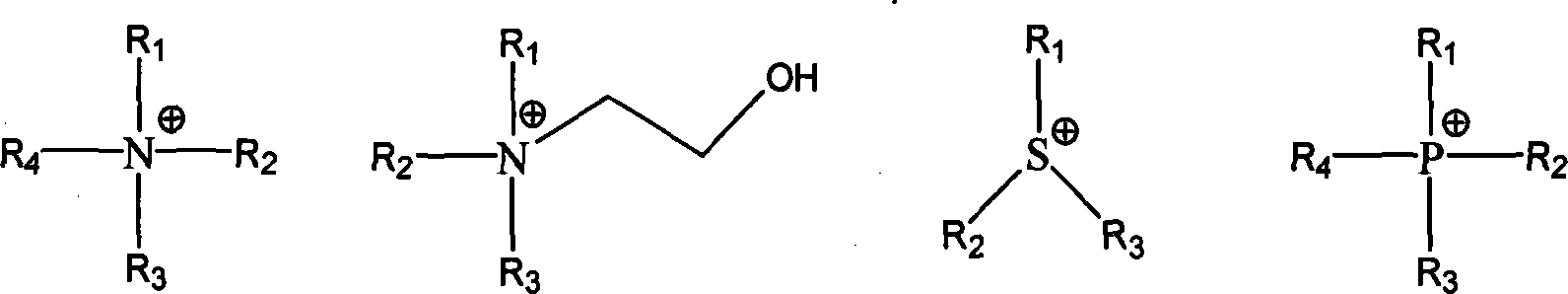

Preparation method of efficient polyethyleneimine modified cellulose-based heavy metal adsorbent

InactiveCN103304820AEasy to useLow toxicityOther chemical processesWater/sewage treatment by sorptionGlycidyl methacrylateBenzoyl peroxide

The invention discloses a preparation method of an efficient polyethyleneimine modified cellulose-based heavy metal adsorbent shown by a formula (I), belonging to the technical field of high-molecular function modification and synthesis of a natural material. By adopting cellulose as a framework, benzoyl peroxide (BPO) as an initiator, a mixture of water and acetone as a solvent and glycidyl methacrylate (GMA) shown by a formula (III) as a monomer, the method comprises the following steps of: performing a free radical-initiated graft copolymerization reaction on the surface of microcrystalline cellulose shown by a formula (II); performing amination on a graft product shown by a formula (IV) by use of graft polyethyleneimine (PEI) shown by a formula (V); and washing and drying the product to obtain a powdery solid product, wherein the reaction is easy to operate, and the conditions are mild. The heavy metal adsorbent prepared by the preparation method has the advantages of excellent adsorption property, large adsorption capacity and fast adsorption, can be regenerated and recycled, and has broad application prospects in the water treatment fields such as control of heavy metal industrial pollutants and the like.

Owner:SHANDONG UNIV

Method for producing glassine paper

InactiveCN102493284AReduce energy consumption for beatingReduce energy billsSpecial paperWater-repelling agents additionSulfateCellulase

The invention relates to a method for producing glassine paper, which is characterized by comprising the following steps: a. respectively carrying out pulping on bleached sulfate needle wood chemical pulp and bleached sulfate broadleaf wood chemical pulpboard, respectively adding an beater auxiliary agent modified cellulase in the pulp for beating; b. preparing the pulp according to weight ratio, adding a sizing agent for mixing, forming by net part dehydration, carrying out shoe pressing and drying; c. passing the paper through at least 3 pressing areas when superpressing. The method of the present invention saves beating energy consumption by 10-15% and steam consumption by 5%.

Owner:YUEYANG FOREST & PAPER CO LTD

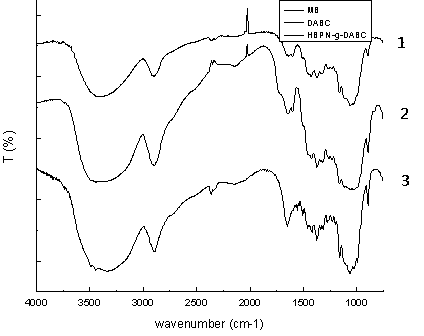

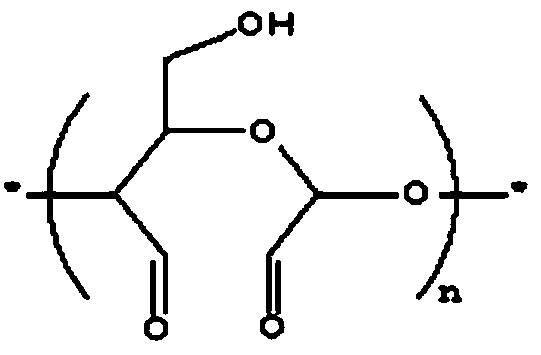

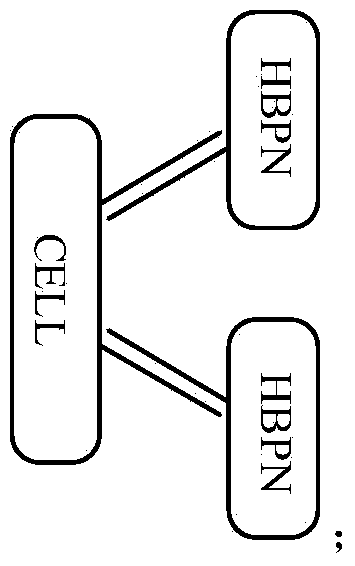

Amino-terminated modified cellulose, and preparation method and application thereof

InactiveCN103554510AIncrease added valueLow added valueWater contaminantsWater/sewage treatment by sorptionEthylenediamineFiber

The invention discloses amino-terminated modified cellulose, and a preparation method and application thereof. The method comprises the following steps: firstly, soaking a bagasse material which is cleaned and dried into constant weight in concentrated alkaline for over 10 hours; washing, carrying out suction filtering and drying to obtain alkaline bagasse fibers; then carrying out an oxidation reaction on the alkaline bagasse fibers and a strong oxidant in a dark condition, so as to obtain dialdehyde bagasse cellulose; with methyl methacrylate and ethanediamine as raw materials, stirring in an organic solvent under dark and oxygen-isolated conditions to carry out a polymerization reaction, so as to obtain an amino-terminated hyperbranched polymer; and finally carrying out a reflux reaction after dissolving the dialdehyde bagasse cellulose and the amino-terminated hyperbranched polymer into the organic solvent, so as to obtain the amino-terminated hyperbranched grafted dialdehyde cellulose. The modified cellulose not only has good adsorptive property on heavy metal ions in a wastewater solution, but also is easy to separate after adsorption. Thus, the amino-terminated modified cellulose has the water purification effects of simple method and low cost.

Owner:GUANGXI UNIV FOR NATITIES

Method for providing a nanocellulose involving modifying cellulose fibers

ActiveUS20110036522A1Increases anionic charge densityReduce energy consumptionNanostructure manufacturePulp properties modificationAqueous electrolyteCellulose fiber

A method for the manufacturing of nanocellulose. The method includes a first modification of the cellulose material, where the cellulose fibres are treated with an aqueous electrolyte-containing solution of an amphoteric cellulose derivative. The modification is followed by a mechanical treatment. By using this method for manufacturing nanocellulose, clogging of the mechanical apparatus is avoided. Also the nanocellulose is manufactured in accordance with the method and uses of the cellulose.

Owner:INNVENTIA

Polymer gel particle for profile control and water plugging of deep parts as well as preparation method thereof

The invention relates to a polymer gel particle for profile control and water plugging of deep parts as well as a preparation method thereof. The particle mainly solves the problems of rapid expansion in the early stage and slow expansion in the later stage, low plugging strength in large channels and the like of profile control and water plugging agents in the prior art. The polymer gel particle for profile control and water plugging of deep parts is used, and is prepared by polymerization of a mixture shown in the following in parts by mass: (1) 100 parts of acrylamide; (2) 0-60 parts of a comonomer; (3) 0.1-15 parts of modified cellulose; (4) 0.001-0.5 parts of a cross-linking agent; (5) 200-2000 parts of water. The technical scheme can better solve the problem, and can be applied to traditional profile control and water plugging technology in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

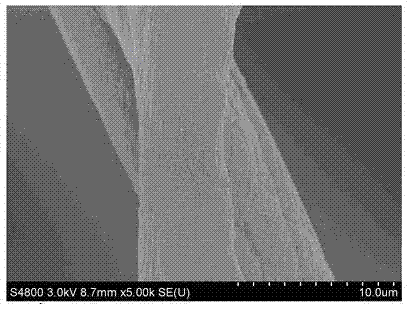

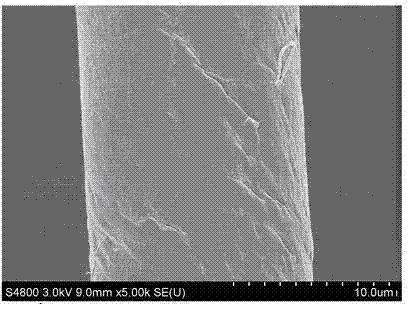

Method for preparing protein modified cellulose fibre

InactiveCN101113535AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsYarnCellulose fiber

The invention relates to a preparation method of a protein modified cellulose fiber, comprising the steps that: (1) a protein and a cellulose are dissolved in ion solution to prepare homogeneous mixing spinning solution; (2) the spinning solution is deaerated, filtered, measured, and extruded out through spinning jet to form spinning rills, and the spinning rills pass through a wet air layer and enter into a solidification bath to be solidified and molded; (3) the yarn is extended, cleaned by water, dried and heat molded, and formed into fiber to prepare the protein modified cellulose fiber. The method has the advantages of environmental protective, low cost, fast spinning speed and high production efficiency, and the prepared fiber has the advantages of comfort and health care, etc.

Owner:DONGHUA UNIV

Dry solids of anionically modified cellulose nanofibers and processes for preparing them

Dry solids of anionically modified cellulose nanofibers with good redispersion are provided by incorporating 5 to 300% by mass of a water-soluble polymer relative to the anionically modified cellulose nanofibers during the preparation of the dry solids of anionically modified cellulose nanofibers.

Owner:NIPPON PAPER IND CO LTD

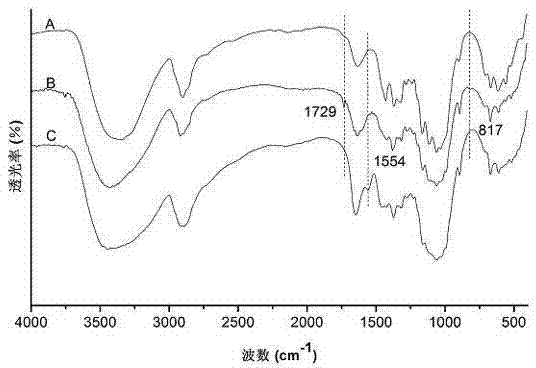

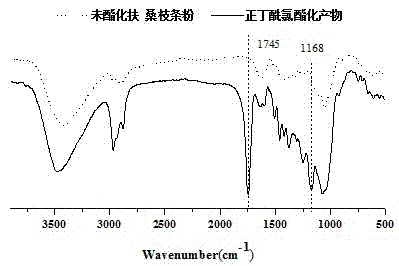

Esterification modification method for wood fiber biomasses

The invention discloses an esterification modification method for wood fiber biomasses, comprising the following steps of: firstly, pretreating wood fiber biomasses, i.e. drying and smashing; carrying out pre-ball milling; adding esterification reagent, and continuously carrying out ball milling to carry out an esterification modification reaction; and washing and drying products after the reaction to obtain the esterified modified products of the wood fiber biomasses. According to the method, various wood fiber biomasses are taken as raw materials, wide in source, low in cost, and high in resource utilization rate, and the conventional mode of the single modified cellulose can be changed; and the wood fiber biomasses are esterified in the process of ball milling, the esterification reaction can be carried out within a dissolved homogeneous system or a heterogeneous system in which the solvent is dispersion medium, and the esterification modification method is simple in modifying technology, environment-friendly, and free from the generation of 'the three wastes', and does not need recover the solvent. The infrared and weighing method result shows that the product is good in esterification effect, very good in practical applicability, and better in economic prospect.

Owner:NANJING FORESTRY UNIV

Compositions and methods for polishing copper

InactiveUS20050104048A1Reduce noise levelOther chemical processesConductive materialNoise levelNonferrous metal

The present invention provides an aqueous composition useful for polishing copper on a semiconductor wafer comprising by weight percent 1 to 15 oxidizer, 0.1 to 1 inhibitor for a nonferrous metal, 0.05 to 3 complexing agent for the nonferrous metal, 0.01 to 5 carboxylic acid polymer, 0.01 to 5 modified cellulose, 0.0001 to 2 salt having a cationic and an anionic component, and balance water, the salt reducing noise level from vibration between the wafer and a polishing pad.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Water-soluble, sulfoalkyl-containing, hydrophobically modified cellulose ethers, process for preparing them, and their use as protective colloids in polymerizations

The present invention relates to water-soluble ionic cellulose ethers from the group of the hydroxyalkylcelluloses which are substituted by on average from 0.001 to 1.0 alkyl group per anhydroglucose unit and which carry from 0.01 to 0.1 sulfoalkyl group per anhydroglucose unit, to processes for preparing them and to the use of water-soluble ionic cellulose ethers from the group of the hydroxyalkylcelluloses which are substituted by on average from 0.001 to 1.0 alkyl group per anhydroglucose unit and which carry from 0.01 to 0.4 sulfoalkyl group per anhydroglucose unit as protective colloids in polymerizations.

Owner:CLARIANT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com