Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1098results about How to "Achieve adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

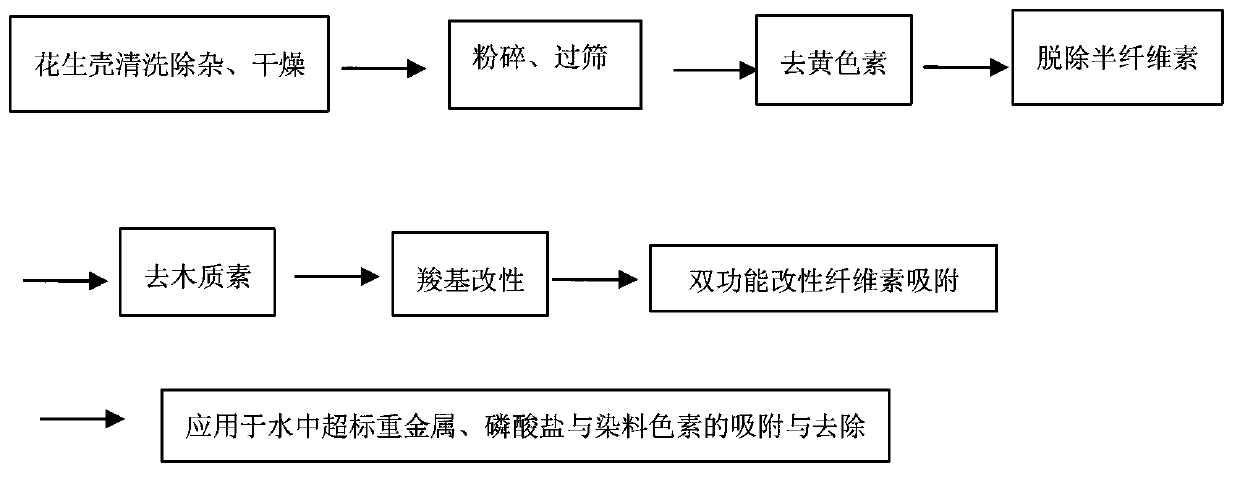

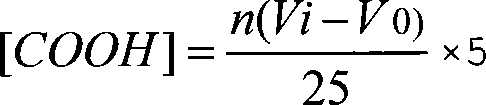

Method for preparing bifunctional modified cellulose adsorbing agent from peanut shells and application of method

InactiveCN103272568AGood biocompatibilityAchieve adsorptionOther chemical processesWater/sewage treatment by sorptionPhosphateSorbent

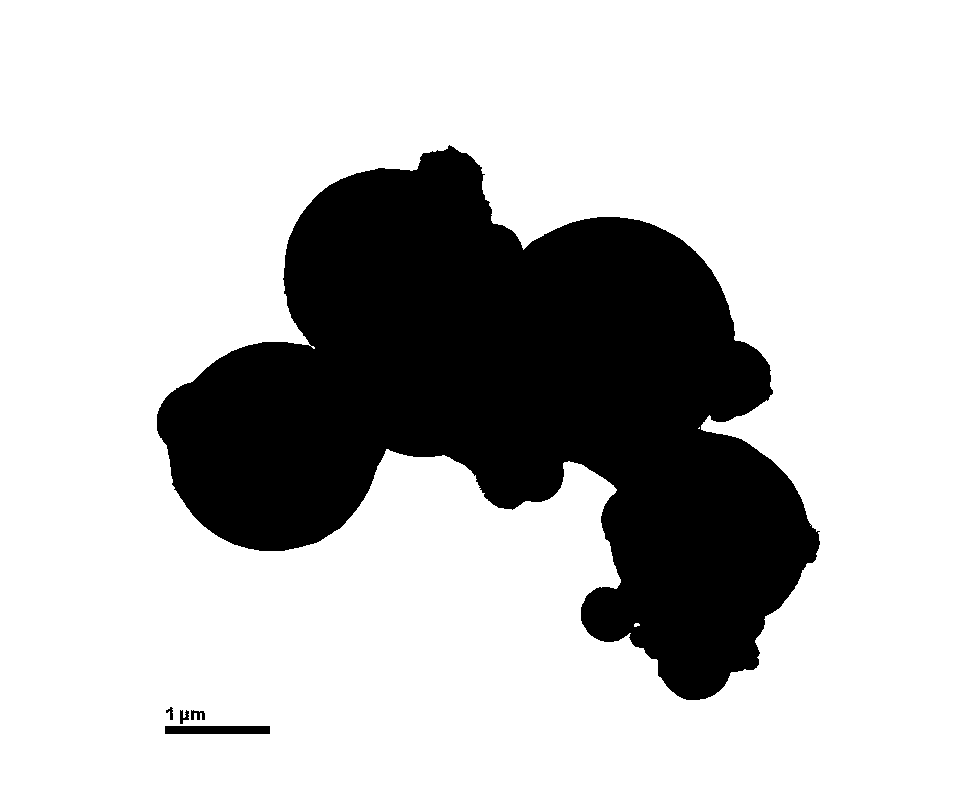

The invention discloses a method for preparing a bifunctional modified cellulose adsorbing agent from peanut shells and application of the method. The method comprises the following preparation steps of: washing, drying and crushing waste peanut shells, which are taken as raw materials, and removing flavochrome, hemicellulose and xylogen from the crushed peanut shells so as to obtain peanut shell cellulose; and performing surface functional modification on the materials through substitution and amidation further so as to finally obtain the amino and carboxy bifunctional modified peanut shell cellulose adsorbing material. The product is powdery and light brownish yellow, and the particle size of the product is 1.5-2.5 microns. The bifunctional modified peanut shell cellulose adsorbing material has a good adsorption effect for excessive heavy metals such as copper, chrome and mercury, phosphate, methylthionine chloride dye, and the like in water. The adsorbing agent is simple in preparation method, low in cost, cheap, easily available, good in biological compatibility and environment-friendly, contains a great deal of functional chelation groups, can realize simultaneous adsorption and removal of negative ions and positive ions, and has the advantages of being recyclable and the like.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Method for preparing fibroin nanofiber and metal organic framework composite film

ActiveCN107051398AImprove filtration efficiencyEasy to operateOther chemical processesAlkali metal oxides/hydroxidesFibroinIon

The invention discloses a method for preparing a fibroin nanofiber and metal organic framework composite film. The method includes: vertically immersing a fibroin nanofiber film into first ligand solution which contains metal ions; then adding second ligand solution, and enabling the fibroin nanofiber film and the two ligand solutions to react for specific time at a specific temperature so as to enable a metal organic framework substance to grow on the surface of the fibroin nanofiber film, so that the composite film is formed; taking out the composite film, washing with deionized water, and drying to obtain the film. By adoption of the method, problems of nonuniformity in nucleating and poor processability in a metal organic frame film preparation process are solved, the film has advantages of simplicity in preparation, high filter efficiency, high capacity, particle uniformity, high stability, high film continuity and the like, the adsorption performance is improved, and adsorption of various organic and inorganic substances and wide application are realized.

Owner:ZHEJIANG UNIV

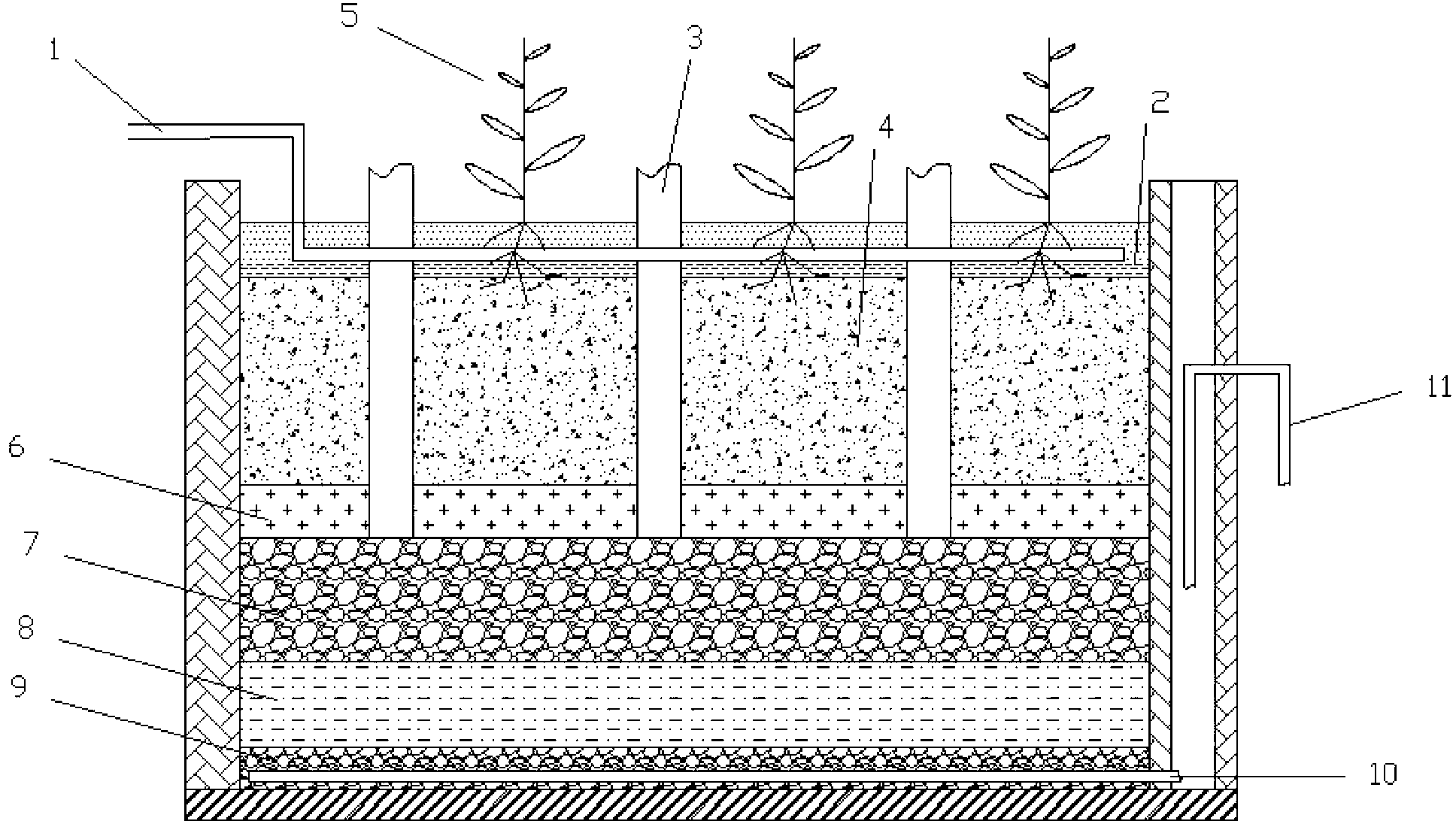

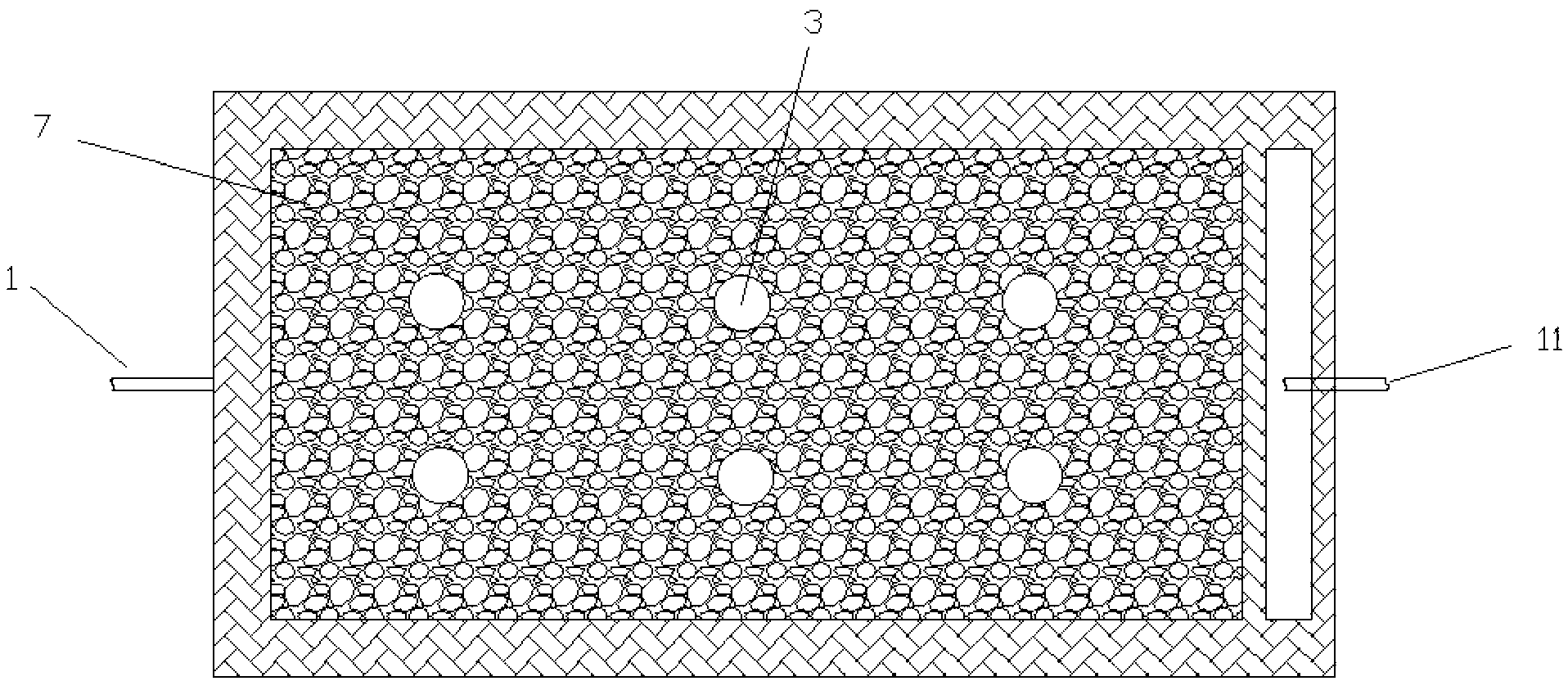

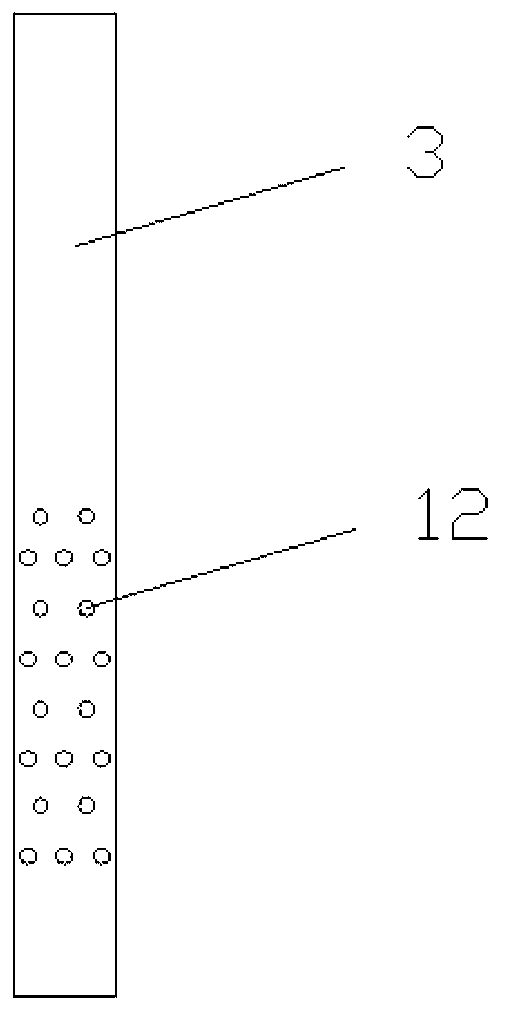

Zonal vertical current artificial wetland system with reinforced denitrification function

ActiveCN103274530AAchieve removalAchieve adsorptionSustainable biological treatmentBiological water/sewage treatmentWater pipeSurface layer

The invention relates to a zonal vertical current artificial wetland system with a reinforced denitrification function, which comprises an upper layer and a lower layer. The upper layer is a nitrification reinforcing zone; the lower layer is a denitrification reinforcing zone; the upper layer comprises a water distribution pipe, a wetland fine filler zone, reoxygenation reinforcing and solid source supplementing pipes, an ammonia nitrogen adsorption-regeneration zone and wetland plants; the lower layer comprises a gravel transition layer, a solid carbon source filling zone, a wetland filler zone, a water collecting zone, water collecting pipes and a siphon drainage pipe; the water collecting pipes are positioned in the water collecting zone and are positioned at the bottommost layer of the wetland system together; the wetland filler zone, the solid carbon source filling zone, the gravel transition layer, the ammonia nitrogen adsorption-regeneration zone and the wetland fine filler zone are sequentially arranged above the water collecting pipes; and the wetland plants are planted on the surface layer of a wetland. The system disclosed by the invention has the advantages of strong continuous denitrification capacity, low operation cost, simplicity in maintenance and the like.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

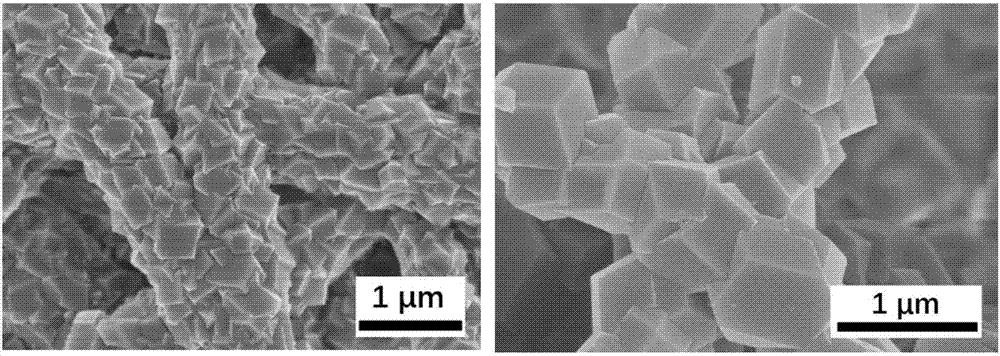

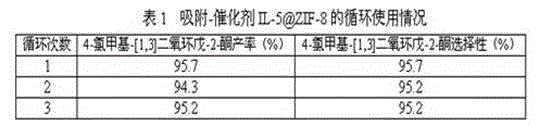

ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent

ActiveCN105149002ALarge capacityHigh activityProductsOrganic chemistryMetal-organic frameworkIonic liquid

The invention discloses a ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent. The ZIF-8 encapsulated amino ionic liquid type carbon dioxide adsorbing-catalyzing agent is prepared according to the following steps: taking the metal organic framework material ZIF-8 as a carrier; taking the amino-group functionalized ionic liquid 1-(3-aminopropyl)-3-methylimidazole chloride as an active component; immobilizing the amino-group functionalized ionic liquid in the super-cages of the ZIF-8 carrier in an in-situ manner during preparation of ZIF-8, wherein 1.5 to 5 mmol of the amino-group functionalized ionic liquid is immobilized in each gram of the adsorbing-catalyzing agent. The adsorbing-catalyzing agent integrates the functions of selective adsorbing and catalyzing into a whole, and can be used for synchronously adsorbing and converting carbon dioxide, so as to reduce the cost of the CUU technology.

Owner:TAIYUAN UNIV OF TECH

Copying plane face mask wearing method and equipment

InactiveCN101904587ASmall footprintImprove labor productivityProtective garmentClothes making applicancesSmall footprintEngineering

The invention relates to copying plane face mask wearing method and equipment. A drum type wearing device is adopted, and the equipment comprises a distribution disk, a copying wheel, a push rod, a slide block bearing, a guide block, a gear, a connecting rod and the like, wherein two ends of the cylindrical surface of the copying wheel are provided with curved grooves with copying lug forming shapes, the copying wheel leads the lug forming during the rotation and is absorbed by the groove of a welding roller, the cylindrical surface of the welding roller is also provided with curved grooves and convex ribs with copying lug forming shapes, the grooves are internally evenly provided with through holes connected to the distribution disk, and the welding roller completes the absorption and the stripping of the copying lug during the rotation as well as the welding, the tipping and the cutting of mask lugs. The invention has the advantages of simple operation of the whole process, small occupation area of the equipment and capability of high-speed operation, wherein more than 200 lugs can be produced in each minute.

Owner:QIANJIANG YATAI PRECISION MACHINERY MOLD

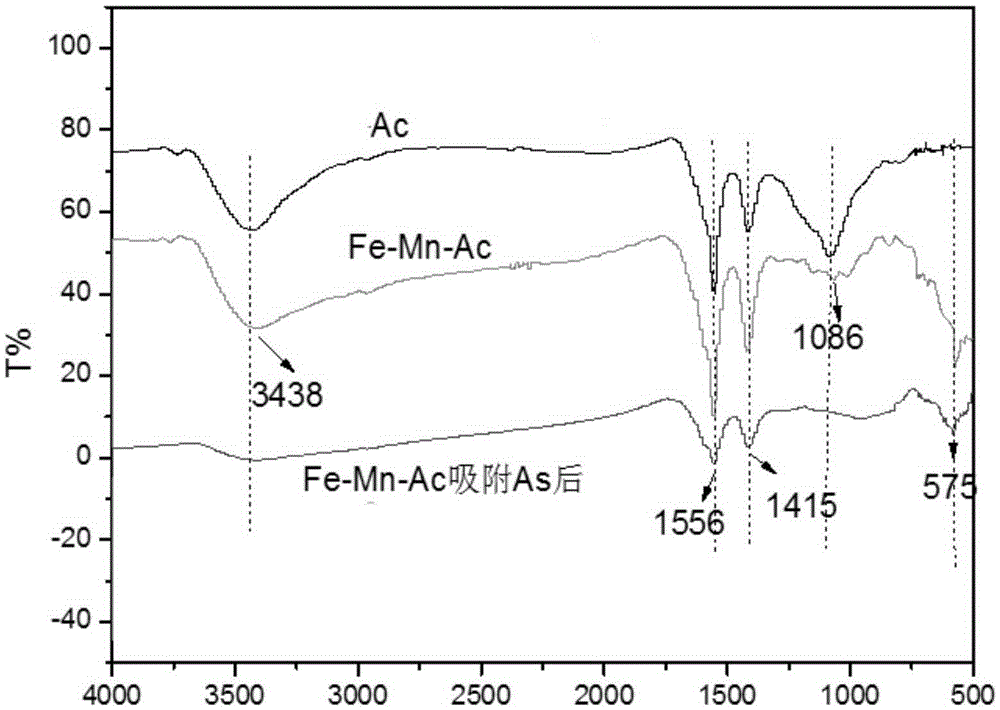

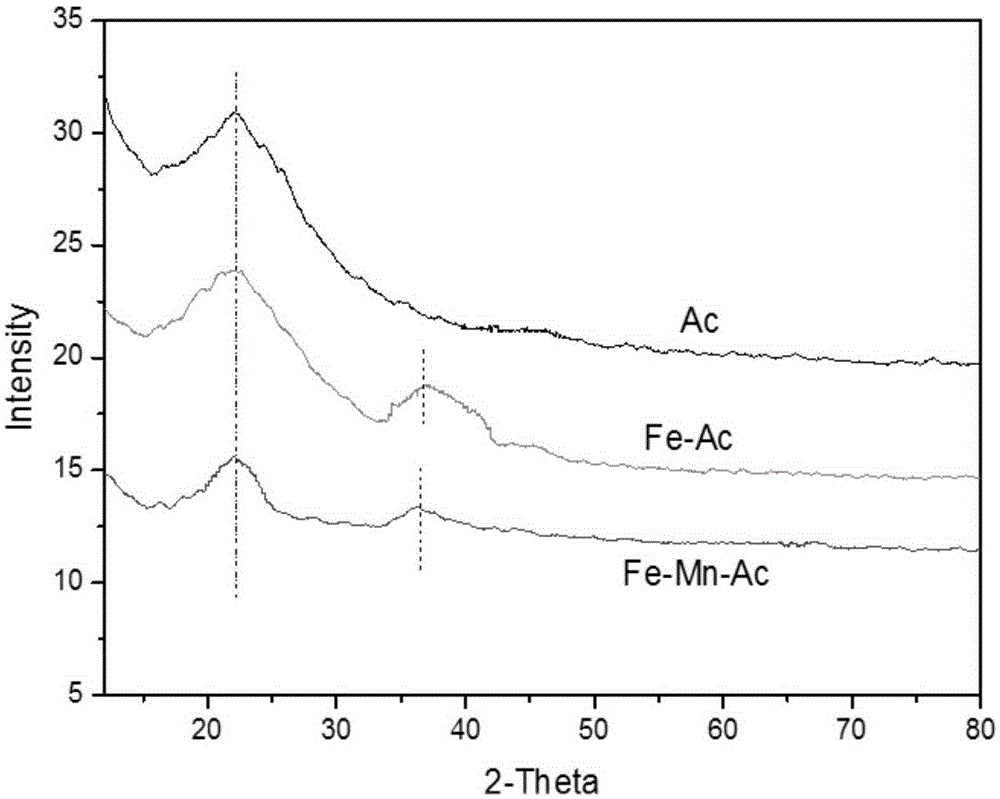

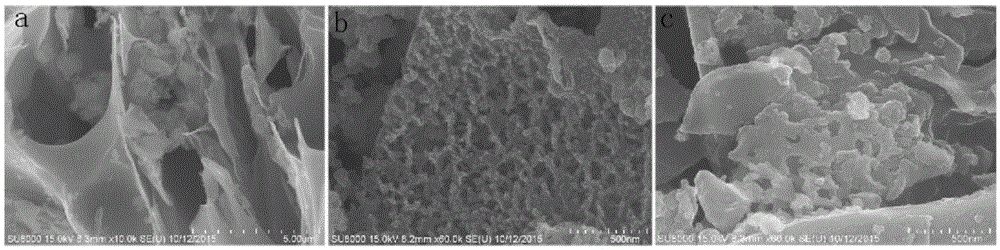

Ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof

ActiveCN105289493AHuge productionIncrease profitOther chemical processesWater/sewage treatment by sorptionActivated carbonSorbent

The present invention relates to a ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof. The technical scheme comprises: preparing straw into straw active carbon, adding to nitric acid, carrying out an acidification treatment to obtain acidified straw active carbon, adding the acidified straw active carbon to a metal iron salt and HCl mixing solution, carrying out a reaction at a room temperature for 22-24 h, heating to a temperature of 95-105 DEG C, carrying out a reaction for 6-7 h to obtain iron modified active carbon, mixing a metal manganese salt and the iron modified active carbon, carrying out a reaction at a temperature of 75-85 DEG C, adding a KMnO4 and KOH mixing aqueous solution, carrying out a reflux reaction at a temperature of 75-85 DEG C, and washing he product so as to obtain the target product. According to the present invention, with the ferromanganese modified straw active carbon adsorbent, the As (III) can be selectively recovered from the solution containing the As (III) ions and the impurity metal ions; and the ferromanganese modified straw active carbon adsorbent has advantages of low cost, high selectivity, high adsorption capacity, and the like.

Owner:LIAONING UNIVERSITY

Transformer cabinet based on self-feedback uniform heat dissipation

ActiveCN111540570AImprove job stabilityIncrease job securityTransformers/inductances coolingTransformers/inductances casingsEngineeringTransformer oil

The invention discloses a transformer cabinet based on self-feedback uniform heat dissipation. The invention belongs to the field of transformer equipment, a special composite heat dissipation sheet can be additionally arranged on a surface of an existing transformer oil tank, matched lifting heat-absorbing balloons are introduced while the heat dissipation of the oil tank is greatly improved, a self-feedback heat dissipation mechanism arranged on the composite heat dissipation sheet is used for sensing the heat distribution condition on the transformer oil tank; phase expansion is carried outaccording to heat distribution; more lifting heat-absorbing balloons are attracted through the magnetic attraction effect to be in contact for heat transfer; the transfer of heat to the lifting heat-absorbing balloons is accelerated; after absorbing enough heat, the lifting heat-absorbing balloons automatically rise to a cup-shaped outer heat dissipation shell to transfer the heat to the outside;the lifting heat-absorbing balloons serve as intermediate media to play a role in temporary heat storage, a heat conduction bridge between the transformer oil tank and the outside is built, the uniform and efficient heat dissipation and cooling of the transformer oil tank are achieved, and, therefore, the working stability and safety of a transformer are improved.

Owner:济宁鲁星电气科技有限公司

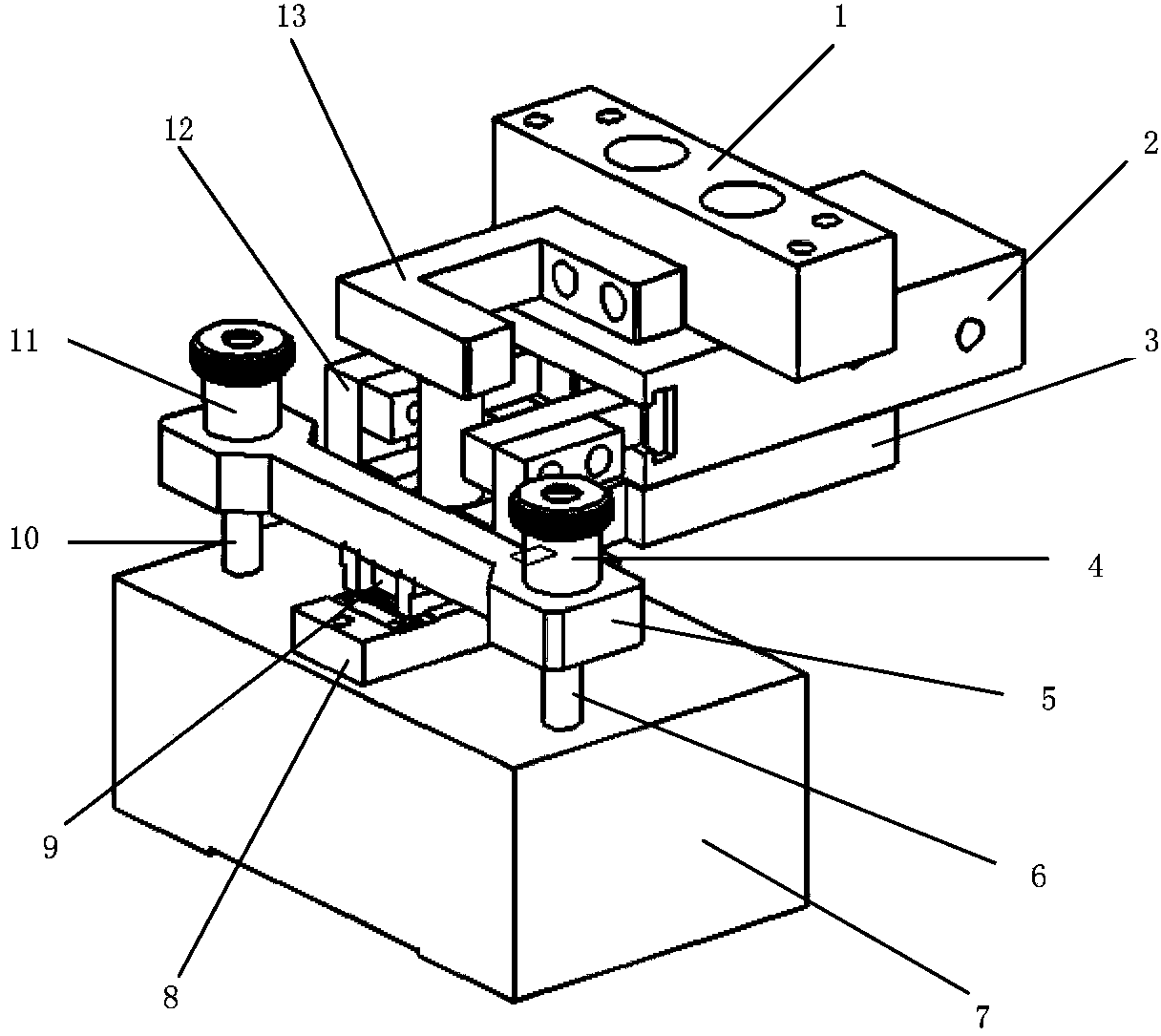

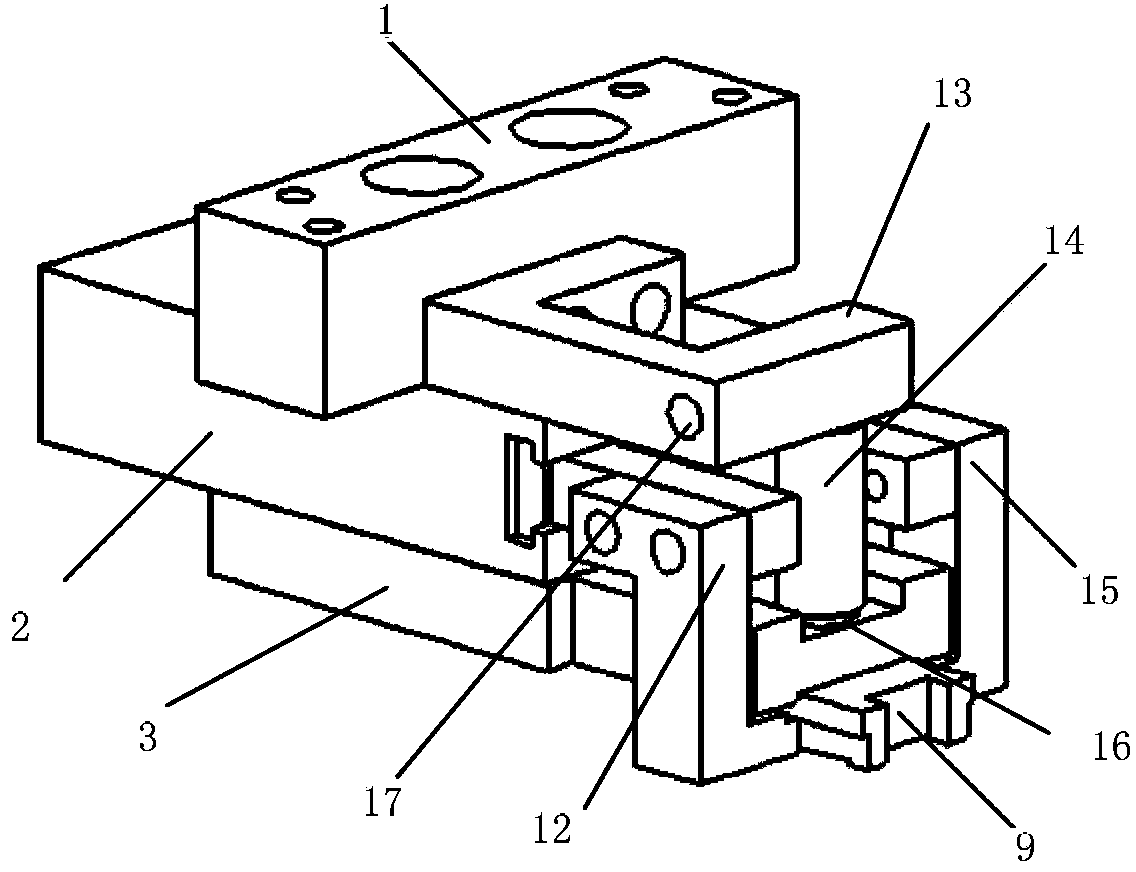

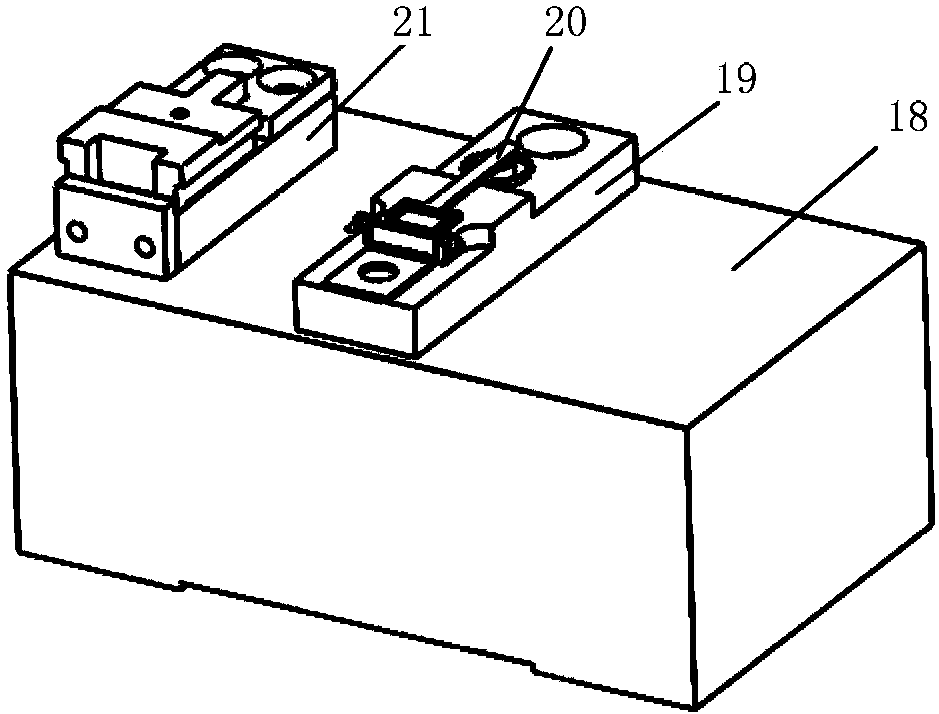

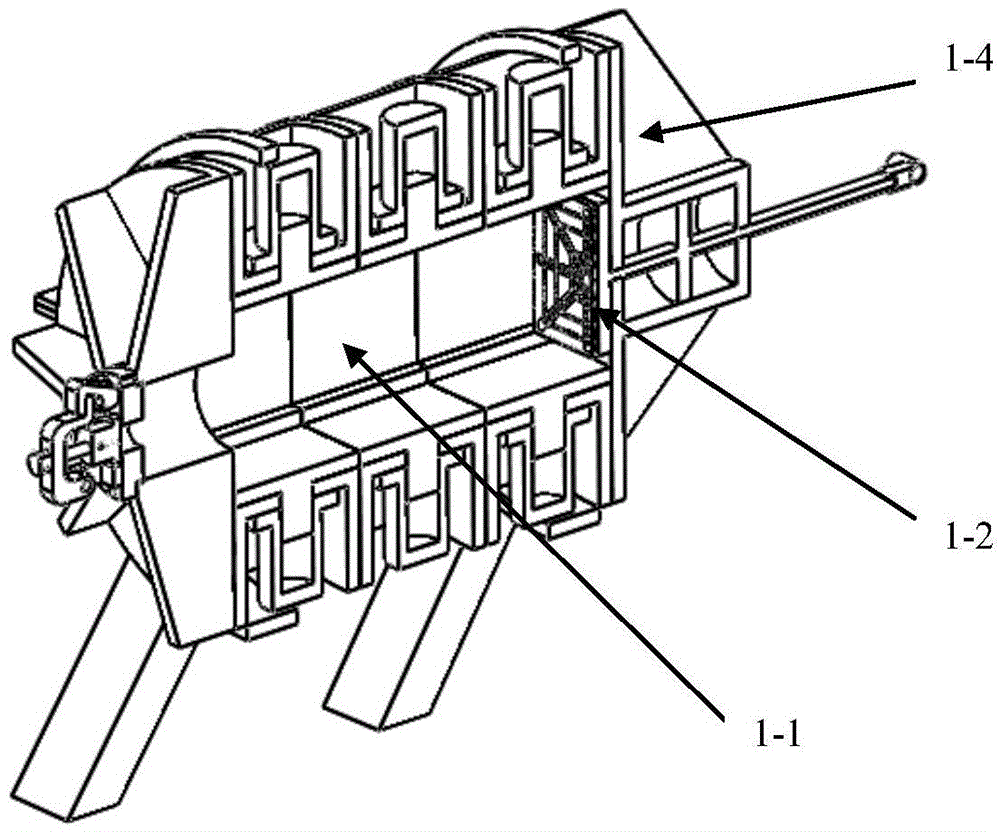

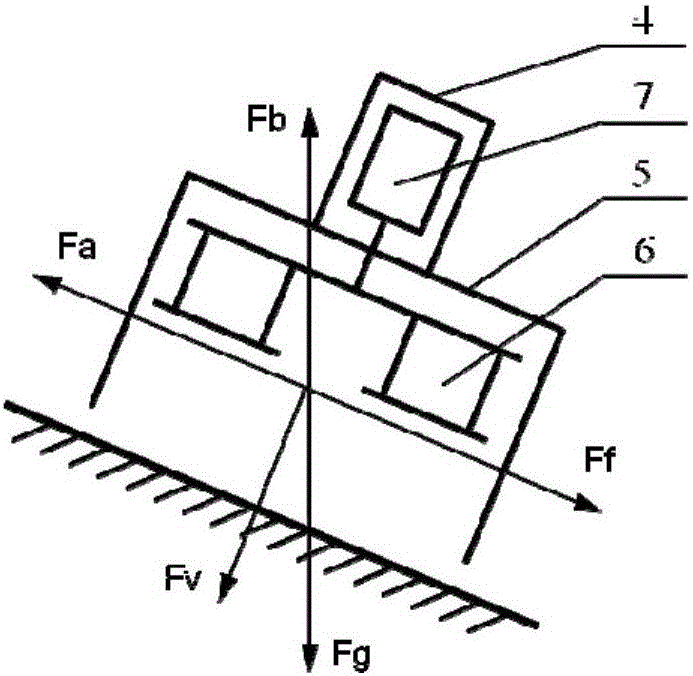

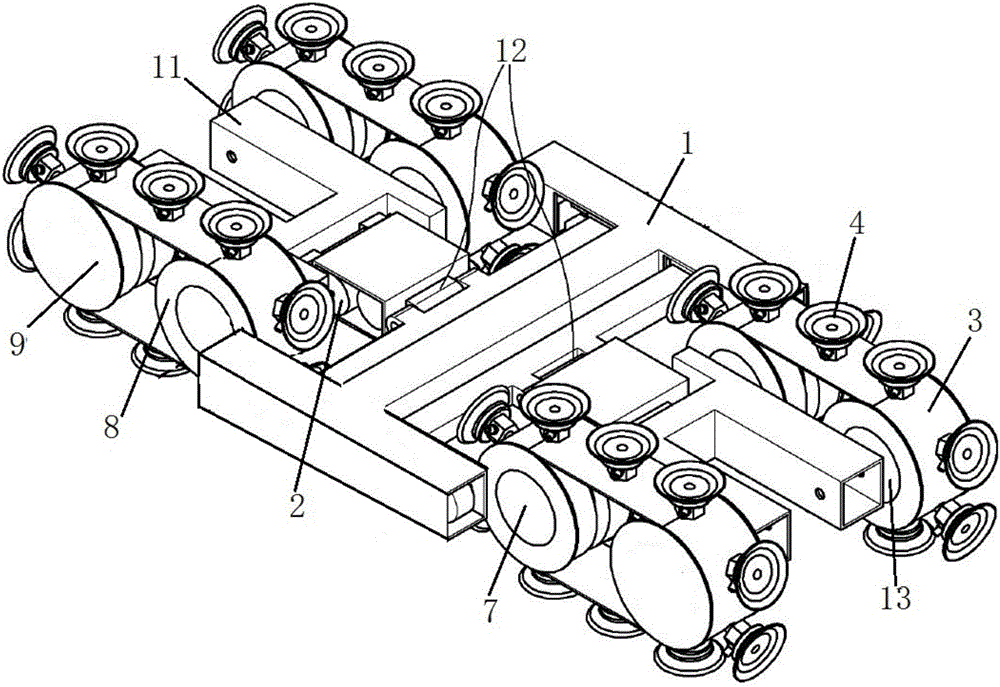

Tiny component assembling device and method

InactiveCN103350333AAchieve adsorptionRealize the assemblyMetal working apparatusMechanical componentsMechanical engineering

The invention relates to the technical field of precision assembly, in particular to a tiny component assembling device and method. The tiny component assembling device is characterized by consisting of a feeding clamp unit, combined adsorbing clamp unit and an assembling clamp unit, wherein the combined adsorbing clamp unit comprises a connecting block, a U-shaped pneumatic connecting block, a sucking disc connecting post, a left clamp finger, a right clamp finger, a sucking disc, a transitional adsorbing block, a positioning block and a pneumatic clamp; the transitional adsorbing block is designed to have a series of different sizes and structures and is used for adsorbing tiny components with various structural characteristics, so that the shift function of a clamp is achieved and the universality of the clamp is improved; the transitional adsorbing block adsorbs, moves and assembles the tiny components in the assembling process, and fixes an assembly after completion of the assembling process, thus ensuring that the assembly precision is not damaged, and achieving precision assembly of the tiny components. The tiny component assembling device and method are applicable to clamping adsorption, movement, assembly and fixation of tiny mechanical components.

Owner:DALIAN UNIV OF TECH

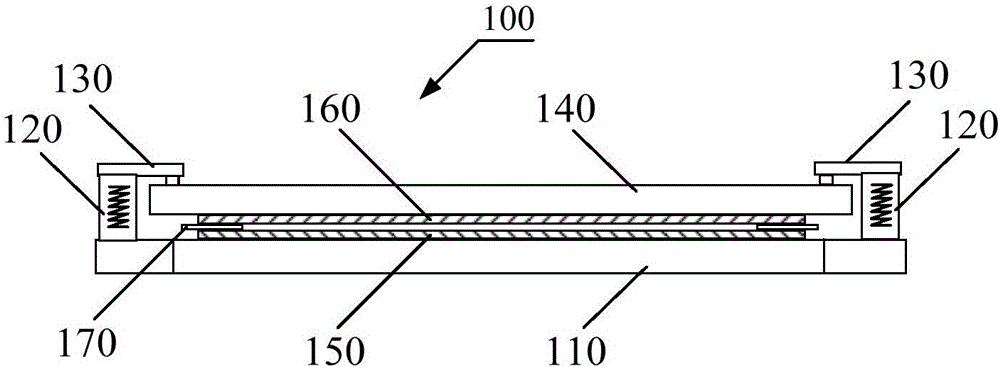

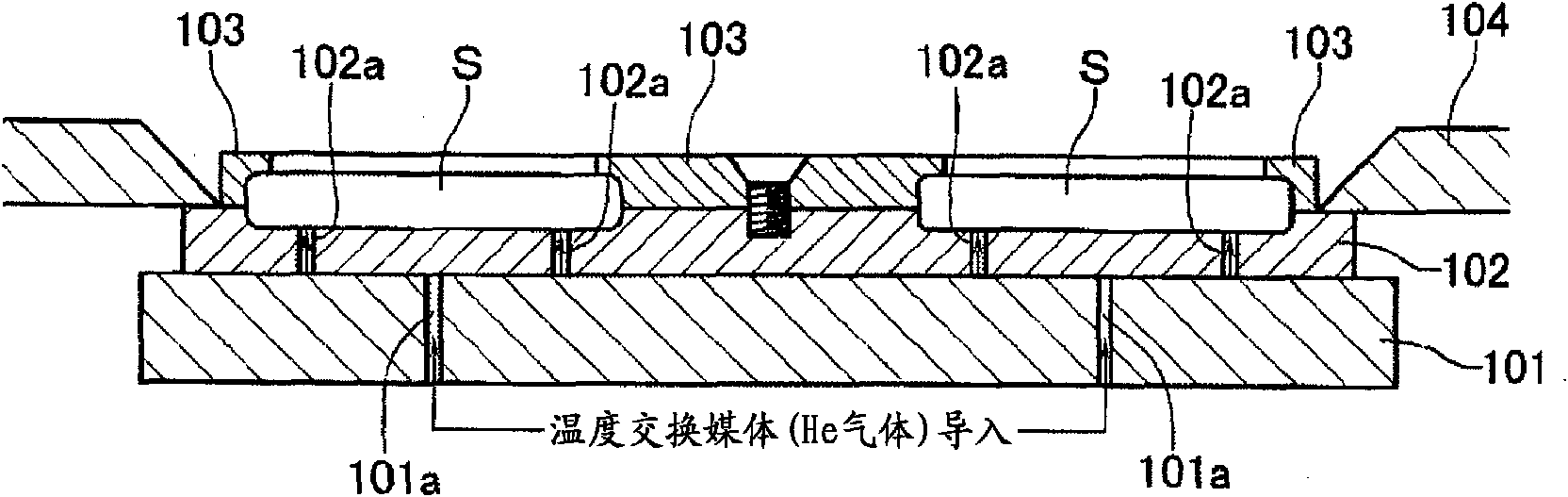

Wafer bonding clamping device, aligning machine, bonding machine and warping substrate adsorption method

InactiveCN106340485AUniform deliveryReduce the difficulty of temperature controlSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlEngineering

The invention discloses a wafer bonding clamping device which comprises a loading platform (110), a clamping mechanism (120), a pressing head (130) and a pressing plate (140). The pressing point of the pressing head (130) in the pressing plate (140) is arranged in an area other than the pressing plate (140) corresponding to a substrate. The pressing plate (140) and the loading platform (110) are made of the same material. The pressing plate (140) is compatible with substrates of all sizes. The invention further discloses an aligning machine and a bonding machine, wherein the aligning machine and the bonding machine use the wafer bonding clamping device. According to the invention, ineffective pressing surfaces can be reduced or eliminated, which facilitates temperature control; the production efficiency is improved; the wafer bonding clamping device has the advantages of uniform pressing performance and improves yield, and is compatible with wafers of all sizes and specifications. The invention further discloses a warping substrate adsorption method, so as to realize the adsorption of a warping substrate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method for large-scale preparation of oxidized graphene and selective adsorption of thorium in water

InactiveCN103130216ALow raw material costEasy to operateCarbon compoundsWater/sewage treatment by sorptionSingle layer grapheneSolid phases

The invention discloses a method for large-scale preparation of oxidized graphene and selective adsorption of thorium in water, belonging to the technical field of treatment of radioactive wastewater in nuclear wastes and environment protection. The method comprises the following specific steps of: oxidizing graphite by adopting an oxidant, adding water and concentrated hydrochloric acid, conglomerating, settling, pouring out, filtrating, washing and drying to obtain graphite oxide, and stripping by ultrasonic waves to obtain a single-layer graphene oxide aqueous dispersion. According to the method, an oxidative product of graphite, which is conglomerated and settled through the concentrated hydrochloric acid, can be very easily purified and separated to obtain graphite oxide, and the industrial large-scale preparation of single-layer graphite oxide is realized. The method has the characteristics of low cost, simple and convenient operation and good reproducibility; and simultaneously oxidized graphene can serve as a solid-phase adsorbent for adsorption of thorium in water and shows high adsorption capacity and selectivity (adsorption capacity qe is 529.6mgTh / g oxidized graphene, and the distribution coefficient Kd is 3047mL / g).

Owner:SICHUAN UNIV

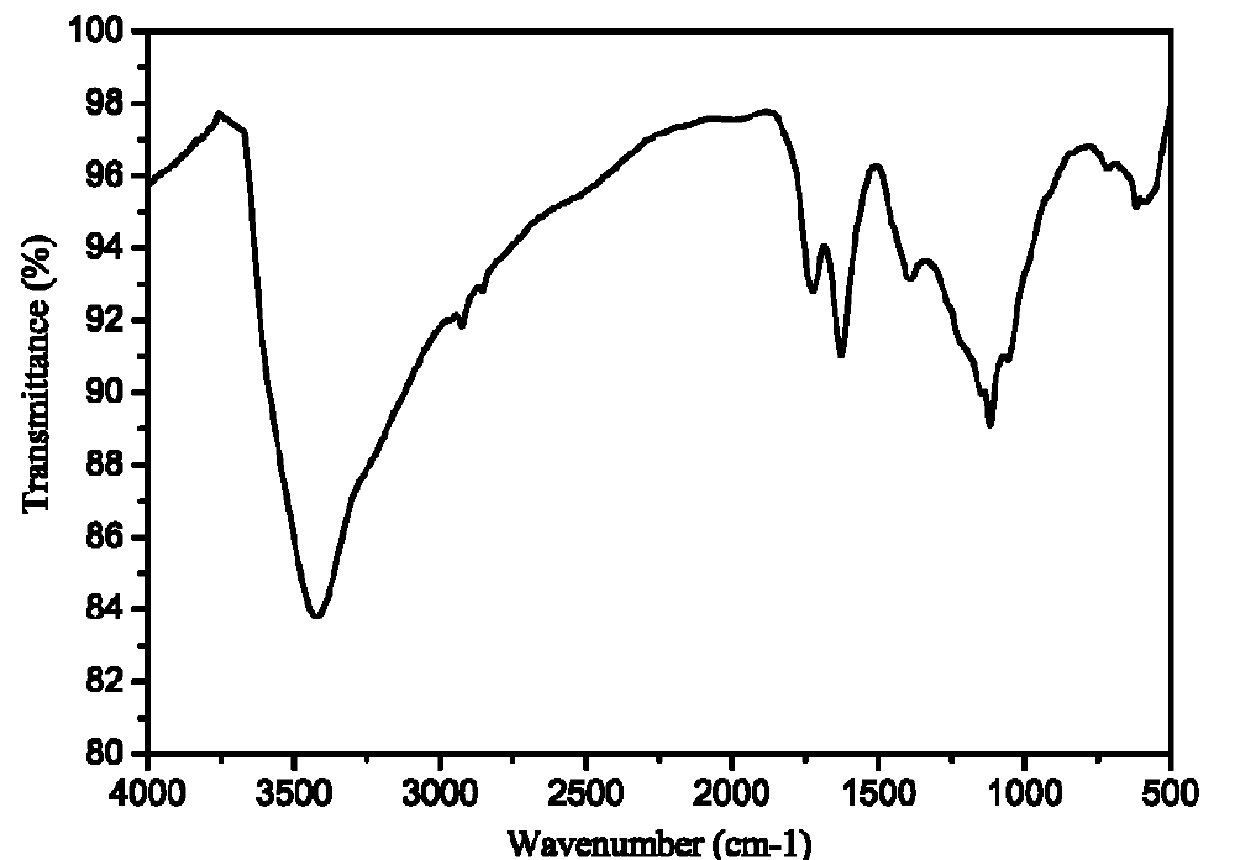

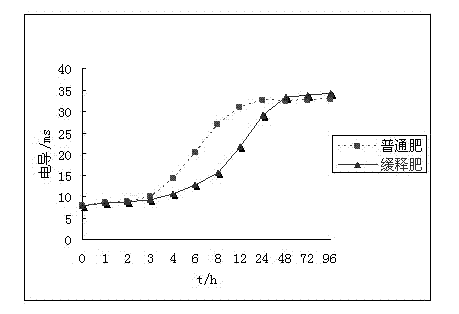

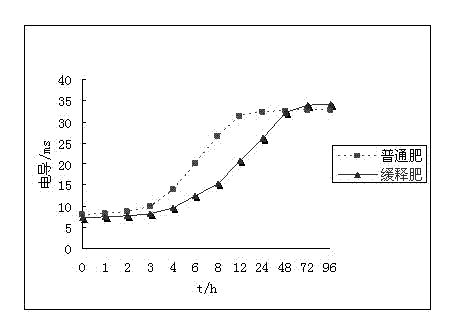

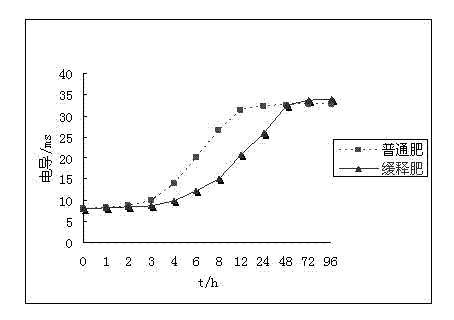

Polymer emulsion coated slow release fertilizer taking nanomaterial as carrier and preparation method thereof

ActiveCN102180731AImprove aggregate structureImprove water retentionFertilizer mixturesEmulsionPolymer emulsion

The invention discloses a polymer emulsion coated slow release fertilizer taking a nanomaterial as a carrier. A preparation method of the fertilizer comprises the following steps of: uniformly mixing a treated nano soil material, approximately fermented fungi residues and a nutritional raw material; and adding an organosilicone modified acrylic ester emulsion which is mixed with a crosslinking agent into the mixture and mixing uniformly to prepare the polymer emulsion coated slow release fertilizer which is provided with a water repellent film on the surface and takes a nanomaterial as a carrier. The fertilizer has the advantages that: adsorption of water and the fertilizer among carriers is realized, a basis is laid for long-acting slow release of the fertilizer, the fertilizer effect and slow release performance of the slow release fertilizer are enhanced, and the quality of an agricultural product is improved.

Owner:成都正光生态工程有限公司

Modified meerschaum, preparation method and application thereof

InactiveCN104888748AImprove adsorption catalytic activityLarge specific surface areaPhysical/chemical process catalystsOther chemical processesWater bathsGranularity

The invention discloses a modified meerschaum, a preparation method and an application thereof. The preparation method comprises the following steps: immersing meerschaum by water with solid liquid ratio being 1:5-1:15, drying and crushing; then placing the purified meerschaum in an acid solution with concentration being 1-5mol / L and continuously stirring for 1-5 hours under water-bath condition at constant temperature of 30-60 DEG C; calcinating meerschaum through acid modification for 2-6 hours under temperature condition being 200-500 DEG C, cooling and crushing to granularity being 80-120 meshes; dipping the meerschaum after heat treatment in a soluble compound solution containing metal ions, stirring for a while under condition of 20-40 DEG C; finally dropping alkali in a mixing solution for adjusting acid-base value, and then processing to obtain the modified supported meerschaum. The modified meerschaum has good effect for catalysis ozone to deeply process the pulping papermaking waste water.

Owner:SOUTH CHINA UNIV OF TECH

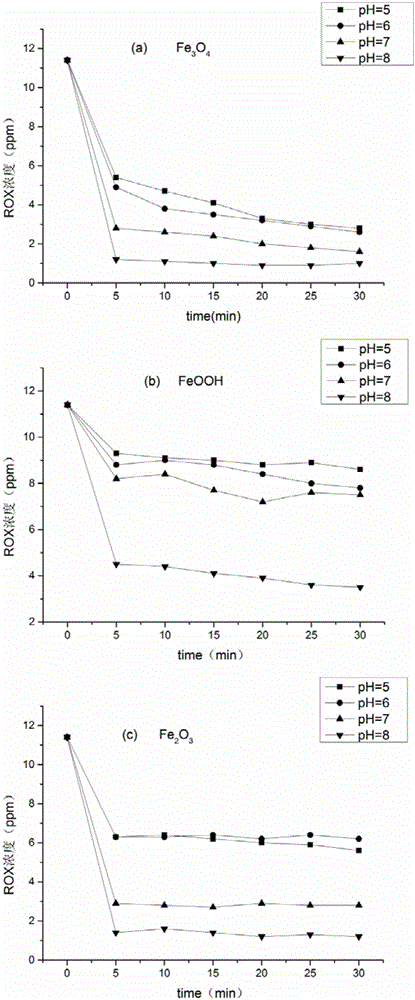

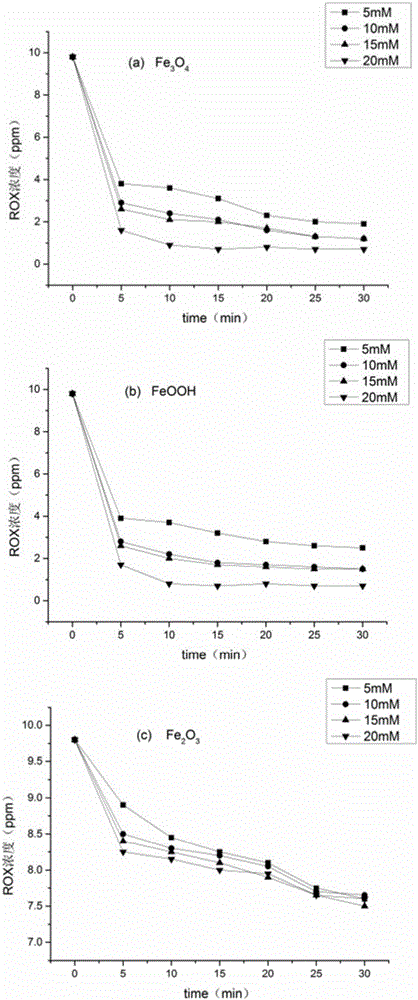

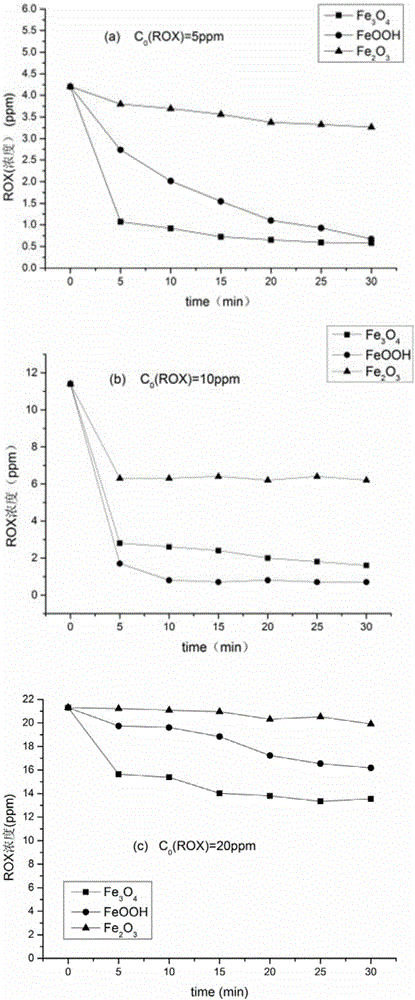

Method for treating arsenic-containing wastewater by using multiphase Fenton system based iron oxide

InactiveCN106277278AImprove adsorption capacityEfficient degradationWater treatment compoundsWater contaminantsBinding stateOrganoarsenic compounds

The invention discloses a method for treating arsenic-containing wastewater by using a multiphase Fenton system based on iron oxide. The method is characterized in that firstly, the pH of the arsenic-containing wastewater is adjusted to range from 2.0 to 9.0, then an iron oxide catalyst and a hydrogen peroxide oxidizing agent are added, so that an organic arsenic compound completes form transformation from organic arsenic to inorganic arsenic in the multiphase Fenton system based on the iron oxide, meanwhile, released inorganic arsenic forms Fe-As chemical coordinate bonds through binding state iron central atoms on the surface of the iron oxide to be effectively adsorbed, and the arsenic pollutant in the arsenic-containing wastewater is removed. Degradation from organic arsenic to inorganic arsenic and adsorption of the inorganic arsenic can be finished simultaneously in one step, the iron oxide serves as an efficient adsorption material of the inorganic arsenic as well as a Fenton reaction catalyst for degrading the organic arsenic to the inorganic arsenic, and the treatment cost of the organic arsenic wastewater is effectively reduced while the reaction efficiency and the operation simplicity are greatly improved.

Owner:HEFEI UNIV OF TECH

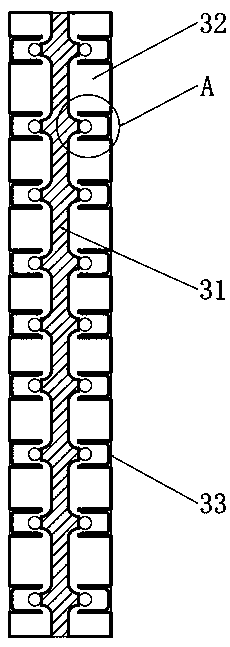

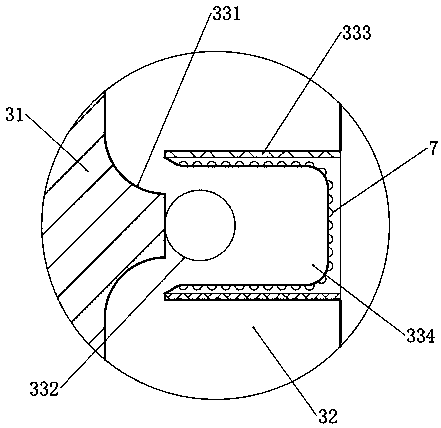

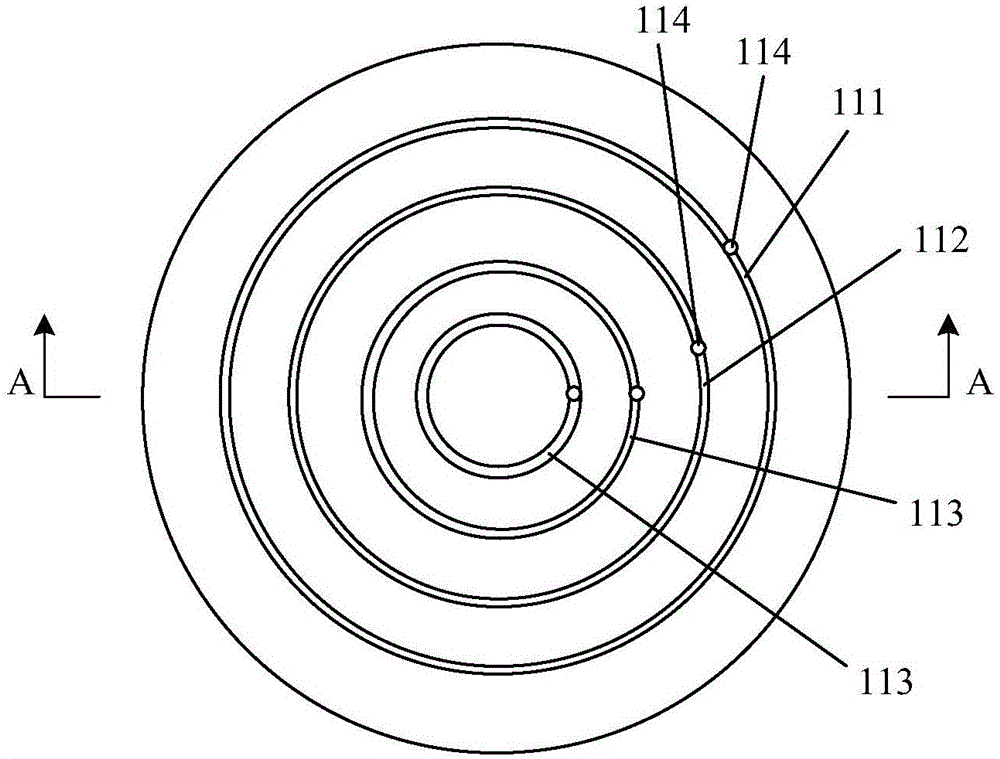

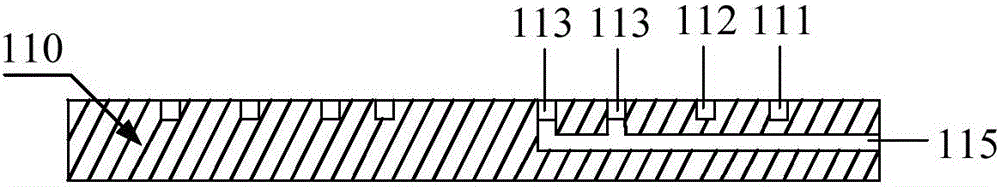

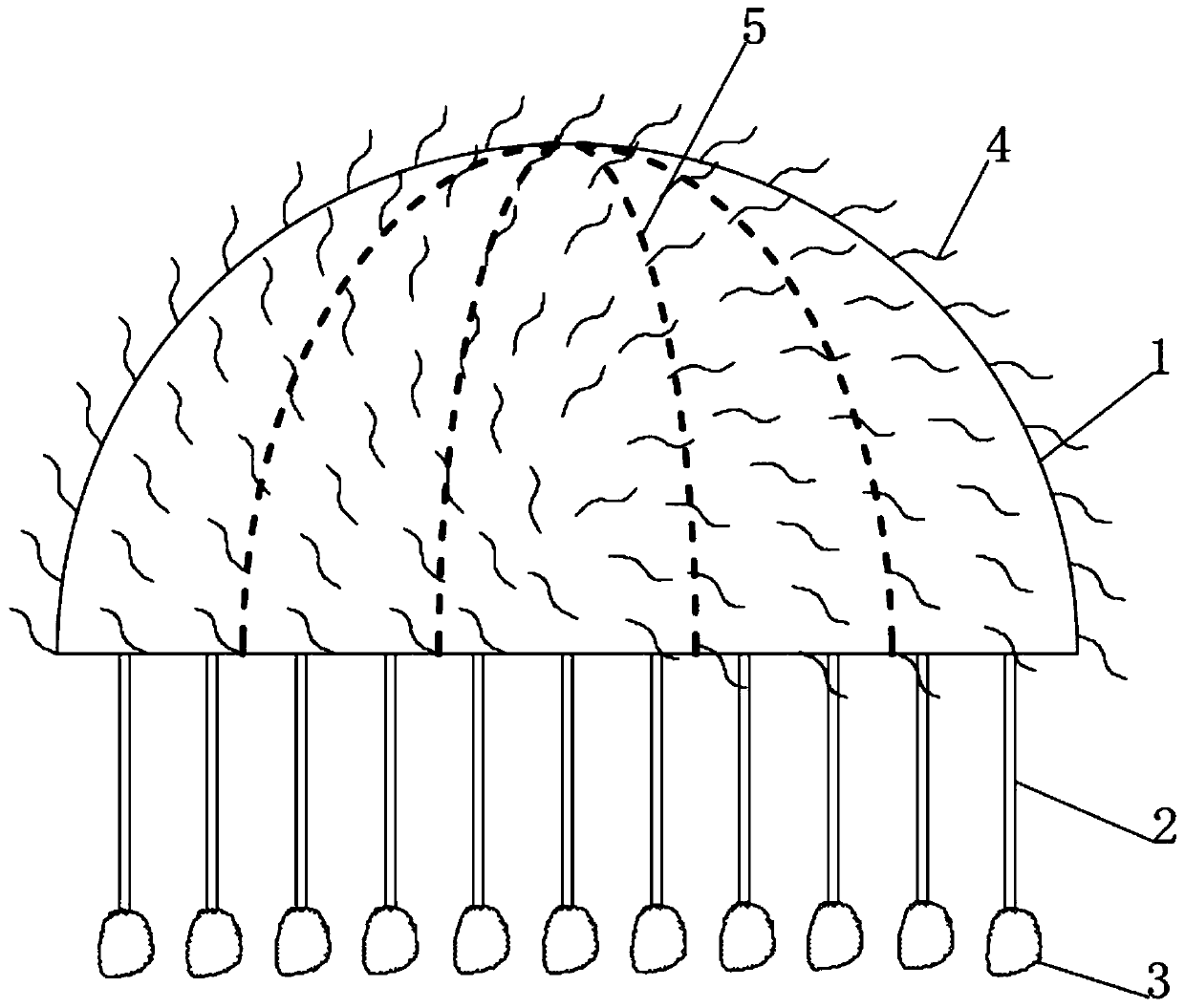

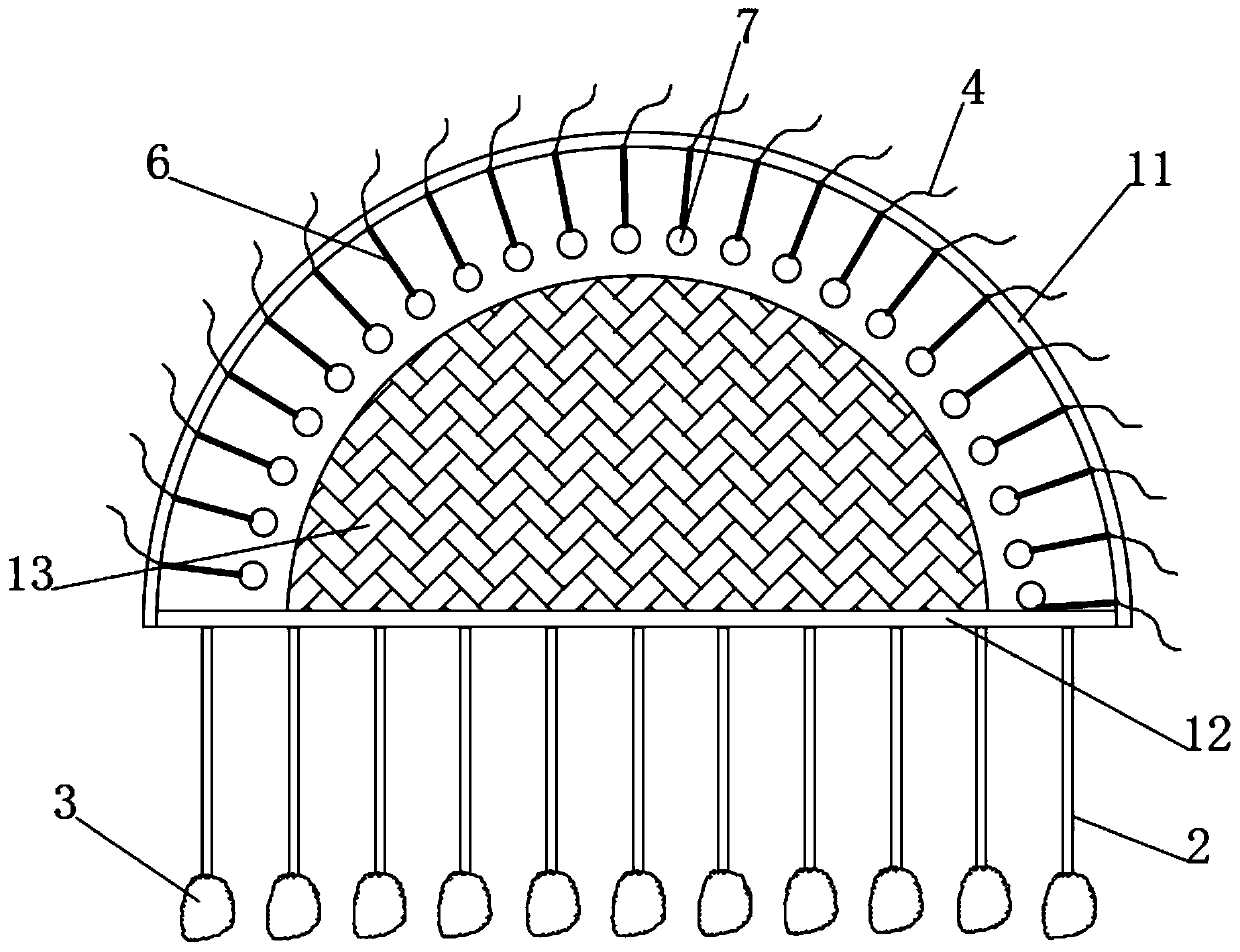

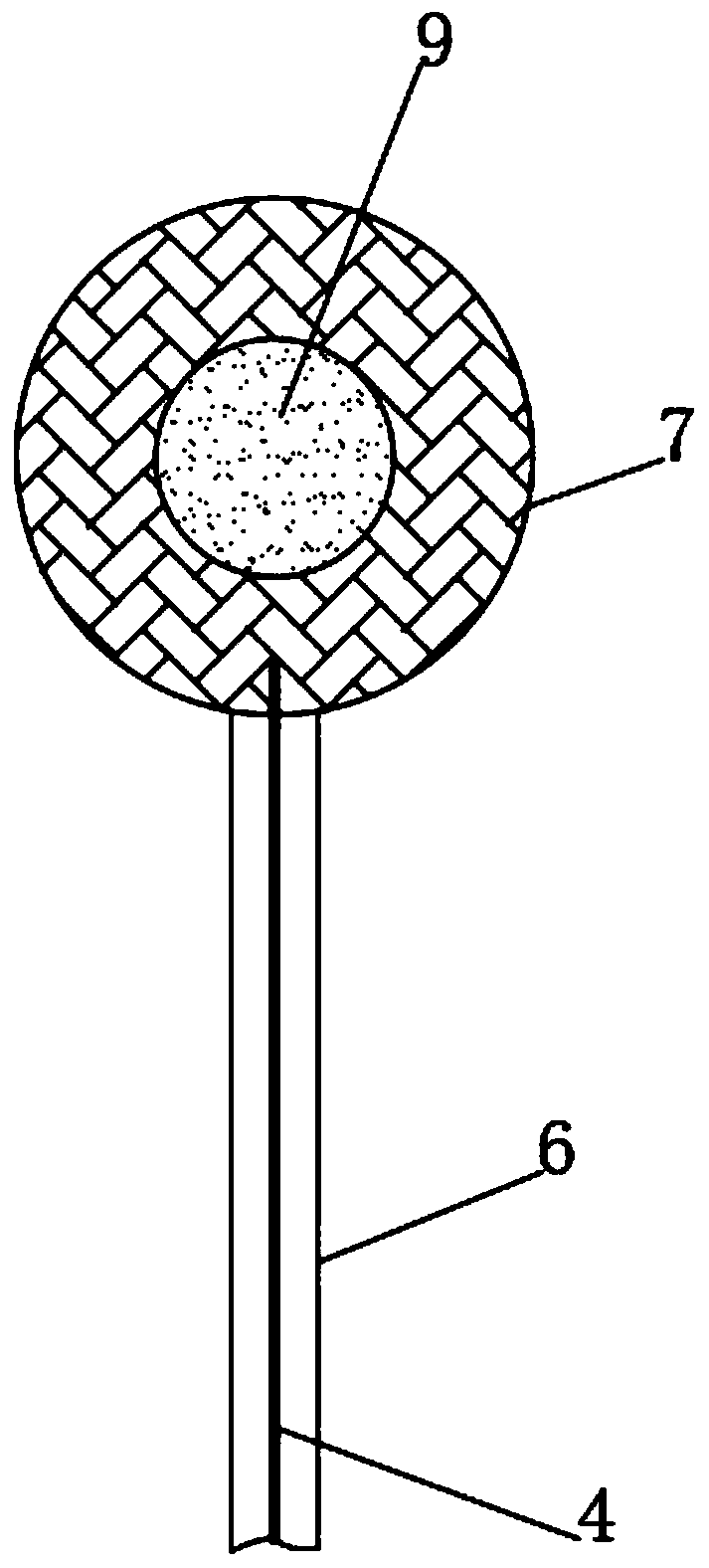

True-triaxial coal and gas adsorption-desorption and outburst test device system and test method

ActiveCN104458490ATrue adsorption stateAchieve adsorptionFuel testingMaterial strength using tensile/compressive forcesAxial pressureSurface type

The invention discloses a true-triaxial coal and gas adsorption-desorption and outburst test device system. The true-triaxial coal and gas adsorption desorption and outburst test device system comprises a cylindrical coal sample chamber structure which is formed by sequentially connecting a plurality of cylindrical units, wherein a plurality of pressure and temperature sensors are uniformly arranged on the outer circumference of each cylindrical unit, four loading devices are symmetrically arranged on the outer circumference of each cylindrical unit, the loading devices stretch into an inner cavity of each cylindrical unit along the radial direction of the cylindrical unit to be connected with loading plates, and lateral stress is applied to briquette coal in the inner cavity of each cylindrical unit by the loading plate; two ends of the cylindrical coal sample structure are respectively provided with a counterforce cover, a surface-type inflating loading disc with the inner side surface being communicated with the inner cavity of the cylindrical coal sample chamber structure is arranged in the counterforce cover on one end and is used for applying the axial pressure, a coal and gas outburst opening is formed in the other end, and an instantaneous release mechanism is arranged in the coal and gas outburst opening. The invention also discloses a test method utilizing the device. By adopting the test device and the test method, the adsorption-desorption characteristics of briquette coal to the gas and the gas outburst mechanism under the condition of different ground stress and different gas pressure can be researched.

Owner:SHANDONG UNIV

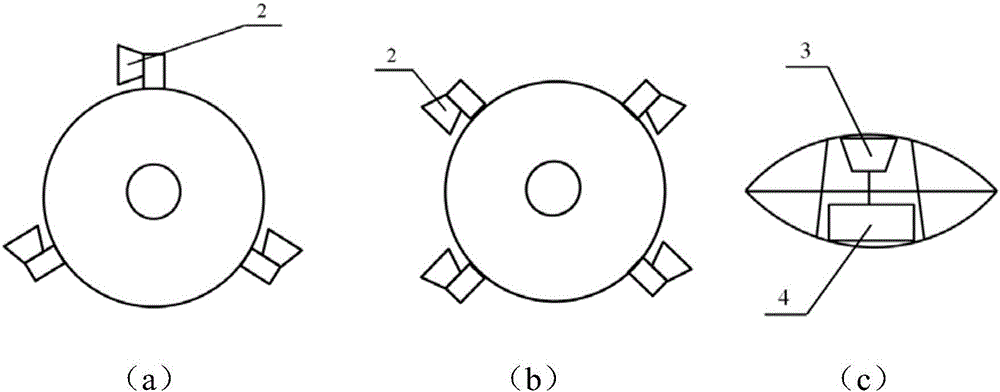

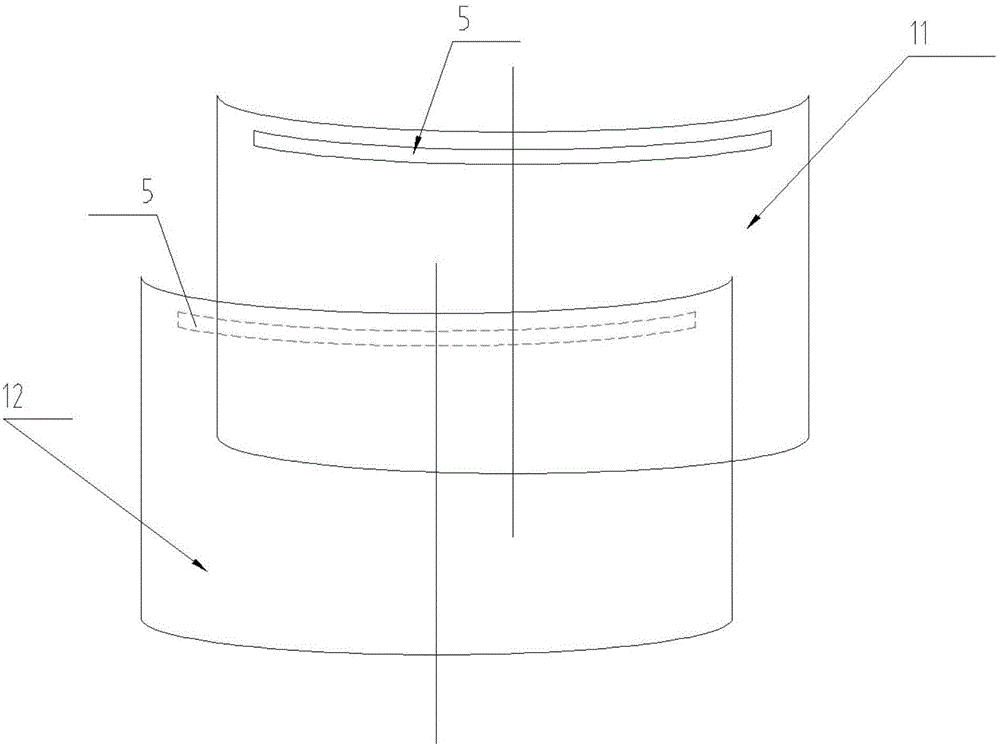

Disc-shaped underwater vehicle based on vortex motion

ActiveCN106218840AReduce resistanceReduce distractionsNavigational aids with satellite radio beacon positioningWatercraft hull designABSORPTION BASEPropeller

The invention discloses a disc-shaped underwater vehicle based on vortex motion. A disc-shaped fairing is adopted. At least one circumferential propeller is arranged in the circumferential direction of the disc-shaped fairing. A vortex generating mechanism and at least one vertical propeller are arranged in the vertical direction of the disc-shaped fairing. The circumferential propellers are used for driving the motion of the vehicle in the horizontal plane of the disc-shaped fairing. The vertical propellers are used for driving the motion of the vehicle in the vertical direction of the disc-shaped fairing. The vortex generating mechanism is used for generating adsorption force relative to the absorption surface. According to the novel technology for achieving object surface absorption based on a vortex adsorption mechanism, the underwater vehicle is made to have high surface adsorption capacity; through the cooperation of the impelling action of the propellers, the vehicle has the omni-directional motion capacity including crawling and swimming, and compared with an existing crawling or swimming underwater vehicle, the disc-shaped underwater vehicle has the advantages that the sailing speed is high, and motion control is swift. An acquisition sensor and operation tools are carried as needed, and the disc-shaped underwater vehicle can be used for carrying out underwater engineering detection, emergency searching, construction operation and the like.

Owner:ZHEJIANG UNIV

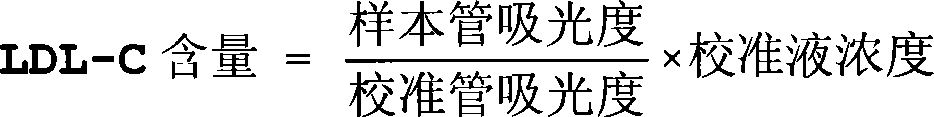

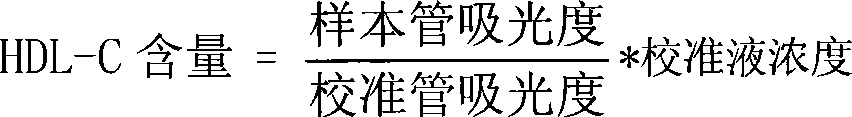

Surface fixed taurine ligand porous membrane material, preparation method and its application in blood fat adsorption separating

InactiveCN101058058AAchieve adsorptionAchieve separationSemi-permeable membranesOther chemical processesLipid compositionBlood plasma

It is aimed to provide a porous carrier surface fixed with taurine absorbed sulfo group. Its average hole radius is made by 0. 05-100mum medical polymer nonwoven cloth modified by 60Cogammacoradiated the polyacrylic acid surface together with porous film, with the help of one aminopropancdiol, 3 EDC activated carboxy group coupling with biologically compatible taurine absorbed sulfo group with the surface fixed with porous film carrier material reinforcing selective absorption and separation effect. It is simple, safe and effective. The material is compatible with blood, with excellent use in plasma absorption separation, clinical blood dynamic purification and waste plasma regeneration and utilization.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

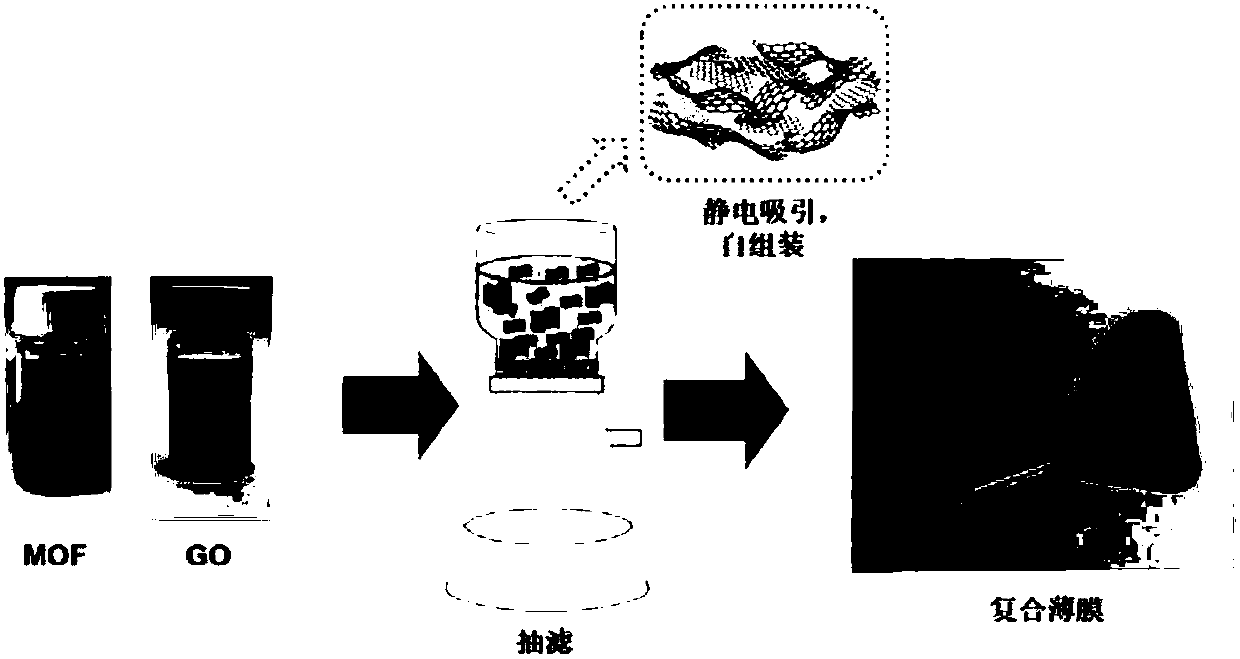

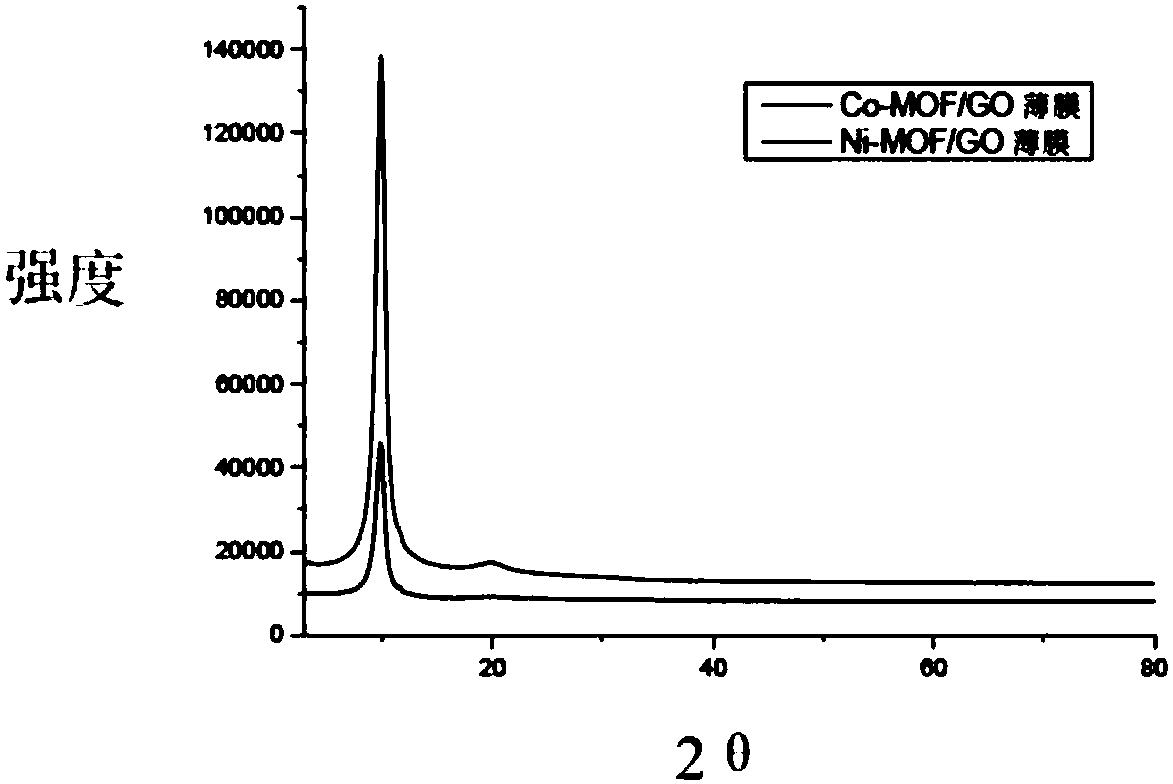

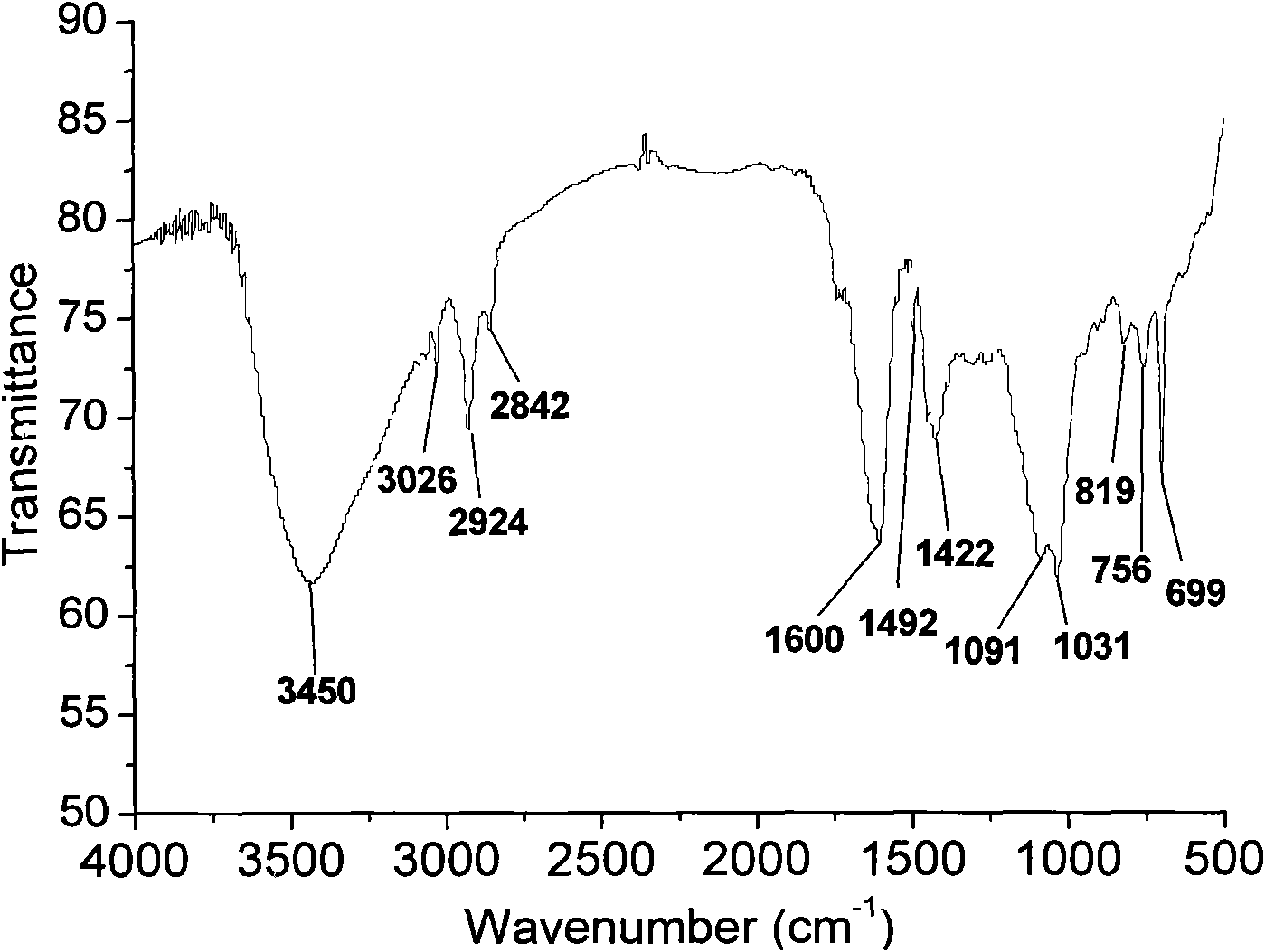

Two-dimensional MOF/ carbon oxide material composite thin film and its preparation method and application

ActiveCN108034263AEasy to operateGood repeatabilityRadioactive decontaminationComposite filmSelf assemble

The application relates to a preparation method of a two-dimensional metal organic framework (MOF) / carbon oxide material composite thin film. The application further relates to a two-dimensional metal organic framework (MOF) / carbon oxide material composite thin film. Besides, the application further relates to an application of the two-dimensional metal organic framework (MOF) / carbon oxide material composite thin film in absorbing radioactive nuclei waste fluid. The invention has the beneficial effects of simple operation and strong repeatability; graphene oxide and MOF can be self-assembled by height layer by layer. Besides, the composite thin film can realize ultra-strong absorbing ability, and the simple method is universally applicable to the compounding of the two-dimensional metalorganic framework containing different center metal ions and the carbon oxide material. These high-quality two-dimensional MOF / carbon oxide composite materials have huge application value in absorption, separation and catalyst domains.

Owner:BEIHANG UNIV

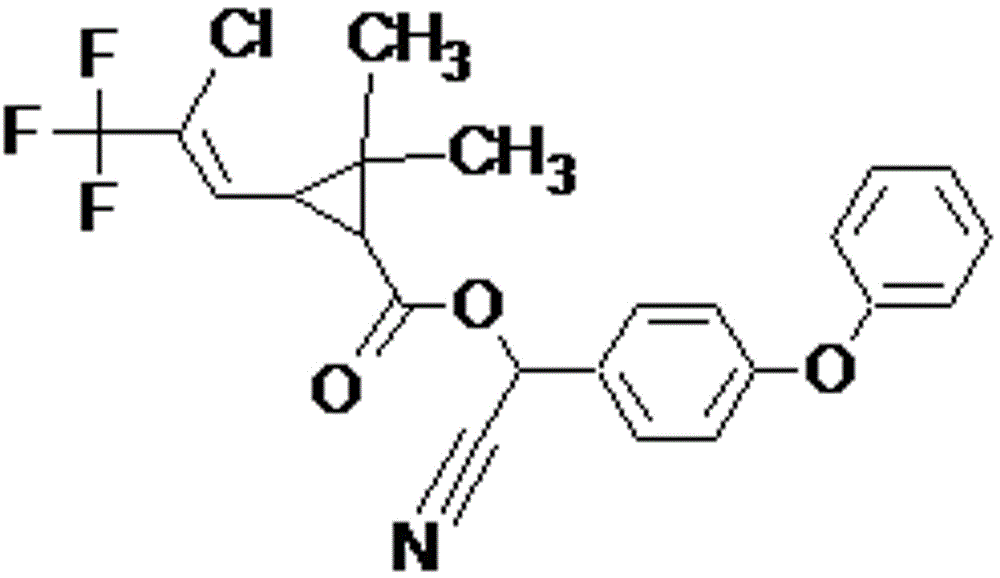

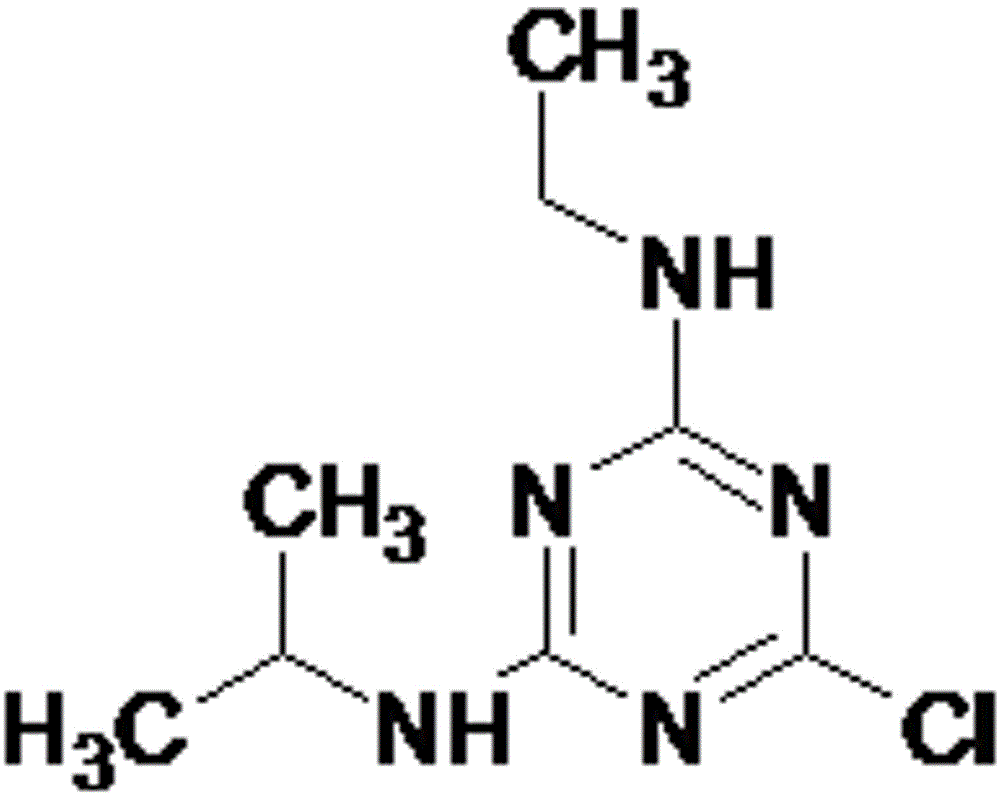

Preparation method of mixed four-template magnetic imprinted polymer and application thereof

ActiveCN106496416AEasy to controlFunctional design optimizationOther chemical processesAlkali metal oxides/hydroxidesMicrosphereTriazine

The invention discloses a preparation method of a mixed four-template magnetic imprinted polymer. The preparation method comprises the following steps of preparation and modification of magnetic microspheres, dissolving, pre-polymerizing, polymerizing, template eluting, drying and the like. The preparation method is characterized in that four matters are used as templates; in a polymerizing process, the modified magnetic microspheres are added to synthesize a magnetic molecular imprinted polymer with specificity identification on triazole matters, pyrethroid matters, triazine matters and carbamate matters. The preparation method has the advantages that the preparation process is easily controlled, the function design is convenient, the prepared polymer has high stability and strength and can resist acid and alkaline, grinding and column loading are not needed, and the efficiency of adsorbing triazole, pyrethroid, triazine and carbamate matters is high; the preparation method is suitable for preparing the microspheres of the mixed four-template magnetic imprinted polymer, and the prepared polymer can be further used for separating and measuring samples when multiple residues of triazole, pyrethroid, triazine and carbamate pesticides in foods, feeds and other samples are simultaneously analyzed.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Metallurgy type refining slag special for ladle and manufacture method thereof

ActiveCN101343680AImprove performance qualityImprove internal qualityProcess efficiency improvementSlagMolten steel

The invention relates metallurgical auxiliary materials used for molten steel refinement in the metallurgy field, in particular to metallurgy type steel ladle refining slag used for deeply desulfurizing and strongly absorbing various impurities in molten steel. The metallurgy type steel ladle refining slag is characterized in that the metallurgy type steel ladle refining slag is composed of the substances according to the weight percentages, namely, high activity lime accounting for 50 percent to 65 percent, fluorite powder accounting for 5 percent to 10 percent, AD30 accounting for 10 percent to 20 percent, magnesia powder accounting for 1 percent to 5 percent and pre-melting type refining slag accounting for 15 percent to 35 percent. The metallurgy type steel ladle refining slag adopts the preparation method that the high activity lime stone, good quality fluorite, AD30, pre-melting type refining slag and magnesia powder are selected as raw material, which are broken into particles of 6 mm to 12 mm according to the component range of the metallurgy type steel ladle refining slag to blend the ratio, and then the particles are packed into finished products according to the weight requirement. The metallurgy type steel ladle refining slag is mainly used for secondary refining for the molten steel without being treated through the refining furnace, the purposes of the effective absorbing of various impurities in the molten steel, the deep desulphurization, and the like in a short time and the refinement of the molten steel are achieved, and the cost of using the refining furnace is saved.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Polystyrene/calcium alginate composite gel microsphere in nuclear shell structure and preparation method thereof

InactiveCN101857698AAchieve adsorptionSynthetic conditions are mildPharmaceutical non-active ingredientsOn/in organic carrierUltrasonic emulsificationFiltration

The invention provides a polystyrene / calcium alginate composite gel microsphere in a nuclear shell structure and a preparation method thereof, relating to biopolymer materials. The polystyrene / calcium alginate composite gel microsphere in the nuclear shell structure takes a polystyrene microsphere as a core and calcium alginate gel as a shell, wherein the grain size of the core is 1-100 microns, and the thickness of the shell layer is 50-800 nm. The preparation method comprises the following steps of: mixing polystyrene microsphere with aqueous solution containing a surface active agent I, and carrying out ultrasonic emulsification to obtain mixed solution A; adding sodium alga acid solution in the mixed solution A, and stirring to obtain mixed solution B; adding organic solution containing a surface active agent II into the mixed solution B, and stirring to obtain mixed solution C; adding calcium chloride solution which has the same volume with the sodium alga acid solution into the mixed solution C under stirring to react, and carrying out vacuum filtration, washing the solution until no calcium ion residue exists on the surface and drying to obtain a product D; and dispersing the product D into water, centrifuging the mixture, pouring out supernate and taking out precipitate to obtain the product.

Owner:XIAMEN UNIV

Bobbin type device for degrading triclocarban (TCC) in water by virtue of dielectric barrier discharge coordinated with activated carbon fiber and method of device

InactiveCN104925889AAchieve adsorptionAchieve modificationWater/sewage treatment by irradiationWater contaminantsActivated carbonBobbin

The invention discloses a bobbin type device for degrading triclocarban (TCC) in water by virtue of dielectric barrier discharge coordinated with activated carbon fiber and a method of the device. The device comprises a cylindrical reactor, a water distributing groove communicated on the upper part of the cylindrical reactor, a circulating buffer container and a rod-like high voltage electrode and a grounding electrode which are respectively connected with the positive and negative electrodes of an alternating current high voltage power supply, wherein the rod-like high voltage electrode is arranged in the cylindrical reactor while the grounding electrode covers the outer wall of the cylindrical reactor; activated carbon fiber layers are fixedly arranged on the inner walls of the cylindrical reactor; porous baffle plates are arranged on the surfaces of the activated carbon fiber layers; the circulating buffer container is respectively communicated with a waste water inlet formed on the side wall of the water distributing groove and a waste water outlet formed in the bottom of the cylindrical reactor to form a waste water circulating pipeline. The device is simple in design and low in equipment investment, the degrading efficiency can be improved by fully utilizing ozone generated by catalysis of the activated carbon fiber, and moreover, regeneration of the activated carbon fiber is realized, so that the device can be applied to treating organic waste water which is difficult to be biochemically degraded.

Owner:NANJING UNIV

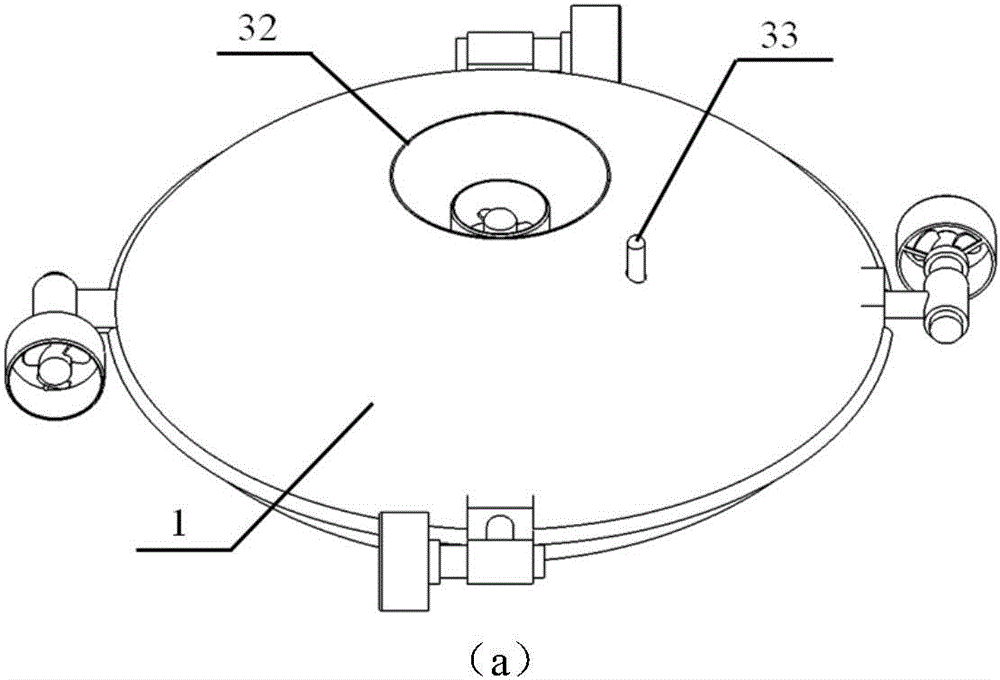

Folding type climbing device for glass curtain wall cleaning robot

InactiveCN106264308AImprove adsorption capacityAchieve adsorptionCarpet cleanersFloor cleanersCouplingEngineering

The invention relates to the technical field of robots, in particular to a folding type climbing device for a glass curtain wall cleaning robot. The folding type climbing device comprises a fixed disc and movable discs. A coupler is installed on the fixed disc. The movable discs are installed on the fixed disc through the coupler and located on the front and back sides of the fixed disc. The movable disc is provided with a track hub and a driving motor. The track hub is sleeved with a track. A cupule is arranged on the track. A valve needle is arranged at the inner end of the cupule. A vacuum connector is arranged on the side wall of the cupule. The inner end of the valve needle penetrates through the track to abut against the surface of the track hub. Due to action of the coupler, the movable discs have the certain rotating effect relative to the fixed disc, when the movable discs are operated, traction force and pushing force can be formed for the fixed disc, it is ensured that the robot can easily pass through the regions of corners or uneven parts of a curtain wall, opening and closing of the cupule can be controlled by controlling the valve needle, and the powerful adsorption capacity is achieved in the device moving process.

Owner:肇庆市小凡人科技有限公司

Wafer conveying tray and method of securing wafer on tray

ActiveCN102067303AEasy to fixDoes not reduce effective areaSemiconductor/solid-state device manufacturingTemperature controlElectrical and Electronics engineering

A wafer conveying tray, wherein temperature control of a wafer is possible at the time of processing, and wherein the wafer can be easily secured without reducing the effective area in the wafer surface and without requiring the labor of attaching the wafer and post-processing. The wafer conveying tray (302) comprises a base formed from an insulator and an electrostatic chuck electrode (306) buried in the base. The terminal of the portion feeding power to the electrostatic chuck electrode is a spring-type terminal (305a), the spring-type terminal is formed so that the tip portion thereof can be brought into contact with the electrostatic chuck electrode, a seal member (305b) is provided near the power feeding portion and is formed so that a temperature exchanging medium does not reach the area where the tip portion of the spring-type terminal contacts the electrostatic chuck electrode, and the wafer (S) can be secured onto the tray by means of the electrostatic chuck. Further, a method of securing a wafer onto this wafer conveying tray by means of the electrostatic chuck is provided.

Owner:ULVAC INC

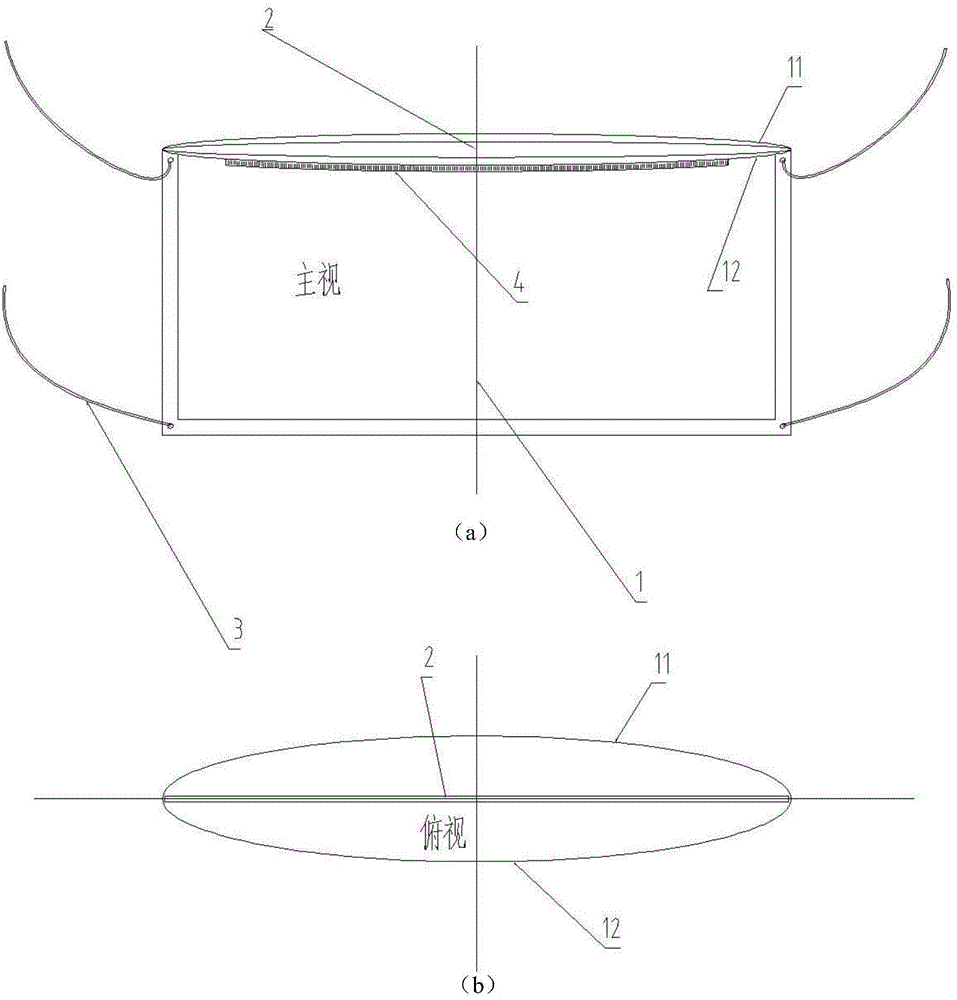

Nano-structure-based anti-haze mask with filtration and adsorption double functions

The invention discloses a nano-structure-based anti-haze mask with filtration and adsorption double functions. The nano-structure-based anti-haze mask comprises a mask main body and a replaceable filter layer material, wherein four corners of the mask main body are provided with tying tapes; the top center of the mask main body is sewn with a plastic nose bridge depression bar; the mask main body consists of a cotton outer layer and a cotton inner layer; three sides of the outer layer and the inner layer are sewn, and upper ends of the outer and inner layers are open and are connected through an adhesive tape to form an internal accommodating cavity; the replaceable filter layer material is accommodated in the internal accommodating cavity. The upper ends of the inner and outer layers are open, so that the filter layer material can be conveniently replaced, and the mask is convenient to clean. The replaceable filter layer material comprises an electrospun nano-fiber filter membrane and a carbon nanometer hollow lattice adsorption membrane, and can simultaneously filter PM2.5 fine particles and adsorb toxic and harmful substances to realize a double protection function. The nano-structure-based anti-haze mask is a protective mask which is high in filter efficiency, can effectively block PM2.5 particles, is high in air permeability, is provided with the replaceable filter material and can be repeatedly cleaned and used.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

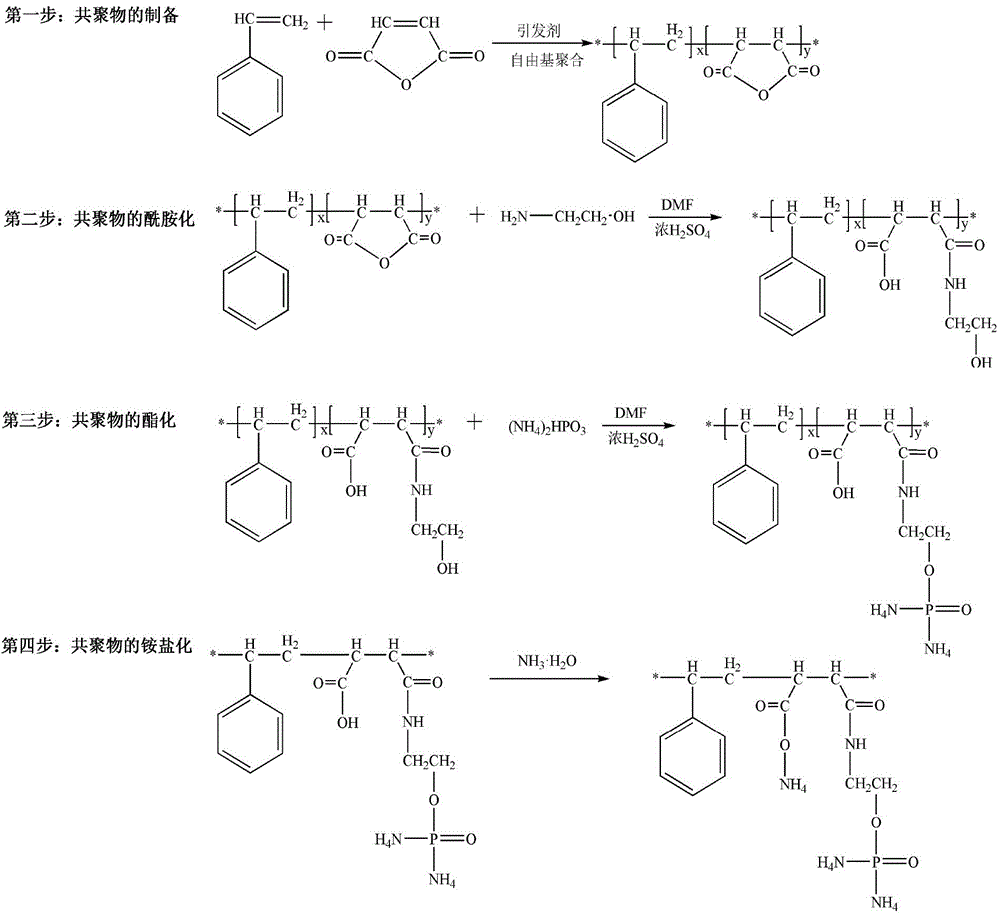

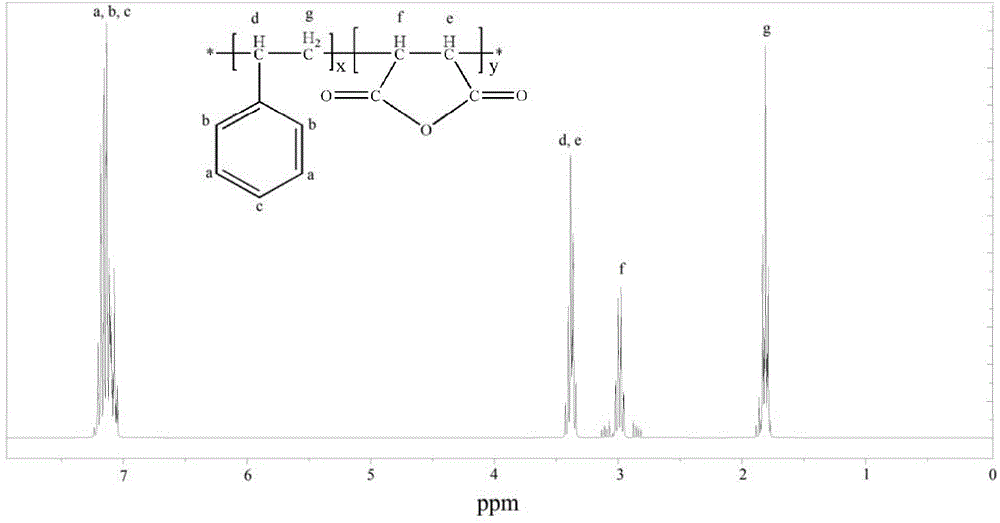

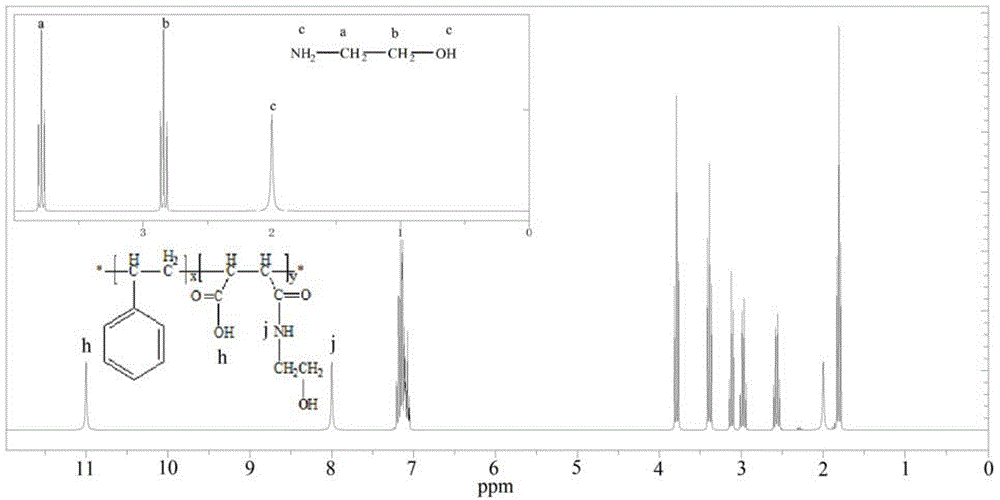

Water-soluble dispersing agent for gel ink and preparation method of water-soluble dispersing agent

The invention discloses a water-soluble dispersing agent for gel ink and a preparation method of the water-soluble dispersing agent. According to the method, styrene-maleic anhydride polyester adopting an amphiphilic structure is modified through ethylene glycol amine and diammonium hydrogen phosphate, and the styrene-maleic anhydride polyester dispersing agent with large steric hindrance and a multi-charge structure is prepared. The dispersing agent has a good dispersion effect on pigments, is especially applicable to preparation of gel ink high-concentration color paste, can be used for preparing gel ink high-concentration color paste with the concentration higher than 40 wt. %, has low system viscosity, good stability and a wide application range and has a wide market prospect.

Owner:LOTUS STATIONERY

Cyclone separation falling type sewage remediation hemisphere

InactiveCN111533280AIncrease contact areaReduce gravityFatty/oily/floating substances removal devicesLiquid separationMicroorganismSludge

The invention discloses a cyclone separation falling type sewage remediation hemisphere, and belongs to the field of water body remediation. When the cyclone separation falling type sewage remediationhemisphere is used in sewage, the particles are pneumatically dissociated to fall into water and gas can be instantly released, the released gas can generate larger impact force to enable the hemisphere to fall off from the paddling zone and release a microbial strain, finally, the pneumatic dissociation particles fall into the water bottom to be embedded into underwater sludge, pores in the sludge can be enlarged in the process of continuously generating the gas, and thus the decomposition efficiency of microorganisms on harmful substances in the sludge is improved; besides, after the pneumatic dissociation particles fall off, the gravity of the remediation hemisphere is reduced, and the dissociation layer is dissolved so that the remediation hemisphere can rapidly float and be unfoldedto be attached to the water surface, the contact area with the water body is effectively increased, the remediation efficiency and effect are improved, sewage and sludge at the bottom of the sewage can be remediated at the same time, and the remediation efficiency is remarkably improved.

Owner:鲍永强

Adsorbing-catalyzing agent based on amino-functionalized ionic liquid and preparation method thereof

ActiveCN105170099ALarge capacityHigh activityProductsOrganic chemistryCatalytic transformationMolecular sieve

The invention discloses an adsorbing-catalyzing agent based on amino-functionalized ionic liquid. The adsorbing-catalyzing agent is prepared by taking a mesoporous moecular sieve SBA-16 as a carrier and amino-functionalized ionic liquid 1-(3-aminopropyl)-3-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole chloride as an active component and grafting the amino-functionalized ionic liquid to the carrier, wherein 1-10 mmol of the amino-functionalized ionic liquid is loaded in every 1 g of the adsorbing-catalyzing agent. The adsorbing-catalyzing agent integrates an adsorption capturing function and a catalytic conversion function into a whole and can achieve synchronous adsorption and conversion of CO2 and reduce the cost of a CUU technique.

Owner:TAIYUAN UNIV OF TECH

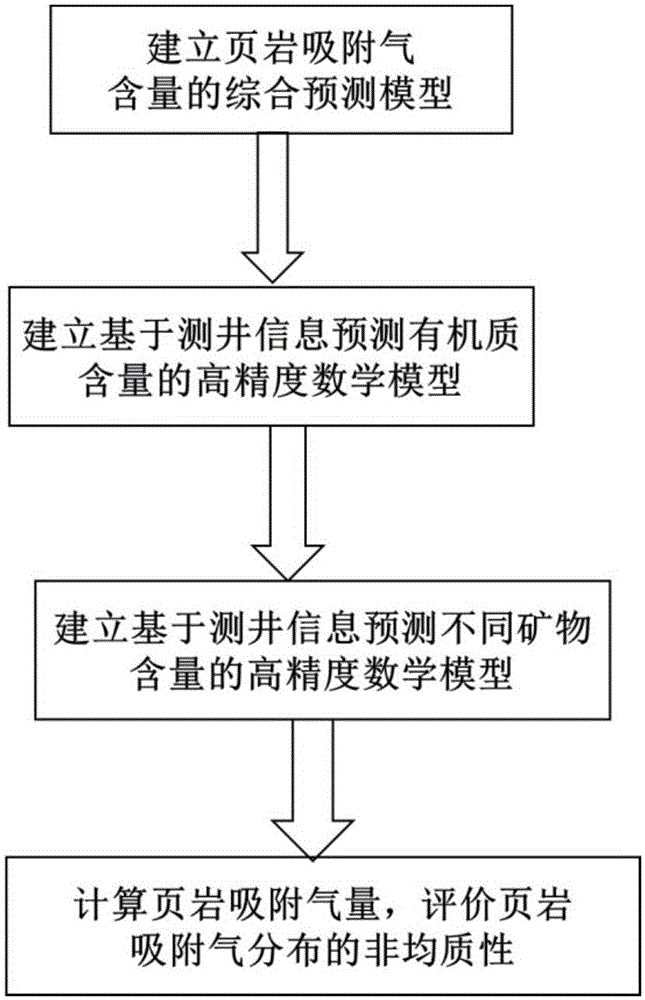

Method for predicting anisotropism distribution of different types of shale adsorbed gases

The invention belongs to the field of unconventional oil and gas exploration and development and specifically relates to a method for predicting the anisotropism distribution of different types of shale adsorbed gases. The method comprises a step 1 of establishing a shale gas adsorbed gas content conceptual model and a comprehensive prediction mathematic model; a step 2 of establishing a high-precision mathematic model for predicting the content of organic matters based on logging information; a step 3 of establishing a high-precision mathematic model for predicting the content of different minerals based on logging information; and a step 4 of computing the shale adsorbed gas amount and evaluating the anisotropism of the shale adsorbed gas distribution. The method establishes conceptual models in different forms, classifies shale adsorbed gases into organic adsorbed gas, clay mineral adsorbed gas, quartz adsorbed gas, other clastic rock mineral adsorbed gas, carbonate mineral adsorbed gas, and other saline mineral adsorbed gas, and establishes a method model so as to compute the content of the adsorbed gases in various forms.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Stainless steel cold rolling waste acid purification system

InactiveCN102839380AAchieve separationAchieve adsorptionIon-exchange process apparatusIon-exchanger regenerationFiltrationAcid washing

The invention belongs to the field of stainless steel processing waste treatment, and relates to a stainless steel cold rolling waste acid purification system. According to the present invention, in stainless steel cold rolling annealing acid washing units, strip steel is required to be subjected to an acid washing treatment to remove oxide scale on the surface of the strip steel; resin adsorption is performed on waste acid generated from acid washing to remove soluble metal ions, wherein the acid washing adopts a mixing acid; the free acid is recycled so as to reduce waste acid emission, reduce production cost, and improve quality of the acid washing product. The acid purification system is an ion exchange system, wherein filtration and resin adsorption are performed on the waste acid liquid to separate iron, nickel and chromium metal salts accumulated in the acid liquid from the acid washing liquid, such that the acid liquid can be reused for stainless steel acid washing. The process principle is the following acid purification system process: carrying out acid washing on the waste acid, adopting a circulation tank, adopting a swirling separator, adopting a filtration unit, adopting a purification system (SAR), and purifying the acid. The waste acid from the acid washing line is filtered through the filtration unit, and then directly enters the acid purification unit (SAR). The free acid water absorbed by the resin bed is substituted by water, and then returns to the acid washing line, and the waste acid enters a wastewater treatment system.

Owner:ZHANGJIAGANG KAINA INFORMATION TECH

Magnetic biochar composite adsorbent as well as preparation method and application thereof

ActiveCN111203180ANo lossNon-destructive modificationOther chemical processesWater contaminantsAdsorption equilibriumSorbent

The invention discloses a magnetic biochar composite adsorbent as well as a preparation method and application thereof, and belongs to the field of biochar materials. Almond shell biomass and ferrousnitrate are used as raw materials, the particle size fraction of the adsorbent is reduced through thermal degradation process magnetization and a mechanical ball milling process, and finally the magnetic biochar composite adsorbent is prepared. The prepared magnetic biochar composite adsorbent is applied to a phosphorus-containing aqueous solution and shaken to adsorption equilibrium at a constanttemperature, and the magnetic biochar adsorbent can be separated from the solution under the action of an external magnetic field after the reaction is completed, so that phosphorus in water is removed, and the adsorbent is separated and recycled. The method has the advantages of low cost, readily available materials, simplicity and convenience in operation, high treatment efficiency and the like, resource utilization, magnetic rapid separation, recovery and reutilization of biomass are realized, the iron-modified precursor is environment-friendly and free of secondary pollution, and the adsorbent can be applied to removal and recovery of excessive phosphorus in industrial and agricultural wastewater.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com