Wafer conveying tray and method of securing wafer on tray

A fixing method and wafer technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of troublesome fixing wafer S, deterioration of cooling efficiency, unreliable fixing stability, etc., and achieve the effect of easy temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

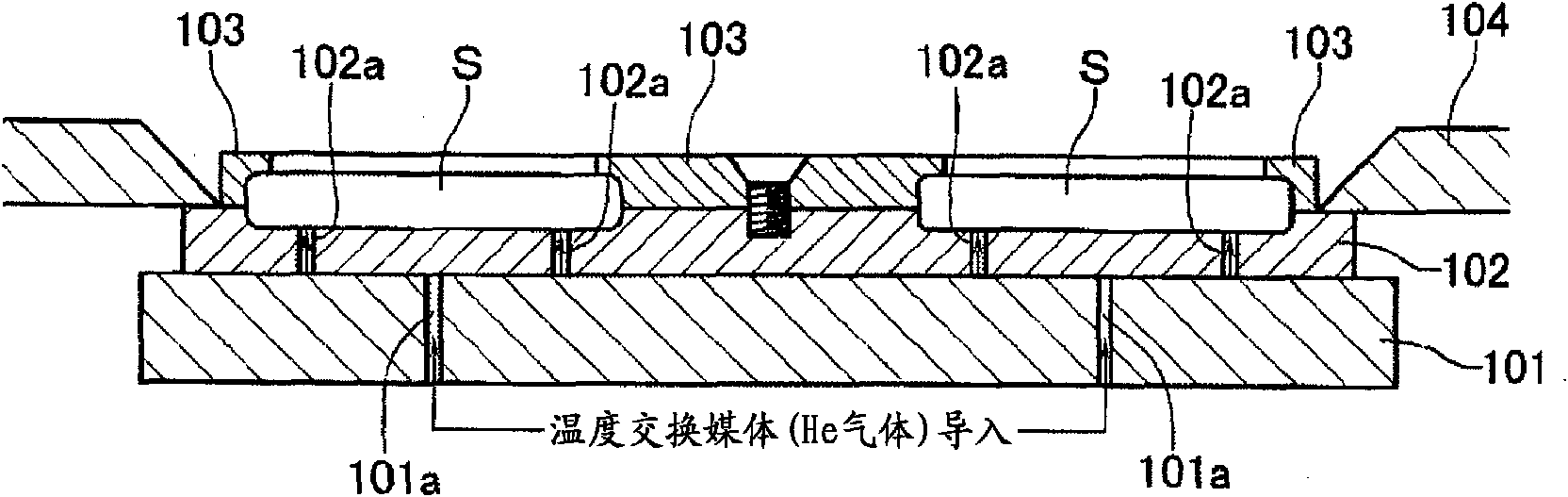

[0040] According to an embodiment of the wafer transfer tray of the present invention, there can be provided a wafer transfer tray including a base made of an insulator, and an electrostatic adsorption electrode made of a conductor embedded in the base, wherein the electrostatic adsorption electrode The terminal of the power supply part is a spring-type terminal. The spring-type terminal is configured so that the front end of the spring-type terminal can contact the electrostatic adsorption electrode through the passage in the tray support table on which the tray is placed, and the wafer can be fixed to the tray by electrostatic adsorption when the power is turned on. Above, a sealing member is provided around the power supply portion in such a way that the temperature exchange medium does not spread to the contact portion between the front end portion of the spring type terminal and the electrostatic adsorption electrode, and the electrostatic adsorption that fixes the wafer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com