Wafer bonding clamping device, aligning machine, bonding machine and warping substrate adsorption method

A wafer bonding and clamping device technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of unusable warped sheets, delay in production time, complicated operation, etc., and eliminate invalid Pressing surface, improving production efficiency, and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

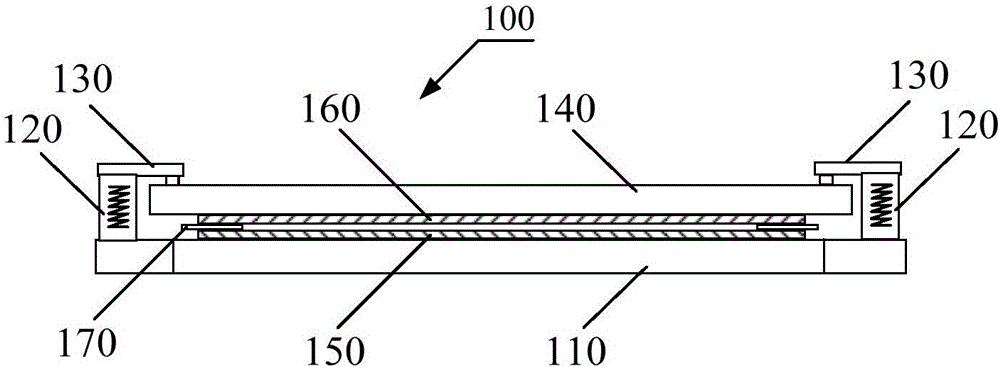

[0054] Such as figure 1 As shown, the first embodiment provides a wafer bonding clamping device 100, which includes a carrying table 110, a clamping mechanism 120, a pressure head 130, and a pressure plate 140. Wherein, the pressure plate 140 is arranged between the carrier 110 and the pressure head 130, the specifications and dimensions of the pressure plate 140 are compatible with the specifications and dimensions of all substrates, and the pressure head 130 is crimped on the pressure plate 140, The pressure head 130 is crimped on the pressure plate 140 and the pressure contact point is set in an area outside the corresponding substrate of the pressure plate 140; the pressure plate 140 is made of the same material as the carrier 110. Among them, the carrying table 110 is used to carry the lower substrate 150 and the upper substrate 160; the clamping mechanism 120 is used to clamp the lower substrate 150 and the upper substrate 160, specifically the clamping mechanism 120 is co...

Embodiment 2

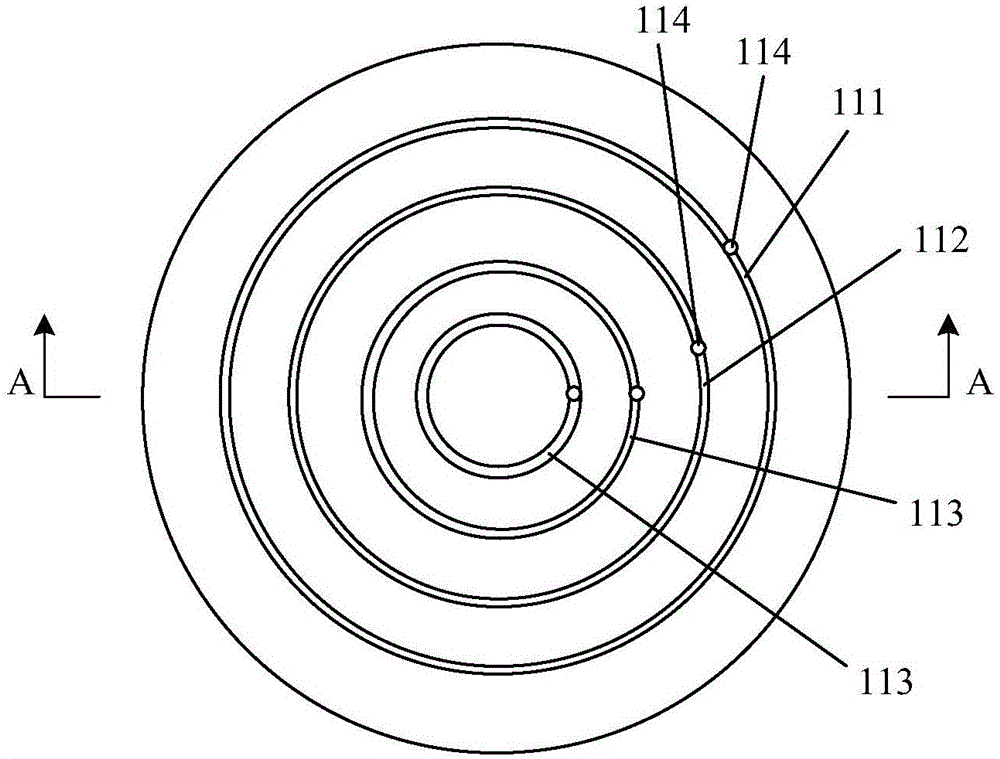

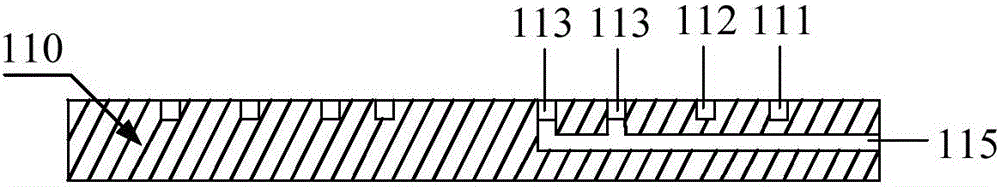

[0059] Such as figure 2 with image 3 As shown, the second embodiment is improved on the basis of the first embodiment. The difference is that the pressure plate 140 and / or the carrying table 110 is provided with a dense-grained suction cup structure. The dense-grained suction cup structure includes several stages of vacuum suction ring grooves arranged in the pressure plate 140 and / or the carrying table 110, and each stage of the vacuum suction ring groove is provided with a vacuum suction hole 114, and each stage has a vacuum suction hole 114. The vacuum adsorption ring groove is connected to the vacuum adsorption hole 114 with a vacuum source of the same or different pressure; the vacuum adsorption hole 114 may also be provided with a switch for controlling the on-off of the vacuum source, the switch may be Solenoid valve or pressure valve or manual valve. At least one vacuum adsorption ring groove is provided in each stage. Among them, the shape of the vacuum suction ring...

Embodiment 3

[0063] Such as Figure 4 with 5 As shown, the third embodiment provides an alignment machine for a wafer bonding system, including a light source 500, an alignment frame 400, a wedge positioning mechanism 300, and a mounting frame 200. The mounting frame 200 has a detachable positive Or, the wafer bonding clamping device 100 of the first or second embodiment described above is installed in the reverse direction.

[0064] In the alignment machine of the third embodiment, the light source accurately aligns the upper and lower substrates through the aligning frame and the wedge-shaped positioning mechanism through the bearing table and the platen 140. The clamping mechanism 120 drives the platen 140 to align the upper and lower substrates. Clamping. Therefore, the present invention also has the effects of reducing or eliminating invalid pressing surfaces, facilitating temperature control, improving production efficiency, and being compatible with all wafer specifications. Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com