Transformer cabinet based on self-feedback uniform heat dissipation

A transformer cabinet, self-feedback technology, applied in the direction of transformer/inductor housing, transformer/inductor cooling, transformer/inductor components, etc., can solve the problems of overheating, affecting the normal use of the transformer, and the heat released by the transformer is not uniform enough. , to achieve the effect of improving the heat dissipation, heat absorption and heat release efficiency of the fuel tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

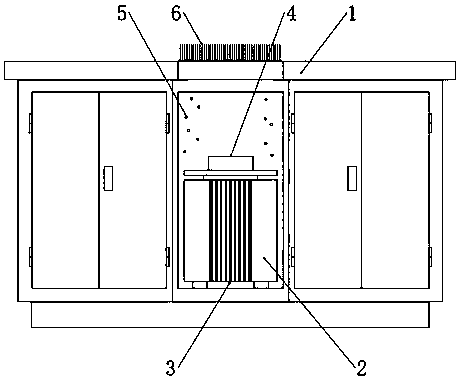

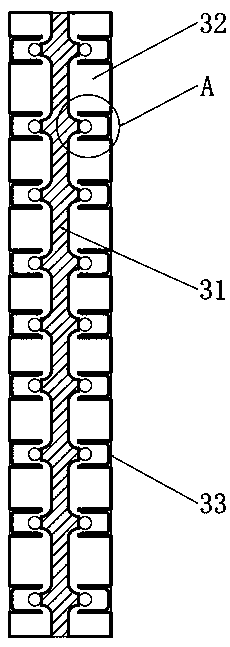

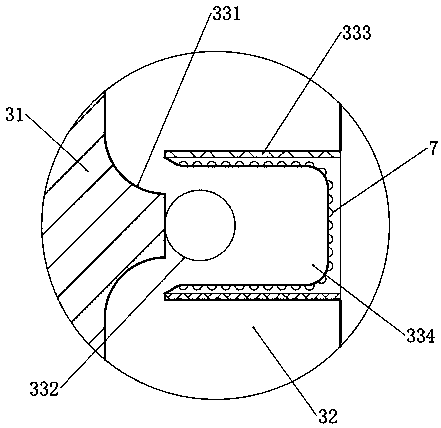

[0043] see Figure 1-2 , a transformer cabinet based on self-feedback uniform heat dissipation, including a transformer cabinet 1, a transformer body 2 is installed in the transformer cabinet 1, and a plurality of evenly distributed composite heat sinks 3 are fixedly connected to the outer surface of the transformer body 2, and the upper end of the transformer body 2 The shunt fan 4 is fixedly connected. On the one hand, the fluidity of the air in the transformer cabinet 1 is maintained through the airflow movement, which promotes the uniformity of the temperature distribution. Type heat sink 3 cooperates to play the role of heat transfer, composite heat sink 3 includes heat conduction substrate 31, the left and right ends of heat conduction substrate 31 are fixedly connected with heat dissipation surface 32, and the outer surface of heat dissipation surface 32 is inlaid with a plurality of evenly distributed The self-feedback heat dissipation mechanism 33 is used to sense the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com