Method for preparing fibroin nanofiber and metal organic framework composite film

A technology of metal-organic frameworks and nanofibers, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Advanced problems, to achieve the effect of uniform particles, high loading capacity, and improve filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of ESF@ZIF-8 Composite Fiber Film by In-Situ Method

[0039] 1cm 2 The square ESF membrane was immersed vertically in 2mL 18.4mM zinc nitrate hexahydrate solution, and an equal volume of 1.38M 2-methylimidazole solution was added after 5 minutes. The purpose of standing still is to ensure that the nucleation in this system is uniform on the surface of the fiber, mix quickly and uniformly (about 10s), place it in a water bath at 38°C, and take it out after 2 hours of reaction. After washing with deionized water several times, the uniform ESF@ZIF-8 composite fiber film was prepared in a vacuum oven at 40°C for 24 hours.

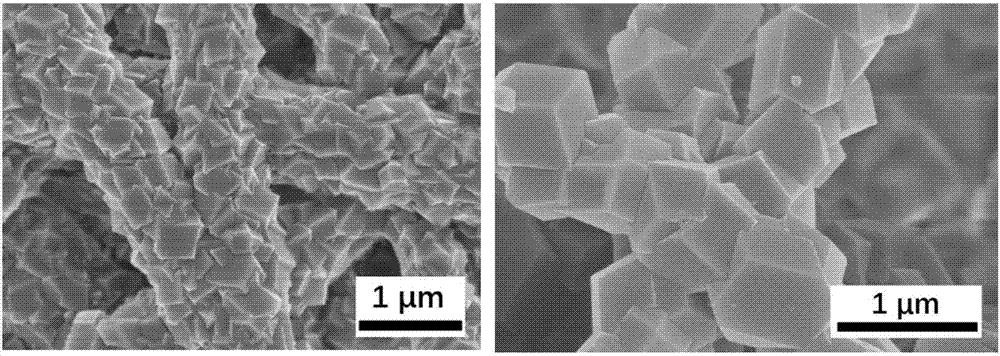

[0040]Continuity, crystallinity:

[0041] The growth of ZIF-8 particles on the fiber surface of the prepared composite fiber film was observed by field emission scanning electron microscope. The results show that compared to the smooth ESF ( figure 1 ), due to the force between the polypeptide and the nanoparticles on the surface of the p...

Embodiment 2

[0055] Preparation of ESF@ZIF-67 Composite Thin Films by In Situ Method

[0056] 1cm 2 Submerge the square ESF membrane vertically in 32.4mM cobalt nitrate hexahydrate solution, let it stand for 5 minutes, add an equal volume of 1.38M 2-methylimidazole solution, mix quickly (about 10s) and place it in a water bath at 80°C , Take it out after 2h of reaction. After washing with deionized water three times, it was kept in a vacuum oven at 40°C for 24 hours to obtain a uniform ESF@ZIF-67 composite fiber film.

[0057] Continuity, crystallinity:

[0058] Field emission scanning electron microscopy was used to observe the growth of ZIF-67 particles on the surface of the prepared composite fiber film. Due to the force between the polypeptide on the surface of the protein fiber and the nanoparticles, the primary nanoparticles (~100nm) were evenly attached to the ESF fibers at the early stage of growth. surface. The nanoparticles grow gradually, and after two hours, from figure 2...

Embodiment 3

[0074] Preparation of ESF@ZIF-8 Composite Fiber Film by In-Situ Method

[0075] 1cm 2 The square ESF membrane was immersed vertically in 2mL 10mM zinc nitrate hexahydrate solution, and an equal volume of 690mM 2-methylimidazole solution was added after 5 minutes. The purpose of standing still is to ensure that the nucleation in this system is uniform on the surface of the fiber, mix quickly and uniformly (about 10s), place it in a water bath at 38°C, and take it out after 2 hours of reaction. After washing with deionized water several times, the uniform ESF@ZIF-8 composite fiber film was prepared in a vacuum oven at 40°C for 24 hours.

[0076] Continuity, crystallinity:

[0077] The growth of ZIF-8 particles on the fiber surface of the prepared composite fiber film was observed by field emission scanning electron microscope. The results show( Figure 7 ), compared to the smooth ESF ( figure 1 )and figure 2 As shown in (left), less ZIF-8 crystals are loaded on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com