Modified polypropylene master batch, melt-blow cloth, preparation method and application thereof

A polypropylene and melt-blown cloth technology, applied in the field of melt-blown cloth and its preparation, modified polypropylene masterbatch, and application of modified polypropylene masterbatch, can solve problems such as reducing the filtration efficiency of melt-blown cloth, and achieve spinnability. The effect of silkiness improvement, spinnability improvement and filtration efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

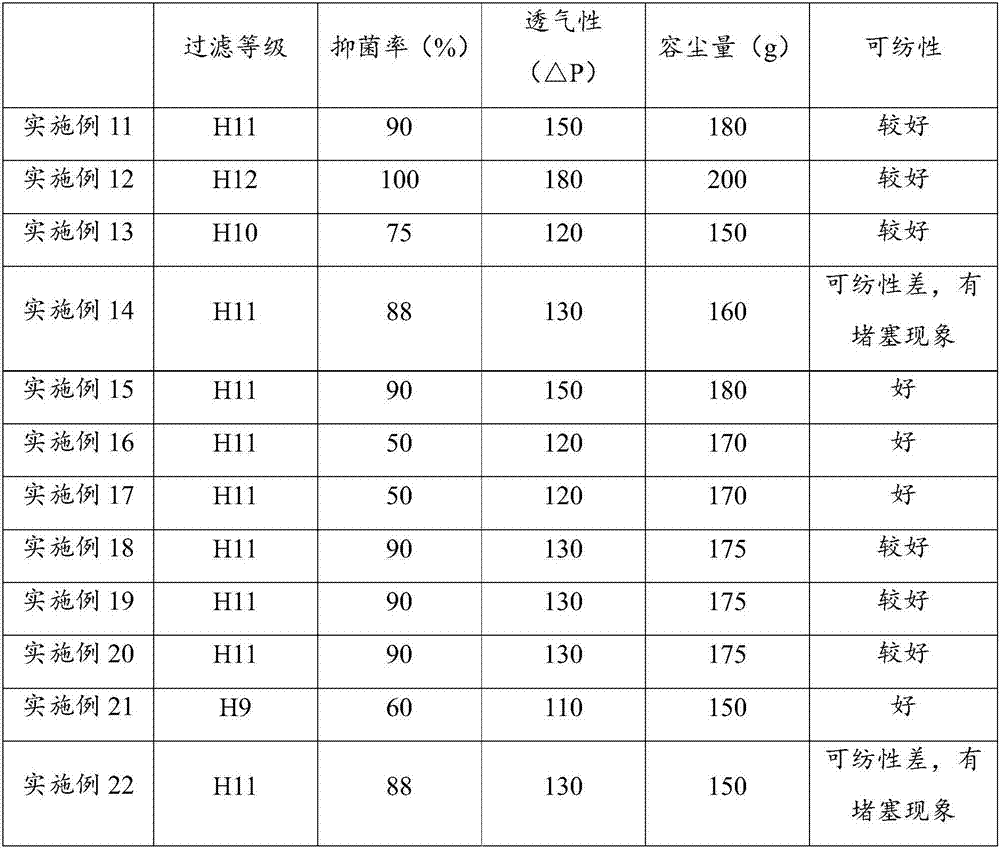

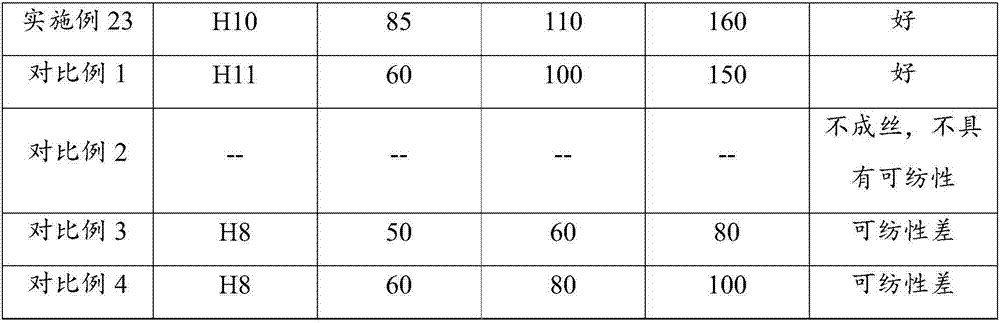

Examples

Embodiment 1

[0060] Production of modified polypropylene masterbatch:

[0061] Graphene powder (graphene C with screening particle size ≤ 10 μm), polypropylene slices, coupling agent (remixed butyl titanate and isopropyl titanate), dispersant (polyethylene wax) and antioxidant (Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester) was added to the high-speed mixer for mixing After being mixed evenly, it is added to a twin-screw extruder, melted and extruded, cooled in a water bath, and cut to make a graphene composite polypropylene masterbatch.

Embodiment 2

[0063] The difference from Example 1 is that the ratio of raw materials is different, and the percentages of graphene powder, polypropylene chips, coupling agent, dispersant and antioxidant are respectively:

[0064] 15%, 82%, 2%, 0.99%, 0.01%.

Embodiment 3

[0066] The difference from Example 1 is that the ratio of raw materials is different, and the percentages of graphene powder, polypropylene chips, coupling agent, dispersant and antioxidant are respectively:

[0067] 5%, 90%, 2%, 2.8%, 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com