Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4380results about How to "Easy to realize industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

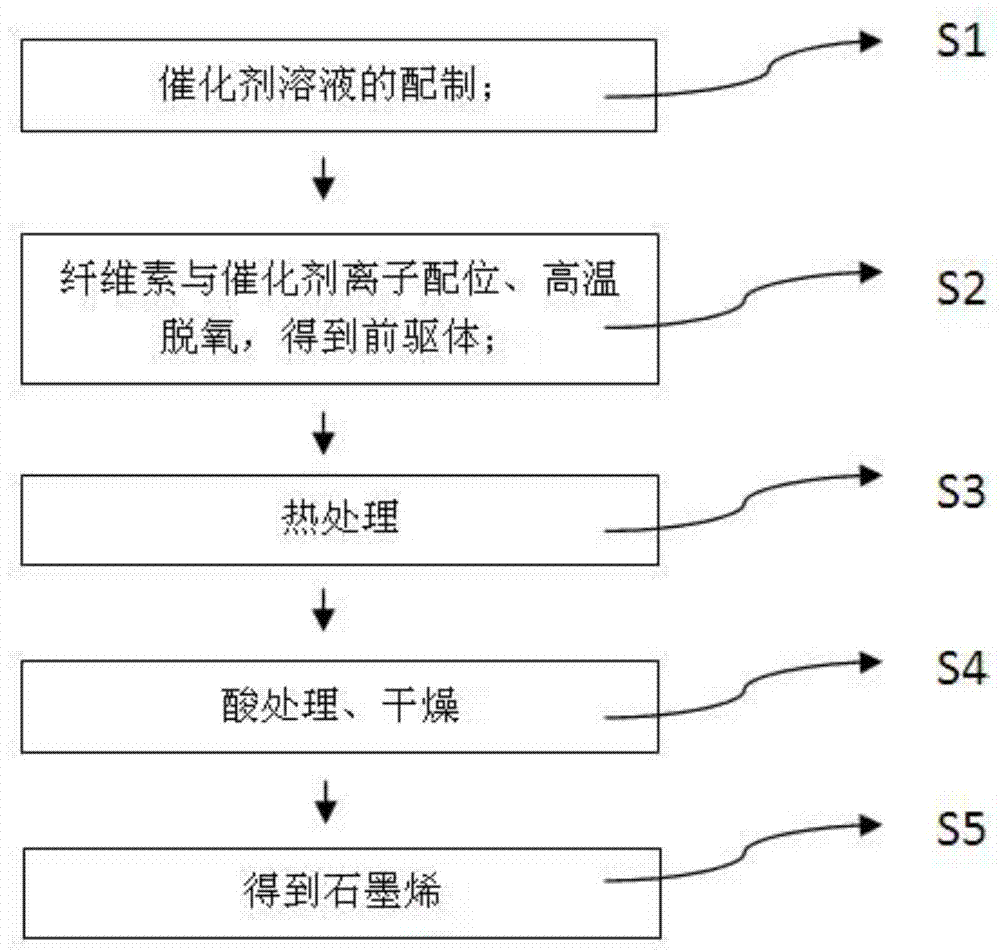

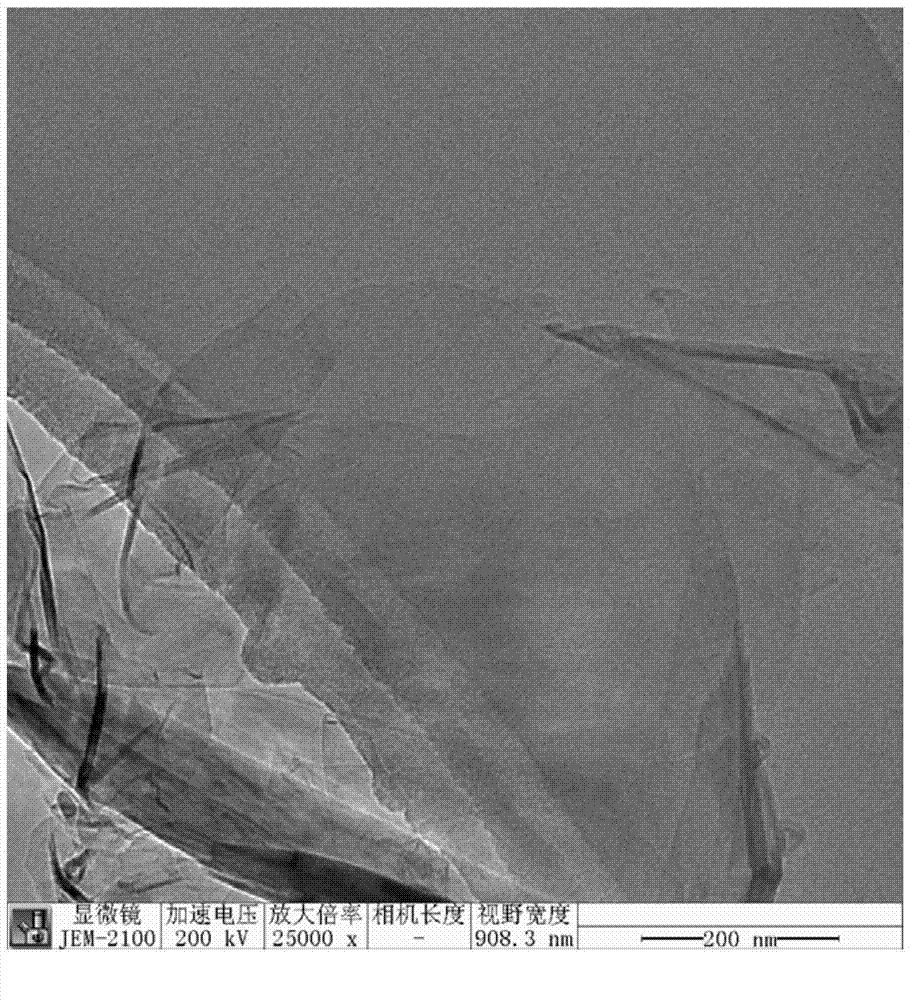

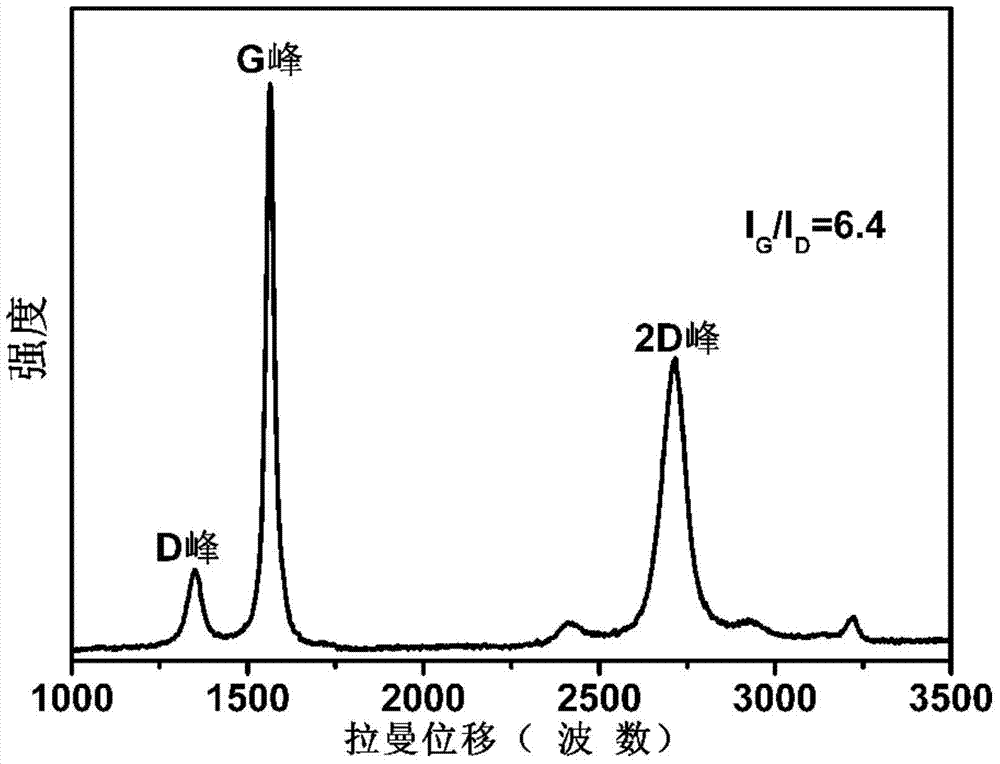

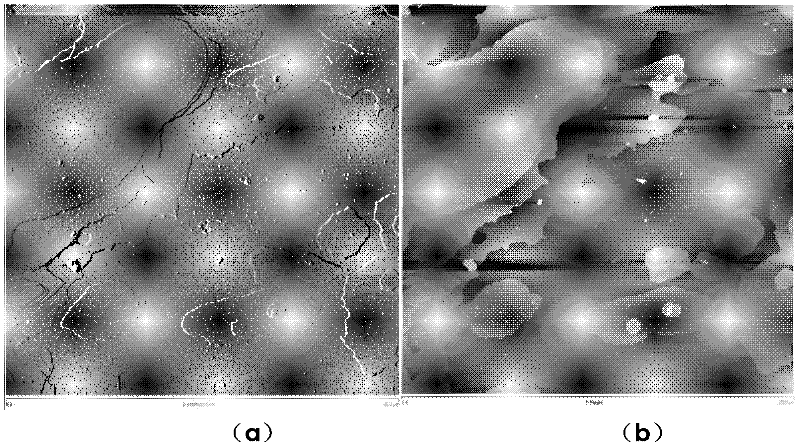

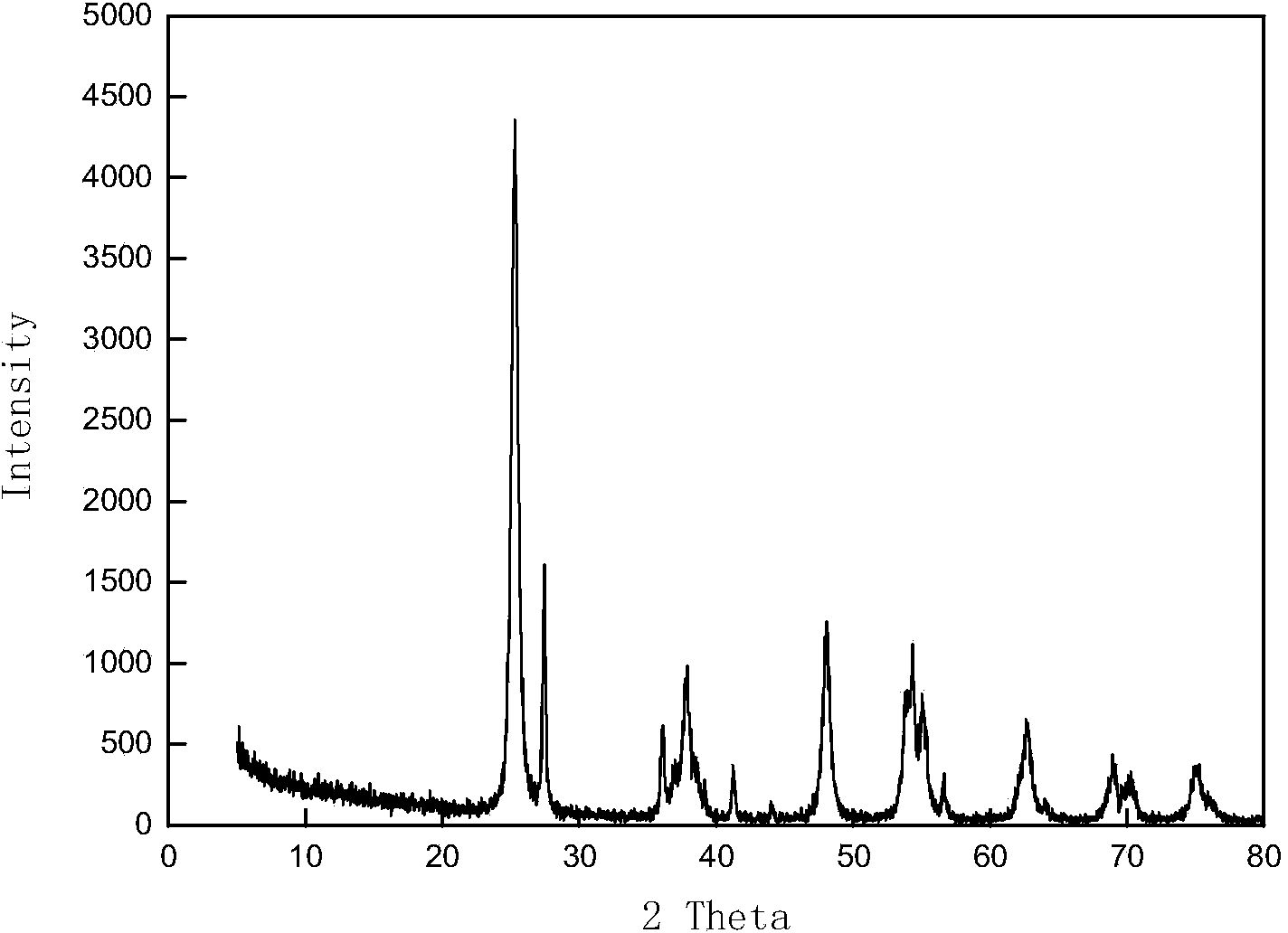

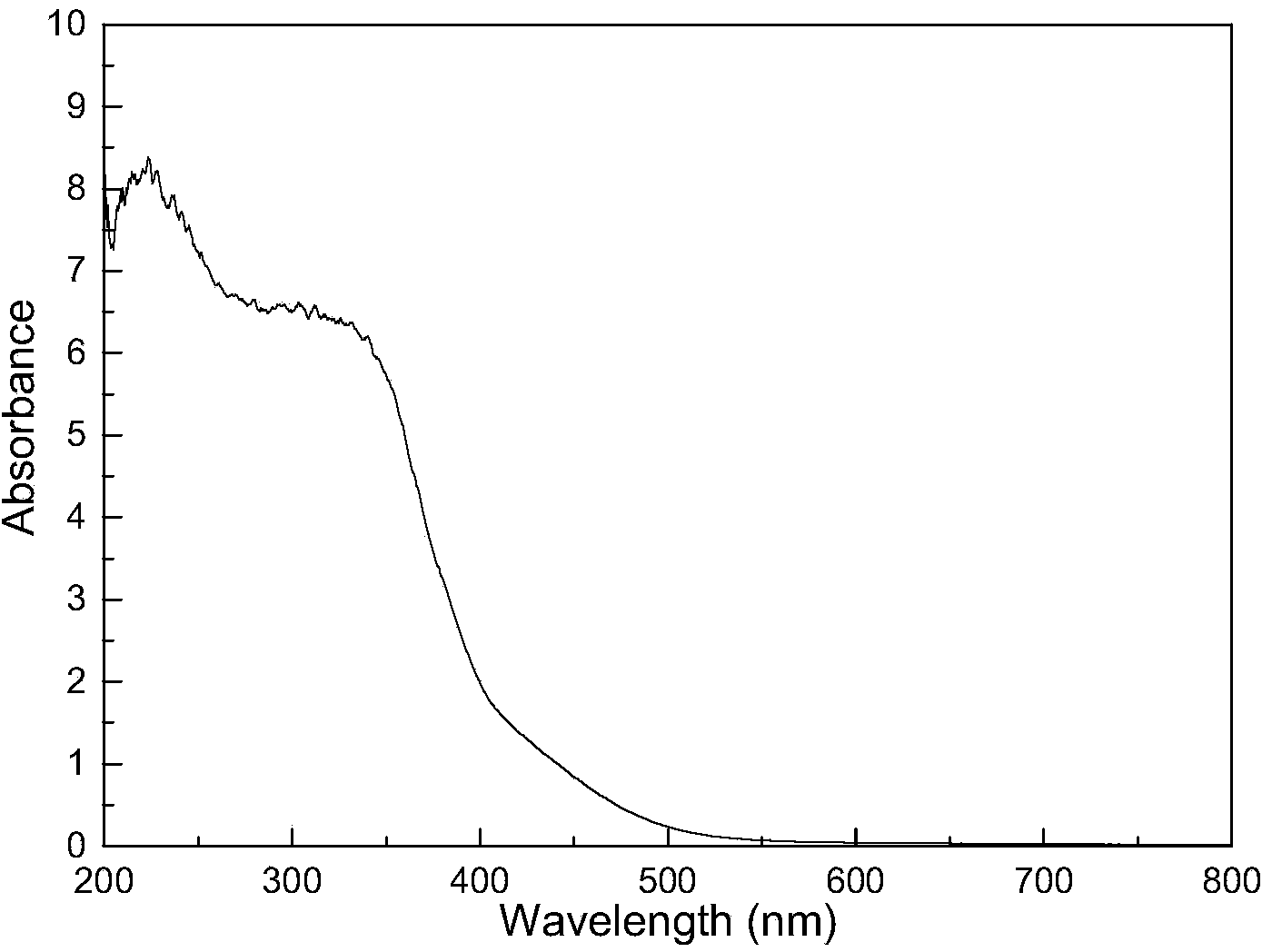

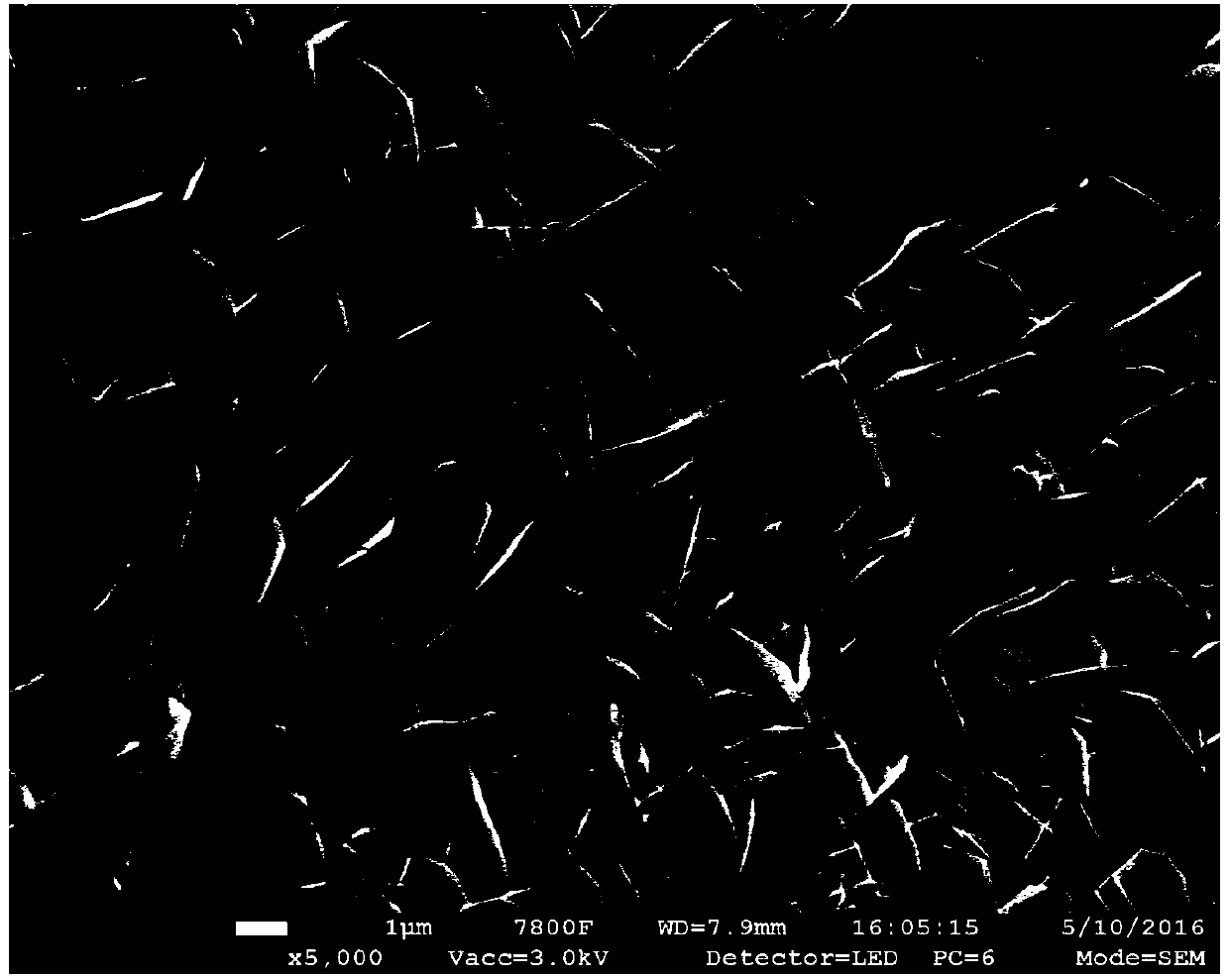

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

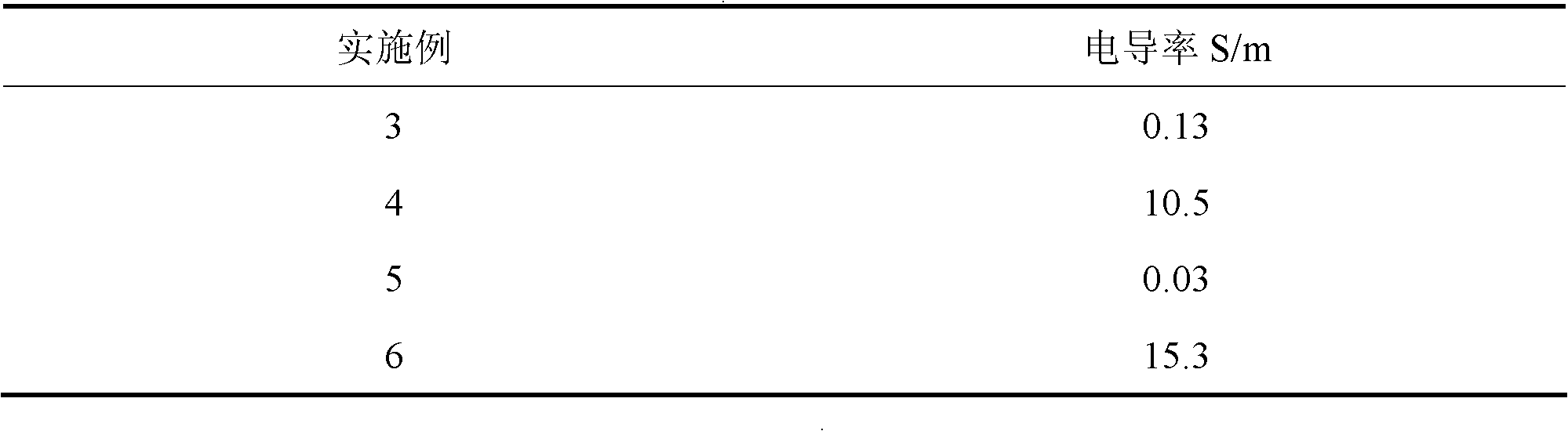

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

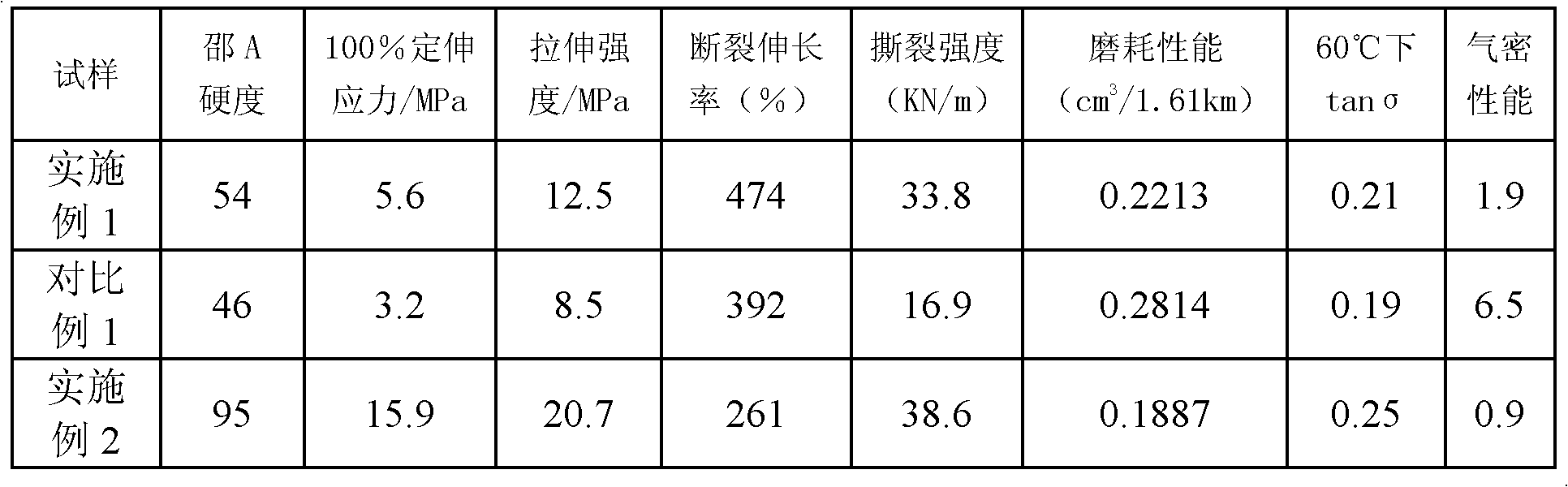

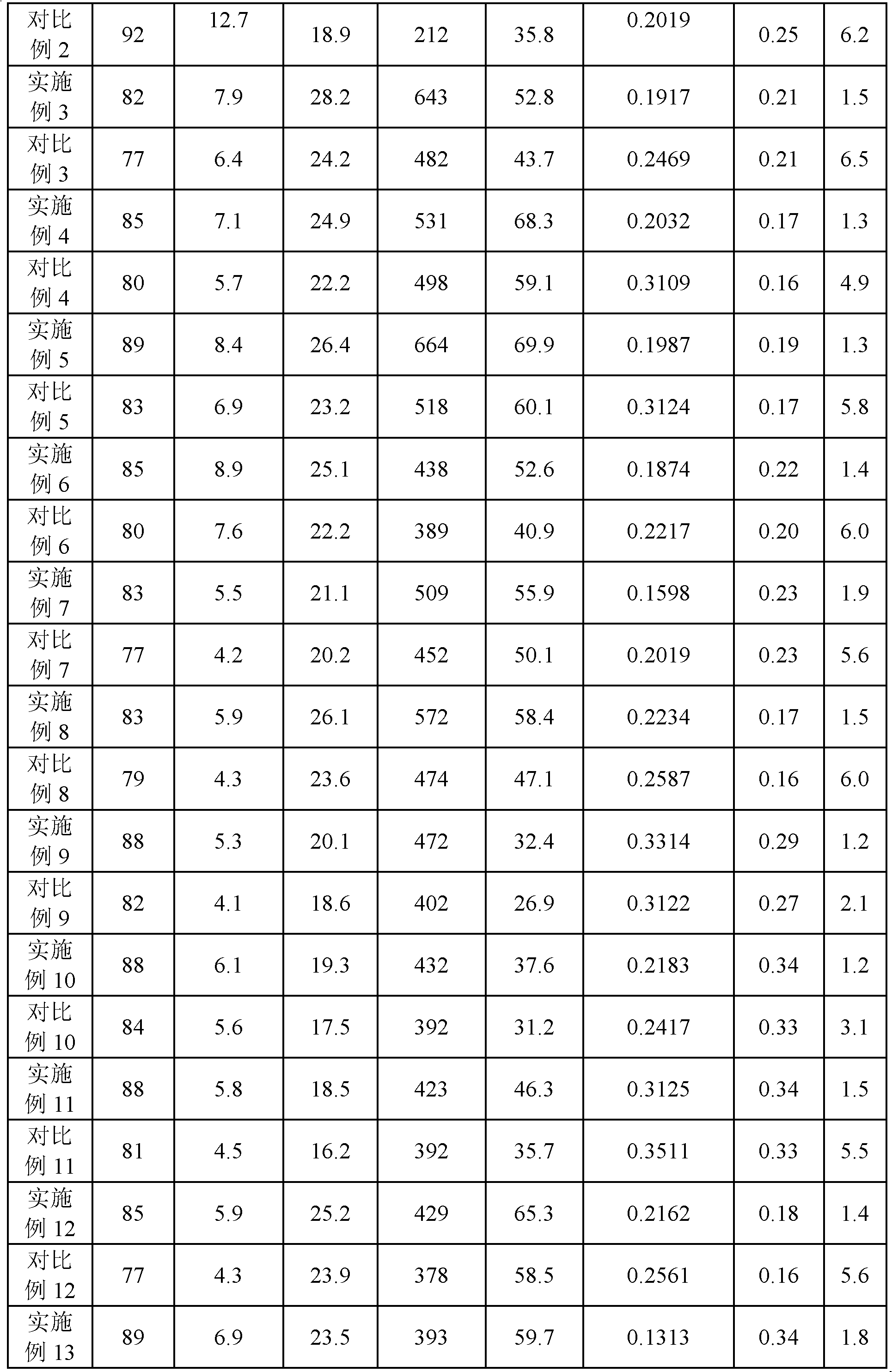

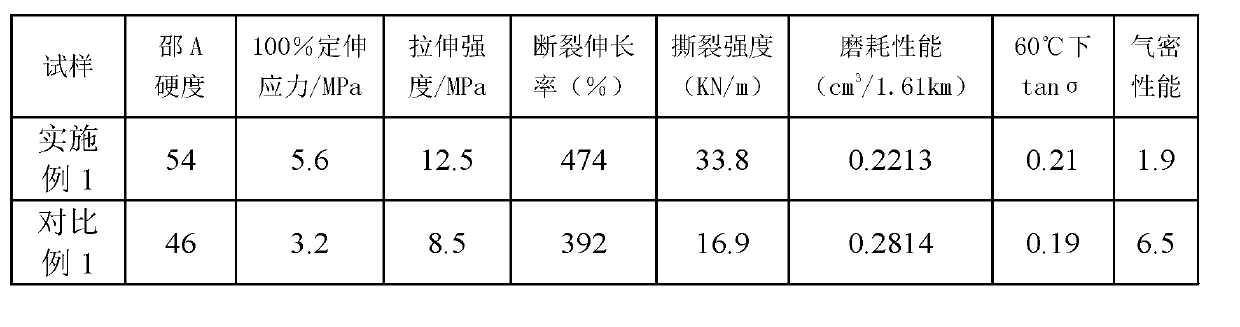

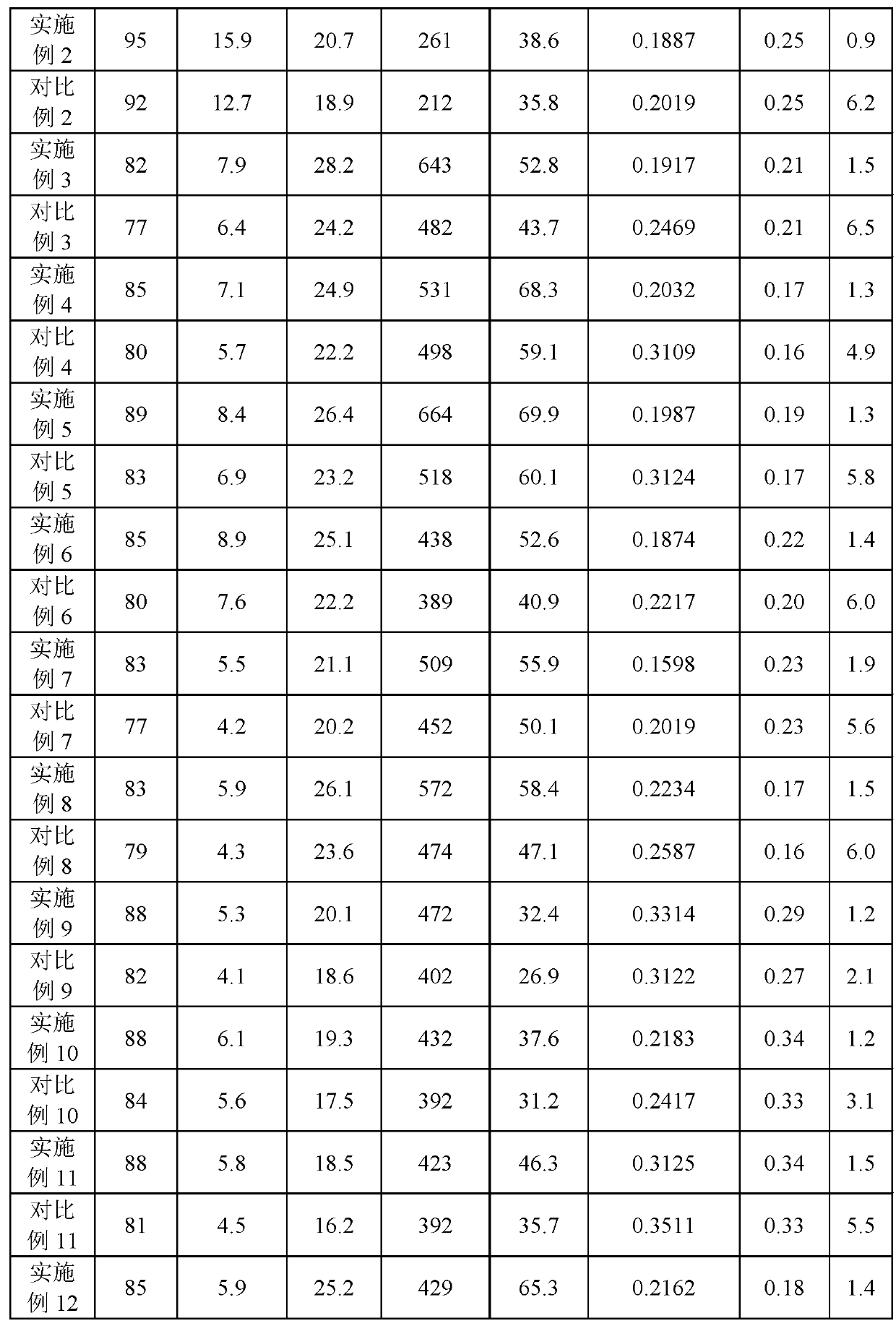

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

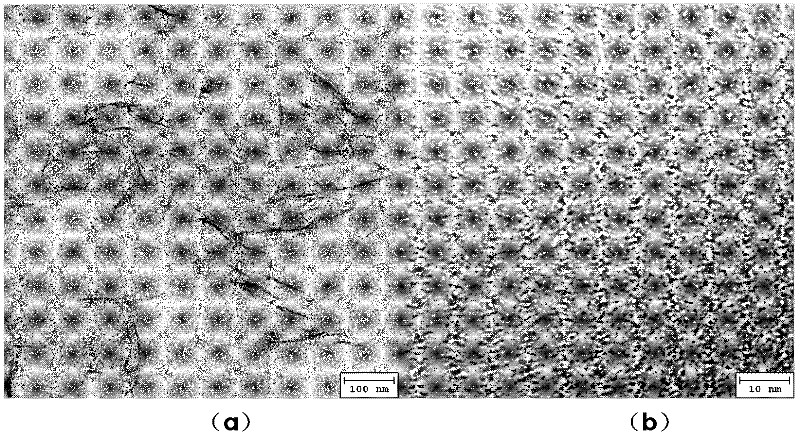

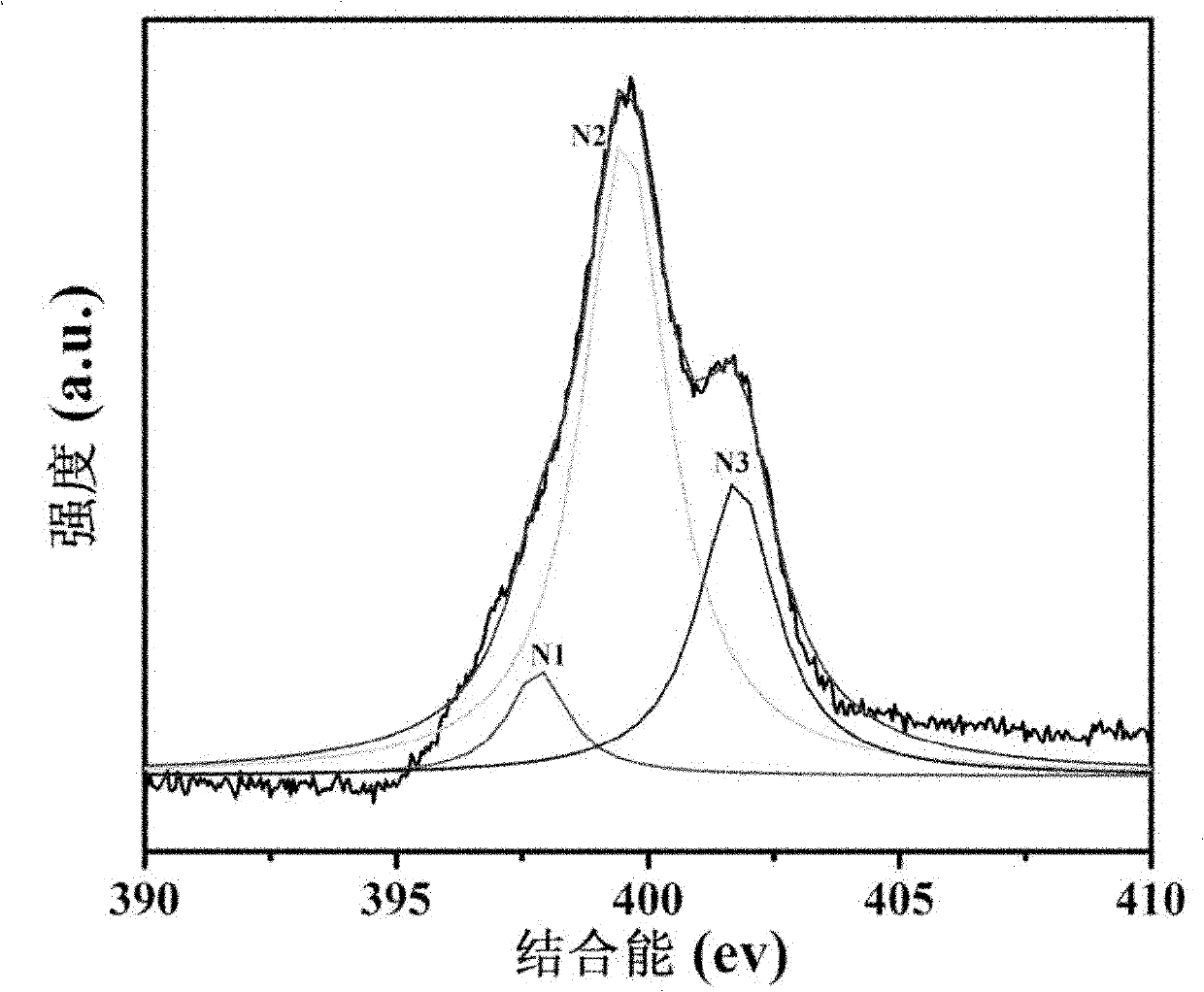

Method for preparing nitrogen-doped graphene material with hydrothermal process

The invention discloses a method for preparing a nitrogen-doped graphene material with a hydrothermal process, relating to a method for preparing the nitrogen-doped graphene material. The technical problems of lower nitrogen content, difficulty in control of nitrogen content, high production cost, complex structure of equipment required by reaction, rigorous reaction conditions, low yield, difficulty in industrialized production and the like in the traditional method for preparing the nitrogen-doped graphene material are solved in the invention. The method comprises the steps of: 1, dissolving graphite oxide in a solvent, adding a surfactant and uniformly mixing; 2, adding a nitrogen-containing compound, and uniformly mixing; and 3, after a hydro-thermal reaction, washing and drying to obtain the nitrogen-doped graphene material. The nitrogen-doped graphene material prepared in the invention has the advantages of higher nitrogen content, controllable nitrogen content, low production cost, simple structure of required equipment, high yield and easiness in realizing industrialized production.

Owner:HEILONGJIANG UNIV

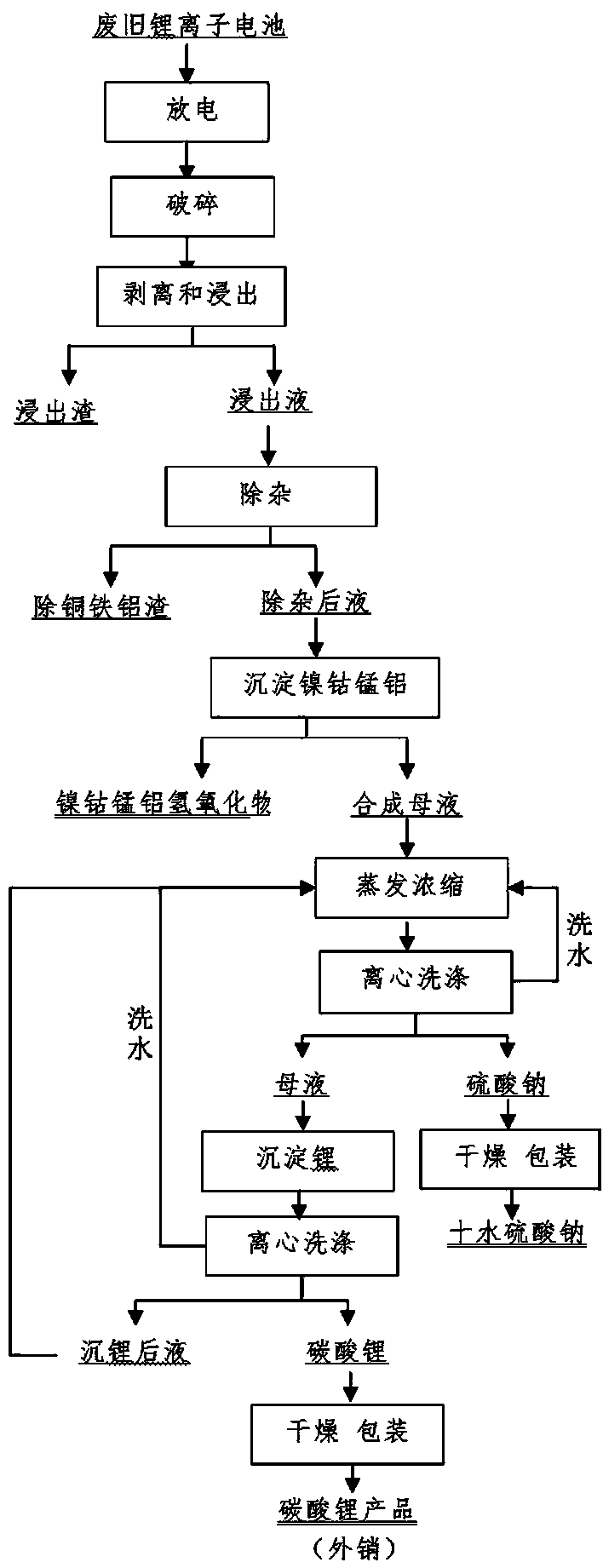

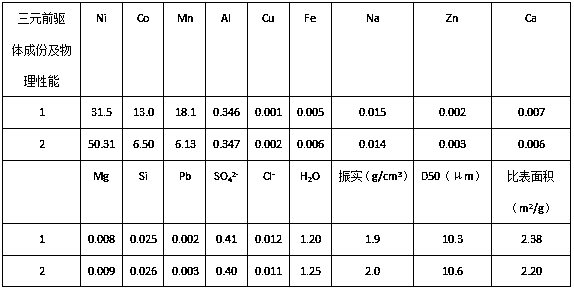

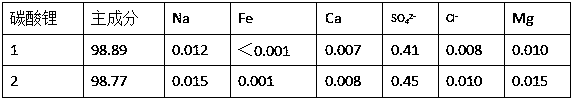

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

Preparation method of graphene/polymer nano composite material

ActiveCN102161785AEvenly dispersedGood mechanical propertiesOther chemical processesMagnetic/electric field screeningUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a graphene / polymer nano composite material, which is characterized by comprising the following steps: adding 0.1-30 parts by weight of graphite oxide into 10-3000 parts by weight of water, and dispersing and exfoliating by carrying out ultrasonic dispersion (the power is 50-500W, and the frequency is 10-100000Hz) at 10-100 DEG C for 15 minutes-5 hours or mechanical lapping for 15 minutes-5 hours or mechanical stirring for 1-48 hours to obtain a graphene oxide water solution; adding the graphene oxide water solution into 100 parts by weight of polymer emulsion of which the solid content is 10-70%; continuing the ultrasonic or mechanical stirring to carry out uniform mixing; demulsifying by adding 1-100 parts by weight of 5-100% demulsifier toobtain a graphene oxide / polymer granular suspension; adding 0.1-100 parts by weight of reducer into the graphene oxide / polymer granular suspension, reducing at 20-100 DEG C for 1-72 hours, filtering,and drying in a drying oven at 20-100 DEG C for 2-72 hours or drying in a vacuum drying oven at 20-120 DEG C under a vacuum degree of 0.1-0.01 MPa for 2-48 hours, thereby obtaining the graphene / polymer nano composite material.

Owner:SICHUAN UNIV

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Super-hydrophobic and super-oleophobic surface preparation technology

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

Carboxymethyl chitosan / oxidized sodium alginate self-crosslinking antibacterial hydrogel material

InactiveCN101463145AStrong antibacterial abilityGood biocompatibilityAbsorbent padsBandagesChemistryBiocompatibility Testing

The invention discloses a self-crosslinking antibacterial hydrogel material containing carboxymethyl chitosan / oxidized sodium alginate. The material is made from the following components by mass percent: 1-35% of carboxymethyl chitosan, 1-25% of oxidized sodium alginate, 0.01-0.5% of nano-silver and distilled water. The material is prepared by the following steps: preparing the carboxymethyl chitosan by a carboxymethylation reaction of chitosan at the temperature of 10-80 DEG C; preparing the oxidized sodium alginate by an oxidation reaction of sodium alginate at the temperature of 10-45 DEG C; respectively preparing aqueous solution of the carboxymethyl chitosan and aqueous solution of the oxidized sodium alginate; adding the nano-silver solution and blending at certain ratio; and allowing self-crosslinking of the components at the temperature of 10-50 DEG C to produce the antibacterial hydrogel material. The antibacterial hydrogel material has the advantages of low cost, environmental protection, simple process and the like; as the carboxymethyl chitosan has good biocompatibility, the oxidized sodium alginate is nontoxic to human body, and the nano-silver has excellent antibacterial property, the obtained material can be applied to wound dressing, hemostatic materials and the like.

Owner:WUHAN UNIV OF TECH

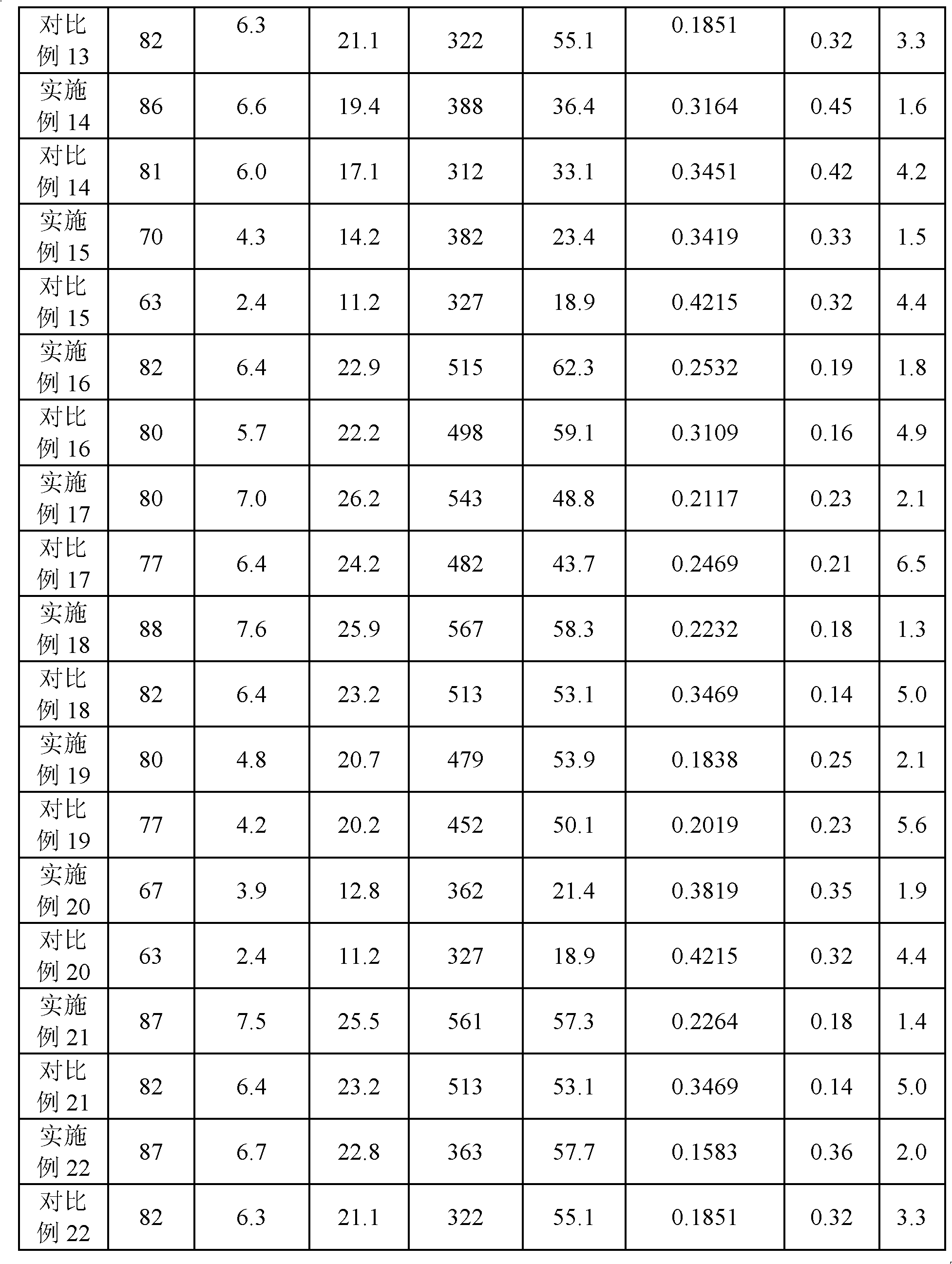

Cellulose aerogel and preparation method for hybrid aerogel thereof

The invention discloses low-cost green cellulose aerogel and a preparation method for hybrid aerogel thereof. The preparation method for the hybrid aerogel of the cellulose aerogel comprises the following steps that cellulose is dissolved into a zinc chloride aqueous solution, centrifugal deaeration is performed, and a uniform and transparent cellulose solution is obtained; the cellulose solution is formed, then the formed cellulose solution is placed into a coagulating bath to be regenerated, in addition, the regenerated cellulose solution is fully washed by use of a solvent, and cellulose solvent gel is obtained; the solvent in the cellulose solvent gel is removed by use of supercritical carbon dioxide drying or freeze drying, and the cellulose aerogel is obtained. Functional filler can be added into the cellulose solution to obtain the hybrid aerogel. By the adoption of different solution forming methods, the cellulose aerogel and the hybrid aerogel thereof in the shapes of sheets, fibers, particles and the like can be prepared. The preparation method is low in cost and is environmentally friendly, and the prepared aerogel is provided with a uniform nano-grade net porous structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

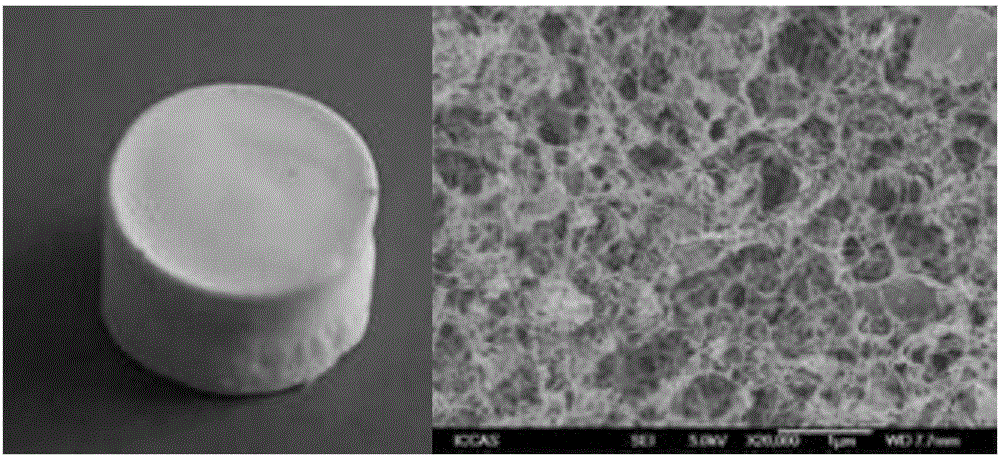

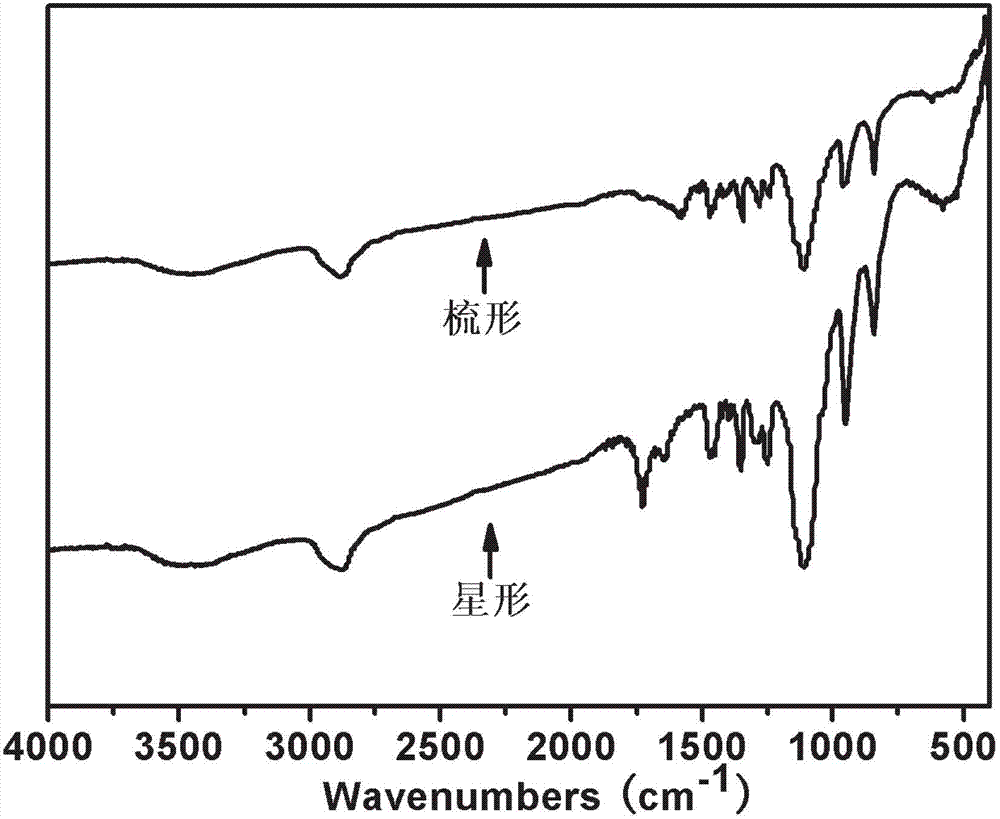

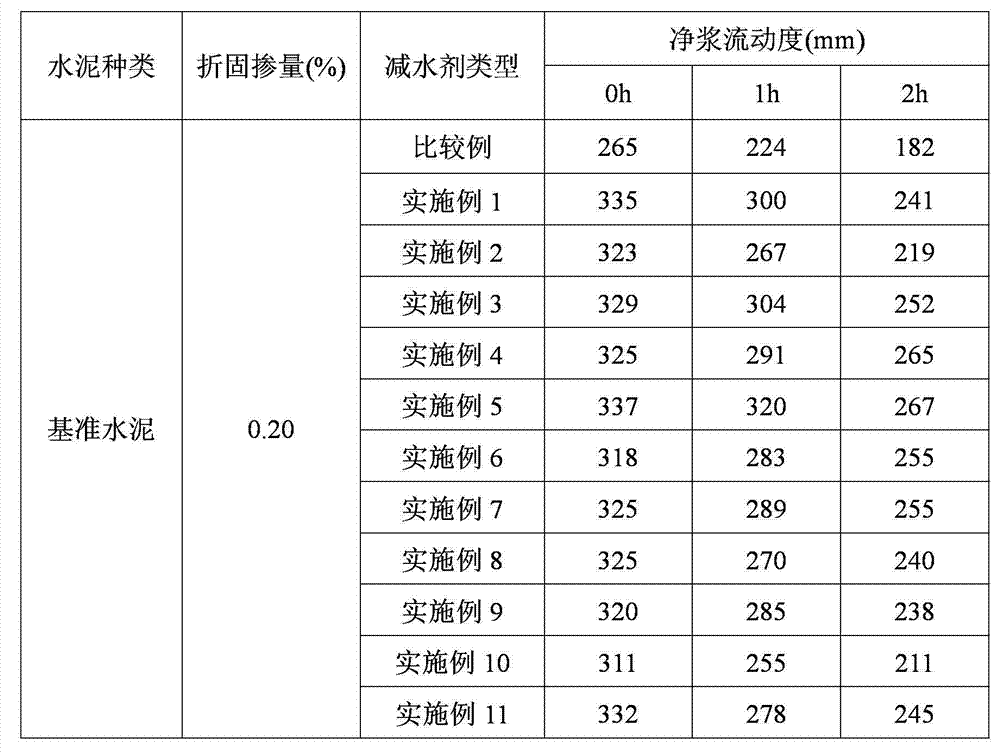

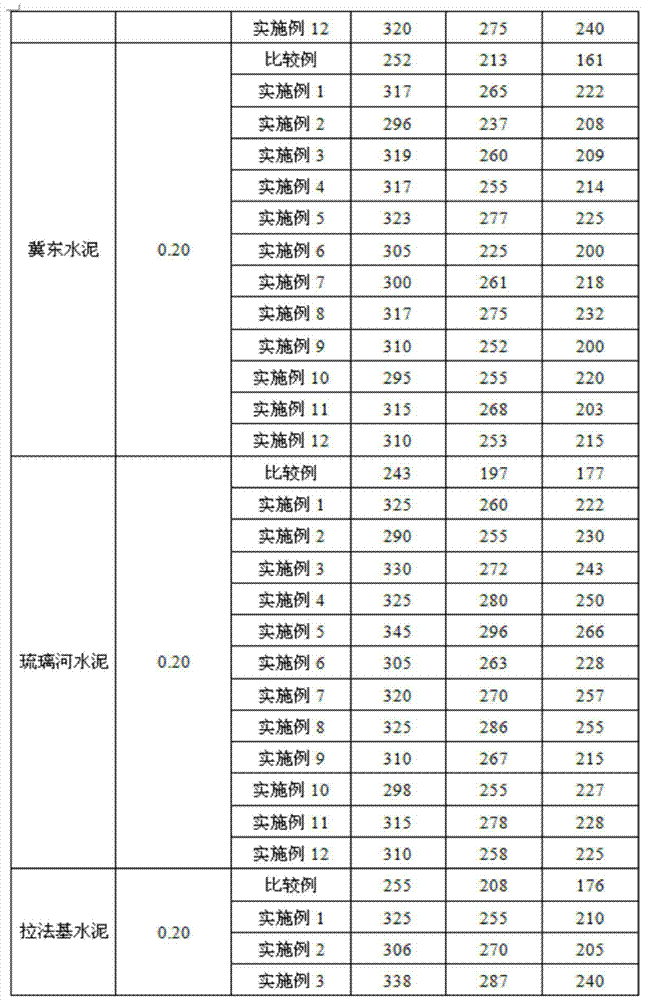

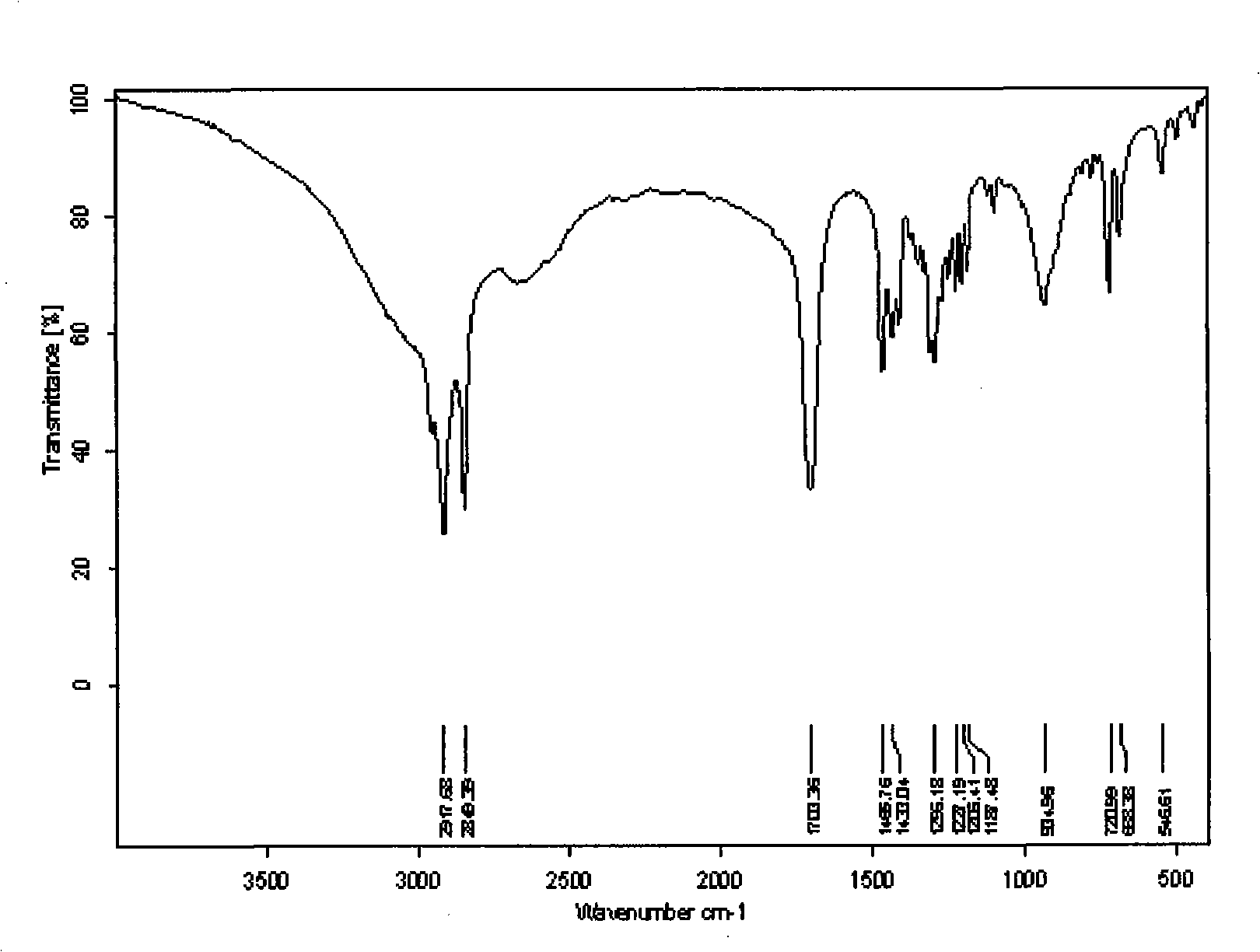

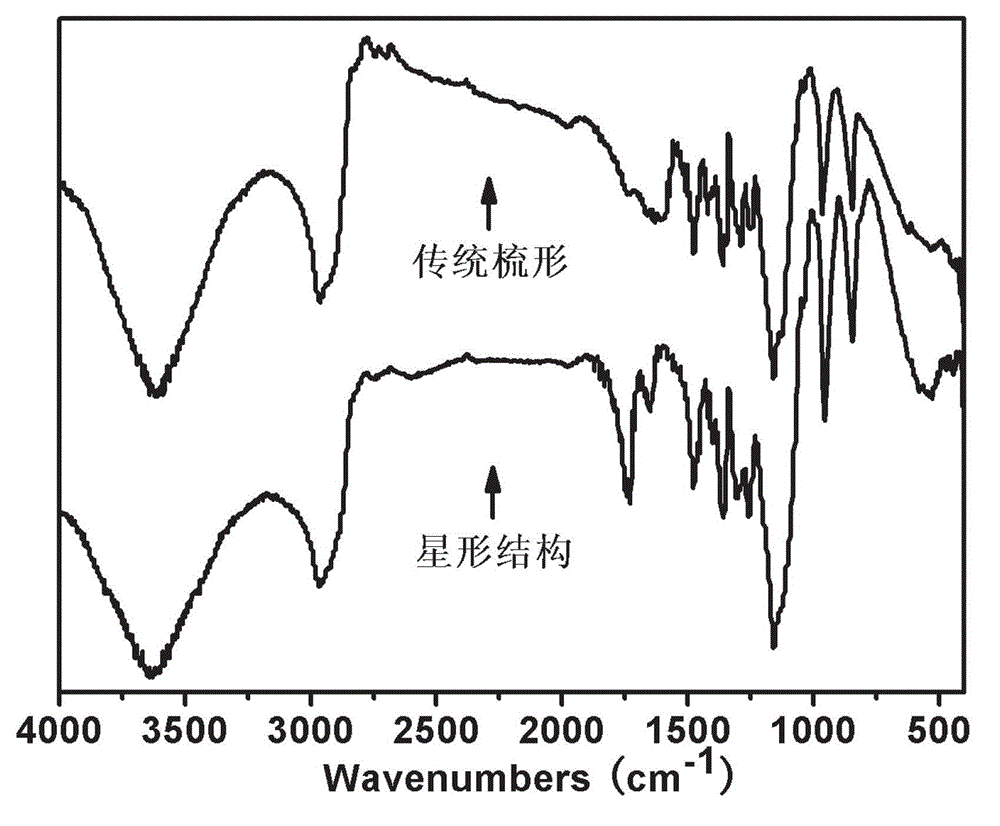

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

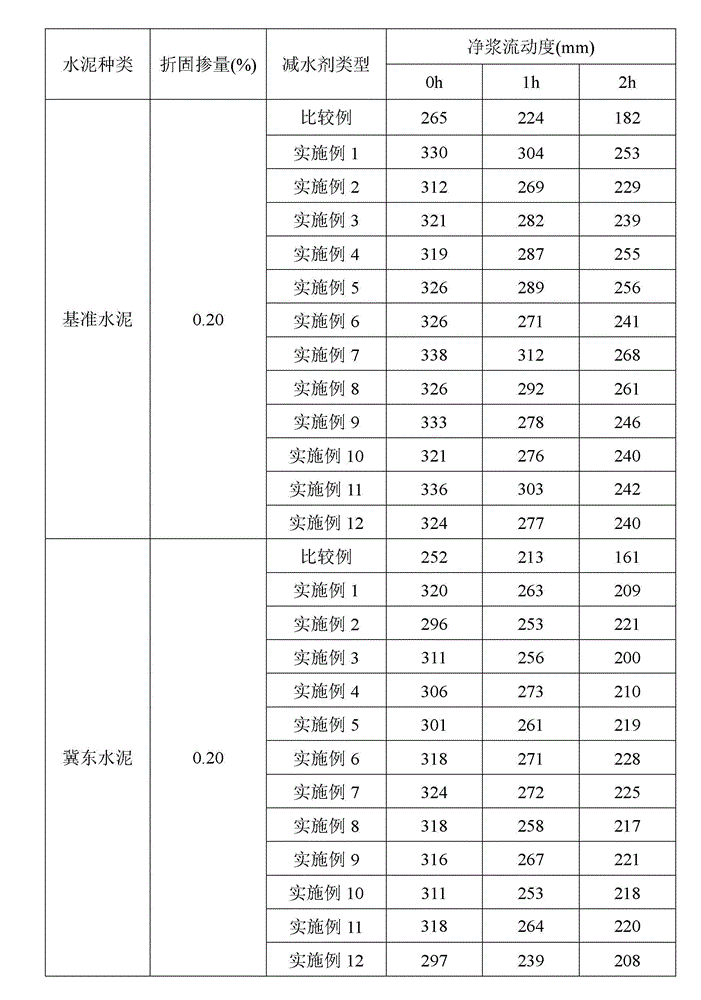

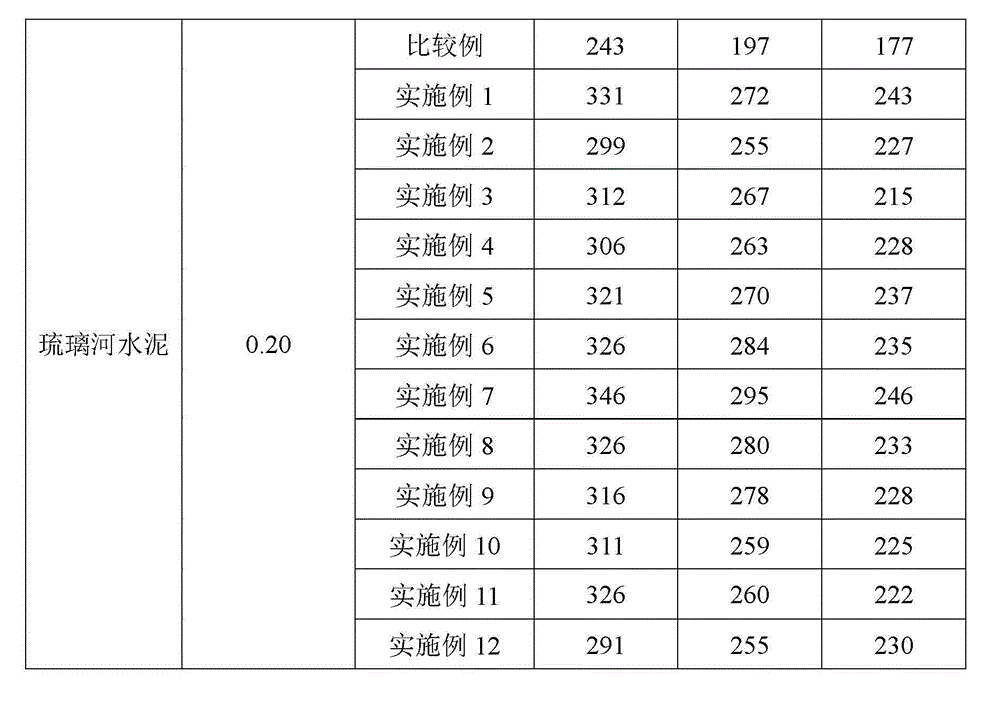

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

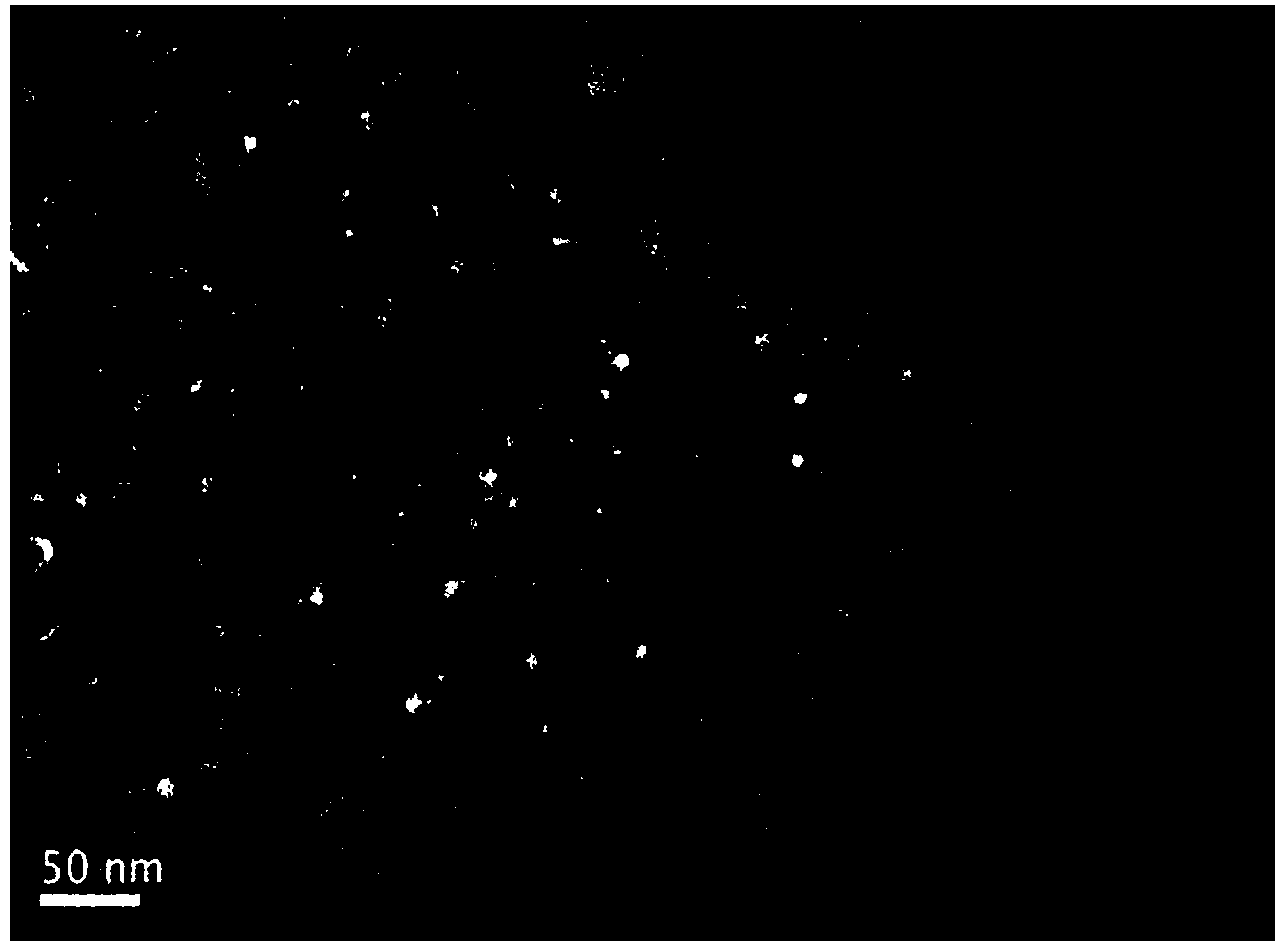

Method for preparing TiO2/g-C3N4 composite visible light catalyst

ActiveCN104307552ASimple processMany photocatalytic active centersPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationMuffle furnace

The invention discloses a method for preparing a TiO2 / g-C3N4 composite visible light catalyst. The method comprises the following steps: firstly, uniformly dispersing a titanium source and a nitrogen source in ethanol, and subsequently dropping water into ethanol so as to obtain a mixed material; evaporating to dry the mixed material in a stirring state so as to obtain a precursor; transferring the prepared precursor to a muffle furnace, and calcining for 0.5-12 hours at 300-800 DEG C in the muffle furnace, thereby obtaining the TiO2 / g-C3N4 composite visible light catalyst. The TiO2 / g-C3N4 composite visible light catalyst can be prepared while TiO2 and g-C3N4 are prepared, and the synthesis of the two compounds TiO2 and g-C3N4 and the preparation of the composite visible light catalyst are achieved at one step; the process is simple, and industrialization production is easy to achieve. The composite visible light catalyst disclosed by the invention is rich in photocatalytic activity center, relatively high in both light absorption rate and photocatalytic activity, and relatively high in photocatalytic degradation rate of organisms.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

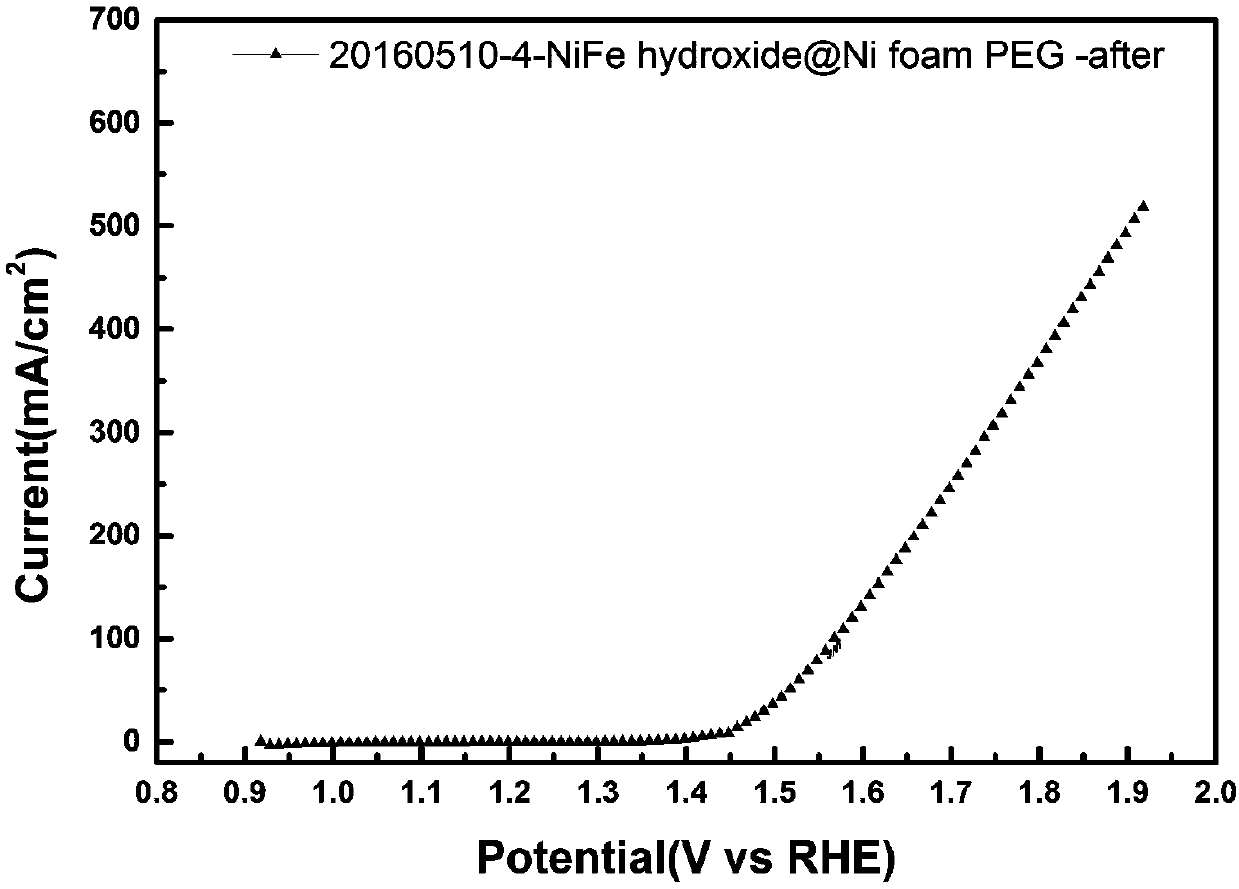

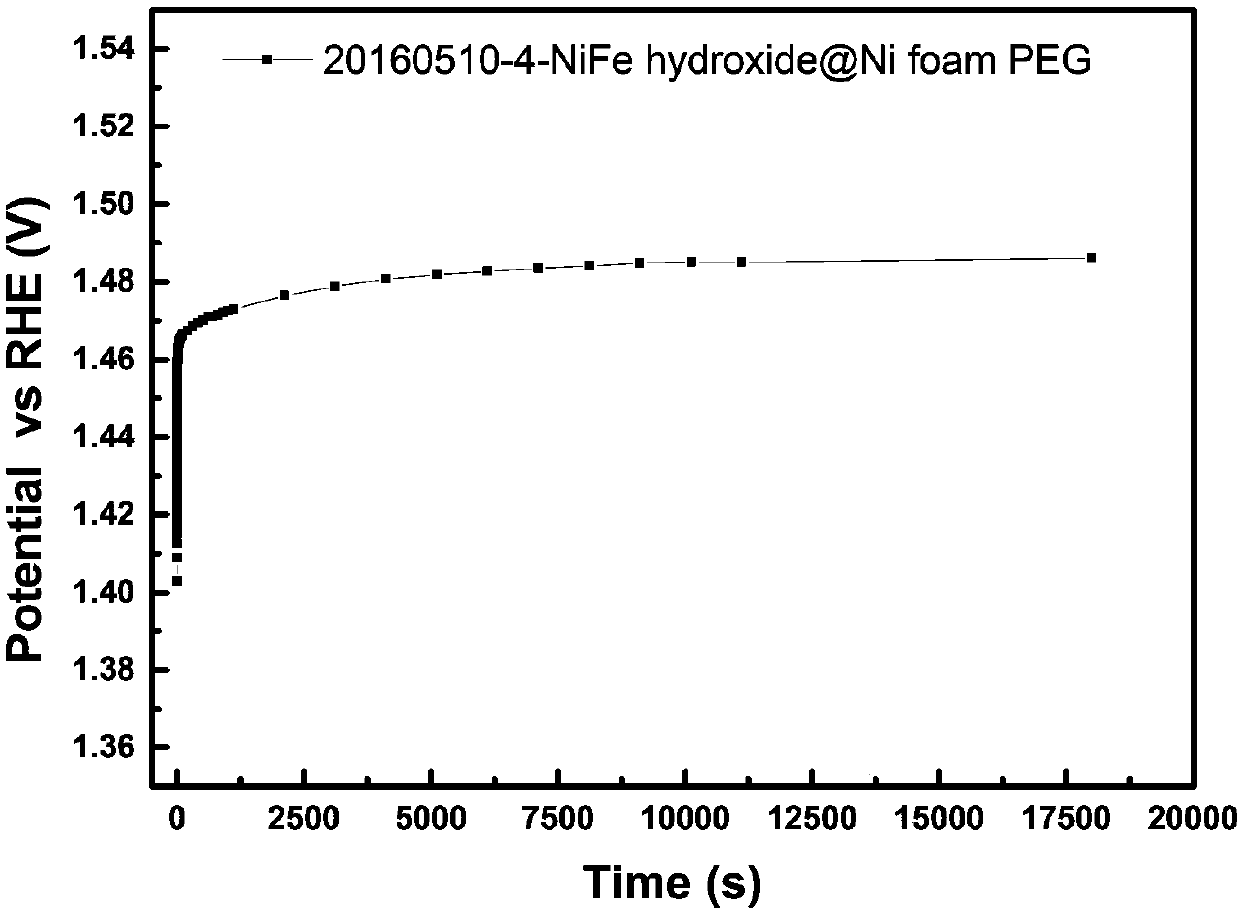

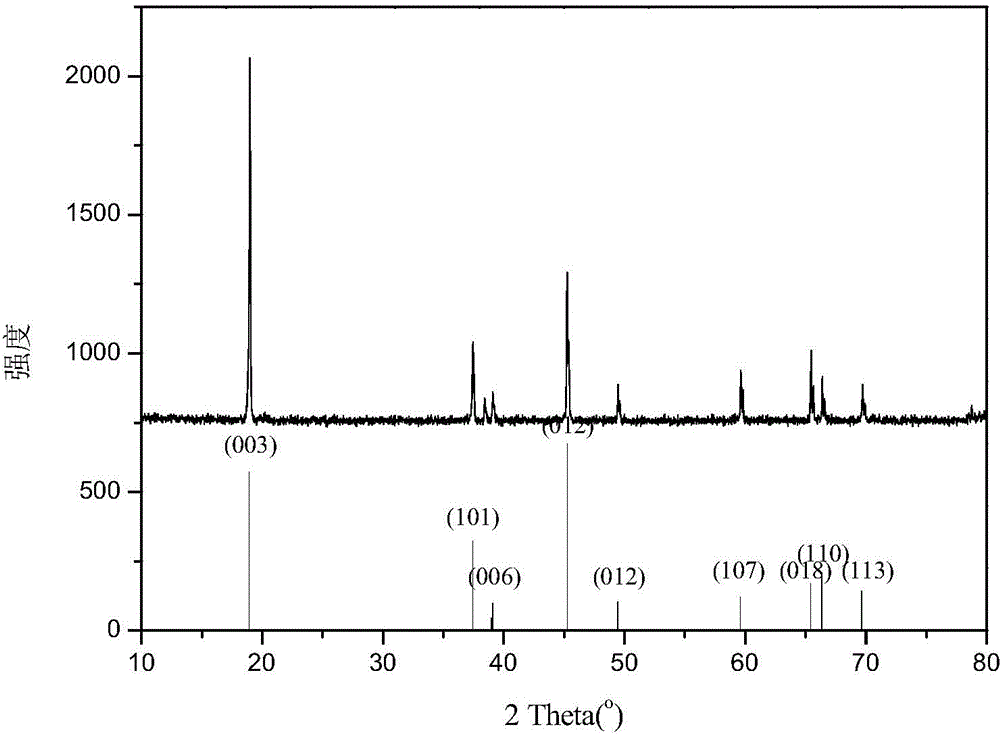

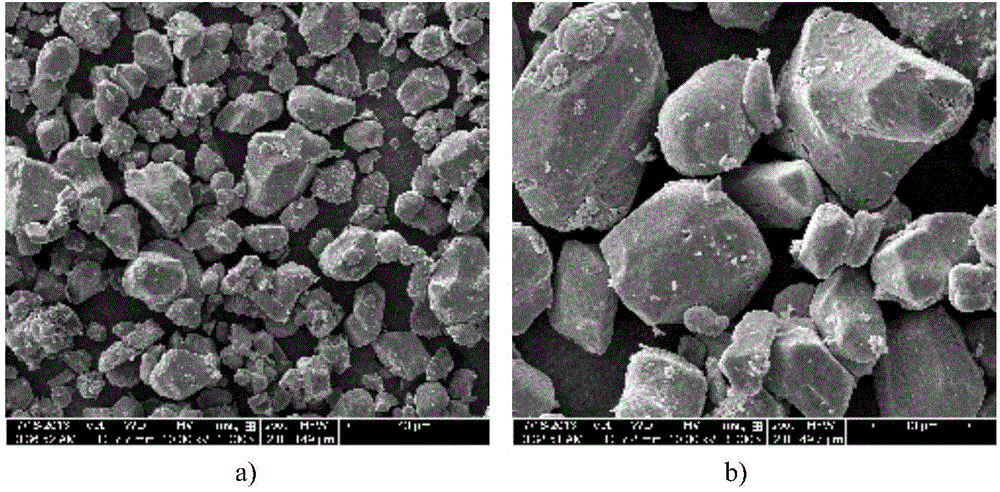

Hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode and preparation method and application thereof

InactiveCN107620087AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisExternal bias

The invention relates to a hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode applicable to alkaline mediums and a preparation method and application thereof. The electrode is applicable to the oxygen evolution reaction in the water-electrolytic hydrogen making process under catalytic alkaline conditions. The hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode and the preparation method and application thereof have the advantages as follows: the nickel-iron hydroxide integrated electrode is shape-controlled, the preparation process is simple and under mild conditions, and the electrode can be used for a water electrolytic tank for hydrogen production from water splitting under external bias potentials; the prepared hydroxyloxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode further has a better performance when being used in an alkaline solid polymer electrolyte (AEM) water electrolytic tank; and besides, an extensive utilization value in achieved in regenerative fuel cells (RFC), photoelectro-catalytic devices and electrolytic hydrogen generators.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

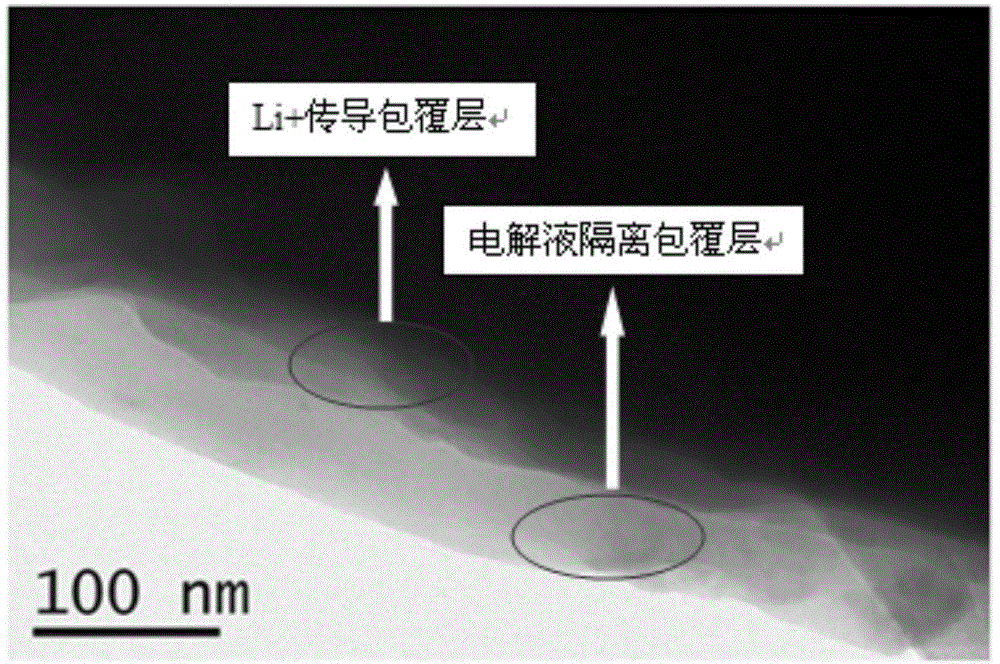

Surface-modified lithium cobaltate material and preparation method thereof

ActiveCN103606674AHigh discharge specific capacityLess side effectsCell electrodesLithiumDouble coating

The invention discloses a surface-modified lithium cobaltate material and a preparation method thereof. The lithium cobaltate material comprises a core particle and a surface-modified layer coating the core particle, wherein the core particle is a lithium cobaltate-based positive material with a structural formula as follows: LixCo(1-y)MyO2, wherein x is greater than 1 and not greater than 1.2, y is not less than 0 and not greater than 0.1, M is a doping element; the surface-modified layer comprises a Li<+1> conducting layer and an electrolyte isolating layer; the core particle is coated by the Li<+1> conducting layer and the electrolyte isolating layer in sequence. According to the invention, by sufficiently utilizing dynamic characteristic that different substances react with residual Li salt on the surface of the lithium cobaltate, and characteristic of final reaction product performance, the lithium cobaltate material with double coating layers is prepared. The material is high in comprehensive performances, has high discharge capacity, high cycling stability and the like. The preparation method disclosed by the invention is simple in process and easily realizes industrial production.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

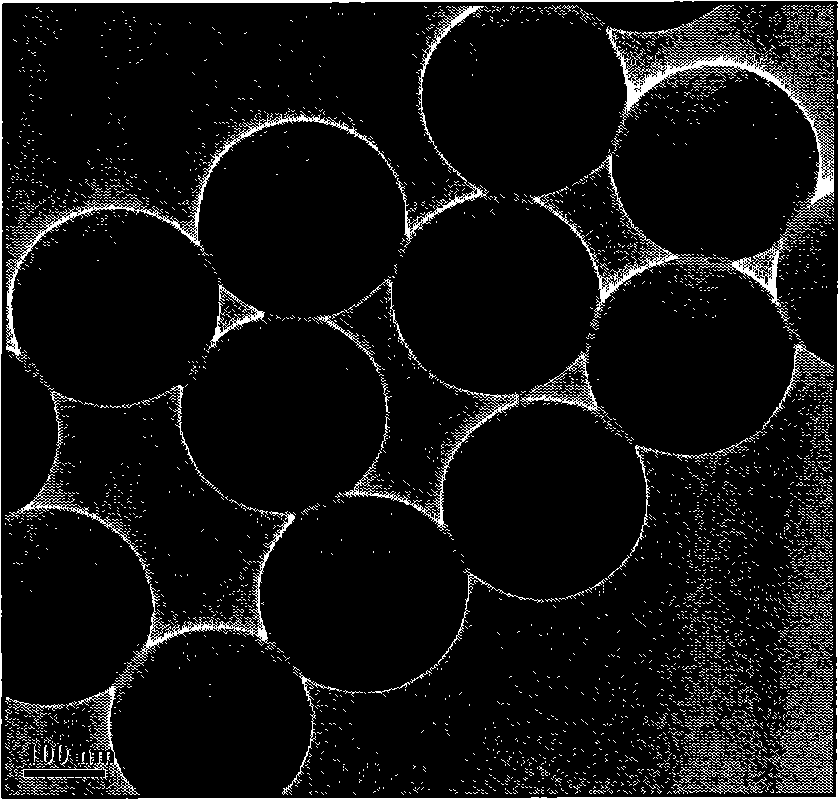

Sol-gel method for preparing earth silicon/titanic oxide hollow microballoon

InactiveCN101274246AFlexible production processRaw materials are cheap and easy to getMicroballoon preparationMicrocapsule preparationPolystyrene microsphereSol-gel

The invention provides a method for preparing an SiO2 / TiO2 hollow microsphere by a sol-gel method. The method is mainly characterized in that cation polystyrene microsphere (PS) is used as a formwork; ethyl silicate and butyl titanate are respectively used as raw material and diluted ammonia is taken as regulator of pH value; a multi-layer organic-inorganic hybrid composite microsphere is obtained by the sol-gel reaction under the temperature of 70-80 DEG C. Formwork particle of the obtained deposition is removed by a calcining process to obtain the SiO2 / TiO2 hollow microsphere. By changing the consistency of reactant, content of surfactant and calcining temperature, the SiO2 / TiO2 hollow microsphere with different spherical shell thickness, density and grain size can be obtained. The hollow microsphere prepared by the method has high photo-catalytic activity, overcomes the shortage that existing preparation method of hollow microsphere can only prepare single shell layer microsphere; the multi-layer hollow microsphere can be prepared, the technique is simple, the cost is low and the preparation method of the invention is suitable for industrialized production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of sulfur-active carbon/graphene composite material

ActiveCN106602013AWide variety of sourcesEasy to prepareCell electrodesLi-accumulatorsActivated carbonSulfur

The invention discloses a preparation method of a sulfur-active carbon / graphene composite material. The preparation method comprises the following steps of (1) pre-processing a biomass raw material; (2) mixing the pre-processed biomass raw material, graphene and an activating agent to form a solid mixed material; (3) performing activation, washing, solid-liquid separation and drying on the solid mixed material to obtain an active carbon / graphene composite material; and (4) combining the active carbon / graphene composite material with sulfur to obtain the sulfur-active carbon / graphene composite material. The composite material provided by the invention has the advantages of simple preparation process step, high efficiency and low energy consumption, and production on a large scale can be achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing conductive composite material by utilizing synergistic reaction of conductive filling material

InactiveCN101240091AImprove efficiencyImprove electrical performanceNon-conductive material with dispersed conductive materialFiberCarbon fibers

A preparation of electric conductive composite by synergism of conductive filler, particularly relates to a preparation of electric conductive composite by synergism between carbon nano-tube and conductive carbon filler. The preparation is characterized by using processing apparatus for high-molecular material to melt mix and granulate after mixing polymer, carbon nano-tube, carbon black, black lead, carbon fiber according to a definite ratio. The preparation is simple to operate, easy for application in industry, can further produce electric conductive composite with great electric conductivity and combination property, which can be widely used in automobile, electric and electronic apparatus, office equipment, industrial mechanism, and can satisfy and expand need of high-molecular materials in various application fields.

Owner:TSINGHUA UNIV

Gas pipeline drag reducer and preparation thereof

The invention relates to a gas pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The gas pipeline drag reducer is characterized in that: the drag reducer is synthesized by long-chain acid and enamine according to a molar ratio of between 1:1 and 2.2:1. The preparation method comprises the following steps that: the long chain acid in proportional quantity is added in a reaction container; a heater is started so as to carry out heating while stirring; when temperature reaches to 100 DEG C, the long chain acid is melted, and the enamine in proportional quantity is added at the same time; nitrogen is fed in to carry out protection, and the mixture is preheated to between 120 and 140 DEG C; after preheating is finished, programmed heating is carried out till temperature is increased to between 210 and 220 DEG C; a stirrer is removed and a vacuum pump is connected to carry out evacuation for 2 to 4 hours; when reaction is finished, brown solid crude product can be obtained after cooling down. The gas pipeline drag reducer has obvious drag reduction effect on gas pipelines, direct source of raw materials, simple operation, moderate reaction conditions, relatively simple process and low requirements on equipment, and is easy to realize large-scale industrialized production.

Owner:PETROCHINA CO LTD

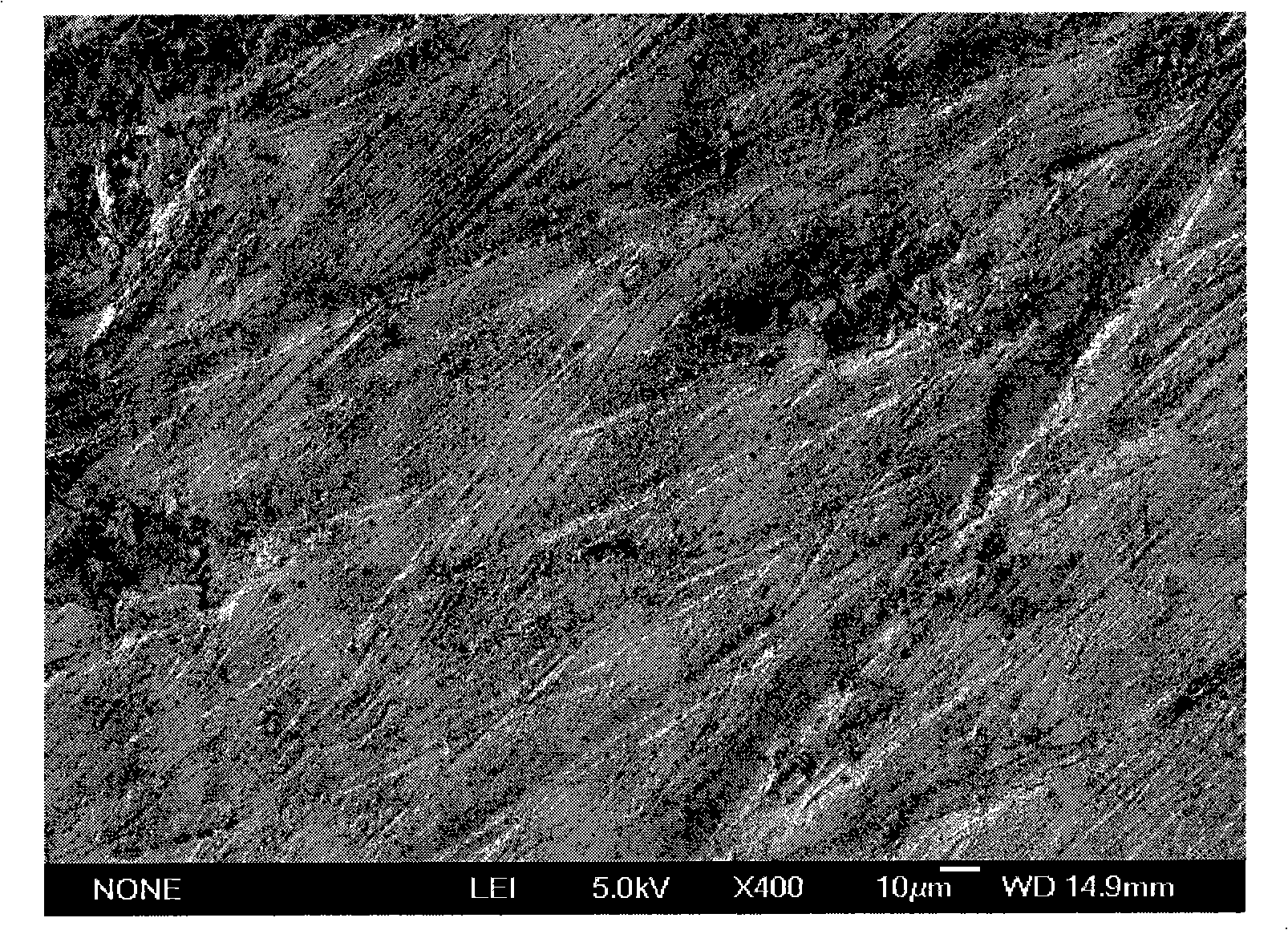

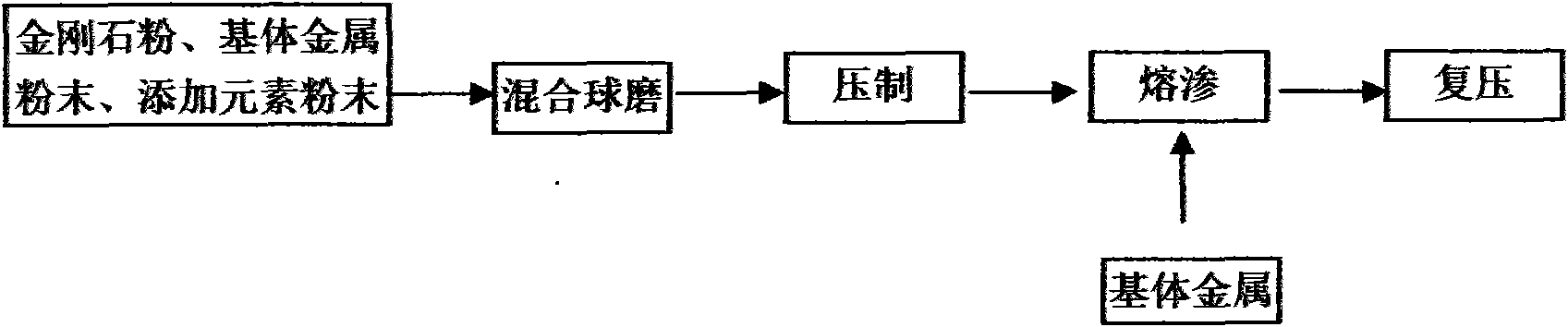

Diamond reinforced metal-base composite material for electronic packaging and preparation method thereof

ActiveCN101649400AImprove wettabilityImprove thermal conductivitySemiconductor/solid-state device manufacturingThermal expansionMetal matrix composite

The invention discloses a diamond reinforced metal-base composite material for electronic packaging and a preparation method thereof. The material comprises the following components by volume percent:30%-90% of diamond, 0.1%-5% of addition element and 10%-70% of metal substrate, wherein the addition element comprises one or more of Zr, Cr, Ti and B and the metal substrate comprises one metal of Ag, Cu and the like. The preparation method of the material comprises the following steps: mixing powder, pressing, infiltrating and pressing again. Owning to the adopted alloy element addition method,the wettability among phases is greatly improved. Therefore the material prepared by the method of the invention has better thermal conductivity, thermal expansion coefficient and mechanical properties compared with the former electronic packaging material and the adopted liquid phase infiltration method has the advantages of simple operation, low cost and capability of mass production.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

Method for preparing graphene oxide/white carbon black/rubber nanocomposite by mechanical blending

A method for preparing a graphene oxide / white carbon black / rubber nanocomposite by mechanical blending belongs to the composite material field. In the graphene oxide / white carbon black / rubber composite prepared by the method provided by the invention, because graphene and white carbon black are inserted with each other, the self-aggregation of the two fillers is effectively suppressed, and thus a composite having high dispersion, high stripping and nanoscale dispersion is obtained. Not only while the composite has higher modulus and lower rolling resistance, but also the wear resistance of a rubber material is substantially improved, and the modulus and tear resistance of the composite are further improved; at the same time, because of the lamellar structure and good self-recovery capability of the graphene oxide, the rubber material is also imparted with good gas barrier performance and self-healing capability, and the nanocomposite has the incomparable advantages to any traditional fillers. The method provided by the invention is simple and easy to implement, low in cost and easy to industrialize, has wide suitability and better economic benefits and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Pyridine saline gas transmission pipeline drag reduction agent and preparation method thereof

ActiveCN101575495AGood drag reduction effectRaw material source directlyOther chemical processesPipeline systemsRotary evaporatorPhosphate

The invention discloses a pyridine saline gas transmission pipeline drag reduction agent and a preparation method thereof. The pyridine saline gas transmission pipeline drag reduction agent is prepared from pyridines compounds, fluo phosphate, and halogenated hydrocarbon according to the mol ratio of 1:1:1-1.5:2:1. The preparation method comprises the following steps: adding the pyridines compounds and the halogenated hydrocarbon of the proportional quantities into a reaction vessel, and under the condition of stirring the mixture in the inert atmosphere, controlling the reaction temperature and reflux for reaction; after the reaction is finished, stopping heating, and cooling the reaction mixture, wherein the upper layer of the reaction mixture is yellowish liquid, and the lower layer of the reaction mixture is a white crystal; in the inert atmosphere, pouring out the yellowish liquid on the upper layer, and crashing the white crystal for suction filtration; putting the white crystal into a heat insulating purifier, adding a solvent into the heat insulating purifier, and in the inert atmosphere, re-crystallizing the mixture for 2-3 times to obtain a white crystal; adding an organic solvent, the white crystal and the fluo phosphate in a certain proportion into the reaction vessel, stirring the mixture in the inert atmosphere, and controlling the temperature for reaction; after the reaction is finished, carrying out suction filtration on the liquid rapidly, and removing undissolved substances to obtain a crude product containing the solvent; and steaming a small amount of the organic solvent from the crude product by a rotary evaporator, then putting the crude product in a vacuum oven to make the organic solvent steamed radically, and obtaining a product.

Owner:PIPECHINA SOUTH CHINA CO

Polyvinyl alcohol polarity sponge plastics and method of producing the same

The present invention provides poly vinyl alcohol polar foam. Water is used as foamer and plasticizer. According to weight, water is 15 portion to 55 portion, and poly vinyl alcohol is 45 portion to 85 portion. The material are dissolved for expansion, melted and processed for foaming. The melting and processing foaming comprises a melting and extruding continuous foaming method and a molding foaming method. The poly vinyl alcohol polar foam is a plate material, sheet material, membrane or bead or square block. The poly vinyl alcohol polar foam of the present invention can be added with crosslinker, molecular composite agent, processing aid, nucleating agent and functional additive. According to the weight portion, the crosslinker is 0 portion to 2 portion, the molecular composite agent 0 portion to 10 portion, the processing aid 0 portion to 10 portion, the nucleating agent 0 portion to 5 portion and the functional additive 0 portion to 30 portion. When the poly vinyl alcohol polar foam of the present invention is used as heavy metal particles, adsorption, filtration and separation material of organic pollutant, the poly vinyl alcohol polar foam has the characteristics of rapid adsorption, easy desorption and capacity of being repeatedly washed.

Owner:SICHUAN UNIV

Surface modified positive pole material of lithium ion cell and preparation method thereof

InactiveCN1731605ALow costCoated evenlyElectrode manufacturing processesLithium compoundsMetal nitrateMolten salt

The invention relates to a lithium battery anode material and method for making same. The said anode comprises base material and surface modification layer or surface coating layer or both of them. The inventive method comprises steps of mixing metal nitrate or other low melting point molten salt with anode material base material; rising temperature 1 to melting the salt and forming perfect lubrication and coating on the surface of base particles; decomposing the salts into oxide in temperature 2 and coating on the base material surface, diffusing into the internal part of particles to form surface modification layer. The invention has the advantages of protecting anode material resolving and phase-change in electrolytic solution.

Owner:ZHEJIANG UNIV

Wastewater treatment method using magnetism biological carrier and magnetic separation technique

InactiveCN101244884AEasy to handleSimple methodWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentTherapeutic effectVolumetric Mass Density

The invention relates to a sewage treatment method of adopting magnetic biological carrier and magnetic separation technique, belonging to the technical field of environmental protection, which comprises the following steps: magnetic biological carrier with density 1.0 to 1.4g / cm<3> and particle diameter 0.043 to 0.315mm is put into an aeration tank, the generated remained sewage can realize mud and water separation by magnetic separation technique, and then is put into a carrier de-molding separator, so as to realize the separation between mud and magnetic carrier, after magnetic separation, the magnetic carrier renews to be placed into the reactor, so as to realize recovery and reutilization of magnetic carrier. When the carrier additive is between 4 and 13g / L, the aeration amount is 50 to 100L / h, air apparent flow rate is 1.8 to 3.5m<3>(m<2> x h), waterpower retaining time is 1-5h, reflux ratio of the mixed liquid is 1-6, after checking, the removal ratio of effluent COD can reach 92.0 to 98.2%. When used for sewage treatment, the method in the invention has advantages of good treatment effect, simple method, strong controllability, and facility for industrial production; while obviously reducing effluent COD, the investment can be reduced and running cost can be lowered.

Owner:UNIV OF SCI & TECH BEIJING

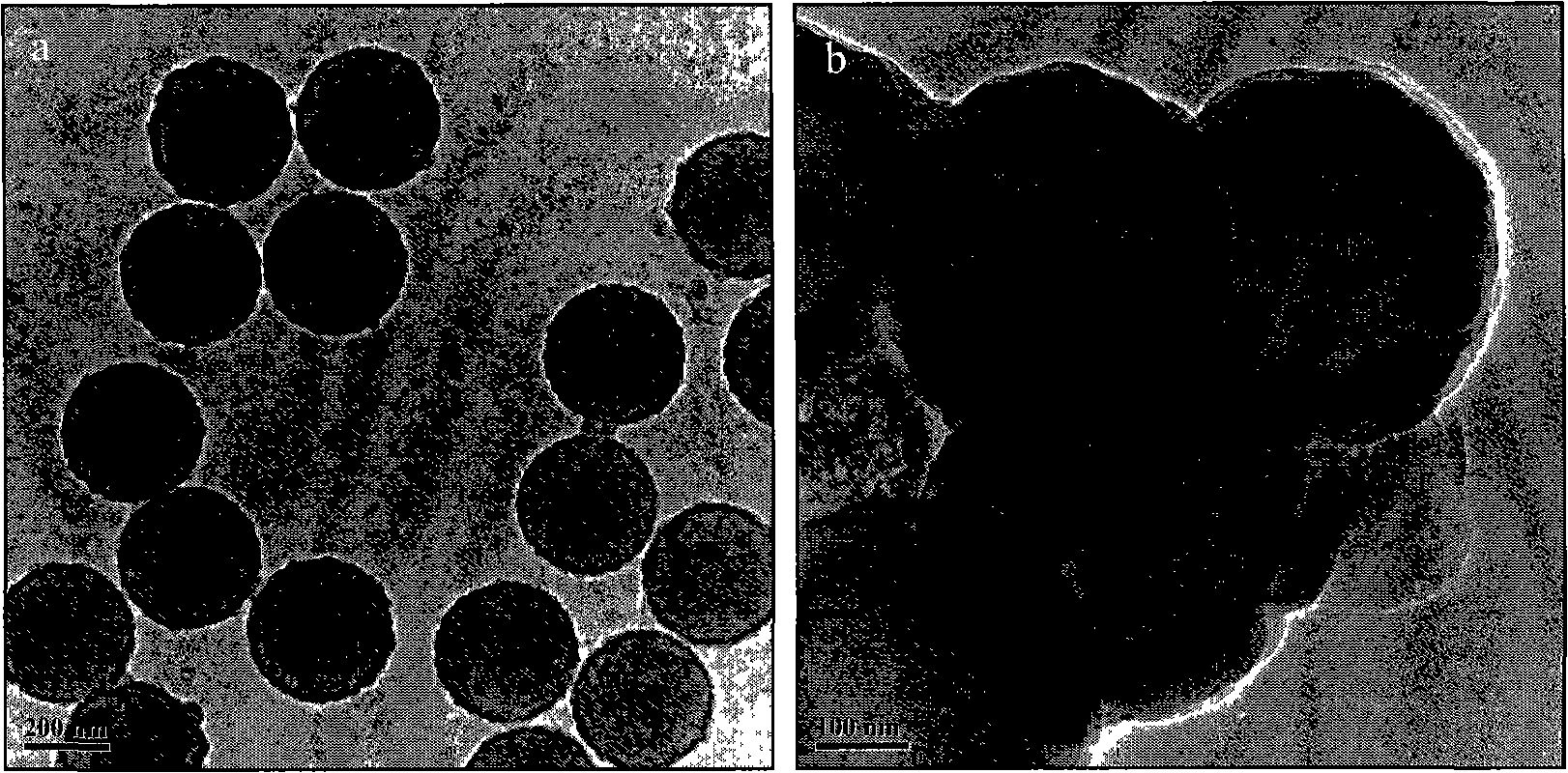

Anode material for double-shell capsule-shaped silicon-based lithium-ion battery and preparation method of anode material

InactiveCN104319401AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesNano siliconCarbonization

The invention discloses an anode material for a double-shell capsule-shaped silicon-based lithium-ion battery and a preparation method of the anode material. In the material, a nano-silicon nuclear is coated by a double-layer carbon shell; a certain space exists between the silicon nuclear and an inner-layer carbon shell. According to the preparation method, the material disclosed by the invention can be obtained by taking a capsule-shaped structural silicon dioxide-coated silicon nano-composite material as a template, performing pyrolysis on an organic carbon source to coat the inner surface and the outer surface of the template silicon dioxide, performing high-temperature carbonization under an inert atmosphere, and finally, etching the silicon dioxide template. According to the material, the first lithium embedding capacity is 3,125 mAh / g; the specific capacity can still be kept at 1,161mAh / g after 30-time repeated charge-discharge cycles. The preparation method provided by the invention is simple in process and environmentally friendly; industrial production is easy to realize.

Owner:SHANGHAI JIAO TONG UNIV

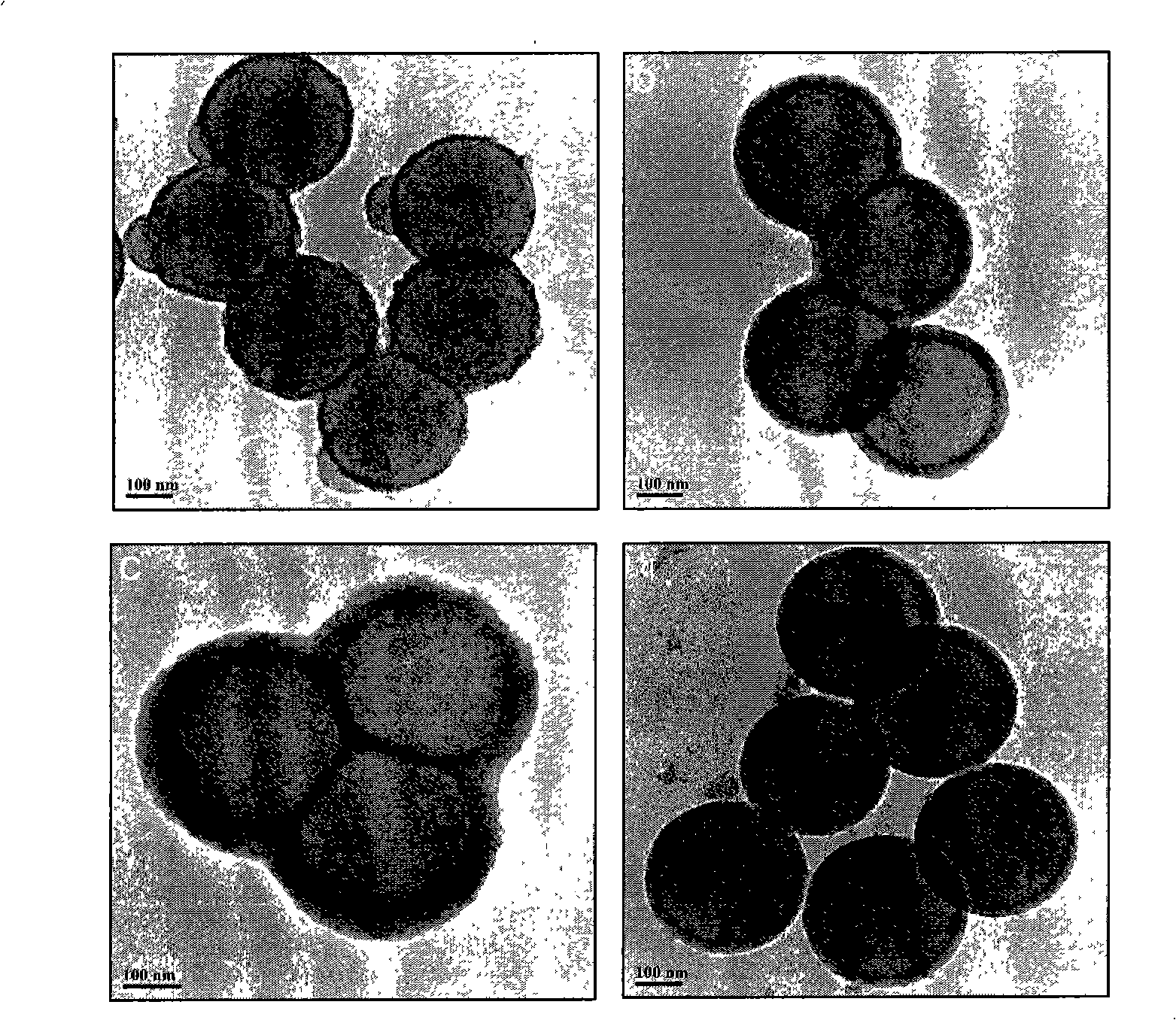

Multicomponent doping spherical lithium iron phosphate anode material and method of manufacturing the same

ActiveCN101369657AImprove conductivityImprove processing behaviorCell electrodesChemical/physical/physico-chemical processesPhosphateMaterials science

The invention provides a multi-doping spherical ferric phosphate lithium anode material and manufacture method thereof, the chemical formula of the anode material is Li1.03-xMgx / 2Fe1-yTiy / 2PO4-z / 2Fz / C, wherein 0<x<=0.1; 0<y<=0.1; 0 <z<=0.1. The anode material according to the invention comprises high unit capacity (>160mAh / g) and compaction proportion (1.45 to 1.75g / cm3), which efficiently enhance conduction ability thereof with excellent unit capacity. The raw material of the anode material according to the invention uses villaumite to reduce reaction activation energy, increase liquidoid during reaction process in order to control product particle feature to obtain spherical particle and enhance compaction proportion, being beneficial to improve manufacture process of electrode paste, simplify preparation and coating of battery paste and process the plate electrode; by being doped with magnesium, titanium and fluorine in the material structure to form semiconductors, the conduction ability of the material can be improved. The invention has simply process, low costs, being convenient to realize industrial manufacture.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Hydroxypropyl chitosan / oxidized sodium alginate self-crosslinking antibacterial hydrogel material

ActiveCN101463144AGood antibacterial effectGood biocompatibilityAbsorbent padsBandagesWound dressingDistilled water

The invention discloses a self-crosslinking antibacterial hydrogel material containing hydroxypropyl chitosan / oxidized sodium alginate. The material is made from the following components by mass percent: 1-25% of hydroxypropyl chitosan, 1-30% of oxidized sodium alginate, 0.01-0.5% of nano-silver and distilled water. The material is prepared by the following steps: preparing the hydroxypropyl chitosan by a hydroxypropylation reaction of chitosan at the temperature of 10-90 DEG C; preparing the oxidized sodium alginate by an oxidation reaction of sodium alginate at the temperature of 10-45 DEG C; respectively preparing aqueous solution of the hydroxypropyl chitosan and aqueous solution of the oxidized sodium alginate; adding the nano-silver solution and blending at certain ratio; allowing self-crosslinking of the components at the temperature of 10-50 DEG C to produce the antibacterial hydrogel material. The antibacterial hydrogel material has the advantages of low cost, environmental protection, simple process and the like; as the hydroxypropyl chitosan has good biocompatibility, the oxidized sodium alginate is nontoxic to human body, and the nano-silver has excellent antibacterial property, the obtained material can be applied to wound dressing, hemostatic materials and the like.

Owner:日照武汉理工大生物医药暨新材料研究院

Preparation process, product and application of new plastic

ActiveCN101982495AImprove thermal stabilityImprove toughnessInsulated cablesInsulated conductorsTemperature controlHigh resistance

The invention provides a process for preparing a new plastic, which comprises the following steps: (1) preparing raw materials; (2) weighing and proportioning the raw materials; (3) mixing PVC powder, stabilizers, packing, plasticizers and other additives, then carrying out high-speed kneading on the obtained mixture, and preplasticizing the mixture so as to obtain a pre-plasticized mixture; (4) mixing the pre-plasticized mixture with TPU particles, carrying out banbury mixing on the obtained mixture under the condition of gradient temperature control so as to obtain colloidal products; (5) carrying out double-screw granulation on the obtained colloidal products; and (6) carrying out sorting, dehydration and packing on the granular products obtained in step 5 so as to obtain the new plastic. The process is simple, the conditions of the process are easy to control, and the process is suitable for large-scale production. The invention also provides a new plastic, which has the characteristics of high resistance to wear and scrape, high elasticity, easy recovery, high flame retardance, ultraviolet resistance, freezing damage (caused by low temperature in the north) resistance, environmental protection, soft handfeel and stick resistance, and the like; and the new plastic can be applicable to wire and cable compound.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

Method for preparing spherical active carbon employing water soluble bitumen

InactiveCN103693641ALow priceWide variety of sourcesCarbon compoundsSpray GranulationActivated carbon

The invention discloses a method for preparing spherical active carbon employing water soluble bitumen. The method comprises the following processes: washing commercial sulfonated asphalt to obtain a complete water-soluble material; preparing a bituminous solution from the obtained water-soluble material or water-soluble mesophase pitch and deionized water; carrying out spray granulation on the bituminous solution, so as to obtain a bituminous ball; carbonizing and activating the bituminous ball, so as to obtain the spherical active carbon. The method has the advantages that the commercial sulfonated asphalt and the water-soluble mesophase pitch are adopted, so that the spherical active carbon is low in price and wide in source, no organic solvent is added in the balling process, the bituminous ball is controllable in particle size distribution, the prepared spherical active carbon is large in specific surface area, and industrial production is easy to achieve.

Owner:TIANJIN UNIV

Sulfuric acid ester gas pipeline drag reduction agents and preparation method thereof

ActiveCN101575497AGood drag reduction effectRaw material source directlyOther chemical processesPipeline systemsGas pipelineSulfuric Acid Esters

The invention discloses sulfuric acid ester gas pipeline drag reduction agents for drag reduction of long-distance pipelines of gas, particularly natural gas and a preparation method thereof. The drag reduction agents are formed by sulfuric acid esters, aromatic compounds and heterocyclic compounds according to the molar ratio of 1:5:1-1.5:10:1. The preparation method comprises the steps of: 1) adding a heterocyclic compound and an aromatic compound with certain proportion into a reactor, adding nitrogen for protection, and stirring for fixed time period at low temperature, and then adding sulfuric acid ester; 2) reacting for certain time to ensure that a formed liquid is changed into opacity and layering from initial lucidity and transparency; 3) using extraction layering to separate a residual liquid and a generated sulfuric acid ester drag reduction agent; and 4) distilling a residual liquid of an organic solvent under reduced pressure to obtain a product in vacuum. The drag reduction agents have obvious effect on the drag reduction of gas pipelines, have the advantages of direct raw material sources, simple operation, mild reaction conditions, relatively simple process and low requirement on equipment, and are easy to realize mass industrialized production.

Owner:PIPECHINA SOUTH CHINA CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com