Cellulose aerogel and preparation method for hybrid aerogel thereof

A cellulose aerogel and a technology for cellulose gel are applied in the field of preparing cellulose aerogel and its hybrid aerogel to achieve the effects of low thermal conductivity, wide sources and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

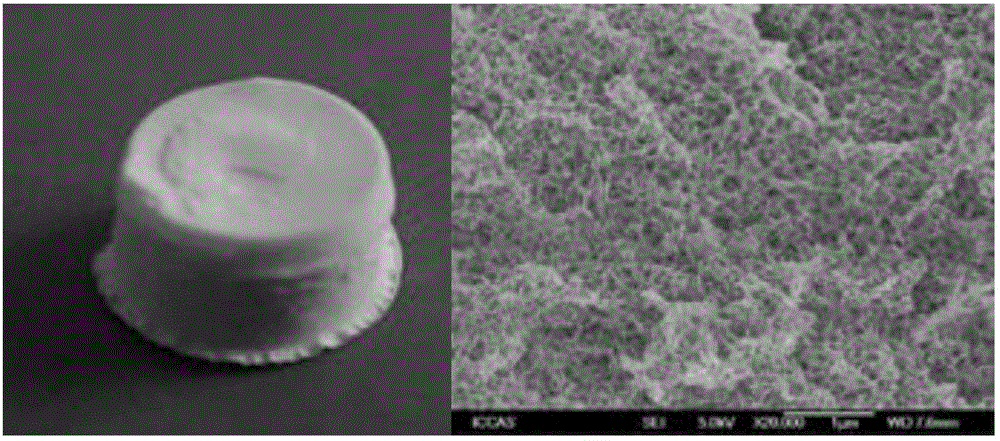

[0038] Embodiment 1, preparation cellulose airgel

[0039] Prepare 100 g of 65% zinc chloride aqueous solution, add 2 g of microcrystalline cellulose, heat up to 60° C. in an oil bath, apply mechanical stirring, and centrifugally defoam to obtain a transparent and uniform cellulose solution. Pour the cellulose solution into the mold to set it. Put the sample into 50% ethanol / water solution, let it stand for 12 hours, take it out, and the cellulose is solidified and regenerated into cellulose gel. Washed several times with ethanol to obtain cellulosic alcohol gel. Ethanol is removed by supercritical carbon dioxide drying technology to obtain block cellulose airgel. The prepared cellulose airgel and its structure such as figure 1 shown. The thickness of the airgel sample is about 5mm and the density is 0.15g / cm 3 , the pore size is nanoscale, and the compressive strength is 2.07MPa when the strain is 20%.

Embodiment 2

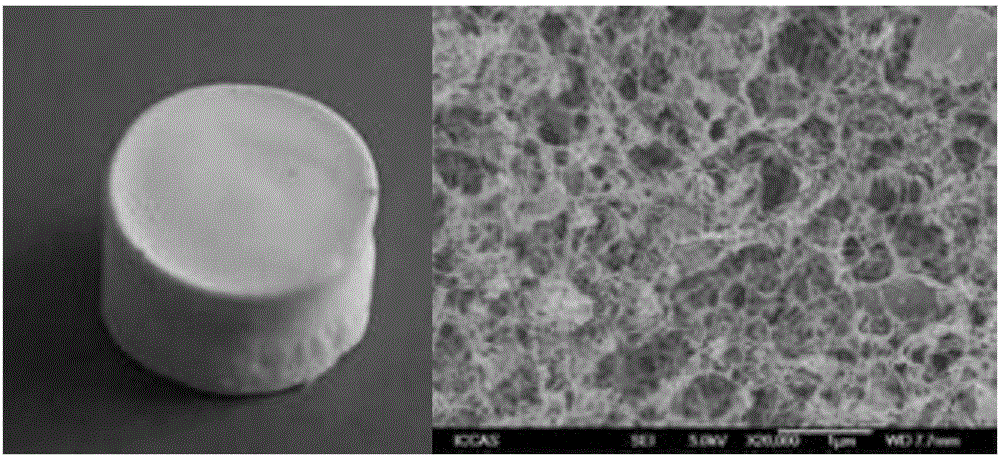

[0040] Embodiment 2, preparation cellulose / nanometer montmorillonite airgel

[0041] Prepare 100g of 70% zinc chloride aqueous solution, add 2g of microcrystalline cellulose, then add 0.1g of nano-montmorillonite, heat up to 60°C in an oil bath, apply mechanical stirring, and centrifugal defoaming to obtain a uniform cellulose hybrid solution. Pour the cellulose solution into the mold to set it. The sample was put into 50% ethanol / water solution, left for 12 hours, and then taken out to obtain a cellulose hybrid gel. After washing with ethanol several times, the cellulose hybrid alcohol gel was obtained. Ethanol is removed by supercritical carbon dioxide drying technology to obtain bulk cellulose / nano-montmorillonite airgel. The prepared cellulose / nano-montmorillonite airgel and its structure such as figure 2 shown. The thickness of the airgel sample is about 5mm, and the density is about 0.18g / cm 3 , the pore size is nanoscale, and the compressive strength when the str...

Embodiment 3

[0042] Embodiment 3, preparation cellulose airgel

[0043] Prepare 100 g of 50% zinc chloride aqueous solution, add 1 g of microcrystalline cellulose, heat up to 40° C. in an oil bath, apply mechanical stirring, and centrifugally defoam to obtain a transparent and uniform cellulose solution. Pour the cellulose solution into the mold to set it. Put the sample in water and take it out after standing for 6 hours. The cellulose is solidified and regenerated into cellulose gel. After washing with water for several times, the cellulose hydrogel was obtained. The water is removed by freeze-drying drying technology to obtain block cellulose airgel. The thickness of the airgel sample is about 5mm, and the density is about 0.1g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com