Method for preparing spherical active carbon employing water soluble bitumen

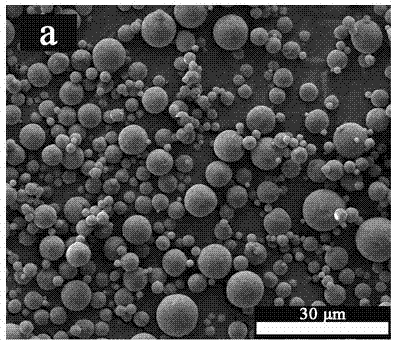

A spherical activated carbon, water-soluble technology, used in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult to clean experimental equipment, difficult to control sphericity, and wide particle size distribution of asphalt spheres. Oxidation non-melting step, easy industrial production, controllable particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. The water solubility of 100g is greater than 70%, the pH value is about 8-9, and the density is 0.98g / cm 3 The commercial sulfonated asphalt was placed in 2L of deionized water and stirred for 1 hour at a speed of 600r / min. Centrifuge after it is fully dissolved, collect the soluble part of the upper layer and dry it in an oven at 90°C for 60 hours to obtain 50g of water-soluble sulfonated pitch;

[0014] 2. At room temperature and at a stirring rate of 100 r / min, add 5 g of the water-soluble sulfonated pitch obtained in step 1 to 495 g of deionized water, stir at constant temperature for 1 hour and set aside;

[0015] 3. Put 500g of the sulfonated asphalt aqueous solution in step 2 under the condition that the feed temperature is 50°C, the outlet temperature is 40°C, and the injection flow rate is 800L / h, the nozzle diameter is 0.75mm, the working pressure is 0.2MPa, and the fan A pressure spray granulator (Shanghai Shunyi Experimental Equipment Co., Ltd., model: S...

Embodiment 2

[0018] 1. Prepare the dried water-soluble sulfonated pitch according to the method described in Example 1 step 1;

[0019] 2. At room temperature and a stirring rate of 150r / min, add 10g of the above-mentioned dried sulfonated pitch to 190g of deionized water, stir at constant temperature for 1 hour and set aside;

[0020] 3. Put 200g of sulfonated asphalt aqueous solution in step 2 under the conditions of feed temperature of 70°C, outlet temperature of 51°C, injection flow rate of 500L / h, using nozzle diameter of 0.75mm, working pressure of 2bar, fan frequency A 50Hz experimental pressure spray granulator (Shanghai Shunyi Experimental Equipment Co., Ltd., model: SP-1500) was used for spray granulation, and 9.8g of asphalt balls with a particle size distribution of 0.5-5.7 μm were obtained;

[0021] 4. The asphalt ball obtained in step 3 is firstly heated to 600°C at a heating rate of 1.5°C / min for carbonization for 1 hour, and then heated to 800°C at a heating rate of 1.5...

Embodiment 3

[0023] 1. Prepare the dried water-soluble sulfonated pitch according to the method described in Example 1 step 1;

[0024] 2. At room temperature and at a stirring rate of 120r / min, add 30g of the above-mentioned dried sulfonated pitch to 270g of deionized water, stir at constant temperature for 1 hour and set aside;

[0025] 3. Use 300g of sulfonated asphalt aqueous solution in step 2 under the conditions of feed temperature of 90°C, outlet temperature of 62°C, injection flow rate of 400L / h, using nozzle diameter of 0.75mm, working pressure of 3bar, fan frequency A 50Hz experimental pressure spray granulator (Shanghai Shunyi Experimental Equipment Co., Ltd., model: SP-1500) was used for spray granulation to obtain 28g of asphalt balls with a particle size distribution of 1.2-5.0 μm;

[0026] 4. The asphalt balls obtained in step 3 are firstly heated to 700°C at a heating rate of 2°C / min for carbonization for 1.5 hours, and then activated at a heating rate of 1°C / min t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com