Method for preparing graphene oxide/white carbon black/rubber nanocomposite

一种复合材料、橡胶纳米的技术,应用在氧化石墨烯/白炭黑/橡胶纳米复合材料的制备领域,能够解决不能够满足绿色环保、抗撕裂性能降低、滚动阻力增加等问题,达到成本低、实现大规模的工业化生产、易于大规模的工业化生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

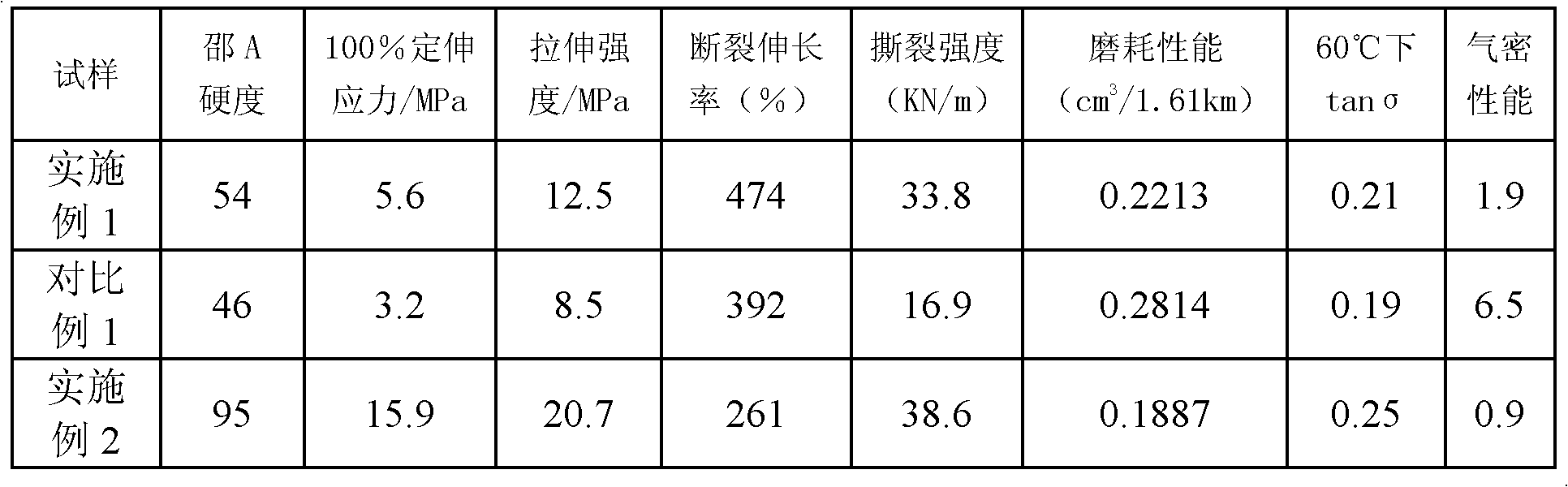

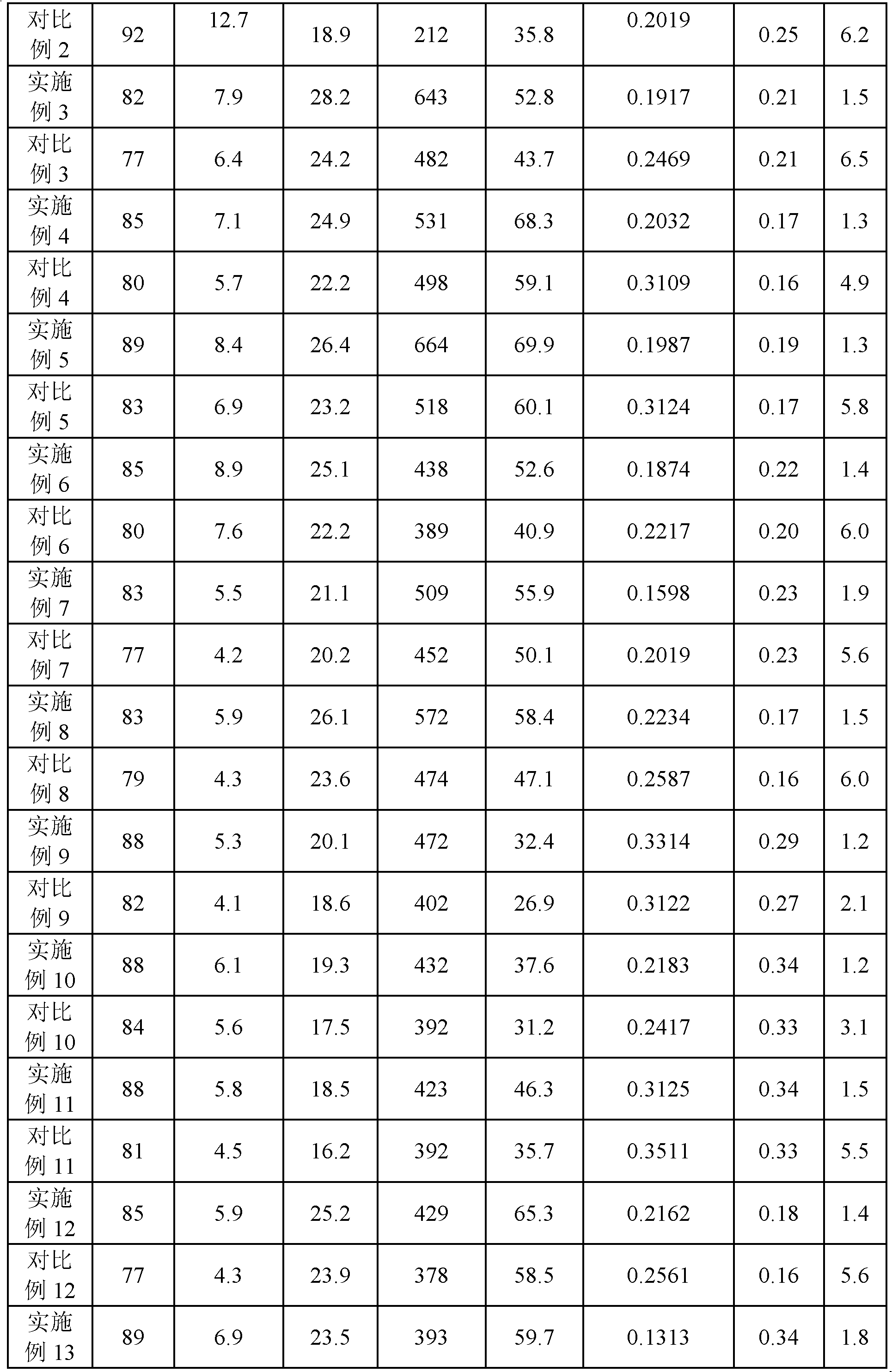

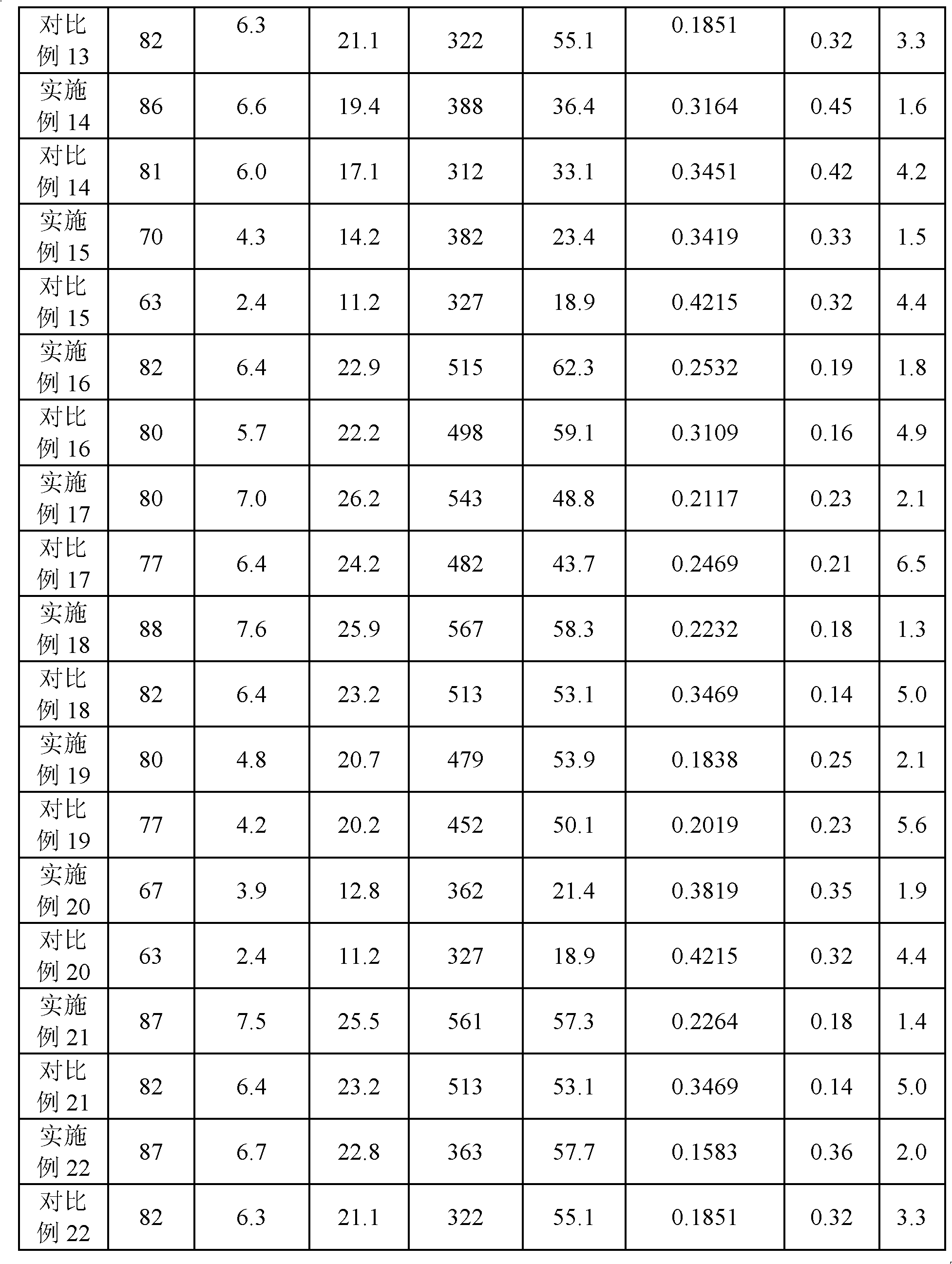

Examples

Embodiment 1

[0033] Weigh 1 g of graphite oxide, add it to 10 kg of deionized water, and ultrasonically disperse for 10 minutes at a power of 0.1 kw to prepare a graphene oxide hydrosol with a solid content of 0.01%. Weigh 1g of precipitation method white carbon black and 0.01g of bis-(γ-triethoxysilylpropyl)-tetrasulfide, add them to the above-mentioned hydrosol, and stir for 30min at a stirring speed of 50r / min. Graphene oxide / white carbon black hydrosol. The graphene oxide / white carbon black hydrosol and 20kg of styrene-butadiene latex with a solid content of 10% were stirred and dispersed for 12h at a stirring speed of 50r / min to obtain stable graphene oxide / silica / styrene-butadiene rubber Compound emulsion. Add the above composite emulsion to a 1% calcium chloride solution under stirring for flocculation, at a stirring speed of 50r / min, until no new flocs are produced in the mixed solution, then flocculate the resulting graphite oxide The micelles of olefin / silica / styrene-butadiene r...

Embodiment 2

[0036] Weigh 20g of graphite oxide, add it to 100g of deionized water, and disperse ultrasonically for 6h at a power of 1000kw, while monitoring the temperature of the system, if the temperature of the system exceeds 80℃, first pause the ultrasonic operation and move the mixture system to 500r / min After stirring for 30 minutes, the temperature of the system is reduced, and then the ultrasonic operation is continued, and then a graphene oxide hydrosol with a solid content of 20% is prepared. Weigh 380g of precipitation white carbon black and 190g of bis-(γ-triethoxysilylpropyl)-disulfide, add them to the above hydrosol, and ultrasonically disperse for 6h at a power of 1000kw, while monitoring the system temperature, If the temperature of the system exceeds 80°C, first pause the ultrasonic operation, move the mixture system to 500r / min stirring, stir for 30min, reduce the temperature of the system, and then continue the ultrasonic operation, and then obtain graphene oxide / white ca...

Embodiment 3

[0039] Weigh 5g of graphite oxide and add it to 500g of deionized water. Disperse ultrasonically for 2h at a power of 300kw while monitoring the temperature of the system. If the temperature of the system exceeds 80℃, first pause the ultrasonic operation and move the mixture system to 300r / min Under constant stirring, stirring for 15 minutes to lower the temperature of the system, and then continue the ultrasonic operation, and then obtain a graphene oxide hydrosol with a solid content of 1%. Weigh 70g of precipitation method white carbon black and 5.6g of bis-(γ-triethoxysilylpropyl)-tetrasulfide, add them to the above hydrosol, and ultrasonically disperse for 2h at a power of 300kw, while monitoring the system temperature If the temperature of the system exceeds 80°C, first pause the ultrasonic operation, move the mixture system to 500r / min stirring, and stir for 30min to reduce the temperature of the system, then continue the ultrasonic operation, and then obtain graphene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com