Method for preparing graphene oxide/white carbon black/rubber nanocomposite by mechanical blending

A rubber nano-composite material technology is applied in the field of preparation of graphene oxide/silica/rubber nano-composite materials, which can solve the problems of being unable to meet the requirements of green environmental protection, reducing tear resistance, increasing rolling resistance, etc., and achieving cost Low, achieve large-scale industrial production, easy to achieve the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

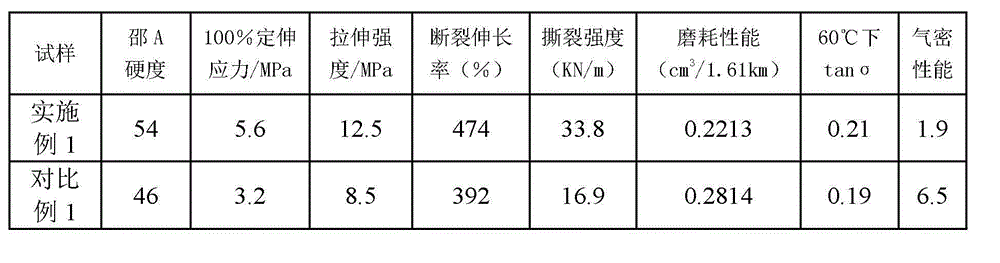

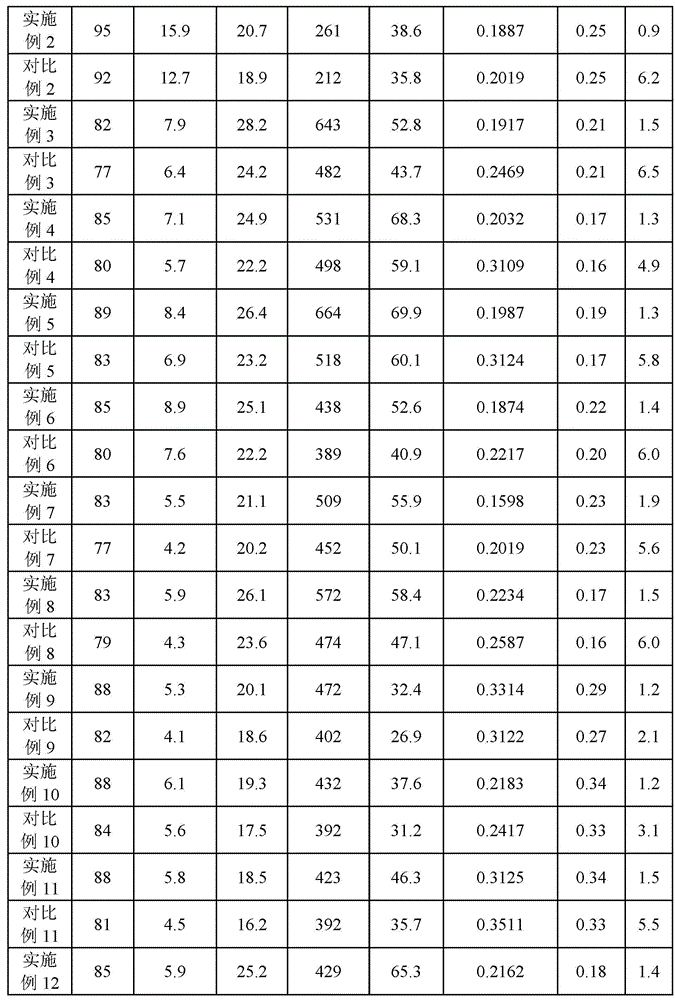

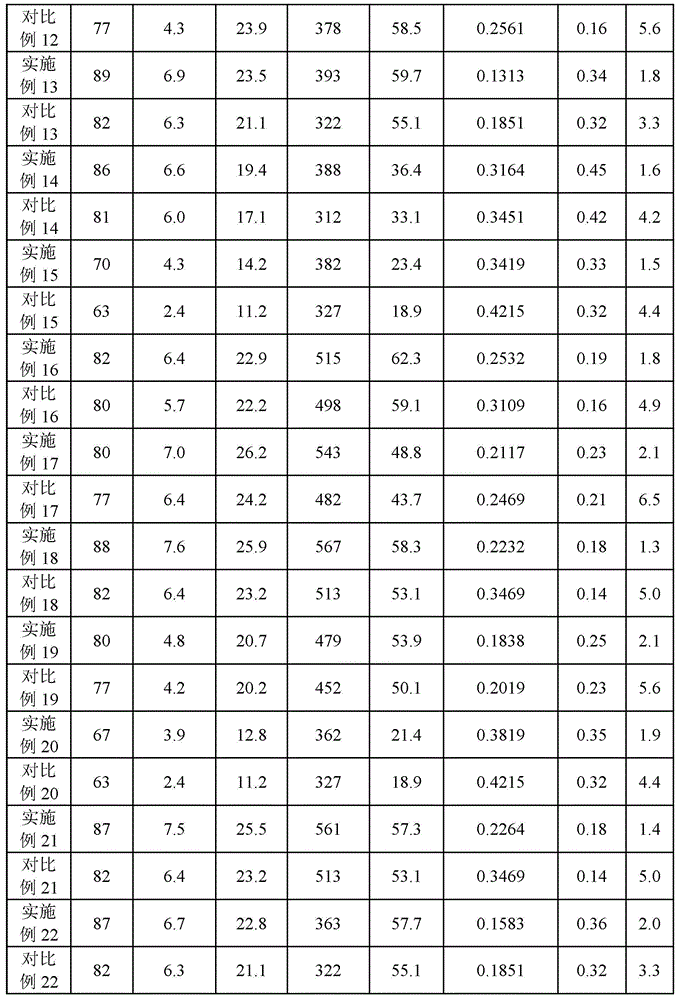

Examples

Embodiment 1

[0033] Weigh 1 g of graphite oxide, add it to 10 kg of deionized water, and ultrasonically disperse it at a power of 0.1 kw for 10 min to prepare a graphene oxide hydrosol with a solid content of 0.01%. Weigh 1g of precipitated white carbon black and 0.01g of bis-(γ-triethoxysilylpropyl)-tetrasulfide, add them to the above water sol, and stir for 30min at a stirring speed of 50r / min to obtain Graphene oxide / silica hydrosol. The above-mentioned graphene oxide / white carbon black hydrosol and 20kg of styrene-butadiene latex with a solid content of 10% were stirred and dispersed for 12 hours at a stirring speed of 50r / min to obtain stable graphene oxide / white carbon black / styrene-butadiene rubber Complex emulsion. Add the above composite emulsion to the calcium chloride solution with a mass concentration of 1% under stirring for flocculation, and the stirring speed is 50r / min, until no new flocs are produced in the mixed solution, and the graphite oxide obtained by flocculation ...

Embodiment 2

[0036] Weigh 20g of graphite oxide, add it into 100g of deionized water, and disperse it ultrasonically for 6h at a power of 1000kw, while monitoring the system temperature. If the system temperature exceeds 80°C, first suspend the ultrasonic operation, and move the mixture system to 500 r / Min stirring, stirring for 30min, after the temperature of the system was lowered, the ultrasonic operation was continued, and then a graphene oxide hydrosol with a solid content of 20% was obtained. Weigh 380g of precipitated white carbon black and 190g of bis-(γ-triethoxysilylpropyl)-disulfide, add them to the above water sol, and ultrasonically disperse for 6h under the power of 1000kw, while monitoring the system temperature, If the system temperature exceeds 80°C, first suspend the ultrasonic operation, move the mixture system to 500 r / min stirring, stir for 30 minutes, and then continue the ultrasonic operation after the system temperature is lowered, and then obtain graphene oxide / whi...

Embodiment 3

[0039]Weigh 5g of graphite oxide, add it to 500g of deionized water, and disperse it ultrasonically for 2 hours at a power of 300kw, while monitoring the temperature of the system. If the temperature of the system exceeds 80°C, first suspend the ultrasonic operation, and move the mixture system to 300 r / Under stirring for 1 min, stir for 15 min to lower the temperature of the system, then continue the ultrasonic operation, and then obtain a graphene oxide hydrosol with a solid content of 1%. Weigh 70g of precipitated white carbon black and 5.6g of bis-(γ-triethoxysilylpropyl)-tetrasulfide, add them to the above water sol, ultrasonically disperse for 2 hours at a power of 300kw, and monitor the system temperature at the same time , if the system temperature exceeds 80°C, first suspend the ultrasonic operation, move the mixture system to 500 r / min stirring, stir for 30 minutes, and then continue the ultrasonic operation after the system temperature is lowered, and then obtain gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com