Preparation method of sulfur-active carbon/graphene composite material

A composite material and graphene technology, applied in the field of electrochemical energy storage, can solve problems affecting battery cycle life, active material dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

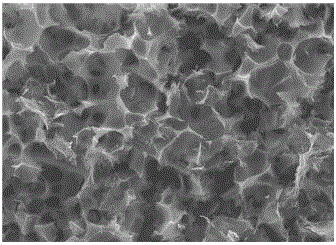

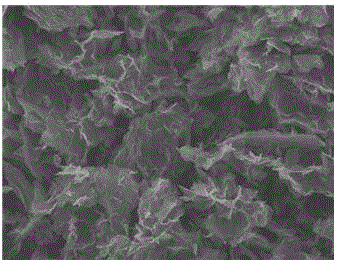

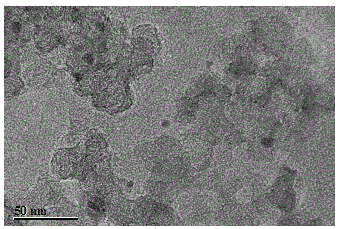

Image

Examples

Embodiment 1

[0139] Example 1: (1) Dry the rice husks naturally for 14 days, then 50.0 g of agate balls with a diameter of 1-1.3 cm are ground, and 100 g of rice husks are sealed in an agate ball mill jar under the protection of argon, and then the ball mill jars Place it on a planetary ball mill and ball mill it at a speed of 580 rpm for 2 hours. The agate ball was taken out with tweezers, the ball-milled sample was sieved with a three-dimensional vibrating sieve, and the 20-mesh sample was washed three times with 5% sulfuric acid aqueous solution and deionized water respectively. Polyethylene membrane (pore size 0.2 micron) was used for solid-liquid separation, and the obtained solid was air-dried at 70 °C for 96 hours; (2) 20 g of biomass and 100 g of graphene were stirred in 50 ml of 10% KOH aqueous solution mix. The time of magnetic stirring is 5 hours, and the temperature is 20 degrees Celsius. A polypropylene bag (pore size 0.2 microns) is used to achieve solid-liquid separation, ...

Embodiment 2

[0140] Example 2: (1) Date stones were dried naturally for 3 days, then 1500.0 g of zirconia balls with a diameter of 3-8 mm were milled, and 200 g of date stones were sealed in a zirconia ball mill jar under nitrogen protection, and then ball milled The jars were placed on a planetary ball mill and ball milled at 300 rpm for 30 hours. The zirconia balls were taken out with tweezers, the milled samples were sieved with an ultrasonic vibrating sieve, and the 50-mesh samples were washed three times with 5% hydrochloric acid aqueous solution and deionized water respectively. Polypropylene membrane (pore size 1 micron) was used for solid-liquid separation, and the obtained solid was air-dried at 100 °C for 24 hours; (2) 100 g of biomass and 10 g of nitrogen-doped graphene were mixed in 100 ml of 20% K 2 CO 3 Stir in the aqueous solution to mix. The time of mechanical stirring is 20 hours, and the temperature is 40 degrees Celsius. A polyethylene bag (pore size 1 micron) is used...

Embodiment 3

[0141] Example 3: (1) Bamboo powder was dried naturally for 30 days, then 500.0 g of aluminum oxide ball milling balls with a diameter of 8-15 mm, 300 g of bamboo powder were sealed in an agate ball mill jar under air protection, and then the ball mill jar Place on a planetary ball mill and ball mill for 60 hours at a speed of 100 rpm. The alumina balls were taken out with tweezers, the milled samples were sieved with an ultrasonic vibrating sieve, and the 80-mesh samples were washed three times with 30% hydrochloric acid aqueous solution and deionized water respectively. A polystyrene membrane (pore size of 2 microns) was used for solid-liquid separation, and the obtained solid was air-dried at 120 °C for 1 hour; (2) 2 g of biomass and 100 g of phosphorus-doped graphene were mixed in 300 ml of 50% by mass Ultrasonic mixing in aqueous NaOH. The ultrasonic frequency is 20 kilohertz, the power density is 500w, the time is 30 hours, and the temperature is 20 degrees Celsius. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com