Nitrogen doped carbon quantum dot as well as preparation method and application thereof

A nitrogen-carbon quantum and carbon quantum dot technology, which is applied in the field of nitrogen-doped carbon quantum dots and its preparation, can solve the problems of expensive raw materials and equipment, troublesome operation, low quantum yield, etc., and achieves good solubility, monodispersity, reaction Simple and easy operation, the effect of excellent luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, prepare 20 mL of citric acid solution with a concentration of 2.0 mol / L, add 5 mg of linear polyethyleneimine (LPEI, M=5050), make the molar ratio of secondary amine: carboxyl group 1:1000, and mix well to obtain Mixed solution; transfer the mixed solution into a hydrothermal reaction kettle and treat at 100°C for 100 hours to obtain a dispersion of nitrogen-doped carbon quantum dots; extract the dispersion of nitrogen-doped carbon quantum dots with acetone, and centrifuge to remove the upper solvent After the waste liquid was dried in vacuum at 120° C. for 8 hours, nitrogen-doped carbon quantum dots were obtained.

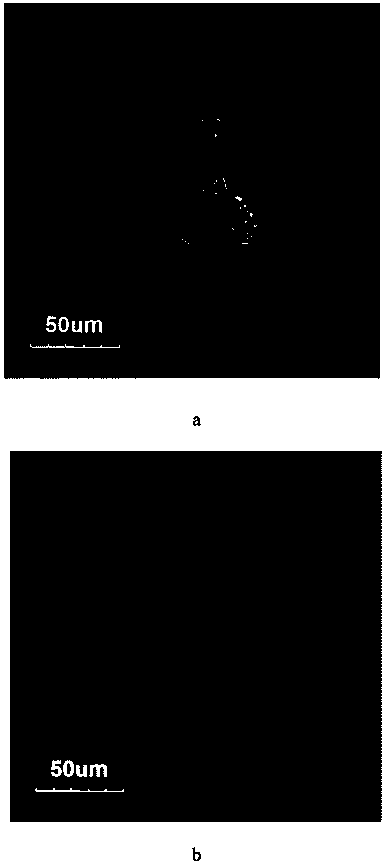

[0033] see figure 1 , is the transmission electron micrograph of nitrogen-doped carbon quantum dots synthesized under this condition. Integrating sphere tests showed that the absolute quantum yield of the obtained carbon quantum dots was 47%. In addition, the peaks of C1s and N1s of the corresponding carbon quantum dots were also dete...

Embodiment 2

[0037] At room temperature, prepare 24 mL of tartaric acid solution with a concentration of 5.0 mol / L, add 20 mg of linear polyethyleneimine (LPEI, M=5050) so that the molar ratio of secondary amine: carboxyl group is 1:500, and mix well to obtain a mixed solution transfer the mixed solution into a hydrothermal reaction kettle, and treat at 200°C for 10 hours to obtain a dispersion of nitrogen-doped carbon quantum dots; extract the dispersion of nitrogen-doped carbon quantum dots with alcohol, and centrifuge to remove the upper solvent waste liquid Finally, after vacuum drying at 150° C. for 6 h, nitrogen-doped carbon quantum dots were obtained.

[0038] figure 2 It is a transmission electron microscope photo of the nitrogen-doped carbon quantum dots synthesized under this condition, and the integrating sphere test shows that the absolute quantum yield of the obtained carbon quantum dots is 42.7%.

Embodiment 3

[0040]At room temperature, prepare 30 mL of lactic acid solution with a concentration of 0.2 mmol / L, add 250 mg of linear polyethyleneimine (LPEI, M=5050) so that the molar ratio of secondary amine: carboxyl group is 1000:1, and mix well to obtain a mixed solution Transfer the mixed solution into a hydrothermal reaction kettle, and process it at 300°C for 0.1 hour to obtain a dispersion of nitrogen-doped carbon quantum dots; extract the dispersion of nitrogen-doped carbon quantum dots with alcohol, and centrifuge to remove the upper solvent waste liquid Finally, after vacuum drying at 100° C. for 10 h, nitrogen-doped carbon quantum dots were obtained.

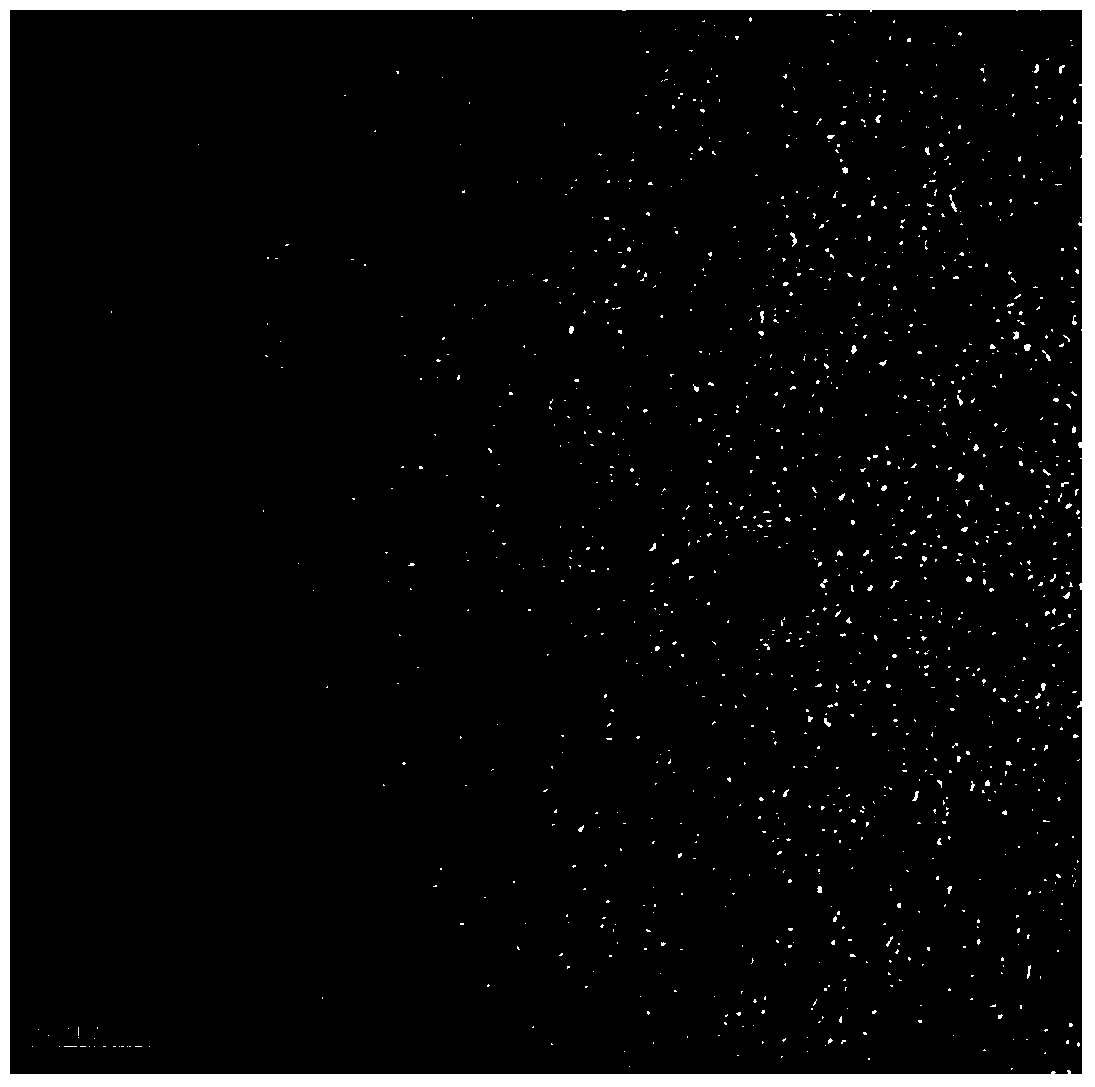

[0041] image 3 It is a transmission electron micrograph of carbon quantum dots synthesized under this condition. Integrating sphere tests show that the absolute quantum yield of the obtained nitrogen-doped carbon quantum dots is 39.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com