Application of fluorescent silica nanoparticles as anti-fake mark

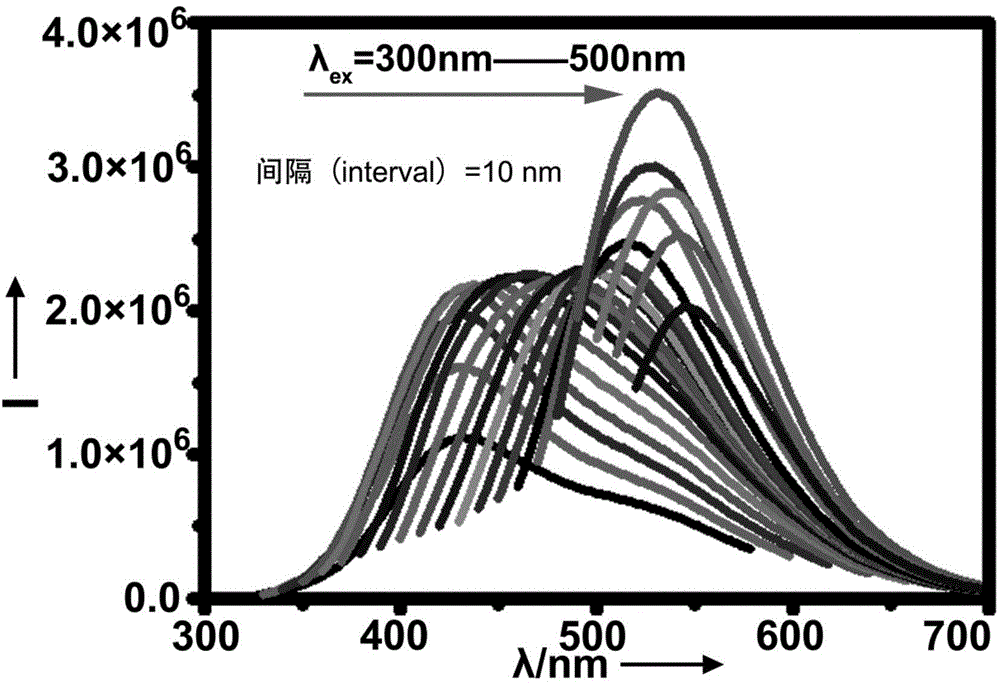

A technology of silicon nanoparticles and anti-counterfeiting marks, which is applied in the field of silicon nanomaterials to achieve good anti-counterfeiting effects, good fluorescent properties, and high quantum yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of fluorescent silicon nanoparticles

[0019] After crushing the rice husk, wash it with deionized water, add 38wt%-5wt% hydrochloric acid, and heat it in a water bath for 1h-10h; wash the acid-treated sample with deionized water until it is neutral, put it in a porcelain crucible, and wash it with alcohol. The lamp is heated until the sample turns into white powder; take a small amount of white powder, add 0.1mol / L-10mol / L NaOH solution, and heat it with microwave radiation for 30min-20h at a power of 15W-1000W and a temperature of 100°C-160°C to obtain a water-soluble permanent silicon nanoparticles.

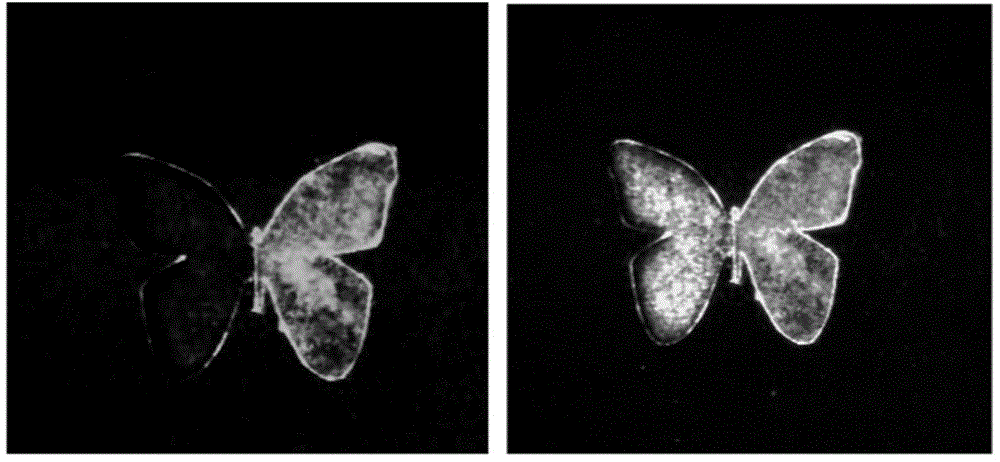

[0020] (2) Using silicon nanoparticles for anti-counterfeiting preparation

[0021] The prepared fluorescent silicon nanoparticles were used as anti-counterfeiting ink for printing patterns.

Embodiment 2

[0023] (1) Preparation of fluorescent silicon nanoparticles

[0024] After crushing the wheat straw, wash it with deionized water, add 38wt%-5wt% hydrochloric acid, and heat it in a water bath for 1h-10h; wash the acid-treated sample with deionized water until it is neutral, put it in a porcelain crucible, and wash it with alcohol The lamp is heated until the sample turns into white powder; take a small amount of white powder, add 0.1mol / L-10mol / L NaOH solution, and heat it with microwave radiation for 30min-20h at a power of 15W-1000W and a temperature of 100°C-160°C to obtain a water-soluble permanent silicon nanoparticles.

[0025] (2) Using silicon nanoparticles for anti-counterfeiting

[0026] The prepared fluorescent silicon nanoparticles were used as anti-counterfeiting ink for printing patterns.

Embodiment 3

[0028] (1) Preparation of fluorescent silicon nanoparticles

[0029] Crush the bagasse and wash it with deionized water, add 38wt%-5wt% hydrochloric acid, heat in a water bath for 1h-10h; wash the acid-treated sample with deionized water until it is neutral, put it in a porcelain crucible, and wash it with alcohol The lamp is heated until the sample turns into white powder; take a small amount of white powder, add 0.1mol / L-10mol / L NaOH solution, and heat it with microwave radiation for 30min-20h at a power of 15W-1000W and a temperature of 100°C-160°C to obtain a water-soluble permanent silicon nanoparticles.

[0030] (2) Using silicon nanoparticles for anti-counterfeiting

[0031] The prepared fluorescent silicon nanoparticles were used as anti-counterfeiting ink for printing patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com