Method of producing and the use of microfibrillated paper

a micro-fibrous paper and paper technology, applied in papermaking, non-fibrous pulp addition, cellulose treatment using microorganisms/enzymes, etc., can solve the problems of low cost constituent, high modulus and strength of materials, and brittleness of materials based on melamine-formaldehyde,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of MFC

[0049]The different kinds of microfibrillated cellulose (MFC) used herein are termed DP-X where X corresponds to the average degree of polymerization (DP) of the specific MFC sample, estimated from viscosity data.

[0050]Oxidation and formation of charged groups on the cellulose fibrils may for example be conducted on cellulose (2 g) suspended in water (150 ml) containing TEMPO (2,2,6,6-tetramethyl-1-piperidinyloxy) (0.025 g) and sodium bromide (0.25 g). The pH was adjusted by adding NaClO and was then maintained at 10.5. To terminate the reaction the pH was lowered through addition of HCl to a pH of around 7. The whole procedure was performed at room temperature. The product was thoroughly washed with water.

[0051]The MFC was prepared from softwood dissolving pulp kindly provided by Domsjö Fabriker A B, Sweden. The pulp was subjected to a pre-treatment step followed by disintegration into MFC by a homogenization process with a Microfluidizer M-110EH, Microfluidics In...

example 2

Preparation of Porous Cellulose Nanopaper

[0055]Cellulose nanopaper films were prepared by vacuum-filtration of a 0.2% (by weight) MFC suspension. Prior to filtration the suspension was stirred for 48 h to ensure well dispersed nanofibrils. All films, except DP-800, were filtrated on a glass filter funnel (11.5 cm in diameter) using Munktell filter paper, grade OOH, Munktell Filter A B, Sweden. Films prepared of DP-800 were filtrated on a glass filter funnel (7.2 cm in diameter) using filter membrane, 0.65 μm DVPP, Millipore, USA. After filtration, the wet films were stacked between filter papers and then dried at 55° C. for 48 h at about 10 kPa applied pressure. This resulted in MFC films with thicknesses in the range 60-80 μm.

[0056]Porous films are prepared by solvent exchange on the filtered film before drying. After filtration the wet film was immersed in methanol, ethanol or acetone for 2 h. The solvent was replaced by fresh solvent and the film was left for another 24 h. Then t...

example 3

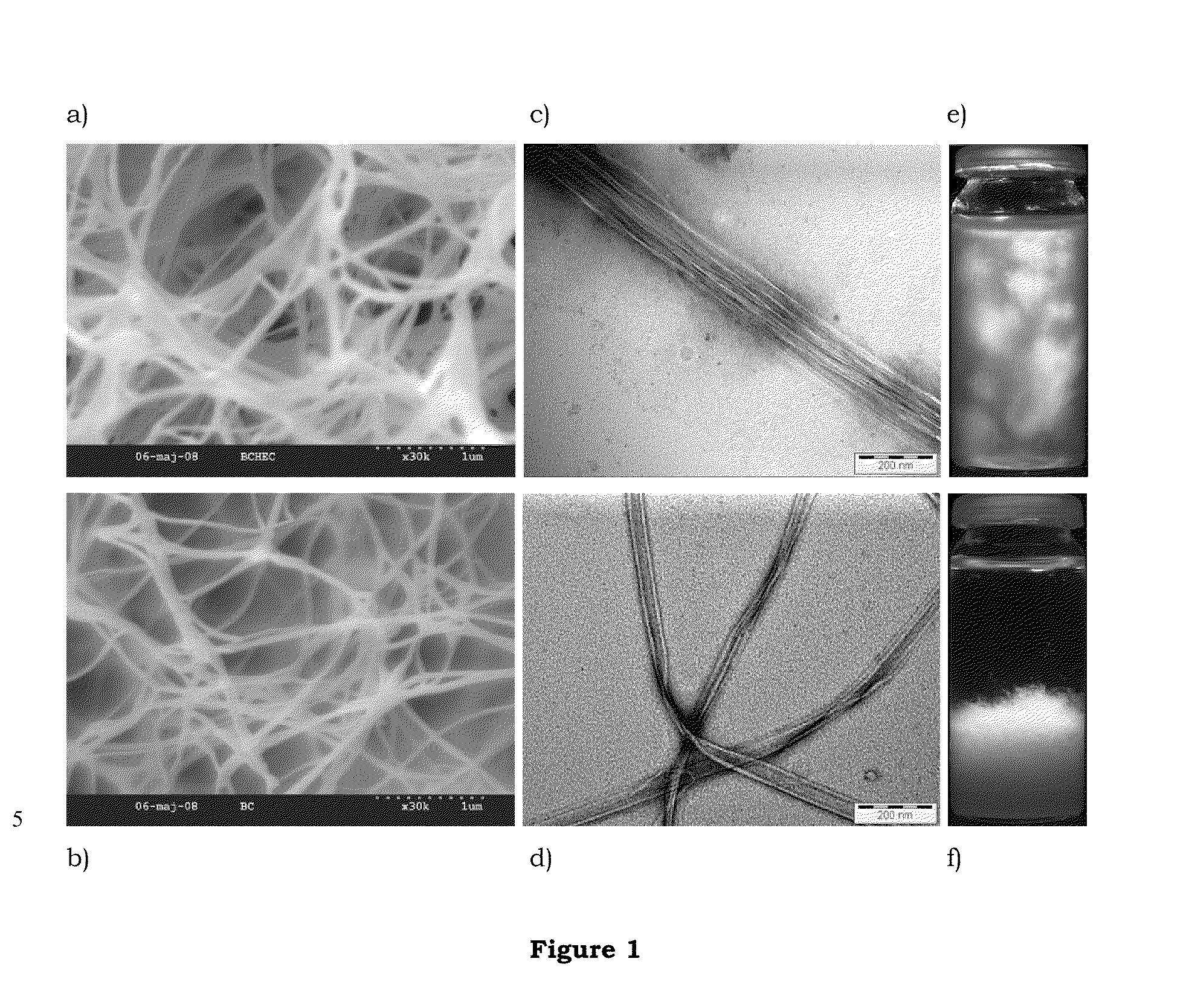

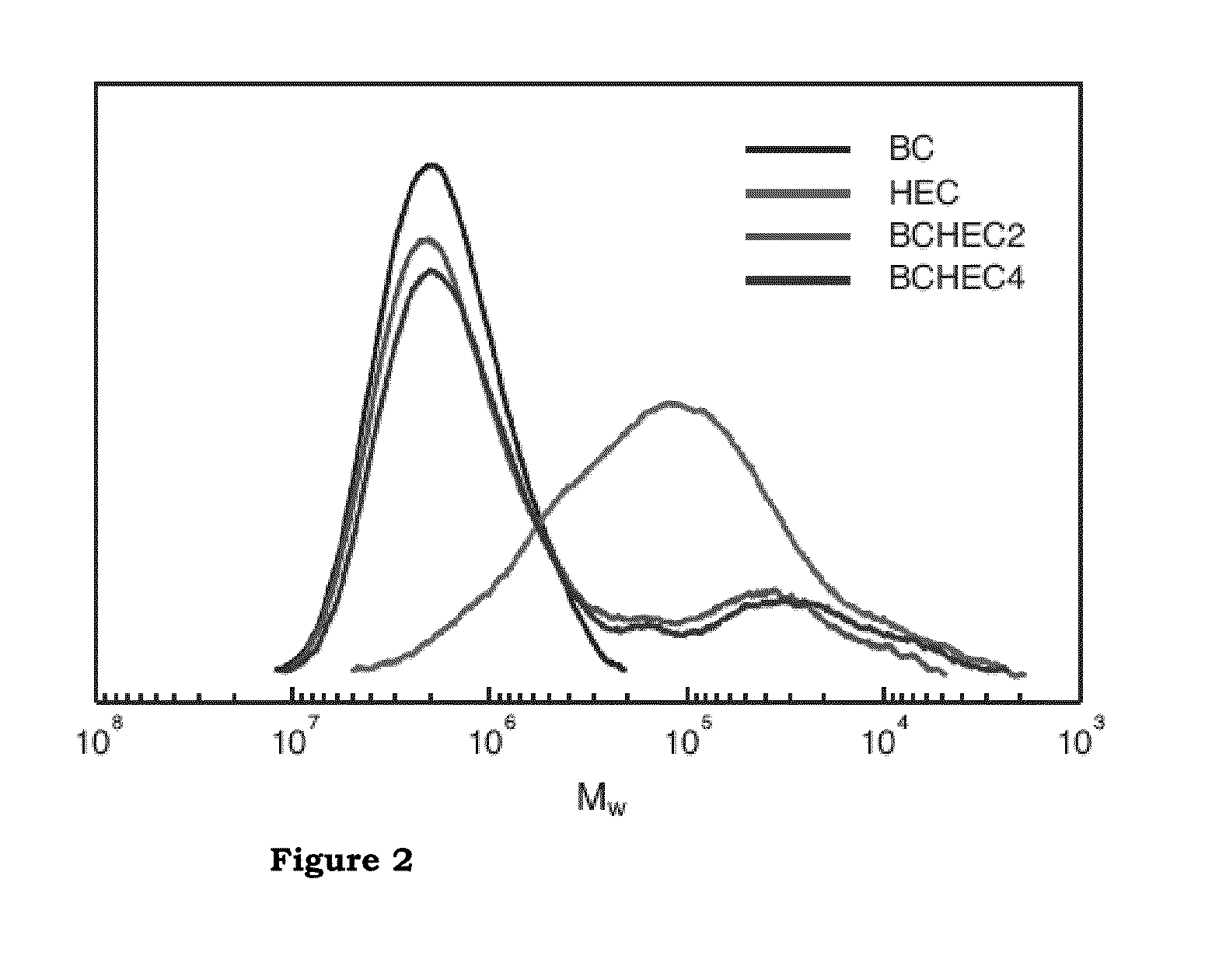

Preparation of Cellulose Nanopaper Using Bacterial Nanofibrils

[0058]The Acetobacter aceti strain was pre-cultivated in the Hestrin-Schramm (HS) medium for 7 days at 27° C., and 5 mL of this pre-culture was used to inoculate 30 mL of fresh HS medium. A series of BCHEC samples were prepared in the presence of 0.5, 1.0, 2.0, and 4.0% (w / v) HEC (Aldrich cat # 308633; average Mw 250,000) in the culture medium. The control BC was obtained by cultivating the bacterium in the absence of HEC in the medium. The control BC and BCHEC fleeces were harvested after 7 days of culture at 27° C. under static conditions. They were treated with 0.1 M NaOH at 80° C. for 3 h and washed with de-ionized water. This process was repeated 3 times and the BC fleeces were finally washed with de-ionized water for several days until neutrality was reached. Aqueous suspensions of BC microfibrils with a solid content of 0.2% were obtained by homogenizing the control BC or the BCHEC fleeces with a Waring® blender. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com