Photogravure press

A gravure printing machine and coating technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of reducing productivity, unable to fit tightly, unable to complete transfer printing, etc., to improve labor productivity, improve service life, Good scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

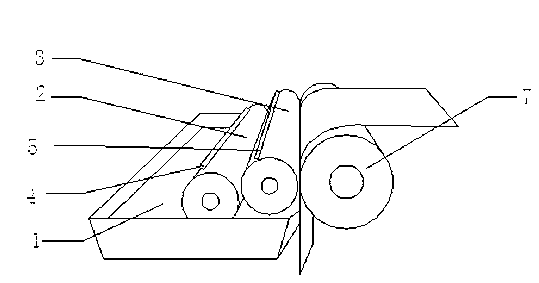

[0031] Such as figure 1 As shown, the present embodiment provides a kind of gravure printing machine, comprises feeding equipment 1, is used for providing coating; Suction roller 2, its peripheral surface is connected with described feeding equipment 1, and described peripheral surface has Form a plurality of depressions in the image area when the paint is filled; the rubber coating roller 3, whose peripheral surface is connected with the suction roller 2, is used to accept the image area formed by the paint on the coating roller 3, and The image area is transferred to the steel plate; it also includes a first scraper 4, which is installed on the first scraper bracket and contacts with the suction roller 2 at a specific angle, and is used to scrape off all of the suction roller 2. The paint outside the image area; the second scraper 5, installed on the second scraper bracket, contacts with the coating roller 2 at a specific angle, and is used to remove the residual paint on th...

Embodiment 2

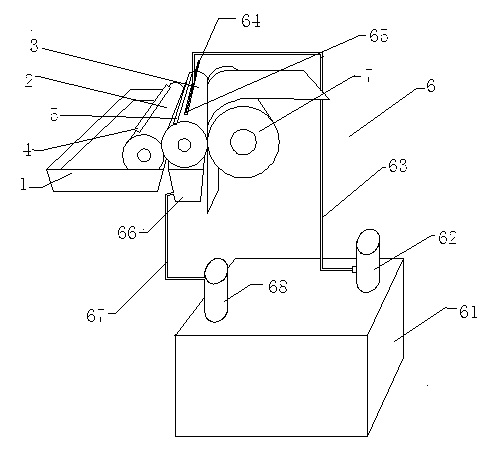

[0040] Such as figure 2 As shown, the gravure printing machine provided in this embodiment is an improvement on the basis of the embodiment. The main improvement is that a cleaning device 6 is added to clean the second doctor blade 5 and the rubber coating roller 3. paint for cleaning.

[0041] The cleaning device 6 includes a liquid supply tank 61, a cleaning solution delivery pump 62 for pumping the cleaning solution delivery tank 61, a cleaning solution delivery pipeline 63 communicated with the cleaning solution delivery pump 62, and a cleaning solution delivery pipe 63 connected to the cleaning solution delivery pump 62. The spray pipe 64 that conveys pipeline communication, described spray pipe 64 is arranged on the axial top of described rubber coating roller 3, has several spray holes 65 on the described spray pipe 64; Described cleaning device 6 also It includes a cleaning solution recovery tank 66 arranged below the coating roller 3; the cleaning solution recovery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com