Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

473results about How to "Stable quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high boiling silicone oil by using organic silicon high boiling substances

The invention relates to a method for preparing high boiling silicone oil by using organic silicon high boiling substances, comprising hydrolyzation of alcohol and neutralization, wherein the organic silicon high boiling substances are hydrolyzed in the mixed liquid of alcohol and water and refluxed for 1-4 hours; nitrogen purging is carried out on the reactant, and then the reactant is added with hydrogen chloride dissolved in urea, zinc oxide and ammonium bicarbonate and in the system thereof. The invention integrally uses the organic silicon high boiling substances and lowers the chlorine content in silicon oil products, ensures the molecular weight and viscosity to be controllable and mass to be more stable; the usage of the neutralizing agent and latent solvent is reduced greatly, thus reducing the production cost; the process is simple and the industrial production is easy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

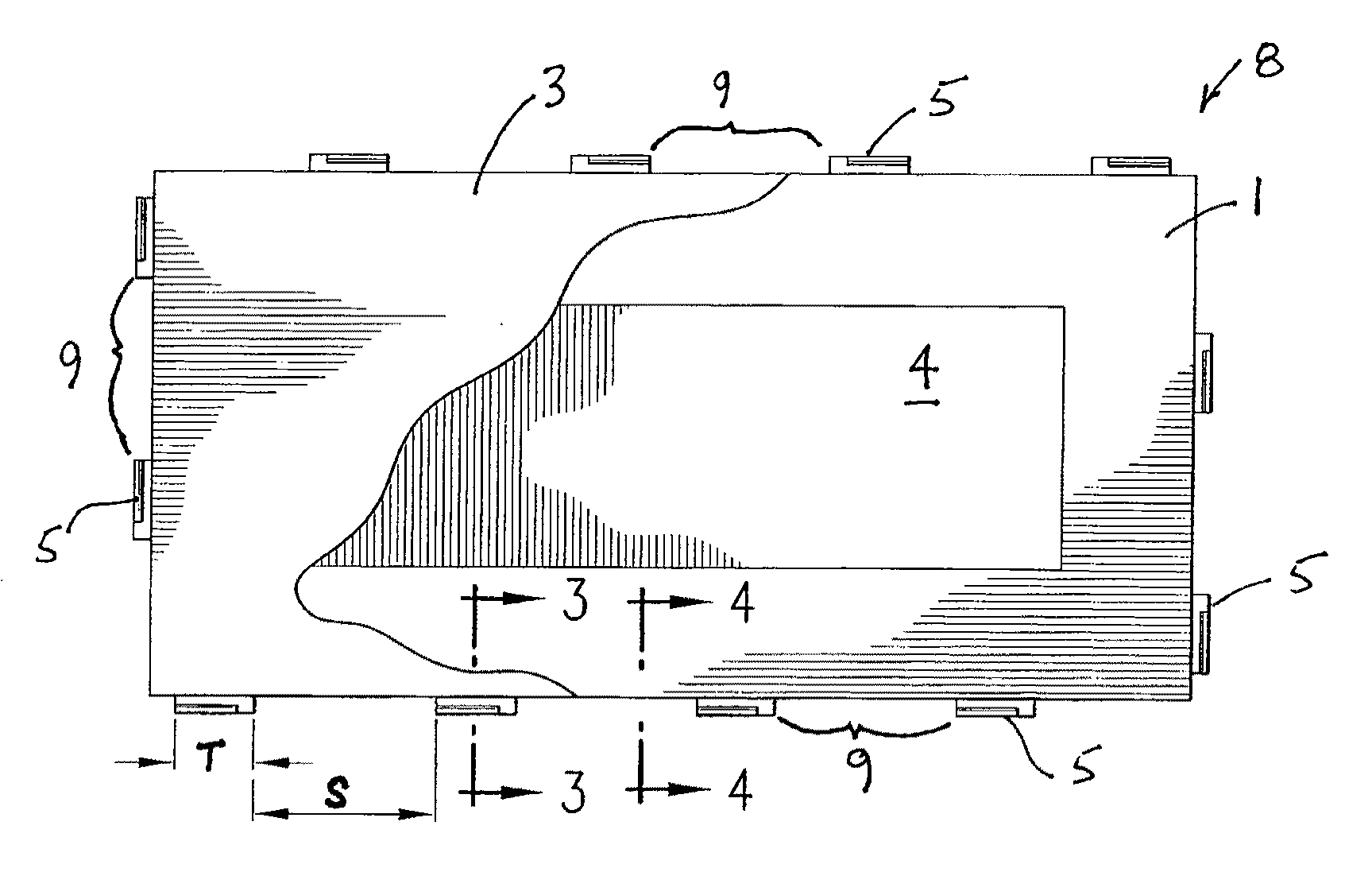

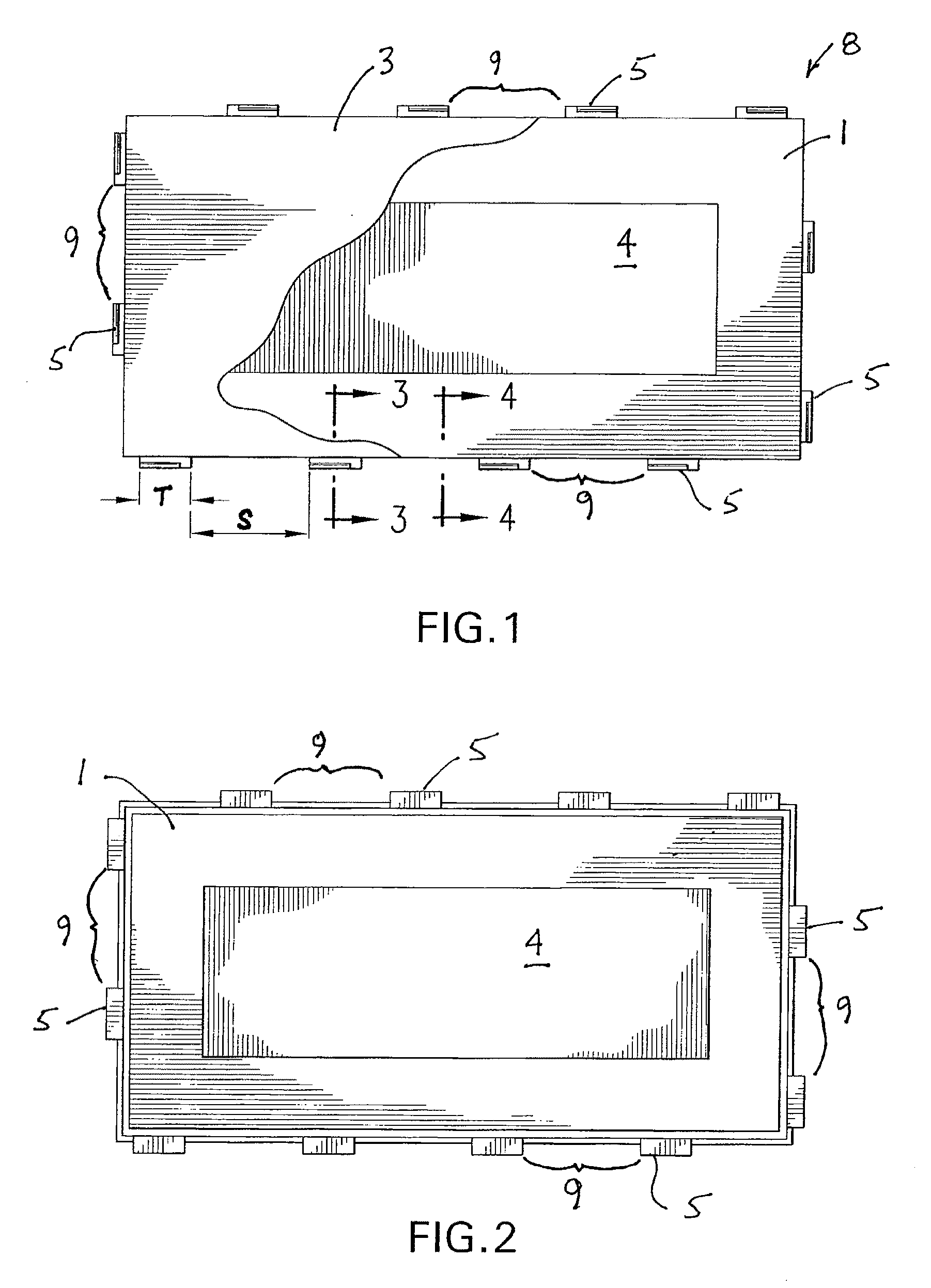

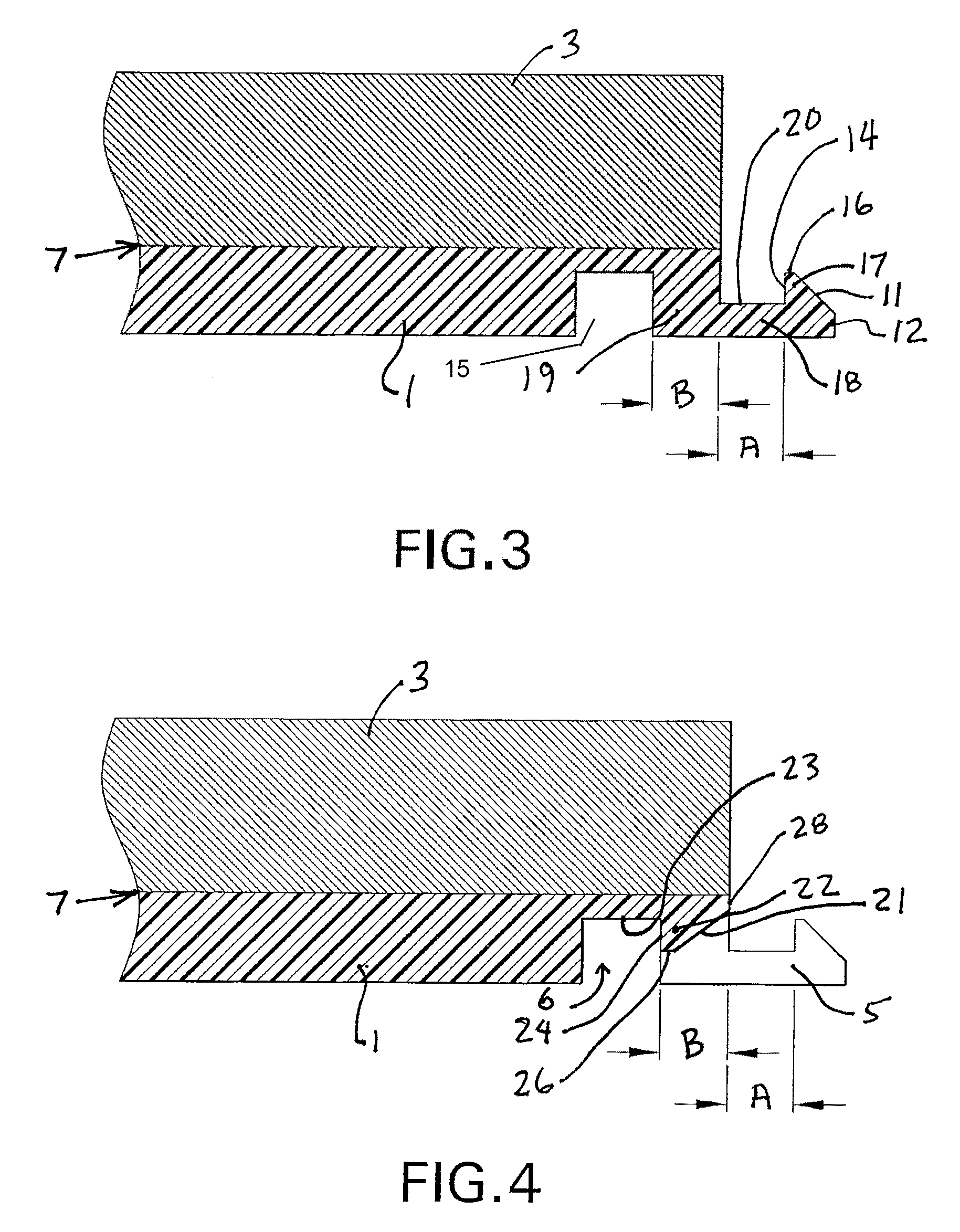

Board assembly

ActiveUS20120317911A1Stable qualityEasily assembleConstruction materialRoof covering using tiles/slatesEngineeringHigh pressure

A floor board assembly convenient to lay is characterized in that, in one embodiment, it comprises a frame, a filler board and an upper material with the frame and filler board affixed to the underside of the upper material. The frame includes latch tongues that extend outwardly from the lower side edges of the frame, and the tongues have locking projections that fit into recesses arranged just inside the periphery of the underside of the frame. The tongues and intervening spaces (with locking bars behind them) are space along the periphery of the board, such that any side of one board may be joined to any side of a similarly configured board. The upper material may be selected from a variety of materials, including LVT (luxury vinyl tile), carpet, high pressure laminate or other decorative material. The filler board may be selected to accomplish reduced cost, and / or improved acoustics. In other embodiments, a frame and / or upper material may be absent. The floor board assembly requires a lower manufacture cost and lower equipment investment, has stable quality, versatility and ease of installation.

Owner:HONG KONG MEI LI SHENG FLOORING +1

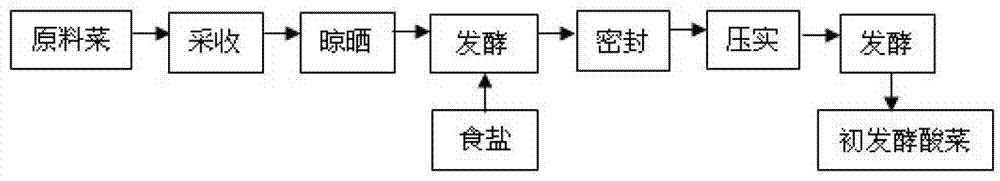

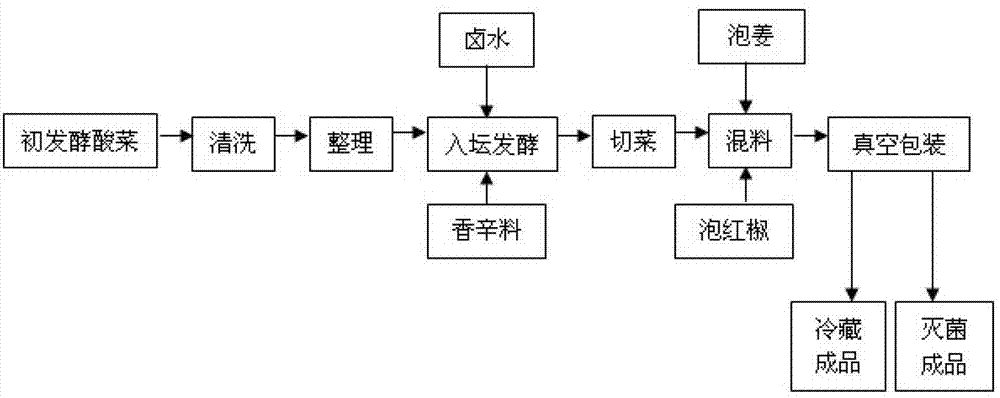

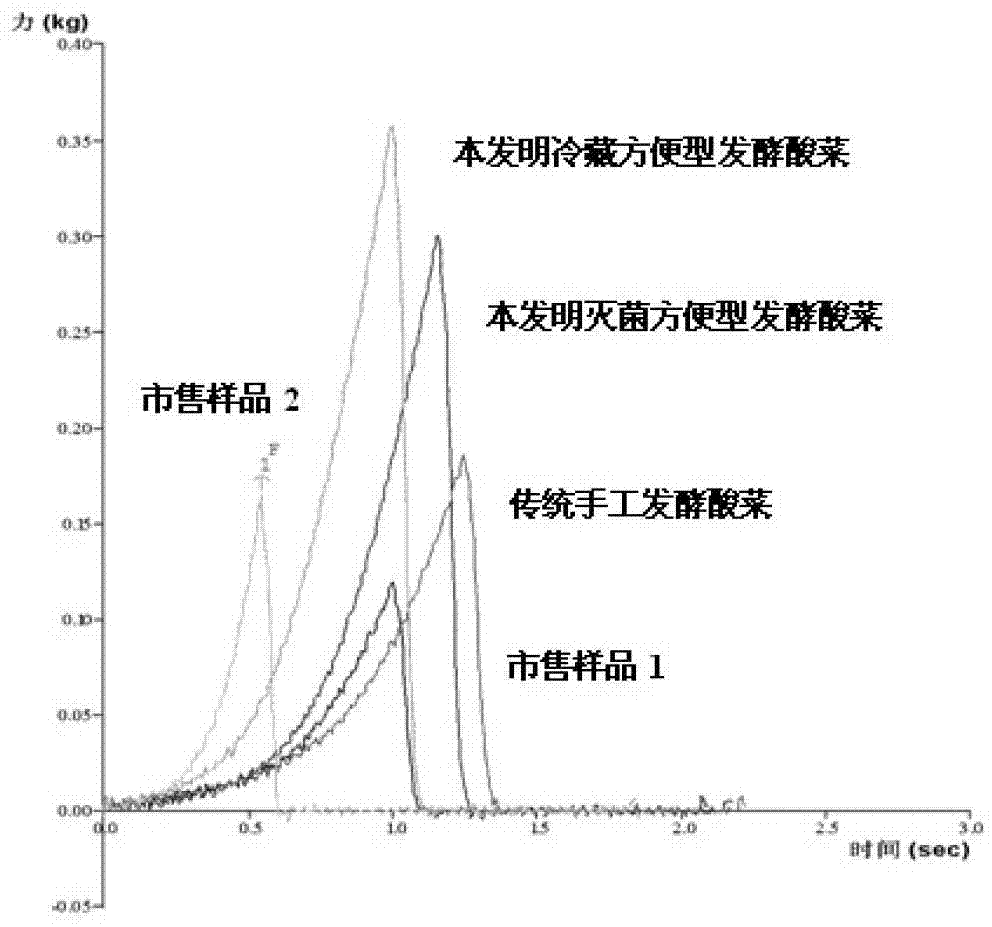

Convenient preparation method of fermented pickled Chinese cabbage

ActiveCN103202448AStable qualityInhibition of hybrid growthFood preparationChemistryOperation safety

The invention discloses a convenient preparation method of fermented pickled Chinese cabbage. The fermented pickled Chinese cabbage is prepared from large fresh leaf mustard and prepared through salt fermentation, washing, finishing, secondary fermentation, cutting, seasoning, vacuum packaging, pasteurization or refrigeration, and air dried cooling. According to the preparation method, the operation is simple and safe, and the fermented pickled Chinese cabbage prepared through the manufacturing method is good in mouth feel, stable in quality and convenient to eat.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Process for preparing high purity sodium heparin by purification of crude sodium heparin

This invention is purification method of raw heparin sodium. The product high-quality heparin sodium could be used for injection. The procedure is as followings: we use raw heparin sodium as material and purify to get high-quality heparin sodium with ion-exchange chromatography, kalium hypermanganicum oxidization, ultrafiltration and organic solvent fractional precipitation in the order we describe here. The ion-exchange chromatography helps remove most of foreign substance and ultrafiltration remove manganese ions, heavy metal ions and pigments. We choose NaCl solution as washing liquid to make sure the separation of heparin sodium and other foreign substances. This invention is advantageous in low cost, stable quality, high yieldness, and the apposite molecular and weight range. It's also approximate for alarge scale production.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

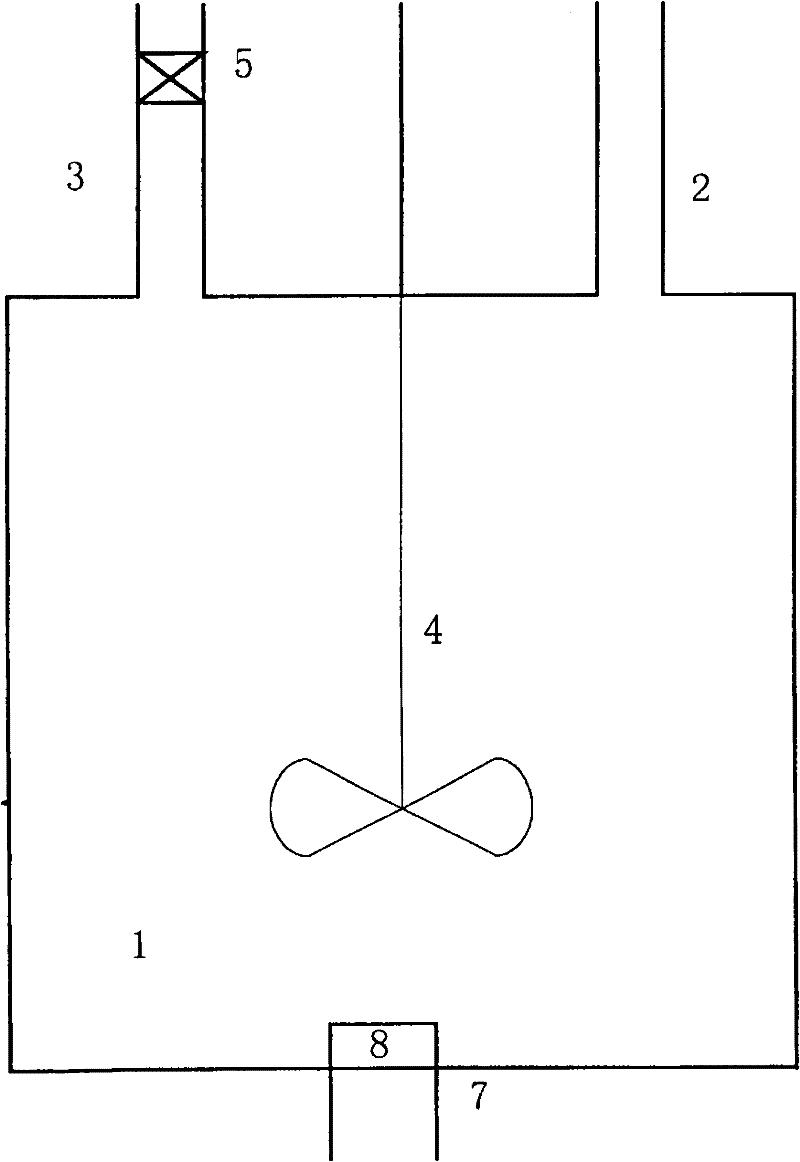

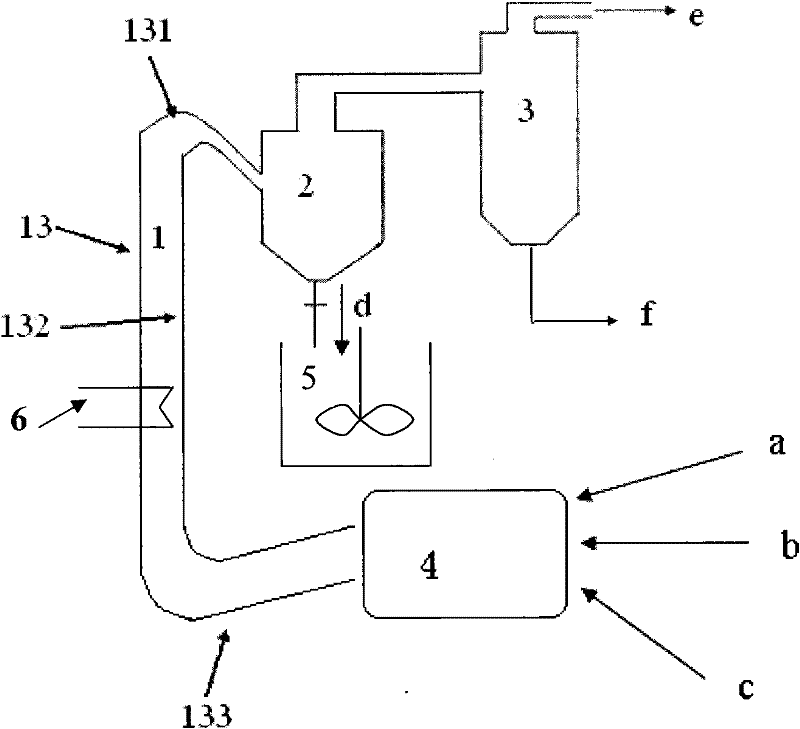

Preparation method of catalytic cracking catalyst

ActiveCN102451736AHigh crystallinityStable qualityCatalytic crackingMolecular sieve catalystsMolecular sieveProduct gas

A preparation method of a catalytic cracking catalyst comprises the following steps: mixing a molecular sieve and gas containing gas-phase SiCl4 to form a mixture flow, allowing the molecular sieve and the gas-phase SiCl4 to contact at 250-700 DEG C for 10 seconds to 100 minutes, mixing the molecular sieve obtained after contacting with the gas-phase SiCl4 with a binder, clay and water, performing beating and granulation to obtain the catalytic cracking catalyst. The preparation method of the catalyst provided by the invention can realize the continuous proceeding of the contact reaction of the molecular sieve and SiCl4; by the uniform mixing of the molecular sieve and the gas containing gas-phase SiCl4, the silicon supplementing reaction is ensured to be performed uniformly and fully; therefore the prepared molecular sieve has a high crystallization degree, more stable quality, and better performance; by controlling the different contact temperatures of the molecular sieve and SiCl4, different reaction conditions and reaction degrees can be controlled; therefore molecular sieve products with different dealuminization degrees can be obtained, and the catalytic cracking catalyst can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of imatinib mesylate

InactiveCN102040587ARelaxed reaction conditionsStable qualityOrganic chemistryComponent separationChemistryPyrimidine

The invention relates to a preparation method of imatinib mesylate using N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidine amine and 4-[(4-methyl piperazine-1-yl) methyl] benzoic acid hydrochloride as starting materials, and quality control method for intermediate in the preparation process and the final product. The overall yield of the process is about 40%, and the process is characterized in that reaction conditions are mild, operations are simple, column chromatography and other time and energy consuming steps can be avoided, quality of obtained products is stable, the purity is greater than 99%, the production cost is low, and the technology is stable and feasible.

Owner:韩南银 +1

Nano-size incombustible polyether polyol polymer and its preparing process and application

A nano-size (10-200 nm) incombustible polyether polyol polymer (MPP) is prepared through dispersing or locally grafting tripolycyanamine, cyanoguanidine and formaldehyde on high-activity polyether polyol at 40-160 deg.C for 5-16 hr. Said MPP has viscosity lower than 2300 MPa.s / 25 deg.C and density of 1.120-1.126g / ml, and can be used along with high-activity polyether polyol and assistant to prepare high-resilience foam polyurethane plastics.

Owner:朱吕民

Cantonese style sausage prepared via mixed bacterial fermentation and preparation method thereof

The invention discloses a cantonese style sausage prepared via mixed bacterial fermentation. According to a preparation method of the cantonese style sausage, raw material meat, water, table salt, sugar, monosodium glutamate, and sodium nitrite are mixed and are subjected to pickling; inoculation of microorganisms is carried out so as to prepare sausage; and the cantonese style sausage is prepared via fermentation. Based on the weight of the raw material meat, 1 to 3.5% of table salt, 1 to 12.0% of sugar, 0.01 to 0.2% of monosodium glutamate, 0.1 to 2% of liquor, 0.005 to 0.015% of sodium nitrite, and 1 to 3% of water are used. The invention also discloses the preparation method of the cantonese style sausage. The cantonese style sausage possesses unique fragrance, is safe and good for health; the preparation method is simple; fermentation is fast; and cost is low.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

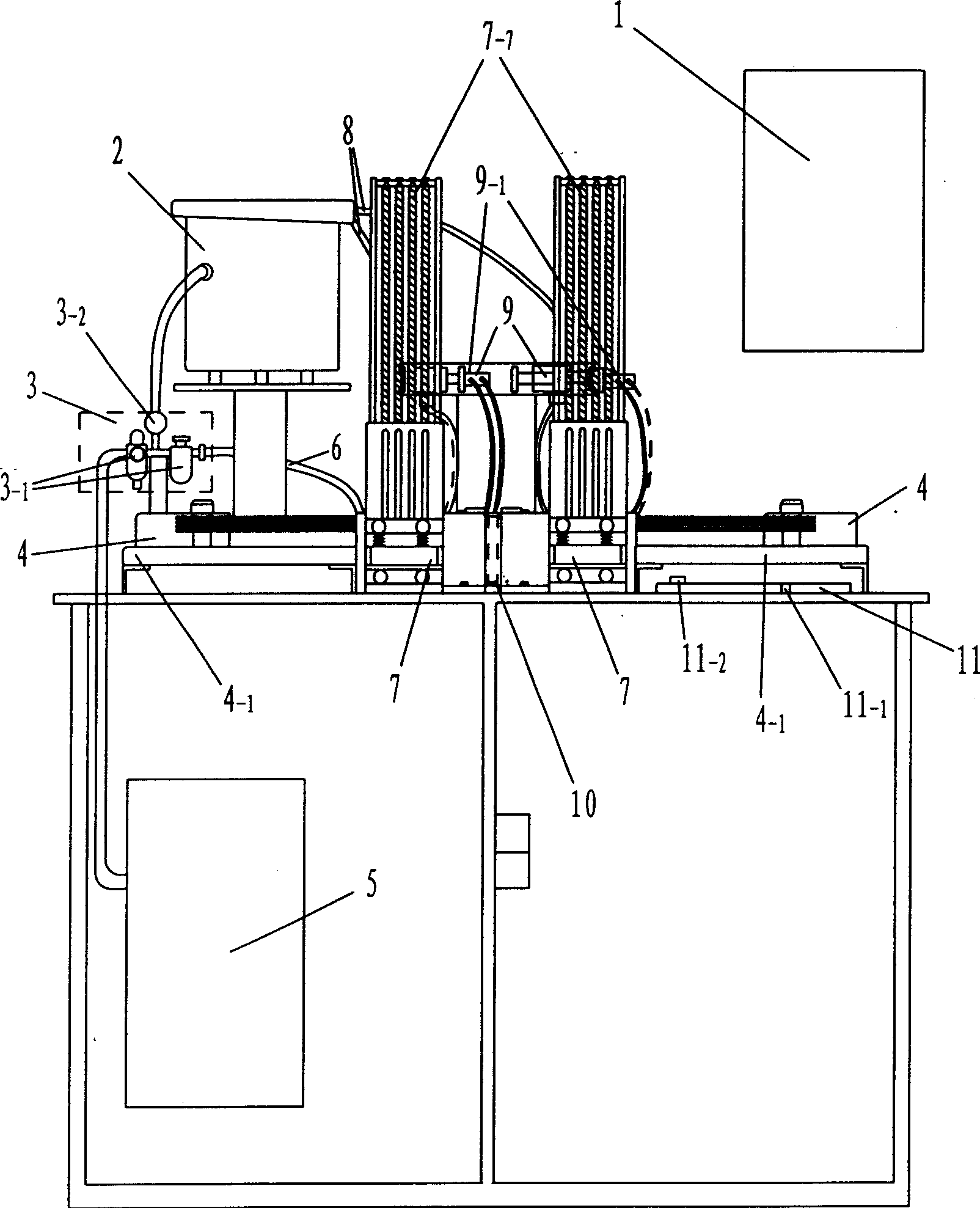

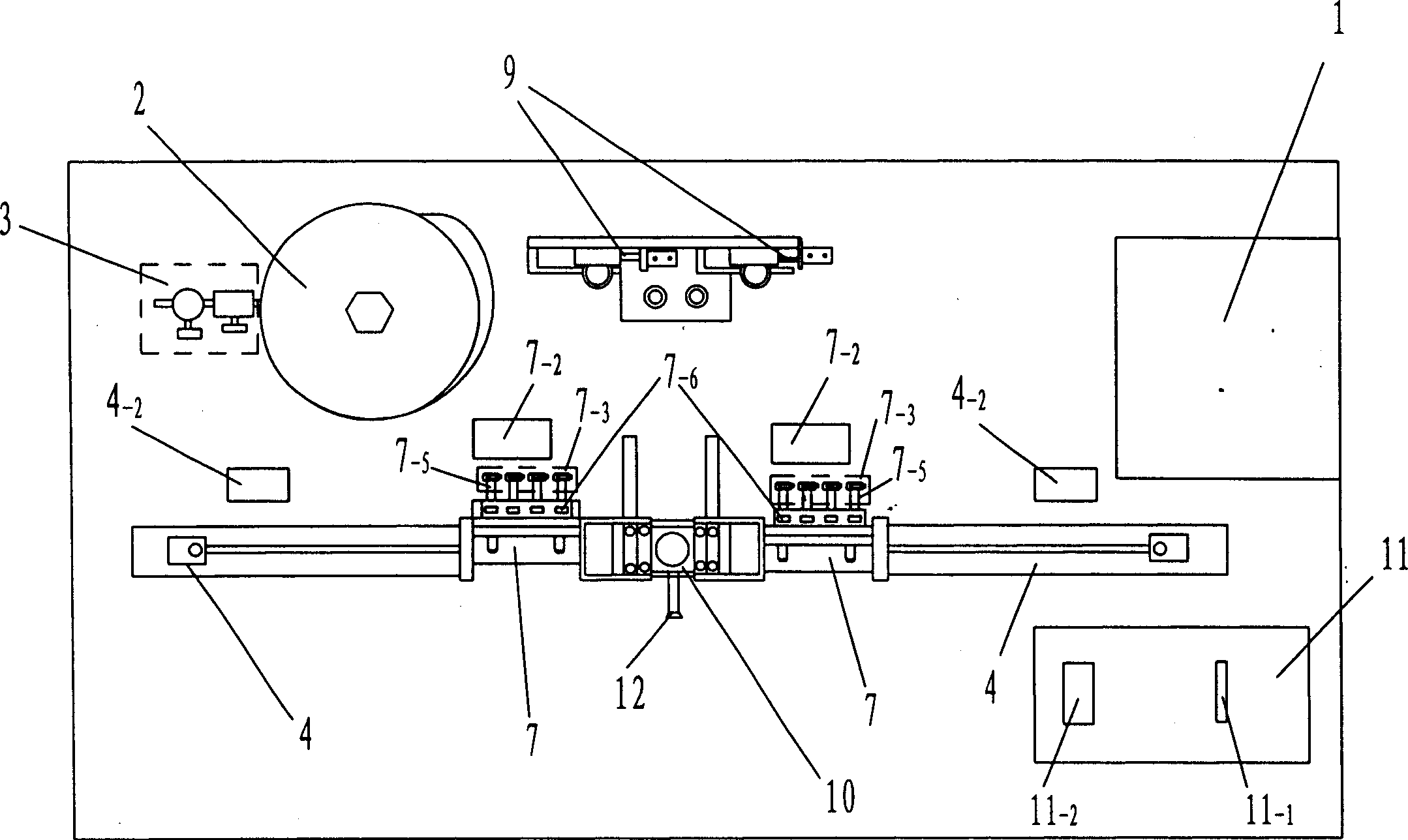

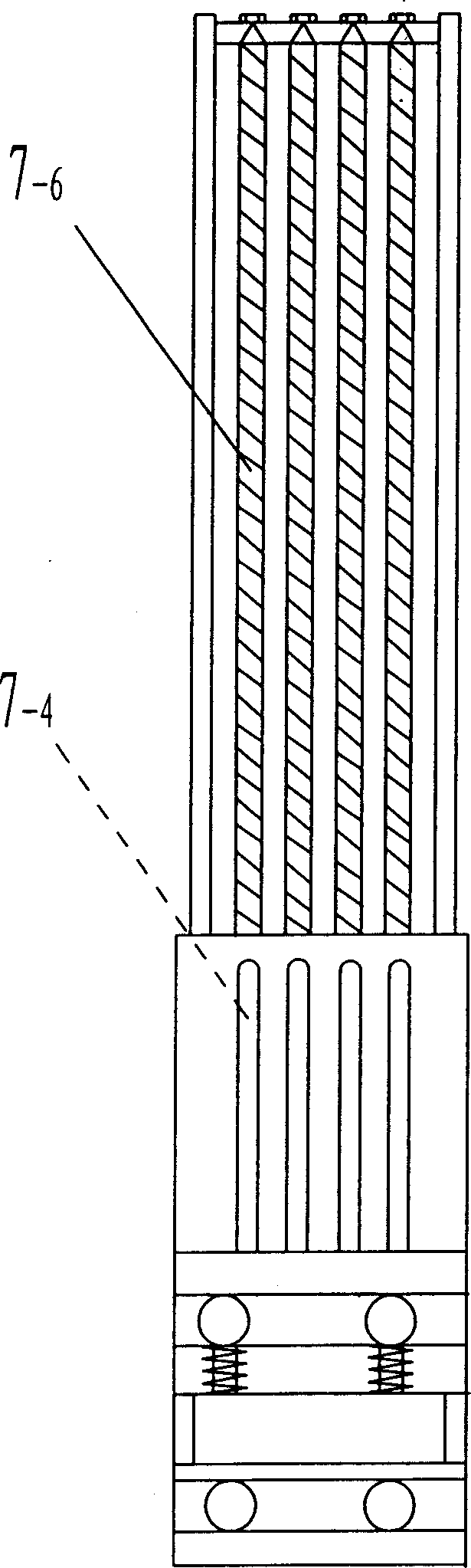

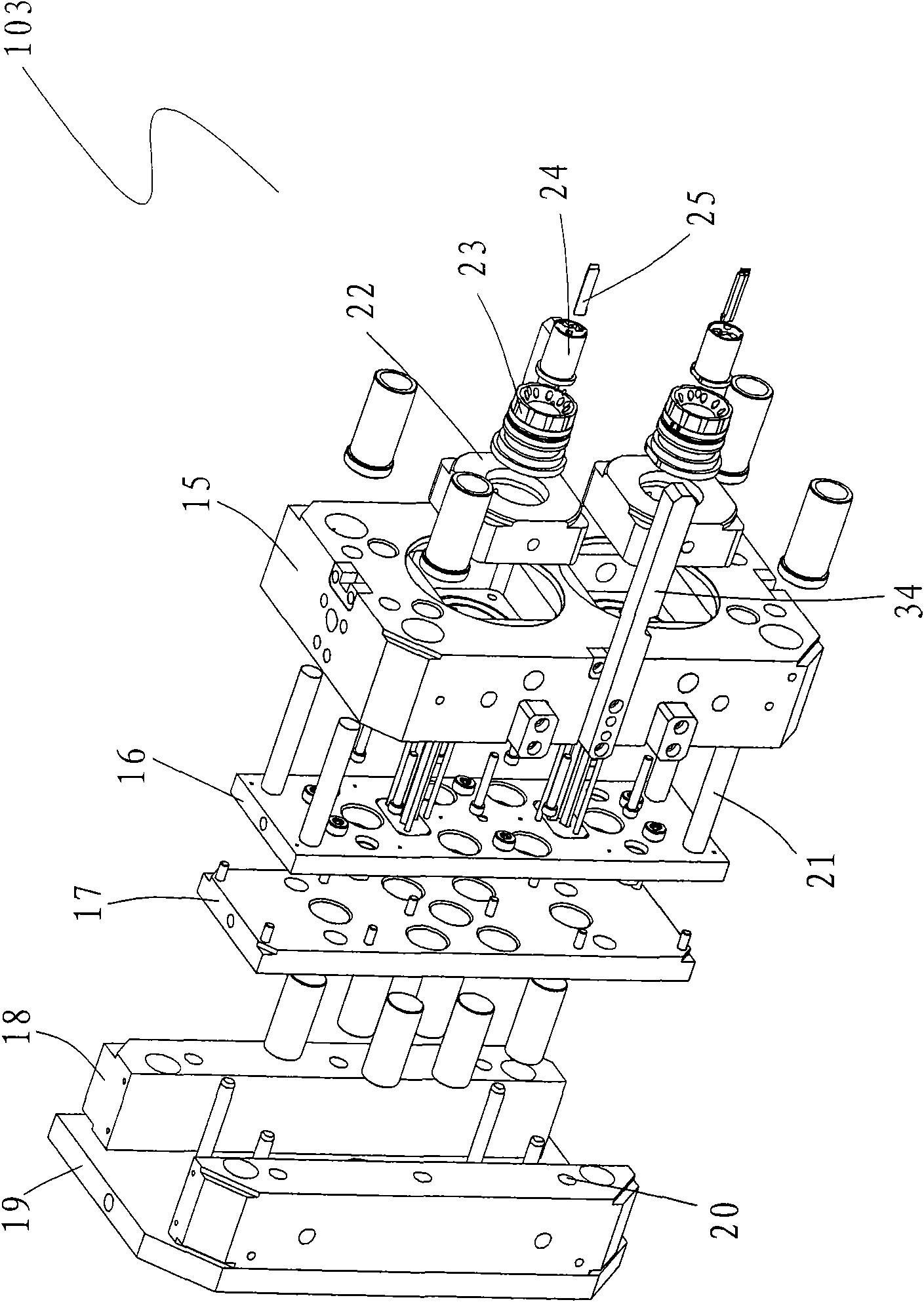

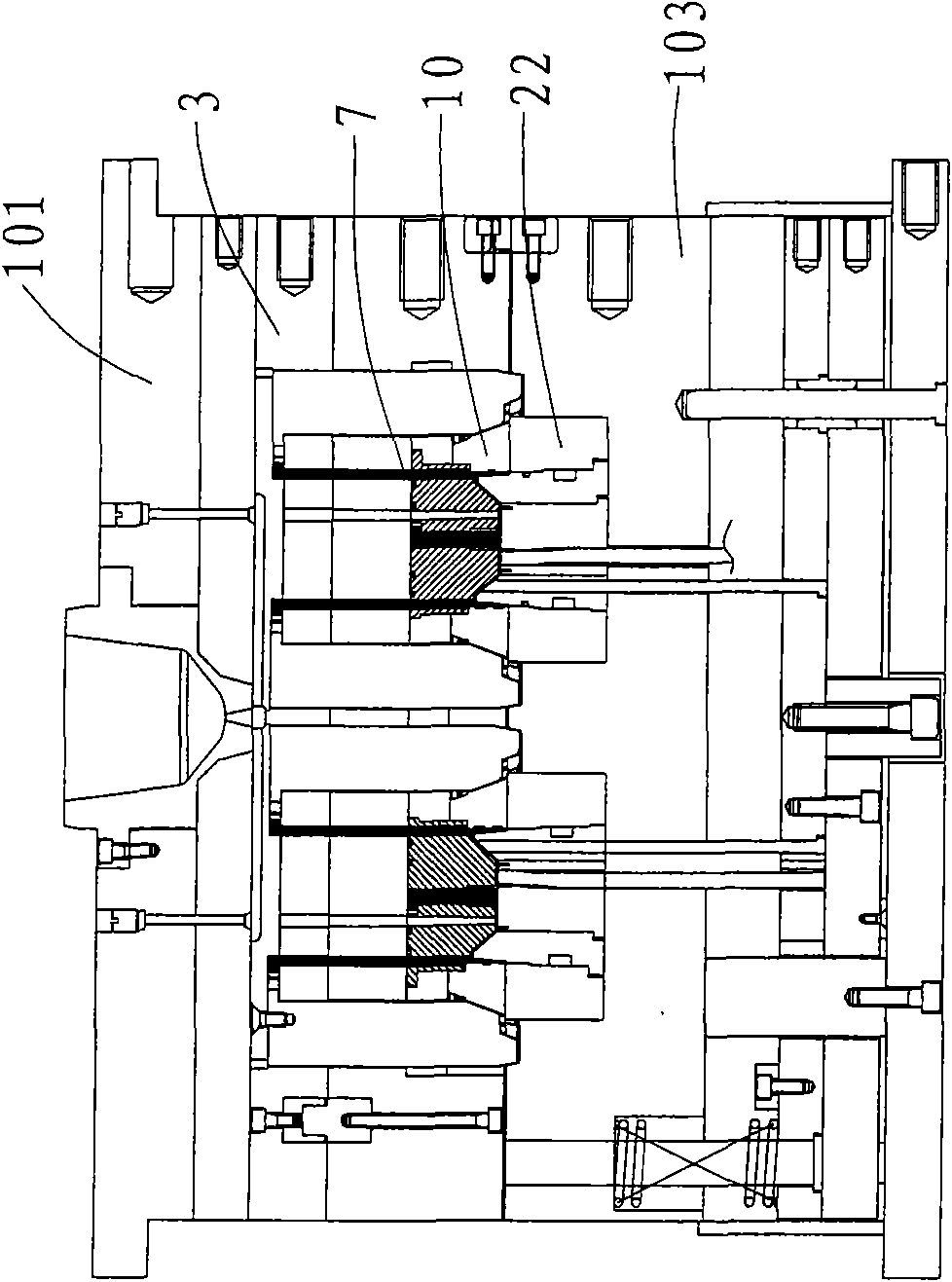

Automatic master assembling device and method with computer control

An automatic lock core assembling machine with computer control is composed of computer controller, vibrating tray, advancing unit, locking plate arranging unit, connecting pipeline, spring distributing and feeding unit, lock core holder, tooth shape recognizing unit and handle. Its assembling method includes such steps as initializing system, reading-in graphic data of key, analyzing tooth-shape, assembling locking plates and springs, and pushing the assembly into lock core.

Owner:HANGZHOU RENREN GRP

Method for producing low-melting-point renewable polyester for sheath-core polyester through glycol degradation

ActiveCN103145957AIncrease added valueStable qualityFilament/thread formingConjugated synthetic polymer artificial filamentsDecanedioic acidDibutyl tin dilaurate

The invention relates to a method for producing low-melting-point renewable polyester for sheath-core polyester. The low-melting-point renewable polyester is prepared from the following raw materials through degradation and polycondensation: (a) renewable raw materials; (b) glycol; (c) one or more of zinc acetate, potassium acetate, manganese acetate, magnesium acetate, lead acetate, cobalt chloride, tetrabutyl titanate, tetraisopropyl titanate and dibutyltin dilaurate; (d) one or more of m-phthalic acid, adipic acid and sebacic acid; (e) one or more of neopentyl glycol, hexanediol, butanediol and polyethylene glycol; (f) catalysts, namely antimony trioxide and cobalt acetate; and (g) a stabilizer, namely trimethyl phosphate. The low-melting-point renewable polyester produced by the method can be applied to the preparation of sheath-core polyester staple fibers, so that the added value of polyester wastes in preparation of renewable polyester staple fibers is increased, and the prepared sheath-core renewable polyester staple fibers have the characteristics of stable quality and excellent quality. The method can be applied to the production of industries, such as non-woven fabrics, flocking and composite materials.

Owner:余姚大发化纤有限公司

Alcohol solution printing ink for wrapping paper of intaglio plate cigarette and preparation method thereof

The invention discloses an alcohol-soluble printing ink for wrapping paper of an intaglio plate cigarette, which is characterized in that the alcohol-soluble printing ink is prepared from the following raw materials by the weight percentage: 1 to 10 percent of polyvinyl butyal, 15 to 85 percent of alcohol and 5 to 75 percent of paints and / or fillers. 1 to 15 percent of solid resin and / or 0.1 to 5 percent of auxiliary agents can be added to the alcohol-soluble printing ink. The invention further discloses a method for preparing the alcohol-soluble printing ink for the intaglio wrapping paper of the plate cigarette. Compared with the traditional alcohol-soluble printing ink for the filter tip of the intaglio plate cigarette, the invention has the advantages of stable quality, high color depth of the printing ink, good printing adaptability, no harmful residue after printed products are dried, clear and bright printing patterns, bright color, good brightness, strong adhesive degree, fading prevention and falling-off prevention of the printing products, good water resistance and excellent friction resistance.

Owner:江苏泰格油墨有限公司

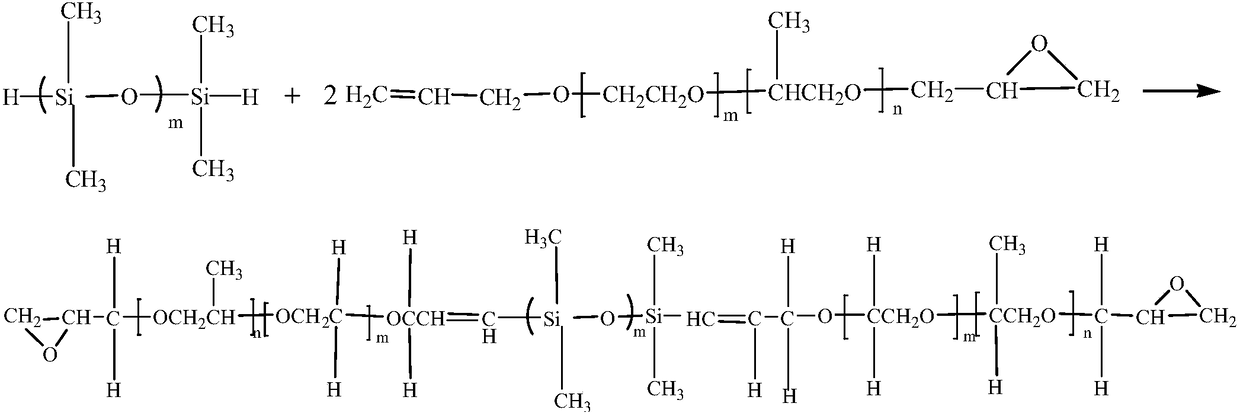

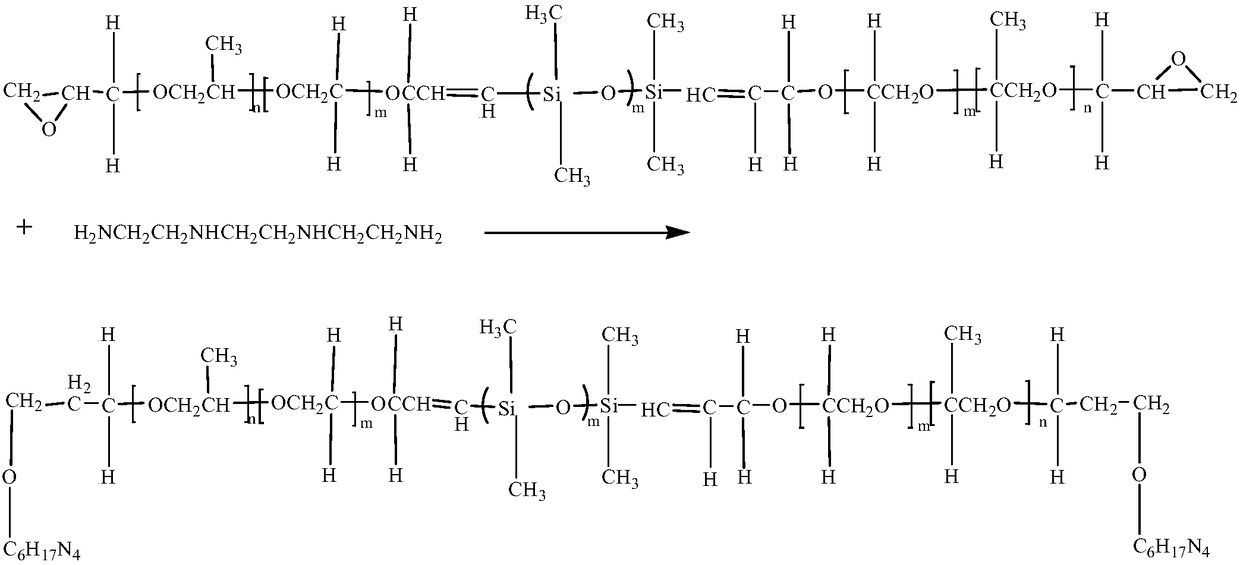

Synthetic method of low-solvent block silicone oil and hand feeling finishing agent containing low-solvent block silicone oil

The invention discloses a synthetic method of a low-solvent block silicone oil. An intermediate is obtained through reaction of end low hydrogen containing silicone oil and allylic epoxy polyether. The low-solvent block silicone oil prepared by the preparation method is stable in quality and the fabric hand feeling finishing agent is prepared by the low-solvent block silicone oil, aiming at different fabrics and the pursuit of the styles of customers, the molecular weight can be changed and the amine in the amination process can be changed; and the end low hydrogen containing silicone oil andthe allylic epoxy polyether of the block silicon oil are low in molecular weight and the polymorphism of the amine in the amination process greatly improve the flexibility of the block silicone oil, and the effects of different styles can be finished for different fabrics or the same fabric, and a corresponding hand feeling style can be effectively sorted out according to customer requirements.

Owner:ZHEJIANG QUEPING TEXTILE CHEM

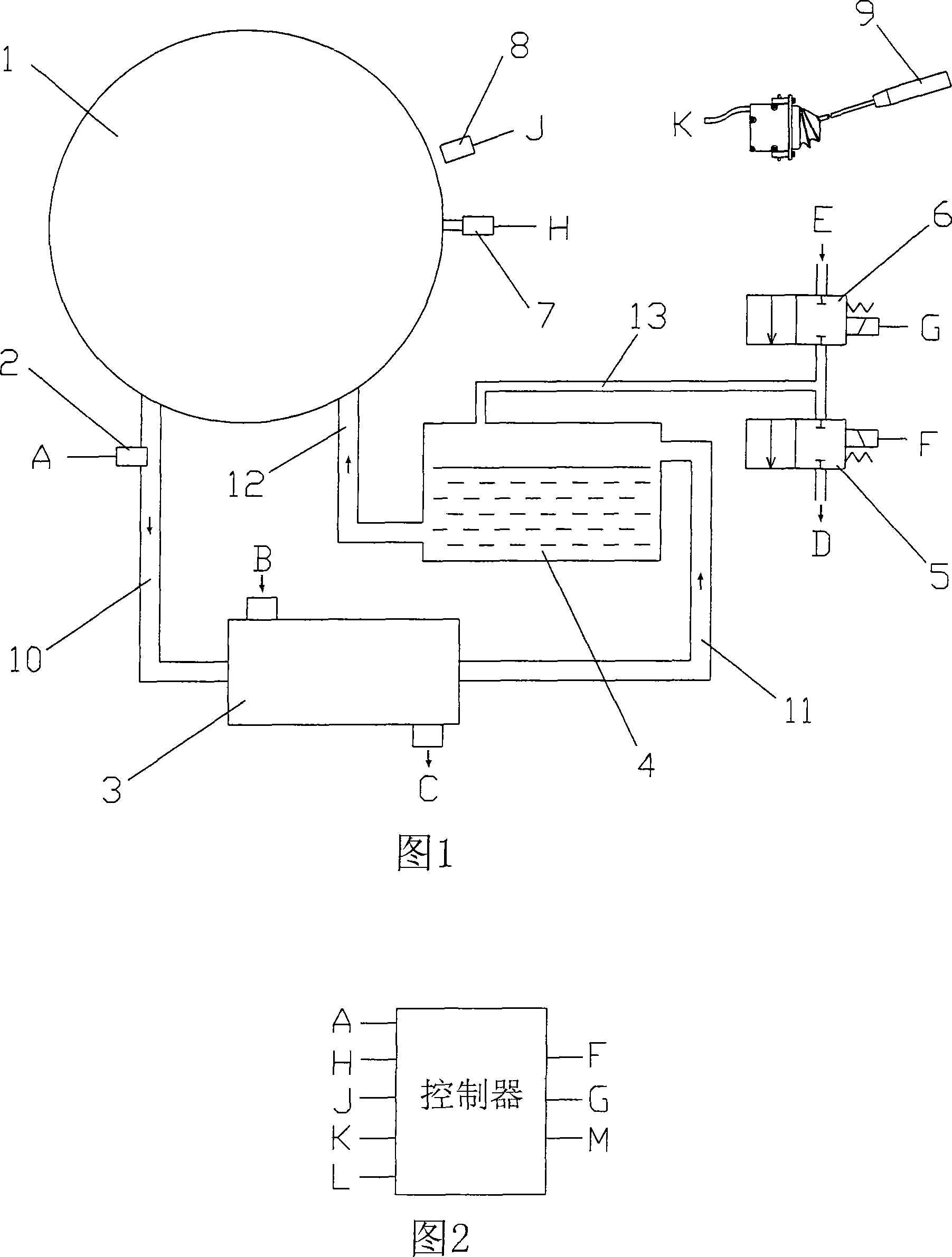

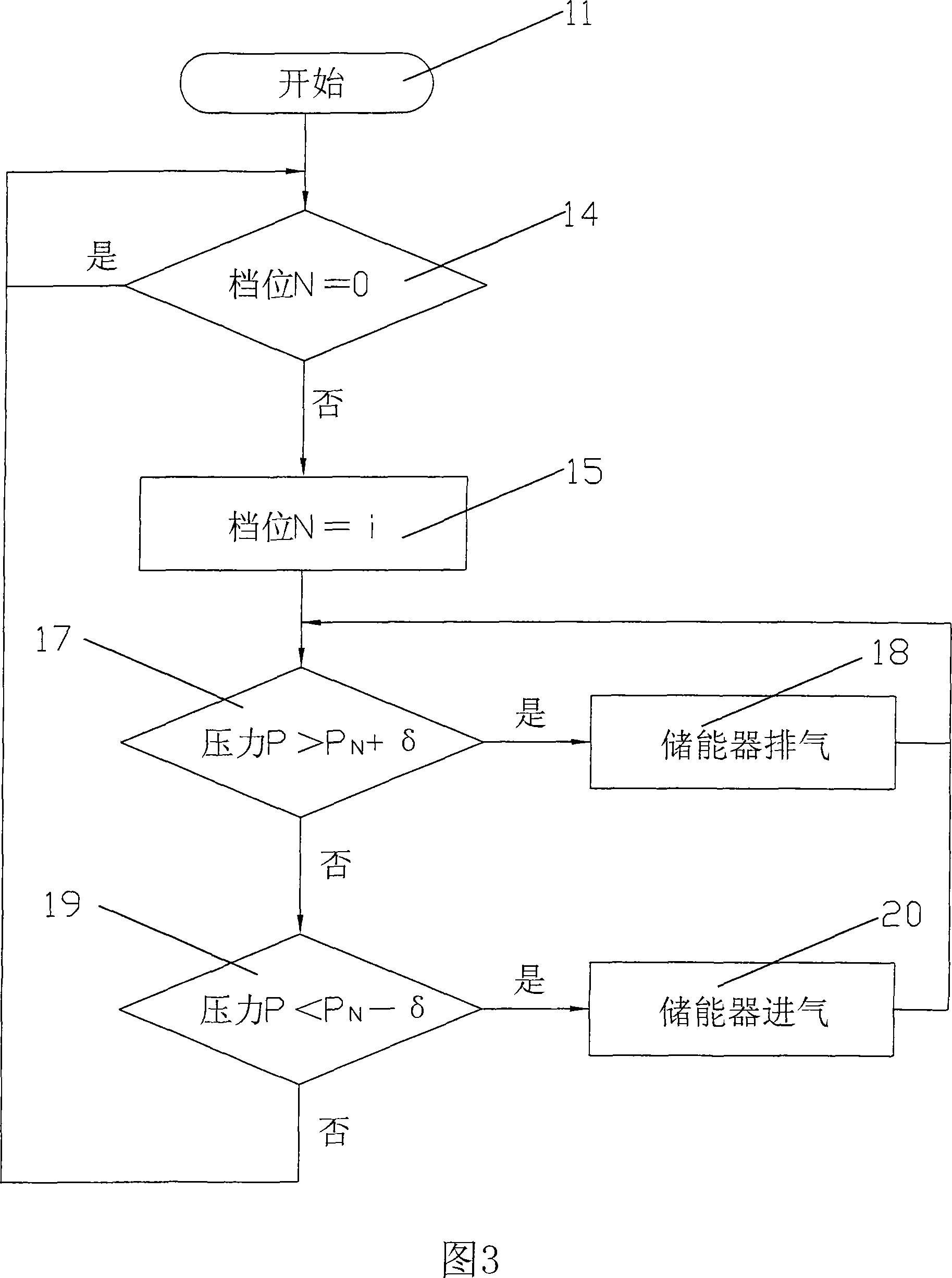

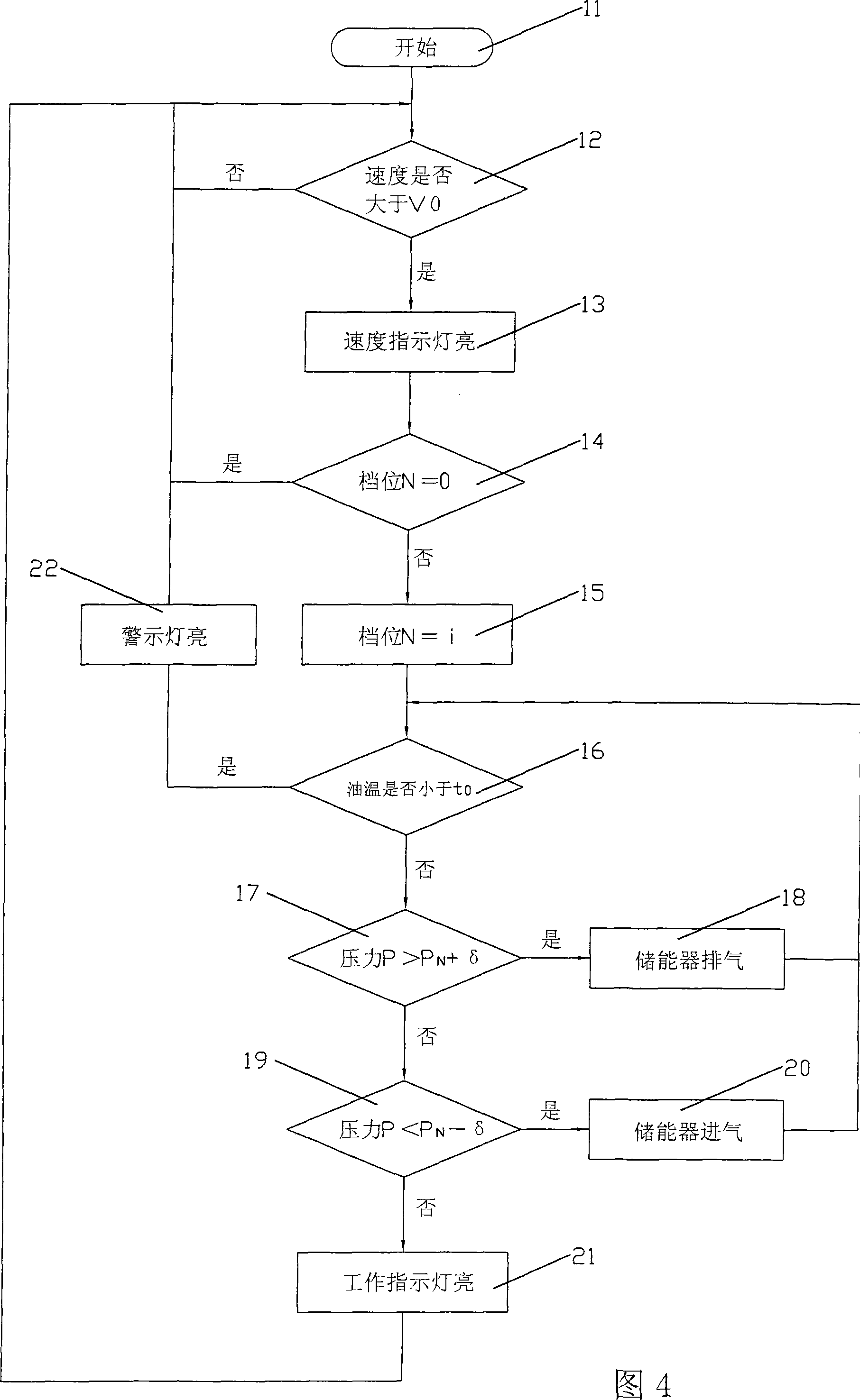

Hydraulic speed buffer control system and control method

The present invention relates to a hydraulic retarder control system and its control methods. The said hydraulic retarder connects with a heat exchanger with water inlet and outlet and accumulator with air vent, which makes up a liquid circuit; the air vent of accumulator distinctively equips with intake magnetic valve between compressed air through windpipe, and equips with air outlet magnetic valve; the pressure transducer and magnetic valve installed liquid circuit of hydraulic retarder and accumulator distinctively connect with control device by electricity, the gear switch connects with control device. The pressure value collected by the said control device compares with gear switch signal corresponding resetting value, when the differental value is bigger than fixed value, supplying electricity to the outlet magnetic valve to reduce pressure of the accumulator. When the differental value is lower than fixed one, supplying electricity to the intake magnetic valve to rise pressure of the accumulator, in order to keep the pressure in the cavity range, the hydraulic retarder can produce a stable inoment of resistance.

Owner:深圳市大为创新科技股份有限公司

Production method of high-capacity high-compaction lithium iron phosphate anode material

ActiveCN103618083AIncrease compaction densityStable qualityCell electrodesPhosphorus compoundsMagnesiumLithium electrode

The invention discloses a production method of a high-capacity high-compaction lithium iron phosphate anode material. The high-capacity high-compaction lithium iron phosphate anode material is prepared by adopting a multi-time compaction and sintering method, a purpose for improving the compaction density, the electrochemical gram capacity and cycling performance of the lithium iron phosphate can be effectively realized, a lithium iron phosphate primary crystalline phase is formed through the primary sintering, titanium, magnesium and manganese crystals are fused into the lithium iron phosphate crystalline structure through the secondary doping sintering, the lithium iron phosphate nanometer crystal is completely coated with carbon through the tertiary sintering after the carbon-cladding, and the conductivity of the lithium iron phosphate monocrystal is improved. A produced lithium iron phosphate lithium-ion battery has the advantages of high charging-discharging efficiency, good cycling stability, high compaction density, large electrochemical gram capacity, good cycling performance and the like, the production cost of a power battery can be greatly reduced, and the lithium iron phosphate is enabled to be an optimal anode material for the power lithium-ion battery.

Owner:HENAN FUSEN NEW ENERGY TECH

New cancer-resisting use of fritillaria cirrhosa total alkaloids and compounds contained in fritillaria cirrhosa total alkaloids

InactiveCN102327571AStable qualitySafe to useOrganic active ingredientsAntineoplastic agentsFritillariaChuanbeinone

The invention provides use of fritillaria cirrhosa total alkaloids in preparing drugs for inhibiting multiplication of eukaryote tumor cells. The invention also provides new cancer-resisting use of compounds in fritillaria cirrhosa. The fritillaria cirrhosa total alkaloids can inhibit the multiplication of the eukaryote tumor cells, has an effect on curing tumors and can be used for curing multiple tumors. With the same dose, the drug effect of the fritillaria cirrhosa total alkaloids is obviously better than the compound peimine and peiminine. The fritillaria cirrhosa total alkaloids have stable quality, are safe to use and are easy to control, the preparation method is simple, and the mass production and clinical use can be conveniently realized. Monomeric compounds such as chuanbeinone, kashmirine, imperialine-beta-N-oxside, isoverticine, isoverticine-beta-N-oxide and peimisine contained in the fritillaria cirrhosa total alkaloids also can inhibit the multiplication of the eukaryote tumor cells and have an effect on curing the tumor; and with the same dose, the drug effect of the monomeric compounds in the fritillaria cirrhosa total alkaloids is obviously better than that of peimine and peiminine, and a new choice for clinically curing the tumor is provided.

Owner:SICHUAN UNIV +1

Injection moulding method of digit wheel and mould thereof

The invention discloses an injection moulding method of a digit wheel and a mould thereof. The method comprises the following steps: closing and molding a font front mould and a rear mould, opening the font front mould and the rear mould, rotating a rotating disc of a double-colored injection machine, rotating the rear mould to a second forming position, closing and molding the rear mould and a wheel body front mould, opening the wheel body front mould and the rear mould, pushing a product out, rotating the rear mould to a first forming position, and the like. The digit wheel mould comprises the front mould and the rear mould, wherein the front mould is a font core front mould, and the rear mould is a font core rear mould. By adopting the digit wheel mould, plastic digits on a digital display measuring meter can not be printed on the surface of the product by a rotary printing process any more, but the model product produced by directly adopting the digit wheel mould, therefore, not only the production process for producing the digit display measuring meter is reduced, the cost is saved, but also any pollution to the environment can not be generated, and the mould is very economicand practical.

Owner:宇科模具(厦门)有限公司

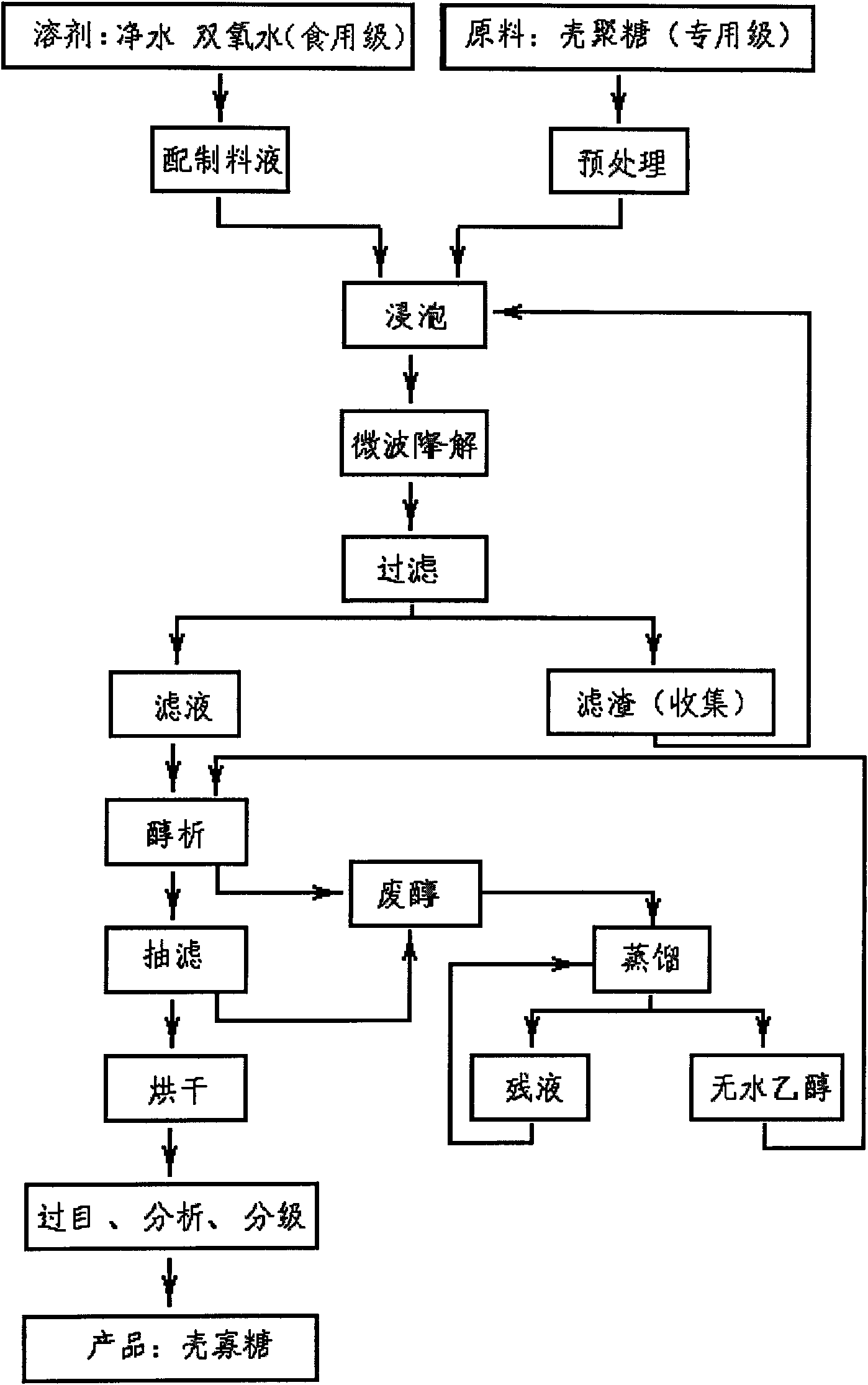

Method for preparing chitosan into water-soluble chitooligo saccharide

The invention relates to a method for preparing chitosan into water-soluble chitooligosaccharide, which comprises the following steps: using chitosan as a raw material, processing the chitosan by rinsing and drying technology, and immersing the chitosan in a material liquid prepared by purified water and edible hydrogen peroxide; carrying out the processing of microwave radiating degradation to form the mixed liquid of low-molecular chitooligo saccharide which can be dissolved in the material liquid and partial undegraded chitosan, and obtaining residual slag of chitosan and a chitooligo saccharide solution by filtration; and sending the chitooligo saccharide solution into absolute ethyl alcohol, and after alcohol precipitation, carrying out sucking filtration and drying to obtain a finished product of water-soluble chitooligo saccharide. The processing technology of microwave radiating degradation is used, and energy is mased by a physical method to degrade high-molecular chitosan into low-molecular water-soluble chitooligo saccharide with a stable structure, thus no other side product of reaction or pollutant is generated in the degrading process. Compared with the preparing method of the prior art, the invention has the advantages of advanced technology, simple procedures, low investment of production facilities, high product purity, stable quality and the like, and developsa wide market application prospect for the chitosan prepared by taking chitin as a raw material.

Owner:赵建发

Multifunctional surface treating agent and use method thereof

ActiveCN104530851AStable qualityExcellent performanceFireproof paintsLiquid surface applicatorsIonSurface finishing

The invention discloses a surface treating agent and a use method thereof, wherein the surface treating agent is used for improving surface properties of a substrate. The invention particularly discloses a multifunctional surface treating agent prepared from the following substances in percentage by weight: 5-50% of a film forming matter, 5-15% of a nano oxide, 0.5-20% of an auxiliary agent and 15-80.5% of deionized water. The multifunctional surface treating agent disclosed by the invention is applied to surface treatment project, and can realize effects of high water prevention, high oil prevention, high transparency, high pollution prevention, high flame retardance and high sun prevention.

Owner:广州市侗富贵化工原料有限公司

A kind of hydrochloric acid vegetable production method

The invention discloses a production method of salted and pickled vegetables, comprising the following steps of: cleaning and airing green vegetables, and then adding salt to pickle for 90-120 days; cleaning and slitting the well pickled green vegetable raw materials; carrying out desalting and dewatering treatment, and then adding the following condiments in parts by weight in terms of 1000 parts of the green vegetables: 150-250 parts of sweet wine, 60-80 parts of crystal sugar, 10-30 parts of hot peppers and 10-20 parts of pickled garlic; and blending, and then placing into a jar again to ferment for 7-10 days so as to obtain the salted and pickled vegetables. The production method of the salted and pickled vegetables is summarized by the applicant by combining with years of production experience of the Dushan salted and pickled vegetable and strictly controlling various parameters and ingredients of a production process. According to the production method of the salted and pickled vegetables, the pickling time of the green vegetables is controlled within 3-4 months according to seasons and temperature, the desalting and dewatering treatment is carried out on the pickled green vegetables to regulate the salt and water contents of the green vegetables, and various condiments and using amounts thereof are carefully chosen to carry out secondary fermentation on the pickled vegetables, and therefore the pure taste and the stable quality of a salted and pickled vegetable product can be achieved.

Owner:贵州省独山盐酸菜有限公司

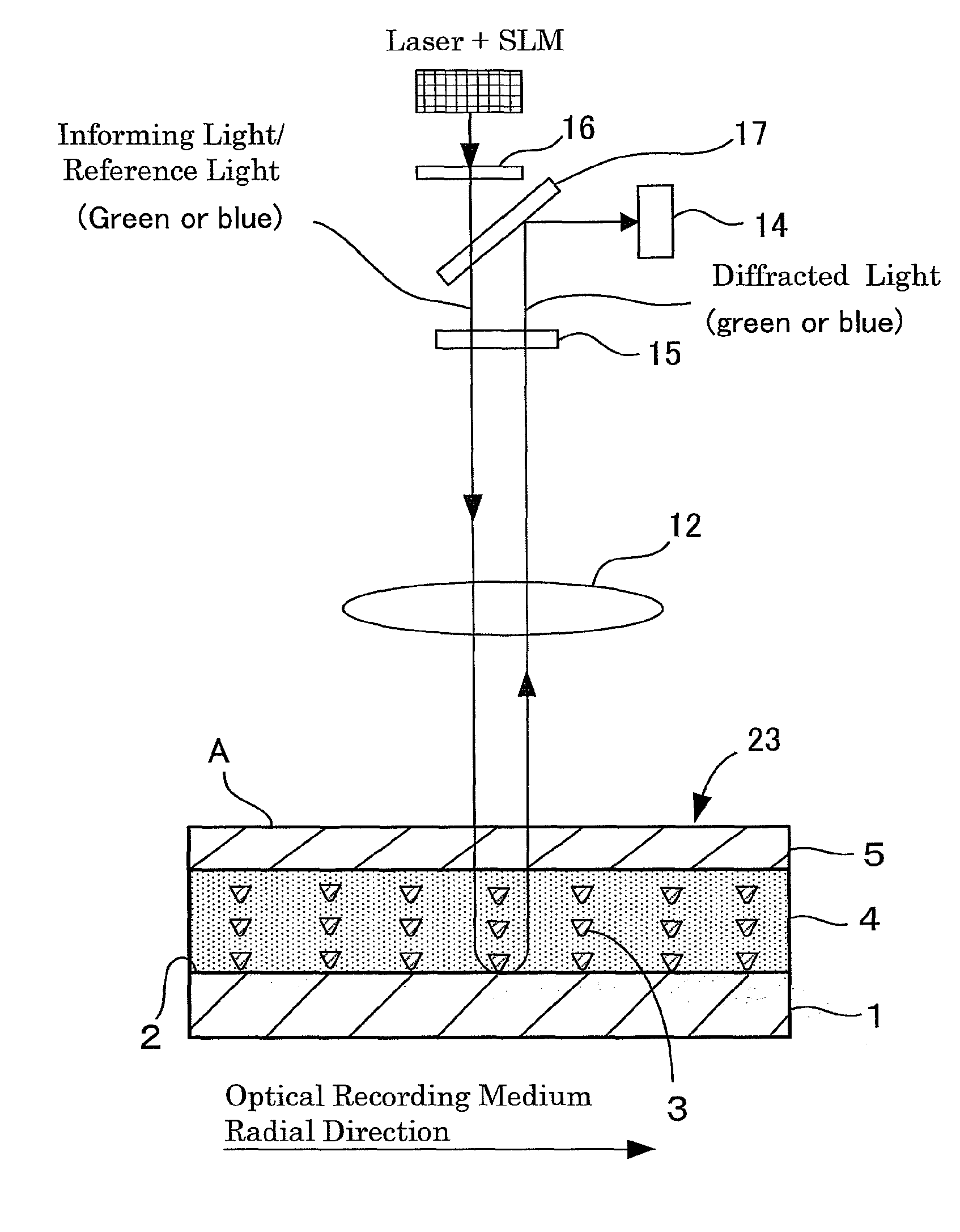

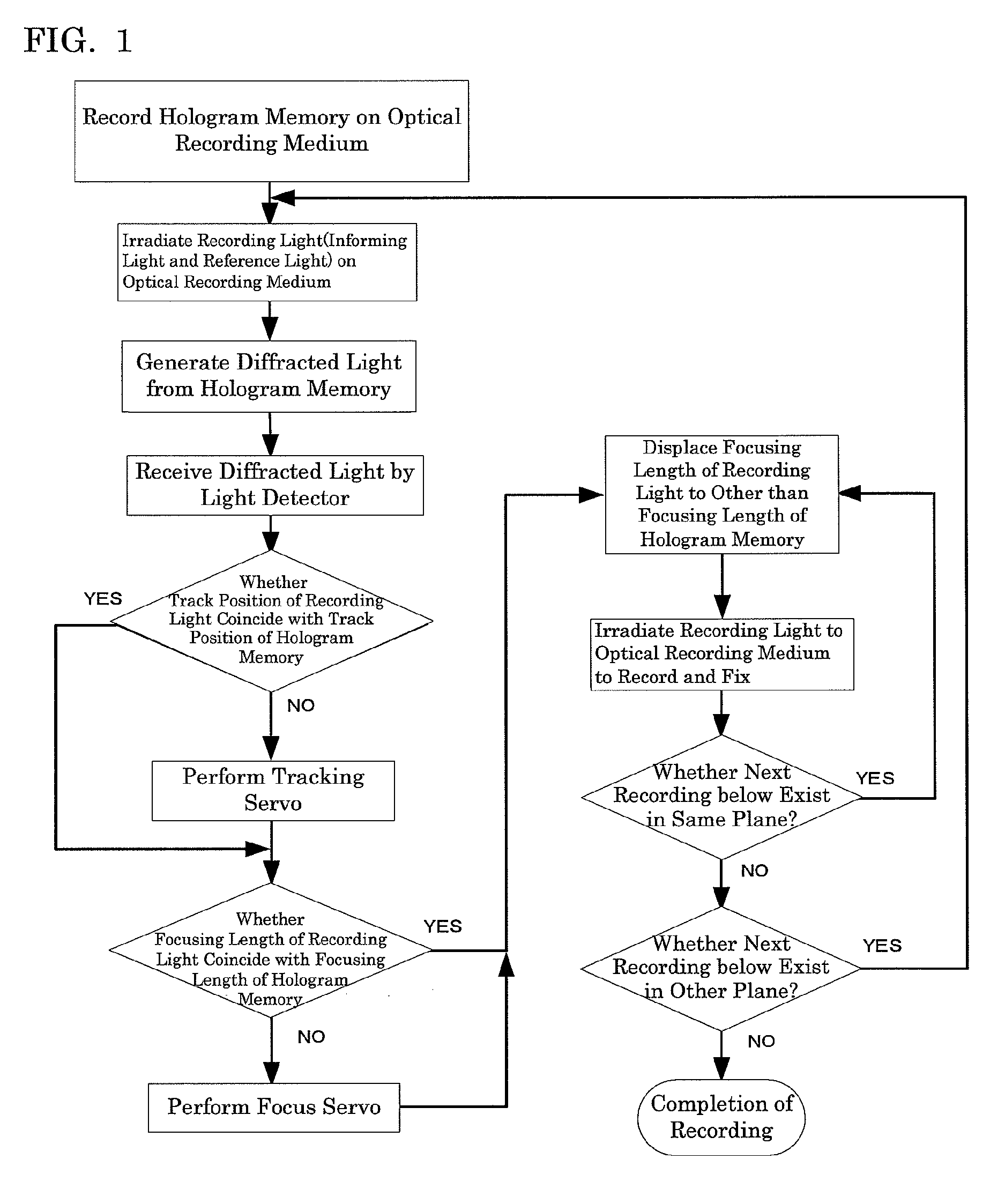

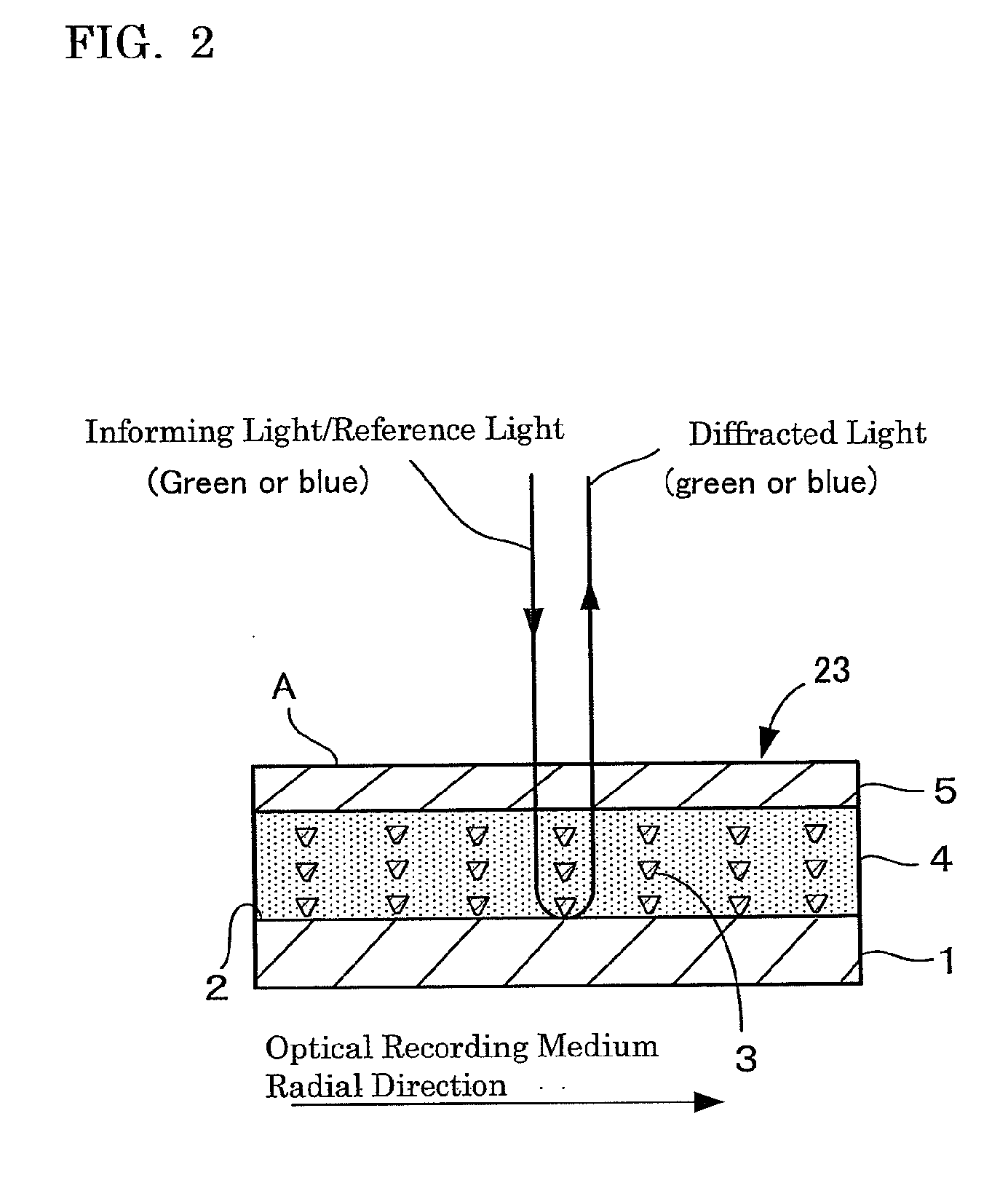

Optical recording method, optical recording apparatus, optical recording medium, and optical recording and reproducing method

InactiveUS20090103415A1Less distortionStable qualityRecord information storageRecording/reproducing/erasing using optical interference patternsLaser lightOptical axis

The present invention aims to provide an optical recording method etc. that provides higher efficiency of recording and reproducing and is uninfluenced by the mismatch of optical axes of plural laser lights induced from accident errors of optical recording and optical reproducing apparatuses when carrying out recording or reproducing, or focus control etc. by use of a laser light, high multiple-recording can be carried out, and layer construction of the recording medium itself is simple.For the purpose, an optical recording method etc. is provided that comprises a first step of recording an interference image, in which a recording light is irradiated at an optional focusing length X1 in thickness direction of the recording layer, an interference image is formed, and the interference image is formed on the recording layer, then multiple bits are recorded per one recording, and a second step of recording an interference image, in which the recording light is irradiated at a focusing length X2 that is different from the focusing length X1 to form a second interference image, and the second interference image is formed and recorded on the recording layer, and then multiple bits are recorded per one recording.

Owner:FUJIFILM CORP

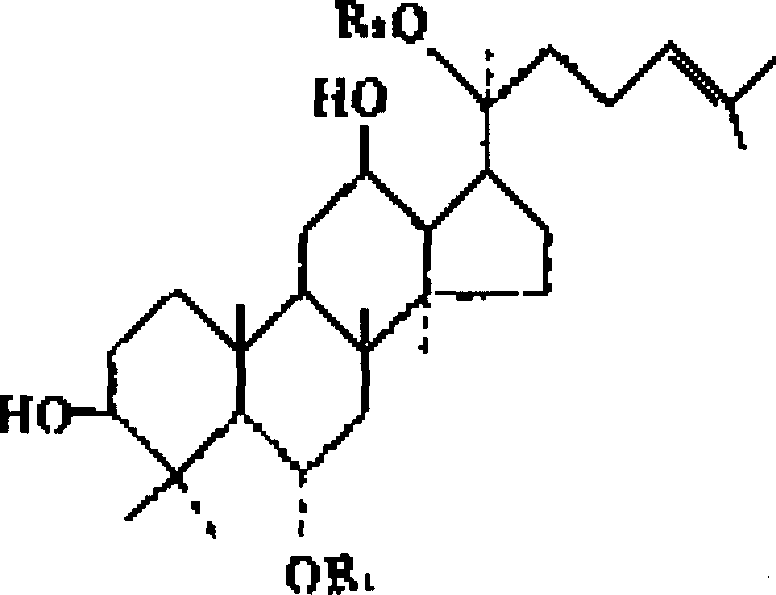

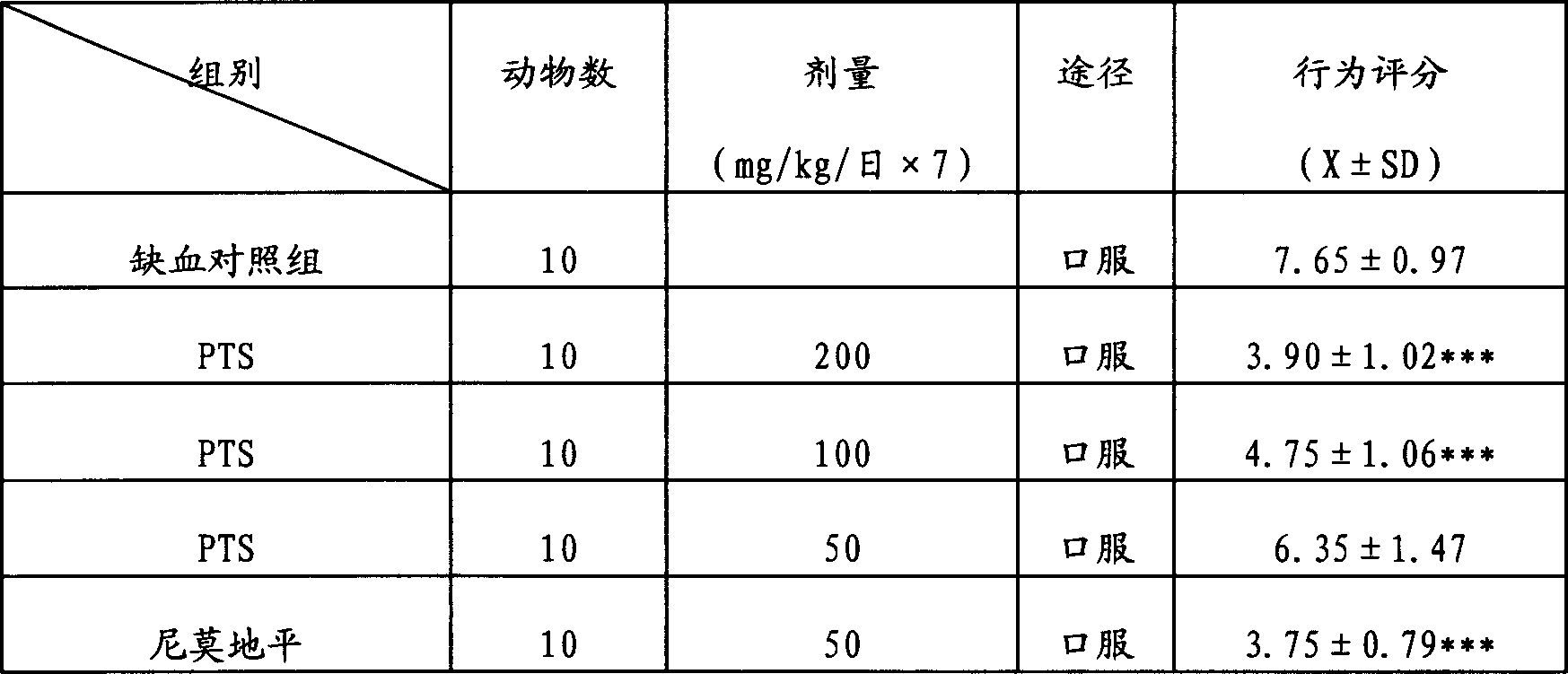

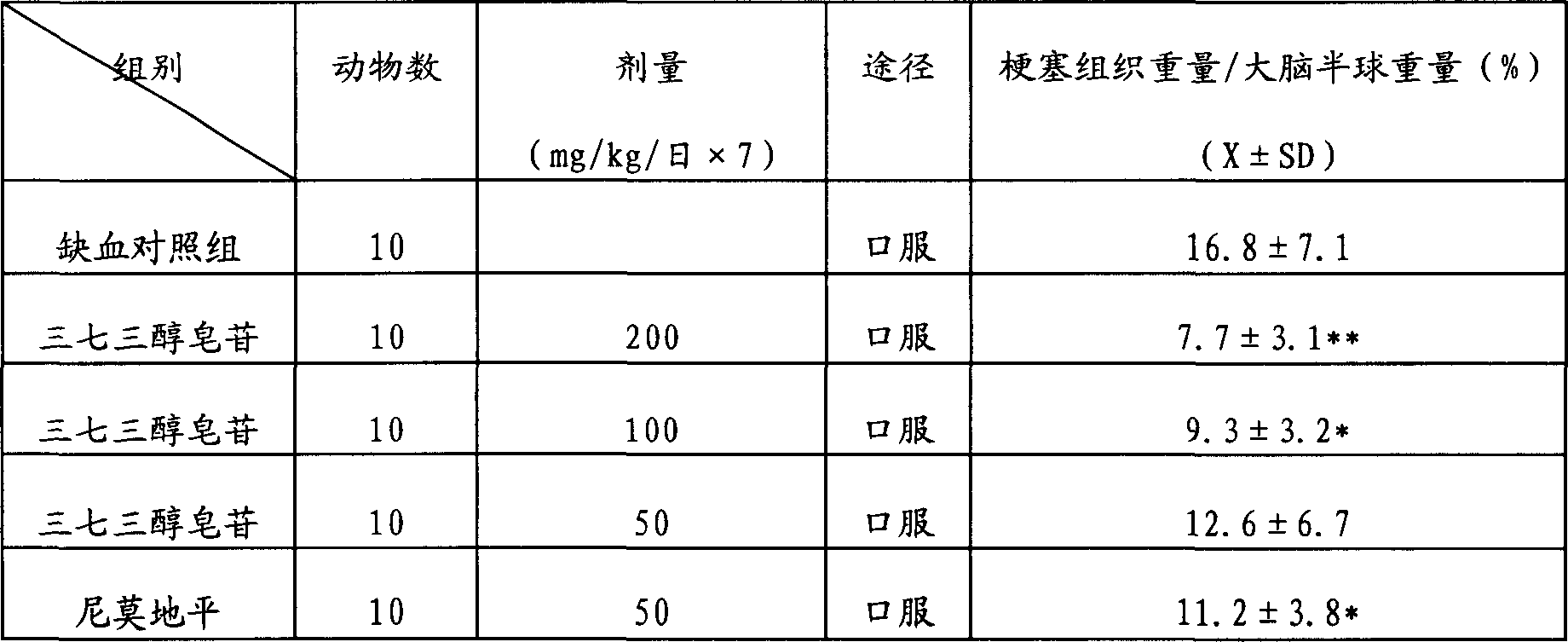

Process for preparing notoginseng triol saponin and use thereof

ActiveCN1699397AIncrease contentStable qualityOrganic active ingredientsSteroidsDrug standardsChemistry

The invention discloses a process for preparing notoginseng triol saponin and use thereof, which includes following steps: crushing the notoginseng, and adding ethanol solution whose concentration is 50 to 90% to immerse and percoalte the notoginseng, and then collecting the percoalted liquid and reducing pressure to concentrate the same, and then using distilled water to dilute the concentrated liquid, and then slowly filling the liquid into the large-hole absorption resin separating column, and using 40% ethanol to elute, and then collecting the 40% ethanol elutriant and refining the same to obtain notoginseng triol saponin. The notoginseng triol saponin extracted by the provided process contains all triol saponin in the notoginseng, wherein contains 156 to 79 % ginsenosiderx Rg, 5.0 to 7.5 % of ginsenosiderx Re, 11 to 14 % triol saponin R1, 78 to 98 % of notoginseng triol saponin. The notoginseng triol saponin can be used in treatment for cardiocerebrovascular embolic disease, and has advantages including high content, stable quality, good colour, low cost, and its organic solvent residual amount complies with drug standard.

Owner:李明劲

Medicament composition for curing vulva inflammation and vulvar pruritus and method of preparing the same

InactiveCN101279005ASimple production processStable qualityDermatological disorderSexual disorderSide effectDisease

The invention discloses a pharmaceutical composition for treating vulvitis and vulvae itching and a preparation method thereof. The pharmaceutical composition has the functions of removing heat, detoxification, demoistening, killing bacterium, relieving itching and removing dirty matters and is used for treating the diseases of itching, redness and swelling and pain in vulvae caused by vulvitis or vaginitis. The pharmaceutical composition adopts the modern preparation technology and can be processed to any formulation of external lotion, embrocation or effervescent tablet for gynaecology treatment which is applicable to the clinical wide application. The pharmaceutical composition is characterized by simple production technique, stable quality, convenient use, safety and no side effect, etc., thus having good efficacy.

Owner:BEIJING ZHONGKE RENHE SCI & TECH

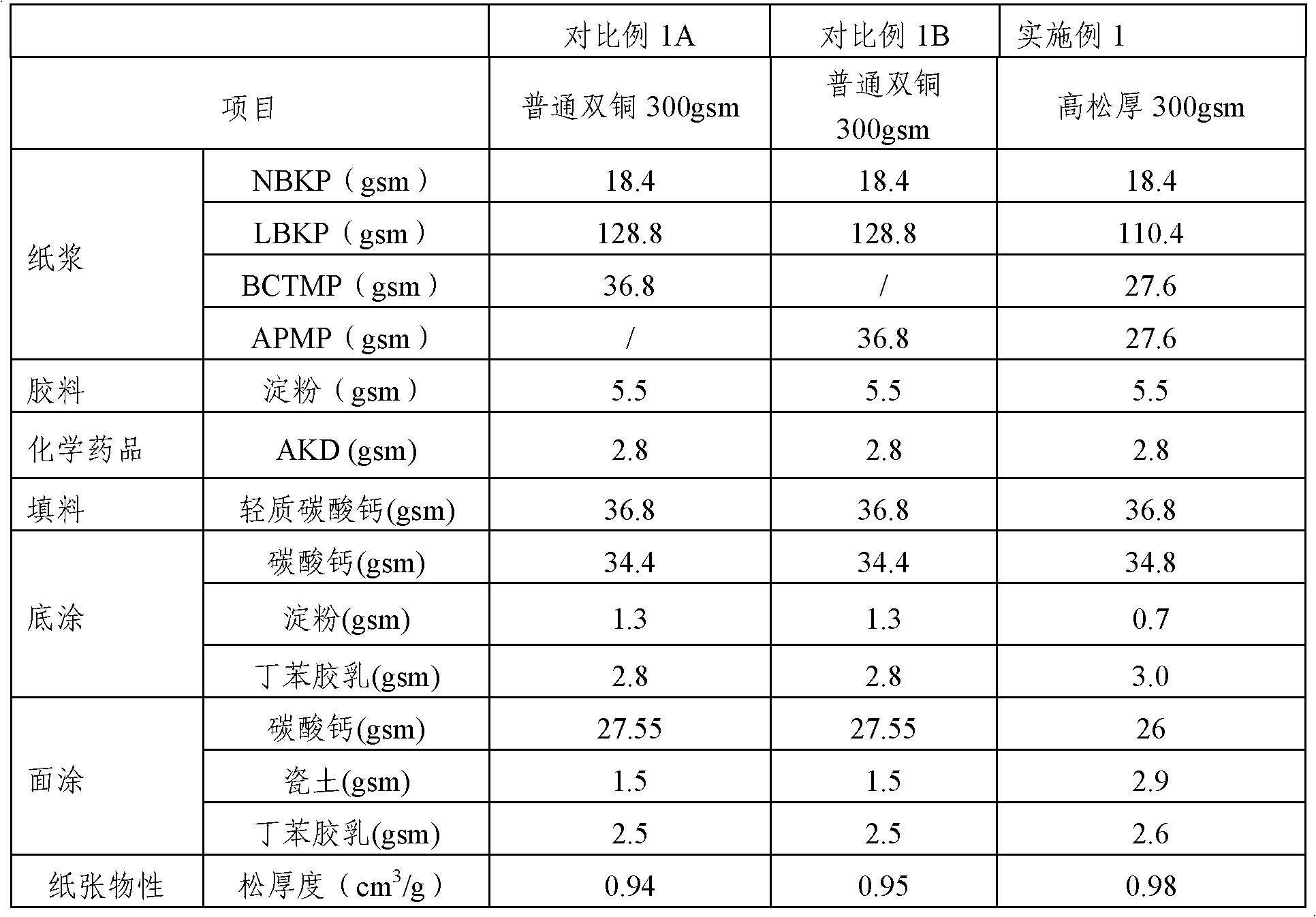

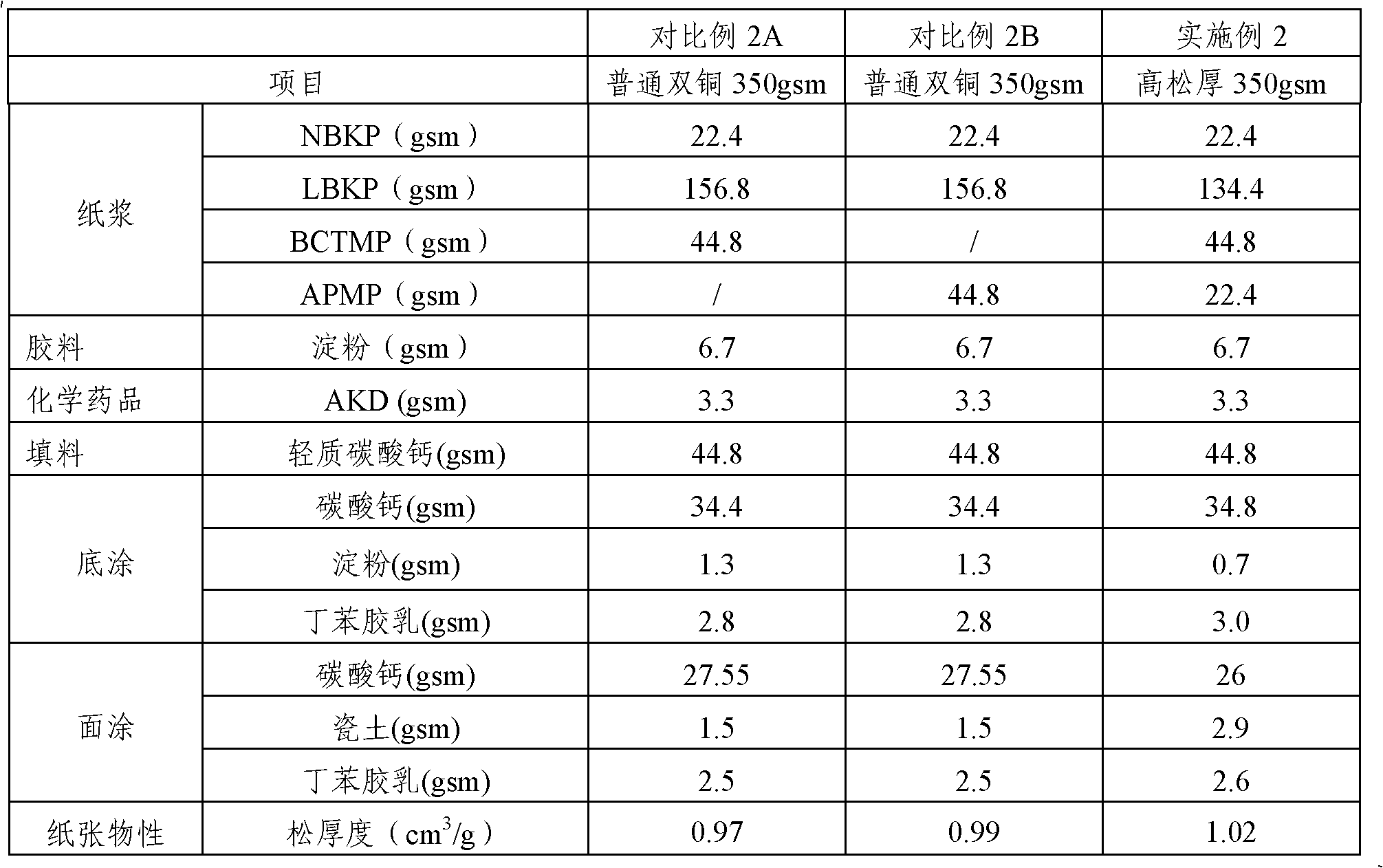

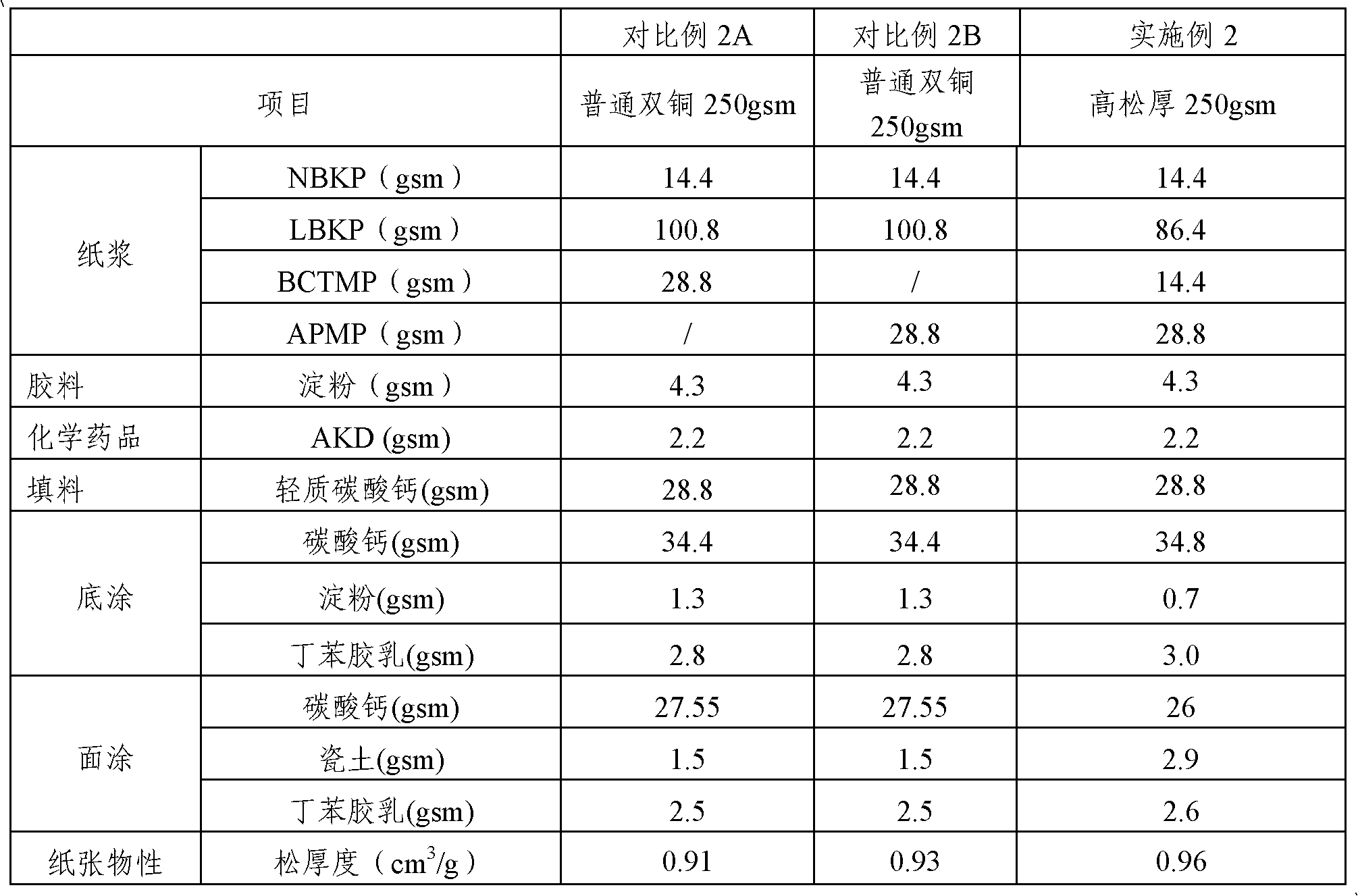

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240AStable qualityAvoid overproductionCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramHardwood

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Composition and mixed feed for preventing and treating porcine epizootic diarrhea

InactiveCN104970224AStable qualityImprove immunityFood processingAnimal feeding stuffProtease preparationAntibody

The invention discloses a composition for preventing and treating porcine epizootic diarrhea. The composition comprises the following raw materials in parts by weight: 0.1-0.8 part of probiotics, 0.02-0.04 part of N-carbamyl glutamic acid, 0.04-0.05 part of protease preparation, 0.2-0.3 part of glyceryl tributyrate, 0.2-0.3 part of acidifying agent and 0.03-0.05 part of egg yolk antibody. With the adoption of the composition disclosed in the invention, the amount of antibiotics used in pig industry is effectively reduced by more than 80 percent, and the porcine epizootic diarrhea caused by porcine epizootic diarrhea viruses can be effectively prevented and treated. In addition, the composition is safe and non-toxic. On the other hand, only a small amount of the composition is needed for adding in feeds, and the quality of the composition is stable. With the addition of the composition, the incidence of the porcine epizootic diarrhea can be reduced by 60-80 percent, and the immunity of the animals is greatly improved.

Owner:青岛大信饲料有限公司

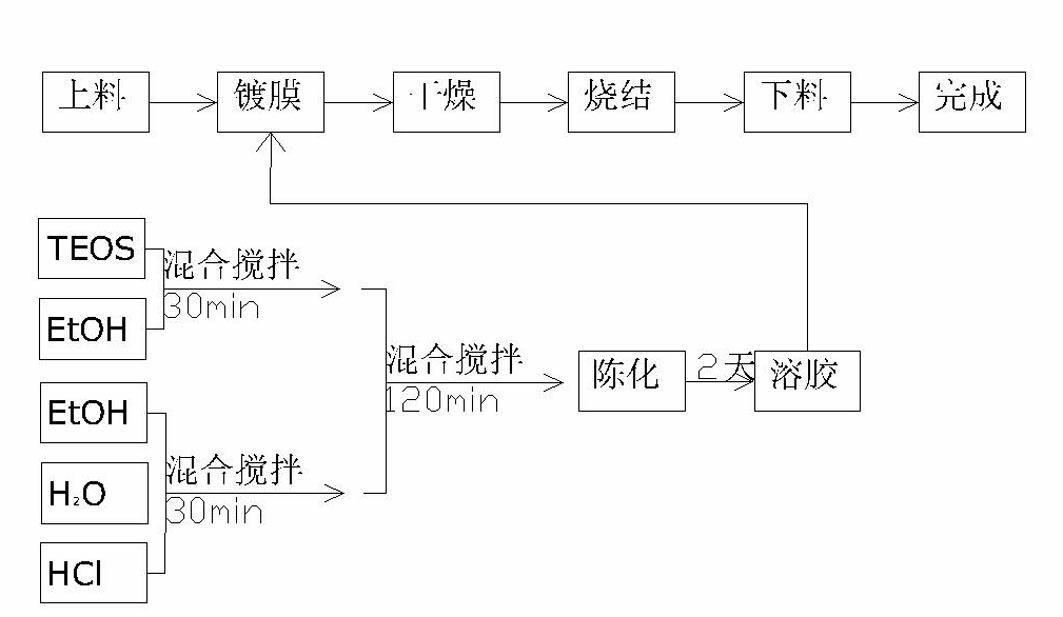

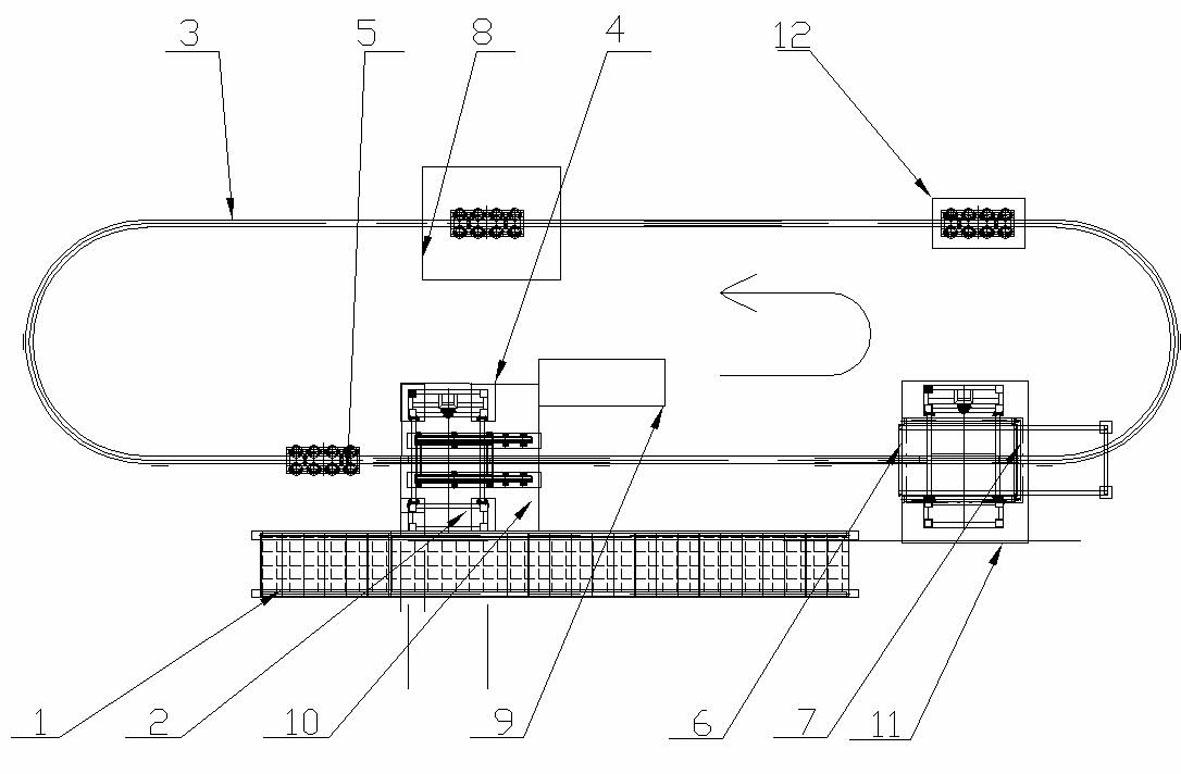

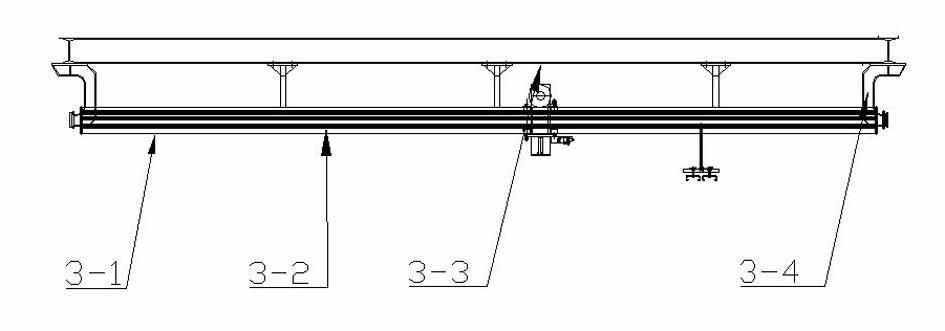

Method for producing anti-reflection coating of cover glass pipe of solar high-temperature heat collecting pipe and production line

The invention discloses a method for producing an anti-reflection coating of a cover glass pipe of a solar high-temperature heat collecting pipe and a production line. The method comprises the following steps of: preparing sol liquid; aging; cleaning, and drying; coating a film; drying; sintering; and cooling. The production line comprises a rail, a self-propelled trolley, a sol tank, a drying device, a sintering furnace, a lifting device and a control device, wherein the rail is provided with an assembly station; the sol tank, the drying device and the sintering furnace are arranged sequentially along the rail with the assembly station at an initial position and are provided with temperature control devices; and the control device is used for controlling the self-propelled trolley to run along the rail and move among the assembly station, the sol tank, the drying device and the sintering furnace. According to the method, the quality of the product is stable, and a solar transmittance ratio of the coating is high.

Owner:SHANDONG LINUO NEW MATERIAL

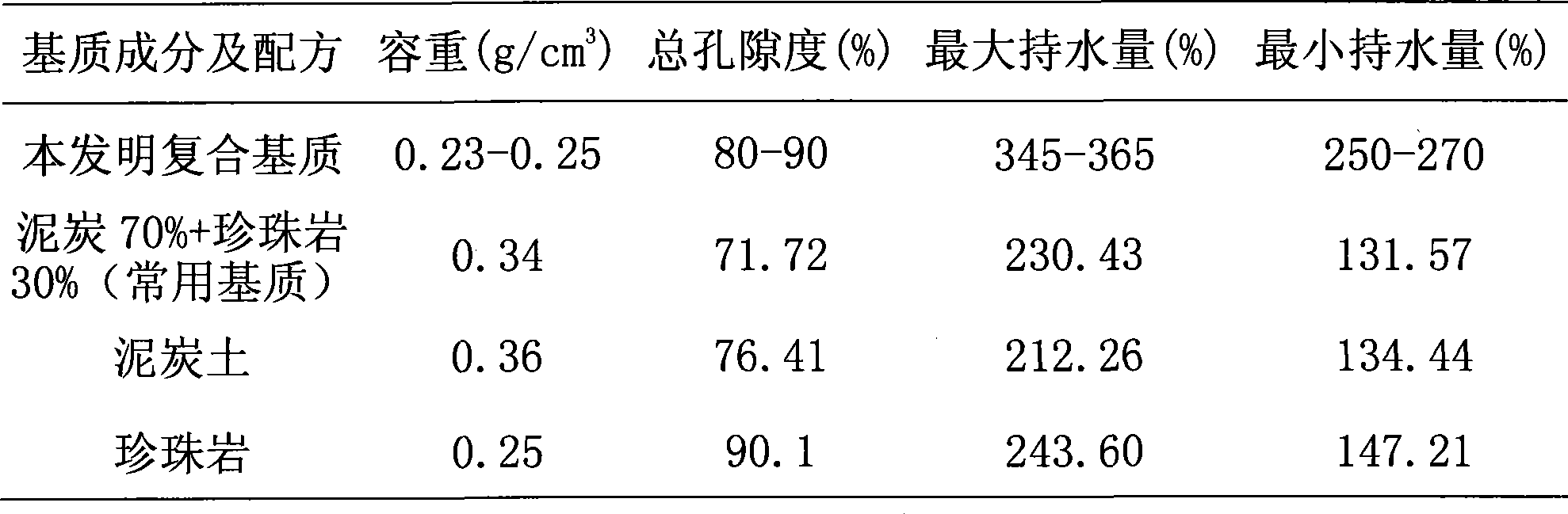

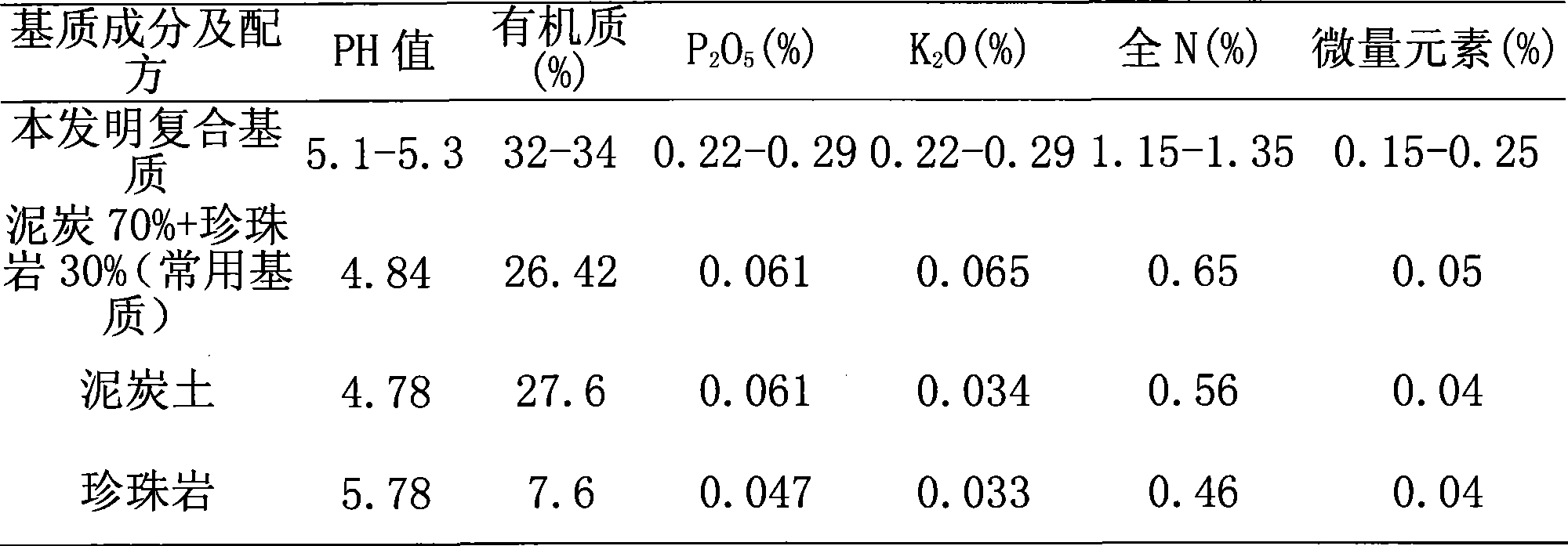

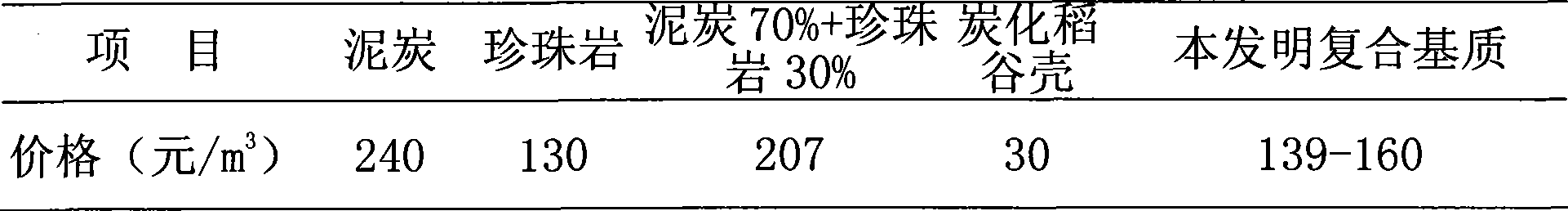

Complex interstitial substance for cyclobalanopsis glauca container raise seedling

InactiveCN101366356ASimple recipeStable qualityCultivating equipmentsSoilless cultivationPerliteNitrogen fertilizer

The invention discloses a compounded medium for Cyclobalanopsis glauca container seedlings, which belongs to the technical field of forest seedling cultivation. The medium can be prepared through the following steps: carbonized rice husks, perlite and peat are mixed into a preformed medium according to the volume ratio of 25 to 35:25 to 35:35 to 50; according to that the mixture ratio of nutrient content of N:P2O5:K2O:Fe:Zn is 14 to 16:3 to 5:3 to 5:0.2 to 0.35:0.1 to 0.25, slow-release nitrogen fertilizer, slightly soluble phosphate fertilizer, potassium fertilizer, iron, zinc trace fertilizer which are sold in markets are made into a slow-release slightly soluble compounded fertilizer; and then the fertilizer and the preformed medium are made into the compounded medium in the proportion of 2 to 3 kg:1m<3>. The medium has the advantages that the medium is simple and reasonable in formulation, stable in quality, convenient to get materials, low in cost, lower in peat consumption, sufficient in fertility, long in fertilizer effect, capable of meeting the demand of Cyclobalanopsis glauca seedlings for nutrients, 23 to 33 percent lower than the prior medium formulation in prices and high in cost performance, and can be popularized and applied in the production of Cyclobalanopsis glauca container seedlings.

Owner:ZHEJIANG SUB TROPICS CROP INST +1

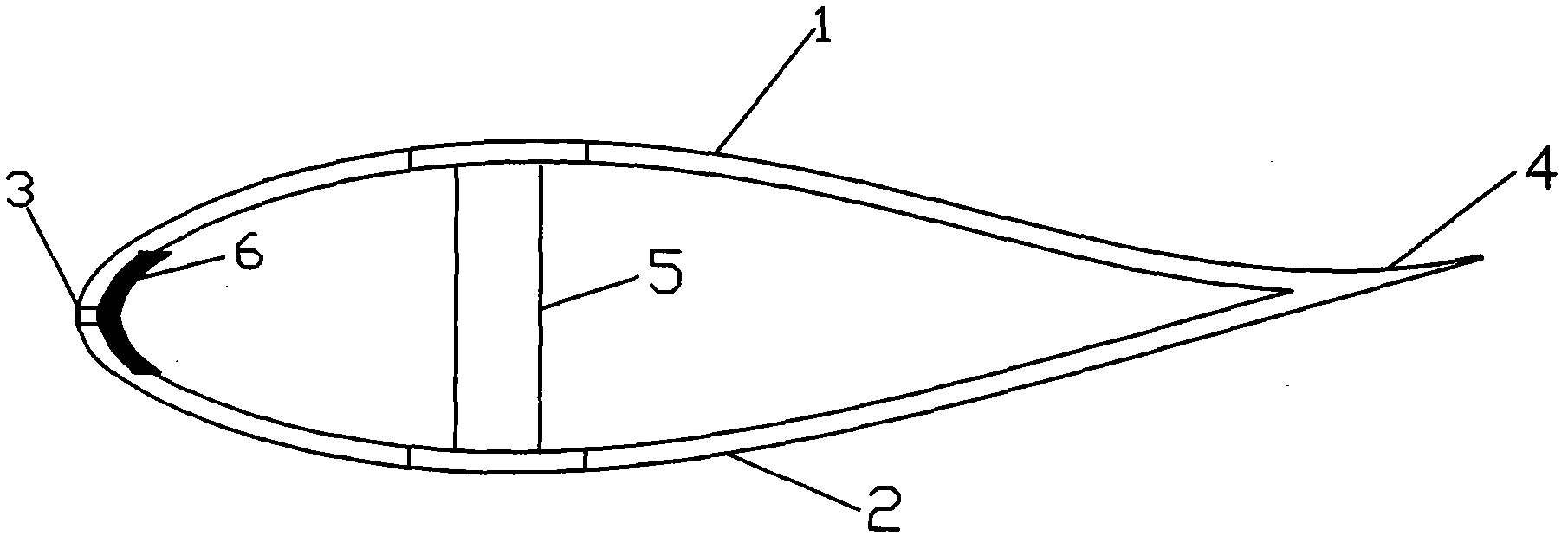

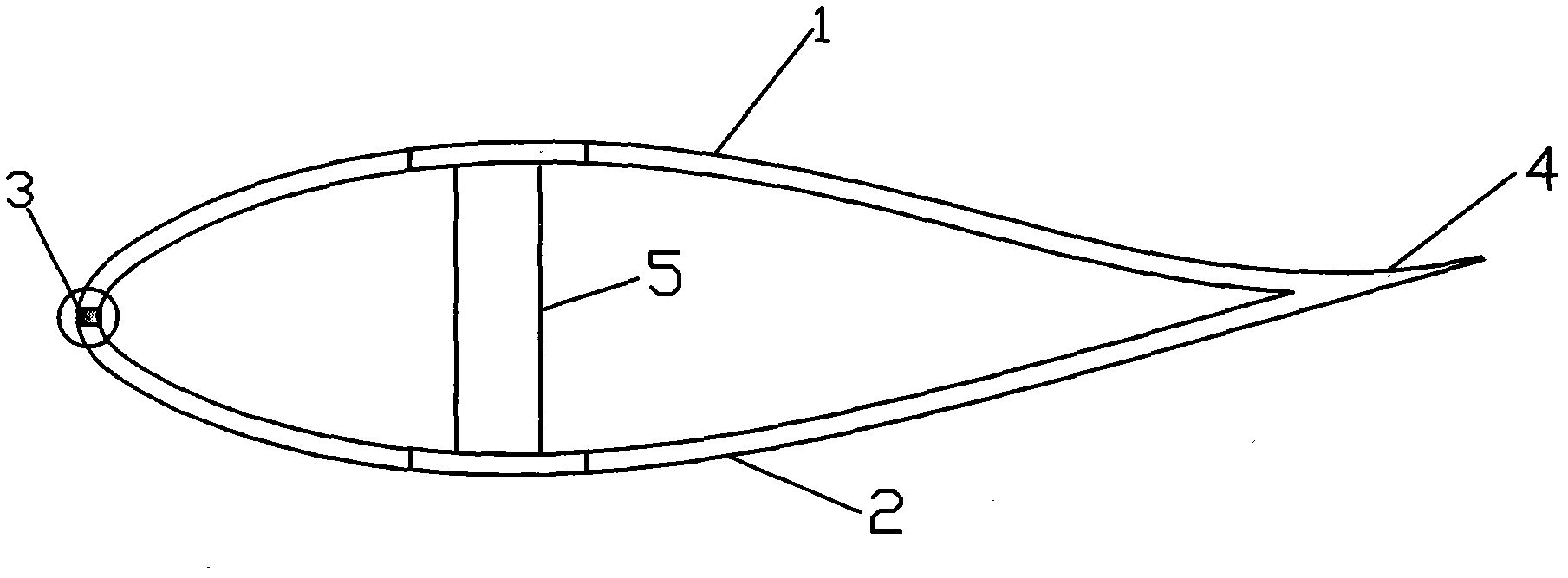

Method for integrally forming blade lower shell of wind power generation machine and front edge adhering angle

The invention belonging to the technical field of composite materials, and provides a method for integrally forming a blade lower shell of a wind power generation machine and a front edge adhering angle. The method for integrally forming the blade lower shell (2) of the wind power generation machine and the front edge adhering angle (6) comprises the steps of: manufacturing a front edge adhering angle die (14), fixing the front edge adhering die, integrally pouring and forming the front edge adhering angle (6) and the blade lower shell (2); integrally pouring and forming the front edge adhering angle and the lower shell by using the front edge adhering angle die (6); and curing the front edge adhering angle by using heat discharged by the curing of the lower shell (2). The problem caused by manual pasting of the front edge adhering angle is effectively avoided, the quality of front edge adhering is improved, time of singly manufacturing the front edge adhering angle and waiting the curing of the front edge adhering angle is saved, operation environment is improved and production efficiency is increased.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

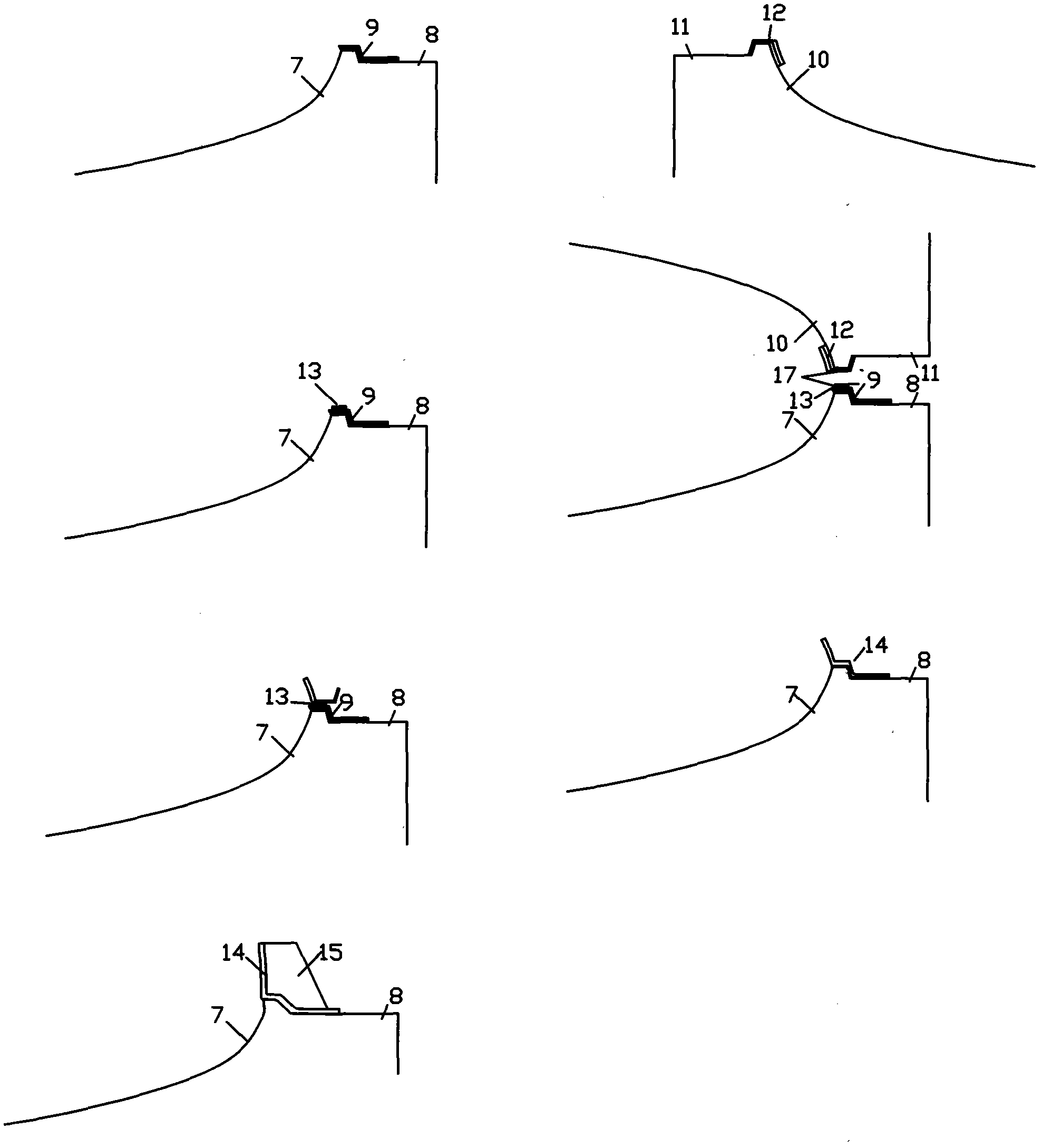

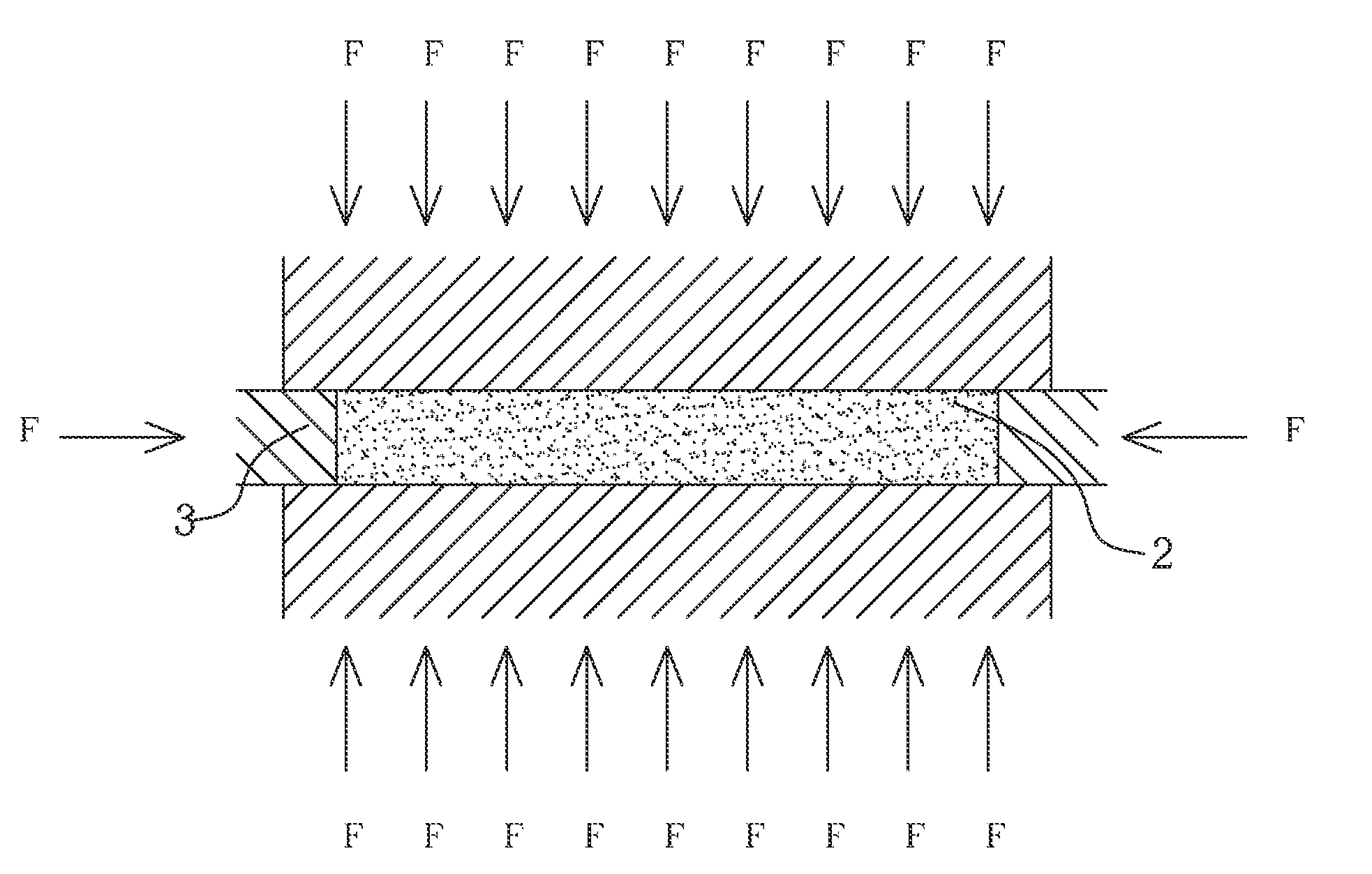

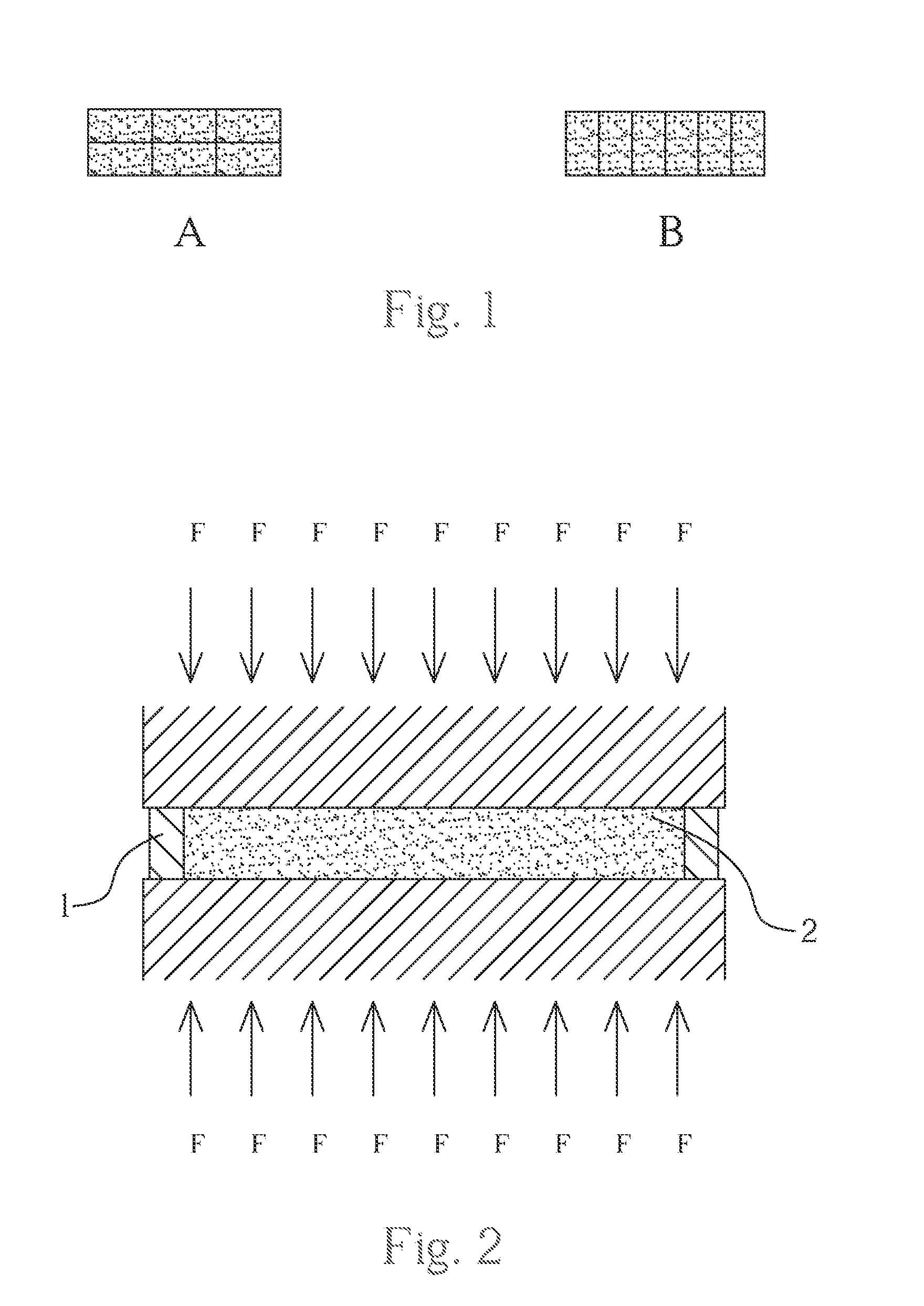

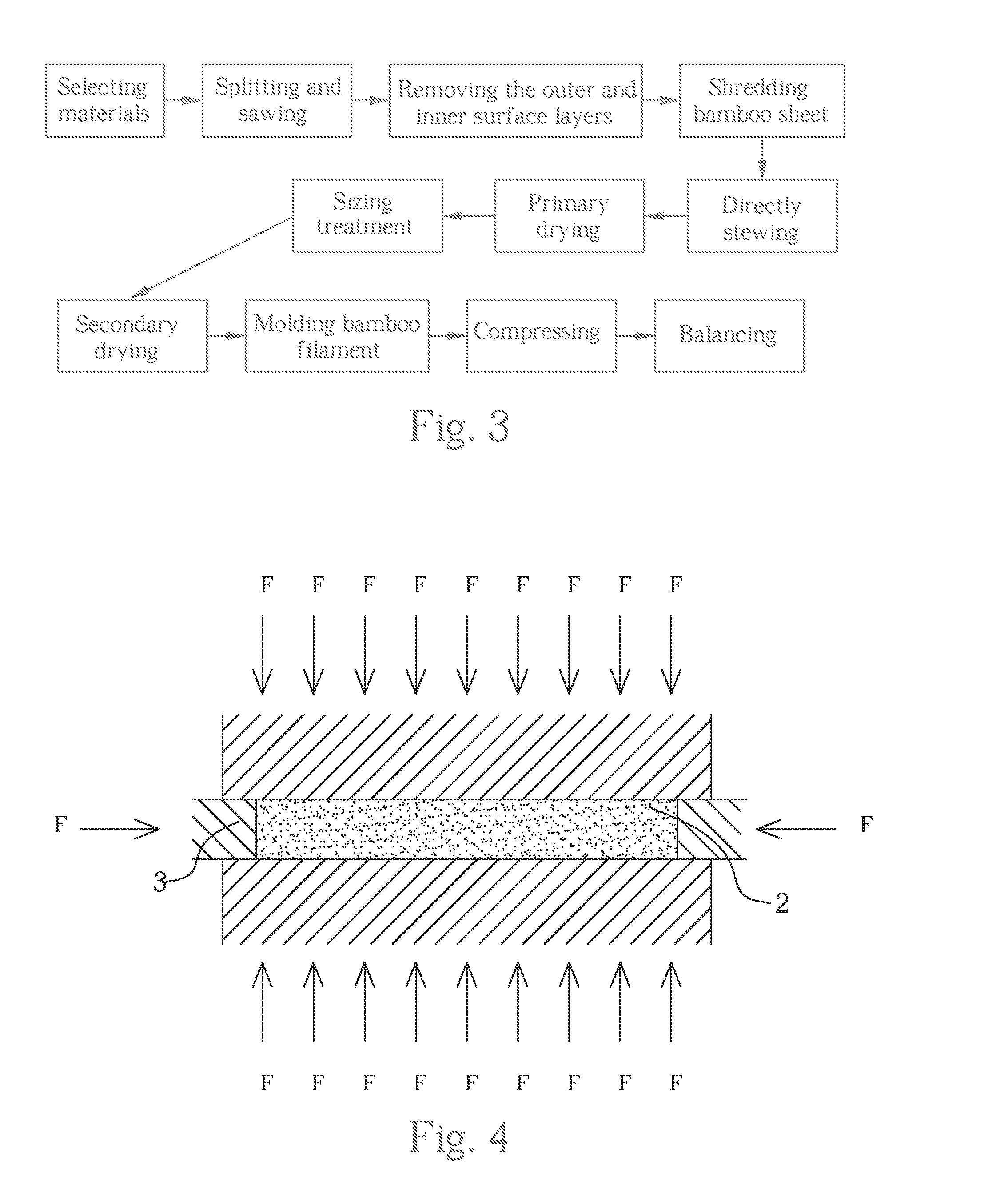

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

InactiveUS20080053570A1Stable qualityEasy to heat and coolStapling toolsWood compressionSizingHot press

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

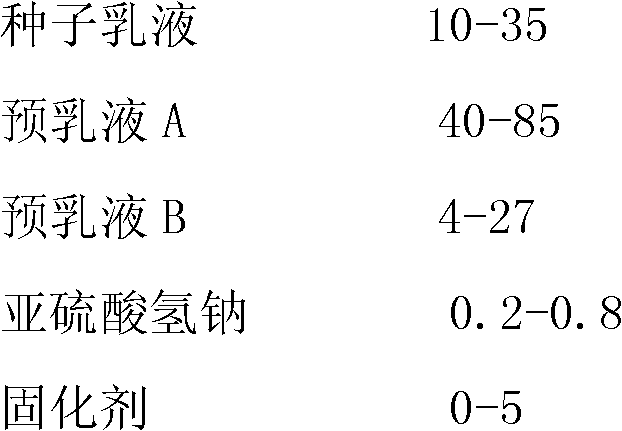

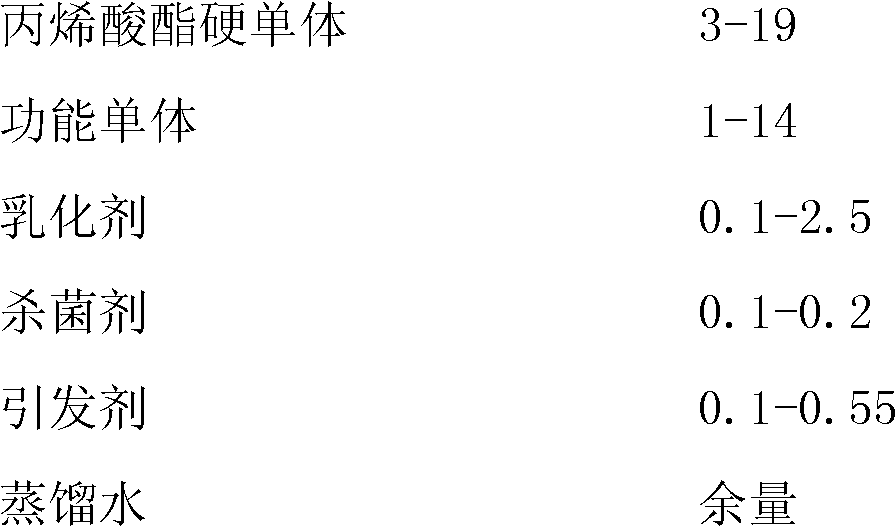

Acrylate emulsion pressure-sensitive adhesive and preparation method thereof

The invention relates to an acrylate emulsion pressure-sensitive adhesive and a preparation method thereof. The acrylate emulsion pressure-sensitive adhesive comprises, parts by weight, 10-35 parts of seeded emulsion, 40-85 parts of pre-emulsion A, 4-27 parts of pre-emulsion B, 0.2-0.8 part of sodium hydrogensulfite and 0-5 parts of curing agent. The acrylate emulsion pressure-sensitive adhesive and the preparation method thereof are characterized in that a common emulsifying agent, the specific adhesive-preparing process and a specific monomer raw material are adopted, the raw material is low in cost and can be easily obtained in the market, and the prepared acrylate emulsion pressure-sensitive adhesive is stable in quality, good in coating performance and wide in application range and can be used for ordinary and high-grade polyethylene protective films, polrvinyl chloride protective films, polypropylene protective films and the like. After prepared protective films are torn off, no pressure-sensitive adhesive is left on the base material surface, and no shadow exists.

Owner:无锡达美新材料有限公司

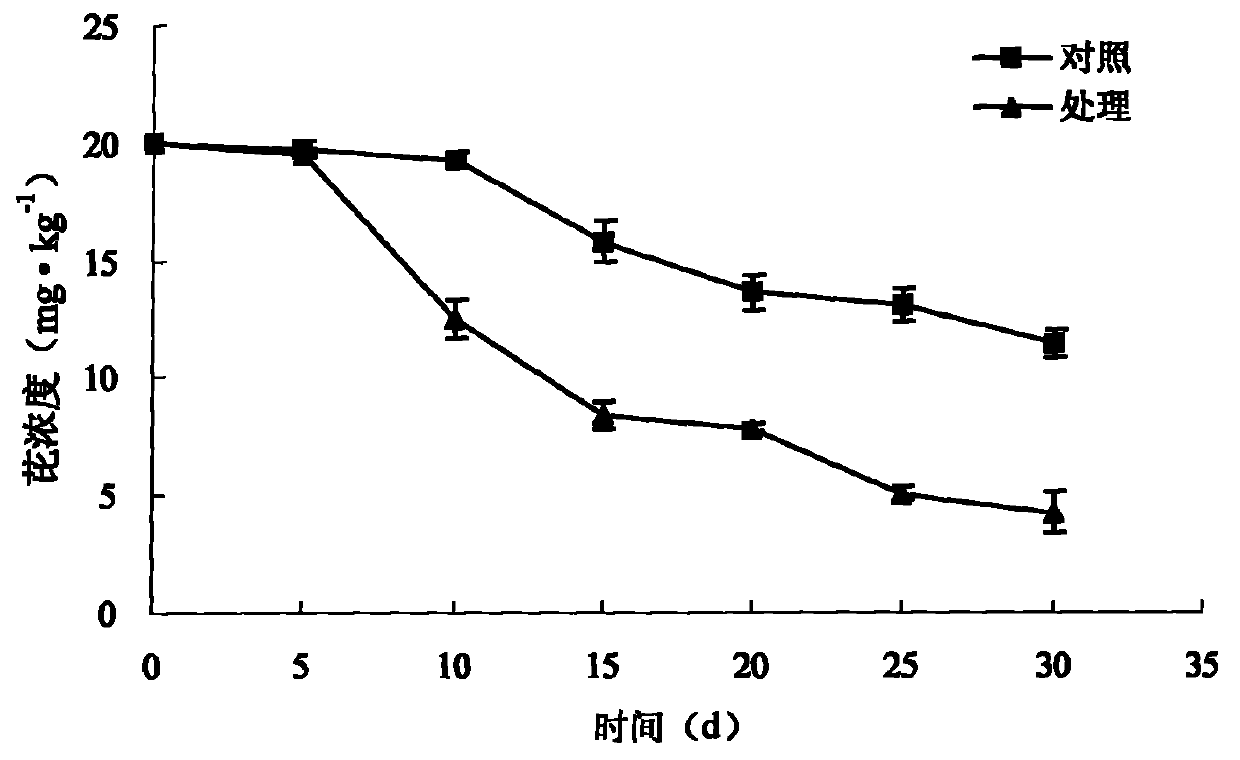

Bacterial strain for generating rhamnolipid biosurfactant and generated microbial inoculum thereof

ActiveCN101948793APromote degradationStable qualityBacteriaContaminated soil reclamationBioremediationGene cluster

The invention provides a bacterial strain KT2440-rhlABRI capable of generating a rhamnolipid biosurfactant and the generated microbial inoculum thereof, which belong to the field of biological high technology. The microbial inoculum is obtained by integrating a gene cluster rhlABRI related to the synthesis of the rhamnolipid biosurfactant in Pseudomonas aeruginosa BSFD5 into chromosomes of a type strain KT2440 of Pseudomonas putida by an unmarked homologous recombination method. The microbial inoculum product can be directly used for promoting the degradation of polycyclic aromatic hydrocarbons pyrene in soil and can be applied to the bioremediation of soil polluted by polycyclic aromatic hydrocarbons.

Owner:JIANGSU SENTAY ENVIRONMENTAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com