Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

260 results about "Tetraisopropyl titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

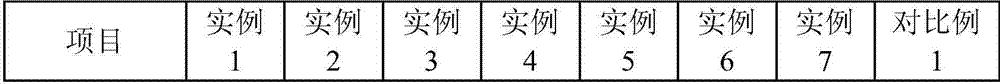

Method for producing silane modified polyurethane sealant by using secondary amino alpha-silane

ActiveCN103694946AHigh hydrolytic activityFast curingNon-macromolecular adhesive additivesOther chemical processesPolyolTetraisopropyl titanate

The present invention discloses a method for producing a silane modified polyurethane sealant by using secondary amino alpha-silane, which belongs to the technical field of production of silane modified polyurethane sealants. The method comprises the following steps: removing water from polyether polyol, preparing polyurethane prepolymer, synthesizing silane-terminated polyurethane prepolymer and preparing the modified polyurethane sealant, wherein in the step of synthesizing the silane-terminated polyurethane prepolymer, the used silane for termination is formed by mixing one or two kinds of compounds selected from a group of secondary amino alpha-silane such as anilino-methyl-triethoxy silane, amine formic acid methyl trimethoxy silane or amine formic acid methyl methyl dimethoxy silane; in the step of preparing the modified polyurethane sealant, a catalyst used in the step is formed by mixing one or two kinds of compounds selected from a group of metal zirconate titanate compounds such as tetra-tert-butyl orthotitanate, tetraisopropyl titanate, tetrabutyl titanate and zirconium n-butoxide. The termination process of the prepolymer is simple, and the silane modified polyurethane sealant produced by the method has fast curing speed.

Owner:湖北新蓝天新材料股份有限公司

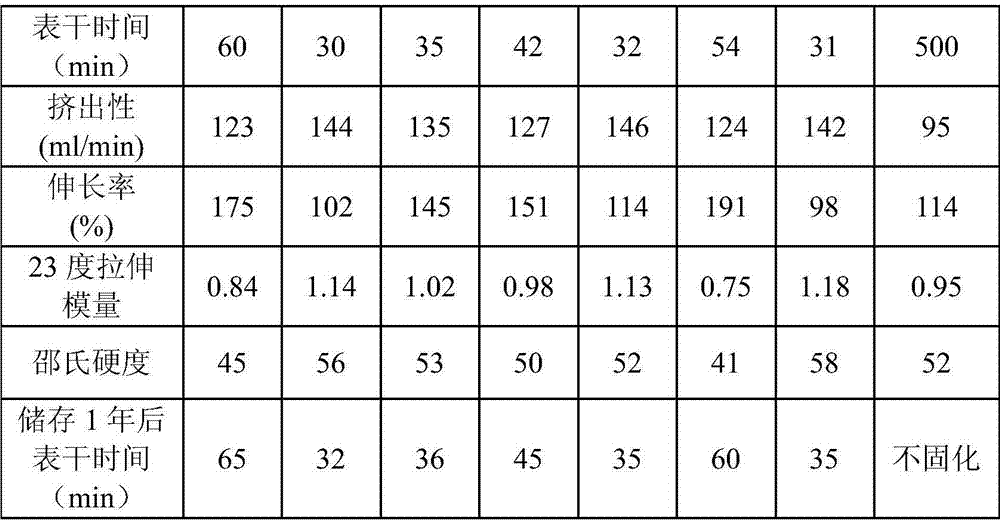

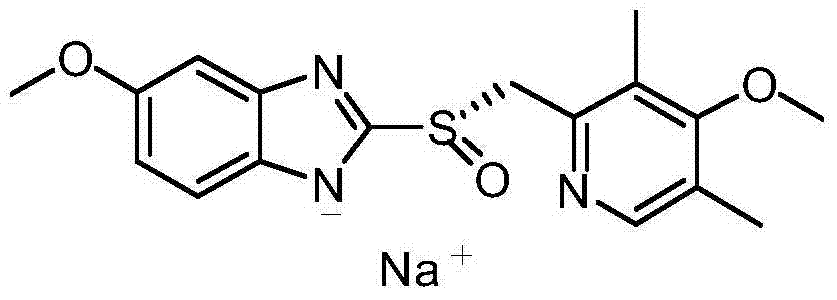

Method for preparing and purifying (L)-pantoprazole sodium

The invention provides a method for preparing (L)-pantoprazole sodium, which comprises the following steps of: oxidizing 5-difluoromethoxy-2-{[(3,4-dimethoxy-2-pyridinyl)methyl]thio}-1H-benzimidazole by using 3,5-diisopropylbenzene hydroperoxide under the catalysis of a tetraisopropyl titanate, D-(-)-diethyl tartrate and N,N-diisopropylethylamine system to obtain S-(-)-5-difluoromethoxy-2-{[(3,4-dimethoxy-2-pyridinyl)methyl]sulfinyl}-1H-benzimidazole, namely (L)-pantoprazole, refining the (L)-pantoprazole, and preparing a salt to obtain the (L)-pantoprazole sodium.

Owner:HC SYNTHETIC PHARMA CO LTD

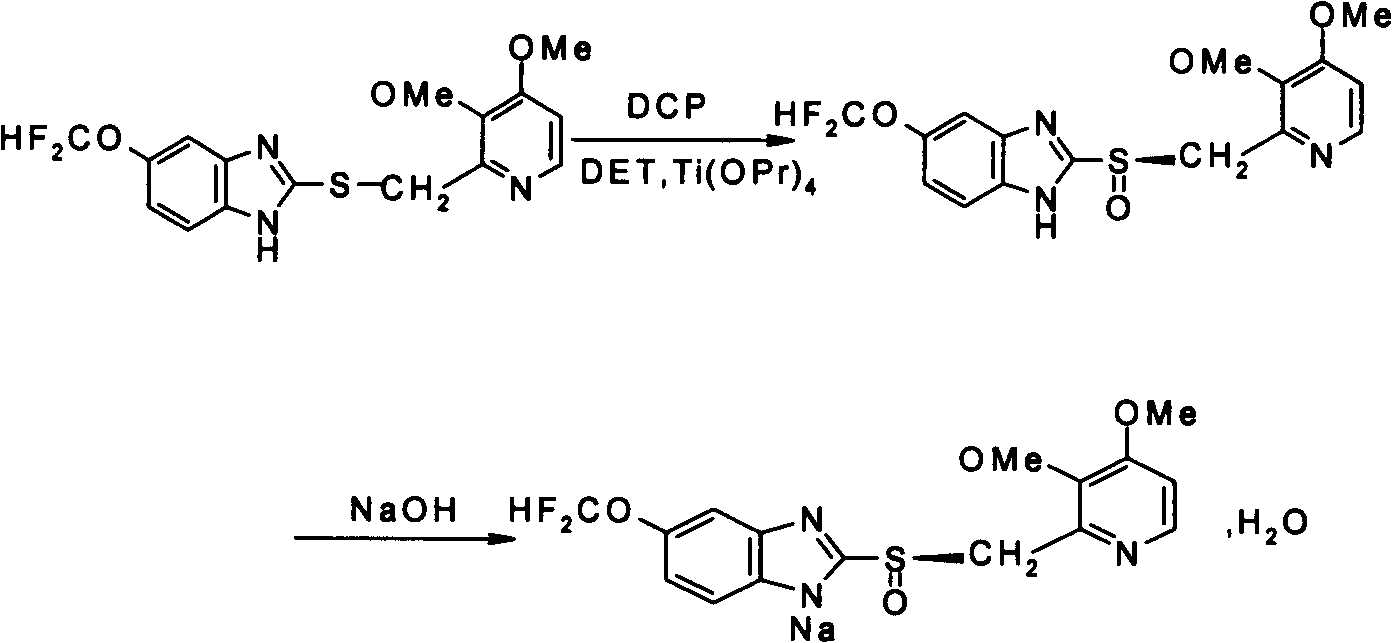

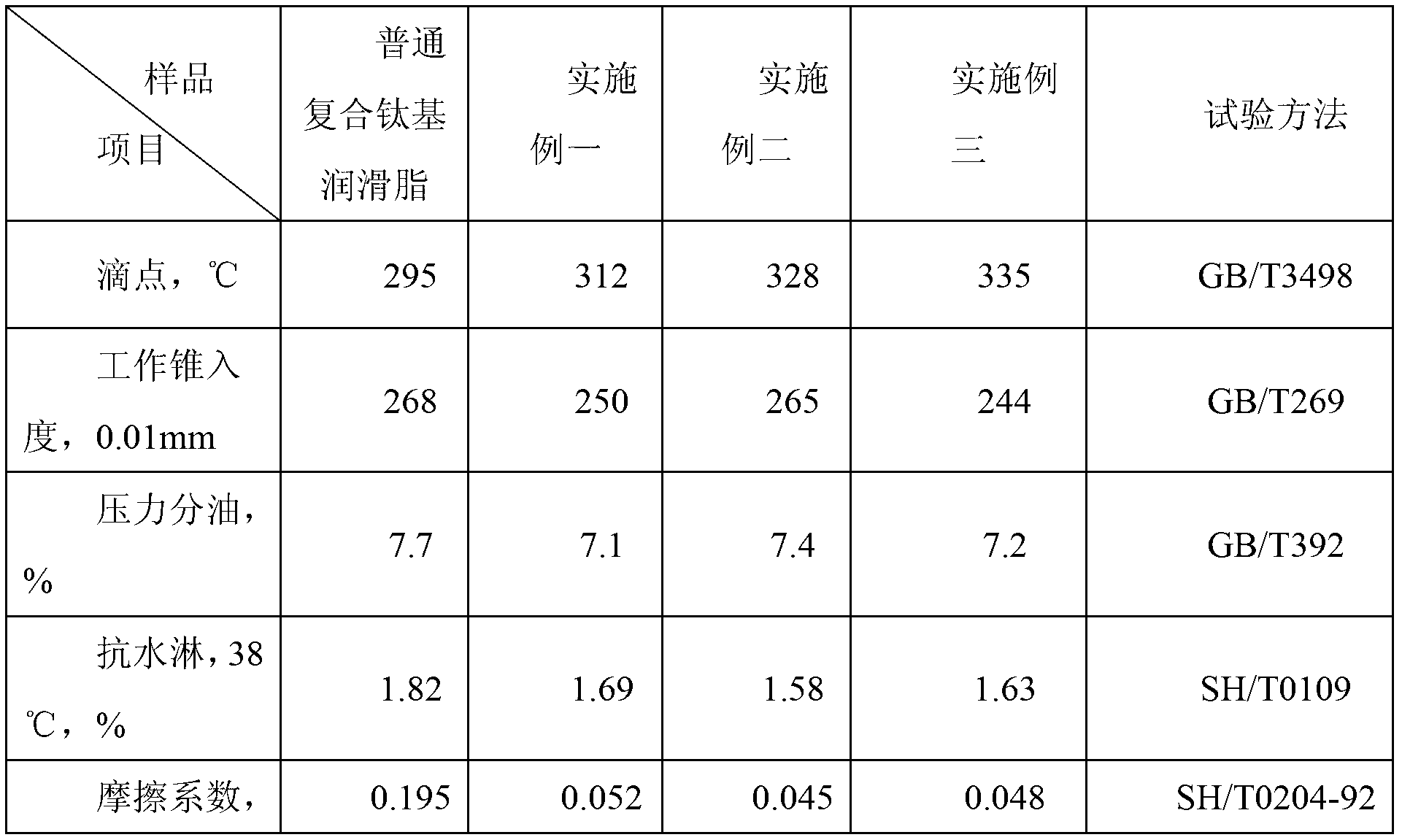

Self-repairing compound titanium-based grease and preparation method thereof

ActiveCN103160369AStable structureImprove heat resistanceLubricant compositionFood industryTetraisopropyl titanate

The invention provides a self-repairing compound titanium-based lubricating grease and a preparation method thereof, and relates to a lubricating grease and a preparation method of the lubricating grease. The lubricating grease has excellent antioxidant ability and bearing capacity, and is capable of repairing the surface of a wearing part and prolonging the service life of the friction part. The lubricating grease is prepared by mixing a base oil, a compound titanium soap thickening agent, an antioxidant additive, an anti-wear reagent at extreme pressure, an antifriction additive and a self-repairing lubricating material together; and the preparation method of the lubricating grease comprises the following steps of mixing the base oil with a high molecular acid and stirring, heating the temperature to the range of 80-90 DEG C, adding tetraisopropyl titanate and a low molecular acid, preserving heat and stirring, increasing the reaction temperature to the range of 120-150 DEG C, and then adding the left base oil and continuing increasing the temperature to the range from 200 to 220 DEG C and stirring; adding the self-repairing lubricating material after grease is formed, and stirring, and then adding other additives, and finally, grinding, homogenizing and degassing, thereby obtaining the self-repairing compound titanium-based lubricating grease. The self-repairing compound titanium-based lubricating grease is used for the automobile industry, the metallurgical industry, the food industry and the aircraft industry.

Owner:HARBIN INST OF TECH

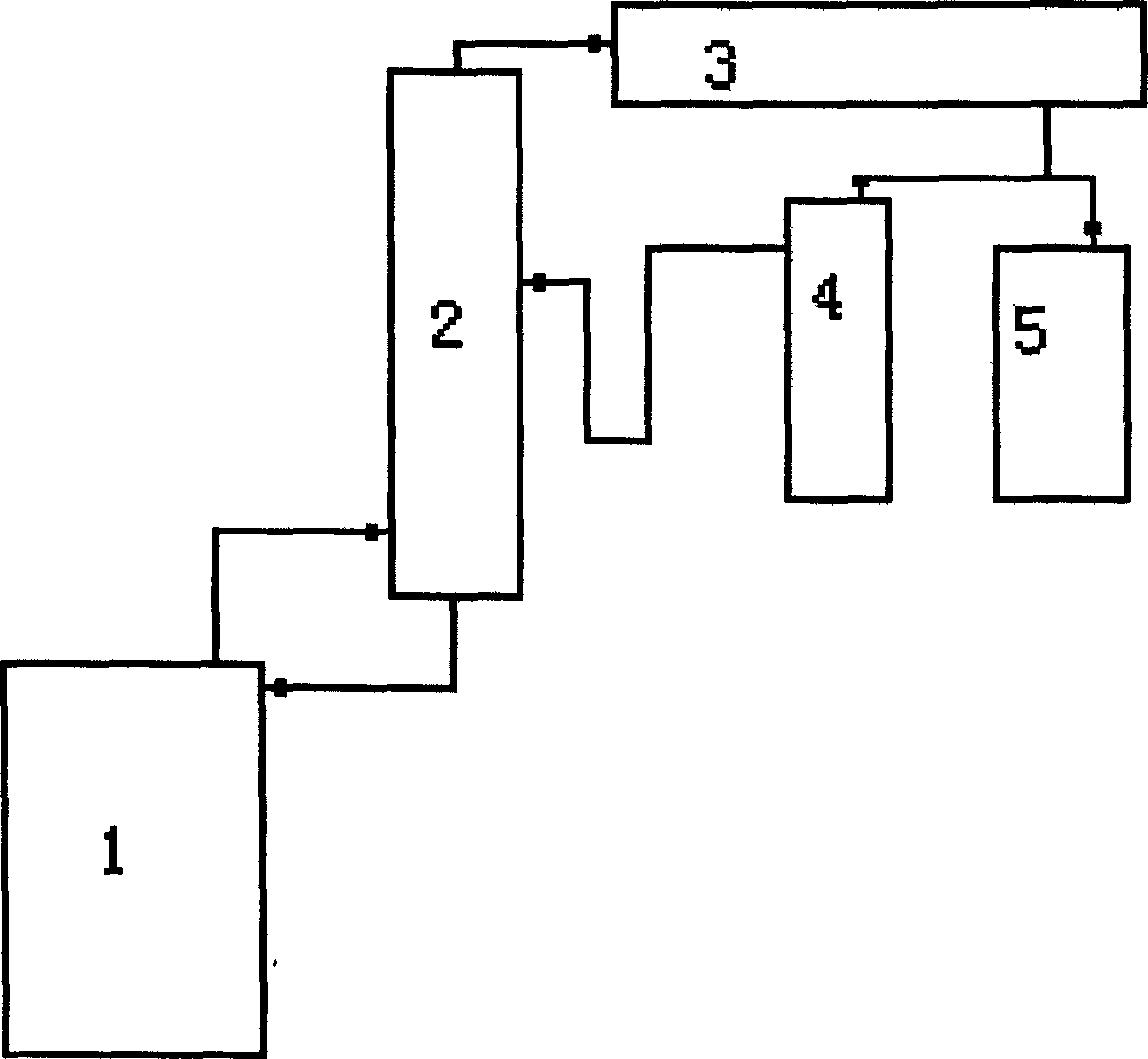

Preparation method of composite titanium radical lubricating grease and product produced thereby

ActiveCN101117605AGood mechanical stabilityThickenersBase-materialsTetraisopropyl titanateDistilled water

The present invention provides a preparation method for compound titanium base grease lubricant, according to the sequence, the following steps are included: firstly, fatty acid and base oil are mixed together and heated, when the temperature is raised to 70 to 90 DEG C, the tetraiopropyl titanate is added in for reaction; secondly, when the temperature is raised to 130 to 150 DEG C, aromatic acid is added in for reaction; thirdly, cool oil is added in for reducing the temperature, and distilled water is added in; fourthly, the temperature is increased to 170 to 200 DEG C for high temperature refining, the rest cool oil is added in, the temperature is reduced, and the reactant is ground to get the end product. The product got from the present invention has obviously better mechanical stability, as well as better abrasion resistance under the extreme pressure than that got from the prior technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

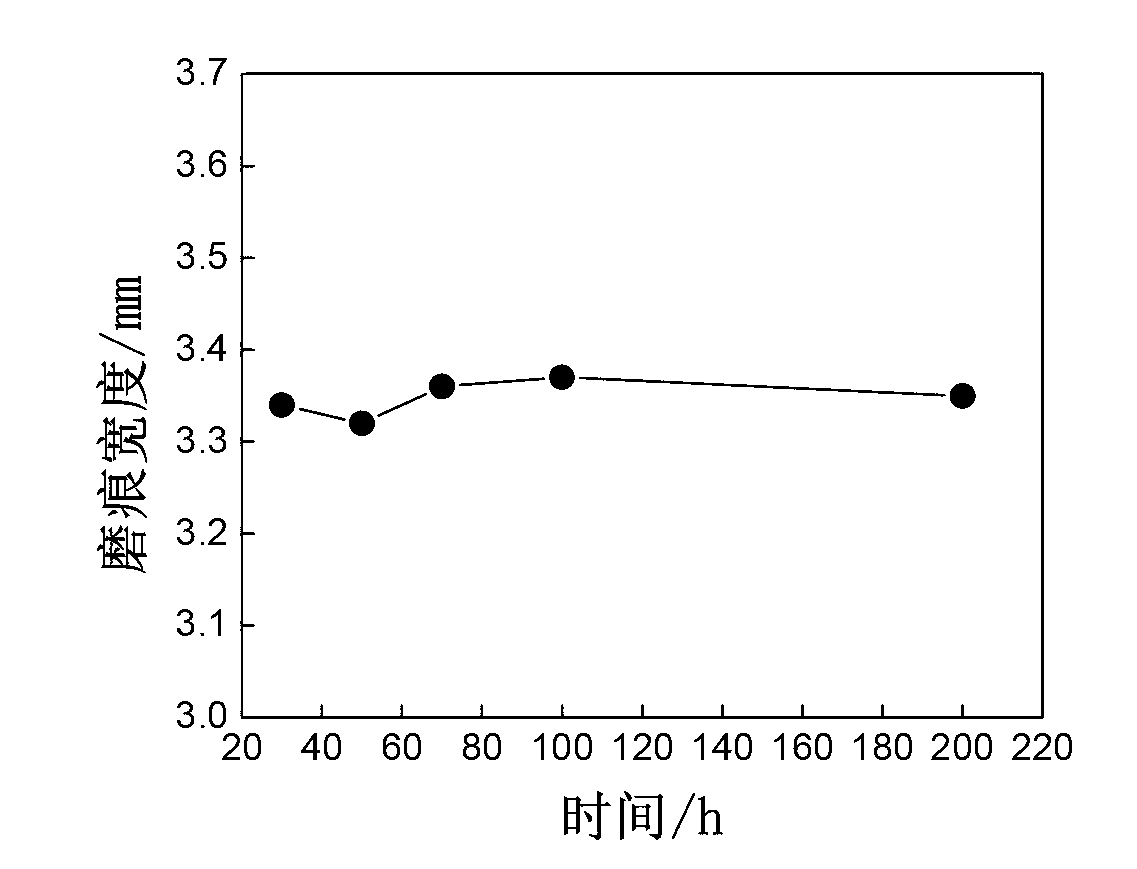

Modified composite titanium-based grease of micron-nano particles and preparation method thereof

InactiveCN103113969AImprove wear resistanceImprove carrying capacityLubricant compositionFriction reductionMicro nanoparticles

The invention relates to modified composite titanium-based grease of micron-nano particles and a preparation method thereof. In order to solve the problem of low antiwear and friction reduction properties of existing composite titanium-based grease, the preparation method comprises the following steps of firstly, mixing fatty acid and a part of base oil and then adding tetraisopropyl titanate, aromatic acid and distilled water; pre-heating the residual base oil and then adding the residual base oil to a reaction system, adding diphenylamine and a micron-nano additive, and grinding after the reaction is finished to obtain the modified composite titanium-based grease of the micron-nano particles. Compared with the composite titanium-based grease, the friction coefficient is reduced by 16.9-29.3%; the diameter of a wear spot is reduced by 21.4-32.7%; the antiwear and friction reduction properties are improved; the prepared composite titanium-based grease has good self-repairing performance by adding hydroxyl magnesium silicate powder with the self-repairing performance; and the modified composite titanium-based grease can be applied to various mechanized equipments and devices.

Owner:尹继辉 +1

Preparation method of nano titanic oxide film for photochemical catalyst

InactiveCN101385967AImprove reaction efficiencyIncrease profitPhysical/chemical process catalystsDeodrantsLow speedLight energy

The invention discloses a preparation method used for a photocatalytic nano-TiO2 film; firstly, butyl titanate is taken as TiO2 former body; ethanol is taken as solvent; ethylene glycol used as inhibitor and polyethylene glycol used as pore-forming agent are added and mixed under room temperature at low speed; subsequently, secondary distilled water and ethanol with a certain proportion are added and uniformly mixed to gain glue A; secondly, titanium tetra-isopropoxide or tetrabutyl titanate is used as main raw material and mixed with isopropyl alcohol and dripped into compounded dilute nitric acid solution so as to gain glue B; glue A and glue B are uniformly mixed and anhydrous alcohol is added to be alcoholysed as TiO2 colloid; meanwhile, stainless steel wire net is pre-disposed by acid-washing and the like and working procedures such as glue-sticking and the like are carried out so as to gain the product. The preparation method has the advantages that the reaction efficiency of the catalyst and the utilization ratio of the light energy can be effectively improved, the film and the carrier form firm combination and keep best crystal form proportion.

Owner:ZHANGJIAGANG PUSHENG OPTOELECTRONICS

Non-aromatic nucleus structure poly-hexahydrobenzene phthalic anhydride dihydric alcohol ester plasticizer and preparation method thereof

InactiveCN101775125ATo achieve the effect of energy saving and emission reductionImprove performancePolyesterResist

The invention relates to non-aromatic nucleus structure poly-hexahydrobenzene phthalic anhydride dihydric alcohol ester plasticizer and a preparation method thereof, belonging to the technical field of the synthesis of low molecular weight polyester compounds of fine chemicals. The invention is prepared by esterifying and polymerizing hexahydrobenzene with dihydric alcohol and n-butyl alcohol with the existing of homogeneous phase composite complex catalyst tetrabutyl titanate or tetraisopropyl titanate catalyst under 140-200 DEG C. The invention meets the requirements of energy conservation and cleaner production, and the prepared product of poly-hexahydrobenzene phthalic anhydride dihydric alcohol ester plasticizer is a novel polyester plasticizer with the characteristics of good compatibility with high polymer material and anti-migratory performance; the polyester plasticizer has the excellent characteristics of good resist-extraction performance, light color, good thermostability and fundamental innocuous performance; the invention is particularly suitable for environmental protection polyvinyl chloride (PVC) plastic product, medical plastic, refrigerator sealing strip, environmental protection PVC cable sheath and can be used as environmental protection assist agent of functional high polymer material for meeting the requirements of oil resistance and anti-migratory performance.

Owner:JIANGNAN UNIV +1

Clean production method for dioctyl phthalate

InactiveCN1884249AReasonable useEmission reductionOrganic compound preparationCarboxylic acid esters preparationWater vaporOctanol

The invention discloses a cleaning manufacturing method of phthalic acid dioctyl, which is characterized by the following: setting esterification and dealcoholization within one equipment; adopting benzoic anhydride and octanol as raw material at 1:2-3 weight percentage; utilizing titanic hydroxide four propyl ester as catalyst; setting addictive quantity at 0.0015%-0.005% in the total material; generating coarse ester in the autoclave under normal pressure; controlling reacting final temperature at 220-240 deg.c; flashing octanol through residual heat in the autoclave; dehydrating excess 60-80% octanol in the esterifying reaction; collecting sedimenting water after condensing; cooling temperature in the autoclave at 170-190 deg.c; inputting water at this temperature; distilling steam in the autoclave; removing residual octanol.

Owner:TIANJIN TIANRONG CHEM

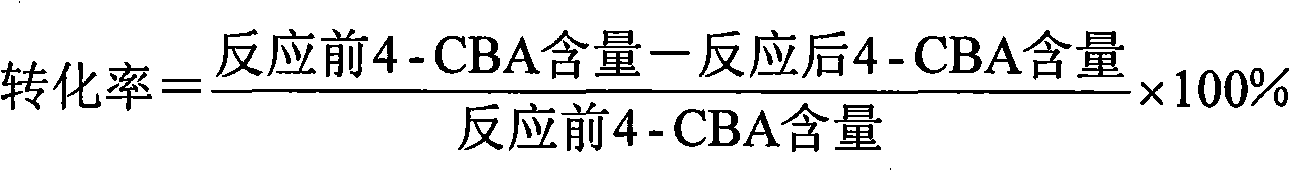

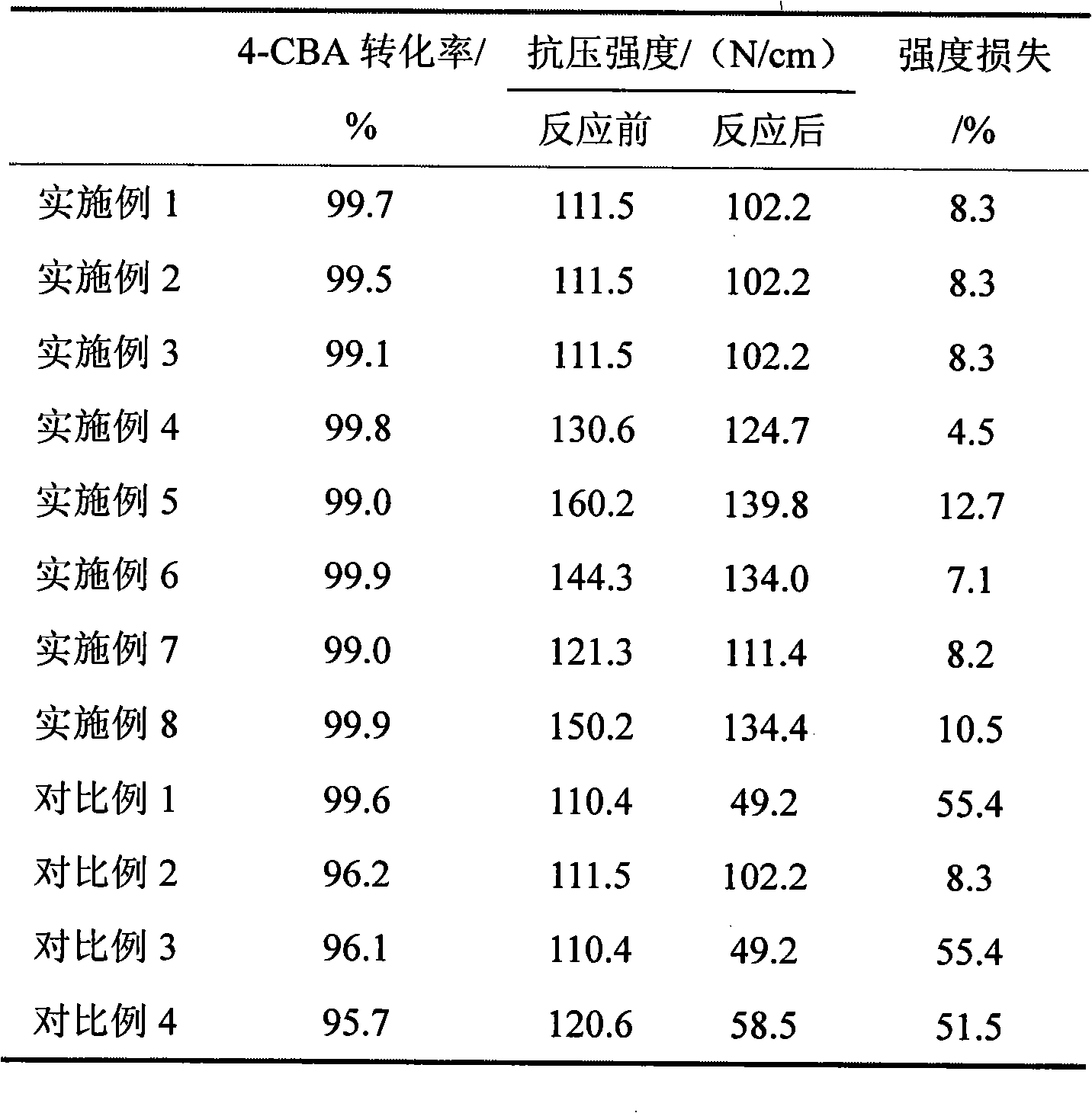

Process for preparing catalyst Pd/TiO2 for hydrogenation of p-carboxybenzaldehyde

ActiveCN101347726AHigh compressive strengthReduced stress field strength factorOrganic compound preparationCarboxylic compound preparationFiberAlkali free

The invention relates to a Pd / TiO2 catalyst used in the hydrogenation of 4-carboxybenzaldehyde; the catalyst takes TiO2 forming material, which is doped with ground alkali-free glass fibers and adopts titanium-containing precursors for surface modification, as the carrier, and is loaded with an active component, metal Pd; the content of metal Pd in the catalyst is 0.2-1.0%, the titanium-containing precursor can be any one of or the combination of tetrabutyl titanate, tetraisopropyl titanate and tetraethyl titanate. The compressive strength of the catalyst is 110-160N / cm; after reaction, the compressive strength of the catalyst is reduced by less than 13%; in the high-temperature and high-pressure water phase environment, the hydrogenation activity of the catalyst is high, and the transformation rate of 4-carboxybenzaldehyde is higher than 99.0%. The preparation method of the catalyst of the invention has simple technique, and the adopted method does not cause any negative impact on the catalyst and is suitable for the industrial production.

Owner:SINOPEC YANGZI PETROCHEM

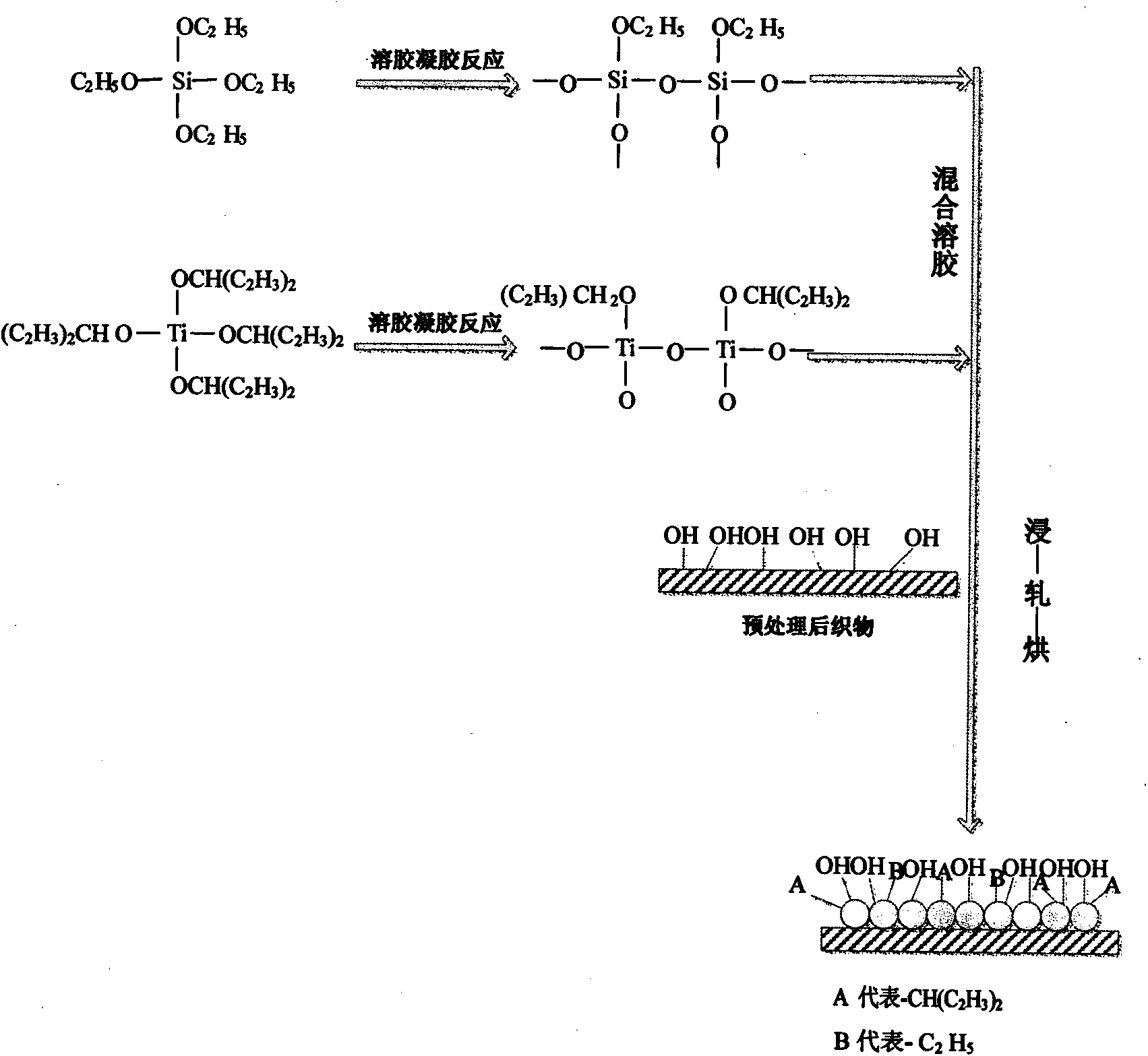

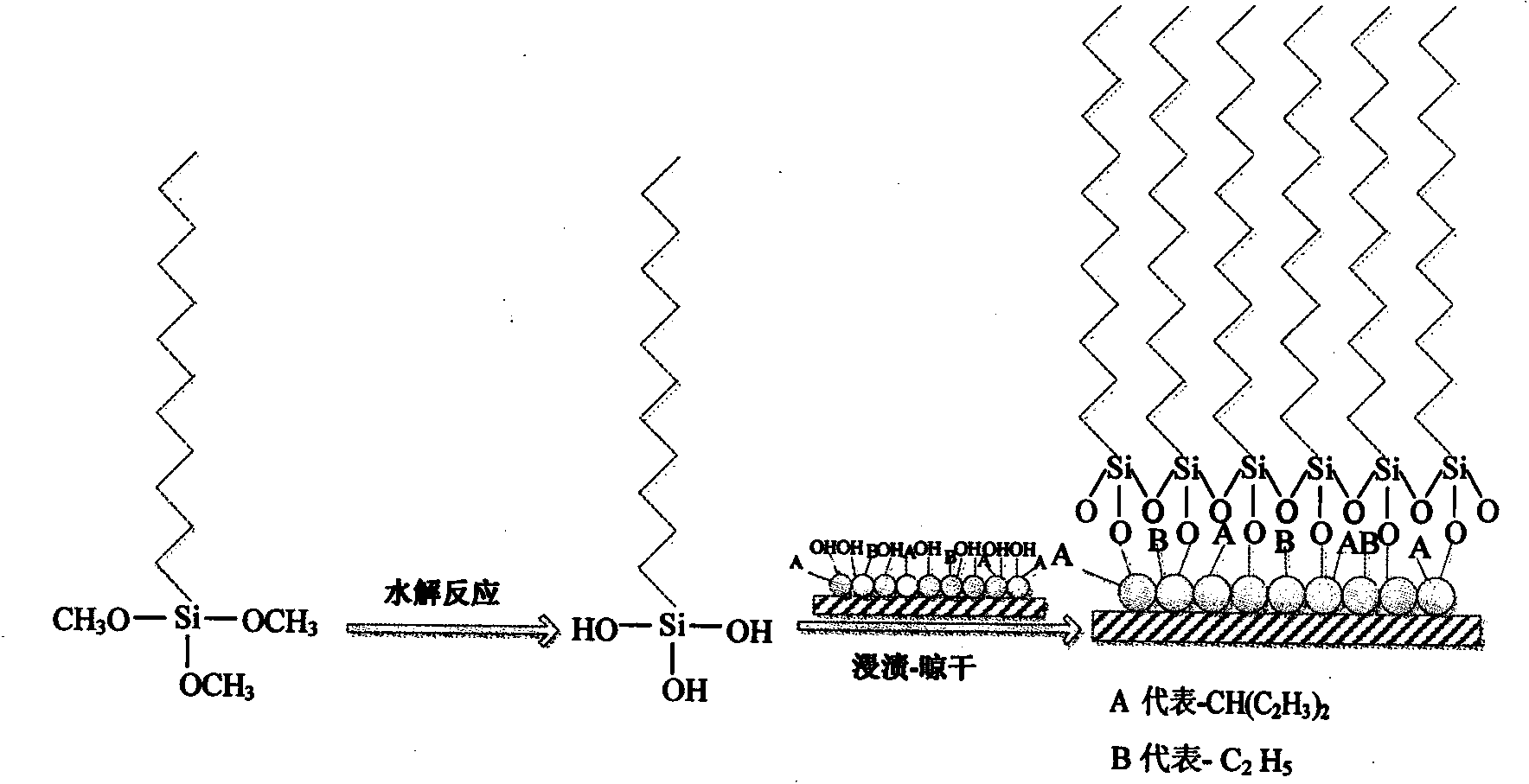

Preparation method of self-cleaning wool fabric

InactiveCN103806262AImprove bonding fastnessImprove efficiencyBiochemical fibre treatmentAnimal fibresImpurityLong acting

The invention provides a preparation method of a self-cleaning wool fabric. The preparation method is characterized by comprising the specific steps of mixing tetraisopropyl titanate, diethanol amine and absolute ethyl alcohol, adding alcohol, and stirring to form TiO2 sol; mixing concentrated ammonia, ethyl alcohol and deionized water, adding a mixed solution consisting of tetraethoxysilane and ethyl alcohol, performing reaction at room temperature for 1-3 hours to form SiO2 sol, and mixing the TiO2 sol and the SiO2 sol to obtain TiO2 / SiO2 mixed sol; removing impurities from the wool fabric, cleaning the wool fabric through a non-ionic washing agent, performing pre-oxidization, and treating the wool fabric through Savinase; immersing the treated wool fabric into the TiO2 / SiO2 mixed sol, and drying and curing after a two-immersion and two-rolling technology is performed; preparing an organosilane modified solution from long-chain alkylsilane, immersing the wool fabric into the organosilane modified solution, and naturally air-drying the wool fabric to obtain the self-cleaning wool fabric. According to the preparation method, the self-cleaning wool fabric has a good self-cleaning effect and a long-act effect. The preparation method is suitable for industrial production.

Owner:DONGHUA UNIV +2

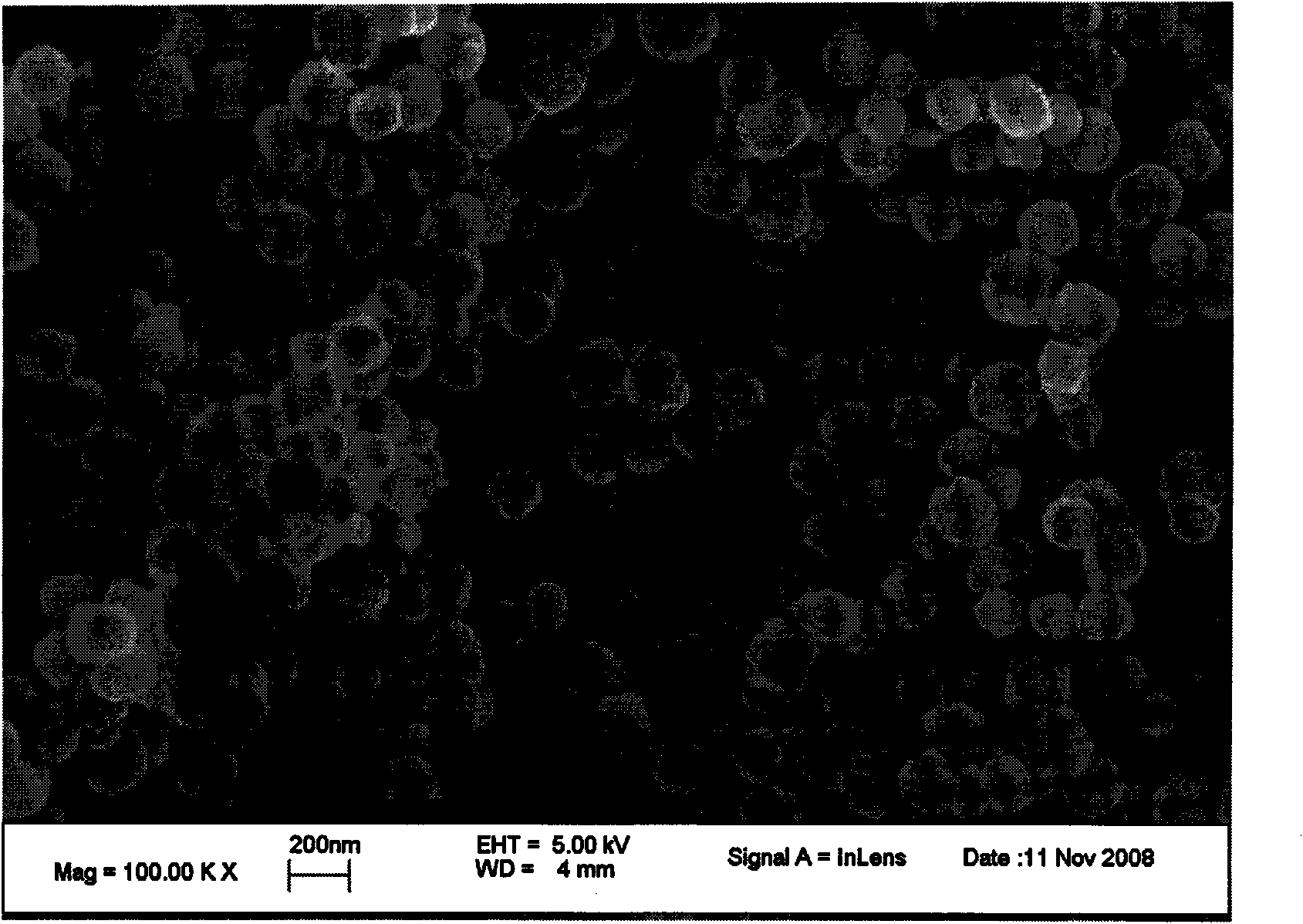

Nano grade titanium silicon molecular sieve and its synthesis technology

InactiveCN1426962AFine grainIncrease switching capacityMolecular sieve catalystsOther chemical processesRadioactive PollutantsSodium hydroxide

A nanometre-class TiSi molecular sieve for removing pollutants of heavy metals and radioactive substance from environment and purifying nuclein has a mole formular Na1+ / -xTi1.5+ / -ySi1+ / -zO5, where x=0.01-0.2, y=0.1-0.5 and z=0.1-0.2. It is prepared from tetrabutyl titanate or tetraisopropyl titanate, ethyl n-silicate, sodium hydroxide and water jointly by the sol-gel method and the hydrothermal synthesis method. Its advantages are fine crystal grain, high reaction activity, low cost, high exchange capacity with radioactive elements and heavy metals, and high thermal stability and radioactive resistance.

Owner:TSINGHUA UNIV

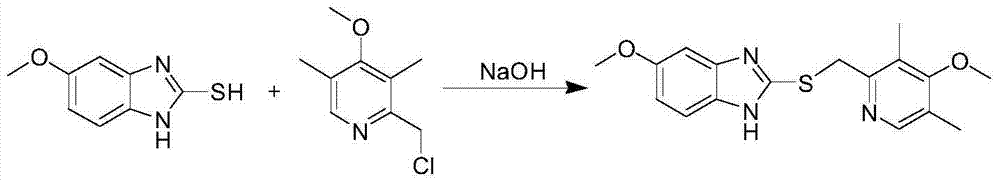

Method for synthesizing and refining esomeprazole sodium

ActiveCN103570686AConvenient sourceSimple and fast operationOrganic chemistryEsomeprazole SodiumTetraisopropyl titanate

The invention relates to a method for synthesizing and refining esomeprazole sodium. The method comprises the following several steps: (1) carrying out condensation by taking 2-sulfydryl-5-methoxybenzimidazole and 2-chloromethyl-3.5-dimethyl-4-methoxypyridine hydrochloride as raw materials to generate prochiral thioether; (2) synthesizing the prochiral thioether into an esomeprazole crude product under the action of D-(-) diethyl tartrate, water, tetraisopropyl titanate, diisopropylethylamine and cumene hydroperoxide, and refining to generate esomeprazole potassium salt; (3) dissolving the esomeprazole potassium salt, then transforming into esomeprazole sodium salt, and refining to obtain a final product. The process of the esomeprazole sodium has the advantages of easiness for operation, good reaction repeatability and higher yield; the obtained product is high in purity and suitable for industrialized production.

Owner:哈药集团股份有限公司 +1

Polybutylene terephthalate (PBT) material special for optical cables and band cables and manufacturing method of PBT material

ActiveCN102181135AHigh molecular weightImprove toughnessFibre mechanical structuresWhitening AgentsReaction temperature

The invention relates to a polybutylene terephthalate (PBT) material special for optical cables and band cables. The PBT material is characterized by comprising the following materials in percentage by weight: 90 to 95 percent of PBT, 3 to 8 percent of polycarbonate, 1 to 5 percent of polypropylene, 0.01 to 0.05 percent of fluorescent whitening agent and 0.01 to 0.05 percent of composite catalyst, wherein the composite catalyst is formed by mixing organic tin compound and tetraisopropyl titanate in a ratio of (0.4-1): (0.6-1). The method comprises the following steps of: adding the raw materials into a stainless steel vacuum polymerization pot in a ratio, performing one-pot composition aggregation under the conditions that the vacuum degree is -0.2 to -0.06MPa, the reaction temperature is 150 to 250 DEG C and the reaction time is 6 to 16 hours, and cooling and packing to obtain the PBT material. The PBT material has the advantages of high molecular weight, high strength, high toughness, low shrinkage and good processing technical performance, and meets the requirements of the optical cables and the band cables on the special material.

Owner:江阴爱科森博顿聚合体有限公司

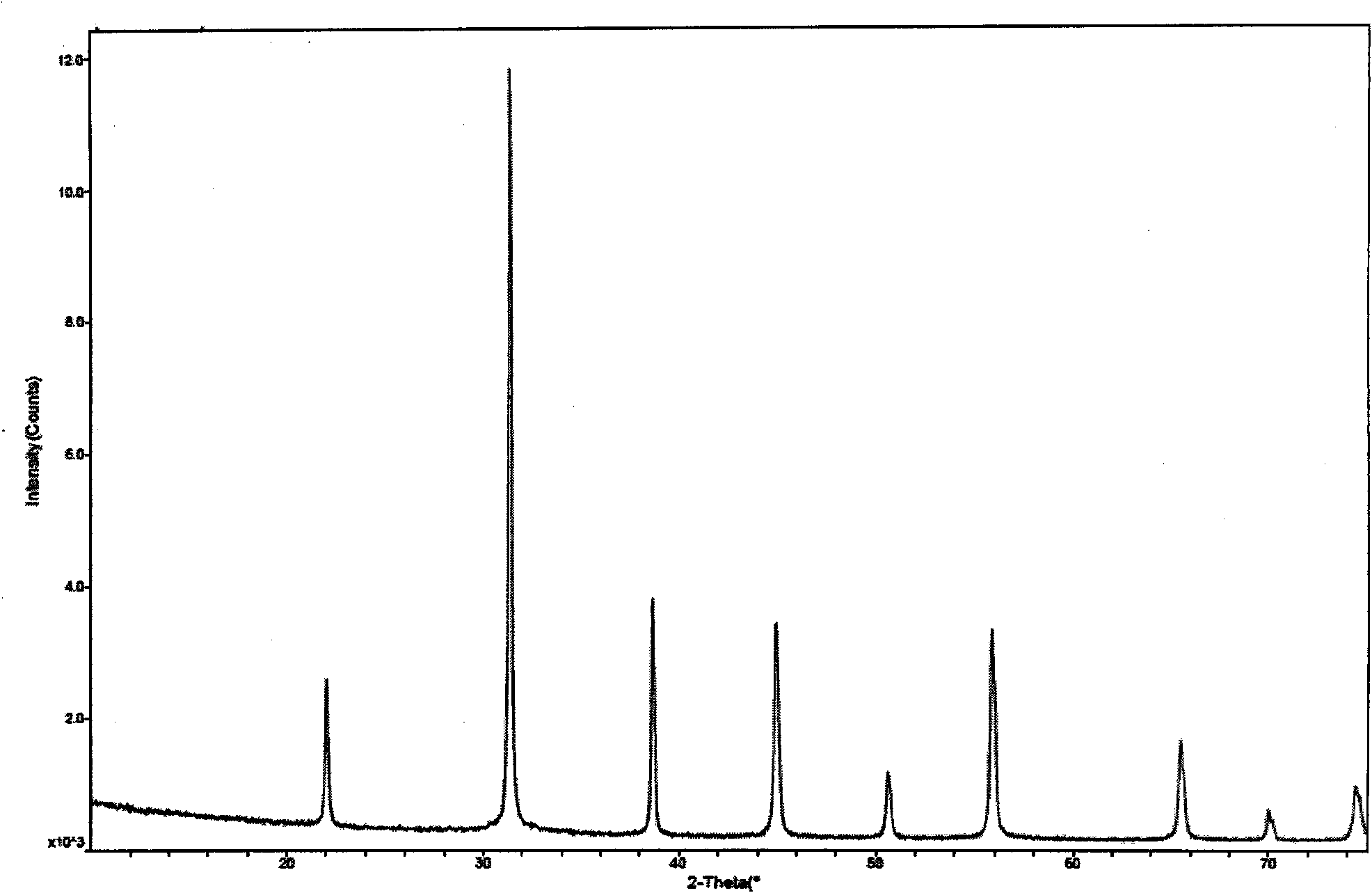

Preparation method of diethylene glycol dibenzoate

InactiveCN102816068ASafe and stable process operationLow costOrganic compound preparationCarboxylic acid esters preparationBenzoic acidActivated carbon

The invention discloses a preparation method of diethylene glycol dibenzoate. Benzoic acid and diethylene glycol are used as raw materials, and a composite catalyst employed is a mixture of tetraisopropyl titanate and a solid titanium base compound. The method comprises steps of: adding by weight 66.5-68.5 parts of benzoic acid and 31.5-33.5 parts of diethylene glycol in a reaction kettle; heating; after complete dissolving of benzoic acid, adding 0.05-0.08 part of the composite catalyst; insulating at a temperature of 190-210 DEG C for 4-6 h to achieve complete reaction; after the reaction, removing alcohol by reducing temperature and pressure to obtain crude diethylene glycol dibenzoate; adding 0.1-0.15 part of diatomite and 0.1-0.15 part of activated carbon; and decolorizing and filtering to obtain the diethylene glycol dibenzoate finished product. The preparation method provided by the invention has characteristics of safe and stable technical operation, low cost, no environmental pollution, short reaction time and high yield of finished product.

Owner:PLASTIC LIGHT CHEM IND LIMITED

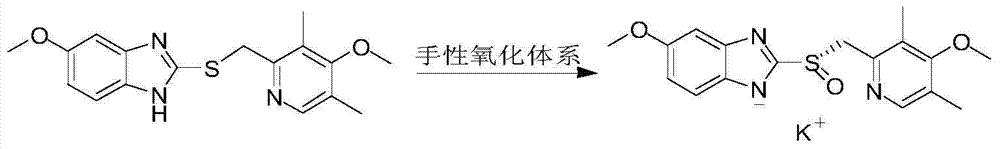

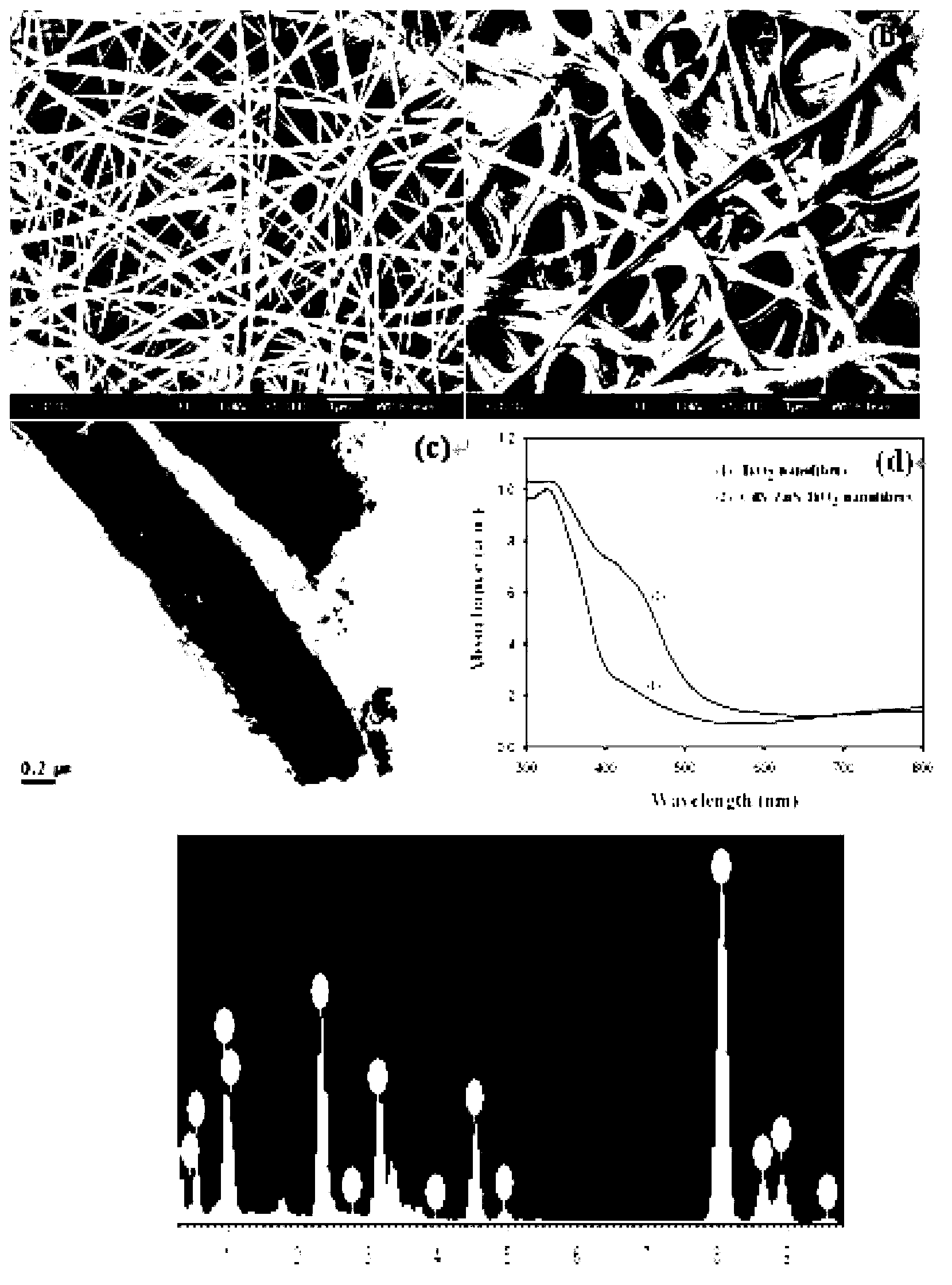

Solvothermal synthetic method of TiO2 hollow-structure submicron spheres

ActiveCN104817106AMild reaction conditionsSimple processTitanium dioxideSolar cellLithium-ion battery

The invention discloses a solvothermal synthetic method of TiO2 hollow-structure submicron spheres, wherein the solvothermal synthetic method comprises the steps of mixing acetylacetone with glycol dimethyl ether to obtain a mixed solvent, adding tetra-n-butyl titanate or tetra-isopropyl titanate with fully stirring, performing a reaction at 160-230 DEG C for 6-24 h in a reaction kettle, naturally cooling a reaction product, and separating, washing and drying the reaction product to obtain the TiO2 hollow-structure submicron spheres. The solvothermal synthetic method is mild in reaction conditions, is simple in process, is uniform in product particle size and is high in yield. The TiO2 hollow-structure submicron spheres have wide applications in the fields of solar cells, photo-catalysis, lithium ion batteries and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

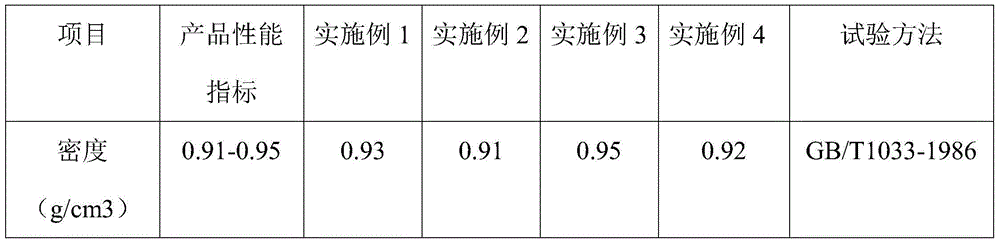

Weather-resistant power pipe

The invention discloses a weather-resistant power pipe. The weather-resistant power pipe is prepared from the following raw materials in parts by weight: 100-150 parts of polypropylene, 5-10 parts of light calcium carbonate, 1-8 parts of flaky talcum powder, 2-10 parts of calcined kaolin, 1-5 parts of brucite powder, 20-40 parts of modified silica fume, 0.2-3 parts of colorant, 2-10 parts of novel nucleating agent, 1-2.7 parts of antioxidant, 0.5-3 parts of polytetrafluoroethylene, 2-12 parts of toughening master batch, 5-20 parts of melamine cyanurate and 5-15 parts of modified crystal whisker; the preparation process of the novel nucleating agent comprises adding 150-180 parts of p-tert-butyl benzoic acid to 200-300ml of tetraisopropyl titanate, reacting at 90-130 DEG C for 3-5 hours and then adding 100-150ml of silicate ester to obtain a solution A, adding the solution A to an ethanol-water mixture, hydrolyzing at 50-65 DEG C for 3-5 hours, filtering and drying, thereby obtaining the novel nucleating agent. The weather-resistant power pipe is high in shock resistance, aging resistance, cold tolerance and thermal resistance.

Owner:安徽宁国市高新管业有限公司

Method for preparing titanium dioxide porous material

The invention discloses a method for preparing a titanium dioxide porous material. The method comprises the following steps: weighing titanate, a hydrolyst, distilled water and a solvent according to a mass ratio of (3-4):(2-5):(1-3):(2-4), mixing and stirring the above four substances, putting into a polytetrafluoroethylene high-pressure reaction kettle, uniformly grinding activated carbon by using an agate mortar, adding obtained activated carbon powder into the reaction kettle, acutely and uniformly stirring so as to obtain gel, putting the reaction kettle into an oven of 150-180 DEG C for 3-8 hours, drying the obtained gel in a drying oven, roasting the dried gel at 500-600 DEG C for 3-6 hours so as to remove an activated carbon template, thereby obtaining the titanium dioxide porous material, wherein the titanate is tetraethyl titanate, tetrapropylorthotitanate, isopropyl titanate or tetra-n-butyl titanate; the solvent is absolute ethyl alcohol, absolute methanol, isopropanol or n-butyl alcohol; the hydrolyst is a mixed liquid of hydrochloric acid and sulfuric acid in a mass ratio of (3-5):(2-3). The raw materials of titanium dioxide prepared by using the method are cheap in price, the preparation process is simple, the titanium dioxide crystal form is mainly anatase, and photocatalytic performance which is relatively good when being compared with the photocatalytic performance of P25 commercial titanium dioxide is achieved.

Owner:华玉叶

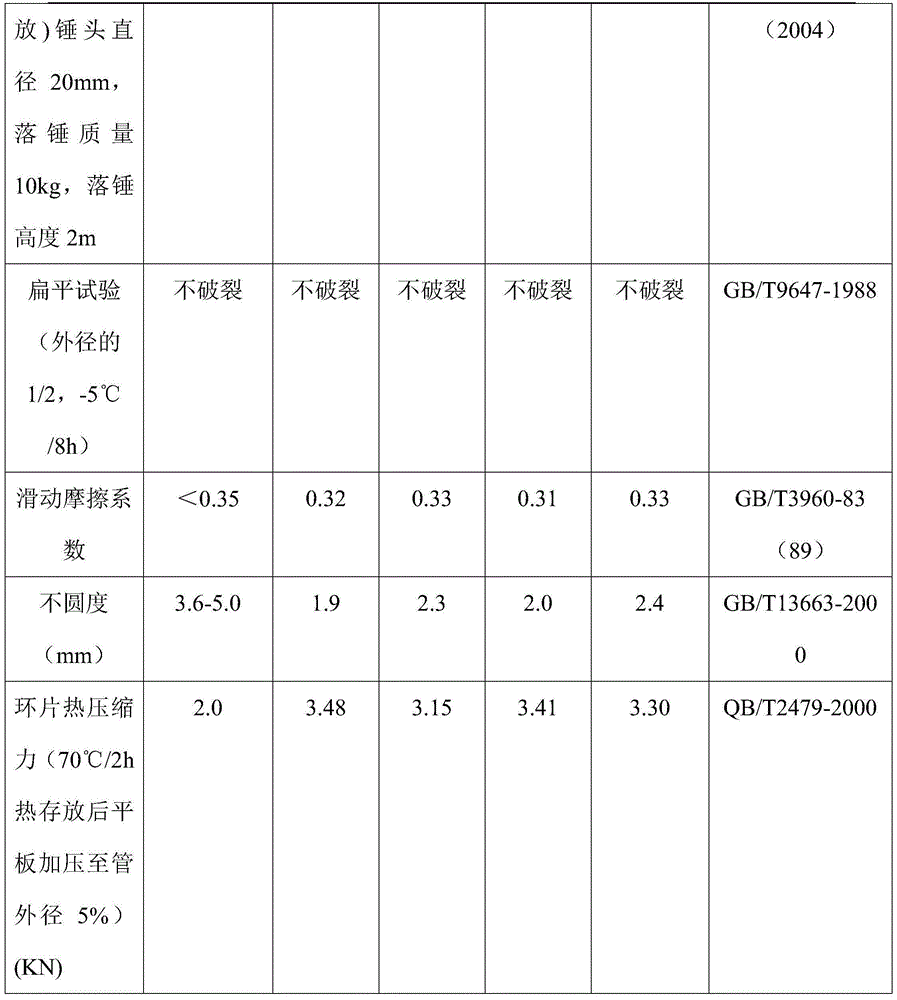

Photocatalyst as well as preparation method and application method thereof

InactiveCN103007966AImprove stabilityEfficient use ofPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberTetraisopropyl titanate

The invention relates to a photocatalyst as well as a preparation method and an application method thereof. The preparation method comprises the following steps of: carrying out electrostatic spinning on TiO2 solution obtained by mixing tetraisopropyl titanate and PVP (Poly Vinyl Pyrrolidone) solution to obtain TiO2 nano fibers; immersing the TiO2 nano fibers into Zn(NO3)2 solution to flush and blow-drying the TiO2 nano fibers; then soaking, flushing and blow-drying the obtained TiO2 nano fibers in Na2S solution to obtain ZnS / TiO2 nano fibers; finally, immersing the ZnS / TiO2 nano fibers into Cd(NO3)2 solution and flushing and blow-drying the ZnS / TiO2 nano fibers; and soaking, flushing and blow-drying the obtained ZnS / TiO2 nano fibers in Na2S solution. According to the invention, the CdS-ZnS / TiO2 nano fibers with a one-dimensional structure are synthesized by adopting an electrostatic spinning technology and the successive ionic layer adsorption and reaction (SILAR) method for the first time. CdS is a narrow-band semiconductor material and ZnS can improve stability of the CdS, and thus, the TiO2 nano fibers subjected to modification of CdS and ZnS not only can widen the adsorption range in a visible region, but also can utilize the SILAR to obtain a CdS-ZnS / TiO2 composite material, better utilizes a visible light source, accelerates effective separation of a photon-generated carrier and improves photovoltaic conversion efficiency.

Owner:HUNAN UNIV

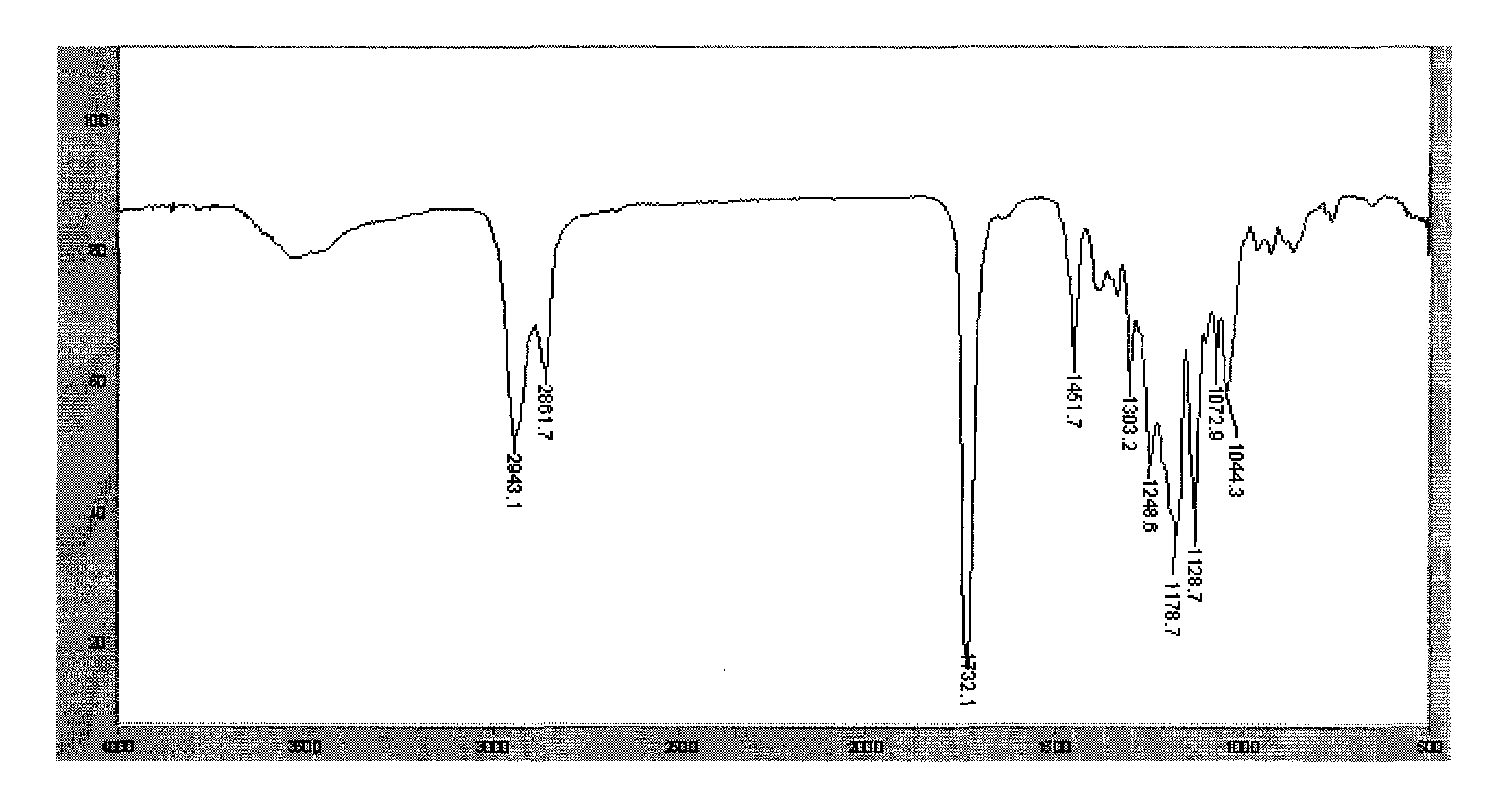

Metal surface silicane treating agent containing tetraisopropyl titanate and preparing method thereof

ActiveCN103060791AImprove corrosion resistancePolarization current density is smallMetallic material coating processesDiethylene glycol monobutyl etherTetraisopropyl titanate

The invention discloses a metal surface silicane treating agent containing tetraisopropyl titanate and a preparing method thereof. The metal surface silicane treating agent containing the tetraisopropyl titanate is prepared form following compositions of, by weight (g) in every 500g of mixed liquor, 1-2g of tetraisopropyl titanate, 1-2g of amine benzoate, 3-5g of rosin, 1-2g of trihydroxyethyl isocyanurate, 10-12g of maleic anhydride, 4-6g of diethylene glycol monobutyl ether, 5-8g of propylene glycol, 2-3g of formic acid, 10-12g of N-(beta-aminoethyl)-gamma- aminopropyl trimethyl (triethyl) oxygroup silicane and the balance deionized water. The metal surface silicane treating agent containing the tetraisopropyl titanate and the preparing method use the rosin as reacting raw materials to polymerize with raw materials of the maleic anhydride, the silicane and the like, and accordingly strong protective film can be formed on the surface of metal, and decay resistance of a metal matrix is strengthened.

Owner:上海蓝烷新材料科技有限公司

Nano conveyor belt and preparation method thereof

InactiveCN101927893AImprove mechanical propertiesAvoid pollutionConveyorsRubber layered productsPolyvinyl chlorideChlorinated paraffins

The invention discloses a nano conveyor belt which consists of tyre fabrics or canvas and a high polymer composite material covered on the fabrics or the canvas, wherein the high polymer composite material comprises the following raw materials in parts by weight: 20-40 parts of chloroprene rubber, 5-10 parts of nitrile rubber, 5-10 parts of natural rubber, 5-15 parts of polyvinyl chloride, 10-20 parts of diocty phthalate, 2-5 parts of chlorinated paraffin, 2-5 parts of antimonous oxide, 2-5 parts of tritolyl phosphate, 0.1-0.3 part of tetraisopropyl titanate, 0.1-0.5 parts of hydroquinone dibenzyl ether, 0.1-0.5 parts of tetramethylthiuram disulfide, 0.3-0.6 part of sulphur, 2-5 parts of carbon black and 1-3.6 parts of nano particles. The nano conveyor belt prepared of the invention is characterized in that the surface resistivity is 1.5*105 omega, and the body resistivity is 3.0*1.3 omega.m; the combustion time is 1.3 second, and the smoldering time is 0 second; and after the nano conveyor belt is soaked in water for 70 hours, the antistatic performance and flame resistance thereof have no obvious change.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Rivastigmine intermediate preparation

InactiveCN101481335AEasy to operateHigh purityCarbamic acid derivatives preparationOrganic compound preparationTetraisopropyl titanateCarbamate

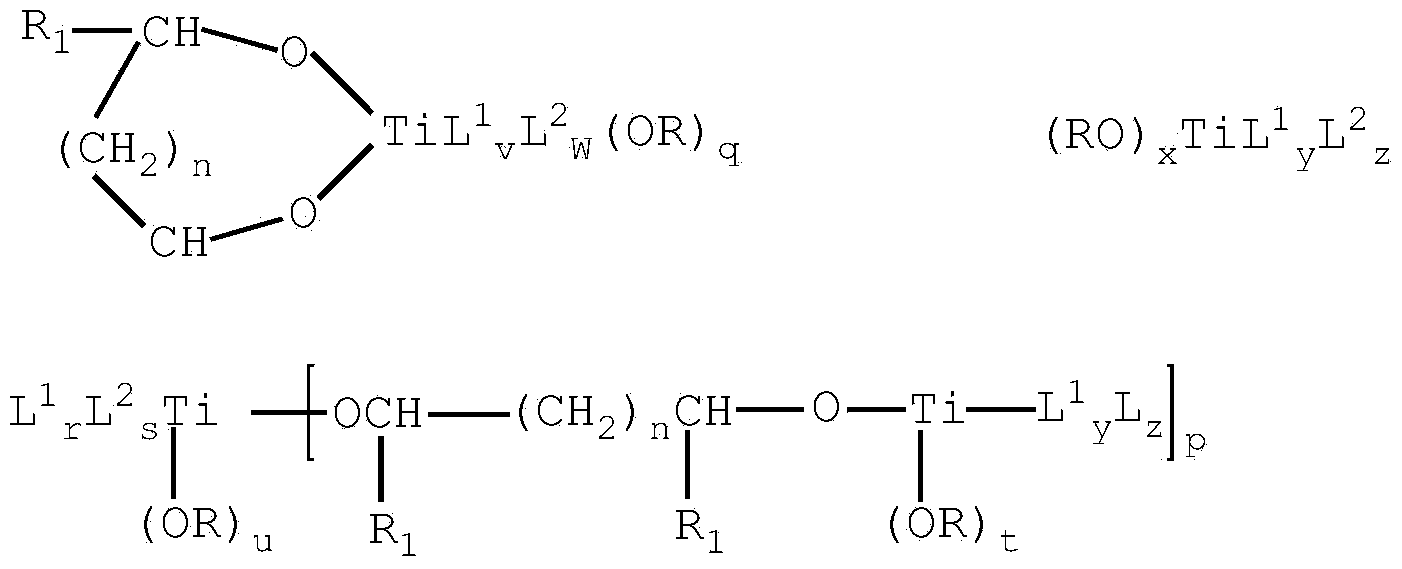

The invention belongs to the technical field of a method for preparing Rivastigmine intermediate. As is shown above, the Rivastigmine intermediate is obtained by causing the following formula to react with chiral amine under catalysis of tetraisopropyl titanate and then carrying out catalytic hydrogenation. In the method, 3-((S)-1- ((S)-1-phenethylamine group) ethide) phenylethyl (methyl) carbamate is obtained under the catalysis of the tetraisopropyl titanate. As the price of the tetraisopropyl titanate is 10% of the price of the currently used ytterbium acetate, the cost advantage is obvious. In addition, the method has the advantages of simple operation, low cost and high purity and yield of the obtained isomer. By adopting the intermediate to synthesize the Rivastigmine, the reaction route is short and the yield is high; the intermediate is the key intermediate for synthesizing the Rivastigmine.

Owner:SHANGHAI INST OF PHARMA IND +1

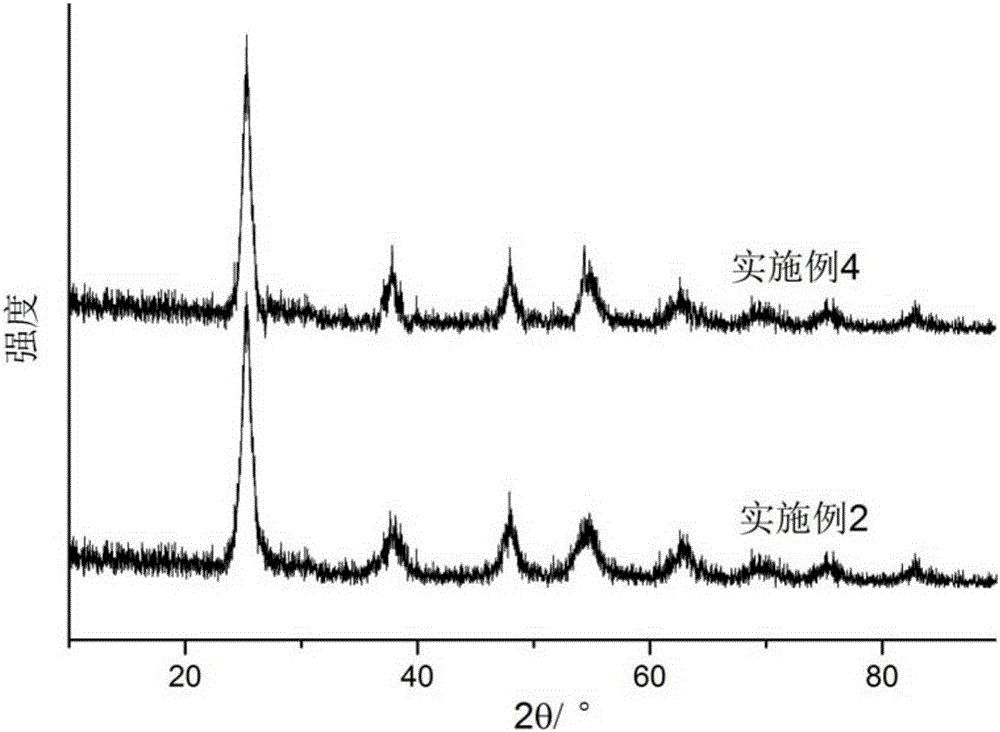

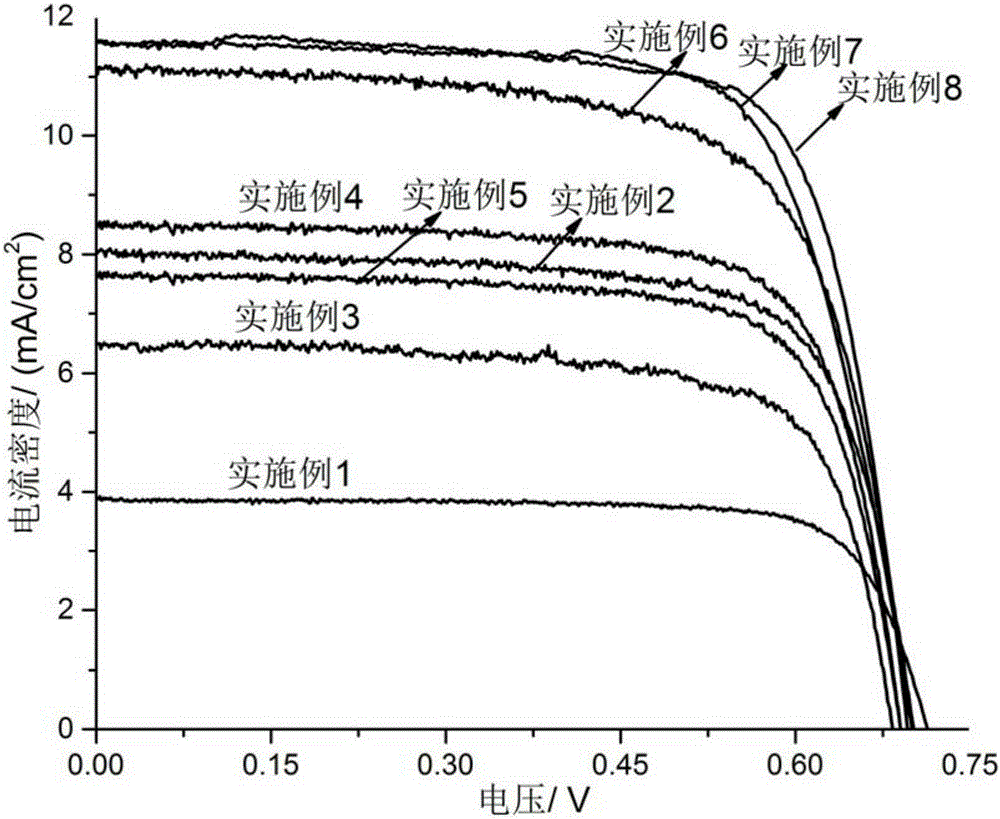

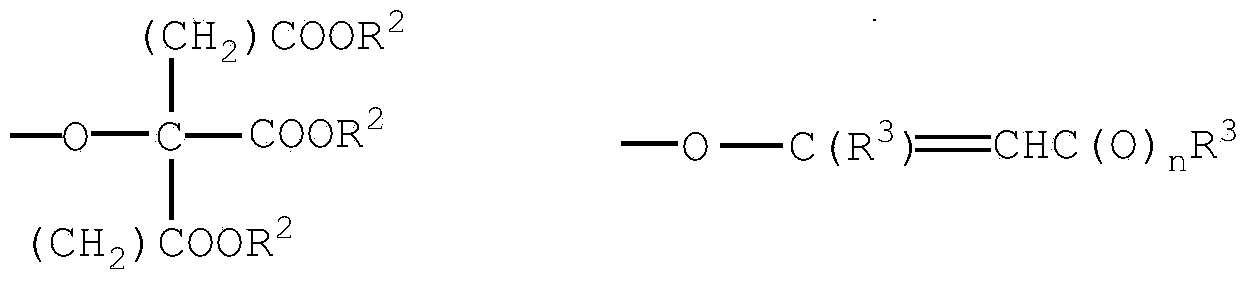

Controllable nanocrystalline TiO2 particle, and preparation method and use thereof

ActiveCN105347392AImprove performanceMaterial nanotechnologyLight-sensitive devicesMaterials preparationTetraisopropyl titanate

The invention belongs to the technical field of material preparation processing, and concretely relates to a controllable nanocrystalline TiO2 particle, and a preparation method and a use thereof. A technical problem to be solved in the invention is to provide the preparation method of the controllable nanocrystalline TiO2 particle. The method comprises the following steps: 1, adding tetraisopropyl titanate into an acidic solution, and stirring and reacting to prepare a titanium sol; 2, carrying out a hydrothermal reaction on the titanium sol; and 3, removing the above obtained liquid phase after the hydrothermal reaction ends, washing until neutrality, and drying to prepare the nanocrystalline TiO2 particle. TiO2 particles with different morphologies, sizes and crystal forms can be prepared through the method as needed.

Owner:PANZHIHUA UNIV

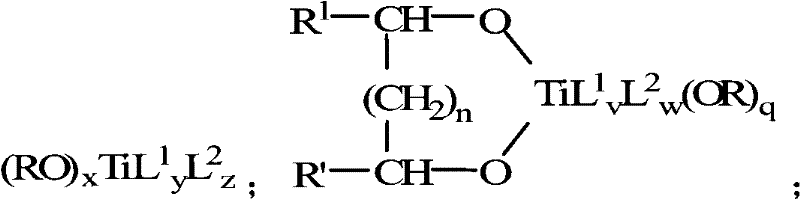

Preparation method of titanium complex with high catalytic activity

ActiveCN102513156AHigh catalytic activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventPhotochemistry

The invention discloses a preparation method of a titanium complex with high catalytic activity. The preparation method comprises the steps of: adding tetraisopropyl titanate in an agitated reactor, finishing dropwise adding triethyl citrate under the condition of stirring within half of an hour, continuously stirring for half of an hour; finishing dropwise adding ethyl acetoacetate within 2-2.5hours, continuously stirring for reacting for 1hour; evaporating generated isopropanol under negative pressure, adding 1,2-propylene glycol in the evaporated generated isopropanol, stirring for reacting for 1 hour, and evaporating isopropanol remained in a system under the negative pressure to obtain a semi-finished product of the titanium complex; and adding organic tin in the semi-finished product of the titanium complex and compounding a solvent to obtain a finished product. The preparation method provided by the invention has the advantages of simplicity in operation, low cost, light product color, higher purity of the isopropanol as a side product, stable quality of the finished product, high catalytic activity, difficulty in crystallization, and longer service life of the catalyst.

Owner:湖北新蓝天新材料股份有限公司

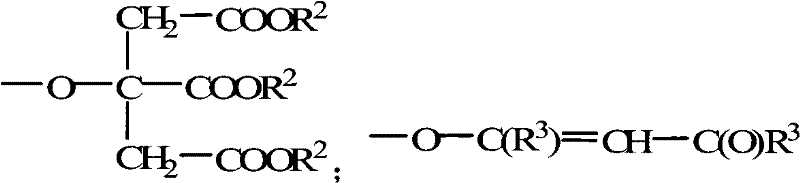

Titanate chelate for single-component dealcoholized room temperature vulcanized silicone rubber and preparation method thereof

InactiveCN103554172ARaw materials are easy to obtainThe process is easy to implementTitanium organic compoundsPolymer scienceBottle

The invention provides a titanate chelate for single-component dealcoholized room temperature vulcanized silicone rubber. Isopropyl titanate, ethyl acetoacetate and 1, 3-propanediol are taken as raw materials. The invention further provides a preparation method of the titanate chelate for the single-component dealcoholized room temperature vulcanized silicone rubber. The preparation method comprises the following steps: (1) adding 1000g of tetraisopropyl titanate into a dry and clean 3000ml three-necked bottle, evenly dropping 111.6g of ethyl acetoacetate into the thee-necked bottle, and stirring for 2h, and then heating by an oil bath or a constant-temperature heater to 40 DEG C; (2) firstly removing isopropanol at normal pressure, then performing removal at reduced pressure till no liquid droplets drop out, cooling, then adding 267g of 1, 3-propanediol and stirring for 3h; (3) heating by the oil bath, and removing a byproduct, namely the isopropanol under the vacuum degree of more than 650 torr for 6-7h; and (4) loading an obtained product into a glass bottle. Raw materials used by the preparation method are simple and easily available, the process is easy to implement, and the production process is easy to control; in addition, the appearance of viscosity peaks can be reduced or avoided.

Owner:深圳市红叶杰科技有限公司

Microwave liquid phase compounding process of high-purity barium titanate powder

The invention relates to a microwave liquid phase compounding process of high-purity barium titanate powder. Main raw materials which are tetraisopropyl titanate or tetrabutyl titanate, barium octahydrate and nitric acid are compounded by microwave auxiliary heating at lower temperature for shorter reaction time to obtain the barium titanate powder in different grain diameter specifications. The process comprises the following concrete steps: (1) hydrolyzing a titanium resource; (2) washing a hydrolyzed product; (3) obtaining the titanium resource; (4) fully dissolving high-purity Ba(OH)2.8H2Oin the pure water in a microwave reaction vessel with a stirring system to obtain barium hydroxide solution; (5) carrying out compounding reaction and obtaining slurry containing barium titanate particles after the reaction; (6) precipitating and washing or filtering the barium titanate slurry obtained in the reaction with high-purity water for many times and then drying to obtain the high-puritycubic phase barium titanate powder. The process has low reaction temperature, short reaction time, controllable particle diameter and high product purity.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Anti-aging MPP (modified polypropylene) electric tube

The invention discloses an anti-aging MPP (modified polypropylene) electric tube which is prepared from the following raw materials in parts by weight: 100-150 parts of polypropylene, 5-10 parts of light calcium carbonate, 1-8 parts of flake talcum powder, 2-10 parts of calcined kaolin, 1-5 parts of brucite powder, 20-40 parts of modified micro silicon powder, 0.2-3 parts of colorant, 2-10 parts of novel nucleating agent, 1-2.7 parts of antioxidant, 0.5-3 parts of polytetrafluoroethylene, 2-12 parts of master batch, 5-20 parts of melamine cyanurate and 5-15 parts of modified crystal whisker. The preparation process of the novel nucleating agent comprises the following steps: adding 150-180 parts of p-tert-butyl benzoic acid into 200-300ml of tetraisopropyl titanate, reacting at 90-130 DEG C for 3-5 hours, adding 100-150ml of silicate to obtain a solution A, adding the solution A into an ethanol-water mixture, hydrolyzing at 50-65 DEG C for 3-5 hours, filtering, and drying to obtain the novel nucleating agent. The anti-aging MPP electric tube has the advantages of high aging resistance, excellent impact resistance, excellent freezing resistance and excellent heat resistance.

Owner:安徽宁国市高新管业有限公司

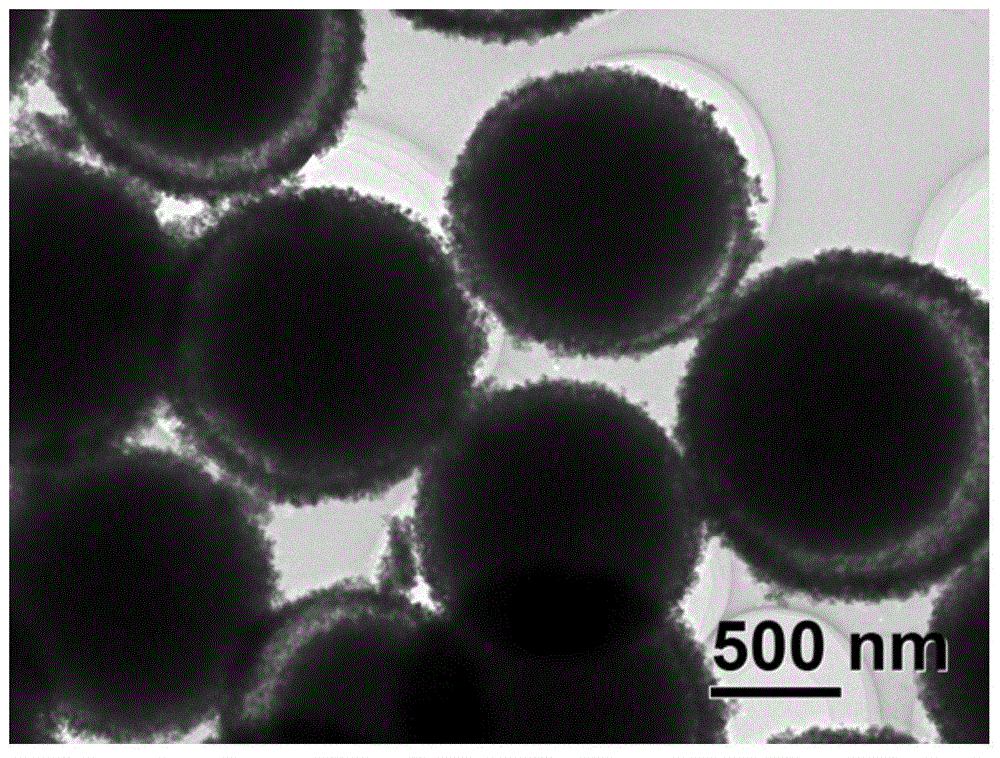

Solvent thermal synthesis method of TiO2 core-shell structure submicron ball

ActiveCN104860350AMild reaction conditionsSimple processTitanium dioxideTetraisopropyl titanatePhoto catalytic

The invention discloses a solvent thermal synthesis method of a TiO2 core-shell structure submicron ball. The solvent thermal synthesis method comprises the following steps: mixing acetylacetone and isopropanol to form a mixed solvent; adding tetrabutyl titanate or tetraisopropyl titanate; sufficiently stirring and reacting in a reaction kettle at 160-230 DEG C for 6-24 hours; and after naturally cooling, separating, washing and drying to obtain the TiO2 core-shell structure submicron ball. The synthesis method has the advantages of moderate reaction conditions, simple method, uniform grain diameter and adjustable size, and high yield. The TiO2 core-shell structure submicron ball synthesized by the method has a wide application prospect in the fields of novel solar batteries, photocatalysis, lithium ion batteries and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

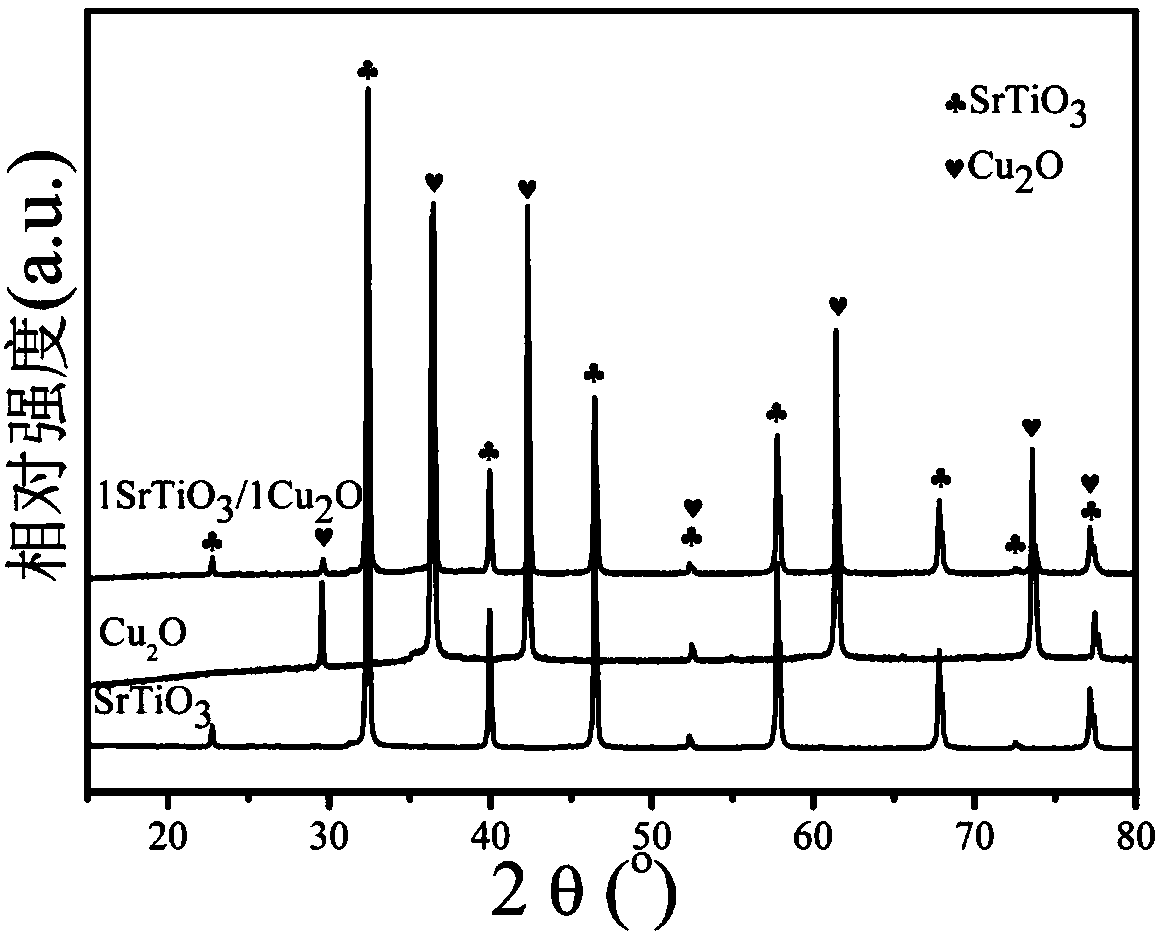

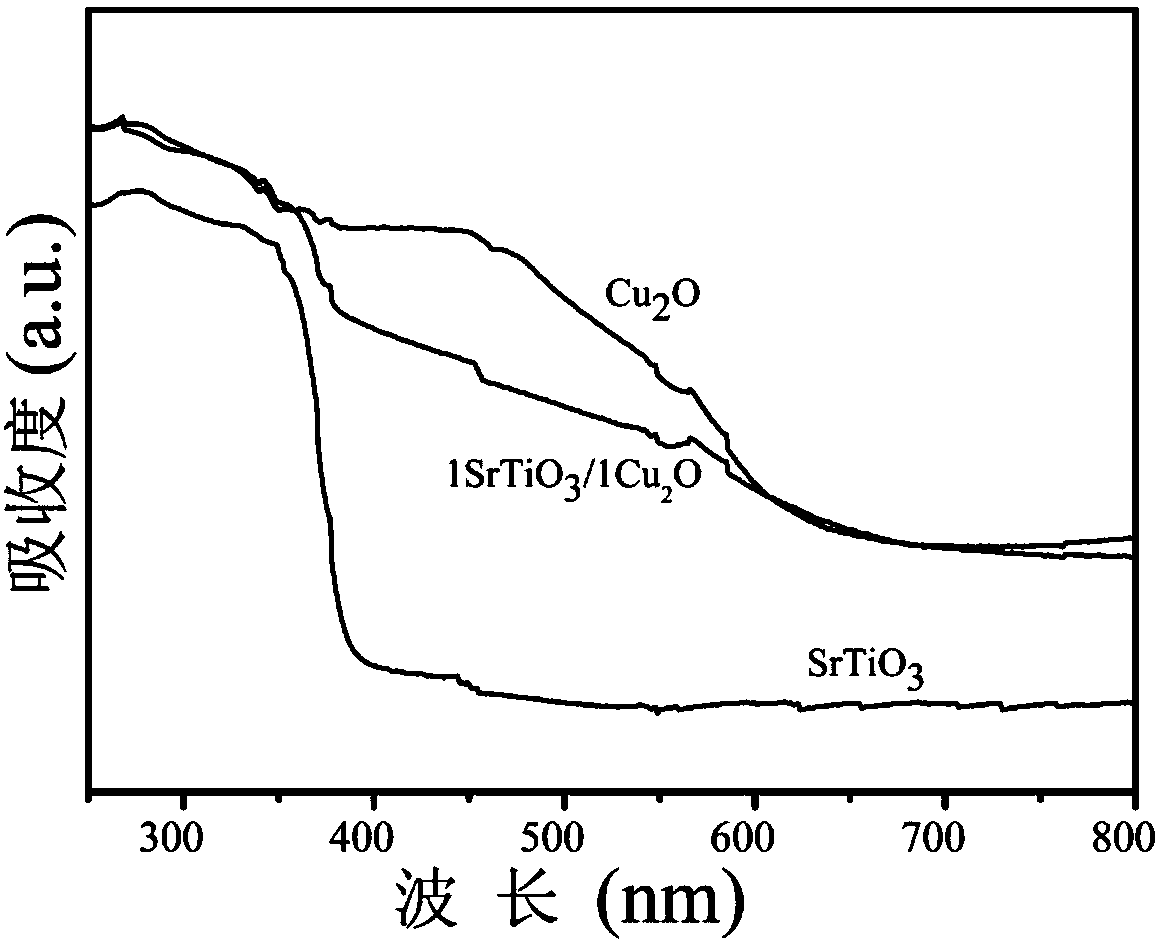

Novel preparation method and application of SrTiO3/Cu2O junction composite nanomaterial

ActiveCN107930633AUseful for pointsWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionStrontium chloride hexahydrate

Owner:JIANGSU UNIV OF TECH

Method for preparing nano TiO2 (titanium dioxide) pastes

InactiveCN102231304AIncrease surface areaImprove surface roughnessLight-sensitive devicesFinal product manufactureTetraisopropyl titanateCitric acid

The invention provides a method for preparing nano TiO2 (titanium dioxide) pastes, and is characterized by comprising the following steps in percentage by weight: adding one part of tetraisopropyl titanate to 2-6 parts of ethylene glycol; heating the mixed solution to 90 DEG C; adding 2-4 parts of citric acid; stirring for 6-24 hours magnetically to form TiO2 sols; adding 2-4 parts of P25 powdersand 0.2-0.8 part of pore forming material; and mixing and grinding to prepare the pastes. The method has the advantage of low sintering temperature and is convenient to package a battery.

Owner:IRICO

Preparation method of modified expanded polystyrene

The invention discloses a preparation method of modified expanded polystyrene. The preparation method of the modified expanded polystyrene comprises the following steps: adding di(dioctyl phosphite) tetraisopropyl titanate into acetone, uniformly stirring, then adding carbon nano tubes for carrying out ultrasonic dispersion, and drying to obtain a nucleating agent; adding water, barium stearate, activated calcium phosphate, nekal, a defoaming agent, an antioxidant, a flame retardant and styrene into a reaction container, uniformly stirring, then sequentially adding dibenzoyl peroxide, tert-butyl peroxybenzoate, dicumyl peroxide and the nucleating agent, uniformly stirring, heating up to the temperature of 90 DEG C, and carrying out heat preservation for 3-4 hours, so that polystyrene is obtained; adding liquid butadiene-acrylonitrile rubber and melamine formaldehyde resin into a reaction container containing polystyrene, heating up to the temperature of 100-110 DEG C, uniformly stirring, adding a foaming agent, and carrying out heat preservation for 3-4 hours, wherein pressure in a heat preservation process is 1-1.2MPa; and cooling to room temperature, and filtering, so that the modified expanded polystyrene is obtained.

Owner:芜湖市京桥精密智造有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com