Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Dibenzyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzyl ether. (C6H5CH2)2O A liquid unstable at room temperature; boiling point 295-298°C; used in perfumes and as a plasticizer for nitrocellulose. Also known as dibenzyl ether.

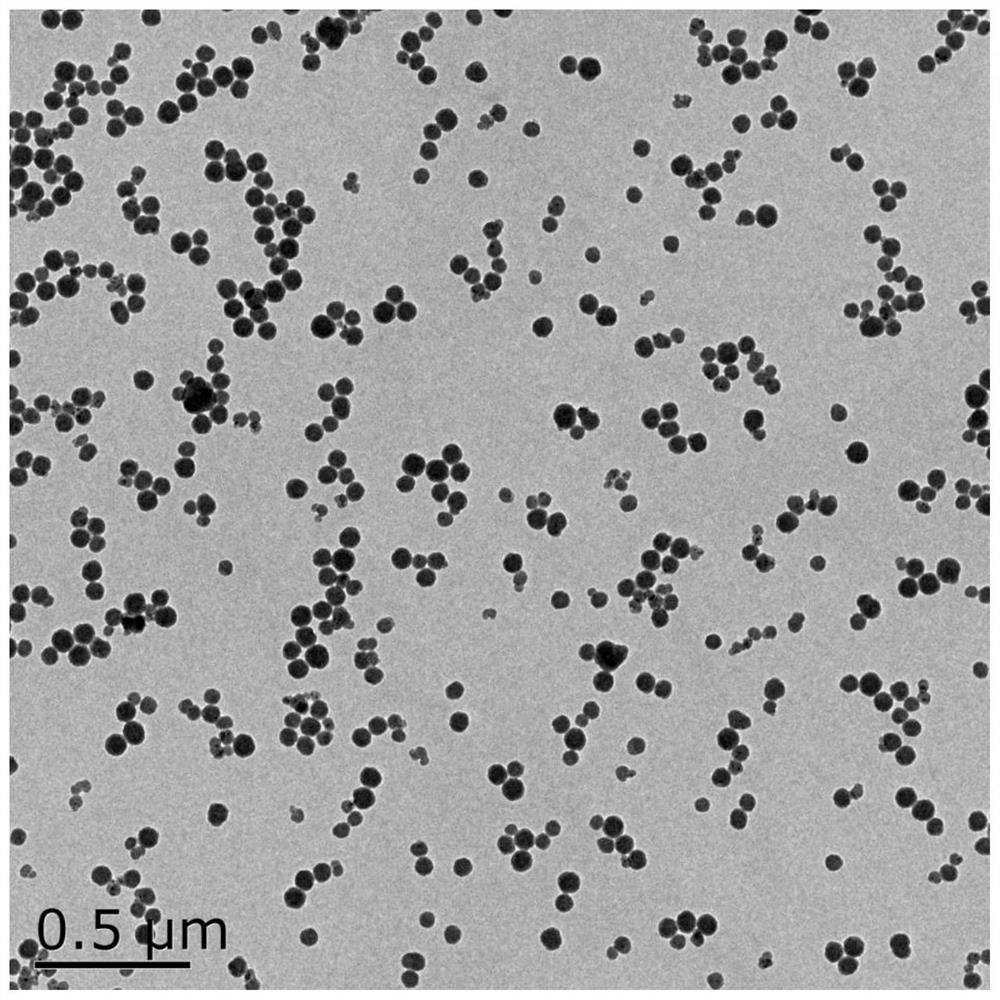

Preparation method and application of RGD-modified ultra-small magnetic iron oxide nanoparticles

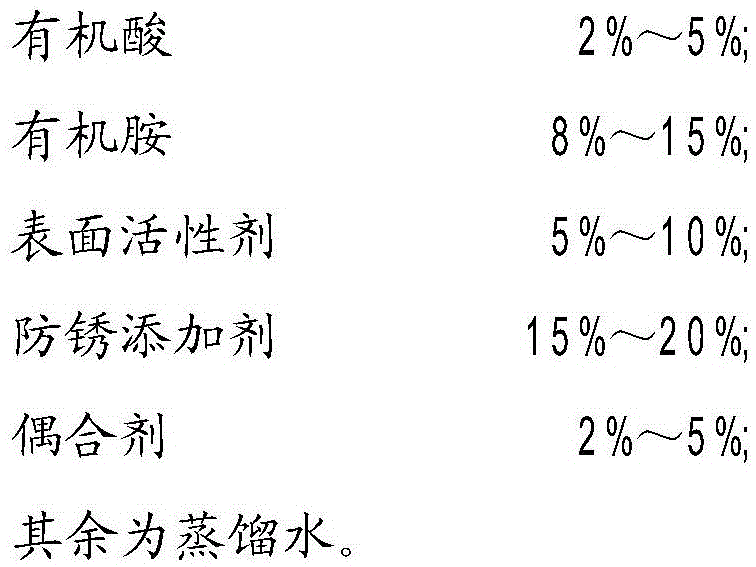

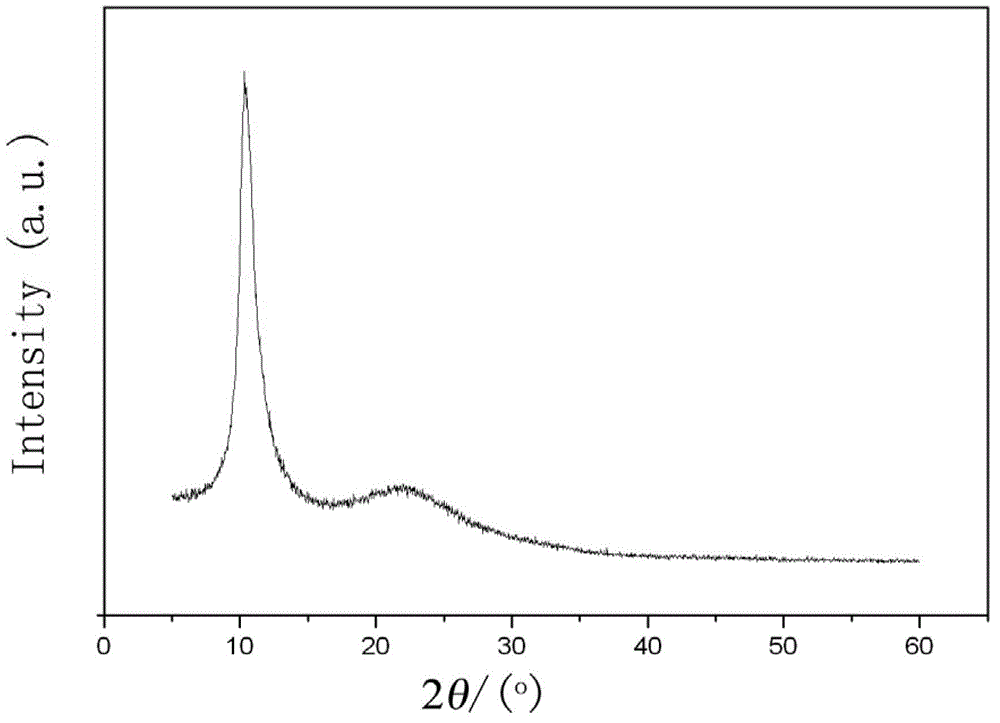

ActiveCN104258425AStrong reducing propertiesHigh crystallinityNMR/MRI constrast preparationsEmulsion deliveryCyclic peptideActive agent

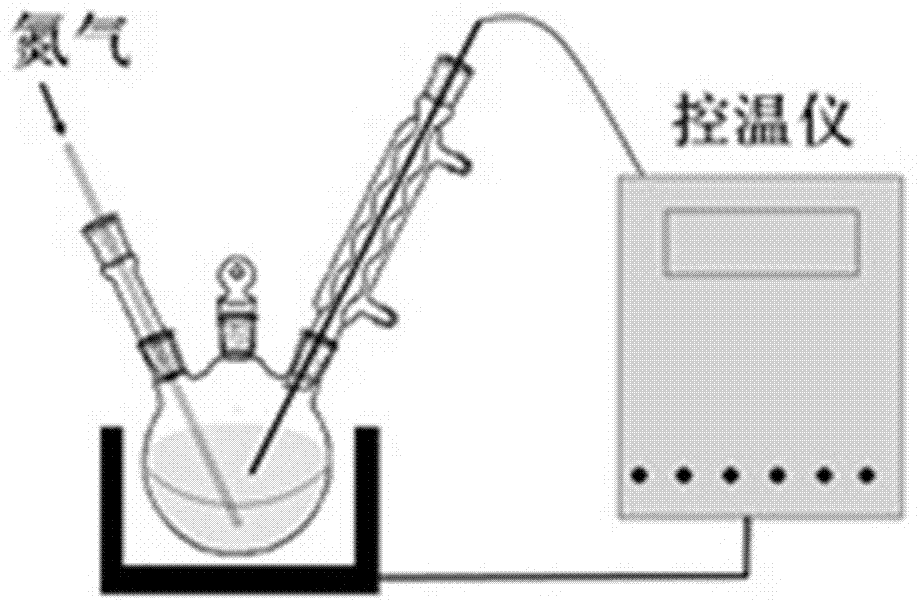

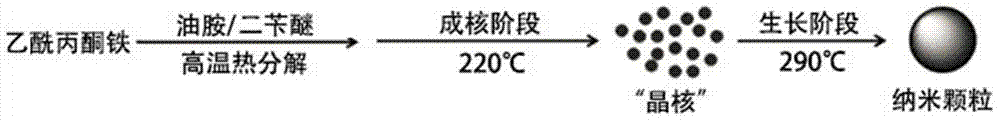

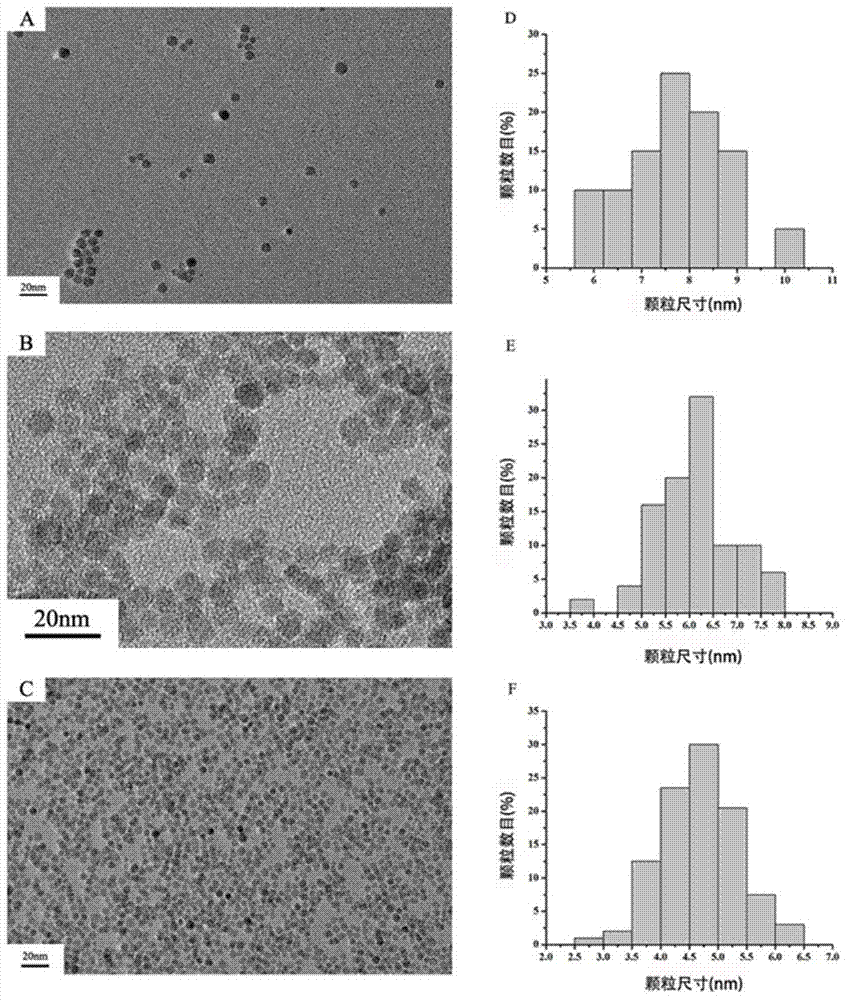

The invention discloses a preparation method of RGD-modified ultra-small magnetic iron oxide nanoparticles. The preparation method comprises the following steps: preparing ultra-small magnetic iron oxide nanoparticles by taking ferric acetylacetonate as a reaction raw material and a precursor, taking oleylamine as a surfactant and a reducing agent and taking dibenzyl ether as a solvent; replacing oleylamine molecules wrapped on the surfaces of the nanoparticles by utilizing dopamine-modified HOOC-PEG-COOH to realize PEG-modification of the surfaces of the nanoparticles; and finally, chemically coupling RGD cyclic peptide by virtue of free carboxyl at the tail end of the PEG to obtain the RGD-modified ultra-small magnetic iron oxide nanoparticles. The method of synthesizing the ultra-small magnetic iron oxide nanoparticles has the characteristics of a simple process, a high raw material conversion ratio, strong repeatability and the like. The synthesized magnetic iron oxide nanoparticles have the characteristics of a regular morphology, an ultra-small dimension, good stability, good monodispersity, high biocompatibility, and tumor specific targeting, and the like, and can be used as a T1-weighted imaging high-performance magnetic resonance imaging contrast agent with a tumor active targeting function.

Owner:SOUTHEAST UNIV

Water solubility high-speed grinding fluid for machining settlement bearing and preparation method thereof

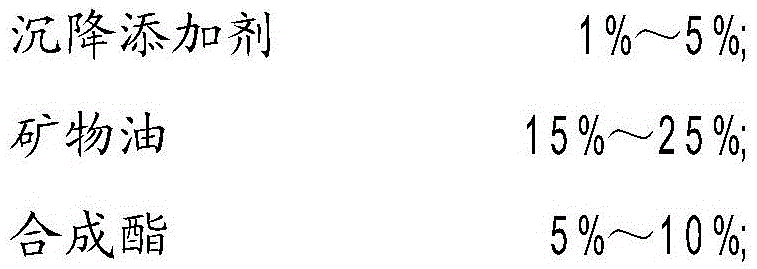

ActiveCN105542931ARaise the pHImprove the lubrication effectLubricant compositionSolubilityHigh-speed grinding

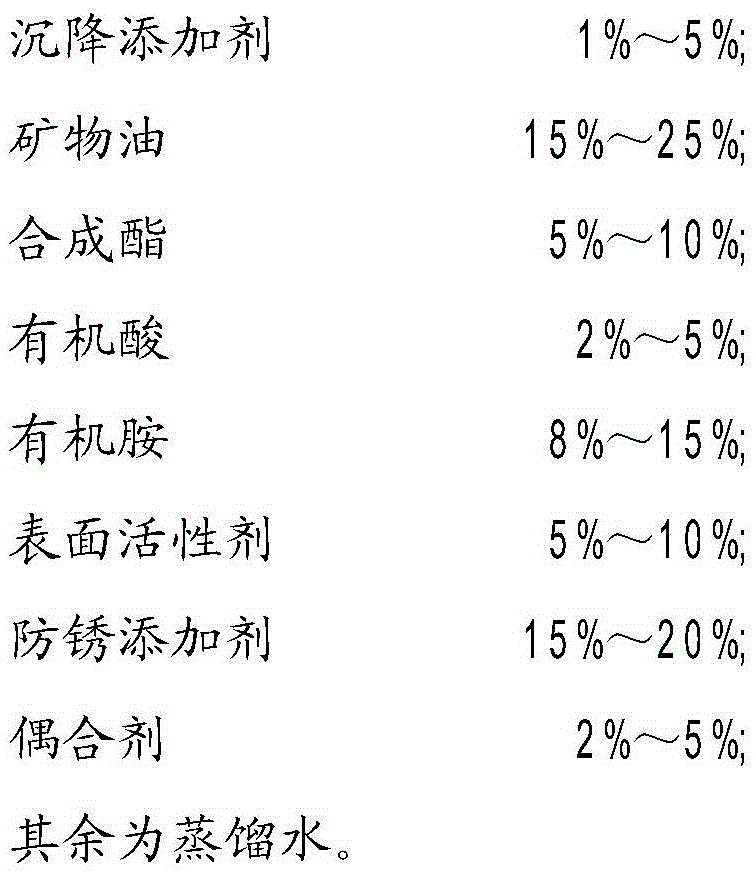

The invention discloses water solubility high-speed grinding fluid for machining a settlement bearing. The water solubility high-speed grinding fluid comprises the following components by weight percent: 1 to 5 percent of settlement additive; 15 to 25 percent of mineral oil, 5 to 10 percent of synthetic ester, 2 to 5 percent of organic acid, 8 to 15 percent of organic amine, 5 to 10 percent of surface active agent, 15 to 20 percent of antirust additive, 2 to 5 percent of coupling agent and the balance of distilled water. The settlement additive is a mixture of fatty amine polyoxyethylene ether, aziridine and dibenzyl ether. The water solubility high-speed grinding fluid has excellent rust resistance, wettability, lubricity and grinding ash settling performance. Meanwhile, the invention provides a preparation method of the water solubility high-speed grinding fluid for machining the settlement bearing.

Owner:QUAKER CHEM CHINA

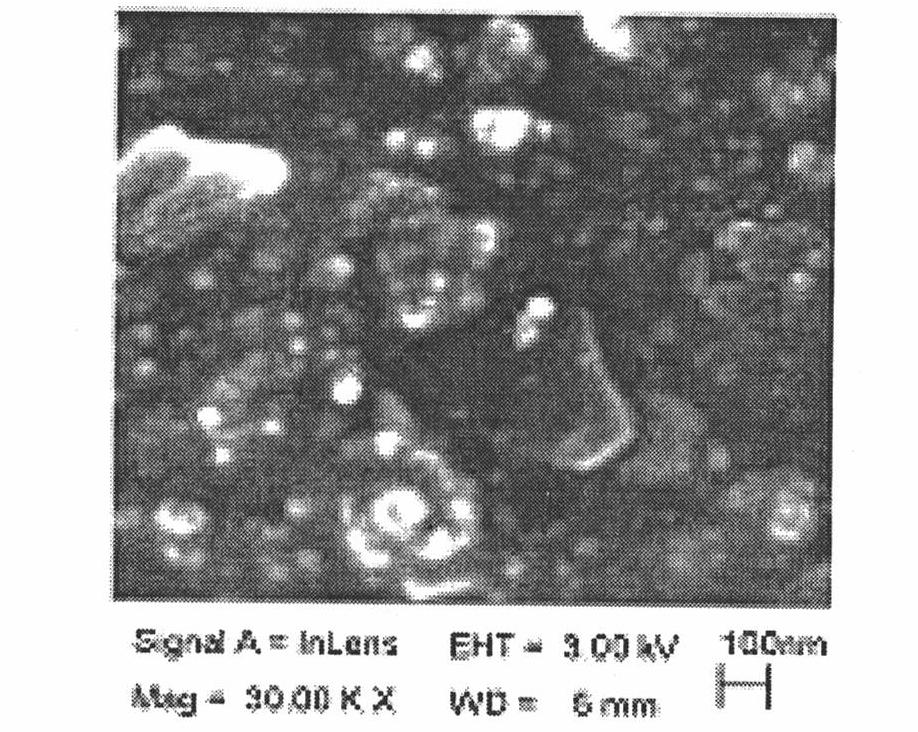

Nano conveyor belt and preparation method thereof

InactiveCN101927893AImprove mechanical propertiesAvoid pollutionConveyorsRubber layered productsPolyvinyl chlorideChlorinated paraffins

The invention discloses a nano conveyor belt which consists of tyre fabrics or canvas and a high polymer composite material covered on the fabrics or the canvas, wherein the high polymer composite material comprises the following raw materials in parts by weight: 20-40 parts of chloroprene rubber, 5-10 parts of nitrile rubber, 5-10 parts of natural rubber, 5-15 parts of polyvinyl chloride, 10-20 parts of diocty phthalate, 2-5 parts of chlorinated paraffin, 2-5 parts of antimonous oxide, 2-5 parts of tritolyl phosphate, 0.1-0.3 part of tetraisopropyl titanate, 0.1-0.5 parts of hydroquinone dibenzyl ether, 0.1-0.5 parts of tetramethylthiuram disulfide, 0.3-0.6 part of sulphur, 2-5 parts of carbon black and 1-3.6 parts of nano particles. The nano conveyor belt prepared of the invention is characterized in that the surface resistivity is 1.5*105 omega, and the body resistivity is 3.0*1.3 omega.m; the combustion time is 1.3 second, and the smoldering time is 0 second; and after the nano conveyor belt is soaked in water for 70 hours, the antistatic performance and flame resistance thereof have no obvious change.

Owner:ZHONGYUAN ENGINEERING COLLEGE

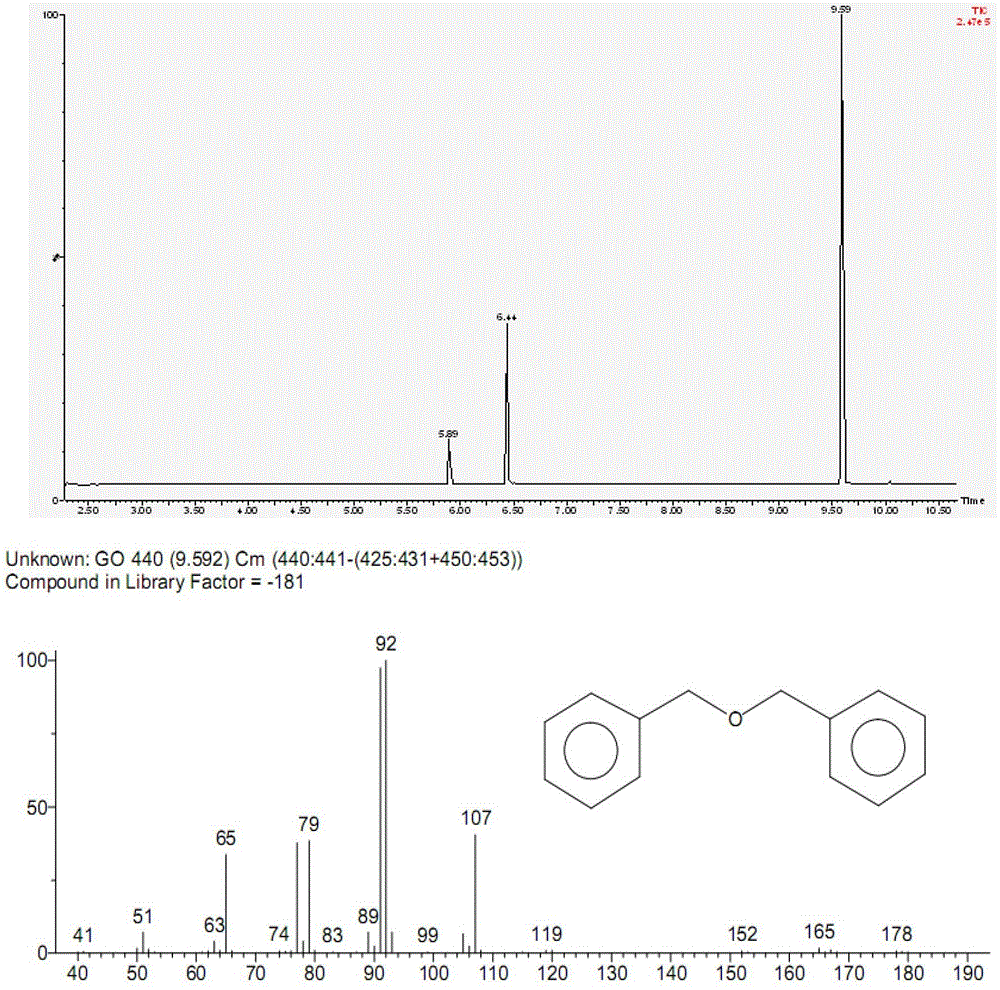

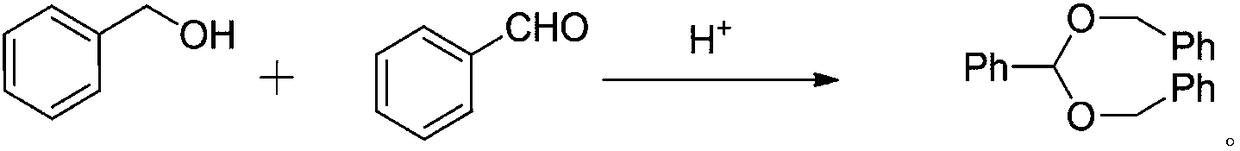

Method of preparing dibenzyl ether from benzyl alcohol under catalysis of graphene oxide

ActiveCN102746123AHigh catalytic activityHigh selectivityPhysical/chemical process catalystsCarbon compoundsReaction temperatureSolvent

The invention discloses a method of preparing dibenzyl ether from benzyl alcohol under the catalysis of graphene oxide. The method is as follows: graphene oxide is used as a catalyst, benzyl alcohol is used as a raw material, then a reaction is carried out at a temperature of 70 to 170 DEG C and a normal pressure for 12 to 36 h under an insulation condition, and a reaction solution is subjected to post-treatment after the reaction is finished so as to prepare dibenzyl ether. According to the invention, graphene oxide is used as the catalyst to catalyze dehydration of benzyl alcohol so as to produce dibenzyl ether, and the catalyst has high catalytic activity, high selectivity and no pollution, is green and environment friendly and can selectively catalyze dehydration of benzyl alcohol to produce dibenzyl ether; no solvent is used in the reaction, no metal participates in the reaction, reaction conditions are mild, and environment friendliness of a resultant is obtained on the premise that the conversion rate of benzyl alcohol and high selectivity of dibenzyl ether are guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Preparation of benzyl acetate

ActiveCN101434539AEasy to operateThree wastes less pollutionOrganic compound preparationCarboxylic acid esters preparationAcetic anhydrideAlcohol

The invention discloses a method for producing jasmal, which mainly adopts dibenzyl ether which is a high boiling waste produced by benzoic alcohol, as a raw material. The dibenzyl ether reacts with acetic anhydride in the presence of solid acid catalysts to obtain a crude product, and then the crude product is refined and purified to obtain an end product. The technology has simple operation process, stability, high efficiency, less pollution of the three wastes and applicability to the industrialized production.

Owner:WUHAN YOUJI IND

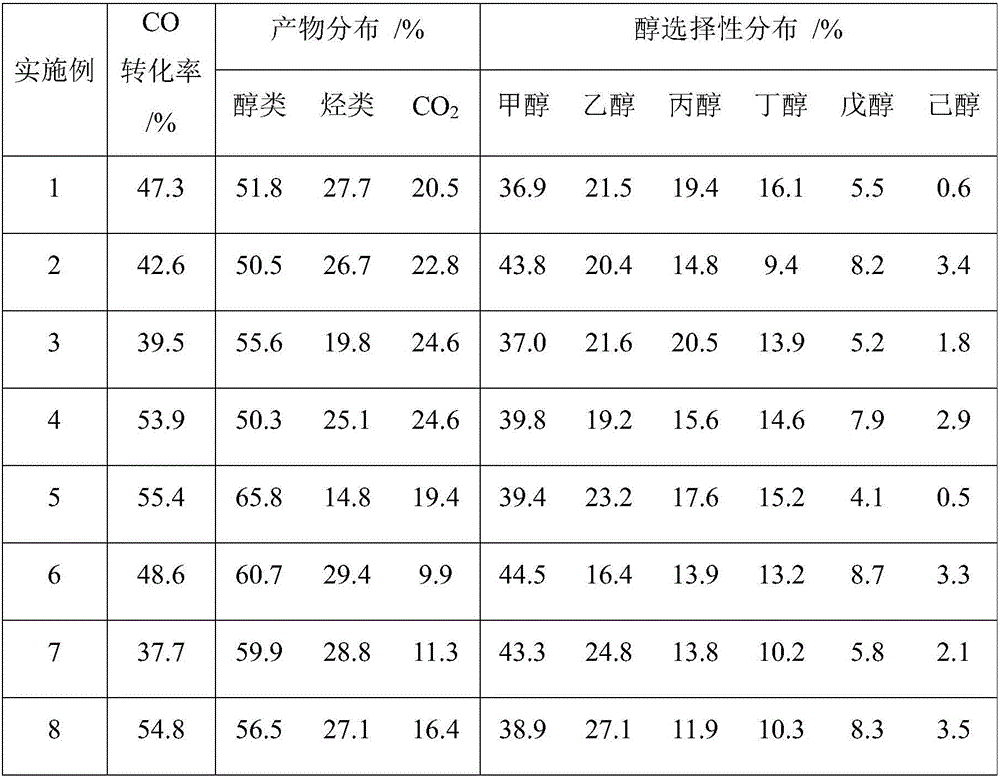

Catalyst for preparing low carbon mixed alcohol through synthesis gas and preparation method thereof

ActiveCN106824197ANovel structureThe synthesis method is simpleOrganic compound preparationHydroxy compound preparationFiltrationActive phase

The invention relates to a catalyst for preparing low carbon mixed alcohol through synthesis gas and a preparation method thereof, which relate to low carbon mixed alcohol. The catalyst is a supported FeCo-alloy@Cu core-shell structure catalyst; a core layer of the core-shell structure is FeCo-alloy; a shell layer is Cu; an active phase of the core-shell structure FeCo-alloy@Cu accounts for 10 percent to 50 percent, and the balance is a carrier. The preparation method comprises the steps of mixing ferric salt, cobalt salt, dibenzyl ether, oleic acid and oleylamine; cooling a solution subjected to heating reaction, washing, centrifuging, and drying to obtain FeCo alloy nano particles which are denoted as the FeCo-alloy; re-dispersing the FeCo-alloy into absolute ethyl alcohol containing polyacrylamide for carrying out ultrasonography; adding a copper-bearing compound, adding an NH3.H2O solution to obtain a solution A, then adding a sodium borohydride solution, and obtaining a solid suspension liquid with the core-shell structure; then adding a carrier, stirring, carrying out extraction filtration, washing, and reducing dried solid to obtain the catalyst.

Owner:XIAMEN UNIV

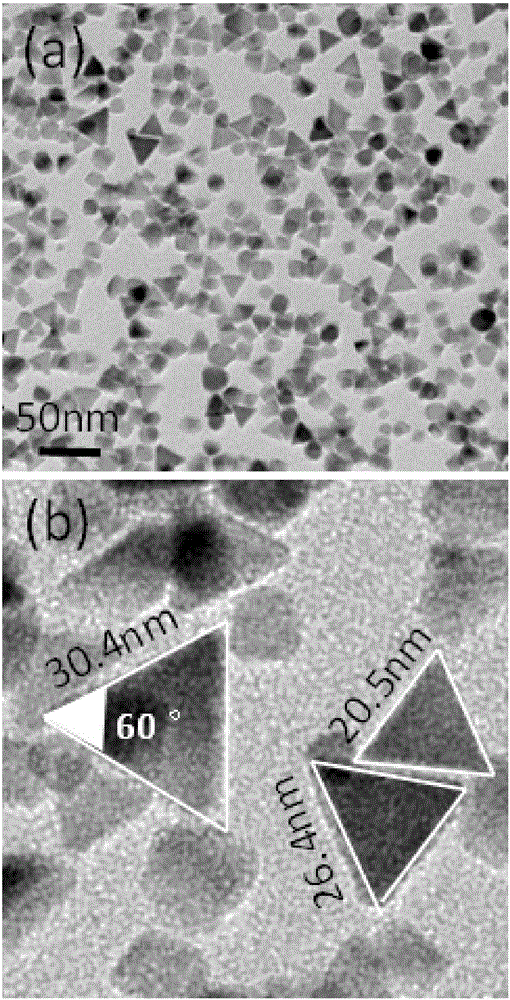

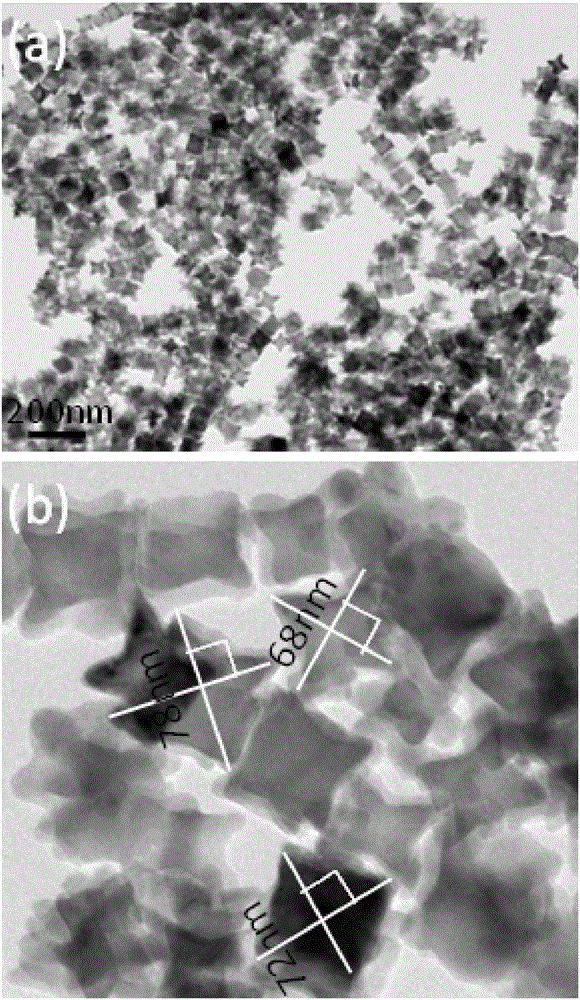

Preparation method of MnFe2O4 nano magnetic material

The invention discloses a preparation method of a MnFe2O4 nano magnetic material. The preparation method comprises the following steps: weighing a manganous salt sample and a ferrite sample according to a specific amount; taking dibenzyl ether as a solvent, adding oleylamine and oleic acid to form mixed liquid, and heating the mixed liquid to obtain a MnFe2O4 nano magnetic material which has a symmetrical structure microscopically, wherein a heating process is carried out under protection of N2 atmosphere; and selecting suitable heating parameters to obtain three-dimensionally symmetric, four-dimensionally symmetric, six-dimensionally symmetric and diamond-shaped symmetric MnFe2O4 nano magnetic materials. The invention provides the preparation method of the MnFe2O4 nano magnetic material. The prepared MnFe2O4 nano magnetic material has good symmetry; the grain size of the MnFe2O4 nano magnetic material is about 50 nanometers; the size of the MnFe2O4 nano magnetic material is close to the size of protein and the size of virus; and the dispersibility is good.

Owner:ANHUI UNIVERSITY

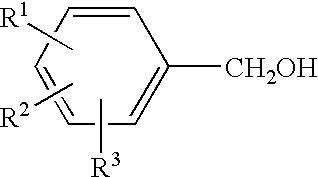

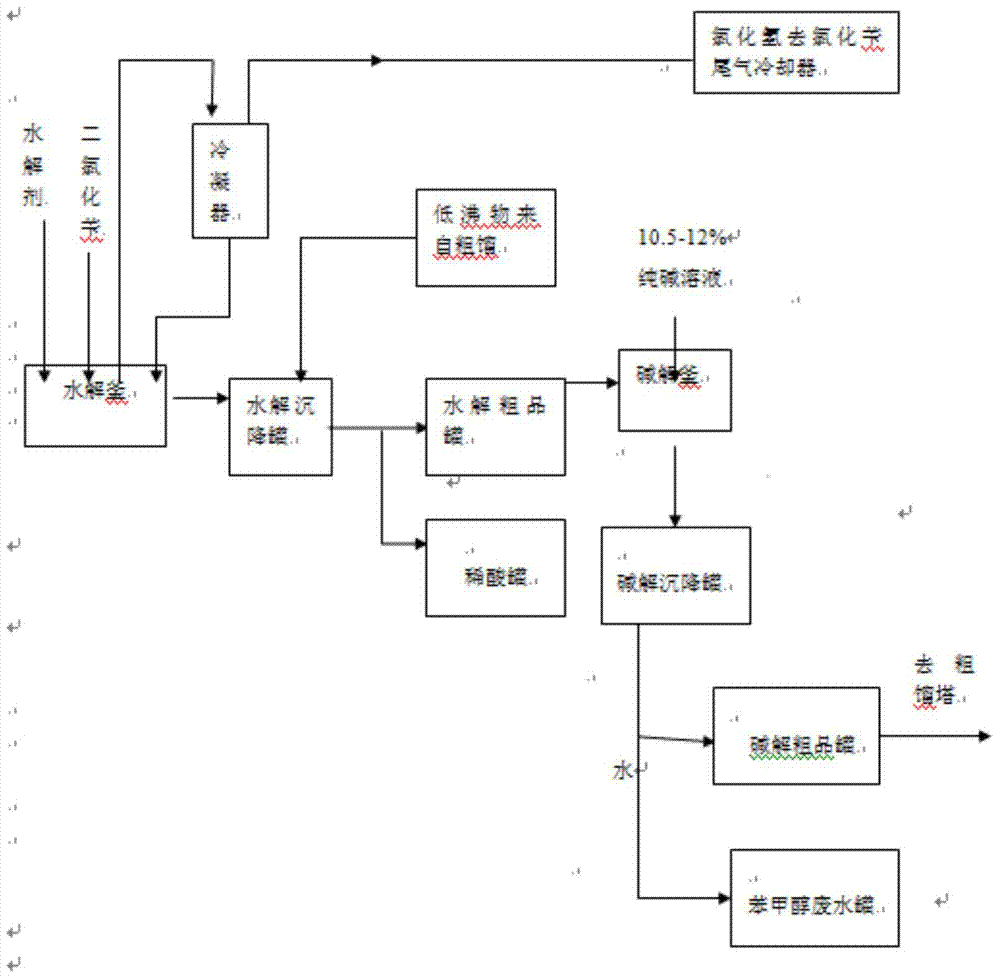

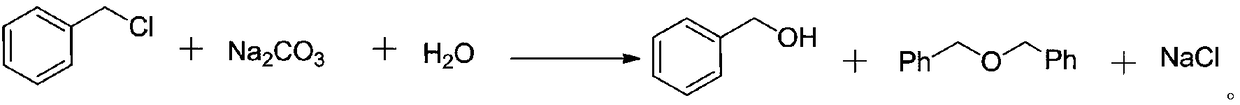

High-selectivity green hydrolysis technology for preparing benzyl alcohol

InactiveCN105924328AAchieve recyclingEasy to handleOrganic compound preparationHydroxy compound preparationWastewaterBenzyl chloride

The invention discloses a high-selectivity green hydrolysis technology for preparing benzyl alcohol. The high-selectivity green hydrolysis technology includes the steps that sodium formate, benzyl chloride, water and organic tertiary amine catalysts are put into a reactor in the molar ratio of (1.05-1.1):1:7.0:0.02, sufficiently mixed and stirred, and subjected to normal-pressure reacting for 8 h to 9 h at the temperature of 100 DEG C to 115 DEG C, heating is stopped, the temperature is reduced to be 95 DEG C to 105 DEG C, caustic soda with the molar weight equal to the molar weight of the benzyl chloride is put, and the mixture continues to be reacted for 2 h to 3 h; the reacted mixture is filtered, solid sodium chloride is removed, the liquid-phase product is cooled, and the organic-phase product is separated; the organic-phase product is subjected to rectification separation, and the high-purity benzyl chloride is obtained; the water-phase product is returned to the reactor again, and repeated hydrolysis reacting is carried out after the raw materials are supplemented; According to the high-selectivity green hydrolysis technology, the benzyl chloride is subjected to hydrolysis with the sodium formate as an assistant and the organic tertiary amine as a catalyst to prepare benzyl alcohol, and the adopted organic organic tertiary amine catalysts are low in price and high in catalysis efficiency; the water-phase product obtained through the reaction can be recycled, high-salt wastewater in the production process of the benzyl alcohol is solved, and meanwhile the content of the dibenzyl ether is greatly reduced, wherein the content of the dibenzyl ether is lower than 3.5%.

Owner:JIANGSU GOLD BRIDGE SALT & CHEM GRP

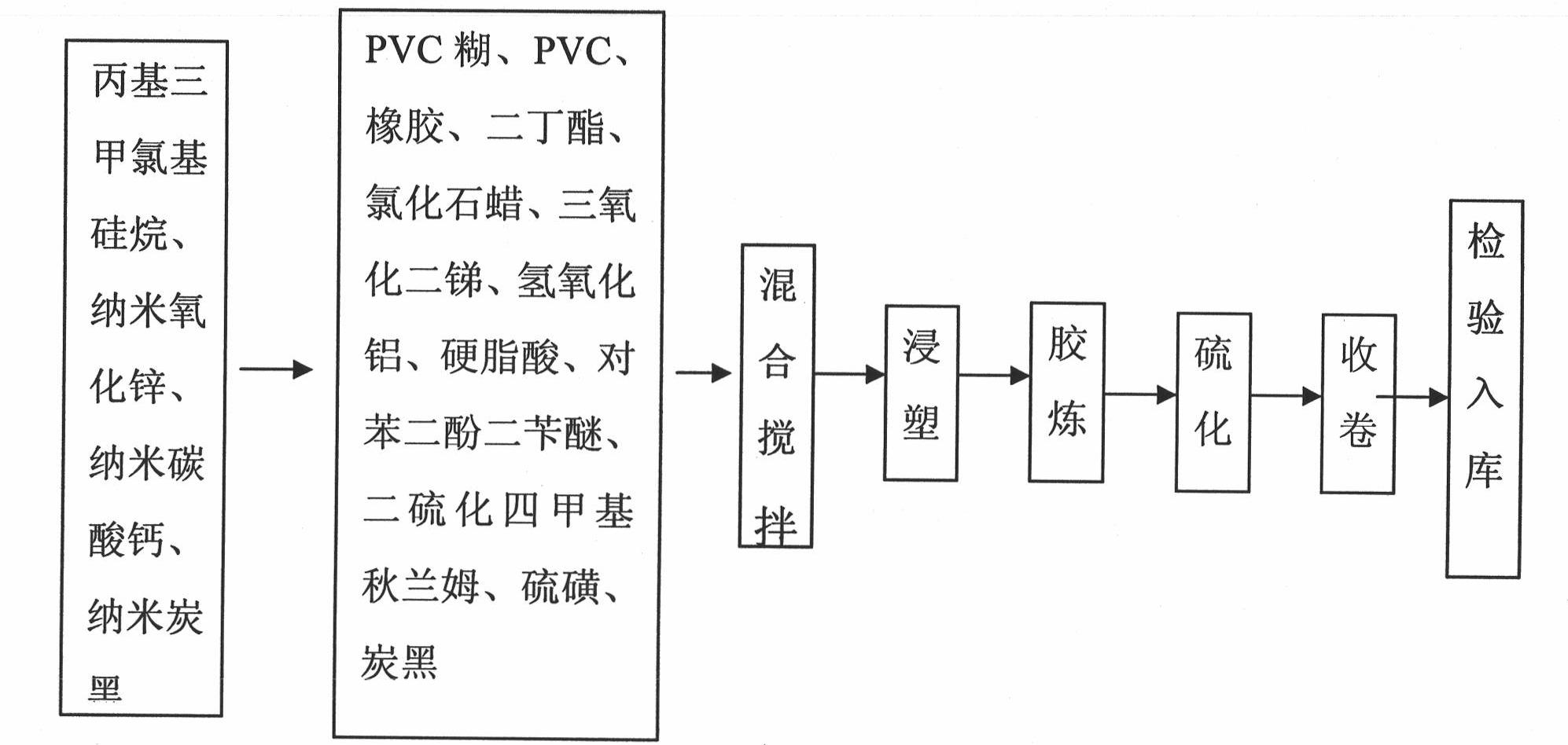

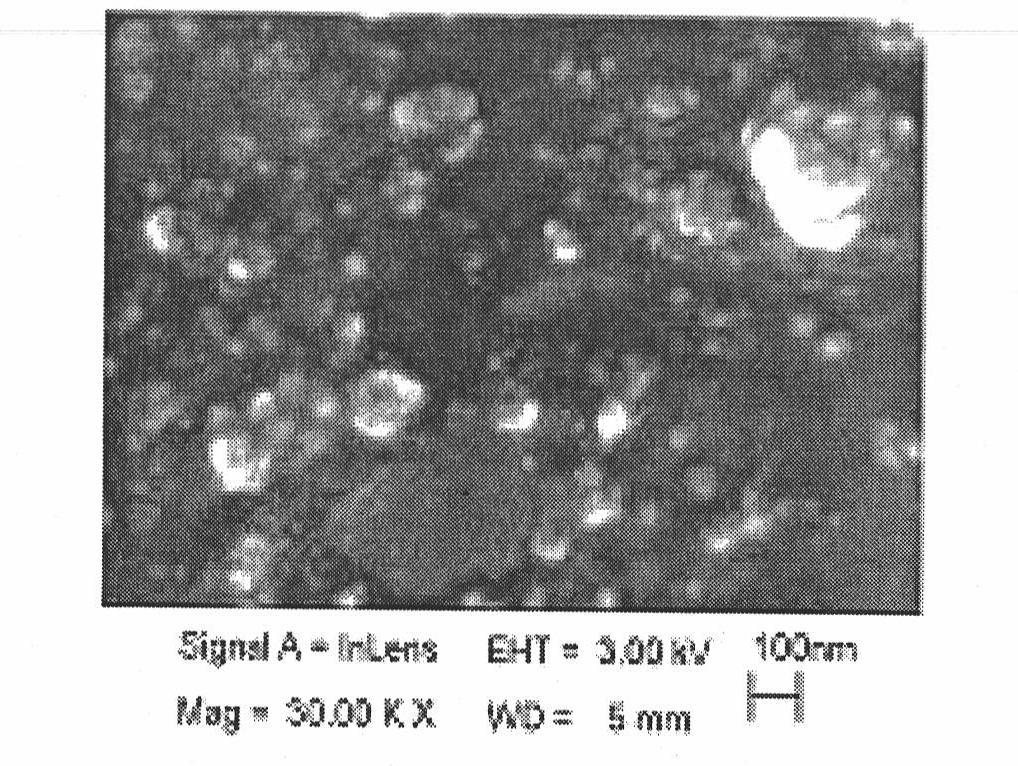

Nano wind tube and preparation method thereof

InactiveCN102079826AHigh resistivityLow resistivityTunnel/mines ventillationAluminium hydroxidePolyvinyl chloride

The invention discloses a nano wind tube and a preparation method thereof. The nano wind tube is made from glass fiber and polymer composite material by the following steps: mixing, dipping, rubber refining, vulcanizing and roll-forming. The above-mentioned polymer composite material is prepared from the following components in certain parts by weight: carbon black, nano carbon black, nano zinc oxide, nano-CaCO3, propyltrimethylchlorosilance, polyvinyl chloride (PVC) paste, PVC, rubber, didutyl ester, chlorinated paraffin, antimony trioxide, aluminium hydroxide, stearic acid, hydroquinone dibenzyl ether, tetramethyl thiuram disulfide, sulfur and the like. The nano wind tube has the advantages of small resistivity, good flame-retardant performance, and can prevent environment and human body from being polluted by nano material filling process.

Owner:ZHONGYUAN ENGINEERING COLLEGE

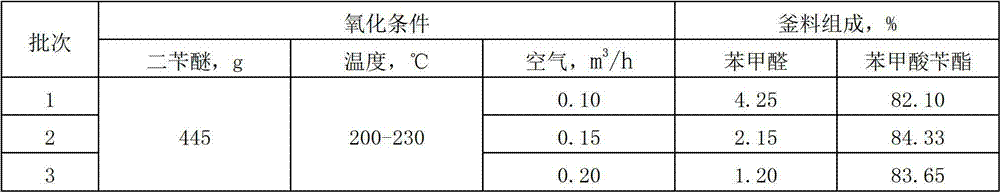

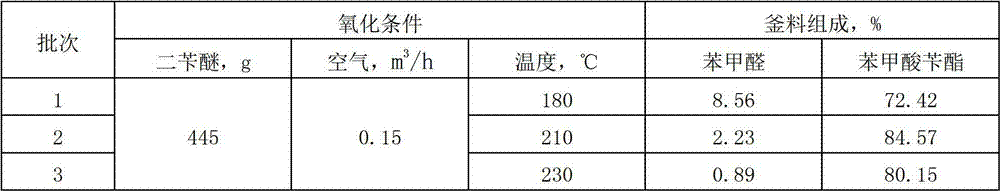

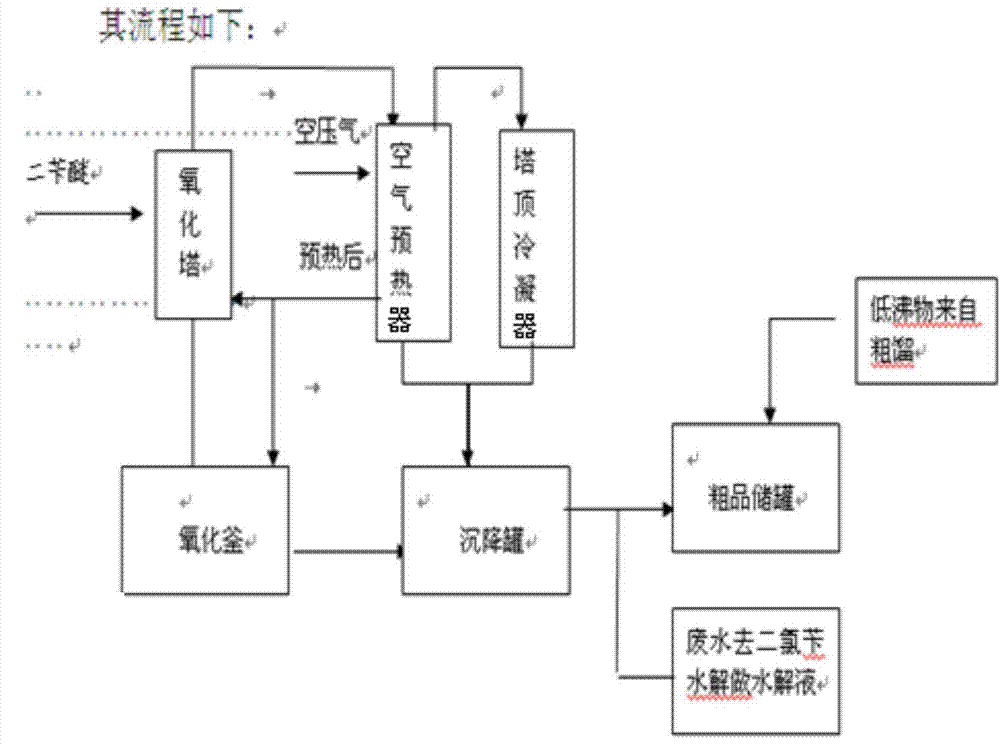

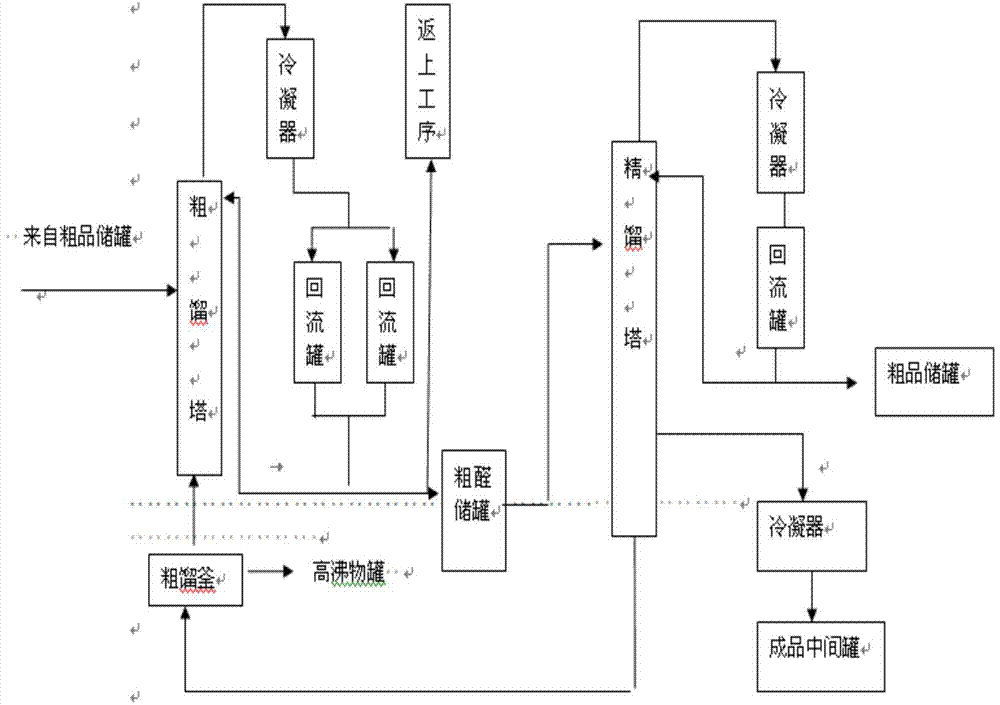

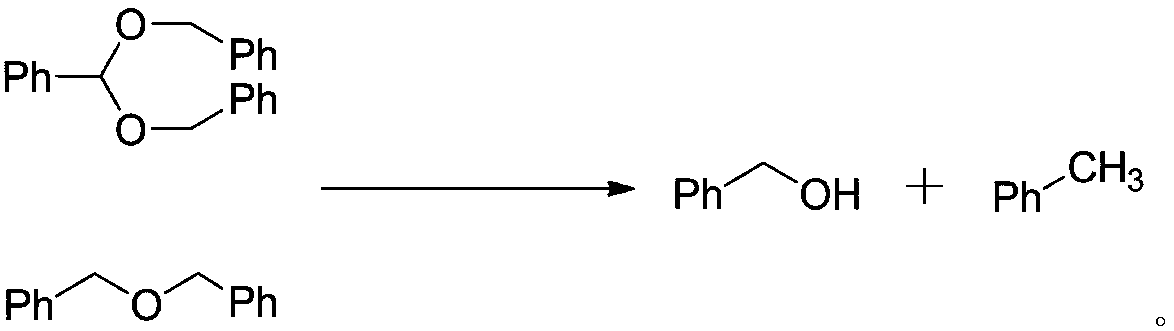

Method for preparing benzyl benzoate by oxidizing dibenzyl ether

InactiveCN102766051AImprove qualityReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationBenzyl benzoatBenzene

The invention discloses a method for preparing benzyl benzoate by oxidizing dibenzyl ether, which comprises steps as follows: A, oxidization; B, rectification and refining; C, acid-alkali neutralization; D, freezing crystallization; and E, centrifugal separation. According to the method disclosed by the invention, by-product dibenzyl ether produced by benzyl alcohol preparation is used as a raw material, so that the defects of other benzyl benzoate preparation methods are well solved; the preparation cost is low, the product quality is good, and no pollution is caused; and therefore, the preparation method disclosed by the invention is the method of preparing high-quality benzyl benzoate by low cost.

Owner:HUBEI GREENHOME MATERIALS TECH INC

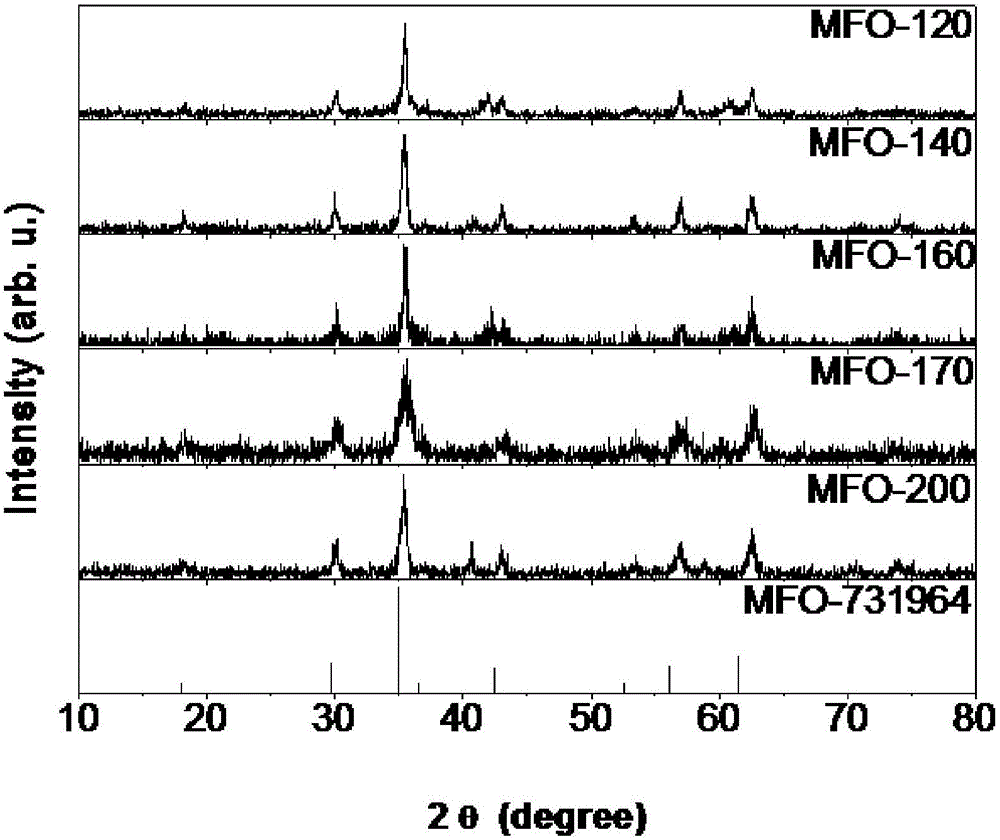

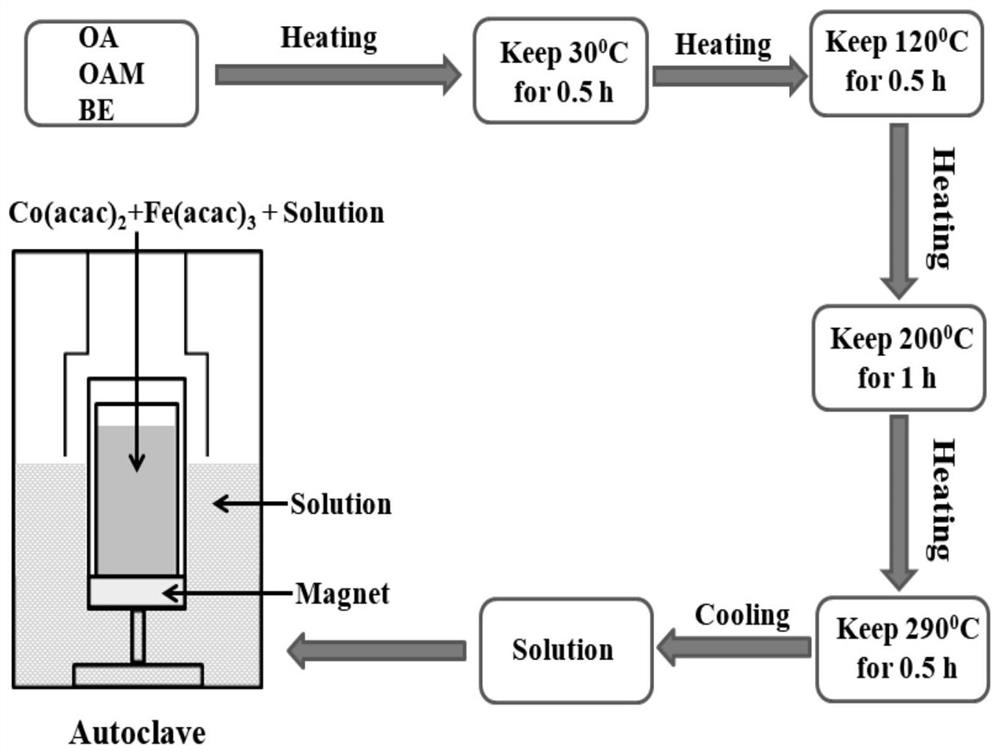

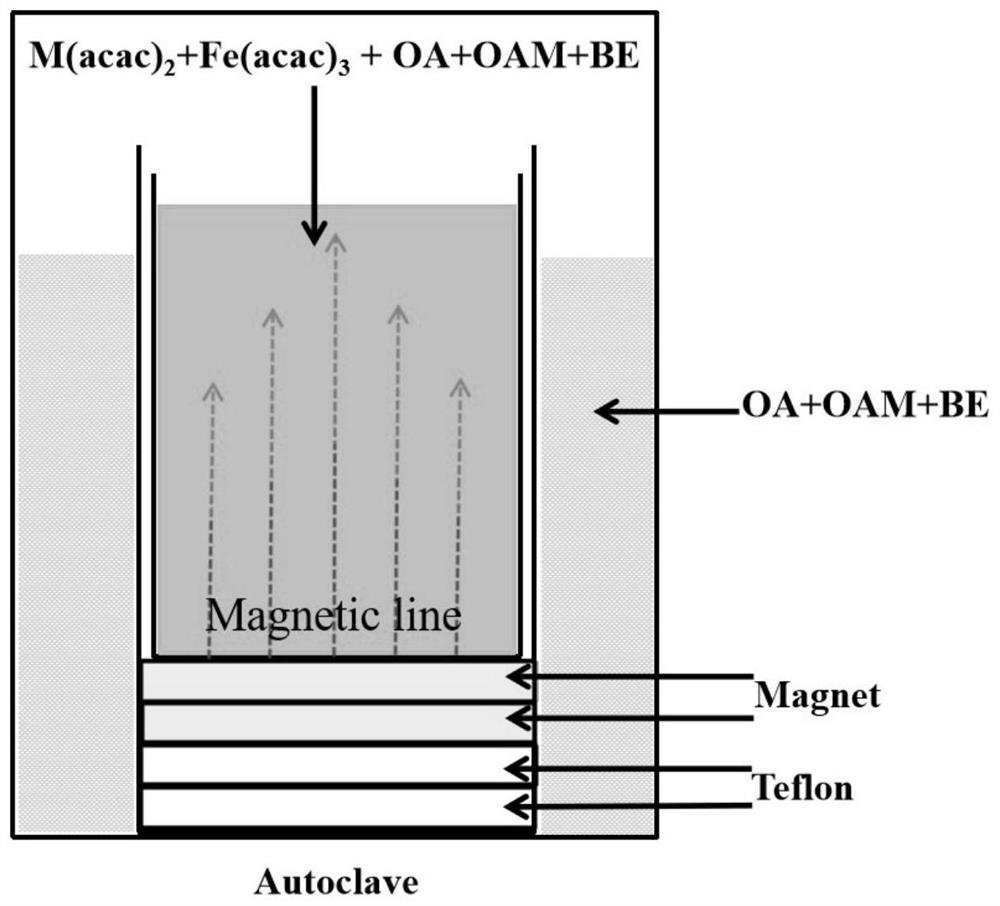

Method for magnetic field assisted solvothermal synthesis of ferrite and method for regulating and controlling magnetic grain size and morphological characteristics

The invention discloses a method for magnetic field assisted solvothermal synthesis of ferrite and a magnetic grain size and morphology characteristic regulation and control method, and belongs to thetechnical field of ferrite preparation and synthesis. The preparation method comprises the following steps of: uniformly mixing oleic acid, oleylamine and dibenzyl ether, heating to remove water or alcohol, and naturally cooling to room temperature; taking iron and acetylacetonate of metal M as raw materials, uniformly mixing the raw materials with a solvent, pouring the mixture into a beaker, putting the beaker into a polytetrafluoroethylene lining of a Hastelloy alloy reaction kettle, and placing a magnet below the beaker in the polytetrafluoroethylene lining; pouring a solvent into the outer side of the polytetrafluoroethylene lining to serve as a heat transfer medium, heating to carry out a solvothermal reaction, thereby obtaining the MFe2O4 ferrite. Through the resistance of the solvent to magnetic ions and particle migration, the dipole interaction force among the magnetic particles and the synergistic effect among the external magnetic field forces, the regulation and control of the size and morphology characteristics of the magnetic crystal grains for preparing the ferrite are realized. By changing the size of the synthetic magnetic field, the magnetic particles with single domain critical size and superparamagnetic critical size can be prepared.

Owner:ANHUI UNIVERSITY

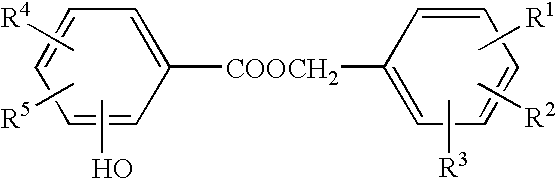

Process for the preparation of hydroxybenzoic benzyl esters

InactiveUS20020128523A1Organic compound preparationOrganic chemistry methodsBenzyl groupAcid anhydride

Owner:LANXESS DEUTDCHLAND GMBH

System and technology for producing benzaldehyde by utilizing benzyl chloride and benzyl alcohol waste materials

ActiveCN104844435ASolve the emission problemIncrease added valueOrganic compound preparationCarbonyl compound preparation by hydrolysisDistillationEconomic benefits

The invention provides a system and a technology for producing benzaldehyde by utilizing benzyl chloride and benzyl alcohol waste materials. The system comprises the main equipment of an oxidizing furnace, an oxidizing kettle, a hydrolyzing kettle, an alkaline hydrolysis kettle, a crude distillation tower, a crude distillation kettle and a rectifying tower. The technological process is simple. The technology solves the discharging problem of the benzyl chloride and benzyl alcohol waste materials, namely dibenzyl ether and benzyl chloride, the waste materials are changed into treasure, and benzaldehyde products with a higher added value are produced. The environmental protection problem is solved, and economic benefits are also created.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

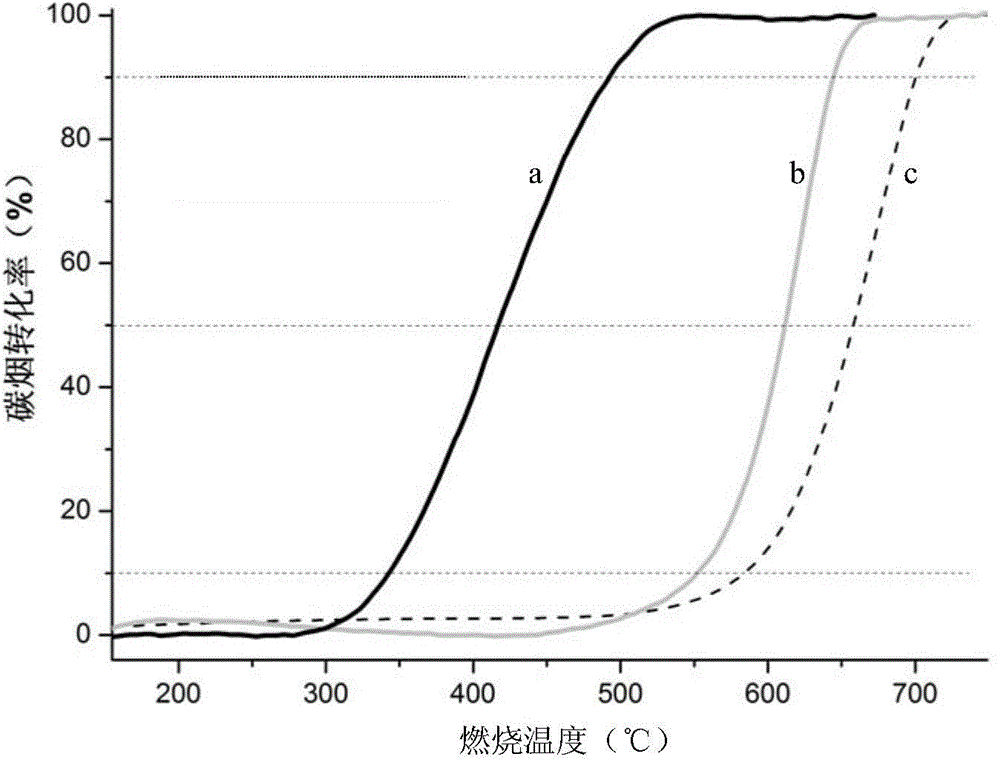

Nano alloy modified cerium oxide powder applied to soot combustion reaction, and preparation method thereof

ActiveCN103551166AHigh catalytic oxidation activityReduce dosageMetal/metal-oxides/metal-hydroxide catalystsCeriumSolvent

The invention discloses a nano alloy modified cerium oxide powder applied to soot combustion reaction, and a preparation method thereof, and relates to cerium oxide powder. The powder is prepared from a platinum nano alloy phase and a cerium oxide or cerium-zirconium mixed oxide carrier. The method comprises the following steps: mixing organic salt of each metal component, and then preparing into a mixed metal ion octyl ether solution or a mixed metal ion dibenzyl ether solution; adding a mixed surfactant to the mixed metal ion octyl ether solution or the mixed metal ion dibenzyl ether solution, so as to obtain a reduction-type mixed metal particle dispersed solution; heating and refluxing the reduction-type mixed metal particle dispersed solution, and then adding a high-polarity alcohol solvent to separate out nano particles in a gathering manner; dispersing into a low-boiling point organic solvent after removing the alcohol solvent in a volatilizing manner, so as to prepare nano alloy disperse precursor solution; putting the carrier into a container, and wetting by using an organic solvent, so as to obtain a wetting vector; injecting the nano alloy disperse precursor solution to the wetting carrier, lastingly stirring until a mobile phase volatilizes, so as to obtain wetting powder; drying and burning, so as to obtain the product.

Owner:XIAMEN XINPUCHUANG PHOTOELECTRIC MATERIALS

Quick-drying protective paint for cast iron

InactiveCN109401390AEffective protectionImprove corrosion resistanceAnti-corrosive paintsEpoxyCopolymer

The invention discloses quick-drying protective paint for cast iron. The quick-drying protective paint is prepared from the following components: styrene-acrylic emulsion, waterborne epoxy resin, tricresyl phosphate, dibenzyl ether, red lead powder, magnesium oxide micro powder, isophorone diamine, ethylene bis stearamide, gul glue, polyacrylate copolymer emulsion and sepiolite powder. According to the quick-drying protective paint, a casting can be effectively protected, the corrosion resistance effect is high, the drying speed is high, and using is convenient.

Owner:安徽省含山县林头郑孙铸造厂

Preparation method and application of zero-valent iron delivery nanoparticles

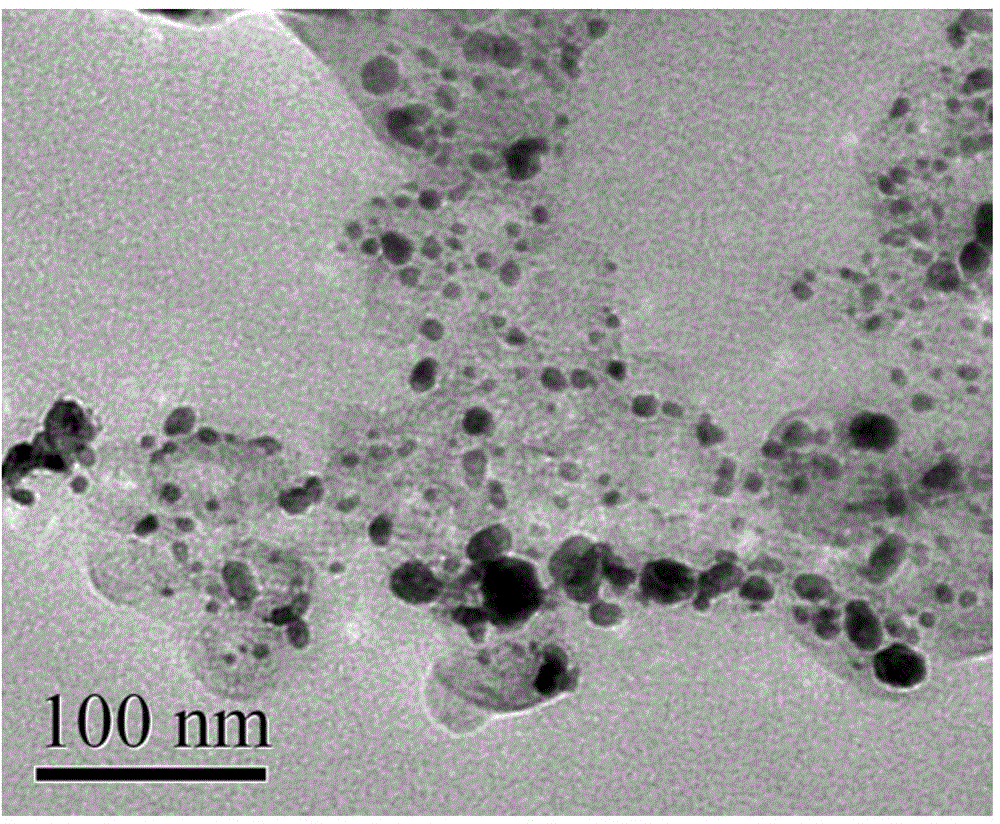

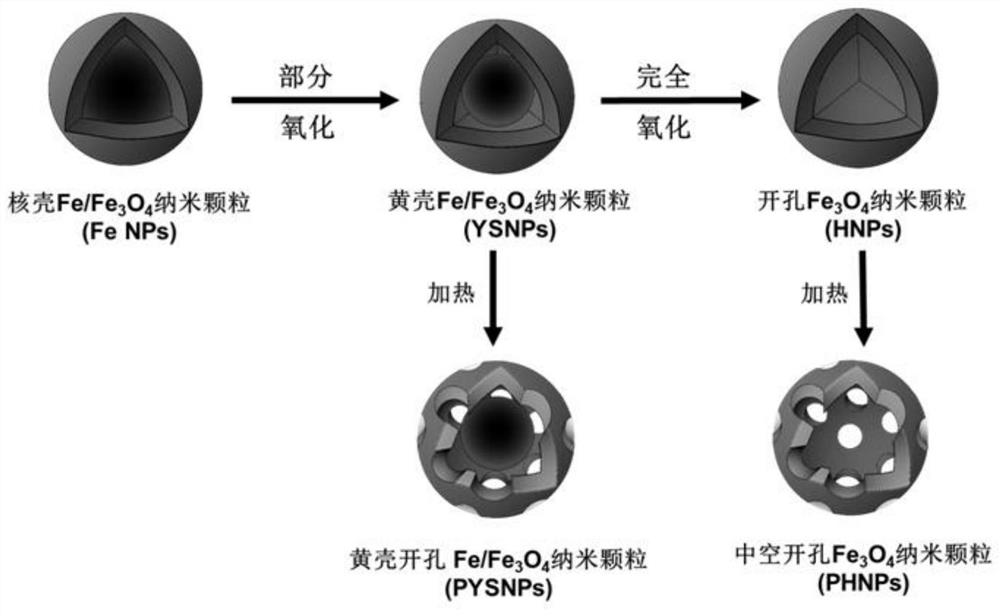

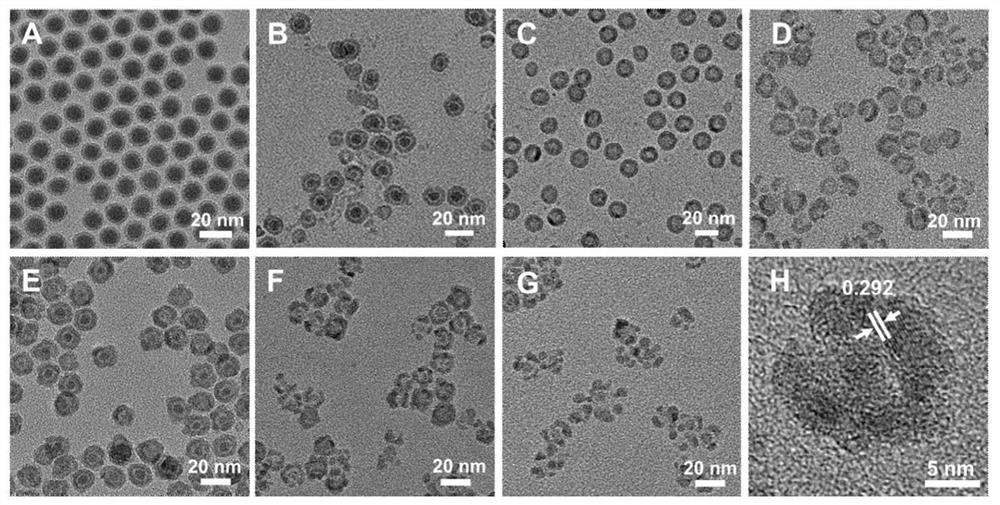

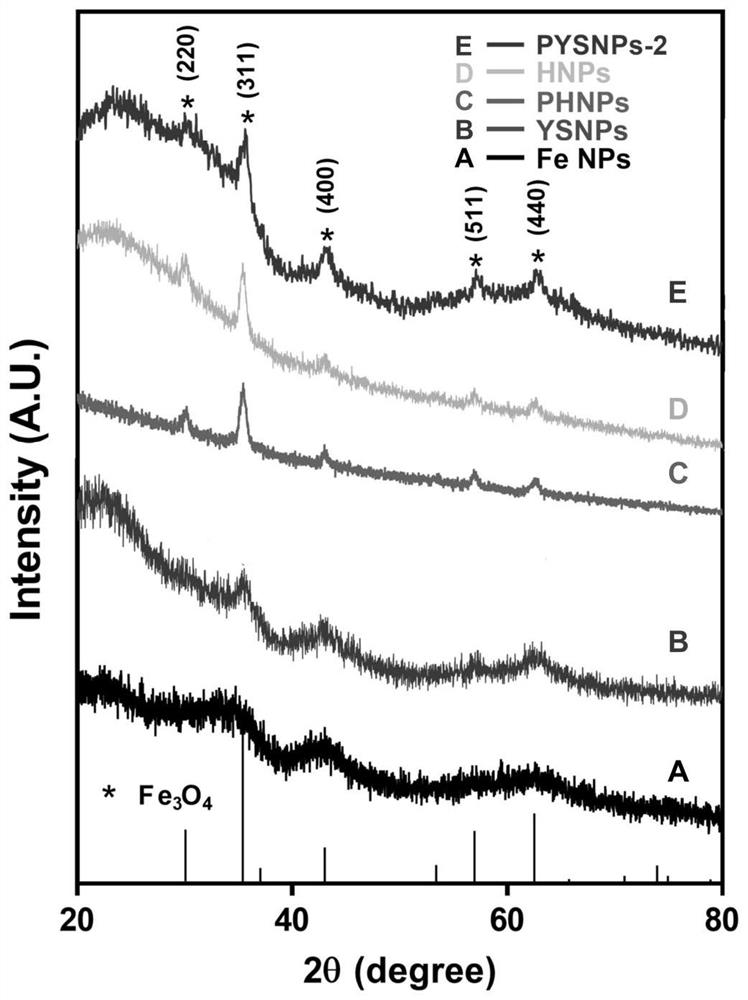

ActiveCN111773393APrecise size controlPrecise control of mesopore sizeHeavy metal active ingredientsNanomedicineTumor targetTumor targeting

The invention discloses a preparation method of zero-valent iron delivery nanoparticles. According to the preparation method, carbonyl iron is used as a precursor, oleylamine is used as a surface ligand, octadecene and dibenzyl ether are used as solvents, trimethylamine oxide is used as an oxidant, and a series of core-shell structure nanoparticles with adjustable morphology, size and crystallinity are prepared by adopting an oil-phase high-temperature pyrolysis method and are used for activity protection and tumor delivery of zero-valent iron. The method comprises the following steps of (1) synthesizing zero-valent iron nanoparticle seeds; (2) synthesizing nanoparticles with different oxidation degrees; and (3) synthesizing nanoparticles with different opening degrees. Finally, the surfaces of the synthesized nanoparticles are modified through dopaminated polyethylene glycol, and iRGD targeting peptide is modified through chemical coupling, so that tumor targeting delivery is achieved. The zero-valent iron delivery nanoparticles synthesized and prepared by the method are controllable in morphology, good in stability and high in biocompatibility, have tumor targeting property, andcan be used for magnetic resonance imaging and tumor treatment.

Owner:CHINA PHARM UNIV

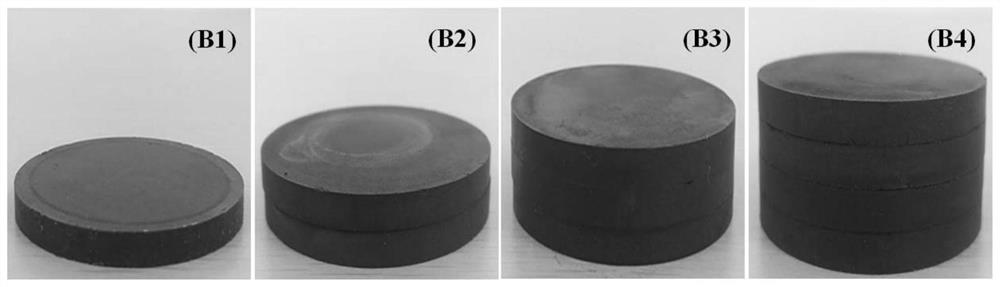

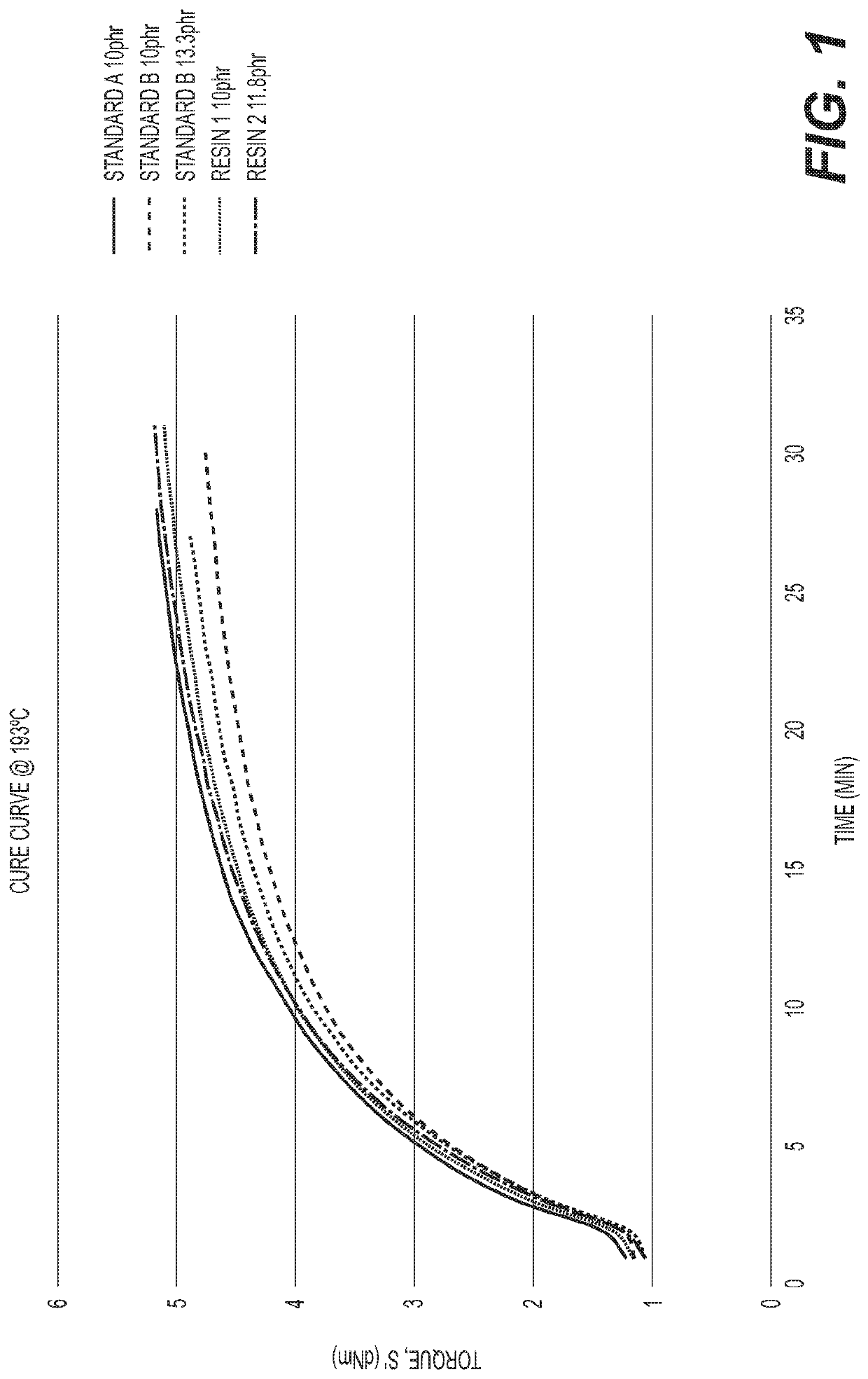

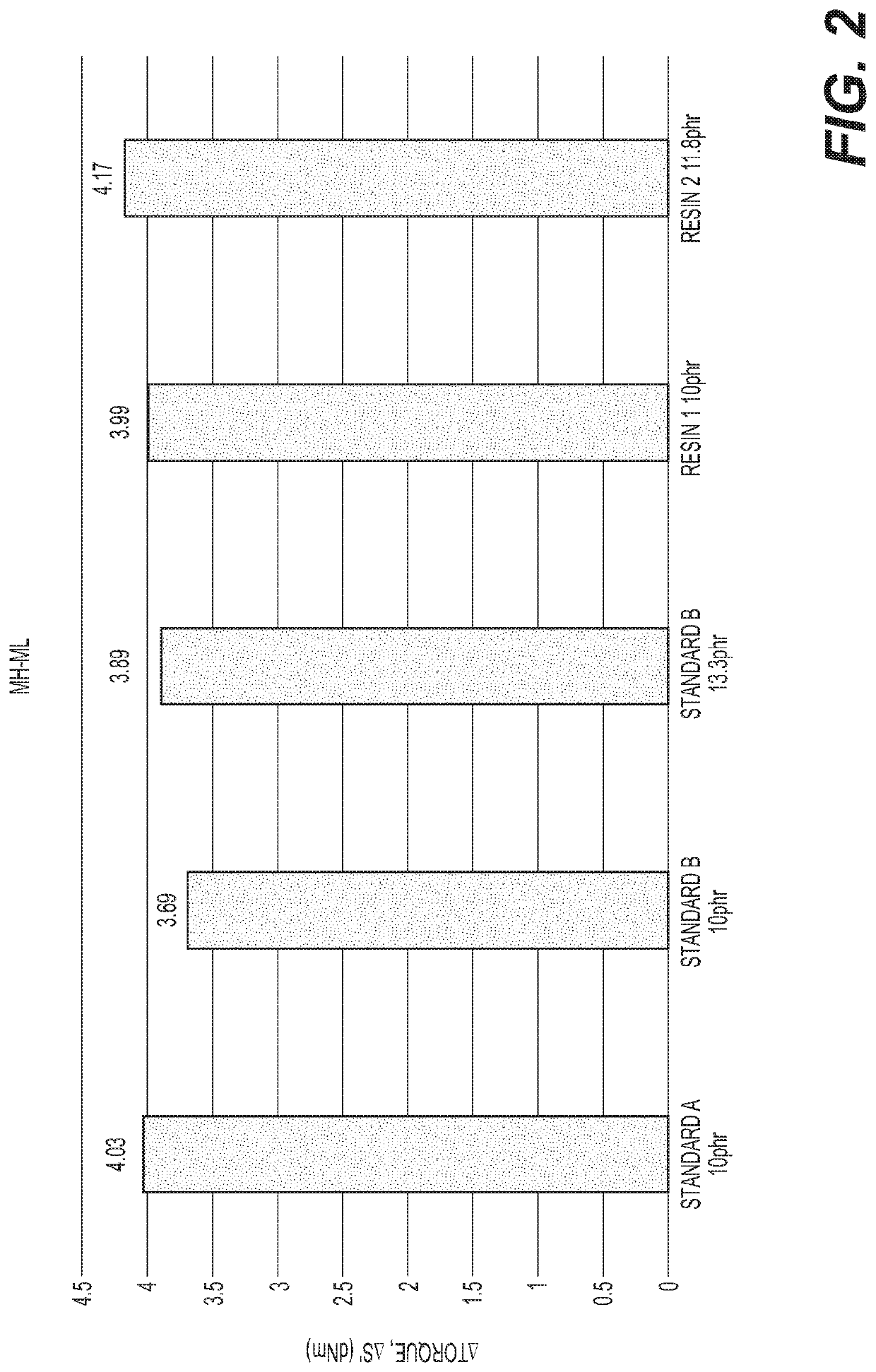

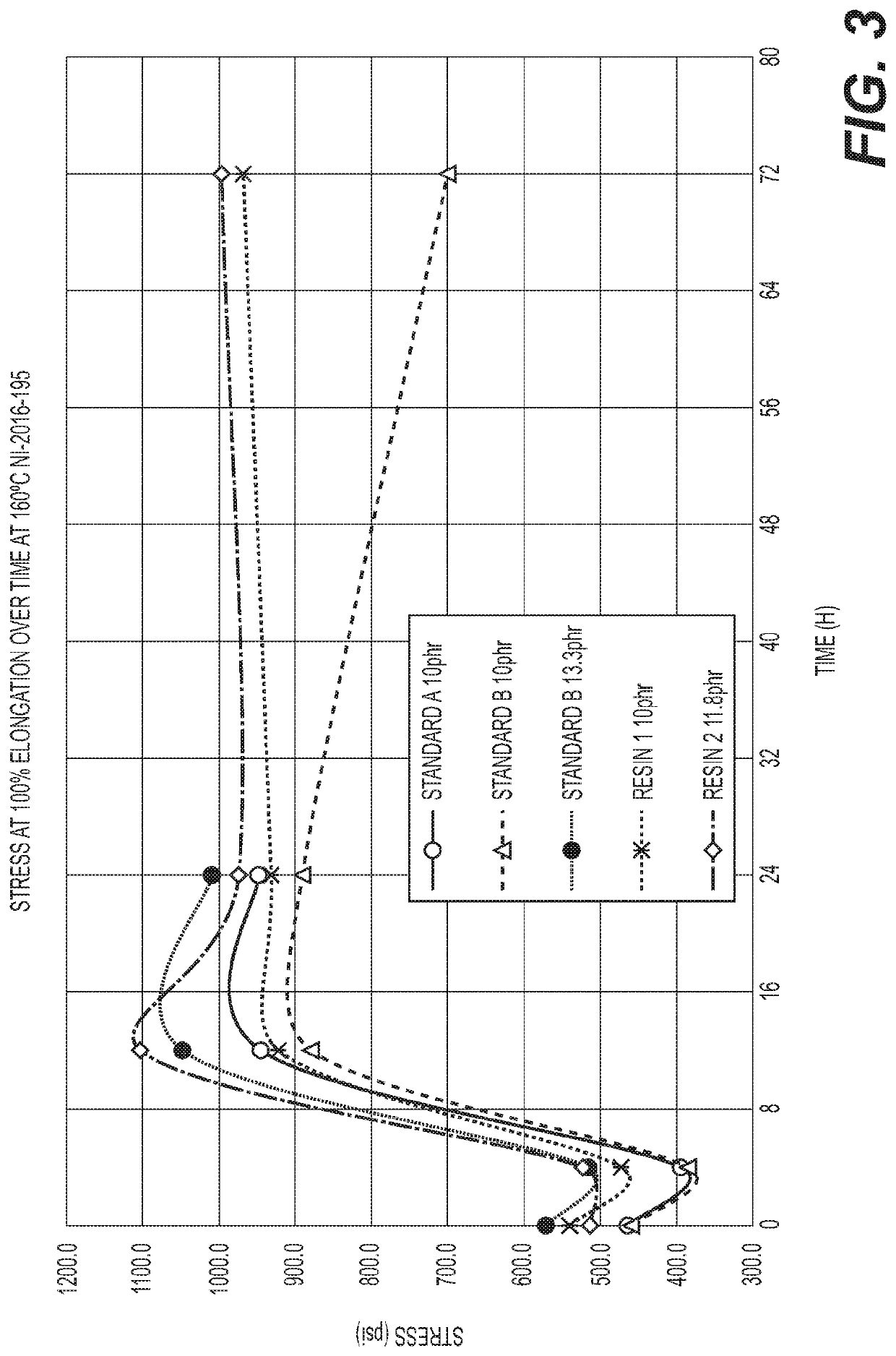

Resins having a high methylol to dibenzyl ether ratio and methods of making the same

This invention relates to resins having a molar ratio of methylol groups to ether groups in the resin is from 0.5:1 to about 2:1. Methods for making the composition are also provided. A bladder formulation comprising resins of the invention is also provided. A vulcanized elastomer composition prepared by vulcanizing the bladder formulation of the invention is also provided. A method of increasing thermal stability in a rubber by curing said rubber with a resin of the invention is also provided.

Owner:SI GROUP INC

Method for treating and recycling tail gas produced during benzaldehyde production

ActiveCN106621695ASignificantly diluted displacementDilution displacementGas treatmentDispersed particle separationActivated carbonBenzaldehyde

The invention discloses a method for treating and recycling tail gas produced during benzaldehyde production. Benzaldehyde tail gas produced in a dibenzyl ether oxidizing process is subjected to the treatment of tail gas dilution, tail gas condensation, tail gas water washing and tail gas adsorption. The tail gas is introduced into a plurality of active carbon adsorption devices to perform multi-layer adsorption, thereby emitting purified tail gas without peculiar smell; steam resolution active carbon is adopted periodically for recycling, so that recycling of active carbon is realized, and the tail gas is adsorbed by the adsorption devices; meanwhile, active carbon in other adsorption devices is resolved and recycled, and the adsorption devices work alternatively, so that continuous adsorption of the adsorption devices is ensured, the working efficiency is increased, the production cost is lowered, and the problem of environmental influence caused by the tail gas is solved.

Owner:HUBEI GREENHOME MATERIALS TECH INC

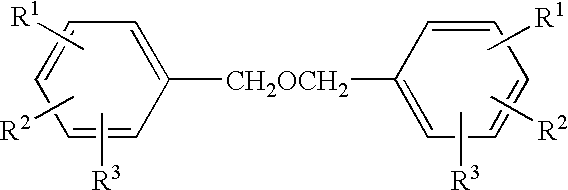

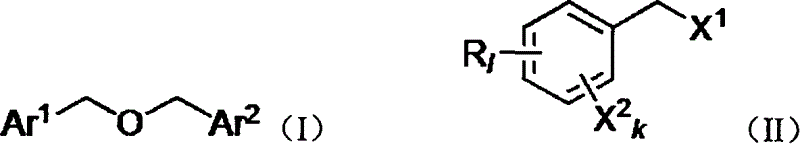

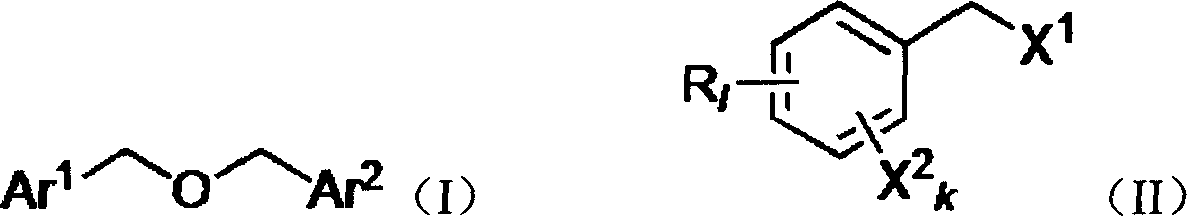

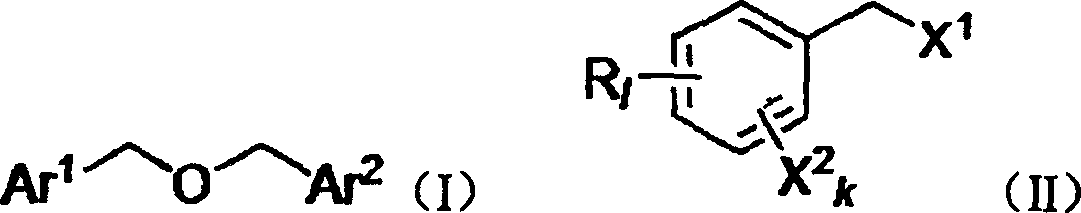

Method for preparing substituted dibenzyl ether

InactiveCN1709848AEmission reductionReduce resource consumptionOrganic chemistryBenzyl groupMetal halides

This invention has disclosed a kind of producing method for substituted dibenzyl ether. This method adopts substituted benzyl halogen react with water to produce substituted dibenzyl ether directly by the catalyst of metal halide. It does not use alkali substance, after separate and concentrate, procreant HX can be regenerated. This method is simple and environmental protection, costs little.

Owner:NANJING UNIV OF TECH

Method for removing benzaldehyde impurities in benzyl alcohol

PendingCN112299955AImprove product qualityPrevent oxidationOrganic compound preparationHydroxy compound preparationBenzeneBenzaldehyde

The invention discloses a method for removing benzaldehyde impurities in benzyl alcohol, which comprises the following steps: opening a steam control valve to heat and dry a cleaned rectification system, introducing nitrogen into the rectification system through an atomizer for 15-30 minutes, and replacing air in the rectification system; under a reduced pressure condition, adding benzyl alcohol to be refined into a rectification system, starting stirring, slowly heating to raise the temperature, controlling the temperature to be 170-220 DEG C and the time to be 30-60 minutes, and discarding collected fractions; and under the condition of stirring, slowly adding a reducing agent into benzyl alcohol in a rectification system, and controlling the quantity of fractions to be 15-30kg / h. The method has the beneficial effects of simple process, high efficiency, environmental protection and large-scale industrial production; impurities and peroxides such as benzaldehyde, cyclohexyl methanol,benzyl chloride, dibenzyl ether and benzene remaining in benzyl alcohol can be efficiently removed, the quality of benzyl alcohol refined by improving the content of benzyl alcohol meets and exceeds related standard requirements of crude drugs and pharmaceutic adjuvants, and the content of benzaldehyde is smaller than 0.001%.

Owner:JIANGSU UNIV OF SCI & TECH

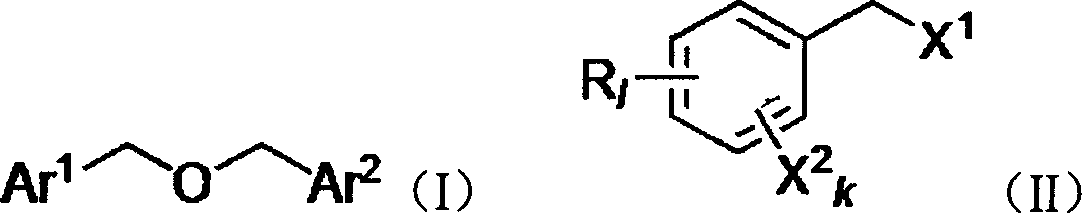

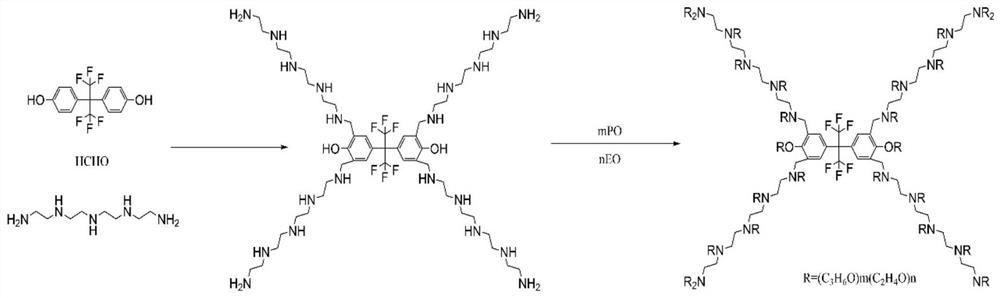

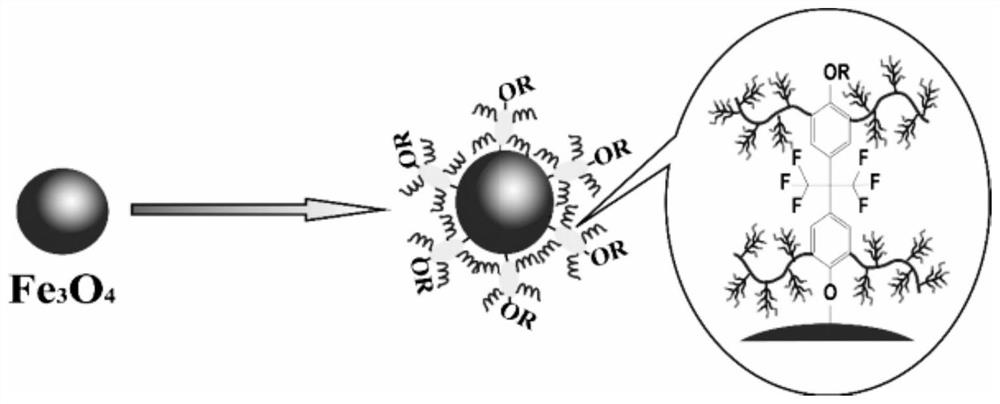

Green fluorine-containing magnetic demulsifier preparation method

InactiveCN113913212AWith demulsification abilityGood compatibilityDewatering/demulsification with chemical meansActive agentMagnetite Nanoparticles

The invention discloses a green fluorine-containing magnetic demulsifier preparation method, which comprises: adding ferric acetylacetonate, oleic acid, dibenzyl ether and hyperbranched fluorine-containing polyether into a solvothermal reaction kettle, carrying out ultrasonic dispersion on the material, carrying out nitrogen deoxygenation, carrying out a solvothermal reaction to obtain a product, repeatedly cleaning with a prepared mixed solution of absolute ethyl alcohol and normal hexane in a volume ratio of 1: 1, and finally drying in a vacuum drying oven to obtain the magnetic demulsifier. According to the invention, the magnetic demulsifier is synthesized by grafting hyperbranched fluorine-containing polyether on the surfaces of magnetic Fe3O4 nanoparticles, a surfactant is mainly adsorbed on the surface of ferroferric oxide in forms of static electricity, covalent bonds and the like, the Fe3O4 nanoparticles have demulsification capability and magnetism, and area demulsifying agent with great development potential, and due to the agglomeration phenomenon is easily caused due to the self structure of the Fe3O4 nanoparticles, the novel magnetic demulsifier is prepared by combining the Fe3O4 nanoparticles with fluorine-containing polyether, so that great development potential is achieved.

Owner:BINZHOU UNIV

Method for recycling and reusing benzyl alcohol rectification by-products

ActiveCN108821948AHigh economic valueThe hydrogenation process is simpleOrganic compound preparationPreparation by oxygen reductionBENZYL ALCOHOL/WATERWaste material

The invention discloses a method for recycling and reusing benzyl alcohol rectification by-products, comprising the following steps: adding benzyl alcohol rectification by-products containing acetal and dibenzyl ether, ethanol and a hydrogenation catalyst into an autoclave, introducing hydrogen and heating to 100 DEG C, reacting for 4-8 h, and separating an organic-phase crude product; carrying out crude distillation on the crude product under reduced pressure, and removing ethanol and most toluene in the crude product; boiling with water at normal pressure, and evaporating water to remove residual trace amount of toluene; and finally carrying out vacuum distillation to obtain the finished product benzyl alcohol. Through one-step chemical conversion, recycling and reusing of dibenzyl etherand acetal which are difficult to separate are realized. Meanwhile, the products after conversion are mainly benzyl alcohol and a small amount of toluene, which are easy to separate and purify; economic value of benzyl alcohol is high; and the market demand is large. Thus, the process is suitable for large-scale production and application. By changing wastes into valuable things, making good useof waste materials and saving resources, the method has great economic and environmental benefits.

Owner:WUHAN YOUJI IND

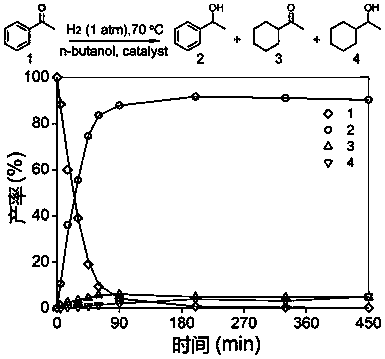

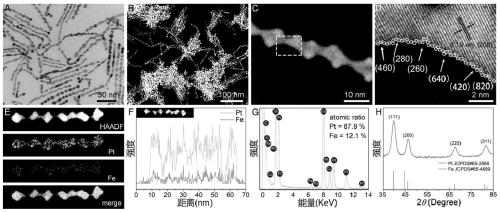

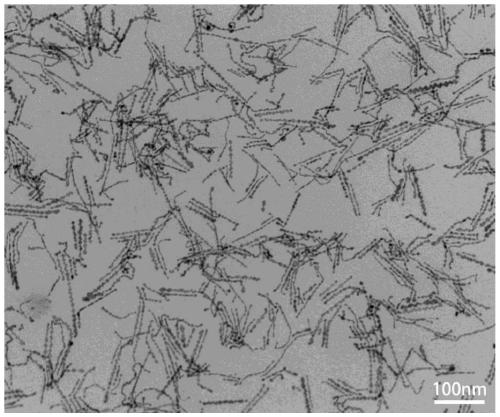

Pt-Fe nano catalyst and preparation method and application thereof

ActiveCN109939696AImprove catalytic performanceHigh selectivityOrganic compound preparationHydroxy compound preparationNano catalystNanowire

The invention provides a preparation method of a Pt-Fe nano catalyst, which comprises the following steps of: preparing a Pt-Fe nanowire;, specifically, the preparation method of the PPt-Fe nanowire comprises the steps of mixing and heating platinum acetylacetonate, cetyl trimethyl ammonium chloride, dibenzyl ether and oleamine, then mixing and heating the mixture with a dibenzyl ether solution ofdodecylcarbonyl triiron and performing cooling, separating, washing and drying to obtain the Pt-Fe nanowire; and mixing the Pt-Fe nanowire, a solvent and active carbon, and then performing stirring,centrifuging and washing to obtain the Pt-Fe nano catalyst loaded on the active carbon. According to the method, the Pt-Fe nanowire with rich high-index surfaces are obtained through the control of reaction conditions, the size and the length of the Pt-Fe nanowire are uniform; in the selective hydrogenation of acetophenone, only carbon-oxygen double bonds of the acetophenone can be selectively hydrogenated, so that benzene ring hydrogenation or over hydrogenation deoxygenation is avoided, a single phenylethanol product is obtained, and the selectivity of obtaining phenylethanol through extremely high hydrogenation is achieved.

Owner:UNIV OF SCI & TECH OF CHINA

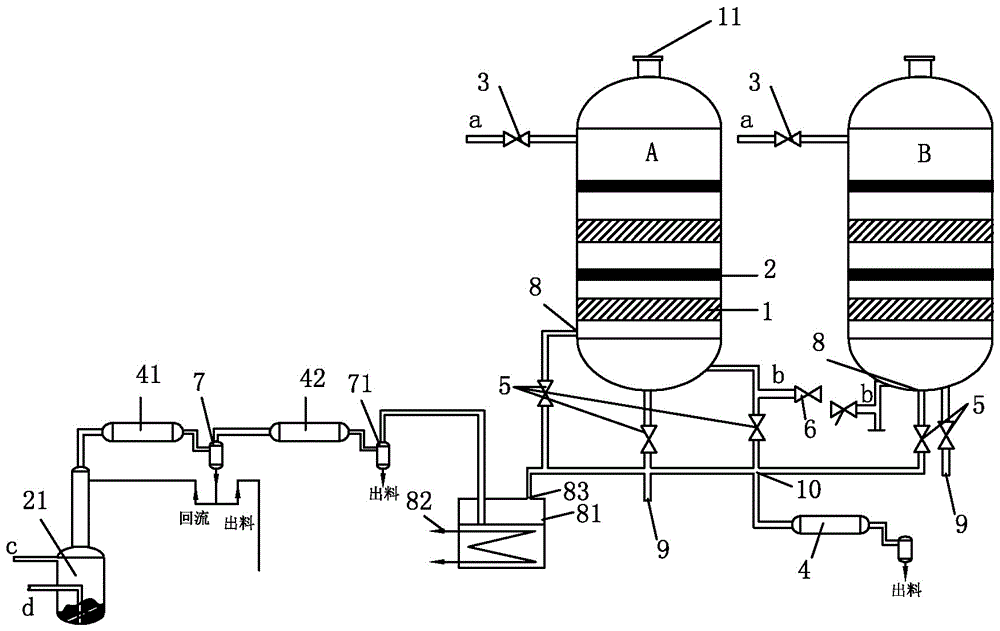

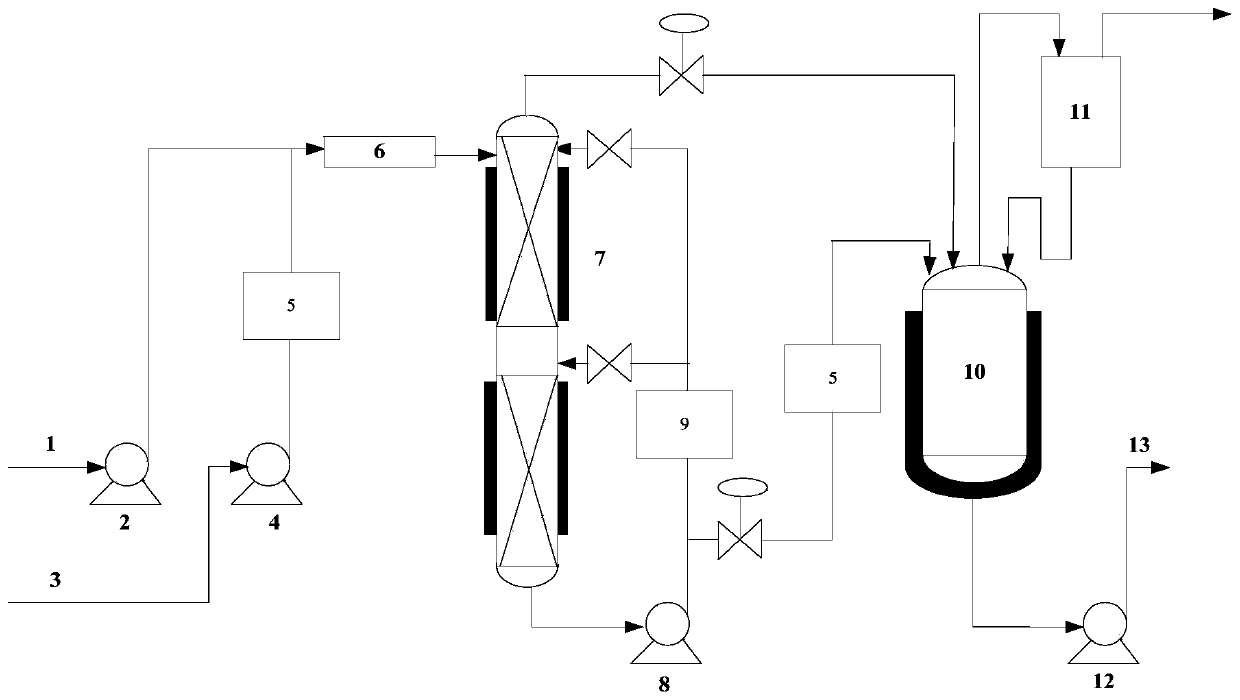

Cascade-pressurization hydrolysis reaction process and system for benzyl alcohol

PendingCN110776398AReduce corrosionShort reaction timeOrganic compound preparationHydroxy compound preparationDistillationCascade

The invention relates to a cascade-pressurization hydrolysis reaction process and system for benzyl alcohol. The process comprises the following steps: subjecting benzyl chloride and a soda ash solution to a rapid reaction in a tower reactor under a low-pressure condition; then further reducing the content of benzyl chloride in the above reactants in a hydrolysis kettle under a normal-pressure condition; and subjecting the obtained crude hydrolysis product of benzyl alcohol to cooling and continuous oil-water separation, and subjecting an oil phase to reduced-pressure crude distillation and rectification to obtain a product. The method has the production characteristics of mild reaction conditions, short reaction time, low dibenzyl ether yield and low requirements on equipment material, can lower project construction cost and production cost, and overcomes the defects of conventional multi-kettle tandem atmospheric pressure hydrolysis production processes and high-temperature high-pressure continuous hydrolysis reaction processes for benzyl alcohol.

Owner:LUXI CHEM GRP

Magnetic ferrite nanocrystal as well as preparation method and application thereof

InactiveCN113548697AGood water solubilityGood biocompatibilityInorganic material magnetismFerroso-ferric oxidesPhosphateOleylamine

The invention belongs to the technical field of nano materials, and particularly relates to a magnetic ferrite nanocrystal, a preparation method and application thereof. The magnetic ferrite nanocrystal is obtained by the following steps: S1, adding ferric acetylacetonate, manganese acetylacetonate, zinc acetylacetonate, oleic acid and oleylamine into dibenzyl ether, and conducting reacting at 105-115 DEG C; S2, raising the temperature to 200-230 DEG C; S3, continuously raising the temperature to 290 to 310 DEG C; S4, conducting cooling, adding ethanol, and performing magnetic separation to obtain modified Fe3O4; S5, mixing the modified Fe3O4, chloroform and DSPE-PEG-COOH to obtain a mixed solution; S6, adding water into the mixed solution, and conducting heating at 50-70 DEG C to obtain Fe3O4-coated COOH; and S7, adding O-benzotriazole-N,N,N',N'-tetramethylurea hexafluorophosphate, N,N-diisopropylethylamine and streptavidin into the Fe3O4-coated COOH, and carrying out a reaction on the Fe3O4-coated COOH and the N,N-diisopropylethylamine and the streptavidin so as to obtain Fe3O4-coated SM.

Owner:徐州捷创生物科技有限公司

Method for preparing substituted dibenzyl ether

InactiveCN1275919CEmission reductionReduce resource consumptionEther preparationBenzyl groupMetal halides

This invention has disclosed a kind of producing method for substituted dibenzyl ether. This method adopts substituted benzyl halogen react with water to produce substituted dibenzyl ether directly by the catalyst of metal halide. It does not use alkali substance, after separate and concentrate, procreant HX can be regenerated. This method is simple and environmental protection, costs little.

Owner:NANJING TECH UNIV

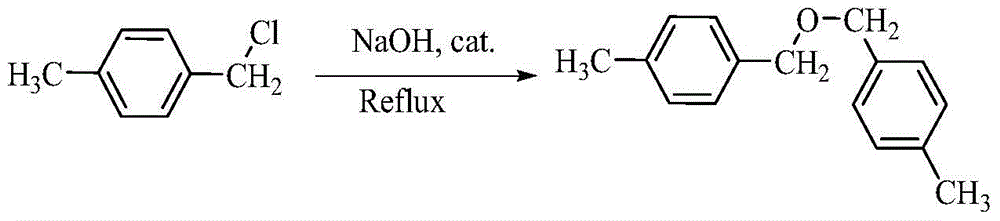

The preparation method of 4,4'-dimethyl dibenzyl ether

ActiveCN104016837BFast conversion rateImprove conversion rateEther preparationFiltrationBenzyl chloride

The invention discloses a method for preparing 4, 4'-dimethyl dibenzyl ether. The method comprises the following steps: 1) adding p-methyl benzyl chloride, an alkali solution and a phase transfer catalyst in a reaction vessel, and full reacting at 106-122 DEG C; 2) cooling and crystallizing reaction liquid, conducting pumping filtration and air drying to obtain a 4,4'-dimethyl dibenzyl ether crude product; and 3) recrystallizing the 4, 4'-dimethyl dibenzyl ether crude product to obtain the 4,4'-dimethyl dibenzyl ether finished product. The preparation method has simple process, high efficiency, and low production cost, and is easy for industrial production.

Owner:WUHAN YOUJI IND

A green hydrolysis process for preparing benzyl alcohol with high selectivity

InactiveCN105924328BAchieve recyclingEasy to handleOrganic compound preparationHydroxy compound preparationWastewaterBenzyl chloride

Owner:JIANGSU GOLD BRIDGE SALT & CHEM GRP

Formula of protective paint for explosion-proof process door

InactiveCN108129919AEffective protectionExtended service lifeRubber derivative coatingsAlcoholUltraviolet

The invention discloses a formula of protective paint for an explosion-proof process door. The formula comprises chlorinated rubber resin, fatty alcohol ether sodium sulfate, dimethicone, dibenzyl ether, glycolic acid, methyl anyl alcohol, sepiolite powder, wollastonite, glyceride of sepiolite powder, and magnesium oxide micropowder. The formula has the advantages that the explosion-proof door canbe effectively protected, the anti-ultraviolet and anti-aging effects are realized, and the service life of the explosion-proof door is prolonged.

Owner:湖北金戈门业有限公司

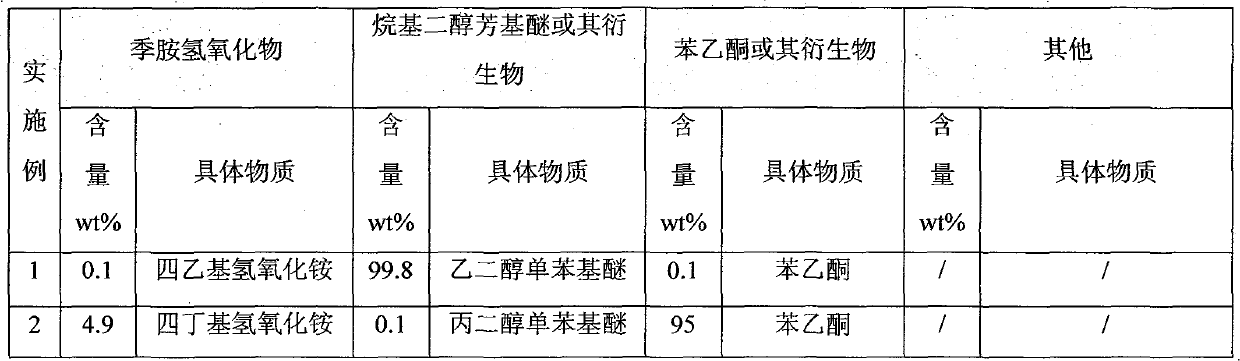

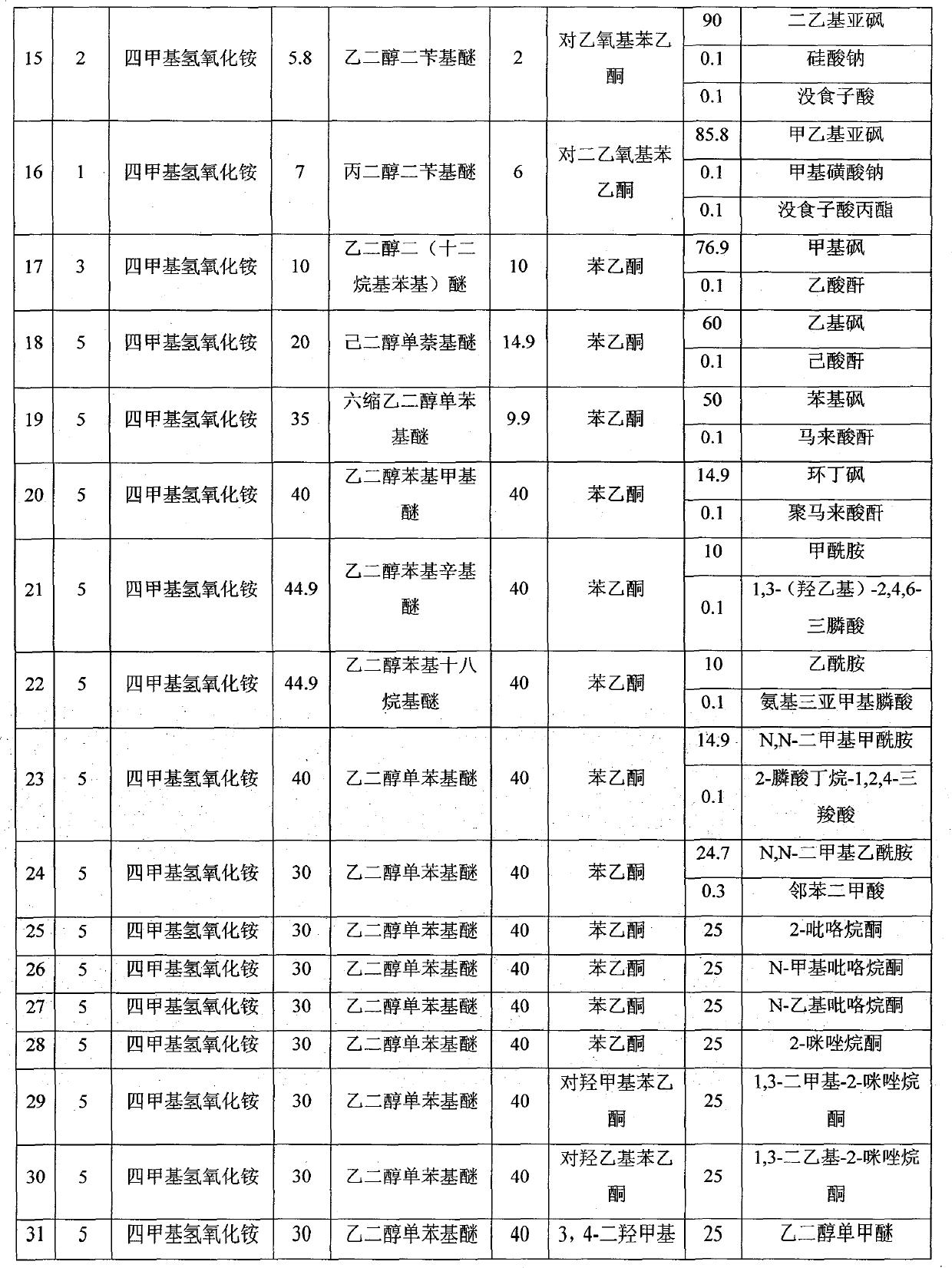

Cleaning composition for removing photoresist

InactiveCN101548241BImprove corrosion inhibitionReduce etch rateNon-ionic surface-active compoundsOrganic detergent compounding agentsAcetophenoneETHYLENE GLYCOL MONOBENZYL ETHER

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com