Green fluorine-containing magnetic demulsifier preparation method

A demulsifier and magnetic technology, which is applied in the field of preparation of green fluorine-containing magnetic demulsifiers, can solve the problems of waste of demulsifiers, inability to recycle, failure to meet the requirements of green development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

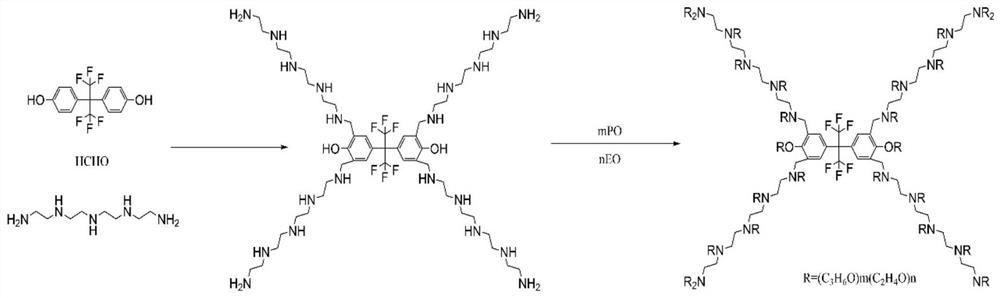

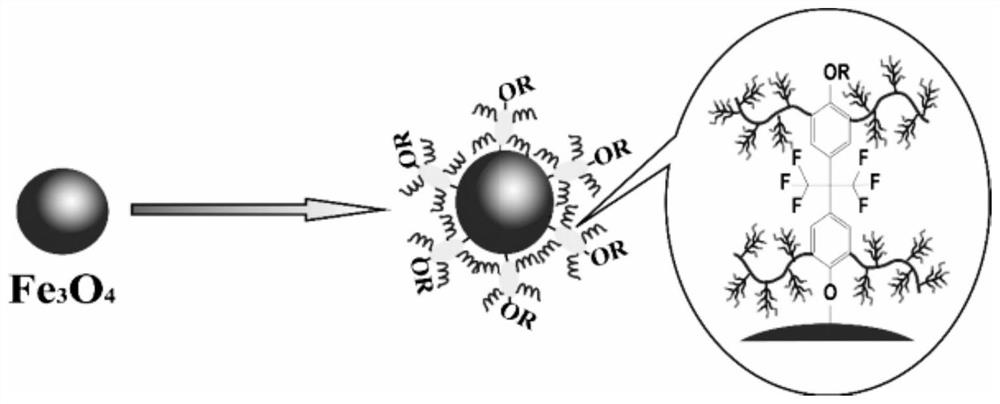

[0033] see figure 1 - Figure 11 , a preparation method of a green fluorine-containing magnetic demulsifier, comprising the following steps:

[0034] (1) Prepare a solvothermal reaction kettle, add iron acetylacetonate, oleic acid, hyperbranched fluorine-containing polyether into the reaction kettle, add the solvent dibenzyl ether, then stir the materials in the reaction kettle evenly, disperse them ultrasonically, and seal the reaction kettle , Purging the reactor with nitrogen to ensure that there is no air in the reactor.

[0035] (2) Heat the reactor to 200-260°C, and keep it warm for 3-8 hours. After the reaction, open the reactor after the temperature in the reactor drops to room temperature, and take out the products in the reactor after the reaction.

[0036] (3) Use a magnet to separate the product, configure a mixed solution of ethanol and n-hexane with a volume ratio of 1:1, clean the separated magnetic demulsifier, and then use a magnet to collect the demulsifier...

Embodiment 1

[0049] Put 0.2g iron acetylacetonate, 0.6g oleic acid, 0.6g hyperbranched fluorine-containing polyether in the reaction kettle, add 30ml dibenzyl ether, ultrasonically disperse the material for 60min, and then use nitrogen to deoxygenate for 60min to ensure that there is no air in the kettle Enter, seal the kettle, put the reaction kettle at 230 ° C for 5 hours, and use a magnet to separate the magnetic product, prepare a mixed solution of ethanol and n-hexane with a volume ratio of 1:1, and clean the separated product , and then use a magnet to separate the product, repeat the above steps 3 times, and dry the product in a vacuum oven at 60°C for 12 hours to obtain Magnetic Demulsifier A1.

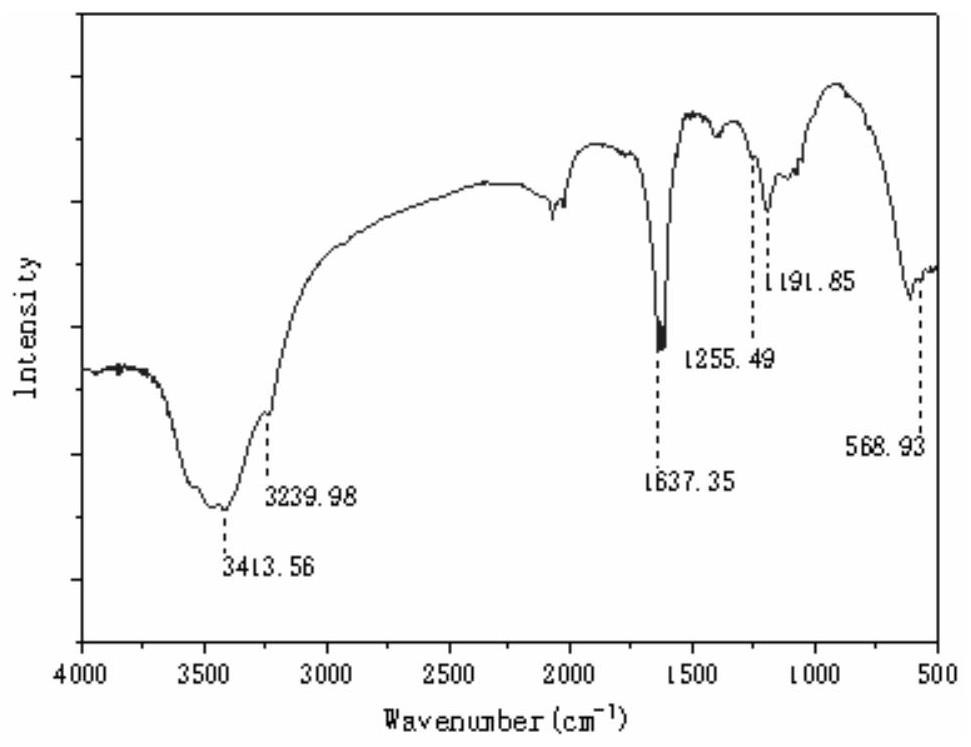

[0050] The demulsifier that embodiment is made has measured its infrared spectrum characterization, as image 3 As shown, among them, 3413.56cm-1 is the stretching vibration peak of -NH- on fluoropolyether, 3239.98cm-1 is the stretching vibration peak of hydroxyl, and 1255.49cm-1 proves th...

Embodiment 2

[0055] Compared with Example 1, the mass ratio of iron acetylacetonate to oleic acid was adjusted to 1:5, the mass ratio of iron acetylacetonate to hyperbranched fluorine-containing polyether was 1:5, and the reaction temperature was 260°C for 3 hours. With the same steps, the magnetic demulsifier A2 was prepared.

[0056] Under the condition of the experimental temperature of 65°C, the demulsification experiment was carried out on the prepared demulsifier sample, and the oil removal rate was calculated after 120 minutes of demulsification. Among them, at a concentration of 1000ppm, the demulsification rate can reach 82.4%. The demulsification results are as follows: Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com