Method for recycling and reusing benzyl alcohol rectification by-products

A technology of benzyl alcohol and by-products, which is applied in the field of recovery and reuse of benzyl alcohol rectification by-products, can solve the problems of difficult recovery and reuse of acetal and dibenzyl ether, cannot remove trace amounts of toluene, and is not easy to separate, so as to achieve environmental protection benefits Outstanding, good economic and environmental benefits, easy separation and purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

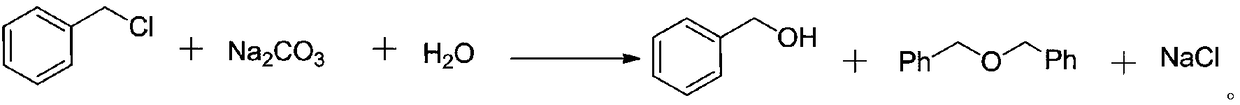

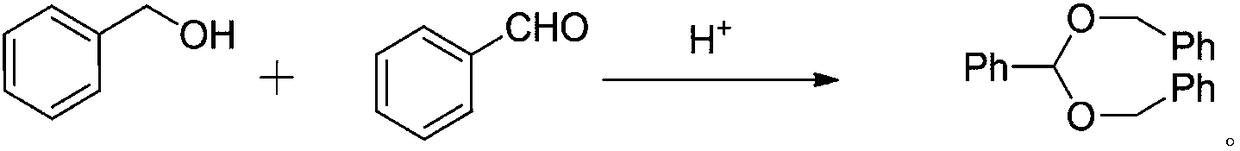

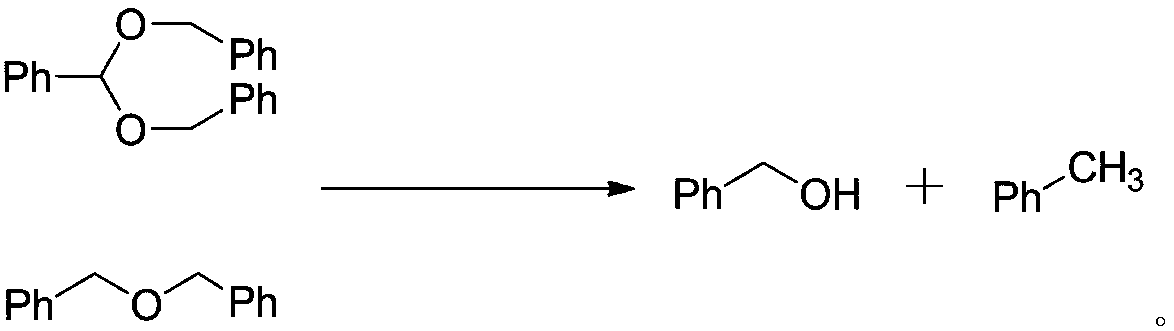

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for reclaiming and reusing benzyl alcohol rectification by-products, comprising the following steps:

[0029] 1) Add 400kg of benzyl alcohol rectification by-products in a 2000L autoclave (after testing, the mass fraction of dibenzyl ether is 37%, the mass fraction of acetal is 60%, and the others are impurities), and 800kg of ethanol with a mass fraction of 95% is added, Raney nickel (mass fraction 50%, water content) 20kg, under stirring, replace the gas in the kettle with hydrogen 3 times; heat up to 100°C, control the hydrogen pressure of the system to be 3-4MPa, the reaction exotherm is obvious, and stop after the hydrogen pressure no longer drops Reaction, about 5 hours. Stand still for 2 hours, absorb the supernatant (ie the crude product of the organic phase), and the catalyst stays in the kettle for the next reaction;

[0030] 2) The crude product of the organic phase first enters the crude distillation tower for crude distillation under reduced press...

Embodiment 2

[0035] 1) Add 400kg of by-products of benzyl alcohol rectification in a 2000L autoclave (after testing, the mass fraction containing dibenzyl ether is 32%, the mass fraction of acetal is 65%, and the others are impurities), add 800kg of ethanol with a mass fraction of 95%, Raney nickel (mass fraction 50%, containing water) 20kg, under stirring, replace the gas in the kettle with hydrogen for 3 times. Raise the temperature to 100°C, control the system pressure to 3.5 MPa, the reaction exotherm is obvious, and the reaction stops after the hydrogen pressure no longer drops, about 6 hours. Stand still for 2 hours, absorb the supernatant (ie the crude product of the organic phase), and the catalyst stays in the kettle for the next reaction;

[0036] 2) The crude product of the organic phase first enters the crude distillation tower for crude distillation under reduced pressure. The conditions for the crude distillation under reduced pressure are temperature 85°C and vacuum 45kpa to...

Embodiment 3

[0041] A method for reclaiming and reusing benzyl alcohol rectification by-products, comprising the following steps:

[0042] 1) Add 400kg of by-products of benzyl alcohol rectification in a 2000L autoclave (after testing, the mass fraction containing dibenzyl ether is 23%, the mass fraction of acetal is 75%, and the others are impurities), add 800kg of ethanol with a mass fraction of 90%, Raney nickel (mass fraction 50%, containing water) 22kg, under stirring, gas in the hydrogen replacement kettle was replaced 3 times. Raise the temperature to 110°C, control the system pressure to 3-4 MPa, the reaction exotherm is obvious, and the reaction stops after the hydrogen pressure no longer drops, about 4 hours. Stand still for 2 hours, absorb the supernatant (ie the crude product of the organic phase), and the catalyst stays in the kettle for the next reaction;

[0043] 2) The crude product of the organic phase first enters the crude distillation tower for crude distillation under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com