Method for catalytically converting lignin into aromatic hydrocarbon by using two-step process

A catalytic conversion and lignin technology, which is applied in the field of catalytic conversion of lignin to aromatics through a two-step method, can solve the problems of difficult balance and high carbon-oxygen bond energy of phenolic oil, and achieve high atom economy and efficient depolymerization , high selectivity and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The representative lignin enzymatic hydrolysis lignin raw material used in this example was purchased from Shandong Longli Biotechnology Co., Ltd., and the lignin raw material was obtained by removing the cellulose of the waste corncob raw material through an enzymatic hydrolysis process. The components and elements of the enzymatic lignin used are shown in Table 1. The content of Klason lignin is 80wt%, the content of sugar is 3wt%, the content of ash is 5wt%, and the content of water is 12wt%. In the element composition, the C content is 62.4wt%, the O content is 31.8wt%, the H content is 5.34wt%, the N content is 0.45wt%, and the S content is lower than the detection limit (ppm).

[0033] Table 1: Components and element composition distribution of lignin used

[0034] components

Klason lignin

Ash

residual sugar

-

(wt%)

80

5

12

3

-

C

O

N

H

S

(wt%) ...

Embodiment 2

[0043] The catalysts are: Ru / HBEA, Ni / HZSM-5, Co / MOR, RuNi / HZSM-5, RuCo / SAPO, NiCo / SiO 2 , RuNiCo / C, etc.

[0044] Preparation of the catalyst: Taking RuNi / HZSM-5 used in the present invention as an example, it was prepared by impregnation method: under stirring conditions, 0.432g of ruthenium trichloride and 2.476g of nickel nitrate hexahydrate were dissolved in 10mL of deionized water, Obtain solution A and solution B; then add solution A and solution B to 4.25g HZSM-5 molecular sieves, stir overnight, and dry the obtained mixture at 80°C, then go through a tubular calciner for calcination and reduction steps, first with Calcined in 100mL / min air atmosphere for 4h, followed by reduction in 100mL / min hydrogen atmosphere for 4h, the catalyst RuNi / HZSM-5 was obtained.

[0045] In this example, add 5.0g organic lignin, 0.5g metal-supported catalyst, and 100mL solvent in a batch type slurry bed reactor (300mL), fill 3 times with nitrogen to remove the air in the reactor 5.0MPa ...

Embodiment 3

[0050] In this example, the phenolic oil obtained from the first step reaction of lignin was used for further deoxidation treatment, and Ru was carried on an acidic carrier as a catalyst. The Ru-based catalyst adopts the formaldehyde liquid phase reduction method. The specific synthesis method is: Weigh 0.254g ruthenium chloride trihydrate and add 100mL water to make a ruthenium trichloride solution, and then add the solution dropwise to 2.0g of different acidic carriers . After the suspension mixture was stirred at room temperature for 5.0 h under magnetic stirring, sodium hydroxide solution was added dropwise to adjust the pH value to 11, and then 5 mL of 37% formaldehyde solution was added dropwise, and heated under reflux in an oil bath at 60° C. for 4 h. After cooling down to room temperature, the catalyst was filtered and washed with water until neutral, and then the obtained catalyst was dried at 80° C. for 12 hours.

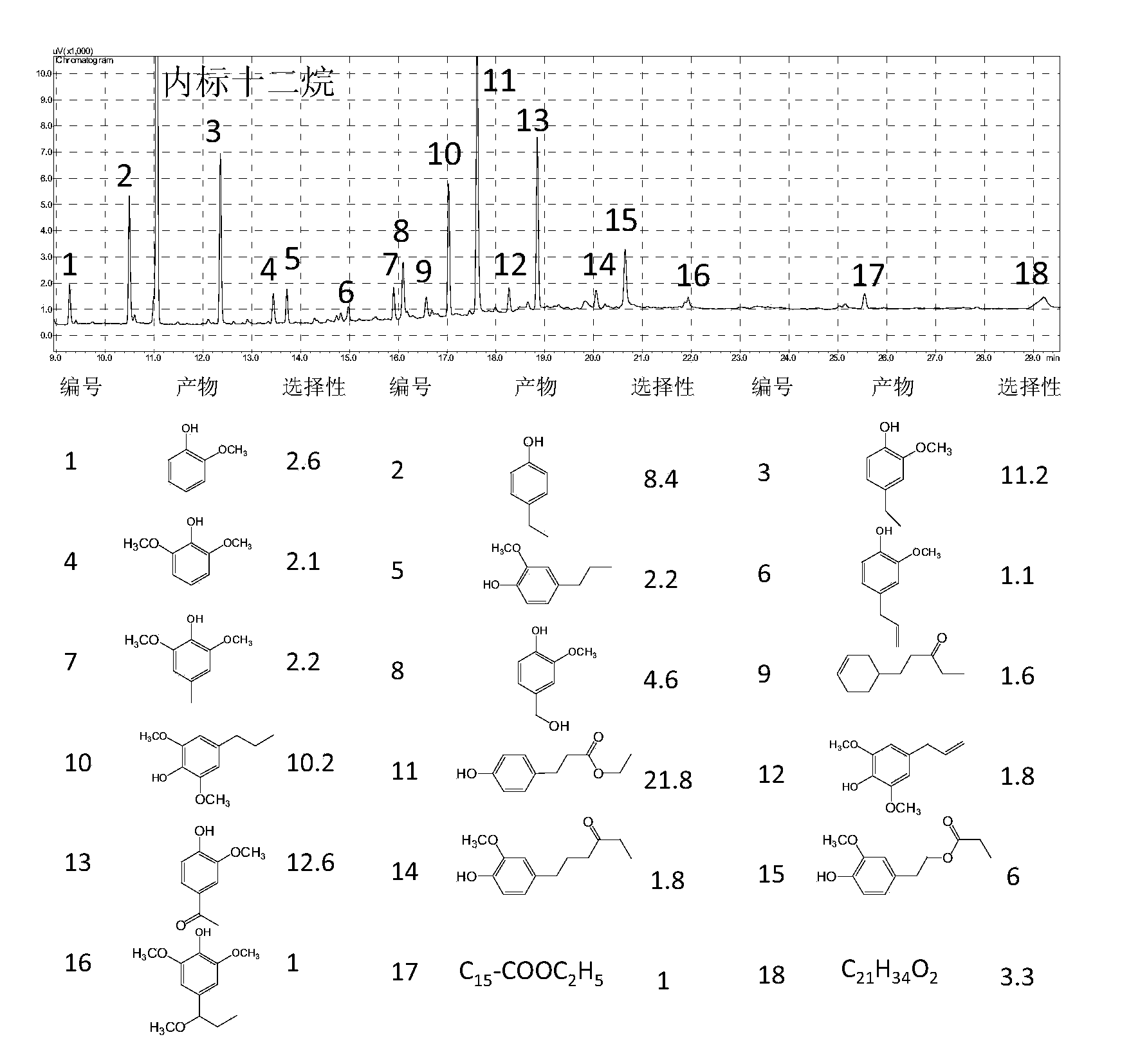

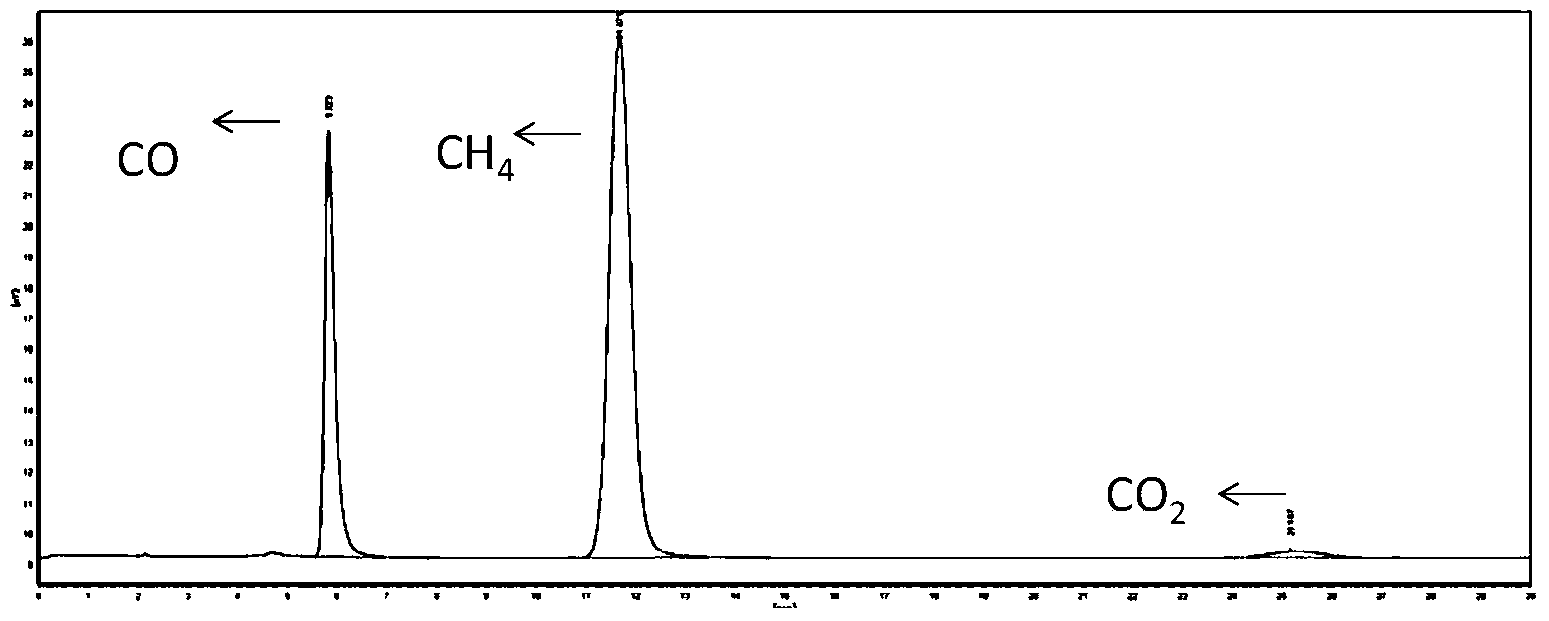

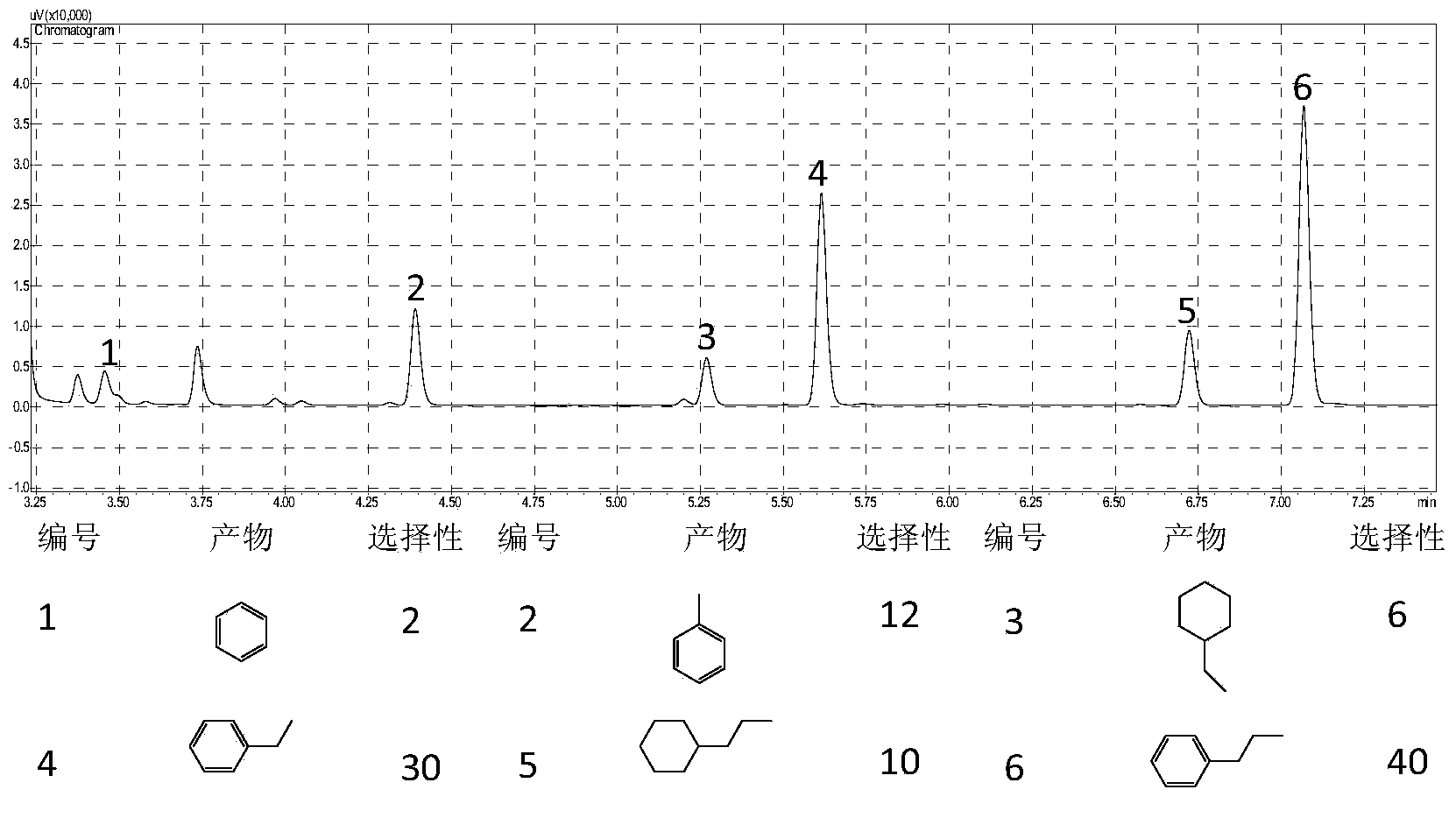

[0051]The representative reaction in the present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com