Nano alloy modified cerium oxide powder applied to soot combustion reaction, and preparation method thereof

A nano-alloy and soot combustion technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. Expensive, raw material cost constraints and other issues, to achieve the effect of maintaining surface oxygen transfer efficiency, simple preparation method, and reducing the maximum weight loss temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

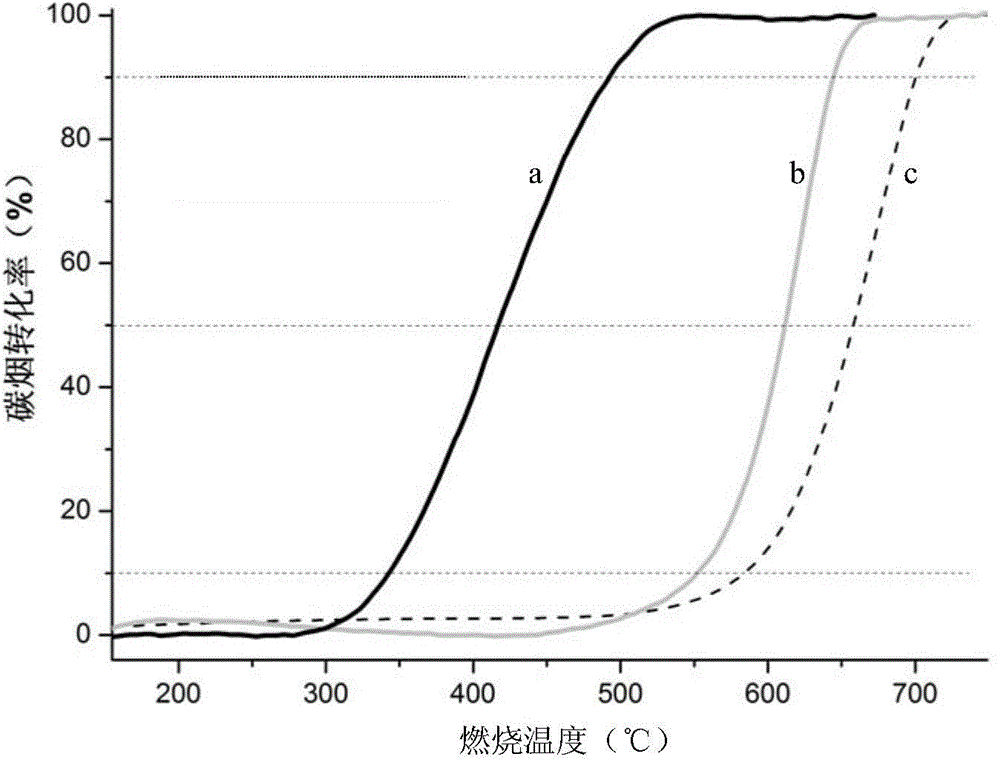

[0027] Mix the commercially available nanometer ceria powder and soot particles according to the mass ratio of 5:1, stir evenly with a medicine spoon, put it into the test crucible of TG-209 thermogravimetric analyzer, under air atmosphere (air flow rate is 20ml / min) from 30°C to 800°C at a rate of 10°C / min. Convert the resulting weight loss curves to conversion curves (see figure 1 ), T 10 , T 50 and T 90 The temperatures were 553°C, 616°C and 640°C, respectively.

[0028] Reference example 3

[0029] Weigh 100ml of a mixed solution of 0.1M cerium nitrate and zirconium oxynitrate (the molar ratio of cerium and zirconium is 9:1), add 1.30g of surfactant PVP, stir evenly, and use 0.4M ammonium carbonate solution as a precipitant to dissolve The metal ions were transformed into basic carbonate precipitates. After stirring continuously for 0.5 h, they were put into a hydrothermal kettle and heated at 160° C. for 16 h. After cooling to room temperature, they were centrifuged...

Embodiment 1

[0032]According to the requirements of the alloy stoichiometric ratio, dissolve 0.77g platinum acetylacetonate (1.97mmol), 0.36g nickel acetylacetonate (1.39mmol), and 0.69g cobalt acetylacetonate (1.93mmol) in dibenzyl ether to obtain a concentrated solution, and mix the concentrated solutions Dibenzyl ether solvent is used to dilute the total molar concentration of the metal components to 0.04mol / L to obtain a mixed metal ion dibenzyl ether solution; under stirring, add 1,2 hexadecanediol to the mixed metal dibenzyl ether solution 2.5mmol, 3mmol of oleic acid and 2mmol of oleylamine, heated and refluxed at 270°C for 40min; after cooling, ethanol was added to precipitate the aggregated precipitate of alloy particles, and after being fully dried, dispersed in toluene to obtain the composition Pt 38 Ni 27 co 35 Nanoalloy dispersed precursor solution.

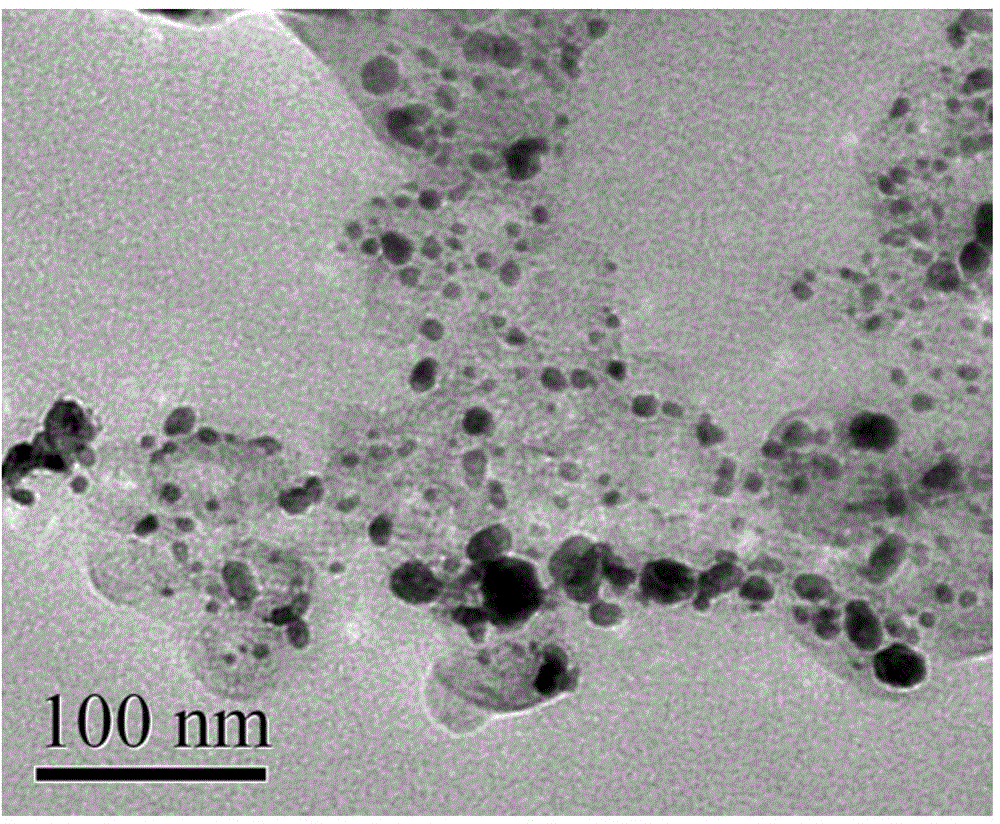

[0033] Put 10g of ceria carrier powder into the container and wet it with toluene; under stirring, inject the nano-alloy disp...

Embodiment 2

[0036] According to the requirements of the alloy stoichiometric ratio, 0.77g platinum acetylacetonate (1.97mmol), 0.36g nickel acetylacetonate (1.39mmol), 0.69g cobalt acetylacetonate (1.93mmol) were dissolved in octyl ether to obtain a concentrated solution, and the concentrated solution was mixed and used The octyl ether solvent dilutes the total molar concentration of the metal components to 0.04mol / L to obtain a mixed metal ion octyl ether solution; under stirring, add 1,2 hexadecane glycol 2.5mmol, oil Add 3mmol of acid and 2mmol of oleylamine, heat and reflux at 270°C for 40min; add methanol after cooling to precipitate alloy particle aggregates, and after fully drying, disperse into n-hexane to obtain the composition Pt 38 Ni 27 co 35 Nanoalloy dispersed precursor solution.

[0037] Put 50g of cerium-zirconium oxide carrier powder into the container, and wet it with n-hexane; under stirring, inject the nano-alloy dispersed precursor solution (nano-alloy content is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com