Universal method for preparing high-stability noble metal monatomic catalyst

A high-stability, catalyst technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of increased metal surface free energy, increased specific surface area, Catalyst deactivation and other problems, to achieve the effect of good stability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

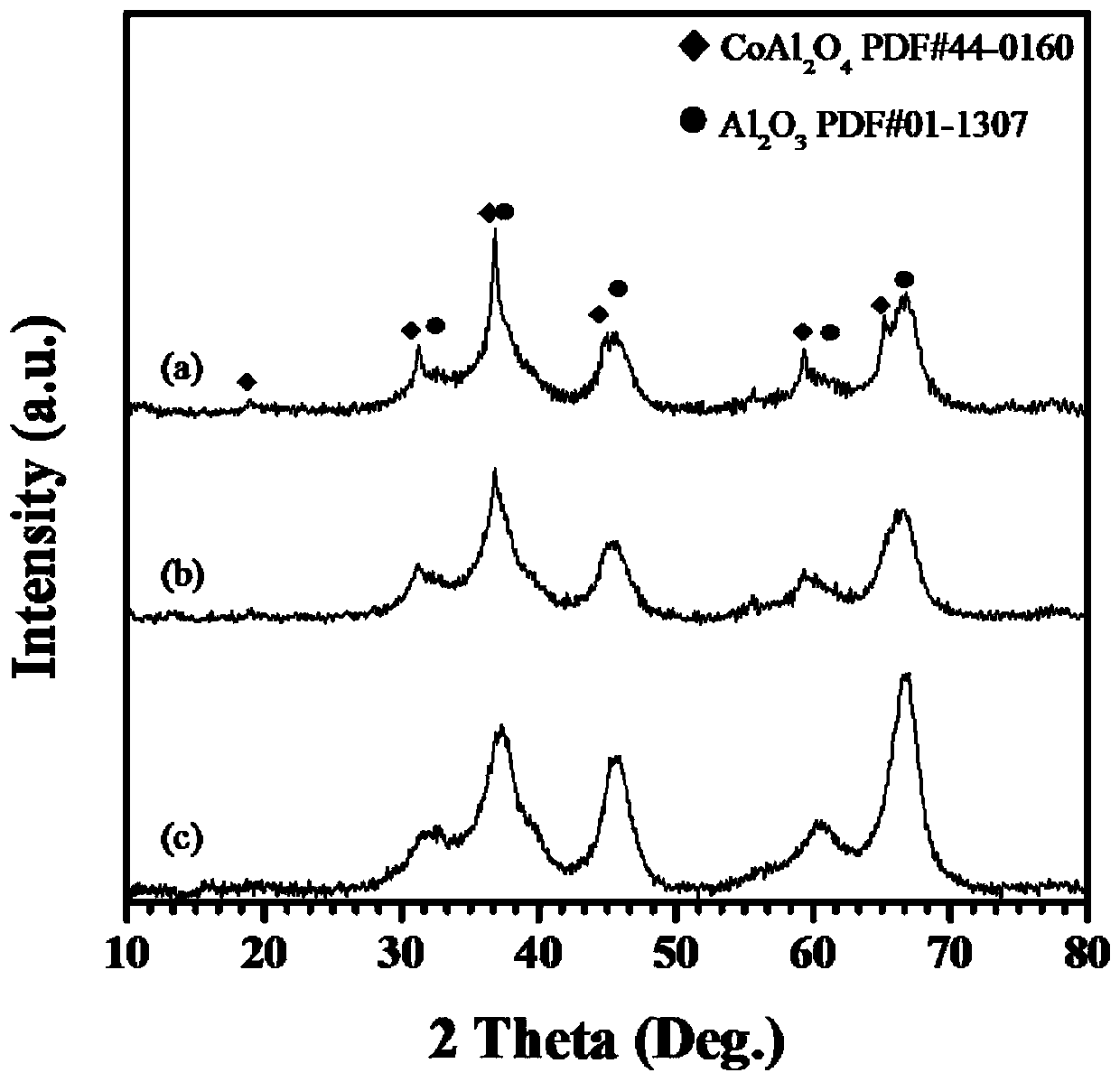

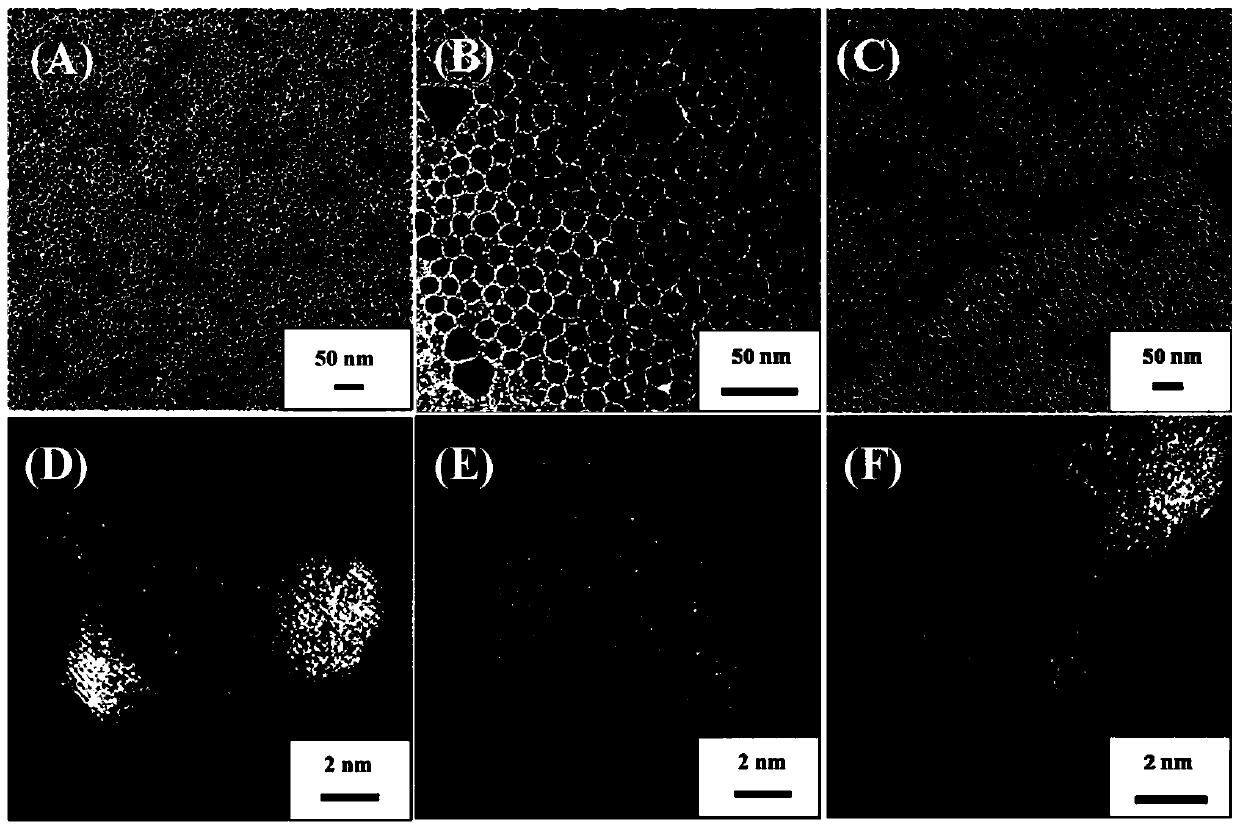

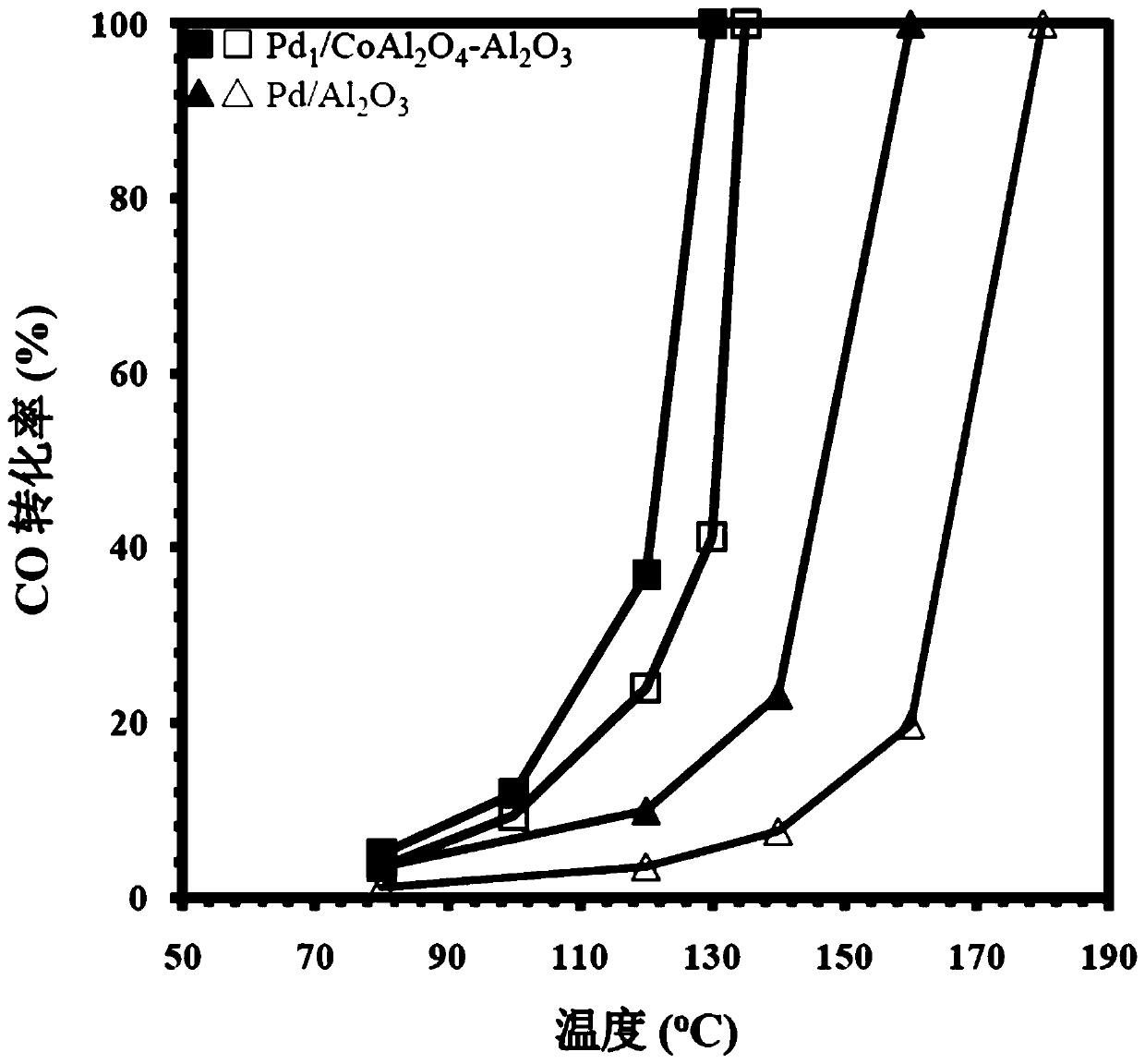

Method used

Image

Examples

Embodiment 1

[0021] Feeding according to the molar ratio of metal M (M=Pd, Pt, Au, etc.) and cobalt is 1:30: Weigh 0.05mmol palladium acetylacetonate (platinum acetylacetonate or chloroauric acid, etc.) and 0.75mmol dicobalt octacarbonyl, add into 5ml of dichlorobenzene, stirred at room temperature for 30min under the protection of argon, and recorded as solution A. Weigh 2 mmol of didodecanylamine and 0.075 g of tri-n-octylphosphine and add them into 7.5 ml of dichlorobenzene, stir and dissolve at 110°C in an argon atmosphere, and record it as solution B. Solution B was heated to 180°C in an argon atmosphere and kept for 10 min, at which time solution A was quickly injected into solution B. And keep it at this temperature for 20 minutes, then lower it to room temperature, and centrifuge to obtain MCo (M=Pd, Pt, Au, etc.) bimetallic nanocrystals with uniform size. The nanoparticles obtained by centrifugation were dispersed in cyclohexane for storage.

[0022] The obtained MCo (M=Pd, Pt, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com