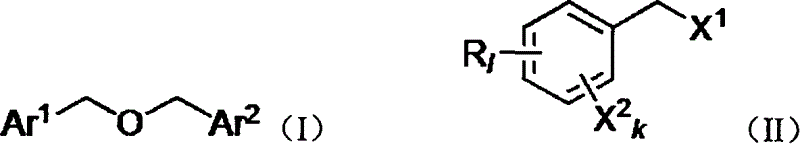

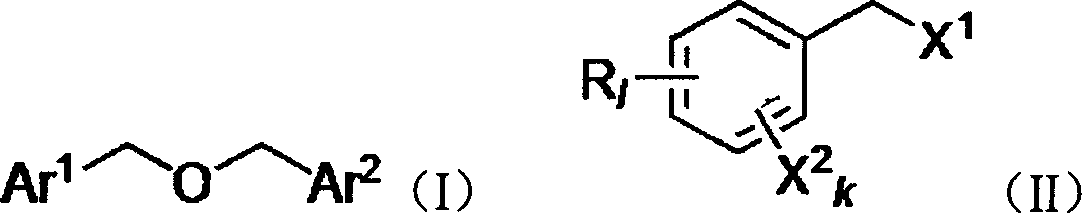

Method for preparing substituted dibenzyl ether

A technology of dibenzyl ether and benzyl halide, applied in the field of preparation of substituted dibenzyl ether, can solve the problems of lack of competitiveness, consumption of a large amount of alkali, and no preparation method of substituted dibenzyl ether, etc., and reduce resource consumption. , the effect of reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of dibenzyl ether by hydrolysis of benzyl chloride

[0030] Take 2.53g of chlorobenzyl chloride, KI0.10g, and 18mL of water into the conical flask, rapidly raise the temperature to 115°C, start to reflux, vigorously stir, and reflux for 48 hours, the reaction pressure is 5 MPa, TLC detection (ethanol-n-hexane, 1:5), the composition does not change. Cool down to about 60°C, add 20mL of toluene for extraction, the temperature will be close to room temperature, and separate the liquids. The aqueous phase was extracted with ethyl acetate (10mL×2) to recover hydrogen halide; the organic phases were combined, dried over anhydrous sodium sulfate, and fully evaporated to dryness (if a small amount of water remained, add 10-20mL of toluene and evaporate to dryness). After passing through a silica gel column (the method and parameters of passing through a silica gel column are well known to those skilled in the art), 1.25 g of a colorless oily product w...

Embodiment 2

[0031] Embodiment 2: Preparation of dibenzyl ether by hydrolysis of benzyl bromide

[0032] The method of Example 1. But the raw material benzyl bromide (3.42g) was reacted for 24 hours. 1.33 g of a colorless oily product was obtained, and 0.78 g of the raw material was recovered.

Embodiment 3

[0033] Example 3: Preparation of 4,4'-dichlorobenzyl ether by hydrolysis of 4-chlorobenzyl chloride

[0034] The method of Example 1. But starting material 4-chlorobenzyl chloride (3.22g), KI (0.17g), reacted for 24 hours. 1.70 g of colorless needle crystal product was obtained, and 0.91 g of raw material was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com