Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

304 results about "High-speed grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-speed grinding (HSG) is a rail care concept developed by the company Stahlberg Roensch from Seevetal, Germany. It is based on the principle of rotational grinding and serves to grind rails at up to 100 kilometres per hour (62 mph).

Ultraviolet-curable white character jet-ink and preparation method thereof

InactiveCN102653650ATest Surface TensionTest storage stabilityInksHigh-speed grindingUltraviolet lights

The invention discloses an ultraviolet-curable white character jet-ink which is prepared from the following components: oligomers, active monomers, titanium pigment, a photoinitiator, a dispersing agent and a surfactant. The invention also discloses a method for preparing the white character jet-ink, which comprises the following steps of: (1) raw material preparation, (2) high-speed shocking dispersion, (3) high-speed grinding, and (4) filtering. The ultraviolet-curable white character jet-ink disclosed by the invention is small in particle size, low in viscosity, good in inkjet performance, capable of being cured rapidly under ultraviolet light, high in hardness of film, and good in adhesion. The preparation method provided by the invention is scientific and reasonable in components, efficient and stable. The jet-ink disclosed by the invention can be widely used for printing various graphics and characters, and is especially suitable to be applied to electronic circuit boards.

Owner:东莞上海大学纳米技术研究院 +1

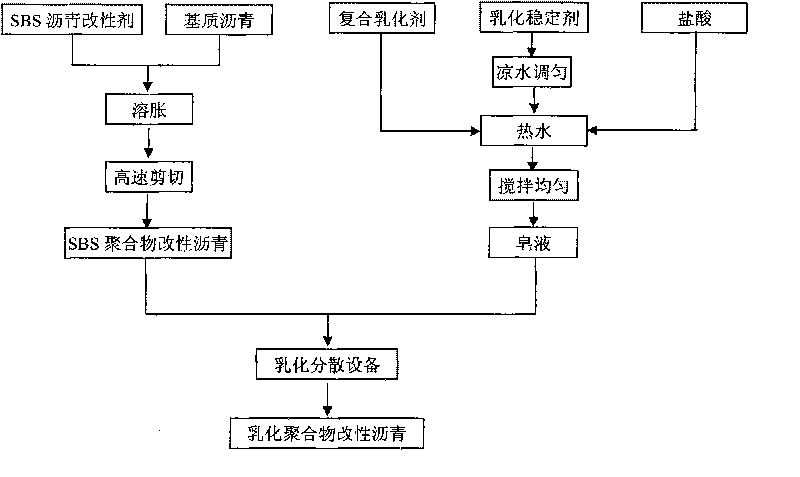

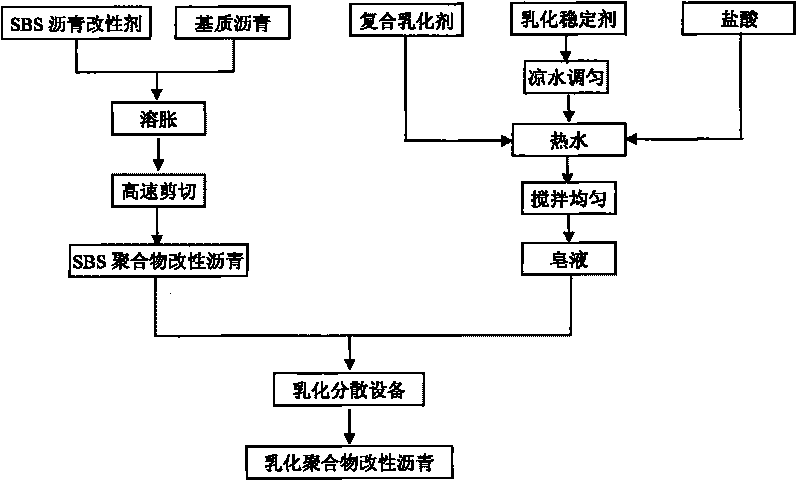

Emulsified SBS polymer modified asphalt and preparation method thereof

InactiveCN101717585AImprove performanceReduce the difficulty of productionClimate change adaptationBuilding insulationsPolymer scienceHigh-speed grinding

The invention relates to an emulsified SBS polymer modified asphalt and preparation method thereof. At present, emulsification and emulsified modified asphalt applied to surfacing is hard to produce and not stable in quality, high temperature performance improvement is not obvious. The raw materials of the invention are matrix asphalt, water, SBS asphalt modifier, compound asphalt emulsifier, emulsification stabilizer and hydrochloric acid; firstly the matrix asphalt is heated, added with SBS asphalt modifier and then stirred to be swelled, high speed grinding by colloid grinder and full dispersion are carried out, and heat preservation growth is carried out to obtain SBS modified asphalt; compound asphalt emulsifier is added into water, emulsification stabilizer smoothened by water in advance is added, and appropriate hydrochloric acid is added to adjust pH value, so as to obtain liquid soap; and finally the SBS modified asphalt is subject to temperature reduction and then mixed with the liquid soap and emulsification dispersion is carried out, thus obtaining emulsified SBS polymer modified asphalt. The invention is applicable to coat tacking, coat sealing, surface treatment, slurry sealing and asphalt pavement recycling, asphalt wet-mixing of road construction and cerement asphalt mortar layer of passenger special line plate type unballasted track.

Owner:深圳路安特沥青高新技术有限公司

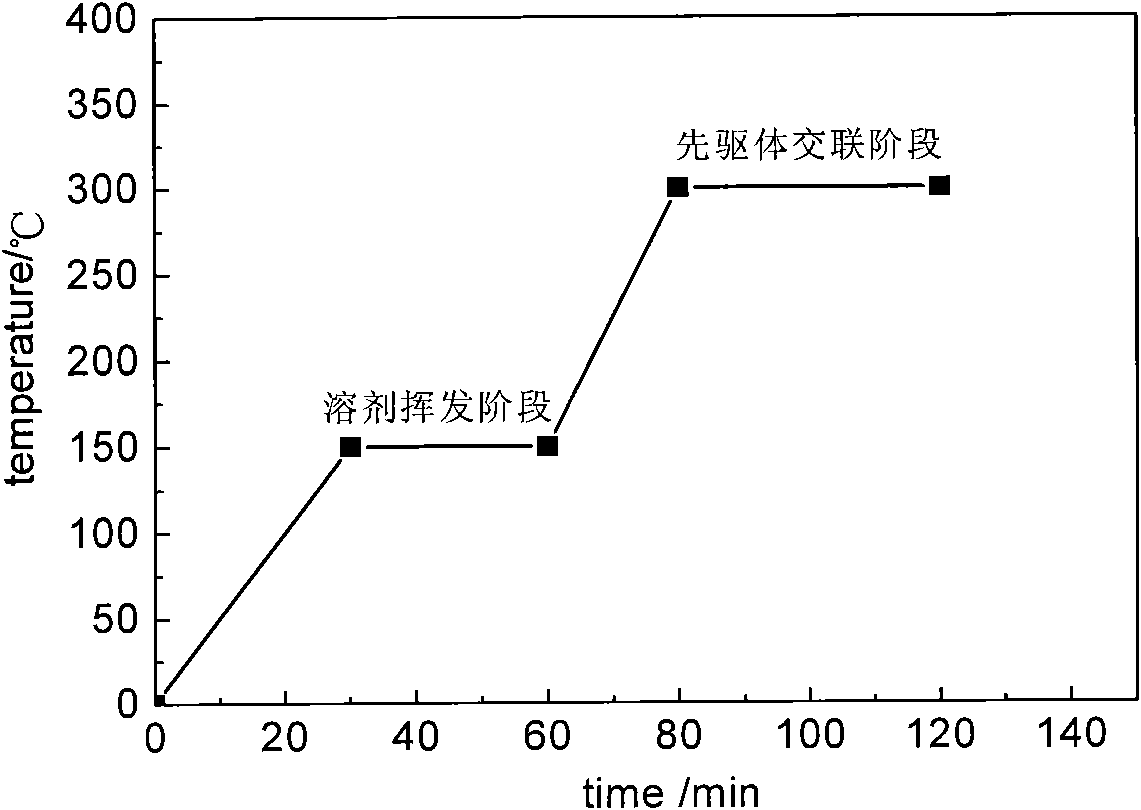

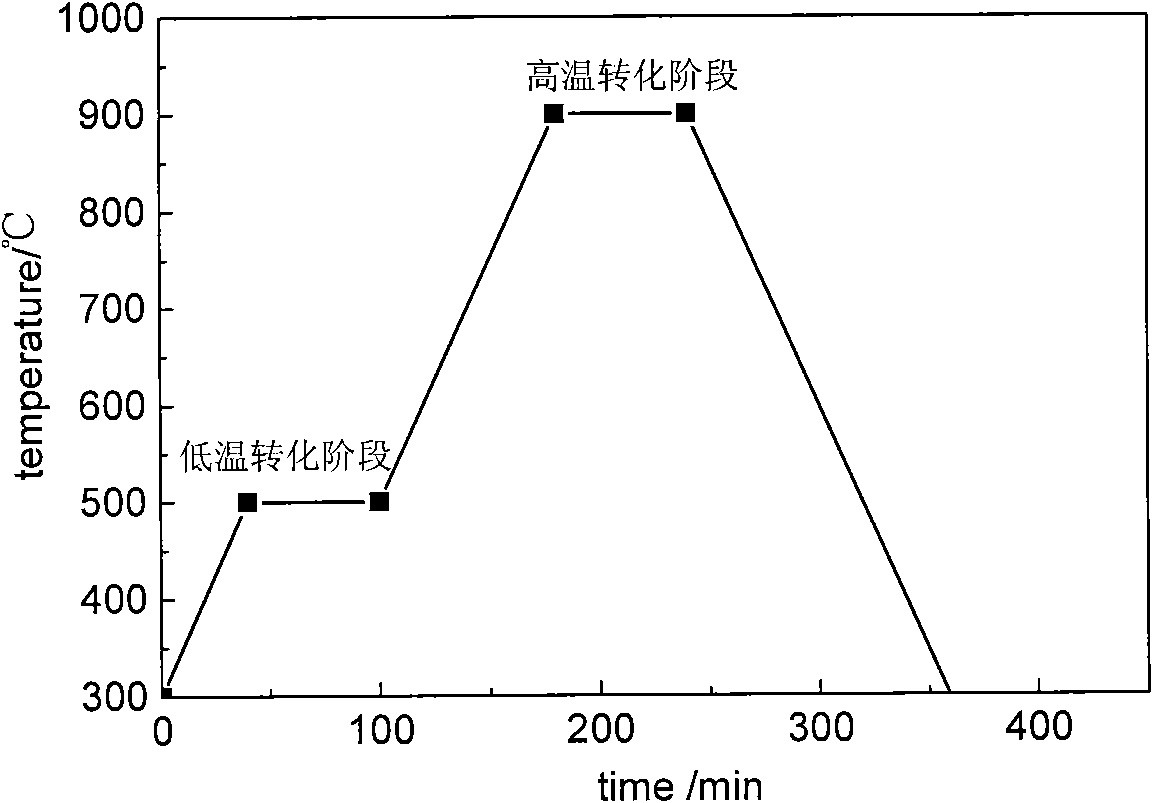

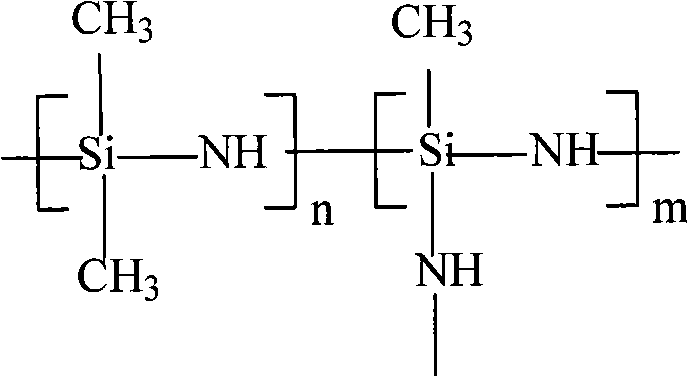

Method for preparing insulating heat conducting ceramic coating from polymer precursor

InactiveCN101654778ASimple preparation processEasy to operateSolid/suspension decomposition chemical coatingCross-linkHeat conducting

The invention relates to a method for preparing an insulating heat conducting ceramic coating, which is prepared from one or more of polymer precursors such as polysilazane, polysiloxane and polycarbosilane serving as a base material, and multiple kinds of ceramic packing and active fillers as well as solvent and various auxiliary agents, and is prepared by the following steps of: 1, adding a certain amount of fillers, solvent and auxiliary agents into a polymer precursor, stirring the mixture evenly, and preparing the mixture into slurry after high-speed grinding; 2, coating the slurry on thesurface of a treated substrate material (comprising metal, ceramic, graphite, a C / C composite material and the like) in a brush coating or spray coating mode; 3, performing vacuum heat treatment on the substrate material with a coating at a temperature of between 100 and 300 DEG C for 1 to 2 hours to ensure that the polymer precursor performs a cross-linking reaction; and 4, performing high-temperature treatment on the treated material under the protection of a gas, namely treating the material at a temperature of between 400 and 1,000 DEG C for 1 to 5 hours, and then naturally cooling to obtain a ceramic coating on the surface of the substrate material. The insulating heat conducting ceramic coating has the characteristics of simple coating and heat treatment technology, excellent insulating property and heat conductivity, good high temperature resistance, excellent high-temperature cracking resistance and the like. The method can be widely applied in electronic and electrical industry.

Owner:BEIJING PANTIAN NEW TECH

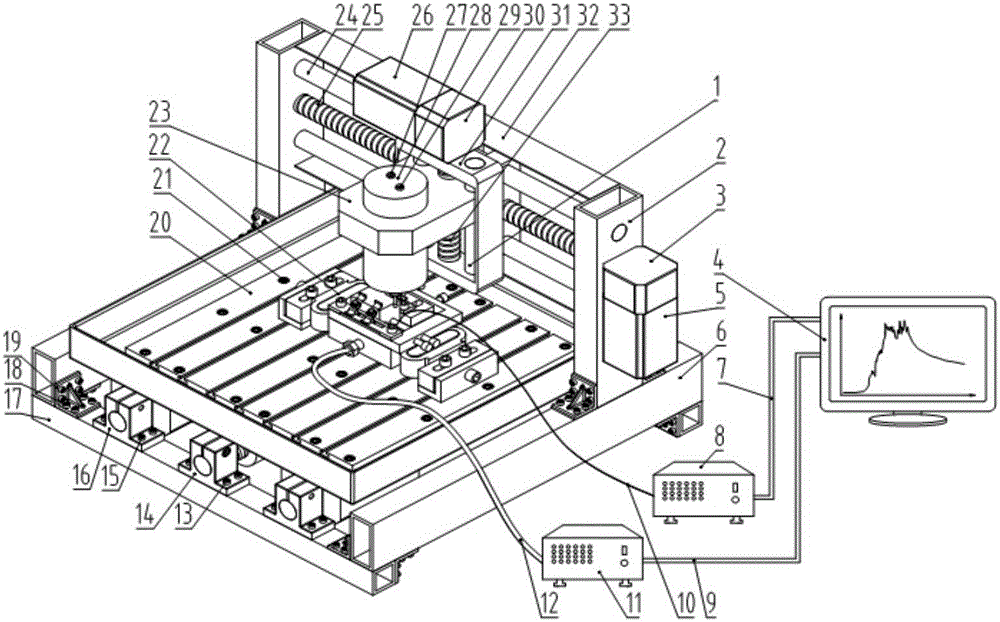

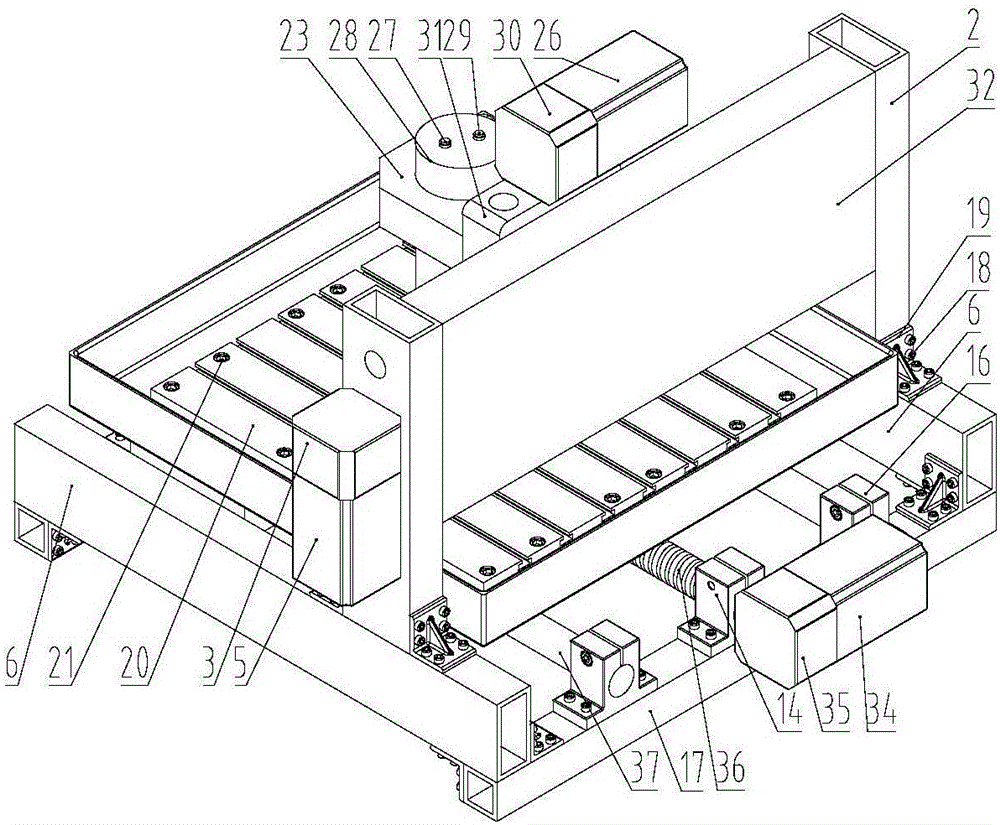

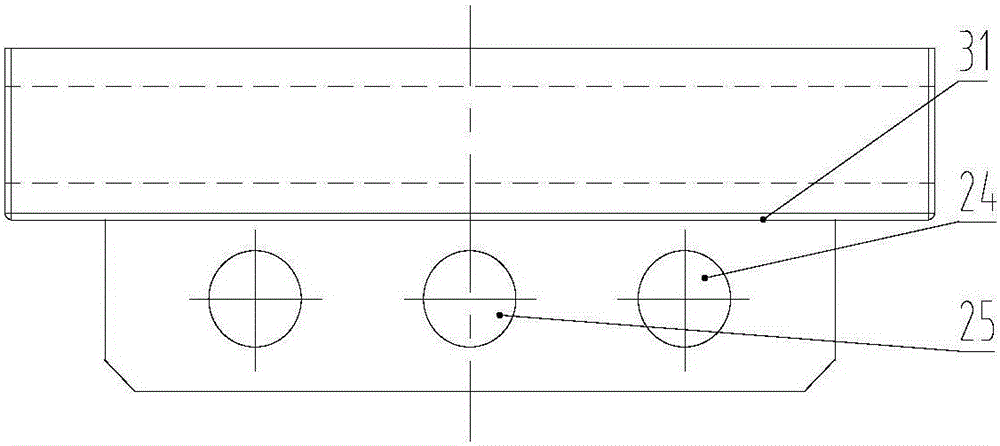

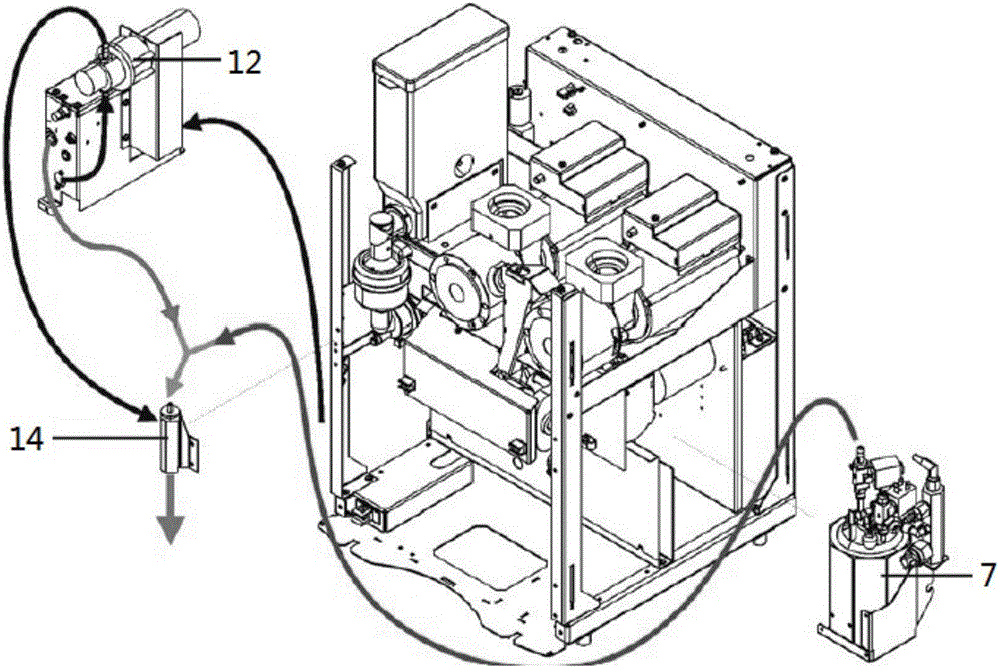

Numerically-controlled full-automatic retainer window grinding machine

InactiveCN103381569AEnsure accuracy andGuarantee stabilityGrinding machinesGrinding work supportsTime efficientBall screw

The invention discloses a numerically-controlled full-automatic retainer window grinding machine which adopts an integral high-rigidity anti-vibration casting machine body; a linear guide rail and a precision ball screw are mounted on the machine body; lengthwise movement saddles, slide seats and transverse adjustment sliding masses are mounted on the left side and the right side of the machine body respectively; high-speed grinding electric spindles are mounted on the sliding masses; a spindle component is mounted at the middle of the machine body; a clamping device component is mounted on the spindle component; conveying belts are mounted on the two sides of the rear part of the machine body; a mechanical hand is mounted at the rear upper part of the machine body; and a workpiece conveying plate is mounted on the outer edge of the left side of the machine body and used for conveying workpieces to the conveying belts. According to the invention, feeding and discharging are performed full-automatically during workpiece grinding, and the purpose that one person operates multiple machines can be achieved, so that both time and labor are saved, the manufacturing cost is lowered greatly, and the production efficiency is improved.

Owner:ANHUI LICHENG MACHINERY EQUIP

Ceramic binder for steel ball grinding wheel

The invention relates to a structure of a grinding material composited with a novel high-shrinkage engineering ceramic binder for the preparation of a grinding wheel and a preparation method thereof. The preparation method is characterized in that: the high-strength high-shrinkage engineering ceramic binder which is prepared from clay, feldspar, boracic glass, bentonite and manganite is composited with the mixed grinding material, the opacifying effect of the boracic glass promotes the glass nucleation, fluxing agents bentonite and manganite powder promote the preparation of the high-strengthhigh-shrinkage engineering ceramic structure, and the ceramic binder for the steel ball grinding wheel is prepared through carrying out cold-press high-pressure molding, and sintering at a certain temperature. Compared with market products, the strength, the combination degree, the elastic modulus and the linear velocity in usage of the steel ball grinding wheel are greatly improved, the geometric dimension of the steel ball grinding wheel is stable, the steel ball grinding wheel which has a high strength, a high hardness and a uniform tissue density and has the advantages of large grinding ratio, high fineness and no workpiece burning under high speed grinding conditions is a special grinding wheel for a novel high efficiency steel ball. So the steel ball grinding wheel can be widely applied to the mechanical steel ball manufacturing industry and is easy to be automated in the industry.

Owner:江苏华东砂轮有限公司

Super-speed grinding experiment method for single abrasive grain

ActiveCN102590000AEasy accessHigh simulationInvestigating abrasion/wear resistanceMaterial removalHigh-speed grinding

The invention relates to a super-speed grinding experiment method for a single abrasive grain, which is used for the grinding process of the single abrasive grain on a grinding wheel under the high-simulation super-speed condition and belongs to the research field of super-speed grinding for difficult-to-process material. The method comprises the following steps of assembling experiment devices, preparing samples, controlling the direction of the grinding wheel, judging the samples and the like. The super-speed grinding experiment method for the single abrasive grain provided in the invention can better simulate the grinding process of the single abrasive grain on the super-speed grinding wheel, grindings with different cutting thickness of the single abrasive grain can be obtained conveniently through the change of the grinding dosage parameter of the experiment, and the material removal mechanism can be researched through the observation for the microstructures of the grindings, so as to provide the experiment support for researching the grinding process of the material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

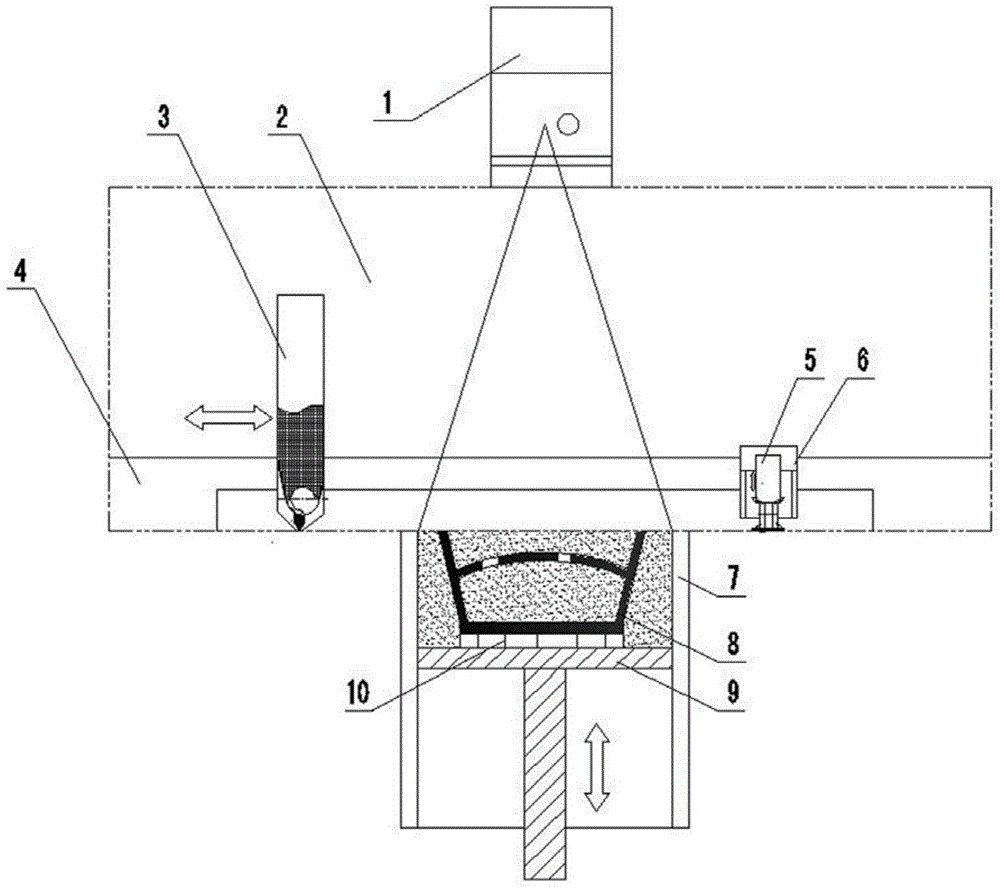

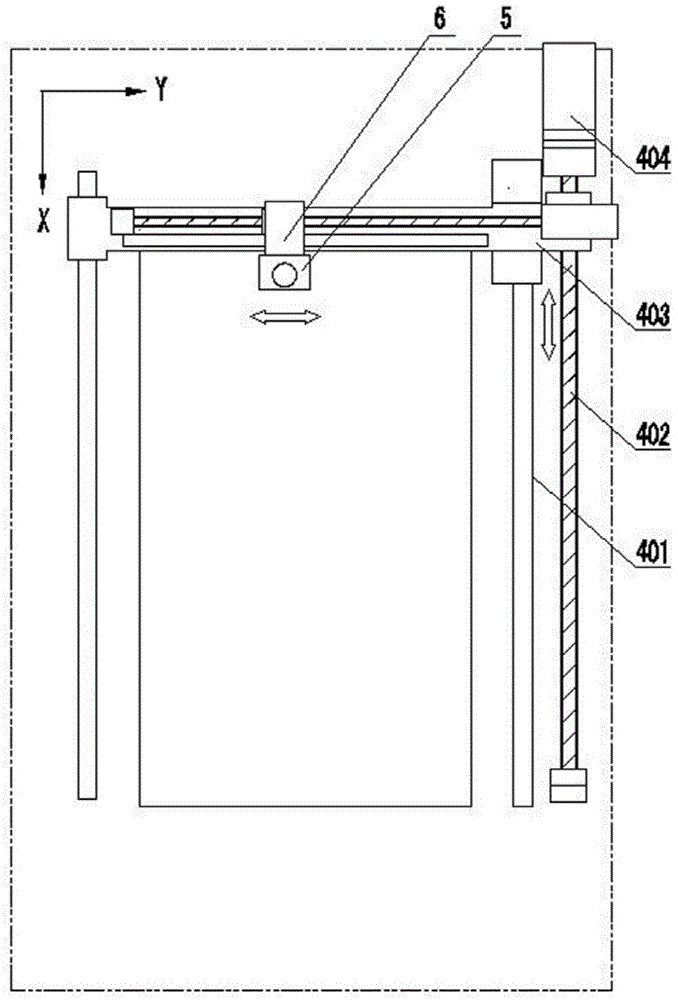

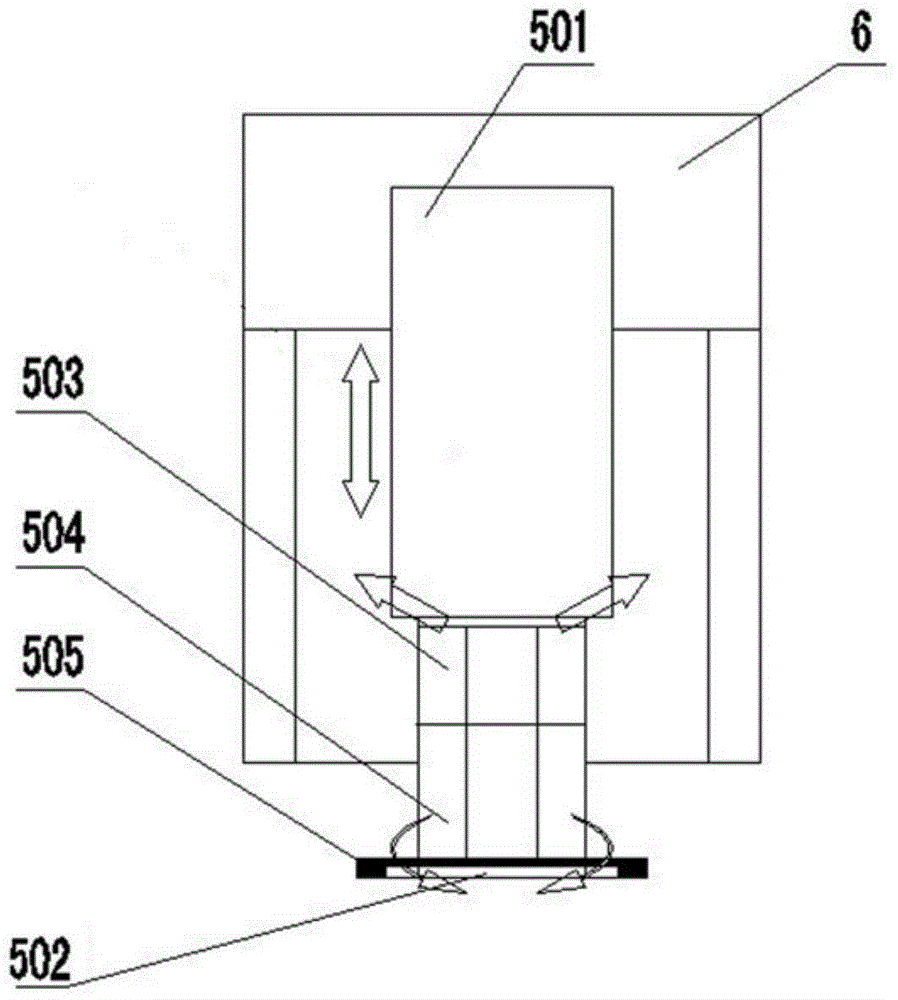

System suitable for metal powder melting material increasing manufacturing

InactiveCN104959603AEliminate bumpsEliminate warpingAdditive manufacturing apparatusIncreasing energy efficiencyHigh-speed grindingGalvanometer

The invention discloses a system suitable for metal powder melting material increasing manufacturing. The system is formed by compositing of a fiber laser galvanometer scanning mechanism and a high-speed grinding head. The fiber laser galvanometer scanning mechanism is provided with an XY workbench. The high-speed grinding head is arranged on a Y axis of the XY workbench through a Y axial sliding block. After multiple layers are manufactured on a workpiece, the high-speed grinding head slides along the Y axis of the XY workbench and carries out the feeding motion in the X axial direction at the same time, and high-speed grinding is carried out on the workpiece. The system suitable for the metal powder melting material increasing manufacturing has the advantages that after the high-speed grinding head is composited with the fiber laser galvanometer scanning mechanism, in the material increasing manufacturing process, scanning is carried out on a powder bed through the fiber laser galvanometer scanning mechanism, metal in a selected area is melted, a protrusion and a warpage in the partial workpiece can be removed by the high-speed grinding head, the upper surface of the workpiece can be maintained in smooth, the residual protruding peak on the surface of the workpiece and the plastic deformation degree can be effectively lowered, and the roughness on the surface of the workpiece is favorable to be lowered.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

Preparation technology of high-speed grinding CBN (Cubic Boron Nitride) ceramic grinding wheel

ActiveCN102009393ALower firing temperatureImprove flexural strengthAbrasion apparatusGrinding devicesHigh-speed grindingMullite

The invention discloses a preparation technology of a high-speed grinding CBN (Cubic Boron Nitride) ceramic grinding wheel, which comprises the steps of: mixing raw materials according to the following part proportion: 30 to 50 parts of feldspar, 40 to 60 parts of boron glass, 3 to 7 parts of K2CO3 and 3 to 7 parts of Na2CO3; firing at high temperature; ball-milling and uniformly mixing nano SiO2 powder, nano mullite powder and pre-melting ceramic powder according to the mass rate of 2:3:5 to obtain a bonding agent; preparing an abrasive layer from 35% of the bonding agent, 8% of white corundum, 7% of alumina hollow ball and 50% of CBN; preparing a transition layer from 35% of the bonding agent and 65% of ceramic balls of 150 meshes; uniformly mixing the weighed materials; adding the materials to a polythene water solution; pressing to form a fixed shape; drying; and sintering in a high-temperature furnace. The preparation technology has the advantages of low firing temperature of the bonding agent, high breaking strength and good bonding performance to abrasives, enhances the wettability of the bonding agent to the abrasives, enhances the cutting efficiency of abrasive particles, reduces the cost, and enhances the enwrapping capability, strength and sintering temperature of the bonding agent to the abrasive, and in addition, CBN strength is not changed and no burning loss is generated on a surface.

Owner:沈阳中科超硬磨具磨削研究所

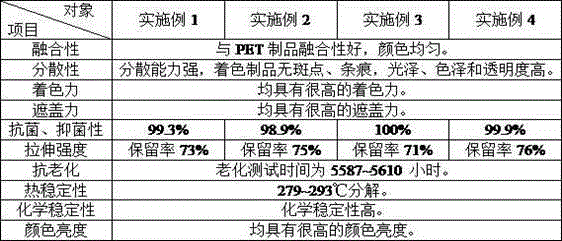

Preparing technology for color master batches

The invention relates to the technical fields of color master batches and preparing technologies thereof, in particular to a preparing technology for color master batches, and particularly discloses a preparing technology for color master batches for high-speed spinning fibers. The preparing technology includes the steps of carrier grinding, coloring material grinding, matched material grinding, assistant grinding, mixed grinding, high-speed grinding, extrusion prilling and drying. The color master batches prepared with the technology can be easily mixed with PET product plastic, and the even coloring effect can be achieved. Dispersibility, coloring strength and covering power are improved, weather resistance, acid resistance, heat resistance and cold resistance are achieved, the chemical stability of pigment is kept, and the color master batches are more environmentally friendly and healthier in the use process.

Owner:JIEDONG PARIS WANZHU SHAHUA TEXTILES CO LTD

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

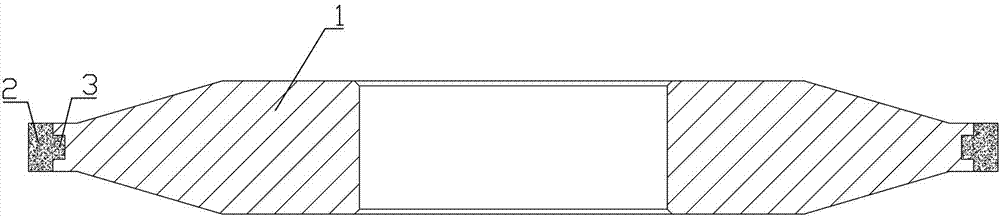

Resin binder superhard material grinding wheel for roller high-speed grinding and manufacture method thereof

InactiveCN103770030AIncreased Fracture Velocity LimitTightly boundAbrasion apparatusGrinding devicesSuperhard materialHigh-speed grinding

The invention aims at solving the problem that high-speed grinding cannot be realized through a hard alloy roller high-speed grinding wheel with low combination strength between a working layer and a base body and provides a resin binder superhard material grinding wheel for roller high-speed grinding and a manufacture method thereof. The grinding wheel comprises a base body and a grinding wheel working layer. A boss is arranged on the grinding wheel working layer. A groove corresponding to the boss is arranged on the base body. According to the grinding wheel, the boss is arranged on the grinding wheel working layer and is matched with the groove of the base body. The structure is favorable to compact combination of the grinding wheel working layer and the base body, increases the fracture speed restriction to the grinding wheel, realizes high-speed operation of the resin binder superhard material grinding wheel, breaks through restriction of low operation speed to the grinding wheel, and provides a better grinding tool for roller high-speed efficient grinding.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

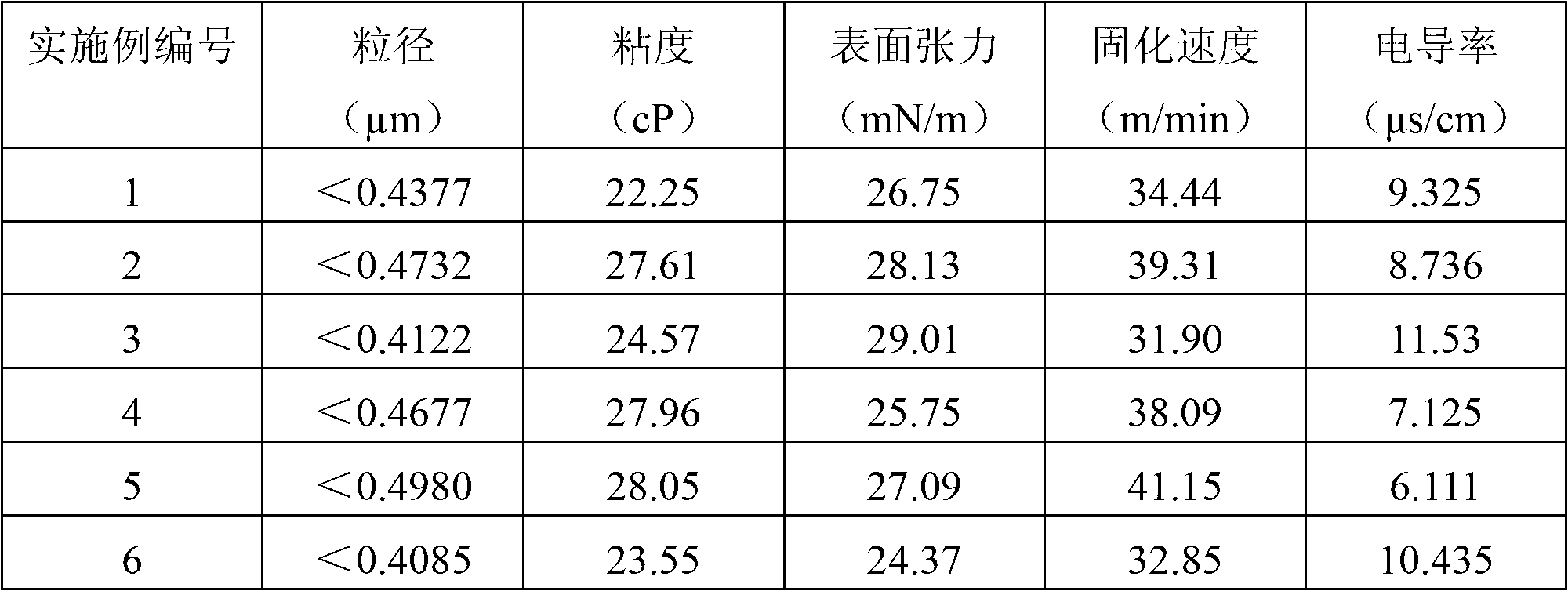

Pinkish red UV ink-jet ink for high-speed ink-jet printing and preparation method thereof

The invention relates to a pinkish red UV ink-jet ink for high-speed ink-jet printing and a preparation method thereof. The pinkish red UV ink-jet ink is used for printing of paper materials and belongs to the technical field of digital printing. The pinkish red UV ink-jet ink comprises, by weight, 15 to 30 parts of color paste, 20 to 35 parts of a monomer, 40 to 50 parts of a film forming resin, and 1 to 10 parts of a photoinitiator. The color paste comprises, by weight, 10 to 25 parts of a pinkish red pigment, 15 to 30 parts of a prepolymer, 40 to 60 parts of a monomer and 4 to 10 parts of a dispersant. The pinkish red UV ink-jet ink is prepared by stirring and high-speed grinding. The pinkish red UV ink-jet ink satisfies ink-jet printing requirements, has particle size less than 0.5 microns, viscosity of 20 to 30cP (at 25 DEG C), surface tension of 20 to 35mN / m (at 25 DEG C), a curing rate of 30 to 50m / min (based on light source linear power of 200W / cm), and conductivity less than 18 microseconds per centimeter.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Low-temperature sintered zirconium silicate grinding ball and preparation method thereof

The invention relates to a low-temperature sintered zirconium silicate grinding ball and a preparation method thereof, relating to a grinding medium. The raw materials of the ball are as follows: zirconium silicate as the substrate material; and a combination of alumina, silicon oxide, zirconia, yttrium oxide, calcium carbonate, magnesium carbonate, potassium carbonate and sodium carbonate as a sintering aid. The raw materials are prepared according to an appropriate mass ratio, and go through ball milling using a ball mill, and high speed grinding by a vertical sand mill then drying to obtain raw material powder for the preparation of the zirconium silicate grinding ball at low temperature. The material powder is shaped to be biscuit balls for sintering to obtain compact, wear-resistant and high-strength zirconium silicon substrate grinding balls.

Owner:江苏金石研磨有限公司

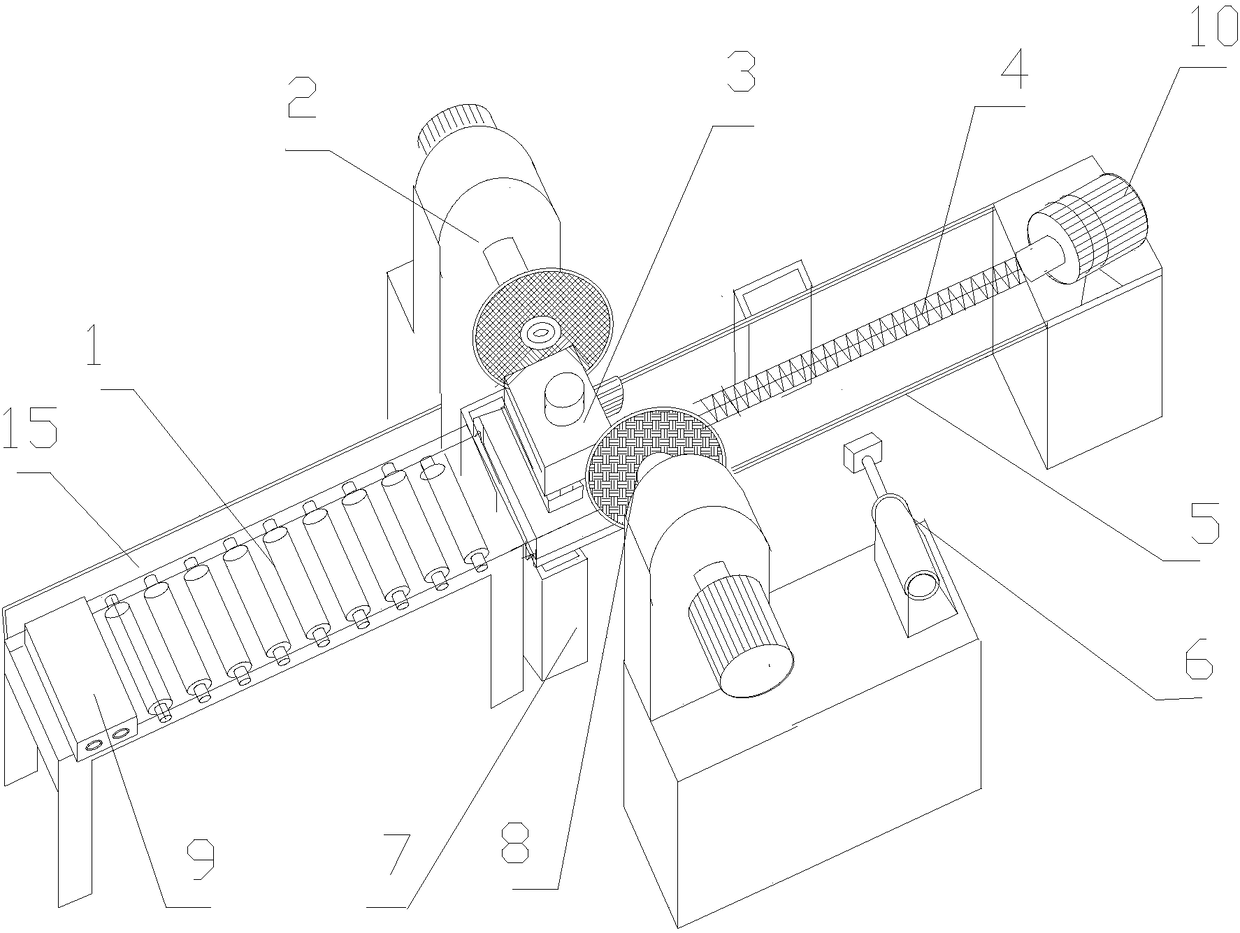

Physical dismounting and recycling device for waste power lithium battery set

InactiveCN108527115AFast cutting speedImprove efficiencyWaste accumulators reclaimingGrinding machinesHigh-speed grindingEngineering

The invention discloses a physical dismounting and recycling device for a waste power lithium battery set. The physical dismounting and recycling device comprises a wheel conveying device, grinding wheel cutting power assemblies, an automatic clamping base, a lead screw transmission pair, a guide rail, a side pushing unloading device and waste boxes. The wheel conveying device is a self-sliding wheel set in which a plurality of wheels are evenly distributed, embedded and installed in a sliding way, and a material positioning baffle is arranged on the left side face. The two grinding wheel cutting power assemblies are arranged, motors for providing power sources are arranged at the end portions, and high-speed grinding wheel sheets are arranged at the front ends of power shafts of the motors. A top oil cylinder 11A is arranged on the automatic clamping base, a top oil cylinder ejector plate 12A is arranged at the end portion of the top oil cylinder 11A, a bottom pushing oil cylinder 11Bis arranged on the back, and a bottom pushing oil cylinder ejector plate 12B is arranged at the end portion of the bottom pushing oil cylinder 11B. An unloading oil cylinder 13A is arranged behind the side pushing unloading device, and a bottom pushing oil cylinder ejector plate 13B is arranged at the end portion of the unloading oil cylinder 13A. The waste boxes are totally arranged at two positions. The physical dismounting and recycling device is high in double-side cutting speed, high in efficiency, compact in structure and simple and reliable in operation.

Owner:贵州中伟资源循环产业发展有限公司

UV conductive ink and preparation method thereof

The invention discloses a UV conductive ink and a preparation method thereof. The UV conductive ink comprises, by mass 20-70 parts of a conductive slurry, 10-40 parts of a film forming resin, 10-30 parts of a monomer and 1-10 parts of a photoinitiator. The conductive slurry comprises, by mass, 20-50 parts of a conductive material, 10-30 parts of the a prepolymer, 2-40 parts of a monomer and 1-15 parts of a dispersant. The preparation method comprises the following steps: mixing the conductive material with the prepolymer, the monomer and the dispersant, stirring the above obtained mixture for 30min for pre-dispersion, and grinding by a high-speed grinding machine at a grinding speed of 1800r / min for 3h to make the above obtained material fully wetted and dispersed in order to obtain the conductive slurry; and mixing the conductive slurry with the film forming resin, the monomer and the photoinitiator, putting the newly obtained mixture into a vessel, arranging the vessel on an HJ-6A type digital thermostat long magnetic stirrer, and carrying out thermostatic stirring at 40DEG C for 0.5h until uniformity to obtain the ink. The production process of the UV conductive ink has little pollution to the environment.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Orthopedic surgery grinding experimental device with cooling and electrostatic atomization film formation functions

The invention discloses an orthopedic surgery grinding experimental device with the cooling and electrostatic atomization film formation functions. The orthopedic surgery grinding experimental device comprises linear three-axis platform, an electric spindle and a workpiece fixing device. The linear three-axis platform can move front and back, left and right, and up and down. The linear three-axis platform comprises an X-axis structure capable of moving left and right, a Y-axis structure capable of moving front and back, and a Z-axis structure capable of moving up and down. The workpiece fixing device is fixed to the Y-axis structure. The electric spindle is fixed to the Z-axis structure and installed at the upper end of the workpiece fixing device. A grinding head is installed at the lower end of the electric spindle, a grinding cooling device is arranged in a grinding head handle or around the grinding head, and an electrostatic atomization film formation device is arranged around the grinding head. The high-speed grinding surgery experimental device can be suitable for drop irrigation type cooling, pouring type cooling, aerial fog type cooling, nano-fluid aerial fog type cooling and grinding region temperature drop modes for phase-change heat transfer type grinding heads, hydrophilic type grinding heads, electrostatic atomization inner-cooling grinding tools and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Numerical control retainer window grinding machine

InactiveCN103394984AEnsure accuracy andGuarantee stabilityGrinding carriagesGrinding machinesNumerical controlBall screw

The invention discloses a numerical control retainer window grinding machine. According to the numerical control retainer window grinding machine, an integrated high-rigidity shake-proof cast machine body is adopted, a linear guide rail and a precise ball screw are arranged on the machine body, a longitudinal moving saddle, a sliding seat and a horizontal adjustment sliding body are arranged on the upper surface of the machine body, a high-speed grinding motorized spindle is installed on the sliding body, a spindle component is installed in the middle of the machine body, a clamping device component is installed on the spindle component, and then workpiece grinding accuracy and stability are ensured by means of the cooperation between full servo control longitudinal movement and high-frequency rotation of a workpiece spindle. The numerical control retainer window grinding machine has the advantages of being high in stability, saving in time and high in efficiency.

Owner:ANHUI LICHENG MACHINERY EQUIP

Diamond grinding wheel

ActiveCN106625296AHigh thermal conductivityGood grinding temperatureAbrasion apparatusGrinding devicesSuperhard materialHigh load

The invention relates to the field of superhard materials, in particular to a diamond grinding wheel which is excellent in impact resistance and shape retention, can bear higher load during a high-speed grind process, and comprises a steel core and an abrasive material ring adhered together through a resin adhesive; the abrasive material ring is characterized by being prepared from the following raw materials in mass percent: 25-50% of diamond abrasive material, 44-72% of a metallic bond and 3-6% of an auxiliary adhesive. The diamond grinding wheel has excellent heat conductivity to facilitate reduction of grinding temperature so as to reduce power loss and increase grinding speed; the auxiliary adhesive in the formula facilitates formation of pores, and the characteristic of high holding force of the metallic bond is combined, so that the chip space can be effectively increased, and the utilization of the abrasive material is more sufficient; and the grinding wheel has the characteristics of high grinding efficiency, low grinding temperature and power loss, high machining precision and long service life.

Owner:磐维科技(青岛)有限公司

Resin reinforced high-speed grinding wheel

The invention relates to a resin-reinforcing high-speed grinding wheel. The invention is characterized in that each group comprises A24<#,, A30<#>, A36<#>, resin liquids, resin powders, sulfur concentrate powders, cryolites, light calcium carbonates and carbon blacks. After a qualified inspection to each group, the components are weighted according to the prescription and are mixed through a 80-mesh sieve, and the mixture is griddled through a 8-mesh sieve to become a finished material. Then the finished material is loosened through the sieve and then is put into a mould. After the material is spread and scraped, a web piece and a bore-ring are put into the mould, and then the mould is put into a pressing machine for pressing, with a pressure of no less than 150MPa and a temperature ranging from 40 to 60 degree centigrade. After the pressure is preserved for 30 seconds the mould is disassembled and the material is put into a furnace for hardening. After hardening, the qualified product is the eligible product. The invention, on a basis of not reducing the product safety and various technical indexes, makes use of the home common raw materials and selects an excellent prescription so as to reduce the product cost and enhance the market competition as much as possible. The invention is characterized in that the strength is high; crash can be avoided and the grinding effect is good.

Owner:沈阳市盛世磨料磨具有限公司

CBN grinding wheel

InactiveCN101602188ALess sticky chipsImprove grinding efficiencyAbrasion apparatusGrinding devicesHigh-speed grindingAbrasive

The invention discloses a CBN grinding wheel which adopts CBN and AlN as main abradant and comprises a binder, an abradant and other additives and belongs to the scope of ultrahard abrasive tools. The invention is characterized in that the abradant is composed of 60-90% of CBN by mass percent and 10-40% of AlN by mass percent; the formula of the grinding wheel is as follows by mass percent: 70-77% of abrasive, 20-26% of binder and 3-4% of other additives. The product of the invention has good heat conductivity, good self-lubricity of the abrasive, high grinding efficiency, long service life and high processing precision of workpieces, thus being applicable to high-speed grinding.

Owner:佛山市华南精密制造技术研究开发院 +1

Preparation method of high specific surface area titanium dioxide for denitration catalyst

InactiveCN106379936ALarge specific surface areaHigh specific surface areaPhysical/chemical process catalystsTitanium dioxideHigh-speed grindingSlurry

The invention relates to a preparation method of high specific surface area titanium dioxide for a denitration catalyst. The preparation method comprises the following steps: (1) taking concentrated titanium liquid in the sulfuric acid method titanium dioxide production process as the raw material, adding a seed crystal, and carrying out pressurized hydrolysis to obtain meta-titanic acid with a high specific surface area; (2) washing the obtained meta-titanic acid for the first time, bleaching the meta-titanic acid, washing the meta-titanic acid for a second time, beating qualified meta-titanic acid after water washing, and controlling the concentration (calculated by titanium dioxide) to be in a range of 120 to 200 g / L; (3) adding an alkaline substance into the meta-titanic acid slurry obtained in the step (2) under stirring so as to adjust the pH value of the slurry to a range of 6.5 to 7.5; (4) subjecting the slurry obtained in the step (3) to aging, which lasts for 30 to 60 minutes, carrying out suction filtration in a vacuum suction device, and washing the filter cake by water, wherein the solid content of filter cake is more than 35%; (5) placing the filter cake obtained in the step (4) in an electric oven to dry the filter cake, wherein the temperature is controlled in a range of 105 to 150 DEG C, and the drying time lasts for 10 to 20 hours; and (6) grinding the material obtained in the step (5) by a high speed grinding machine to obtain the high specific surface area titanium dioxide.

Owner:NANJING TITANIUM DIOXIDE CHEM

Variable heat source model-based non-circular-profile workpiece high-speed grinding temperature prediction method

InactiveCN108151885AImprove effectivenessImprove practicalityRadiation pyrometryCalorimeterHeat fluxHigh-speed grinding

The invention discloses a variable heat source model-based non-circular-profile workpiece high-speed grinding temperature prediction method. The method comprises the steps of collecting the power andtemperature data of a non-circular-profile workpiece during the high-speed grinding process; establishing a variable heat source distribution model for non-circular-profile grinding; based on the variable heat source distribution model and the non-circular curved-surface grinding heat source loading method, carrying out temperature finite element simulation on the non-circular-profile workpiece during the high-speed grinding process; based on a heat distribution ratio calculation method for the surface temperature of the workpiece, correcting the heat flux density. According to the invention,aiming at the high-speed grinding process of the non-circular-profile workpiece, the variable heat source distribution model and the heat distribution ratio calculation method for non-circular-profilegrinding are established, and a heat source loading method suitable for non-circular contour grinding temperature simulation is provided. The heat source loading problem for the non-circular curved surface is solved. Meanwhile, the temperature field of each grinding arc zone during the high-speed grinding process of the non-circular contour workpiece can be accurately predicted. Compared with theprior art, the method is simple to operate, strong in applicability and high in accuracy.

Owner:HUNAN UNIV OF SCI & TECH

Yellow UV ink-jet ink for high-speed ink-jet printing and preparation method thereof

The invention relates to a yellow UV ink-jet ink for high-speed ink-jet printing and a preparation method thereof. The yellow UV ink-jet ink is used for printing of paper materials and belongs to the technical field of digital printing. The yellow UV ink-jet ink comprises, by weight, 20 to 30 parts of color paste, 20 to 35 parts of a monomer, 30 to 55 parts of a film forming resin, and 1 to 10 parts of a photoinitiator. The color paste comprises, by weight, 15 to 30 parts of a yellow pigment, 15 to 30 parts of a prepolymer, 40 to 55 parts of a monomer and 5 to 15 parts of a dispersant. The yellow UV ink-jet ink is prepared by stirring and high-speed grinding. The yellow UV ink-jet ink satisfies ink-jet printing requirements, has particle size less than 0.5 microns, viscosity of 20 to 30cP (at 25 DEG C), surface tension of 20 to 35mN / m (at 25 DEG C), a curing rate of 30 to 50m / min (based on light source linear power of 200W / cm), and conductivity less than 18 microseconds per centimeter.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

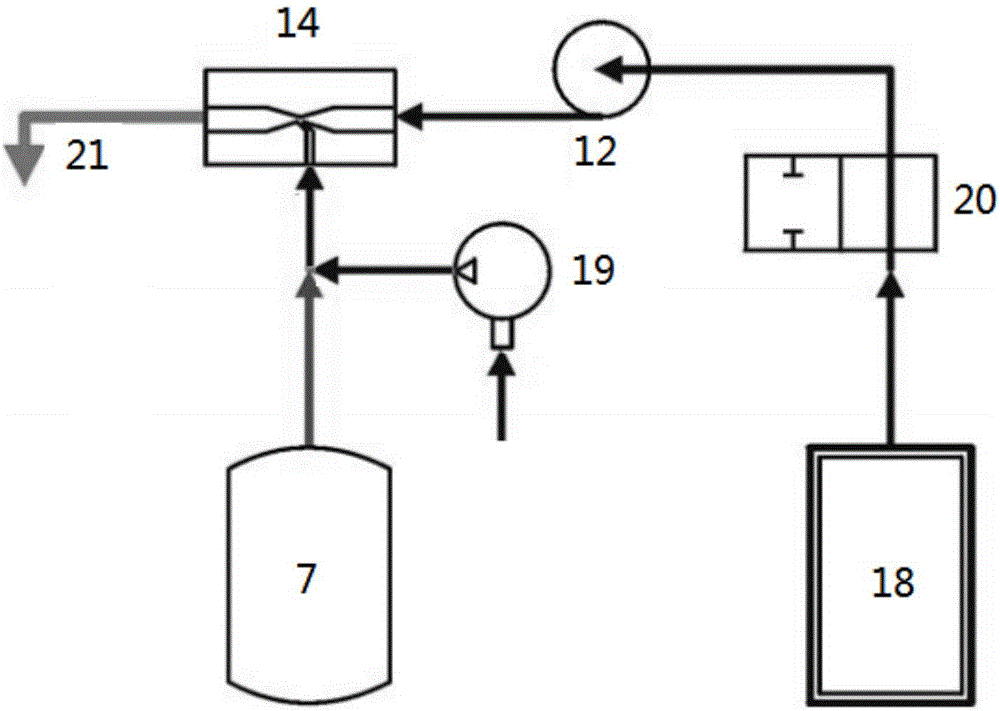

Full-automatic coffee machine brewing device based on fresh milk

The invention relates to a full-automatic coffee machine brewing device based on fresh milk. A machine body is provided with a coffee bean container, a main control board, a coffee chute, a high-speed grinding device, a coffee machine power supplying unit, an extraction unit power device, a steam boiler, an extraction unit, a coffee slag barrel, a gating safety switch, an extraction unit safety baffle plate, a milk pump, a chocolate mixing bowl discharging port, a milk bubble generating device, a chocolate mixing bowl, a chocolate powder discharging end and a chocolate powder box. The full-automatic coffee machine brewing device based on fresh milk is advantageous in that a problem of lack of fineness of milk bubbles due to different pressure near and far from an air outlet of the present milk bubble generating device can be solved; coffee beans are grinded by a high-speed axial motor; with a special coffee extraction unit, water in the boiler can be pumped into the extraction unit for extraction and collection; production capacity can be improved and high demand for better taste can be achieved by the machinery and technology; full-automatic extraction and recovery can be achieved; and labor dependence can be greatly reduced.

Owner:FRFURT INVESTMENT BEIJING

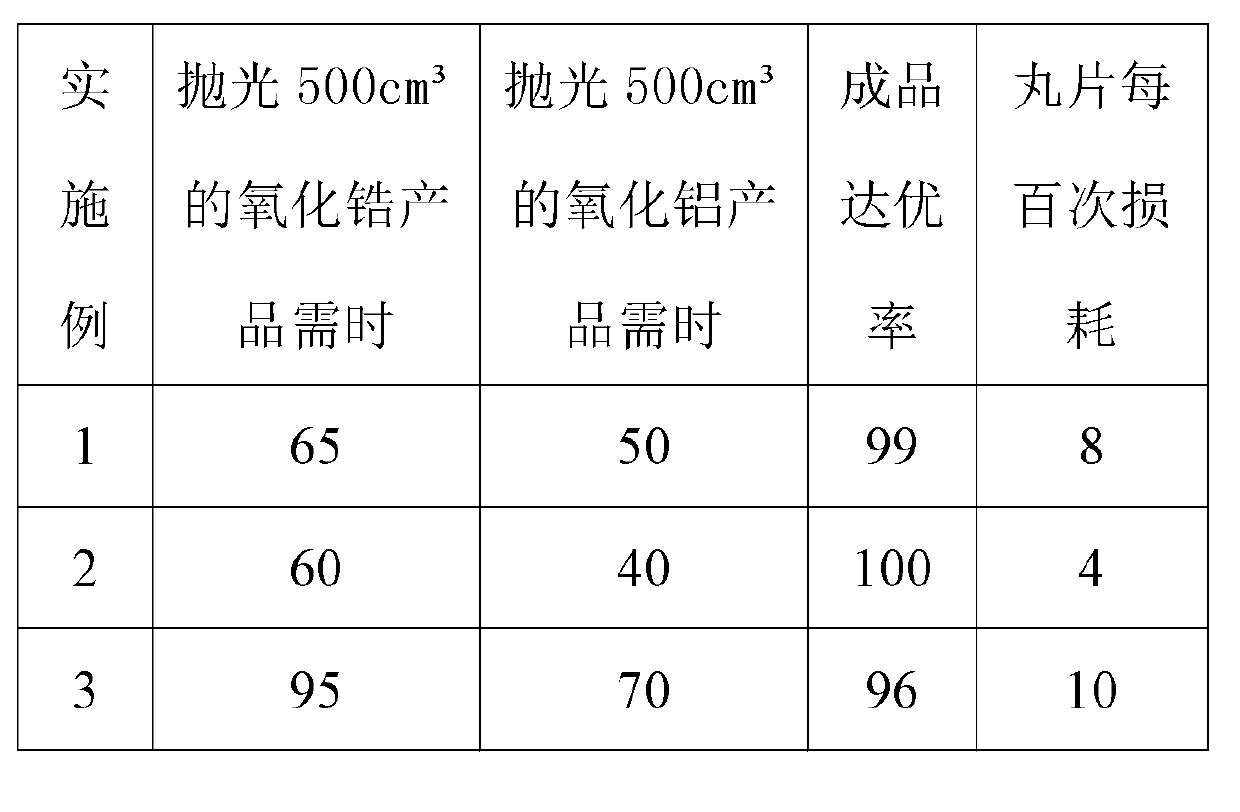

Formulation of zirconium oxide and aluminum oxide ceramic mirror polishing pellet tablet fixation grinding material

ActiveCN103273432AEnsure consistencyEnsure high efficiencyPolishing machinesFlexible-parts wheelsZirconium hydrideHigh-speed grinding

The invention relates to a formulation of a zirconium oxide and aluminum oxide ceramic mirror polishing pellet tablet fixation grinding material. A conventional fixation grinding material can not undergo high-speed grinding when being used for zirconium oxide and aluminum oxide ceramic mirror polishing, and therefore machining efficiency is low. The formulation is characterized by comprising the following components of copper powder, diamond powder, resin powder, silicon carbide powder and graphite powder, namely by weight ratio, 50.0-52.0 parts of the copper powder, 10.0-11.5 parts of the diamond powder, 9.5-12.0 parts of the resin powder, 2.0 parts of the silicon carbide powder and 2.0 parts of the graphite powder. According to the formulation, wear resistance is fully considered, surface shape adjustment is small, thermal conductivity is good, water cooling can be easily conducted, and efficiency of mirror polishing is greatly improved. By adopting produced fixation grinding material pellet tablet to machine zirconium oxide products and aluminum oxide products, machining surface quality can be greatly improved, and the surfaces of the products reach 18 nanometers (Ra).

Owner:衢州飞瑞特种陶瓷有限公司

Manufacturing method of large-sized ceramic high-speed grinding wheel

InactiveCN103029048AImprove drying conditionsGuaranteed StrengthGrinding devicesHigh-speed grindingUltimate tensile strength

The invention discloses a manufacturing method of a large-sized ceramic high-speed grinding wheel. The manufacturing method comprises the following steps of: step 1, preparing binding agent; step 2, mixing to obtain forming materials; step 3, starting a mold rotating machine, and sieving the forming materials; step 4, stripping a mold; step 5, naturally drying; step 6, putting into a drying room, and drying; step 7, placing into a kiln; step 8, sintering; step 9, drawing, and step 10, processing. The manufacturing method has the advantages that the drying condition of the grinding wheel is improved, a sintering and warming curve is improved, the stability during sintering is improved, and the strength of the grinding wheel and the finished product yield are further ensured.

Owner:CHANGSHU JULI GRINDING WHEEL

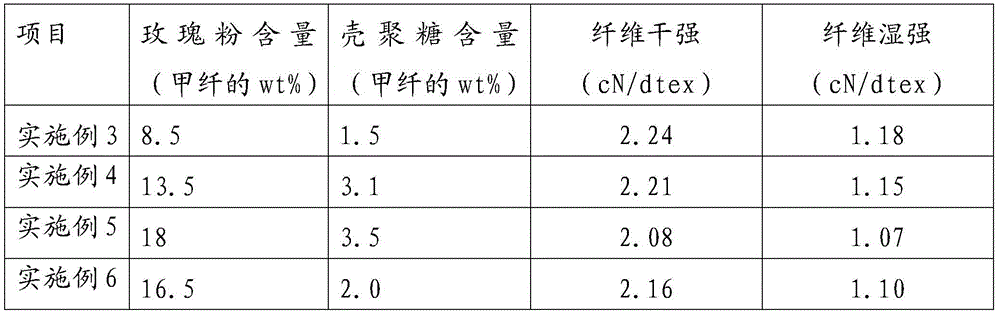

Microcapsule type rose-modified regenerated cellulose fiber and preparation method thereof

ActiveCN105671665ANot easy to come outWon't be lostArtificial filaments from viscoseFiltrationHigh-speed grinding

The invention discloses a microcapsule type rose-modified regenerated cellulose fiber and a preparation method thereof. Honeycomb silica particles are adopted as a packaging material, nanoscale rose powder and chitosan powder are evenly mixed and packaged in honeycomb micropores of honeycomb silica, rose powder microcapsules are prepared and dissolved in water, a dispersant, a stabilizer and a crosslinking agent are added, the mixture is evenly mixed, an emulsion is prepared after high-speed grinding and filtration, the prepared emulsion is mixed with a spinning solution to be subjected to spinning formation in a coagulating bath, and the microcapsule type rose-modified regenerated cellulose fiber is obtained after an after-treatment process. The prepared modified cellulose fiber has the rose-specific fragrance and elegant pleasant aroma, has effects of nourishing skin, maintaining beauty and caring skin and has healthcare functions of soothing nerves, resolving depression, relieving fatigue, promoting wound healing, resisting bacteria and the like.

Owner:湖州珠力纳米材料科技开发有限公司

Preparation method of whole-bean soybean milk by adopting dry enzyme treatment

InactiveCN106417631AShort manufacturing cycleSmall particle sizeMilk substitutesFood scienceCelluloseHigh-speed grinding

The invention relates to the field of food processing, and especially relates to a preparation method of whole-bean soybean milk by adopting dry enzyme treatment. The preparation method of the whole-bean soybean milk by adopting the dry enzyme treatment comprises the following processes: screening soybeans; performing high-speed grinding on the screened soybeans so as to prepare soybean powder; adding water into the soybean powder in a certain proportion so as to prepare raw soybean milk; cooking the raw soybean milk; cooling the cooked soybean milk; adding cellulose, and carrying out cooling; and then, carrying out preservation. The preparation method of the whole-bean soybean milk by adopting the dry enzyme treatment provided by the invention obviously shortens production cycles of the soybean milk; moreover, soybean dregs are retained so as to prevent nutrients from losing, so that the prepared soybean milk is richer in nutrition. The prepared soybean milk has small average grain sizes, as well as higher stability and yield compared with tradition soybean milk.

Owner:SICHUAN AGRI UNIV

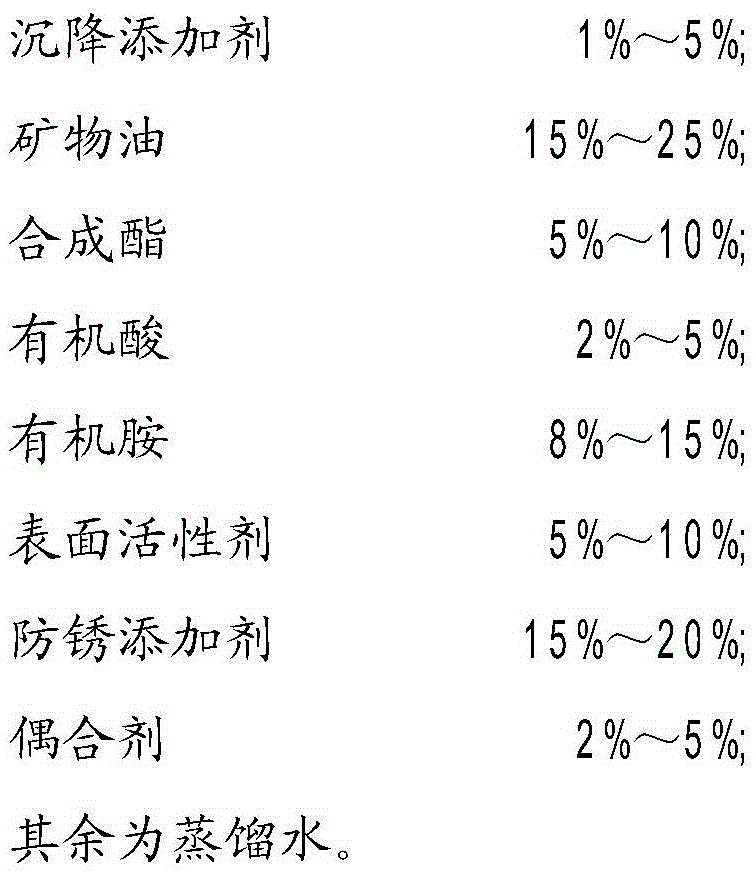

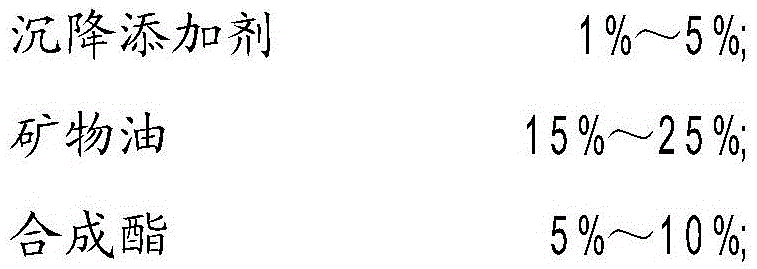

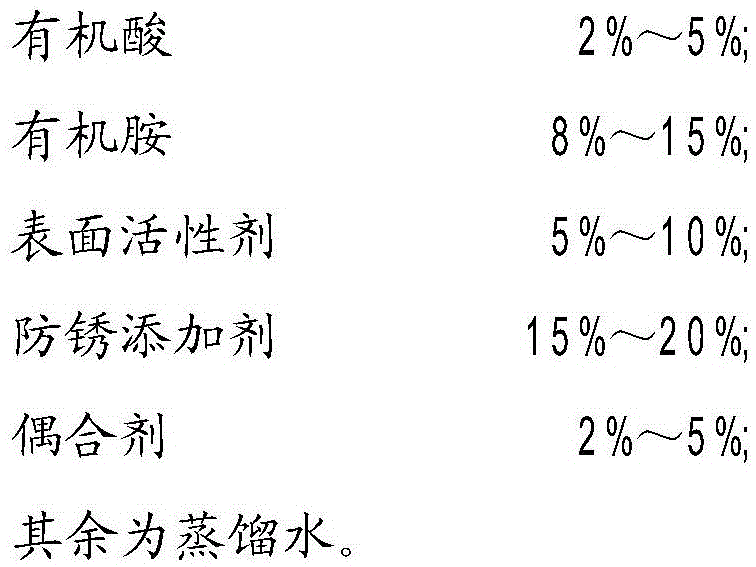

Water solubility high-speed grinding fluid for machining settlement bearing and preparation method thereof

ActiveCN105542931ARaise the pHImprove the lubrication effectLubricant compositionSolubilityHigh-speed grinding

The invention discloses water solubility high-speed grinding fluid for machining a settlement bearing. The water solubility high-speed grinding fluid comprises the following components by weight percent: 1 to 5 percent of settlement additive; 15 to 25 percent of mineral oil, 5 to 10 percent of synthetic ester, 2 to 5 percent of organic acid, 8 to 15 percent of organic amine, 5 to 10 percent of surface active agent, 15 to 20 percent of antirust additive, 2 to 5 percent of coupling agent and the balance of distilled water. The settlement additive is a mixture of fatty amine polyoxyethylene ether, aziridine and dibenzyl ether. The water solubility high-speed grinding fluid has excellent rust resistance, wettability, lubricity and grinding ash settling performance. Meanwhile, the invention provides a preparation method of the water solubility high-speed grinding fluid for machining the settlement bearing.

Owner:QUAKER CHEM CHINA

BOPET (Biaxial oriented Polyethylene Terephthalate) ultraviolet shielding master batch and manufacturing method thereof

ActiveCN107418159AEasy to prepareImprove filtering effectArtifical filament manufactureMonocomponent polyamides artificial filamentPolyethylene terephthalate glycolHigh-speed grinding

The invention relates to BOPET (Biaxial oriented Polyethylene Terephthalate) ultraviolet shielding master batch. The BOPET ultraviolet shielding master batch is prepared from the following raw materials in parts by weight: 70 to 90 parts of polyethylene terephthalate, 1 to 5 parts of a dispersant, 5 to 20 parts of a coloring agent, 10 to 20 parts of a nano-grade ultraviolet absorbent and 5 to 10 parts of meta-aramid fibers. According to the BOPET ultraviolet shielding master batch provided by the invention, the coloring agent is ground through a high-speed grinding machine; the aramid fibers are added and the nano-grade ultraviolet absorbent is matched, so that a dispersion effect of the coloring agent and the ultraviolet absorbent is good; meanwhile, the fibers are also dispersed well and have no tangling phenomenon; the filtering performance is good and a BOPET ultraviolet shielding film prepared from the BOPET ultraviolet shielding master batch has a ultraviolet shielding rejection rate reaching 100 percent, and the film haze is less than 2; the master batch is used for producing the BOPET ultraviolet shielding film; a net replacing period is long, and film-forming performance is good. The invention further relates to a preparation method of the BOPET ultraviolet shielding master batch.

Owner:广东彩艳股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com