Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

842 results about "Manganite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganite is a mineral composed of manganese oxide-hydroxide, MnO(OH), crystallizing in the monoclinic system (pseudo-orthorhombic). Crystals of manganite are prismatic and deeply striated parallel to their length; they are often grouped together in bundles. The color is dark steel-grey to iron-black, and the luster brilliant and submetallic. The streak is dark reddish brown. The hardness is 4, and the specific gravity is 4.3. There is a perfect cleavage parallel to the brachypinacoid, and less-perfect cleavage parallel to the prism faces. Twinned crystals are not infrequent.

Sputtering target for oxide thin film and process for producing the sputtering target

ActiveUS20110168994A1Lower bulk resistanceHigh densityConductive materialVacuum evaporation coatingIndiumRare earth

Disclosed is a sputtering target that can suppress the occurrence of anomalous discharge in the formation of an oxide semiconductor film by sputtering method and can continuously and stably form a film. Also disclosed is an oxide for a sputtering target that has a rare earth oxide C-type crystal structure and has a surface free from white spots (a poor appearance such as concaves and convexes formed on the surface of the sputtering target). Further disclosed is an oxide sintered compact that has a bixbyite structure and contains indium oxide, gallium oxide, and zinc oxide. The composition amounts (atomic %) of indium (In), gallium (Ga), and zinc (Zn) fall within a composition range satisfying the following formula: In / (In+Ga+Zn)<0.75

Owner:IDEMITSU KOSAN CO LTD

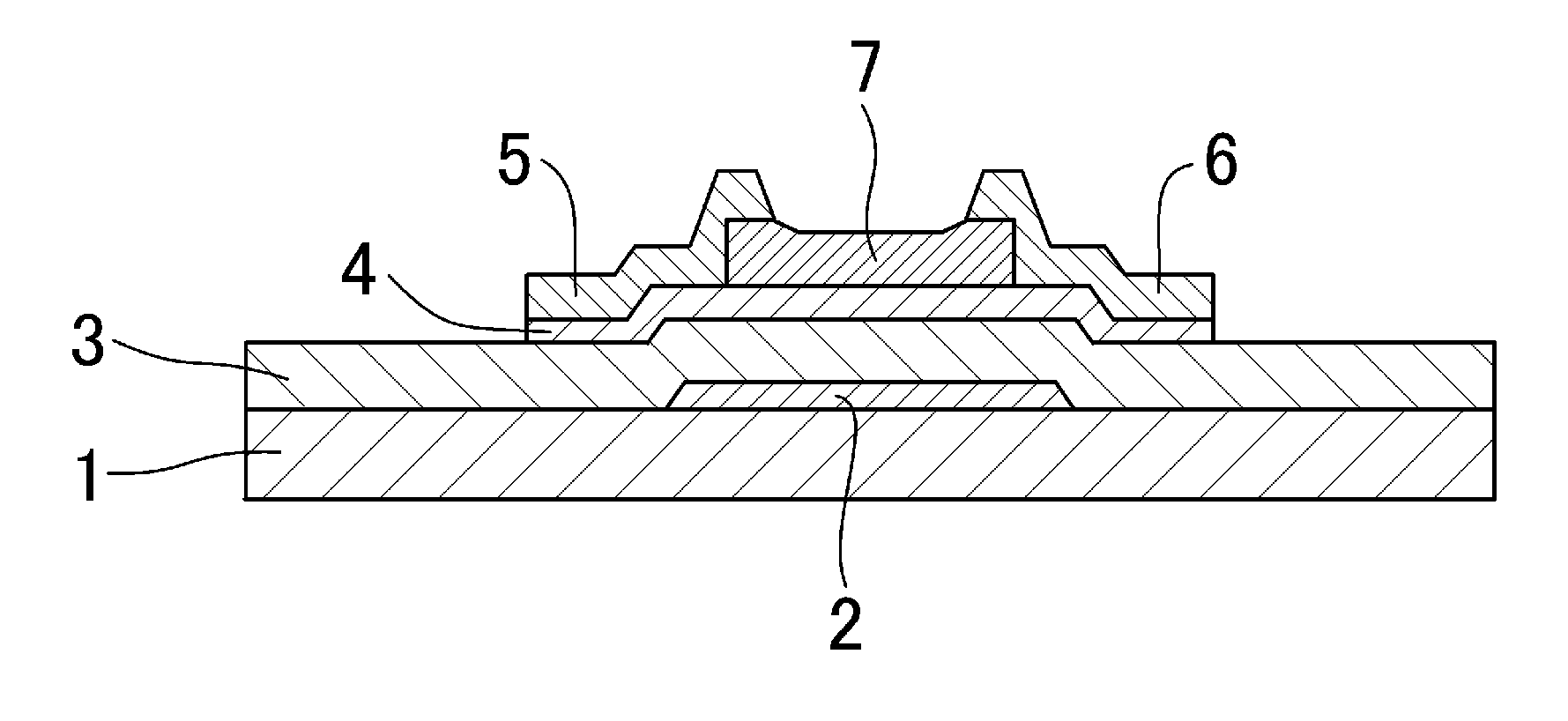

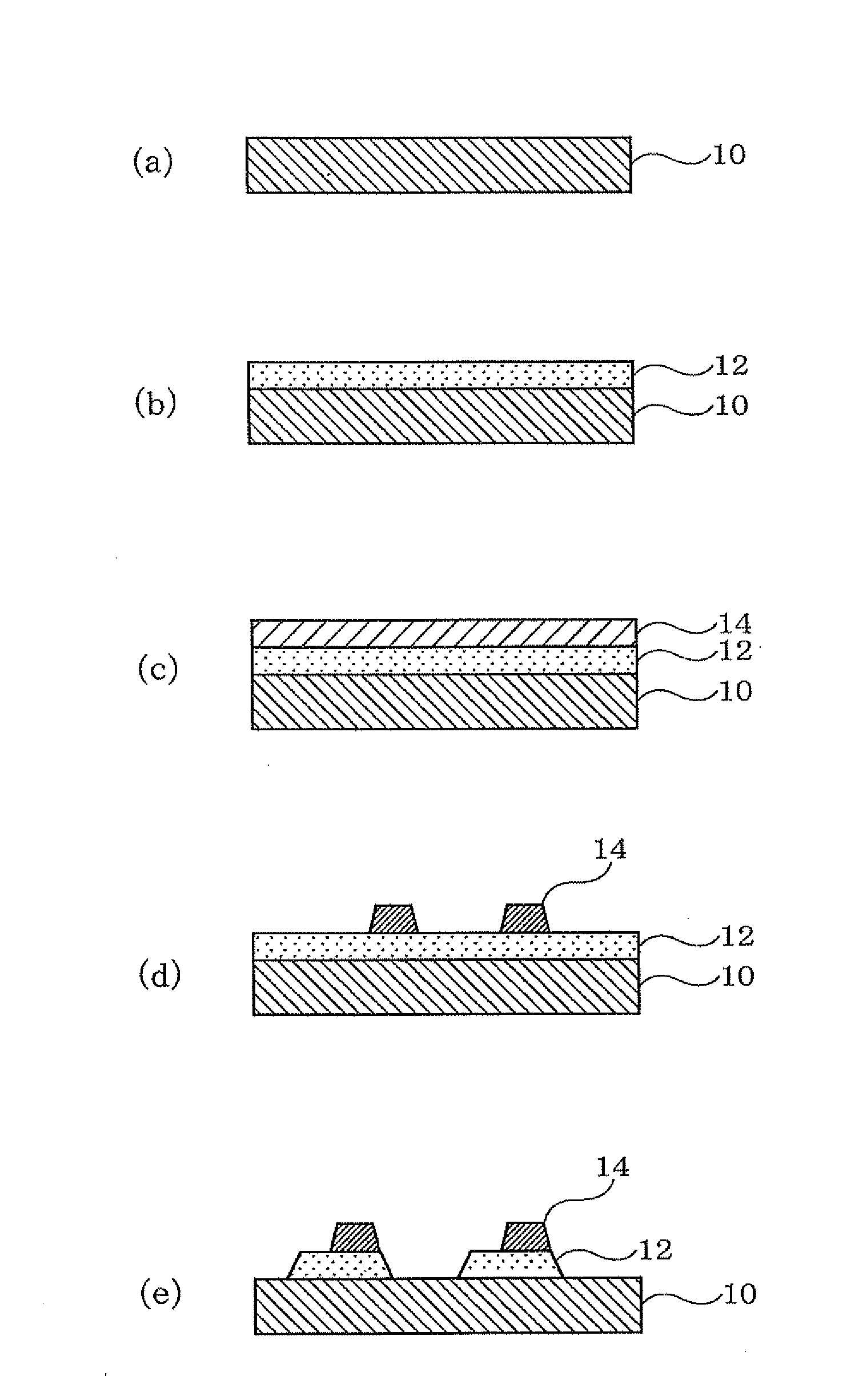

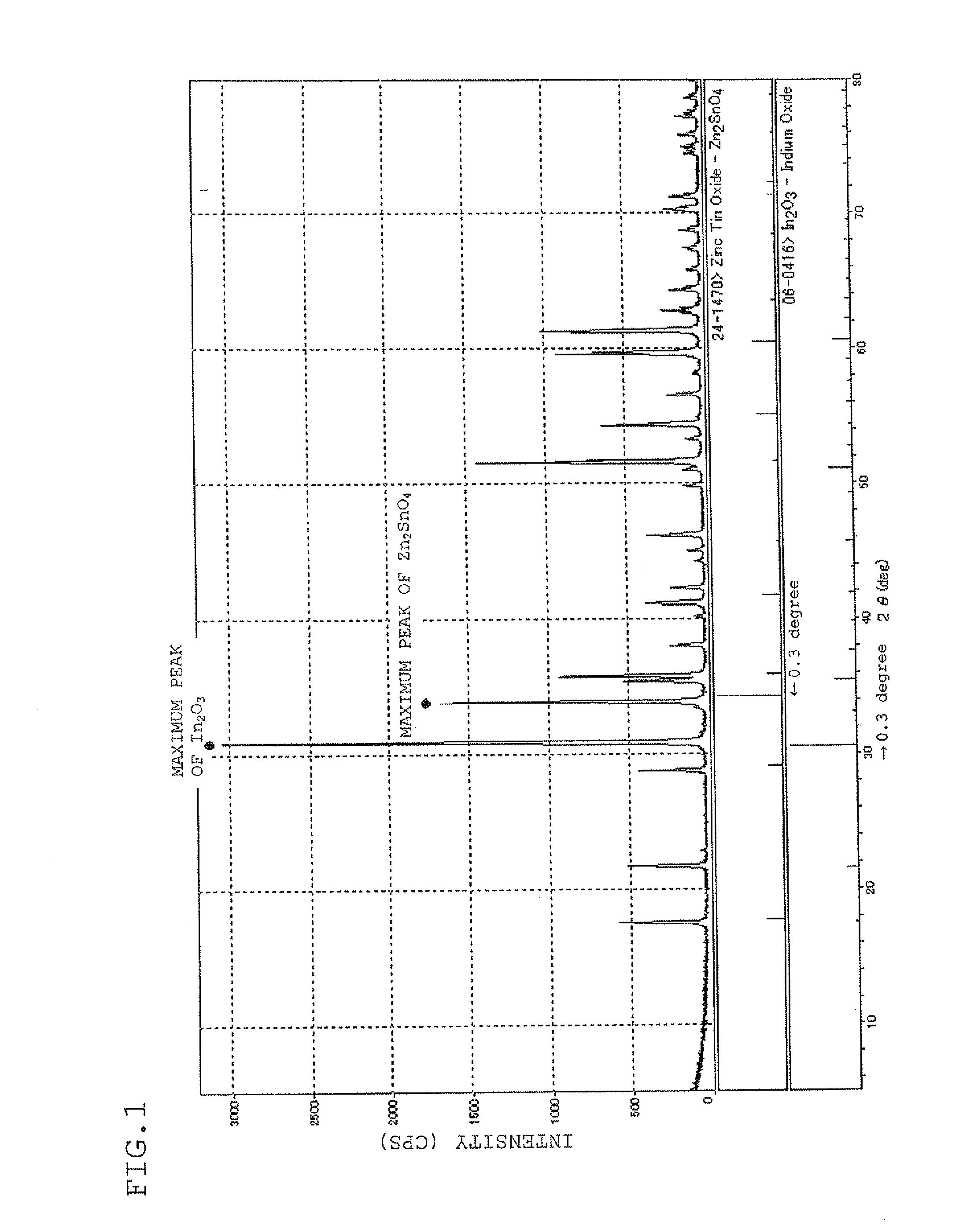

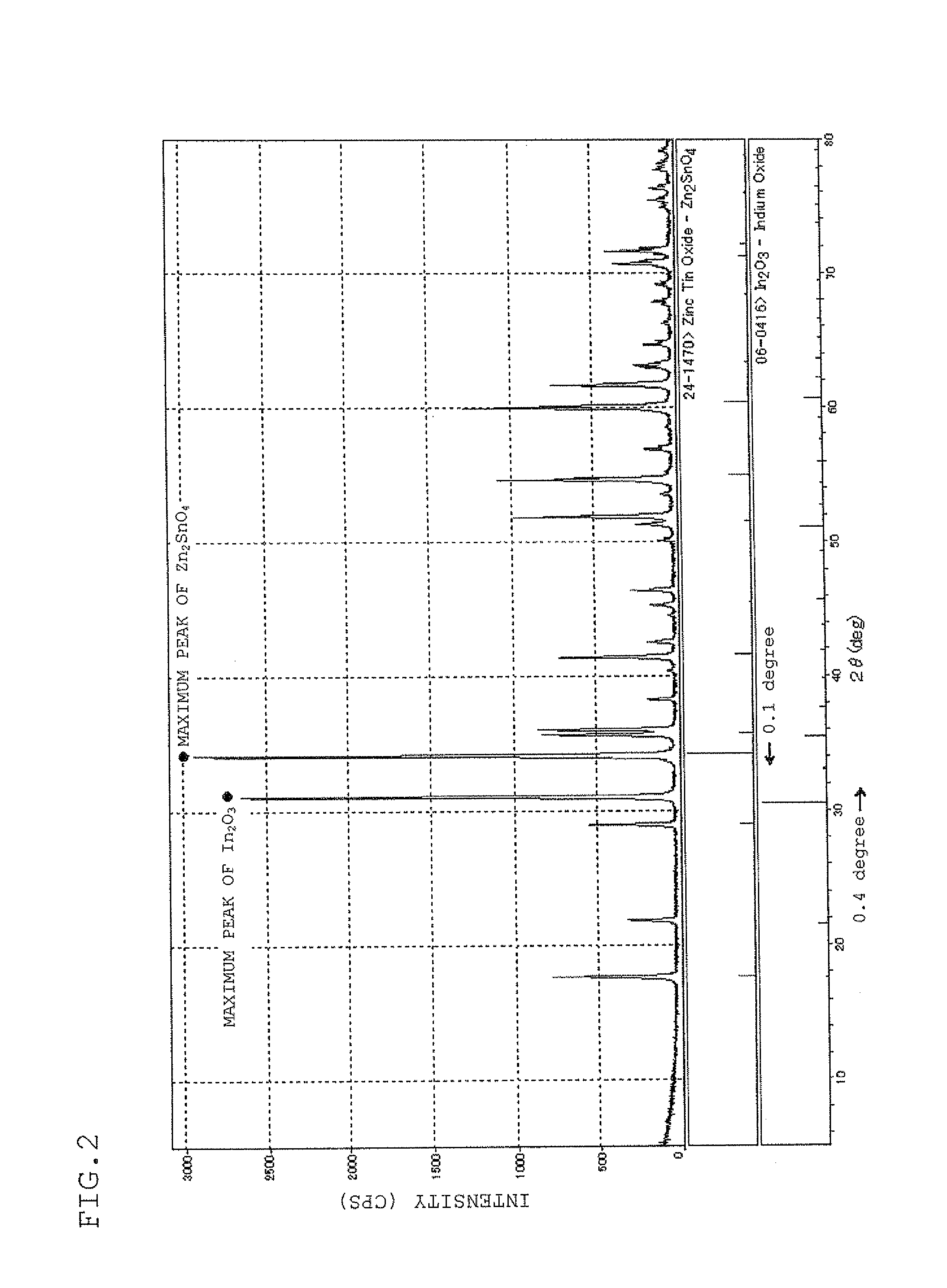

Sputtering target, transparent conductive film and transparent electrode

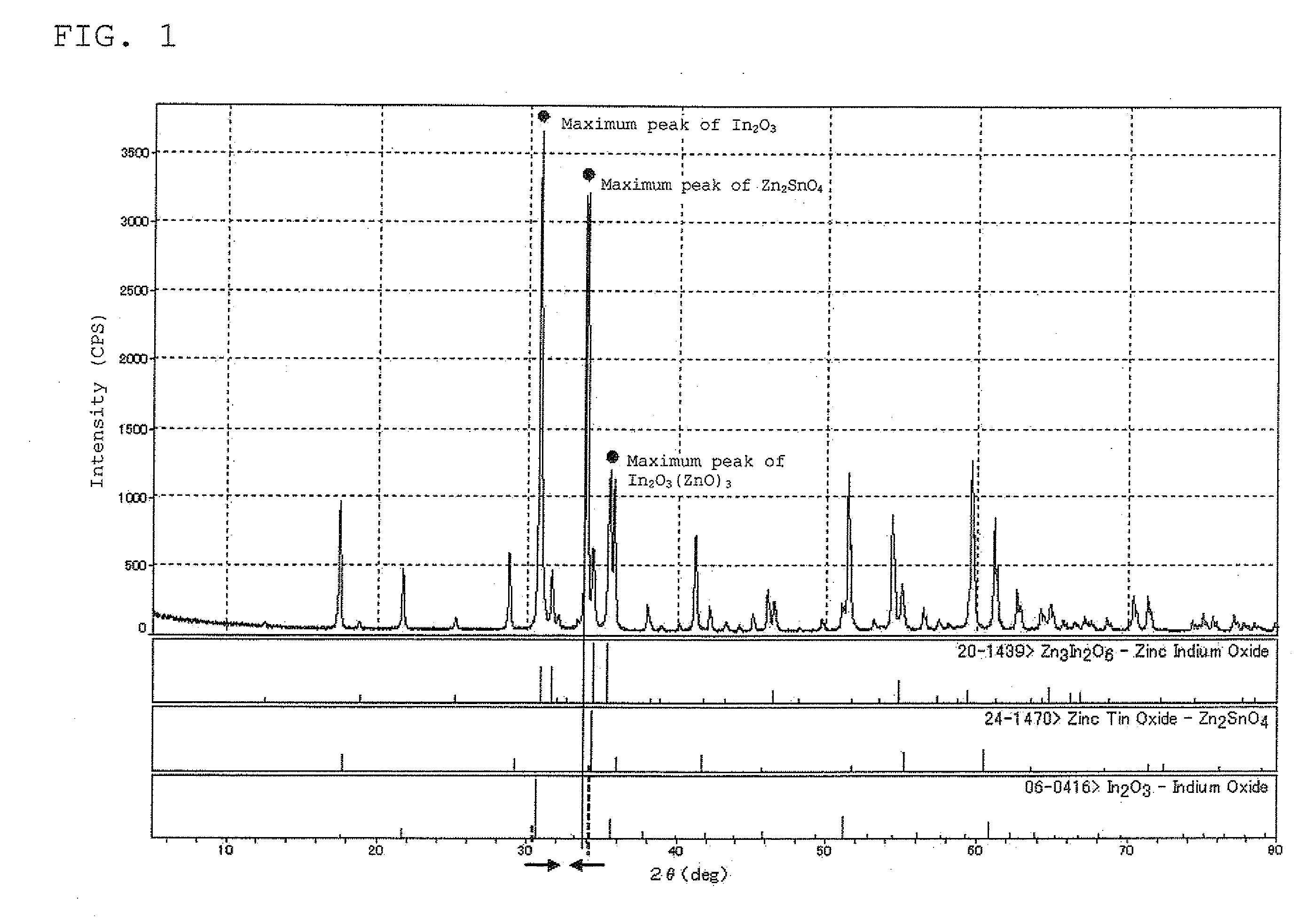

ActiveUS20100170696A1Lower resistanceHigh densityNon-insulated conductorsConductive materialIndiumX-ray

A sputtering target which is composed of a sintered body of an oxide which contains at least indium, tin, and zinc and includes a spinel structure compound of Zn2SnO4 and a bixbyite structure compound of In2O3. A sputtering target includes indium, tin, zinc, and oxygen with only a peak ascribed to a bixbyite structure compound being substantially observed by X-ray diffraction (XRD).

Owner:IDEMITSU KOSAN CO LTD

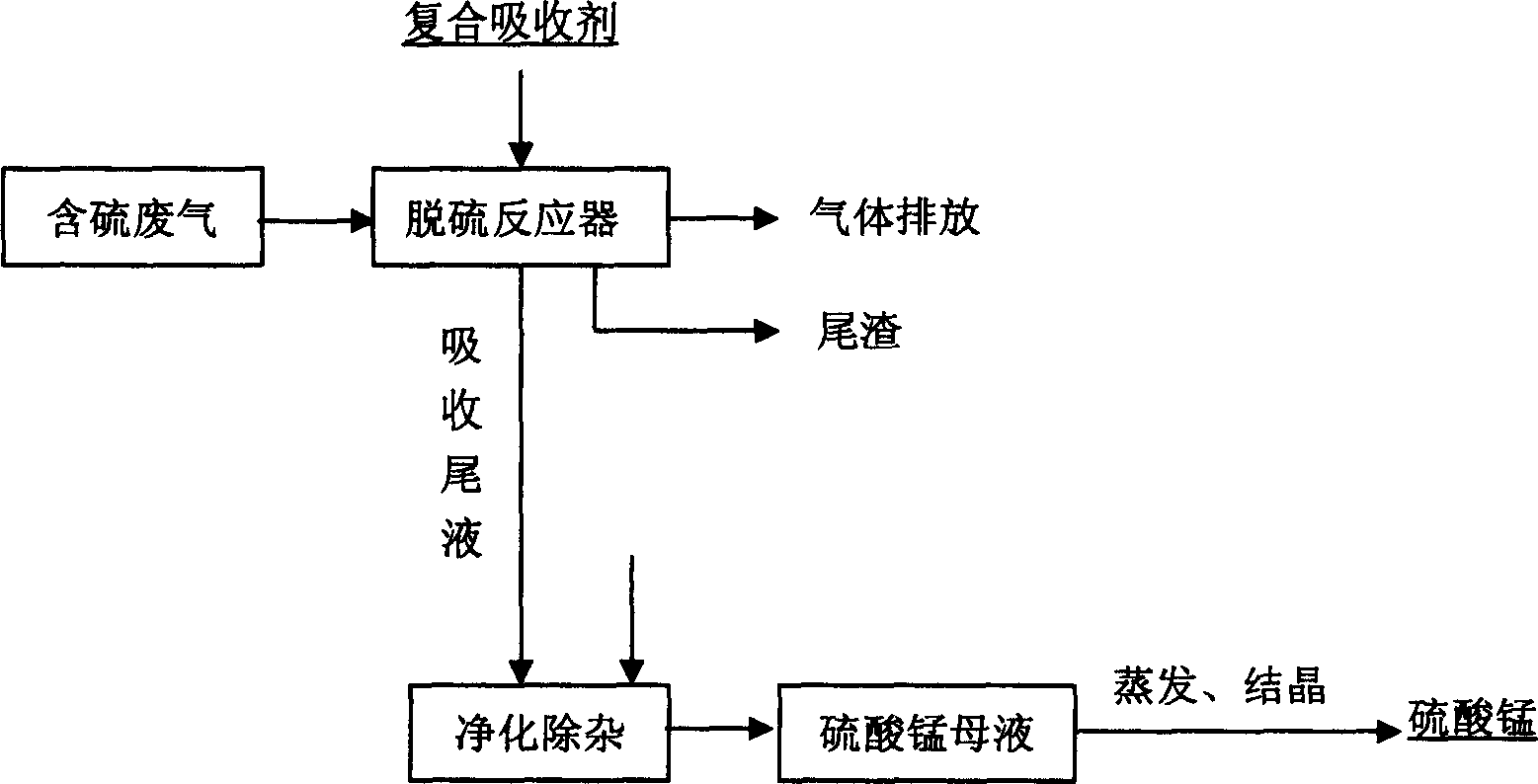

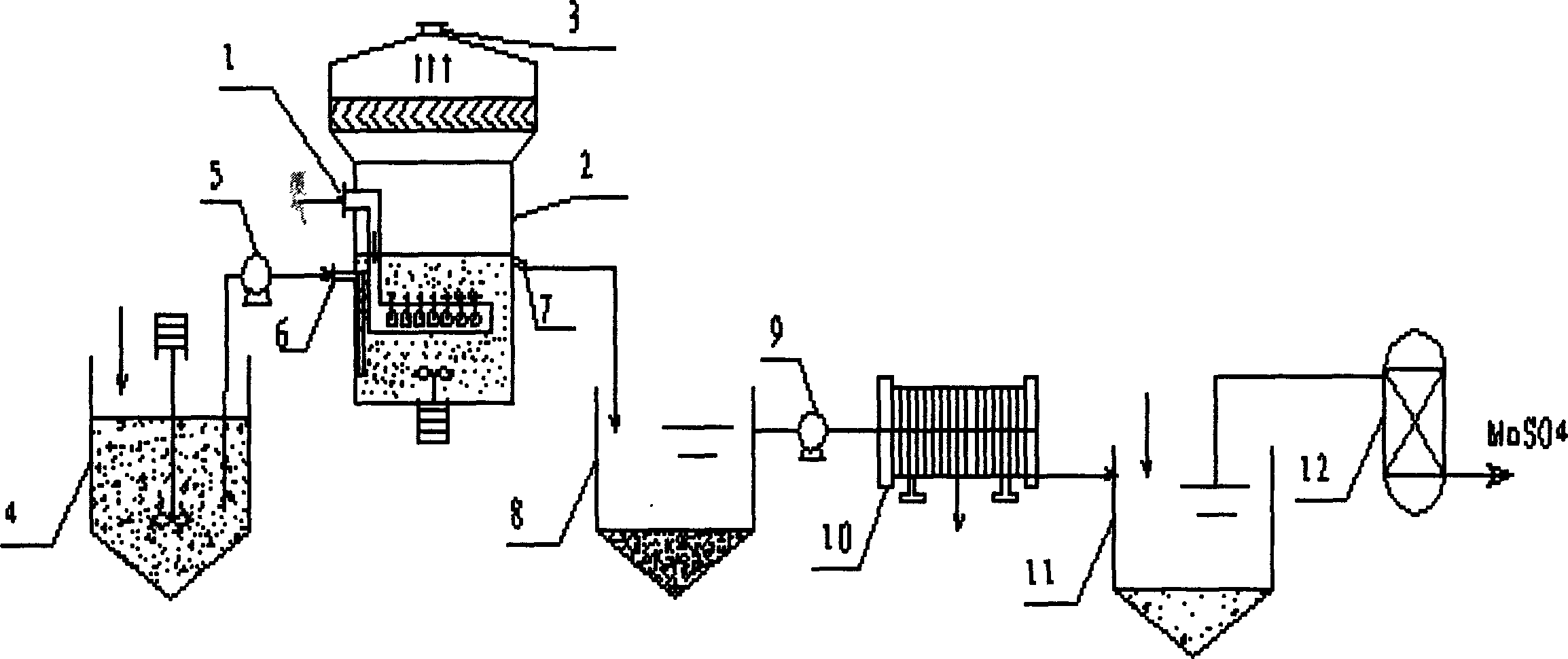

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

Production method for manganese sulfate by using biological cellulose and low-grade manganese ores

The invention discloses a production method for manganese sulfate by using low-grade manganese ores. According to the method, manganese sulfate with high purity can be produced by using waste low-grade manganese ores with manganese content of 10% to 20%, manganese tailing or manganese-containing solid waste residue. The method comprises the steps of preparation of raw materials, a slaking reaction, a leaching reaction, neutralization and purification of leachate, etc. According to the invention, production of manganese sulfate is not restricted by the grade of manganese ores, and low-grade manganese oxide ores with a grade greater than 10%, manganese tailing or manganese-containing solid waste residue can be fully utilized; produced manganese sulfate has high yield and high purity and is a very important industrial fundamental product; almost no external heat supply is needed, low energy consumption is achieved, production cost is low, it does not need to turn over and mix materials in the process of the reactions, the reactions are smooth, no toxic gas is generated, and no environmental pollution is produced; discharge of three wastes (waste gas, waste water and industrial residue) reaches national discharge standards for environmental protection, and there is no dust pollution in a workshop.

Owner:陈昆先 +1

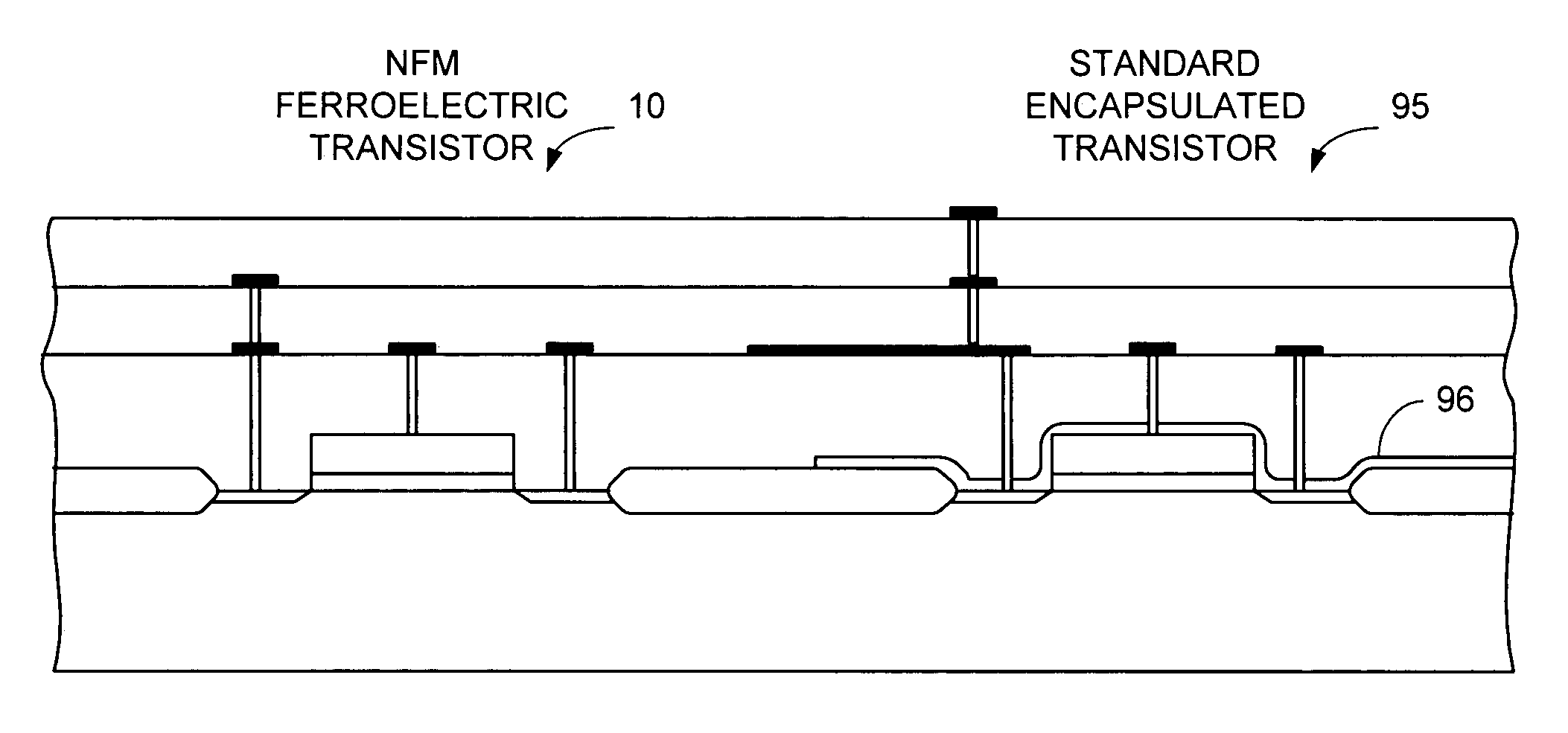

Single transistor rare earth manganite ferroelectric nonvolatile memory cell

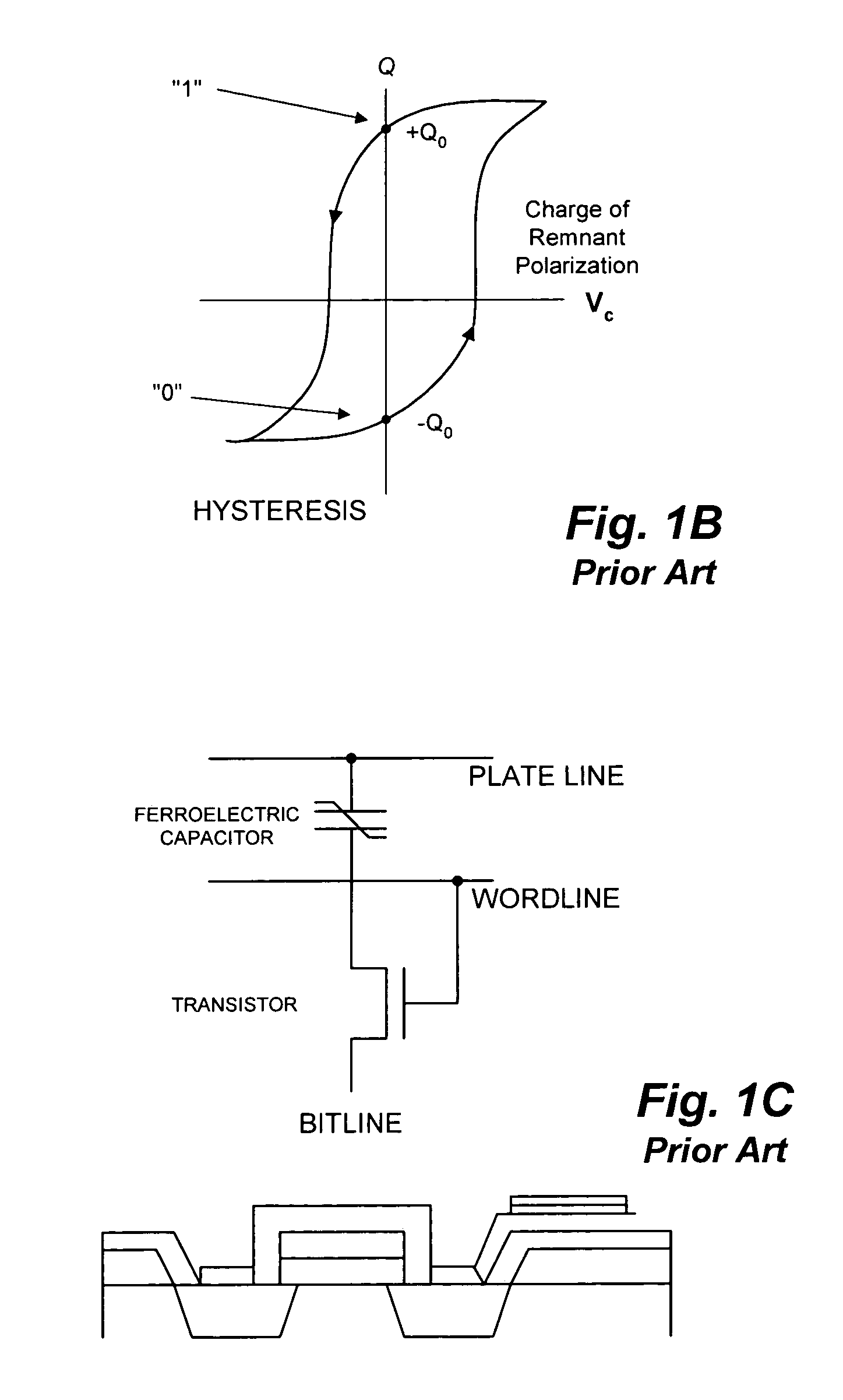

InactiveUS7030435B2Avoid problemsLow vapor pressureTransistorSolid-state devicesInterfacial oxideRare earth

A memory device is formed of the one transistor cell type. Such a device has a substrate, a ferroelectric layer which is a film of rare earth manganite, and an interfacial oxide layer being positioned between the substrate and the ferroelectric layer. The invention includes such a device and methods of making the same.

Owner:COVA TECH

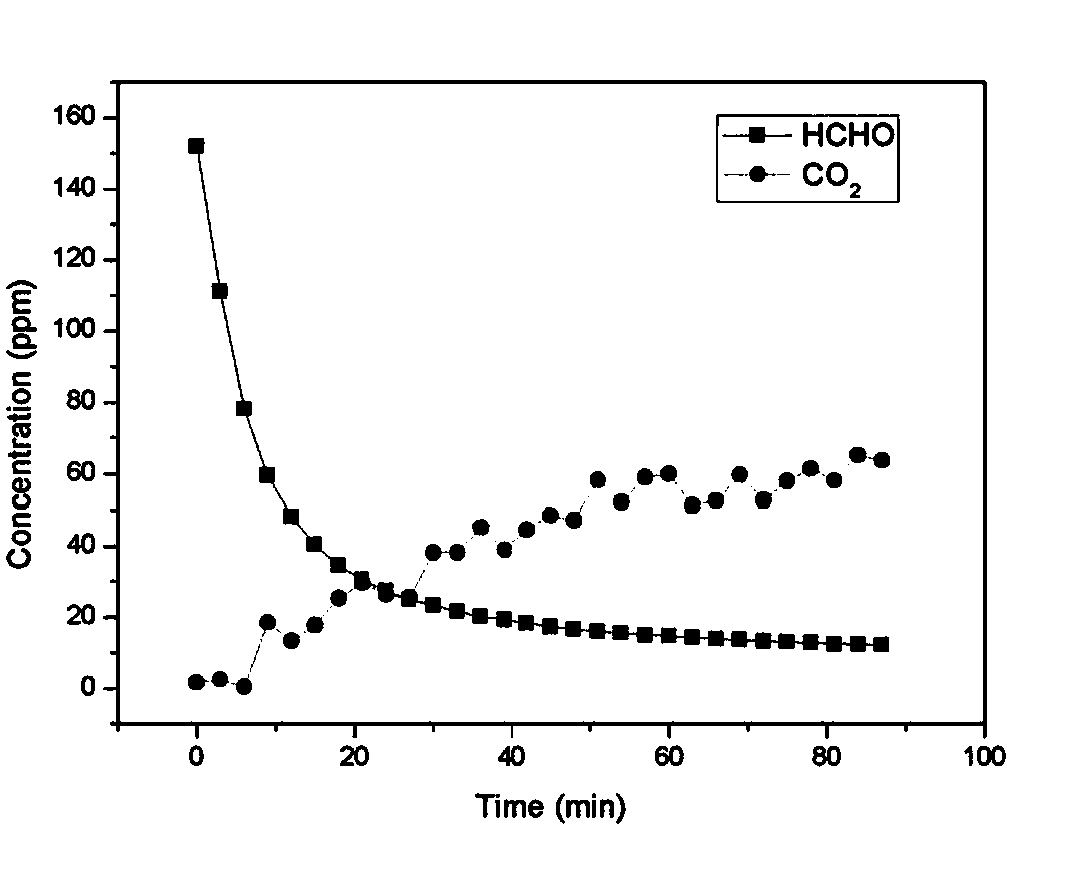

Air purification material and preparation method and application thereof

ActiveCN104190251AEfficient decompositionQuick removalDispersed particle separationFiberParticulates

The invention relates to an air purification material and a preparation method and application thereof, belonging to the technical field of chemical catalytic decomposition, in particular belonging to the technical field of decomposition of formaldehyde pollutants in environment air. The air purification material comprises a base material and manganese oxide, wherein the manganese oxide is supported on the base material, the base material is honeycomb ceramics or a fiber material with a particle filtering function, and the manganese oxide is birnessite manganese oxide prepared from permanganate and oxalate. The air purification material can effectively decompose formaldehyde pollutants in indoor air and can rapidly and constantly remove the formaldehyde pollutants in indoor air at room temperature. The air purification material can be regenerated through heating, so that the service life of the material is prolonged and the practical application is facilitated.

Owner:TSINGHUA UNIV

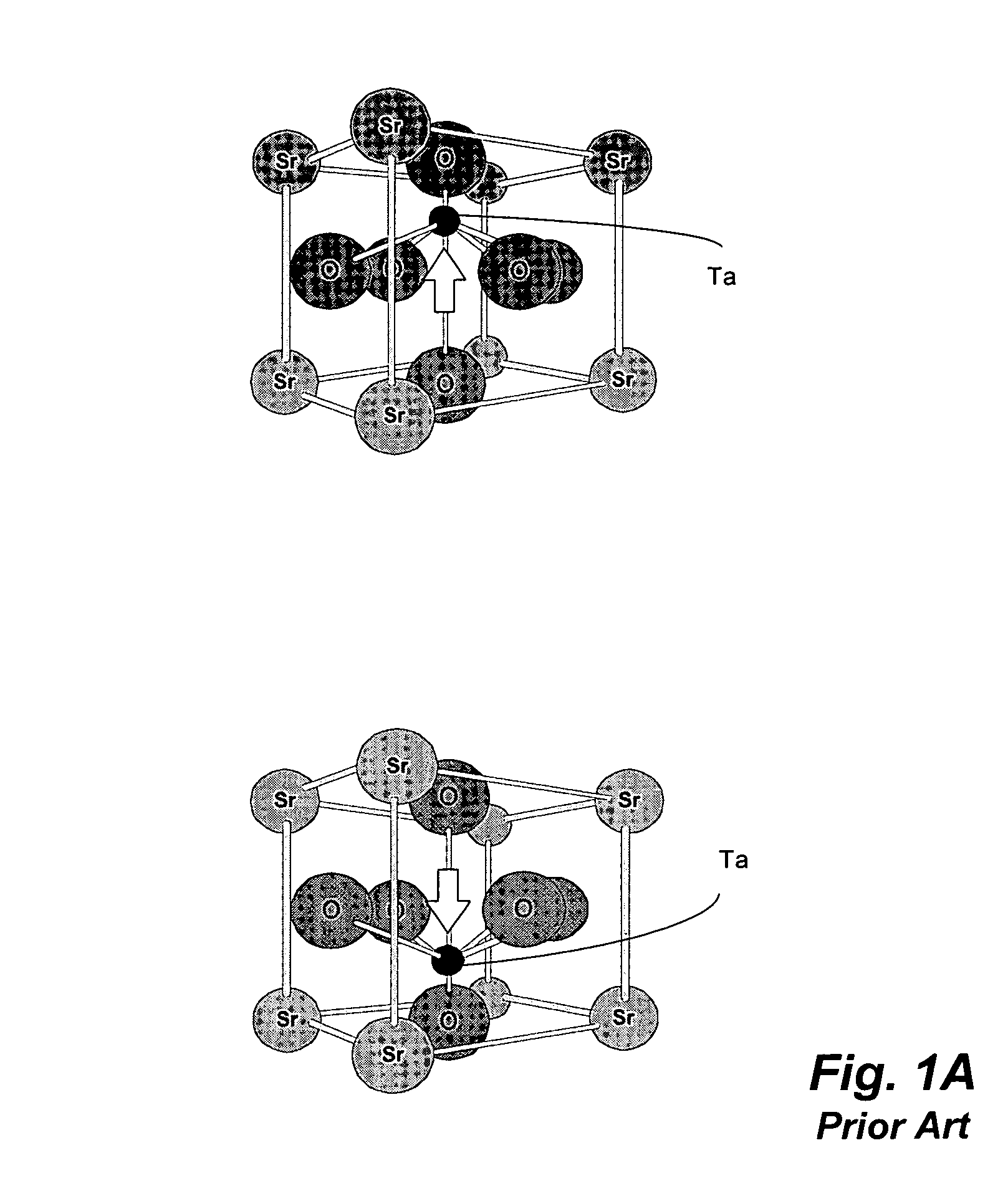

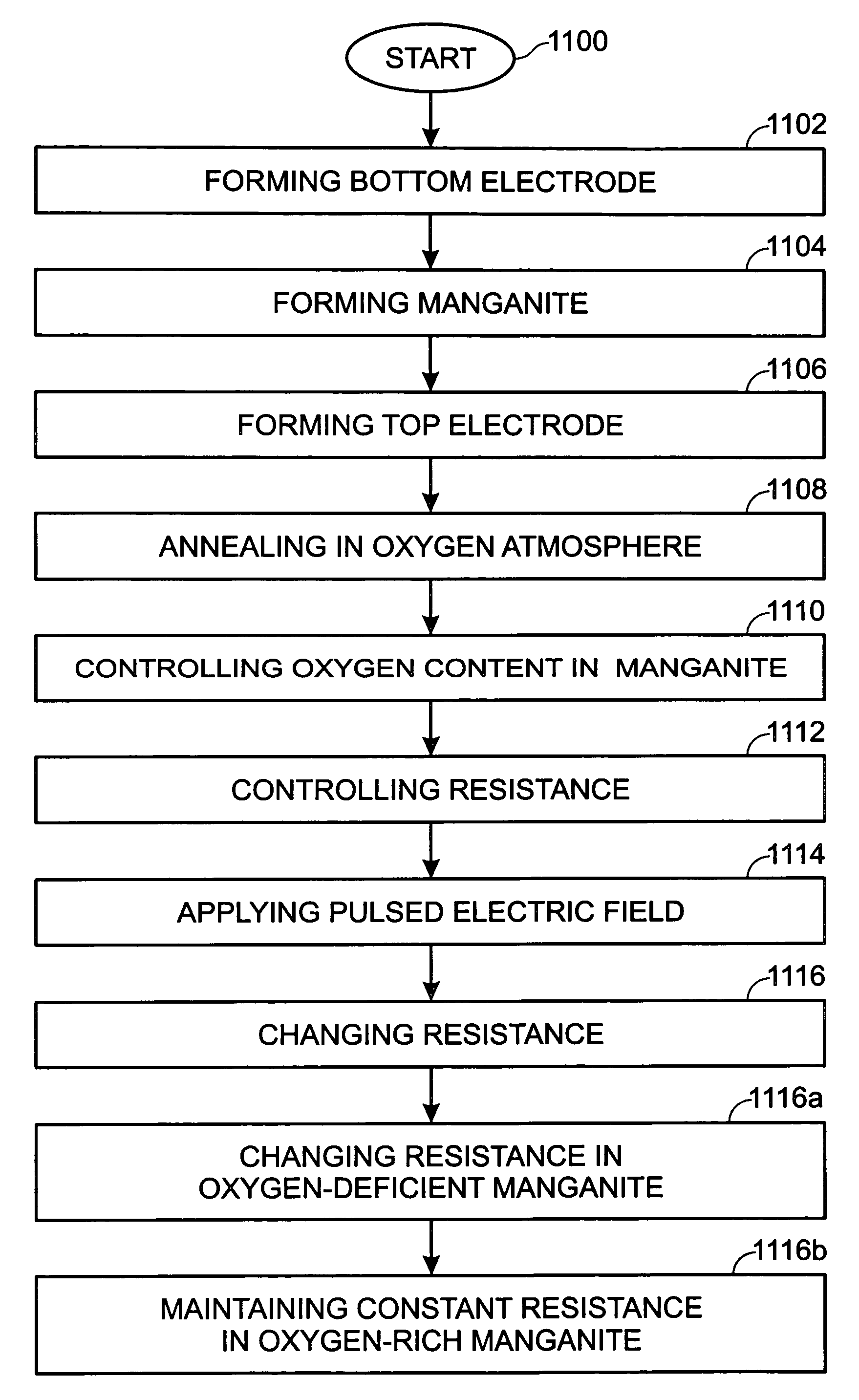

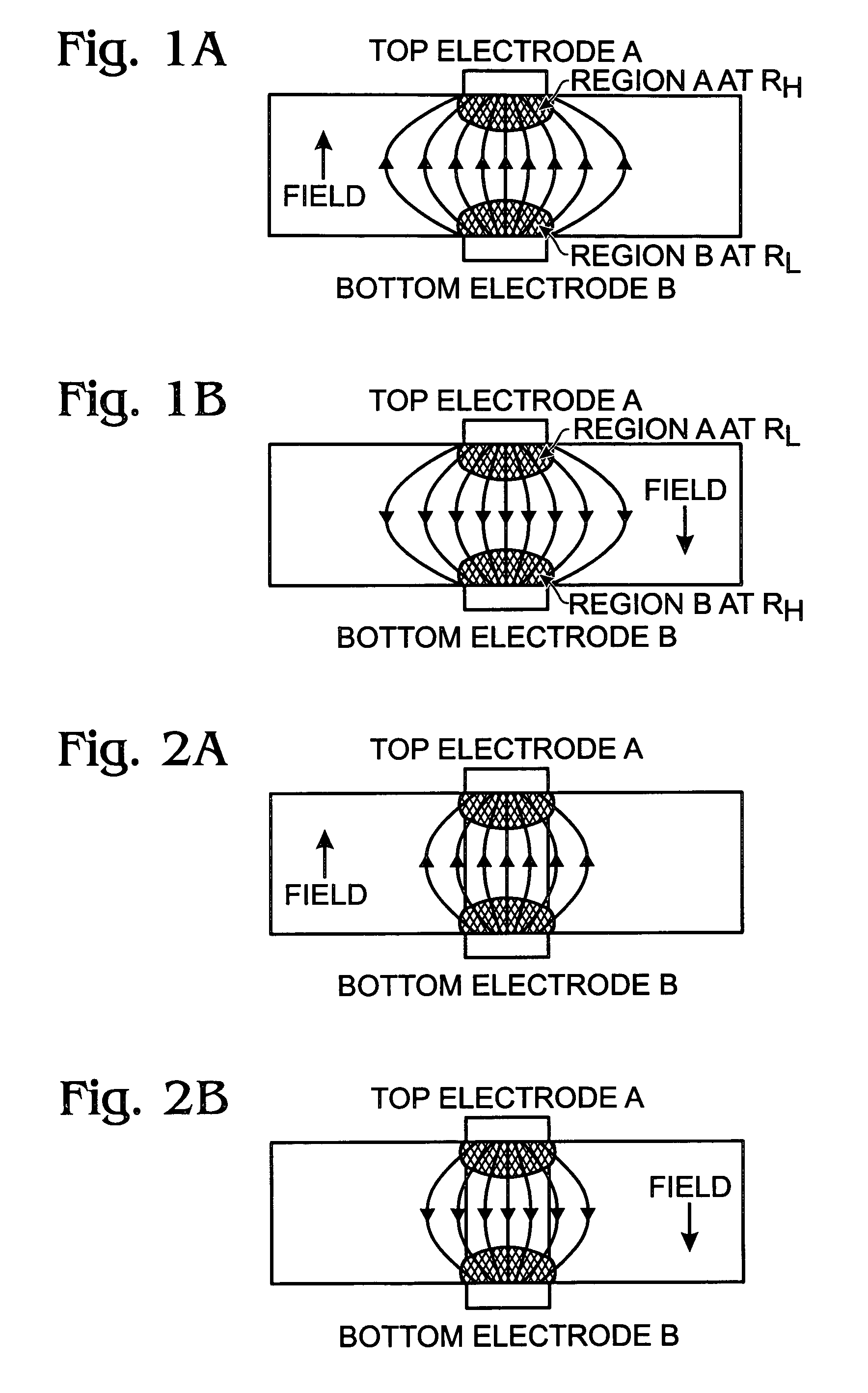

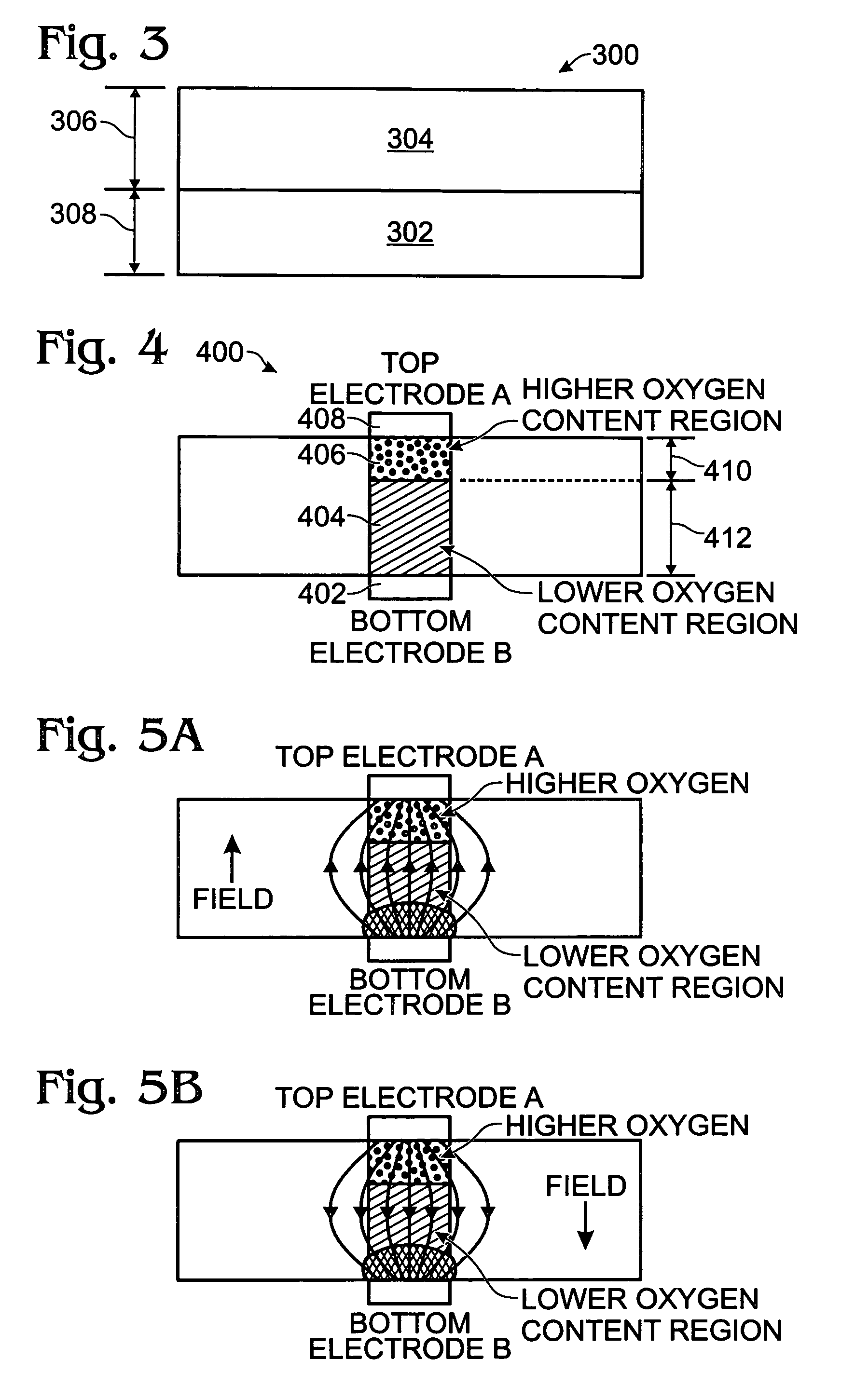

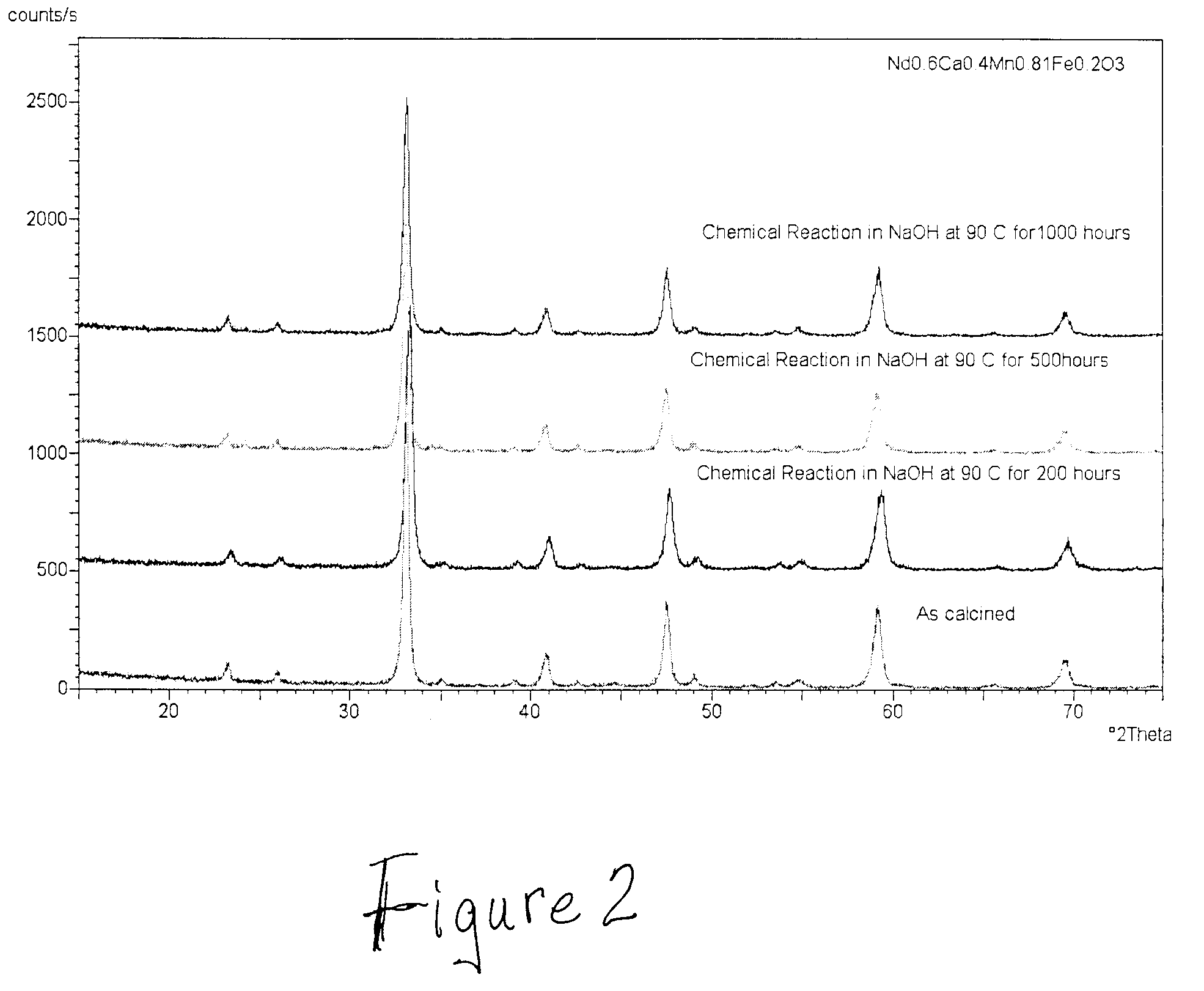

Oxygen content system and method for controlling memory resistance properties

ActiveUS6972238B2Reliably programmedCombustion-air/fuel-air treatmentSolid-state devicesHigh resistanceManganese oxide

A memory cell and method for controlling the resistance properties in a memory material are provided. The method comprises: forming manganite; annealing the manganite in an oxygen atmosphere; controlling the oxygen content in the manganite in response to the annealing; and, controlling resistance through the manganite in response to the oxygen content. The manganite is perovskite-type manganese oxides with the general formula RE1-xAExMnOy, where RE is a rare earth ion and AE is an alkaline-earth ion, with x in the range between 0.1 and 0.5. Controlling the oxygen content in the manganite includes forming an oxygen-rich RE1-xAExMnOy region where y is greater than 3. A low resistance results in the oxygen-rich manganite region. When y is less than 3, a high resistance is formed. More specifically, the process forms a low resistance oxygen-rich manganite region adjacent an oxygen-deficient high resistance manganite region.

Owner:XENOGENIC DEV LLC

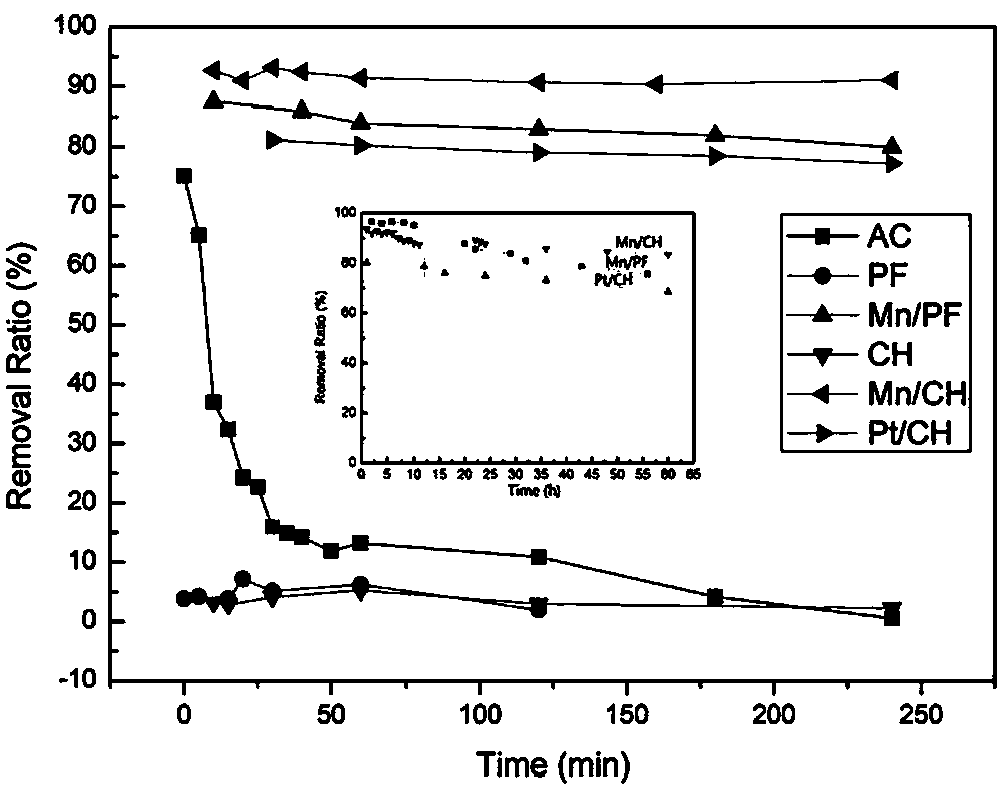

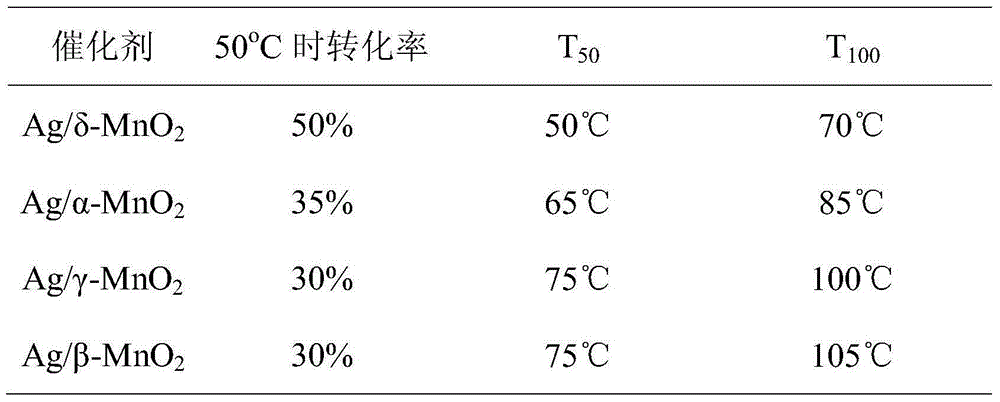

Use of manganite catalyst in catalytic oxidation of formaldehyde

ActiveCN105013322AHigh catalytic activityAchieve full (100%) conversionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMetal catalystManganese

The invention provides a use of a manganite catalyst in catalytic oxidation of formaldehyde. The manganite is gamma or / and delta crystal form manganese dioxide. The delta crystal form manganese dioxide as a formaldehyde catalytic oxidation catalyst has the advantages of 1, a formaldehyde catalytic oxidation ignition temperature is low, a conversion ratio is 37% under conditions of a high formaldehyde concentration of 170ppm, a high airspeed of 100000mL / (g.h) and a temperature of 50 DEG C, conversion is complete at a temperature of 80 DEG C and the activity of the unprecious metal catalyst is high on the list, and 2, stability is excellent, the crystal form before and after catalytic reaction is stable and a catalytic conversion rate is kept in a long-term activity test.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Gas diffusion electrode and catalyst for electrochemical oxygen reduction and method of dispersing the catalyst

An improved gas diffusion electrode composed of a perovskite-type oxide dispersed in a mixture of carbon black and a hydrophobic binder polymer. An improved catalyst for use in the electrochemical reduction of oxygen comprising a perovskite-type compound having alpha and beta sites, and having a greater molar ratio of cations at the beta site. A particularly good reduction catalyst is a neodymium calcium manganite. An improved method of dispersing the catalysts with carbon in a reaction layer of the electrode improves performance of the electrode and the oxygen reduction process. This is provided by adding carbon black to an aqueous solution of metal salts before it is heated to a gel and then to a char and then calcined. Optionally, a quantity of the desired oxide catalyst can be premixed with a portion the carbon before adding the carbon to an aqueous solution of the metal salts to be heated. The amount of premixed metal oxide is chosen in conjunction with the amount of metal salts to provide the desired molar ratio after heating and calcining of the aqueous solution.

Owner:CERAMTEC

Method for extracting high-valence manganese from manganese carbonate ore

This invention has provided one kind of method to leach high price manganese from manganese carbonateore, which belongs to the hydrometallurgy domain. It takes the glucose or the plant biomass and sulfuric acid as reducing agent of high pricemanganese in manganese carbonate ore, adopting microwave radiation glucose to promote high price manganese to revert, the concrete step includes: Takes 1 copy 100-200 sieve manganese carbonateore, add 10 -20 copy water to modulate the pulp; Again add 60% density sulfuric acid to pulp, the load ratio of mineral powder and sulfuric acid is 1: 6 -9; Simultaneously, add glucose or plant biomass, the load ratio of mineral powder and glucose or plant biomass is 10 -15: 1, stir evenly; radiate under 500 -1000W microwave, stir and respond for 4-10min, leach temperature is controlled at 50degree C-60 degree C, then get lixivium by filtering. This invention has the merits of lower reaction temperature, reducing acid consume and reduce leaching time of the manganese ore, high thermal using and respond rapidly.

Owner:CHONGQING UNIV

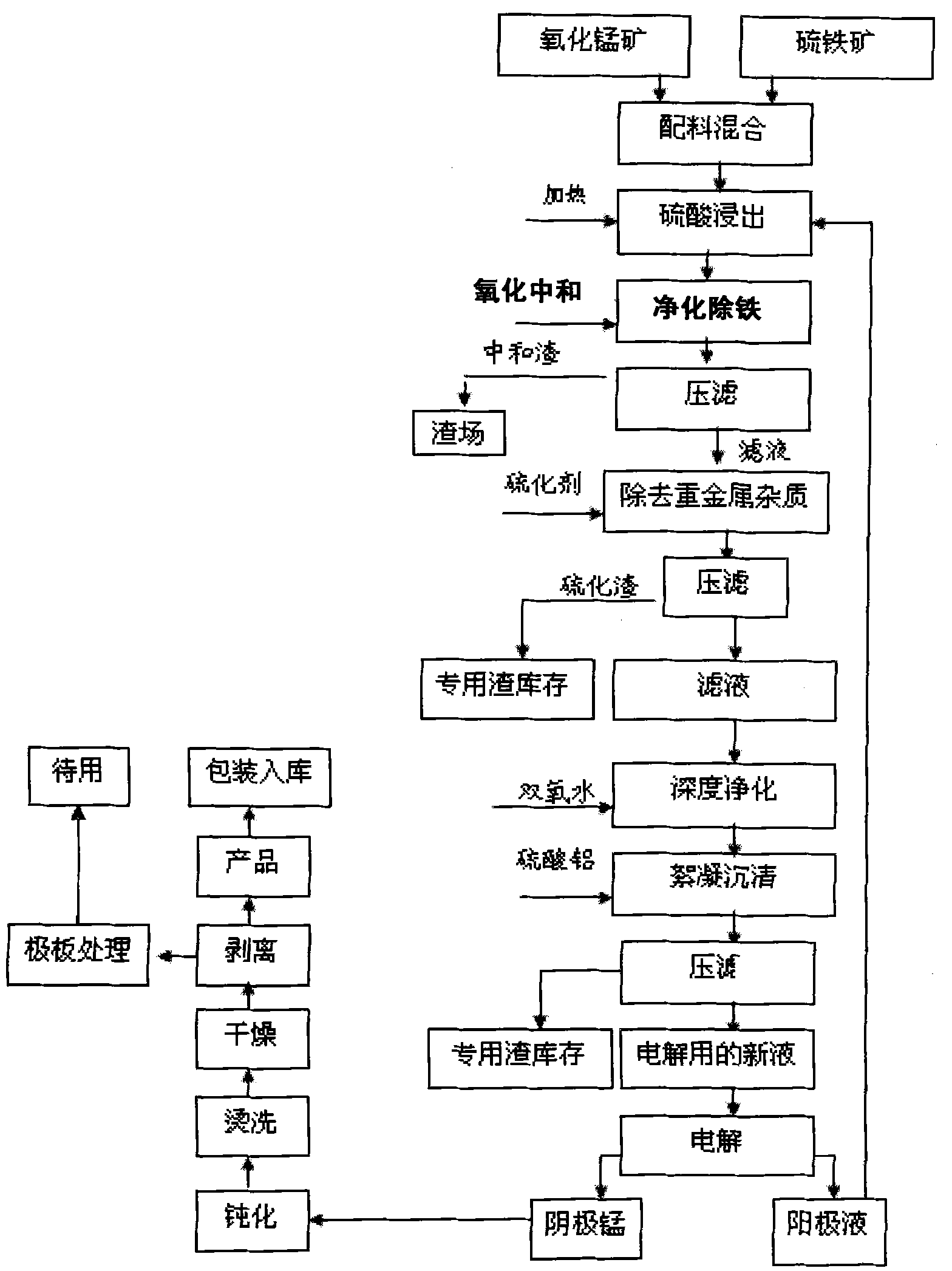

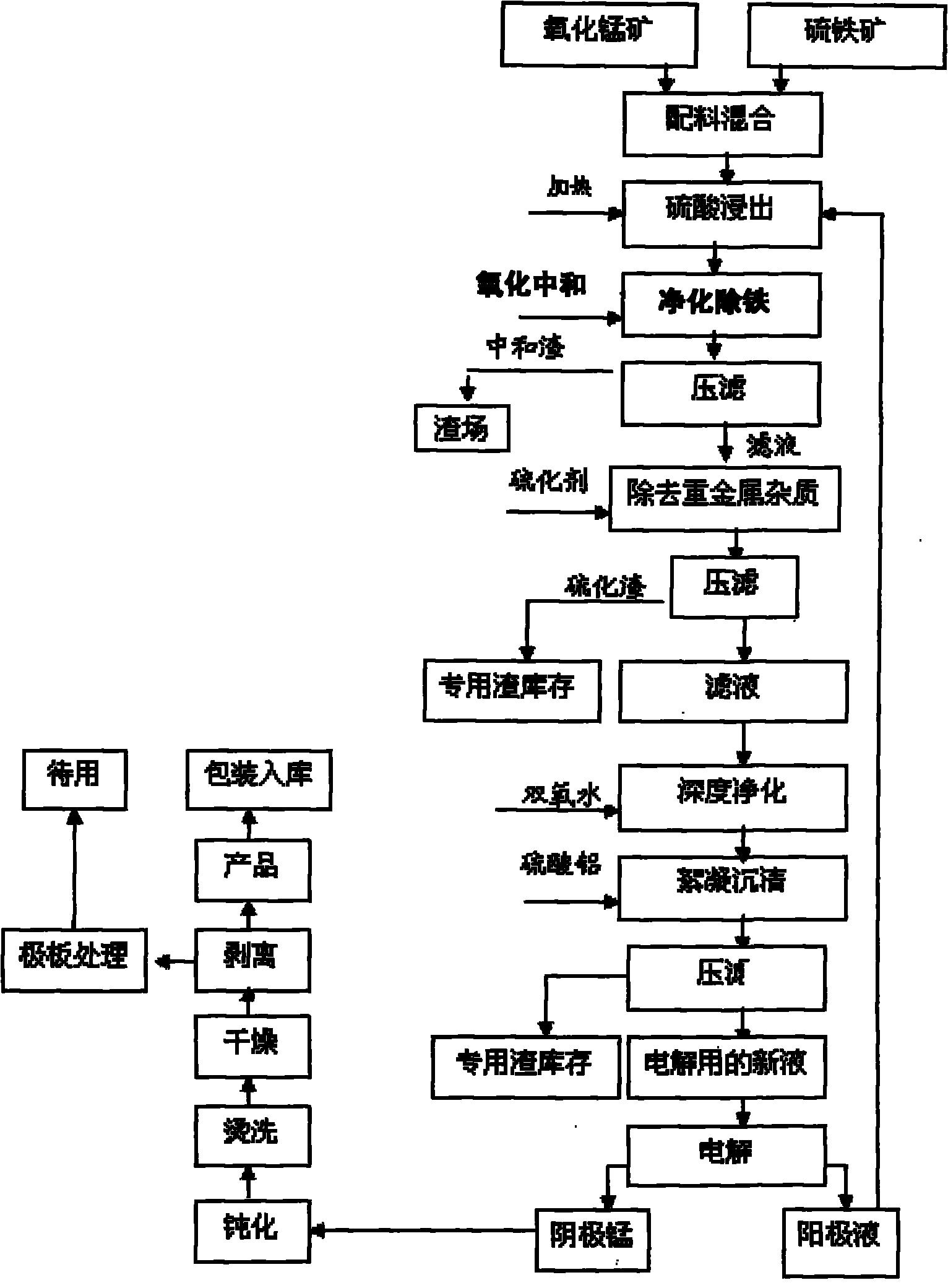

Improved device and method for producing electrolytic manganese metal by two-ore method

InactiveCN101845562AMature production processAdvanced and reliable technologyPhotography auxillary processesProcess efficiency improvementL&D processPyrite

The invention discloses an improved device and method for producing electrolytic manganese metal by a two-ore method. The method comprises the following steps of leaching, purifying, deeply purifying and electrolyzing; and two ore raw materials for electrolyzing the manganese metal by the two-ore method are low-grade manganese oxide ores and pyrite ores respectively, wherein the low-grade manganese oxide ores are with the manganese content of 15-25%, and the pyrite ores are tailings (the pyrite ores) of the mineral dressing of non-ferrous metal ores or primary ores. The method has the advantages that a product contains C and S, has low impurity and short production flow, is used for deeply purifying a manganese sulfate solution to eliminate the influence of reductive impurities in the solution on the electrolytic process, thereby realizing the normal electrolytic production and improving the quality of products. The method especially creates ways for the development and the utilization of low-grade lean manganese oxide ores and tailings (the pyrite ores) of the mineral dressing of non-ferrous metal ore.

Owner:陈宇

Production technology of preparing manganeisen from low grade manganese mine

InactiveCN102382977ANo pollution in the processLow costProcess efficiency improvementTunnel kilnManganese

A production technology of preparing manganeisen from low grade manganese mine. Low grade manganese mine with a metal manganese content of 15-30% is dried, added with reducing agent, catalyst, solvent and bonding agent and mixed well to prepare a composite material; the low grade manganese mine composite raw material is placed in a rotary kiln or a tunnel kiln, heated to 400+ / -80 DEG C by energy of gas or natural gas with an air excess coefficient controlled at 0.9-1.0, with a heating speed of 1-4 DEG C / min at a normal temperature, wherein the furnace is kept in a weak reducing atmosphere, and insulated for 0.5-5 h; then the low grade manganese mine composite raw material is heated to 750+ / -80 DEG C with a heating speed of 2-5 DEG C / min and insulated for 0.5-5h; finally the low grade manganese mine composite raw material is heated to 1100+ / -150 DEG C and insulated for 0.5-6h; gas pressure in the furnace is kept at 0.12-0.15 MPa during heating and insulation; after the reaction, the material is cooled and treated with magnetic separation to obtain the manganeisen and tailings. The manganeisen comprises 15-20% of metal Fe, 65-75% of metal Mn, less than 5% of gangue, 1.0-6.5% of carbon, less than 0.15% of phosphor and less than 0.15% of sulfur, can be used as a raw material for smelting of high-quality manganeisen by a converter or an electric furnace and has low cost and wide application prospect.

Owner:CENT SOUTH UNIV

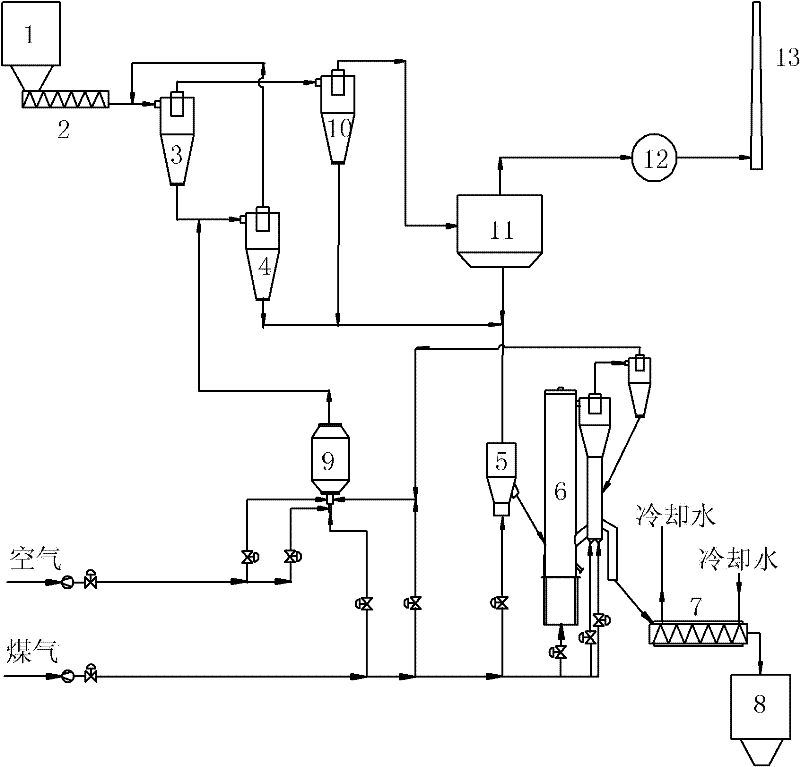

Fluidized low-temperature reduction device and reduction method for powdery manganese oxide ores

The invention relates to a fluidized low-temperature reduction device and a fluidized low-temperature reduction method for powdery manganese oxide ores. The device comprises a feeding unit, a preheating unit, a reduction roasting unit and a cooling unit which are connected from top down, wherein the reduction roasting unit is connected with a combustion chamber; and the combustion chamber is connected below the preheating unit. In the reduction method, tail gas formed in the reduction process enters the combustion chamber combusts with supplementary gas and air to form flue gas; and the flue gas is subjected to countercurrent heat exchange with the manganese oxide ores. The fluidized low-temperature reduction device and the reduction method have the advantages that: the gas can be used as a reducer and also can be used as fuel; and the utilization rate of the gas is 100 percent. In the reduction device, the reduction temperature of the manganese oxide ores is low, so a manganese-containing phase which is insoluble to sulfuric acid is avoided, and heat carried by the manganese oxide ores is reduced by over 30 percent. The manganese oxide ores in a fluidized reduction roasting furnace are in the bubbling fluidized state, the heat transfer efficiency, the mass transfer efficiency and the reaction efficiency are high, the distribution of retention time is uniform, and the reduction rate of the manganese oxide is more than 98 percent.

Owner:深圳中科九台资源科技有限公司

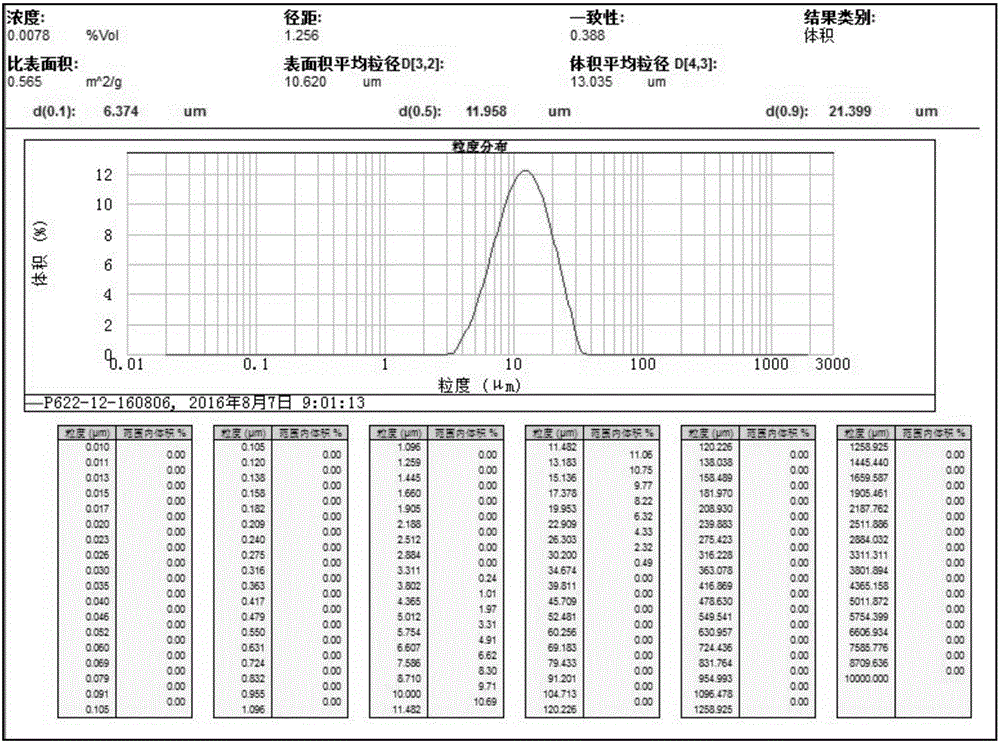

Nickel cobalt lithium manganite precursor of nanosheet agglomeration secondary particle and preparing method thereof

ActiveCN106745336ALarge granularityPromote prolapseMaterial nanotechnologyCell electrodesLithiumMicrometer

The invention provides a nickel cobalt lithium manganite precursor of a nanosheet agglomeration secondary particle. The growth mode inside the precursor is hexagonal nanosheets which are stacked, the side length of the hexagonal nanosheet is 200-500 nanometers, and the thickness is 70-200 nanometers; the particle size of the agglomeration secondary particle D10 is bigger than or equal to 6 micrometers, D50 is equal to 9-15 micrometers, and D90 is smaller than or equal to 30 nanometers. The preparing method of the nickel cobalt lithium manganite precursor of the nanosheet agglomeration secondary particle comprises the steps of firstly preparing a soluble mixed brine solution, adding ammonium hydroxide as a base solution of a reaction kettle, and adjusting the pH of the base solution to be 11-12; inflating nitrogen into the reaction kettle and starting stirring; adding the soluble mixed brine solution, a strong alkaline solution and ammonium hydroxide into the reaction kettle for a stirring reaction, after the reaction for some time, making unqualified feed circularly pumped into the reaction kettle, and aging, compressing and washing an overflowed feed; after washing, drying, screening and storing the material. The nickel cobalt lithium manganite precursor of the nanosheet agglomeration secondary particle is better in uniformity and electrochemical performance; moreover, the product stability is good.

Owner:SHANSHAN ENERGY (NINGXIA) CO LTD

Method for preparing manganese sulfate by reduction leaching of manganese ore using discard molasses and sulfuric acid

InactiveCN1884099AHighlight substantive featuresSignificant progressManganese sulfatesSulfateManganese oxide

The invention discloses a new preparing method of manganese sulfate through manganese oxide in the manganese ore in the leaching manganese ore extracting and manufacturing technological domain, which comprises the following steps: grinding manganese ore; moulding ore paste through water; adding sulfuric acid and waste molasses in the ore paste; stirring at 40-100 deg.c to obtain leaching liquid; neutralizing the leaching liquid through limestone; adding ammonia sulfate to remove heavy metal ion; adding ammonium fluoride solution to remove Ca2+, Mg2+; evaporating; condensing; crystallizing; drying to produce manganese sulfate with over 98 percent purity and 93 percent manganese collecting rate.

Owner:GUANGXI UNIV

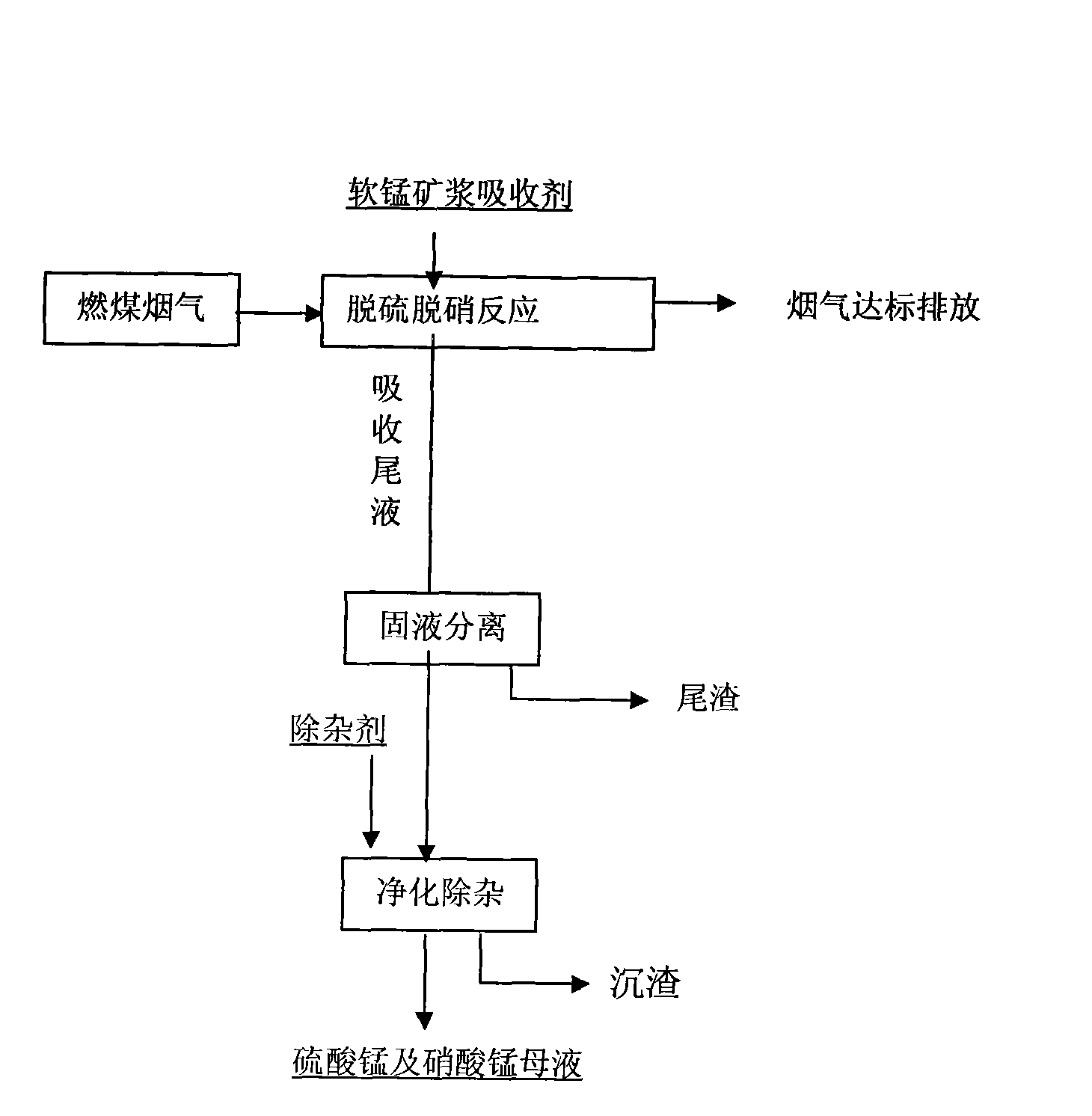

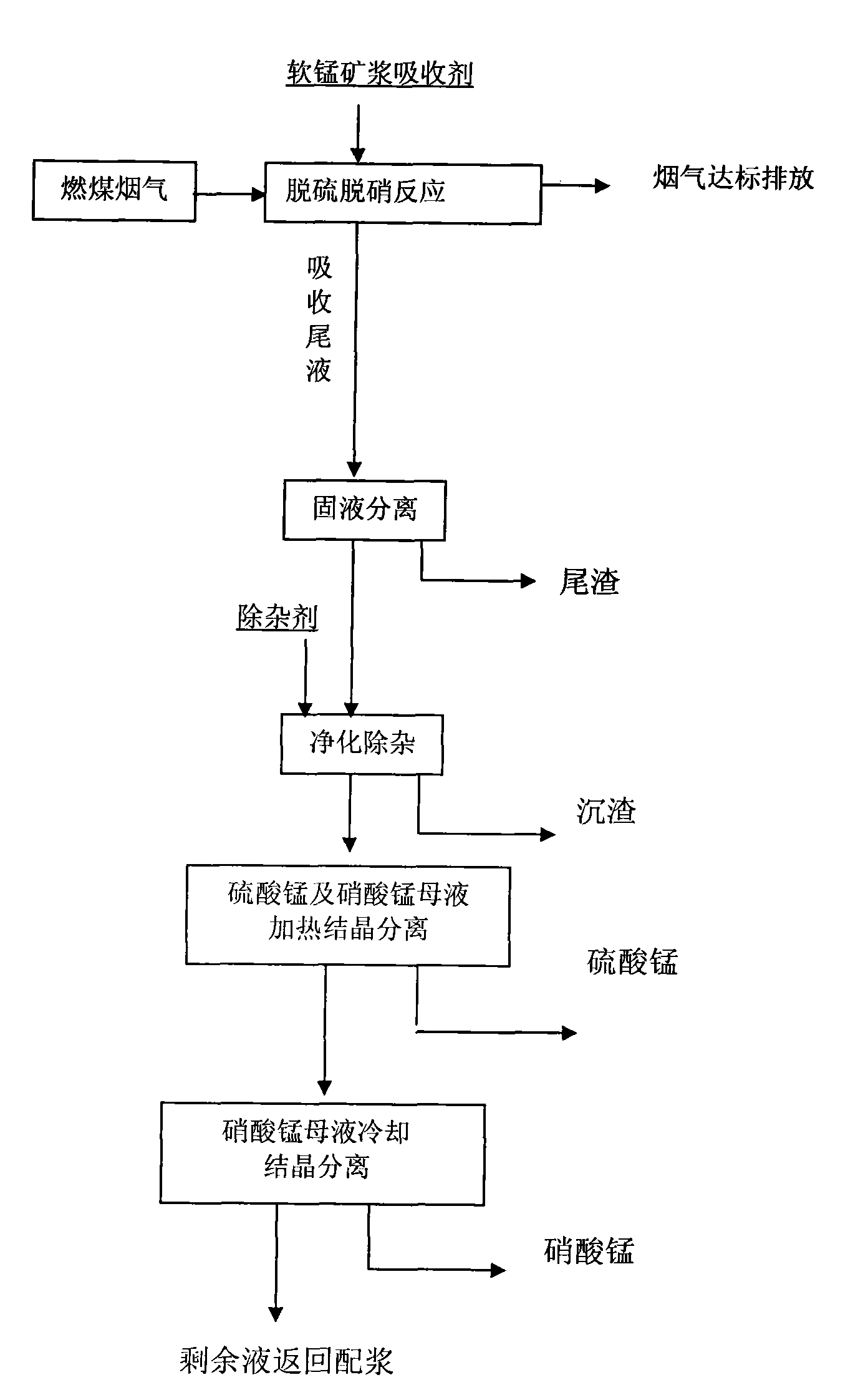

Synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation

ActiveCN101574617ARich reservesLow priceDispersed particle separationProcess efficiency improvementSolubilityPyrolusite

The invention discloses a synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation. The method mainly comprises the following steps: pyrolusite, water and metal-chelator are prepared into pulp which is taken as an absorbing agent; sulfur dioxide and nitrogen oxides in the flue gas are synchronously absorbed and removed by the absorbing agent; the flue gas is discharged when the purification reaches a standard; the primary product of the mixed mother solution of manganese sulfate and manganese nitrate is obtained after absorbing tail solution is purified; and by utilizing the different solubility of manganese sulfate and manganese nitrate at same temperature, the mixed mother solution is heated firstly to cause the manganese sulfate therein to be crystallized and separated, next, the left mother solution is cooled to cause the manganese nitrate therein to be crystallized and separated, and the left solution is returned to preparation pulp for recycling. No waster water is discharged in the whole process, thereby achieving the purposes of controlling waste by waste, recycling sulfur resources and improving the comprehensive utilization value of pyrolusite. The method is characterized by high desulphrization and denitration efficiency and manganese utilization rate, little secondary pollution, obvious economic benefit and the like.

Owner:SICHUAN UNIV

Gray manganese ore leaching out process

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Ceramic binder for steel ball grinding wheel

The invention relates to a structure of a grinding material composited with a novel high-shrinkage engineering ceramic binder for the preparation of a grinding wheel and a preparation method thereof. The preparation method is characterized in that: the high-strength high-shrinkage engineering ceramic binder which is prepared from clay, feldspar, boracic glass, bentonite and manganite is composited with the mixed grinding material, the opacifying effect of the boracic glass promotes the glass nucleation, fluxing agents bentonite and manganite powder promote the preparation of the high-strengthhigh-shrinkage engineering ceramic structure, and the ceramic binder for the steel ball grinding wheel is prepared through carrying out cold-press high-pressure molding, and sintering at a certain temperature. Compared with market products, the strength, the combination degree, the elastic modulus and the linear velocity in usage of the steel ball grinding wheel are greatly improved, the geometric dimension of the steel ball grinding wheel is stable, the steel ball grinding wheel which has a high strength, a high hardness and a uniform tissue density and has the advantages of large grinding ratio, high fineness and no workpiece burning under high speed grinding conditions is a special grinding wheel for a novel high efficiency steel ball. So the steel ball grinding wheel can be widely applied to the mechanical steel ball manufacturing industry and is easy to be automated in the industry.

Owner:江苏华东砂轮有限公司

Production method of electrolytic manganese metal

The invention discloses a production method of electrolytic manganese metal, which sequentially comprises the following steps: (1) simultaneously adding mixed ore powder of manganese dioxide ores, sulfurous iron ores and manganese carbonate ores and sulfuric acid into a leaching combination tank, heating to 90-95 DEG C, performing leaching combination reaction for 4-6 hours, and performing solid-liquid separation to obtain a rough manganese sulfate solution; (2) performing two-stage purification on the rough manganese sulfate solution to remove impurities, wherein in the primary purification process, SDD or BaS is added for impurity removal, and then aluminum sulfate is added for purification; and in the secondary purification process, 10-30% of deep impurity removal agent is added, and then ammonium sulfide is added for zinc removal; reacting for 1-2 hours, checking and regulating the pH value to 6.0-8.0, performing pressure filtration, then transferring into a standing tank, and standing; and (3) injecting the purified manganese sulfate solution into an electrolytic tank, controlling the pH value of an electrolytic tank solution to be 7.0-8.0, and electrolyzing for at least 24 hours to obtain the electrolytic manganese metal product. According to the method disclosed by the invention, manganese ore resources are reasonably utilized, and the production cost is lowered.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

High casting speed continuous casting covering slag used for ultra-low-carbon steel

ActiveCN101530896AAvoid negative effectsReduce carburizationProcess efficiency improvementSteelmakingFire retardant

The invention relates to assistant materials used for continuous casting of steelmaking, in particular to a high casting speed continuous casting covering slag used for ultra-low-carbon steel, comprising pre-melt material and accessory material. The percentage proportion of chemical components of the pre-melt material is as follows: 30 to 40 percent of CaO, 35 to 45 percent of SiO2, 3 to 10 percent of Al2O3, 1 to 5 percent of MgO, 4 to 8 percent of F, 6 to 12 percent of Na2, 0.5 to 3 percent of B2O3, and the rest is micro-impurity contained in the materials. The alkalinity, namely CaO / SiO2, of the pre-melt material is 0.70 to 1.05; the viscosity is 0.2 to 0.5Pa.s; and the pre-melt material is processed by pre-melting. The accessory material comprises 0.7 to 0.9 percent of simple-substance carbon and 0.25 to 1.5 percent of boron flame retardant, wherein a small part of the boron flame retardant is added in the form of borax and the majority of the boron materials is pre-melted into the pre-melt material; and the content of B2O3 in the pre-melted slag is 0.5 to 3 percent. The accessory material also comprises 0.2 to 0.8 percent of CaSi powder and 0.8 to 4.0 percent of manganese minerals. The high casting speed continuous casting covering slag not only can effectively reduce the carburetion of the covering slag to molten steel, but also can avoid negative impact on the metallurgical physicochemical property of the covering slag.

Owner:BAOSHAN IRON & STEEL CO LTD

Recycling method of positive electrode piece of lithium ion battery

InactiveCN105576314AEfficient removalImprove structural propertiesSolid waste disposalTransportation and packagingManganeseSodium-ion battery

The invention discloses a recycling method of a positive electrode piece of a lithium ion battery, aiming at solving the problem of recycling of a nickel cobalt lithium manganite (nickel cobalt lithium aluminate) positive electrode piece and a lithium cobaltate positive electrode piece generated in a production process of the lithium ion battery. According to the technical scheme disclosed by the invention, the recycling method comprises the following steps: 1, crushing the electrode pieces by classes; 2, immersing with an organic solvent; 3, carrying out stirring treatment; 4, filtering with a sieve net; 5, carrying out centrifugal separation; 6, immersing with an alkaline solution; 7, carrying out the centrifugal separation again; 8, drying and removing iron; 9, carrying out ICP (Inductively Coupled Plasma) analysis; and 10, calcining the materials. The recycling method disclosed by the invention can be used for effectively recycling waste materials of the positive electrode pieces of the waste lithium ion batteries, so that the cost is saved; and by immersing with the alkaline solution and carrying out a plurality of times of separation and washing, impurities, such as metal aluminum, in powder grains can be effectively removed. With the adoption of the recycling method, a positive electrode material and an aluminum foil can be completely separated, and the positive electrode material keeps a relatively good structure and electrochemical properties; and the synthesis of a precursor is not needed and the adding amount of a lithium salt is relatively less.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Method for restraining generation of manganous dithionate in process of leaching sulfur dioxide gas out of pyrolusite

The invention discloses a method for restraining the generation of manganous dithionate in the process of leaching sulfur dioxide gas out of pyrolusite, which comprises the following main technical measures: (1) pyrolusite pulp is prepared by stirring and mixing in the proportion that 100-500g of pyrolusite and 0.2-100g of granular active carbon are added into 1L of water; (2) in a synchronous reaction process of absorbing the sulfur dioxide gas by the pyrolusite pulp, desulphurizing and leaching manganese, the pH value of the pyrolusite pulp is controlled to be lower than 3.5 by blowing oxygen or air into the pyrolusite pulp. The method restraining the generation of the manganous dithionate does not need to extra consume sulphuric acid and guarantee an oxido-reduction potential by extra adjusting the concentration of Fe<3+> / Fe<2+>, is easy to meet the requirement of industrial process production and can guarantee the concentration of a manganese sulfate mother liquor.

Owner:成都合众新能源科技有限公司

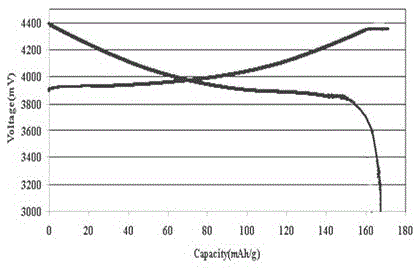

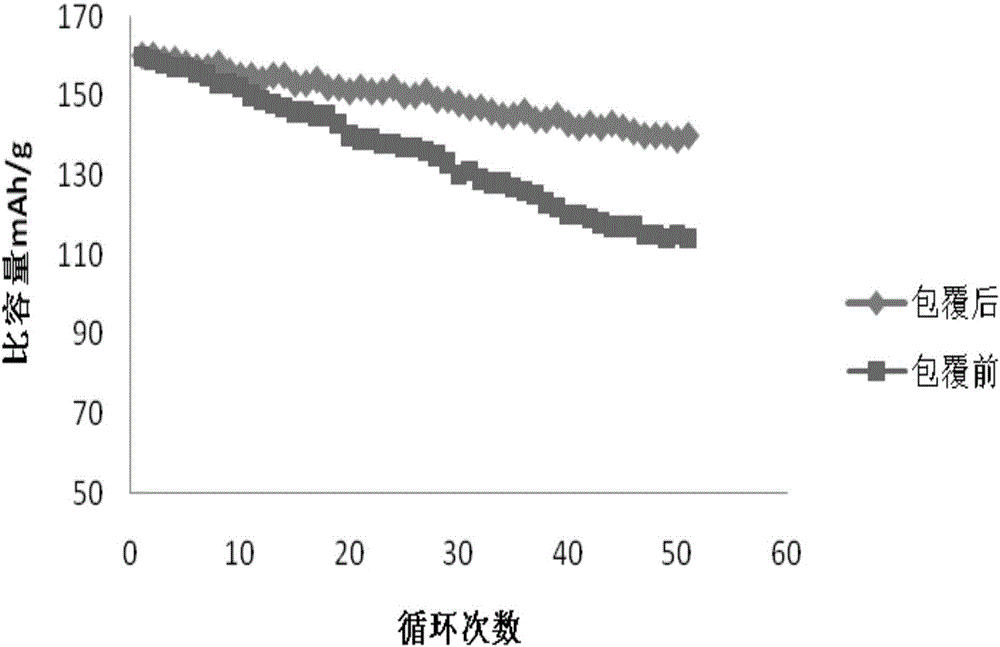

Modified nickel, cobalt and lithium manganite three-element material and preparation method thereof

ActiveCN106299320AImprove cycle performanceLittle changeCell electrodesSecondary cellsCyclic processLithium

The invention provides a modified nickel, cobalt and lithium manganite three-element material and a titanium dioxide layer compounded on the surface of the nickel, cobalt and lithium manganite three-element material. The titanium dioxide layer is creatively compounded on the surface of the nickel, cobalt and lithium manganite three-element material, the surface microstructure change of the NCM three-element material in the first-time charging process is effectively decreased, and the first-cycle efficiency is improved. In addition, due to the fact that titanium dioxide serves as a shell layer and form a core-shell structure with the NCM material, only lithium ions can pass through the titanium dioxide layer, and nickel and manganese ions cannot pass through, dissolution of Ni and Mn in the three-element material in the cycling process is reduced, and the cycle performance of the three-element material is optimized.

Owner:GREE ELECTRIC APPLIANCES INC

Method for producing manganese sulfate from manganese oxide ores

ActiveCN104817116ANo pollution in the processReduce energy consumptionManganese sulfatesDithionateDecomposition

The invention provides a method for producing manganese sulfate from manganese oxide ores. The method comprises the steps of mixing the manganese oxide ore powder with an appropriate amount of carbon reducing agent such as pulverized coal evenly, adding concentrated sulfuric acid without adding water and mixing evenly to obtain a mixture, controlling the initial concentration of the sulfuric acid in the mixture to be greater than or equal to 70%, curing the mixture by use of reaction heat via self-heating reduction and reducing the quadrivalent manganese in the manganese ores into bivalent manganese, mixing the cured material with water for stirring and leaching, and filtering the leached ore pulp to obtain a leachate, adding an appropriate amount of manganese oxide ores to the leachate to realize the oxidative decomposition of manganese dithionate, and performing neutralization, purification and impurity removal and crystallization on the solution obtained by filtering to produce the manganese sulfate. The method has the advantages that the low-cost easily available carbon reducing agent such as the pulverized coal is utilized to directly reduce the manganese oxide ores at a low temperature, and therefore, the energy consumption and the cost are low and the smoke pollution problem of reducing roasting is avoided; the manganese oxide ore powder is utilized to realize the oxidative decomposition of the manganese dithionate in the manganese sulfate solution and therefore, the quality of the manganese sulfate product is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Flotation method of low ore grade manganous carbonate ore

The invention relates to a process that raw mine is ground into powder which is added with water to be prepared into pulp. Under certain pH value, inhibitor of carboxymethylcellulose nano solution, industrial water glass and tannin solution are added proportionally for absorbing calcium, magnesium and silicate. Then, sodium oleate is added as a collector for closed circuit circulation floating. Foam products after the floatation are flushed by water and then enter a sedimentation tank for the sedimentation or the pressure filtration. Thus, manganese concentrate fines above 20 percent are obtained. In the process, floatation is implemented on low grade poor manganese mine containing 10-14 percent of manganese, carbonaceous rock with the manganese content of 4-9 percent and electrolytic manganese leached slags with the manganese content of 1-3 percent to obtain manganese ore fines, the manganese content of which reaches above 20 percent. The recovery of manganese is more than 85 percent. And non-manganese emission for tailings can be realized. The manganese resources are lead to have extremely high utilization rate. Produced products can also lower acid consumption and ammonia consumption for electrolytic manganese production of downstream industry of manganese mines.

Owner:HUAYUAN QIANGHUA MINING

Sputtering target, transparent conductive film and transparent electrode

ActiveUS20110121244A1High densityConductive materialVacuum evaporation coatingIndiumTransparent conducting film

Owner:IDEMITSU KOSAN CO LTD

High activity deoxidant, and its preparing method

ActiveCN101003014ALarge capacityExtend the life cycleNitrogen purification/separationOther chemical processesOxygenHigh activity

A high-activity deoxidant for the deep deoxidization of N2, H2, CO, CH4, C2H4, C3H6, etc is composed of active component (the low-valence oxide of Mn and Fe) and the carrier chosen from cement, gypsum, kaolinite, alumina, diatomite, etc. Its preparing process is also disclosed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for treating ammonia nitrogen wastewater

ActiveCN101559988AEasy to desorbLow costOther chemical processesCombustible gas purificationPyrolusiteSorbent

The invention provides a method for treating ammonia nitrogen wastewater, which relates to a method for treating the ammonia nitrogen wastewater by using an adsorption method. The method is characterized in that in the treating process, a natural manganese mineral is used as an adsorbent to perform adsorption reaction with the ammonia nitrogen wastewater so as to remove the ammonia nitrogen in thewastewater. The natural manganese mineral is crushed into a manganese mineral adsorbent of 0-2 millimeters, the pH value of the wastewater containing the ammonia nitrogen is adjusted to be between 2and 12 by using acid or alkali, then the manganese mineral adsorbent contacts and is mixed with the ammonia nitrogen wastewater to perform adsorption, and the adsorption can be performed by adopting afixed bed adsorption column or in a stirring and mixing mode. When the fixed bed adsorption column is adopted for adsorption, the manganese mineral after being crushed is classified to remove fine particles for the best so as to improve the permeability of the adsorption column; and in the same way, when the stirring and mixing mode is adopted, the manganese mineral after being crushed is classified to remove coarse particles for the best so as to reduce the abrasion to equipment. The natural manganese mineral applicable to the method comprises a terrestrial manganese oxide mineral, an oceanpolymetallic nodule, an ocean cobalt-rich incrustation and a terrestrial manganese nodule, the natural manganese minerals usually contain manganese minerals of cryptomelane, todorokite, birnessite, vernadite, rancieite, pyrolusite and the like, have good pore structure and large specific surface area so as to have good adsorption property, and can be used as the adsorbent for treating the ammonianitrogen wastewater after being crushed into certain particle size, and the manganese minerals have the advantages of simple process, easy reproduction and stable performance.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for dry desulfurization and demercuration of sintering flue gas containing mercury by means of low-grade pyrolusite

InactiveCN105688647AReduce the cost of desulfurization and mercury removalSpeed up entryGas treatmentDispersed particle separationPyrolusiteFlue gas

The invention discloses a method for dry desulfurization and demercuration of sintering flue gas containing mercury by means of low-grade pyrolusite. The method comprises the steps that 1, the low-grade pyrolusite is obtained and placed in a reactor; 2, dedusting is conducted on the sintering flue gas to remove dust containing sulfur and mercury in the sintering flue gas, then the dedusted sintering flue gas with the temperature of 100-200 DEG C is introduced into the reactor at the flow rate of 1-8 L / min to enable the sintering flue gas to make contact with the low-grade pyrolusite, SO2 in the sintering flue gas reacts with the low-grade pyrolusite to achieve desulfurization, and residual mercury in the sintering flue gas is adsorbed by pyrolusite to achieve demercuration; 3, the sintering flue gas subjected to desulfurization and demercuration is directly discharged through an exhaust port of the reactor. The method has the advantages that desulfurization and demercuration cost is low, desulfurization and demercuration efficiency is high, the process is simple, and the recovery rate of byproducts is high.

Owner:GUIZHOU UNIV

Direct production of electron grade high purity trimangnese tetraoxide from ores

InactiveCN1644513AImprove resource utilizationImprove product qualityManganese oxides/hydroxidesOxygenManganese oxide

Production of electronic high purity manganic manganous oxide by manganese oxide ore is characterized by taking manganese oxide ore as materials, immersing manganese from manganese oxide ore under ordinary pressure and temperature by sulfur dioxide, removing iron, copper, nickel, lead heavy metal ion in manganese sulfate mother liquid, obtaining purified manganese sulfate solution, coordinating the ammonia water and ammonium acid carbonate, depositing manganese, obtaining hydrated manganic hydroxide and manganese carbonate mixture, high temperature roasting the mixture, cooling washing for 3-5 times, drying to obtain manganic manganous oxide or inducing directly the purified manganese sulfate solution into ammonia water, regulating pH value 8-10 with solution temperature 50-70deg.C, inducing the dried air or oxygen for 6-9hrs, washing 3-5 times, filtering, drying to obtain manganic manganous oxide . It achieves low cost, high utilizing rate and product purity.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com