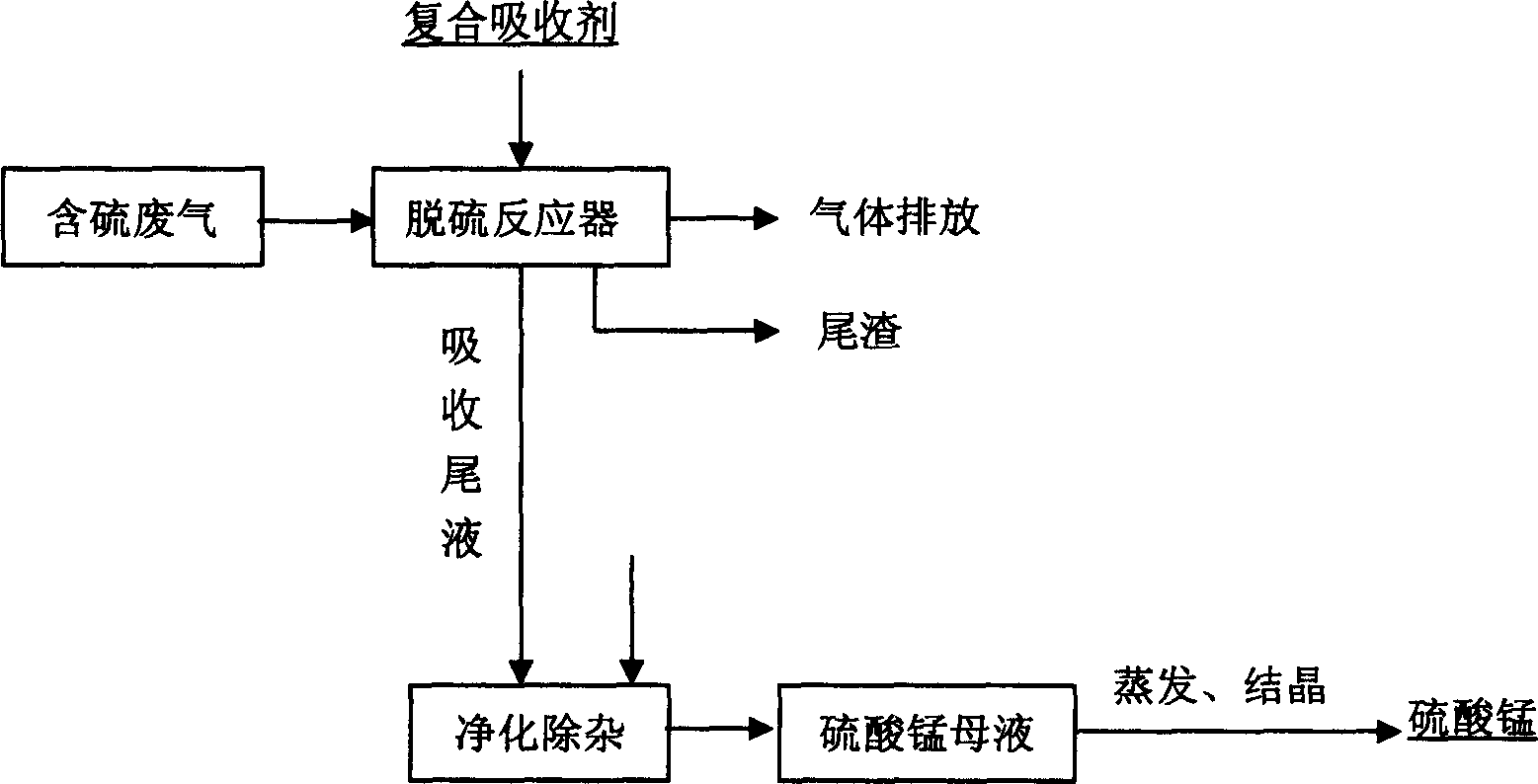

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

A waste gas desulfurization and buffering agent technology, which is applied in chemical instruments and methods, separation methods, manganese sulfate, etc., can solve the problems of impact, low utilization rate of manganese, low absorption rate and leaching rate, etc., to increase added value and realize resources The effect of chemicalization and saving sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

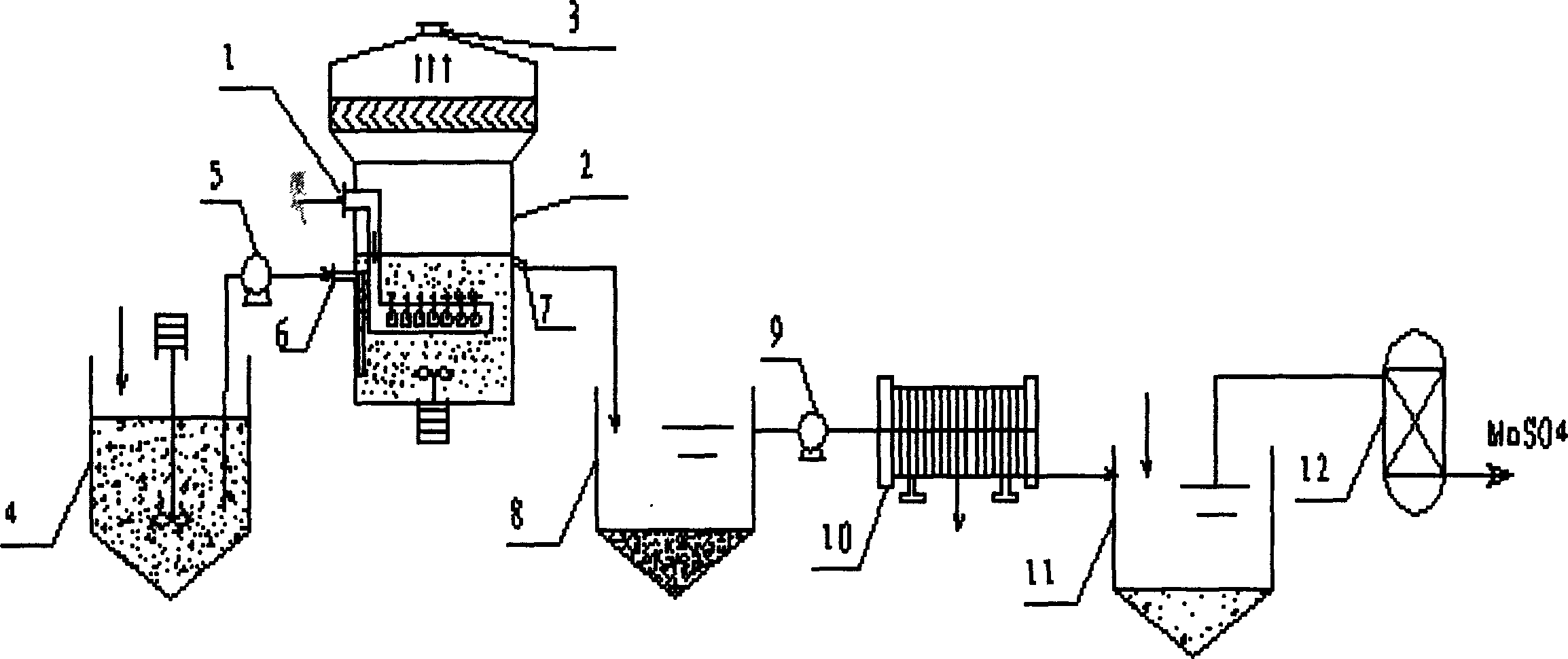

[0036] The exhaust gas treated in this embodiment is coal-fired boiler exhaust gas, and the by-product of production is manganese sulfate. While recovering sulfur resources from the exhaust gas, the value of pyrolusite is increased, and the sulfur and manganese resources are comprehensively utilized to treat a scale of 35T / h. coal-fired boilers as an example. The amount of exhaust gas to be treated is 60000Nm 3 / h, the sulfur dioxide content in the exhaust gas is 3000ppm, and the oxygen content is 8%, the technological process of the present embodiment is as follows image 3 shown. First mix pyrolusite and manganese carbonate in a mass ratio of 9:1, then mix with water in the slurry tank 4 equipped with a stirrer to make a slurry with a liquid-solid ratio (mass ratio) of 3:1, and pass the slurry pump 5 Pour into the desulfurization reactor 2 from the pulp inlet 6, containing SO 2 After the waste gas is dedusted by wet dedusting, cooled and humidified, it enters the gas disp...

Embodiment 2

[0039] The exhaust gas treated in this embodiment is coal-fired boiler exhaust gas, and the by-products produced include electrolytic manganese, high-purity manganese carbonate and ammonium sulfate, and the value-added comprehensive utilization of pyrolusite is carried out while recovering sulfur resources from the exhaust gas. Taking the treatment of a coal-fired boiler with a scale of 35T / h as an example, the amount of waste gas to be treated is 60000Nm 3 / h, the sulfur dioxide content in the exhaust gas is 3000ppm, and the oxygen content is 8%, the technological process of the present embodiment is as follows Figure 4shown. First mix pyrolusite and manganese carbonate at a mass ratio of 15:1, and then mix them with water in the slurry tank 4 equipped with an agitator to form a slurry with a liquid-solid ratio (mass ratio) of 8:1, and pass the slurry pump 5 from the slurry inlet 6 into the desulfurization reactor 2, containing SO 2 After the waste gas is dedusted by wet d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com