Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Increase char formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intumescent fire retardant composition and method of manufacture thereof

InactiveUS20030158314A1Reduce smokeEasy to processFireproof paintsSpecial tyresGraphiteFire retardant

One embodiment of an intumescent composition comprises a halogenated polymer, antimony oxide, and intercalated graphite, while one embodiment of an intumescent additive mixture comprises antimony oxide and intercalated graphite. One embodiment of the method of making an intumescent composition comprises melt blending a halogenated polymer with antimony oxide, and intercalated graphite.

Owner:APTIV TECH LTD

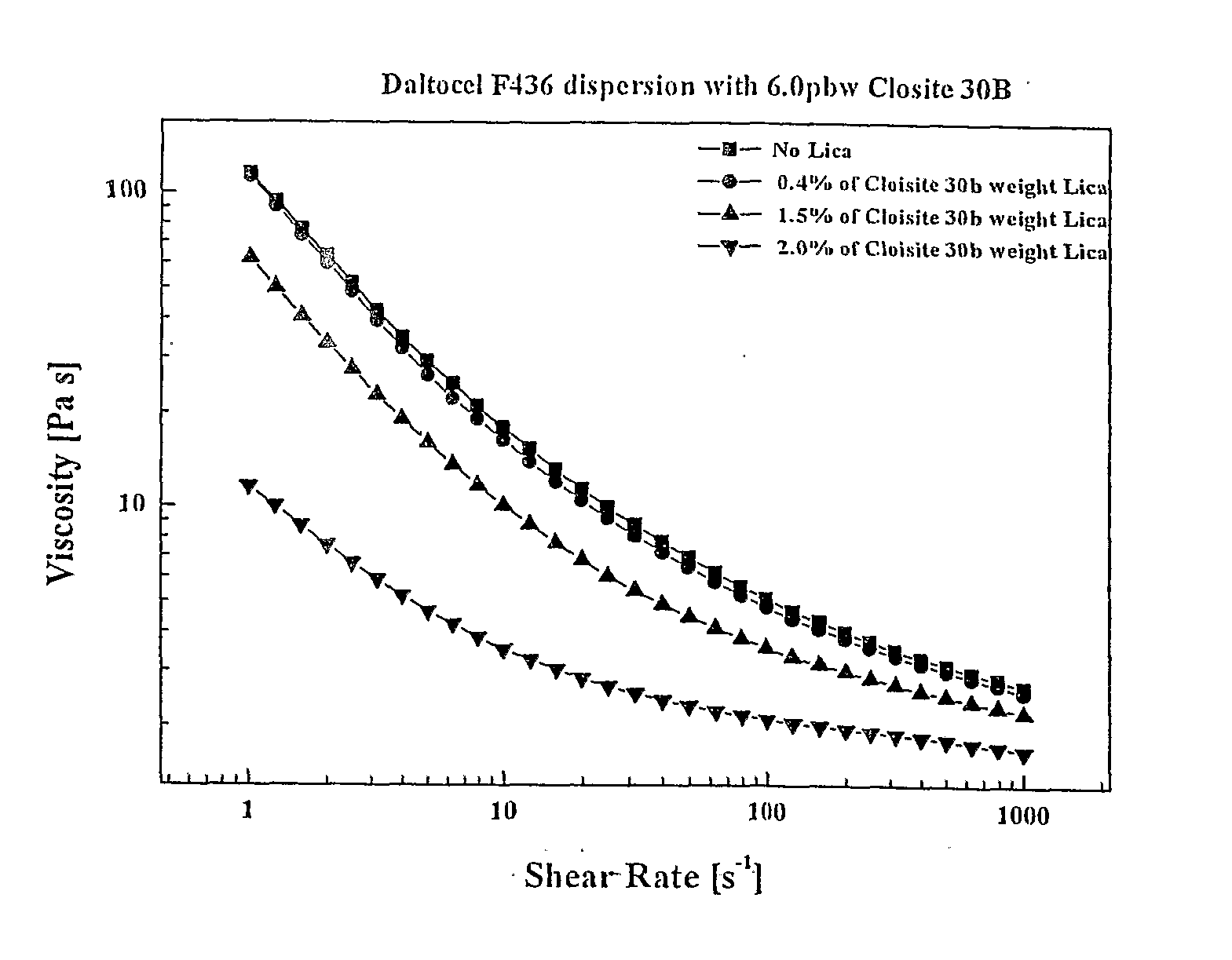

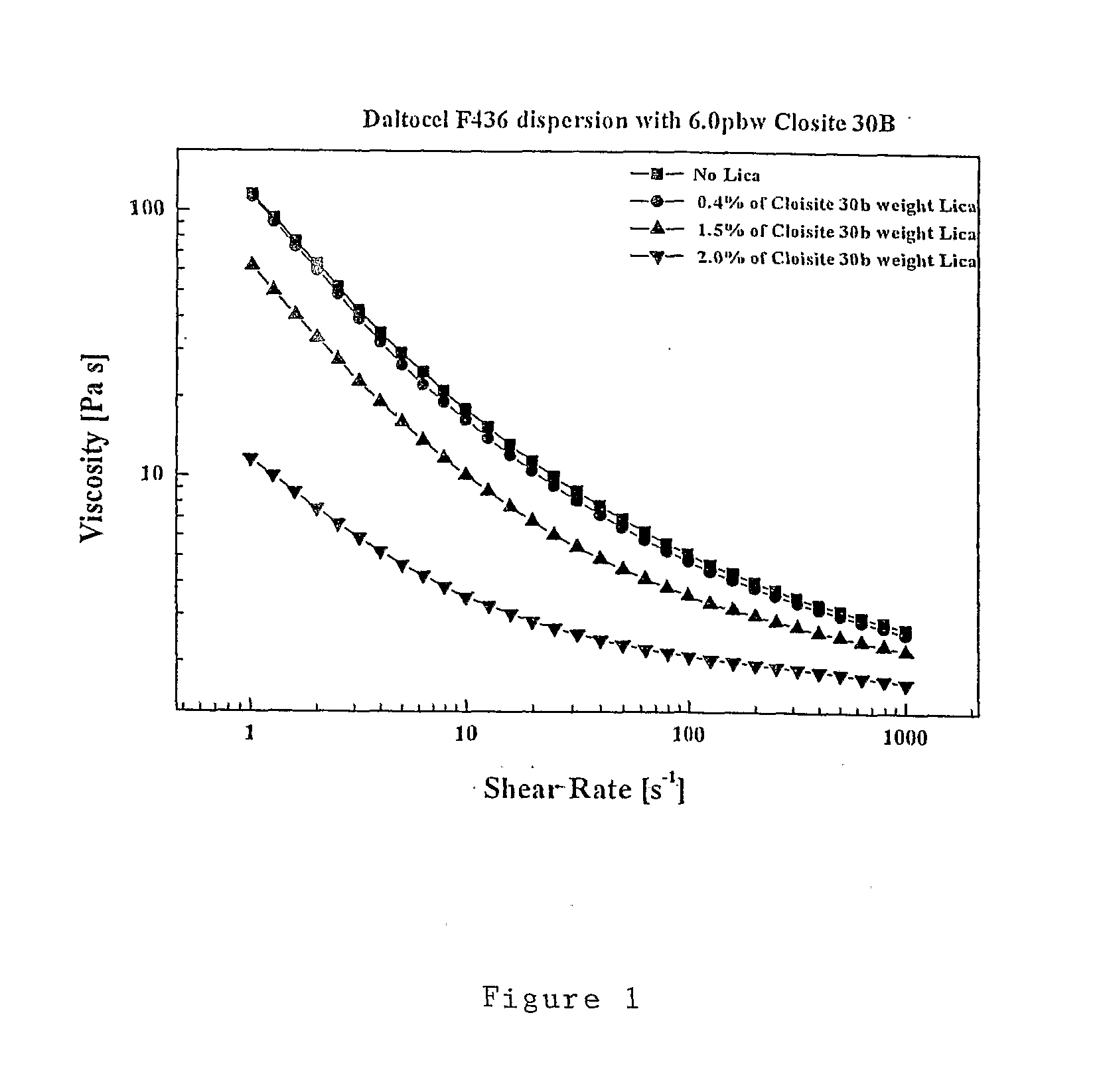

Fire Retarded Flexible Nanocomposite Polyurethane Foams

InactiveUS20070227748A1Reduce oxygen ingressCompromised rapid mixingFire rescueBoring toolsMedicinePolyurethane

The present invention relates generally to flexible polyurethane foam compositions that incorporate partially and / or totally exfoliated, clay based nanocomposite material. The invention also relates to the foams formed from the compositions, the preparation of the foams and uses thereof.

Owner:UNIV OF STRATHCLYDE

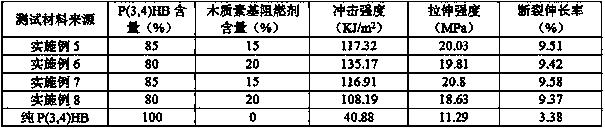

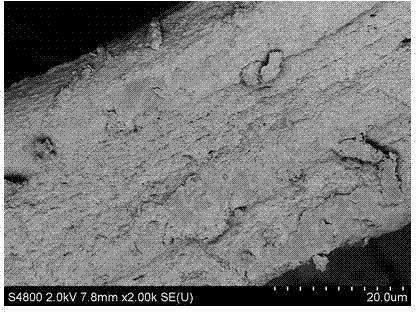

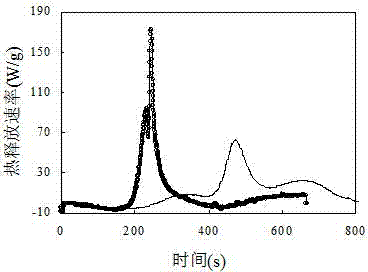

Preparation method and application of lignin-based intumescent flame retardant

ActiveCN104371116AIncrease char formationImprove flame retardant performancePolyesterPolymer science

The invention discloses a preparation method of a lignin-based intumescent flame retardant. The preparation method comprises the steps of carrying out esterification reaction on phosphoric anhydride and lignin through optimizing reaction temperature, reaction time, reactant ratio and solvent selecting ratio and other process conditions; then, enabling the reaction product to react with melamine to obtain the lignin-based intumescent flame retardant which is integrated with an acid source, a carbon source and an air source and is high in char formation quantity and good in flame retardance. When the lignin-based intumescent flame retardant is independently applied to a P(3,4)HB biopolyester material or is applied to the P(3,4)HB biopolyester material after being compounded with other flame retardants, the compatibility of the lignin-based intumescent flame retardant and a matrix is good, so that the flame retardance of the material can be remarkably improved, meanwhile, the mechanical property of the material can also be improved, and a P(3,4)HB flame-retardant composite material with excellent comprehensive properties can be prepared. By using the preparation method disclosed by the invention, the yield is high; a reactant is basically nontoxic; the process conditions are easy to control; the operation process is simple; the lignin serving as a main raw material is an abundant regenerative resource, so that the price is low; and therefore, the lignin-based intumescent flame retardant is favorable in application prospect.

Owner:NANJING FORESTRY UNIV

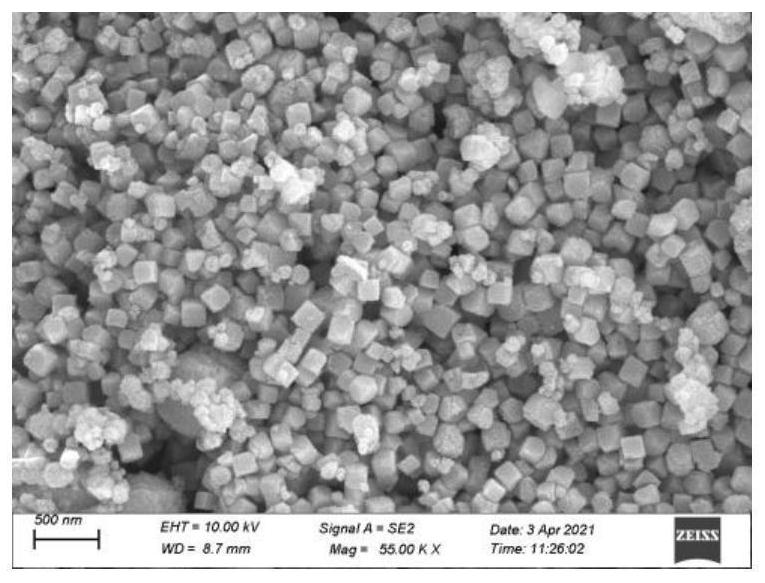

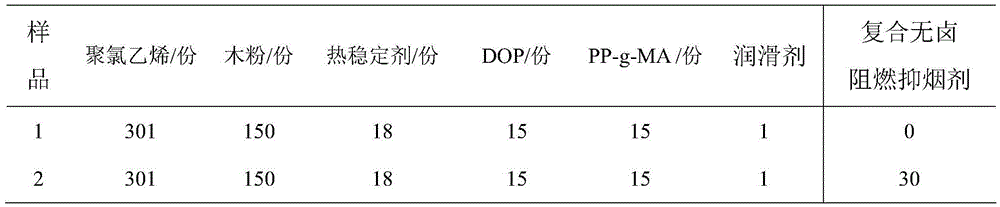

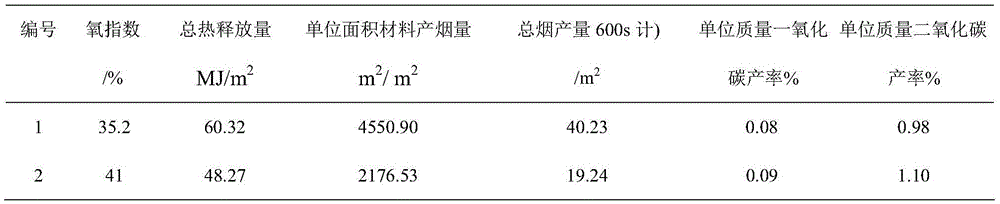

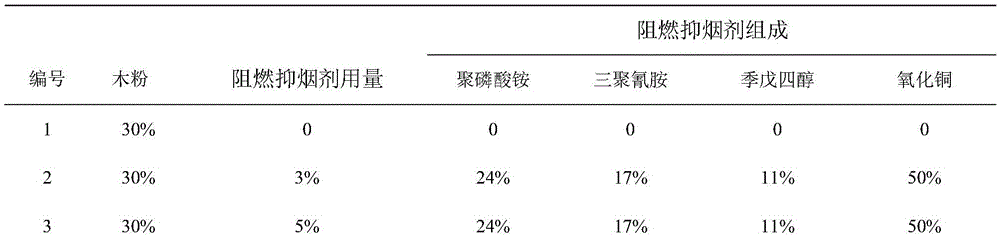

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

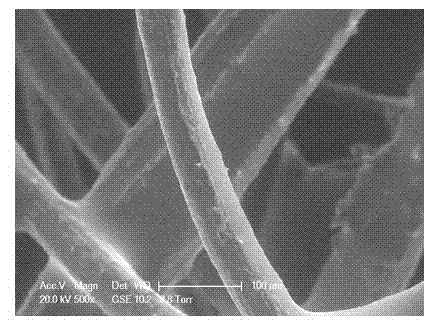

Flame-retardant polylactic acid material of ternary composite flame-retardant system and preparation method thereof

The invention discloses a flame-retardant polylactic acid material of a ternary composite flame-retardant system and a preparation method of the flame-retardant polylactic acid material. The ternary composite flame-retardant system comprises hibiscus cannabinus, nano-zinc oxide and a polymer type phosphorus-containing fire retardant. The preparation method of the flame-retardant polylactic acid material comprises the following steps: (1) performing alkali treatment on the hibiscus cannabinus, and assembling and loading the nano-zinc oxide on the processed hibiscus cannabinus surface; (2) dissolving the polymer type phosphorus-containing fire retardant in chloroform, adding the hibiscus cannabinus loaded with the nano-zinc oxide in the chloroform containing the polymer type phosphorus-containing fire retardant, stirring for a while, adding polylactic acid particles, and when the polylactic acid is completely dissolved and the solution is free of bubbles, forming film on a glass plate, volatilizing at room temperature, and drying; (3) adding the dried thin film in a twin-screw extruder, extruding, cooling and pelletizing the material to prepare the flame-retardant polylactic acid material of the ternary composite flame-retardant system. The flame-retardant polylactic acid material is simple in formula, free of halogen, environment-friendly and high in flame retardant efficiency, can reduce molten drop phenomenon, and effectively reduces further spreading of fire.

Owner:NANJING UNIV OF SCI & TECH

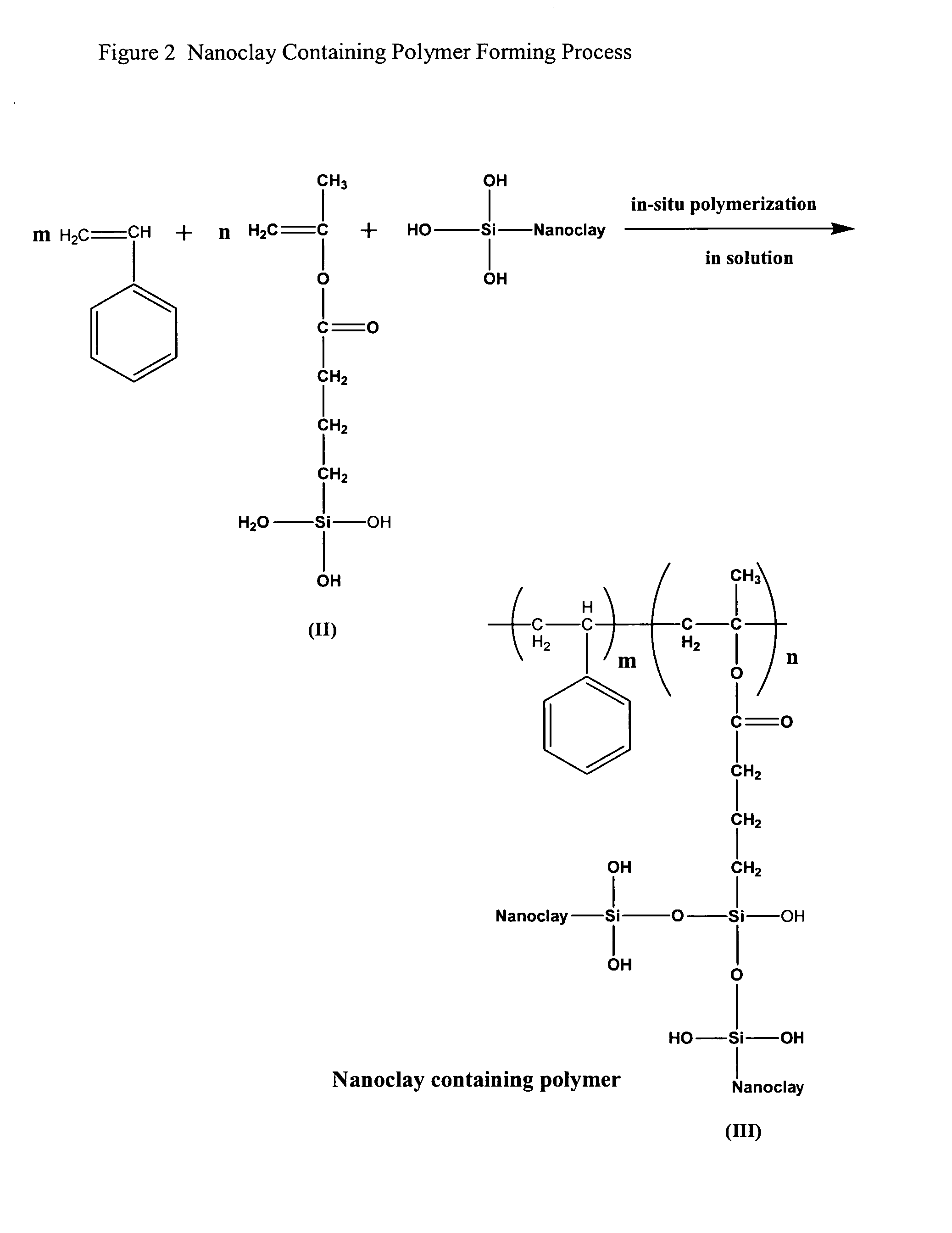

Polystyrene foam containing a modifier-free nanoclay and having improved fire protection performance

Polymer extruded or expanded foams that contain modifier-free nanoclays are provided. The addition of modifier-free nano-clays to extruded or expanded foam products improves the thermal properties, mechanical properties, and fire performance properties. Water or a water-containing compound is used as a carrier for the modifier-free nanoclays. The final foamed products may be utilized in building application such as foamed insulation products and in underground applications such as highway insulation. A preferred modifier-free nanoclay is Na+MMT. Modifier-free nanoclay particles may be injected into a polymer during an extrusion foaming process. In another embodiment of the invention, polymer beads containing water / nanoclay particles are formed using inverse emulsion / suspension polymerizations and expanded or extruded into a foamed product. In a further embodiment, a modifier-free nanoclay particle is encapsulated in a super-absorbent material, which may be used in an expanding or extruding process.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Polyvinyl chloride (PVC) cable sheath material and preparation method thereof

InactiveCN102250435AExcellent low temperature/high temperature performanceIncrease char formationPlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxidePolyvinyl chloride

The invention discloses a polyvinyl chloride (PVC) cable sheath material and a preparation method thereof. The PVC cable sheath material comprises 100 parts of PVC resin, 30-50 parts of plasticizer, 3-7 parts of compound stabilizer, 20-40 parts of active calcium carbonate, 5-15 parts of kaolin, 5-15 parts of aluminum hydroxide, 3-6 parts of antimony trioxide, 3-5 parts of zinc borate and 0.5-1.5 parts of aromatizer. In the cable sheath rubber disclosed by the invention, through the optimal combination of aluminum hydroxide, antimony trioxide and zinc borate, the carbonization amount is improved by approximate 50%; the smoke generation amount during naked flame combustion is reduced by 30-50%, and the limiting oxygen index (LOI) is improved to 33; by selecting a proper plasticizer, the material has excellent low-temperature and high-temperature resistance at the same time, and the use temperature of the material is (-30)-90 DEG C; and a mint-flavored essential oil aromatizer is added to the material, so that the obtained product has aromatic odor and has the actions of eliminating nausea, nervousness and tension headache and dispelling mosquito.

Owner:WUXI MINGZHU CABLE

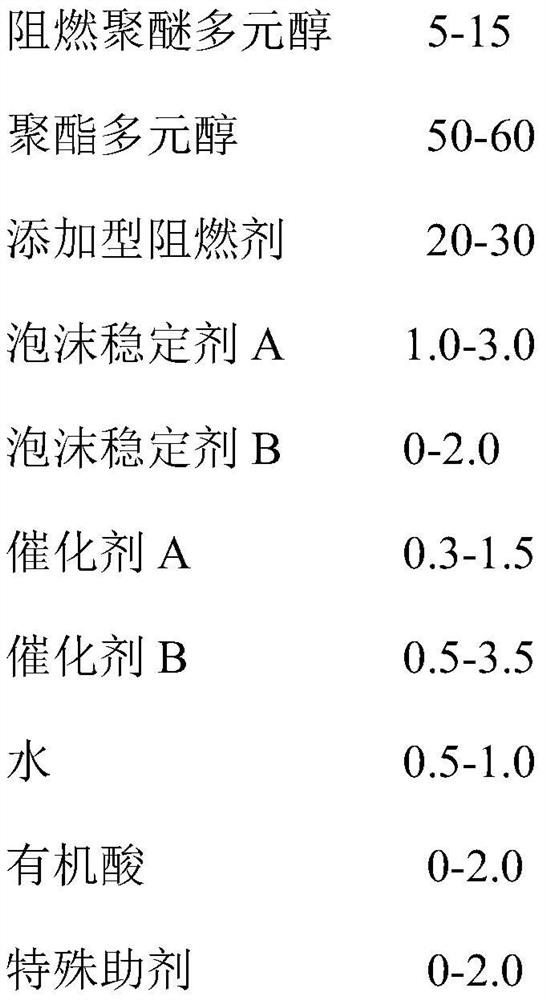

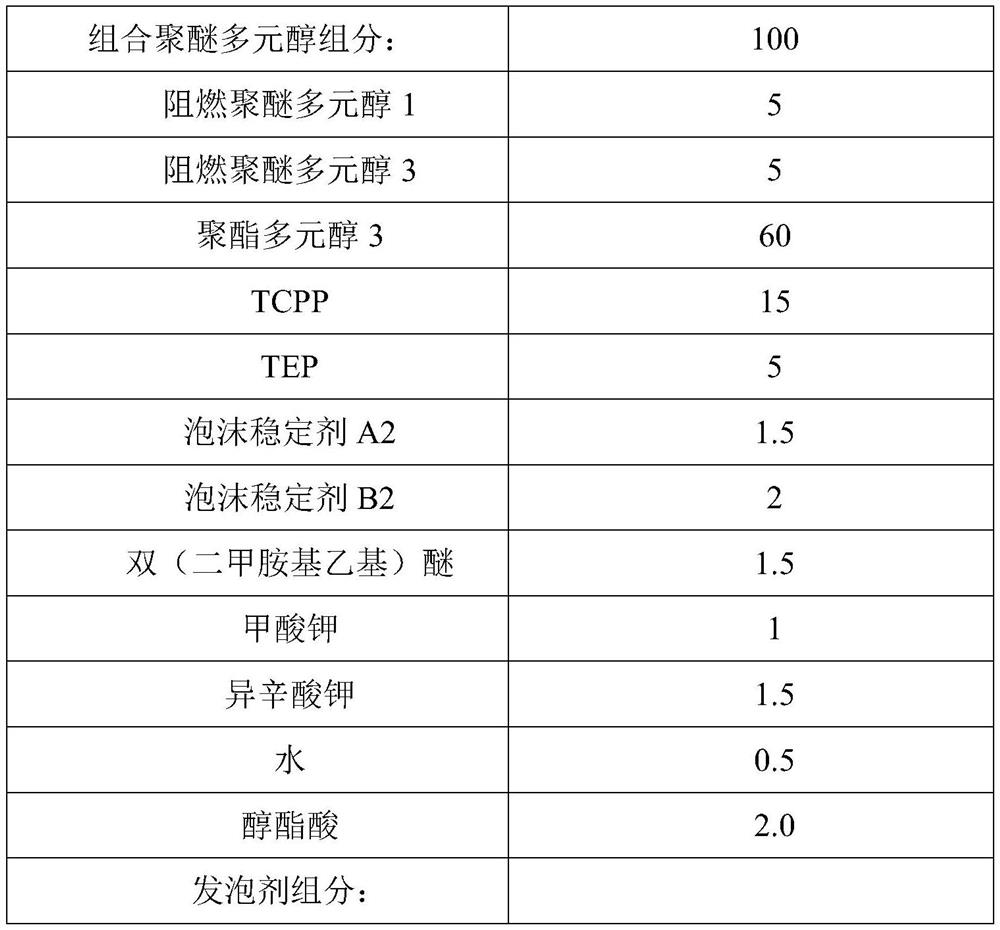

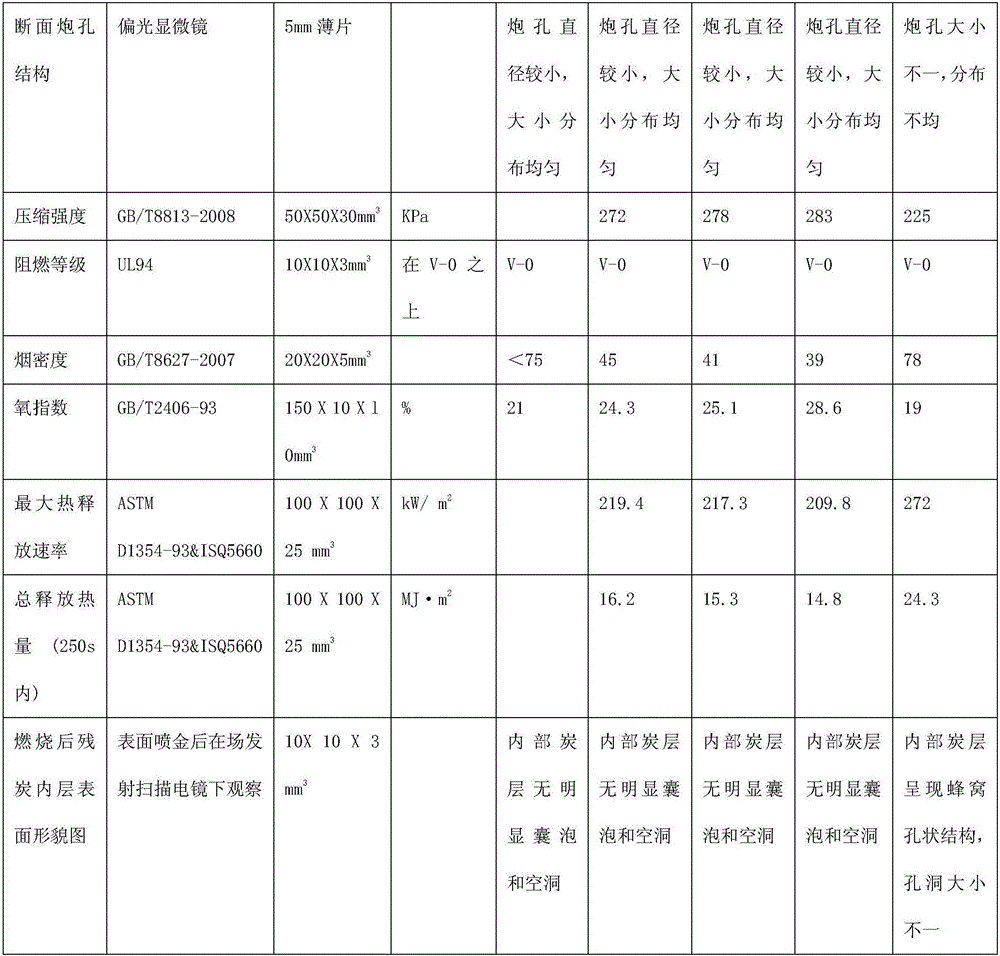

Alkane foaming B1-grade flame-retardant polyurethane rigid foam and preparation method thereof

The invention discloses alkane foaming B1-grade flame-retardant polyurethane rigid foam and a preparation method thereof. Alkane is adopted as a foaming agent, polyether / polyester polyol with a specific flame-retardant effect, a catalyst, a foam stabilizer, a flame retardant, other special assistants and the like are matched to prepare combined polyether, and the combined polyether reacts with polyisocyanate to generate high-index PIR foam. The B1 flame-retardant polyurethane rigid foam disclosed by the invention is mainly suitable for a continuous line production process, and has the advantages of high flame retardance, environmental protection, low density, high production tolerance, excellent foam performance and the like compared with other types of PIR plate foam.

Owner:WANHUA CHEMYANTAI RONGWEI POLYURETHANE CO LTD

PVC cable insulating material and preparation method thereof

InactiveCN102153825AExcellent low temperature/high temperature performanceIncrease char formationPlastic/resin/waxes insulatorsAluminium hydroxidePolyvinyl chloride

Owner:WUXI MINGZHU CABLE

Inflaming retarding system and preparation method of inflaming-retarding real silk

ActiveCN102828408AIncrease char formationReduce smoke productionFibre treatmentSilane couplingChemistry

The invention discloses an inflaming retarding system and a preparation method of an inflaming-retarding real silk. The inflaming retarding system is a phosphorus-silicon collaborative system, wherein a phosphorus component is methacryloyloxyethyl dimethyl phosphate and a silicon component is a vinyl silane coupling agent. The preparation method comprises the following steps of: preparing an inflaming-retarding working solution and adjusting the pH (Potential of Hydrogen) value of the working solution to 4-4.5; immersing a real silk textile into the inflaming-retarding working solution, and heating the real silk textile at 80-85 DEG C for 10-60 minutes; and washing the real silk textile by water and drying the real silk textile to obtain the inflaming-retarding real silk. A fire retardant provided by the invention is durable, and no formaldehyde is released in an inflaming retarding and sorting process; and the smoke amount of the real silk textile in a combustion process is as low as required.

Owner:苏州盛泽科技创业园发展有限公司

Method for preparing inflaming-retarding wool fabric and inflaming-retarding working solution

InactiveCN102660869AStrong chemical bondOvercome the lack of washing resistanceFibre treatmentLiquid/gas/vapor textile treatmentNitrogenAmmonia

The invention discloses a method for preparing inflaming-retarding wool fabric and an inflaming-retarding working solution. The working solution contains the following components by weight: 15-30% of phosphorus-nitrogen components, 0.1-0.5% of ammonia water, 0.1-0.3% of initiator and the balance water, wherein the phosphorus-nitrogen components are formed by phosphorus-containing components and nitrogen-containing components, and the weight ratio of the phosphorus-containing components to the nitrogen-containing components is 1:(0.5-1). The wool fabric to be processed is processed in the inflaming-retarding working solution in a twice-soaking twice-rolling method, the dipping time is 1-3 minutes, mangle expression is more than 90%, and the inflaming-retarding wool fabric can be obtained through steaming, washing and drying. The method can remarkably reduce using amount of the phosphorus-containing components, can improve inflaming-retarding efficiency and is favorable for industrial production.

Owner:SUZHOU UNIV

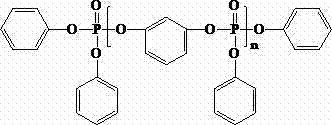

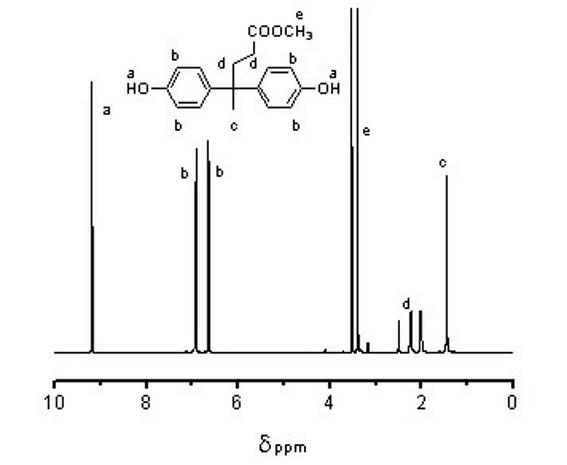

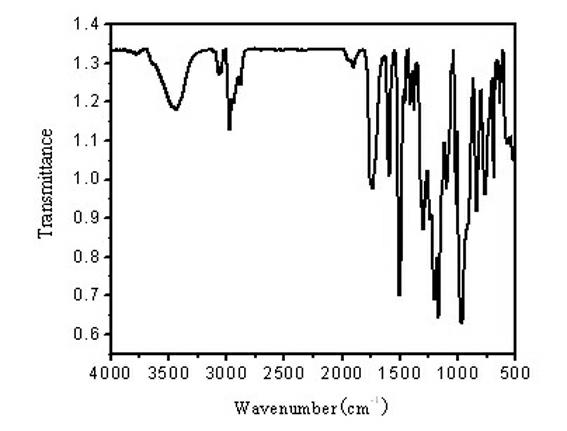

Phosphate ester polymer intumescent flame retardant and preparation method thereof

InactiveCN102417596AImprove thermal stabilityIncrease char formationGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

The invention discloses phosphate ester polymer intumescent flame retardant and a preparation method thereof. Polyhydroxyl acid compound serves as raw materials, and carboxyl is protected by esterification; and in the presence of phase transfer catalyst, with an interfacial polymerization method that esterified polyhydroxyl compounds, such as diphenolic acid methyl ester and phenyl dichlorophosphate, serve as main raw materials, an obtained intermediate polymer comprises a polyhydroxyl acid methyl ester and phenyl dichlorophosphate reaction unit. The synthesis method has the advantages of simple technology and cheap and abundant raw materials, is easy to operate and is suitable for industrial production; and the reaction is easy. The intermediate polymer and amido compound carry out esteramine solution reaction under the action of the catalyst to obtain the intumescent flame retardant. The flame retardant does not contain halogens and belongs to the environmentally-friendly flame retardant. The structural general formula (III) of the phosphate ester polymer intumescent flame retardant is showed as follows.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

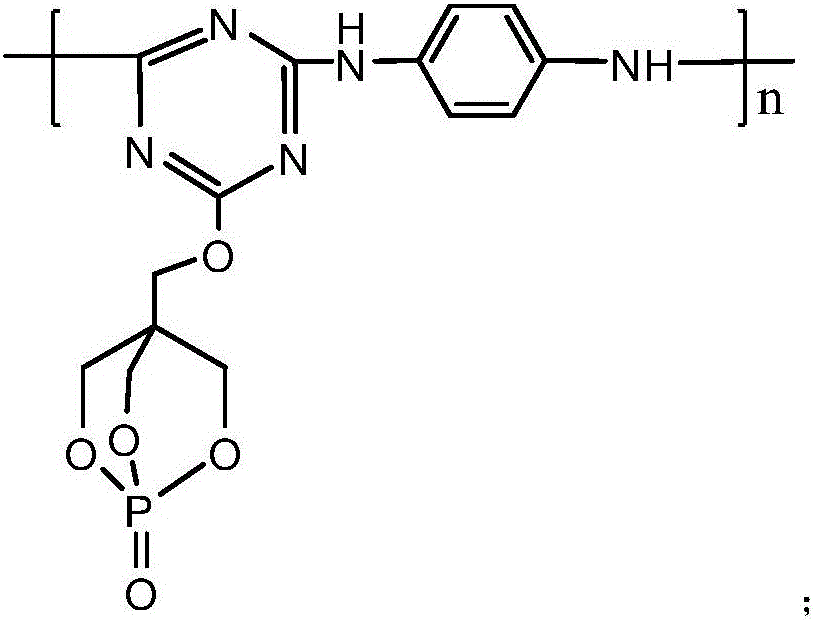

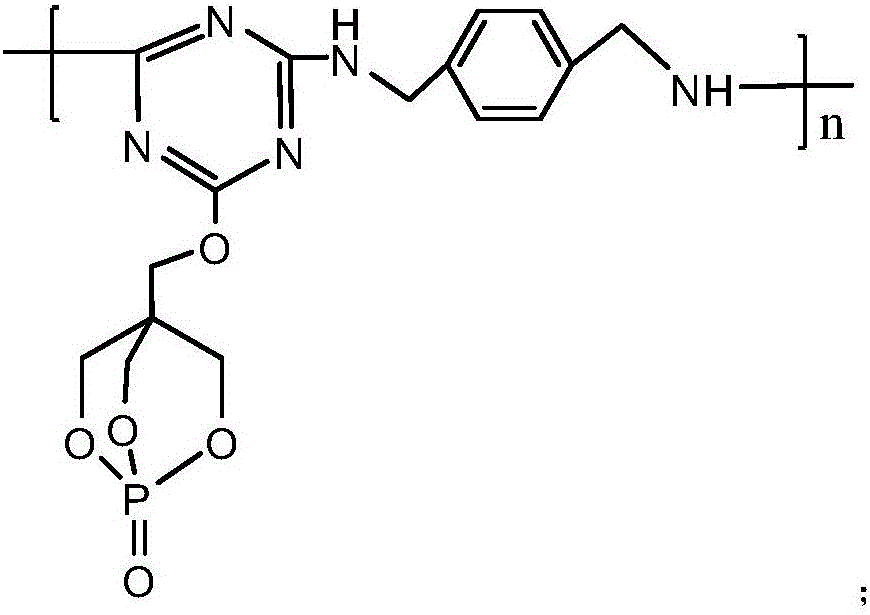

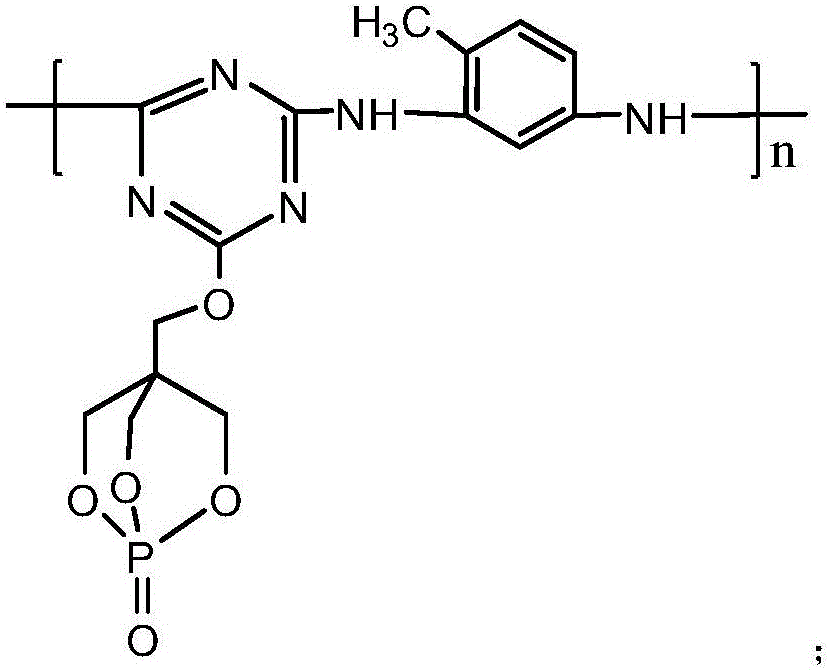

Halogen-free expanding flame retardant containing polymeric macromolecule triazine rings and preparation method of halogen-free expanding flame retardant

The invention discloses a halogen-free expanding flame retardant containing polymeric macromolecule triazine rings and a preparation method of the halogen-free expanding flame retardant. According to the flame retardant, benzodiazepines diamine is introduced, the thermal stability of products is improved, the charring forming amount is increased, and the flame retardant is directly applied to various thermoplastic and thermosetting materials without the synergistic effect of an APP. Meanwhile, each single triazine ring contains 1-oxy-phospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octyl group, is high in contents of phosphorus and hydroxyl, and can serve as a reactive and expanding flame retardant. The flame retardant belongs to a polymerization reaction product formed by substituting 1-oxy-phospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and benzodiazepines diamine with cyanuric chloride and connecting the triazine rings with one another.

Owner:NANJING FORESTRY UNIV

Preparation method of flame retardant paper

InactiveCN110130148ALow costHigh whiteness of paperPaper/cardboardIgnifugeants additionAmmonium polyphosphateChemistry

The invention relates to a preparation method of flame retardant paper, and belongs to the technical field of paper flame retardant materials. Through a sol-gel method, the surface of ammonium polyphosphate is modified by methyl triethoxysilane to prepare microcapsule wrapped ammonium polyphosphate; the waterproof performance and heat stability of ammonium polyphosphate are improved; the heat stability and char forming amount of flame retardant paper in a high temperature zone are enhanced; the heat release during the combustion process is effectively reduced, the flame retardant performance of flame retardant paper is obviously strengthened; the porosity and strong adsorbing performance of diatomite are utilized, diatomite, modified ammonium polyphosphate, antimony pentoxide, and aluminumhydroxide carry out in-situ polymerization to prepare a composite flame retardant having a good smog absorbing performance; diatomite is taken as the carrier, due to the porosity and strong absorbingperformance of diatomite, in-situ polymerization happens on the surface of diatomite and in the pores of diatomite; the prepared composite flame retardant has a strong flame retardant performance; due to the added composite flame retardant, paper has a good flame retardant effect, at the same time, the physical properties of paper are barely influenced, the paper quality is improved, and the application range is enlarged.

Owner:陈莉玲

Environment-friendly flame-retardant hard polyurethane foaming plastic

The invention provides environment-friendly flame-retardant hard polyurethane foaming plastic. Polyisocyanates, polyether polyol, a foaming agent, a foam stabilizing agent, a catalyst, glycerinum and a flame retardant are taken as raw materials, wherein the flame retardant is synthesized novel halogen-free flame retardant 1-butyl-3-methylimidazole dibutyl ester ionic salt ([Bmim]DBP); the polyether polyol, the foaming agent, the foam stabilizing agent, the catalyst, the glycerinum and the flame retardant are uniformly stirred and mixed in a certain ratio at the room temperature in a high-speed dispersing machine, are further stirred and mixed uniformly with polyisocyanates added in a certain ratio, are subjected to foam molding in a mold, and are aged, so that the environment-friendly flame-retardant hard polyurethane foaming plastic can be obtained.

Owner:滕钜海

A preparing method of an environmental friendly flame-retardant polycarbonate composite material

InactiveCN105348763AChange surface propertiesGood compatibilityPotassium perfluorobutanesulfonatePhosphate

A preparing method of an environmental friendly flame-retardant polycarbonate composite material is disclosed. The method includes mixing nanometer zinc oxide, nanometer titanium dioxide, nanometer aluminium hydroxide, glass fibre, kaolin, nanometer zinc stannate, ferrocene, zinc molybdate, basic sodium aluminium carbonate, calcium stearate, zinc stearate and a silane coupling agent KH-540 to obtain a modified filler; melting and extruding polyvinyl butyral, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, styrene-acrylonitrile copolymer, melamine resin and the modified filler in a twin-screw extruder to obtain dispersed master batch; adding polycarbonate, the dispersed master batch, tris(2,4-diisobutyl) phosphate, hexaphenoxycyclotriphosphazatriene, potassium perfluorobutanesulfonate, bisphenol A bisphthalonitrile, a plasticizer and an oxidant into a twin-screw extruder, melting and extruding. The composite material prepared by the method is good in heat resistance and excellent in flame retardance.

Owner:ANHUI GUANGYUAN TECH DEV

Polyurethane/PVC crosslink cable compound for automobile cables and preparation method of polyurethane/PVC crosslink cable compound

InactiveCN105131578AGuaranteed wear resistanceKeep low temperaturePlastic/resin/waxes insulatorsCross-linkPliability

The invention discloses a polyurethane / PVC crosslink cable compound for automobile cables. The polyurethane / PVC crosslink cable compound is characterized by being prepared from the following raw materials in parts by weight: 100-102 parts of polyether urethane, 20-21.5 parts of diethyl aluminium hypophosphite, 17-18 parts of melamine cyanurate, 4.3-4.5 parts of aluminium titanate, 50-52 parts of PVC, 1.6-1.8 parts of a cross-linking agent TAIC, 6-7 parts of calcium stearate, 20-22 parts of acetyl tributyl citrate, 4-5 parts of zinc oxide, 3-4 parts of sodium stannate, 3-4.2 parts of liquid paraffin, 2-2.5 parts of urea, 1-1.2 parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 9-11 parts of 600-mesh calcium carbonate, 5-6 parts of high abrasion furnace black and 2-3 parts of maleic acid di-n-butyl ester. According to the polyurethane / PVC crosslink cable compound for automobile cables and the preparation method of the polyurethane / PVC crosslink cable compound, provided by the invention, by scientific and reasonable compatibility of the components and the controllable process, the product prepared by adopting the preparation method has excellent abrasive resistance, can maintain flexibility at a low temperature, is firm, not liable to cracking, and long in service life.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

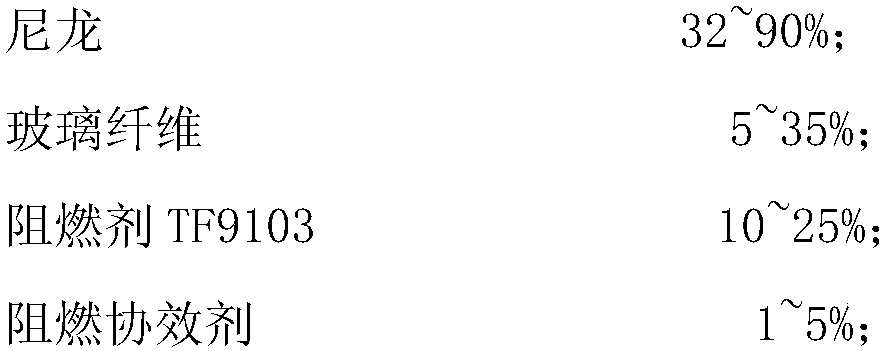

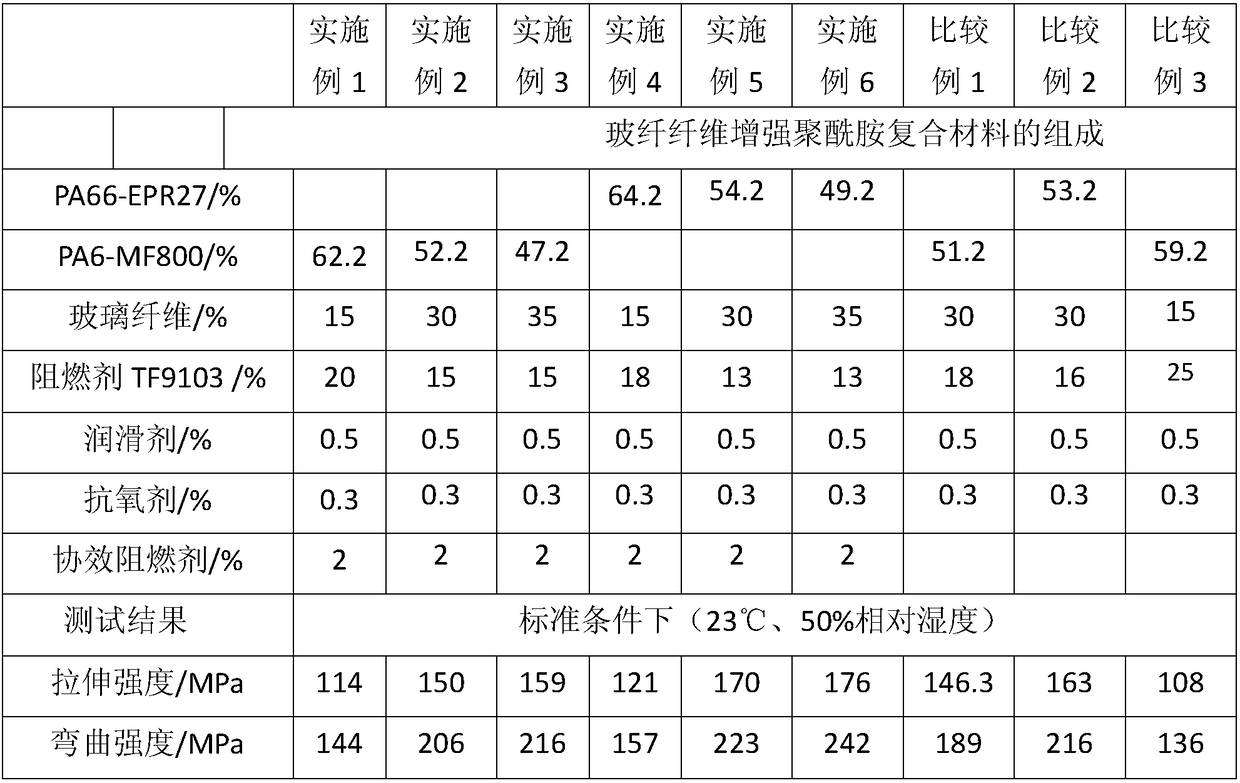

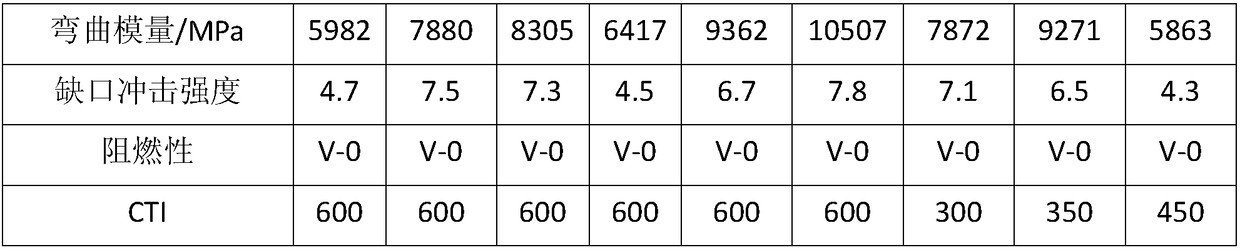

Environment-friendly, high-performance and high-CTI flame retardancy enhanced nylon material and preparation method thereof

The invention discloses an environment-friendly, high-performance and high-CTI flame retardancy enhanced nylon material and a preparation method thereof. The material is prepared from the following components in percentage by weight: 32-90% of a nylon raw material, 5-35% of glass fiber, 10-25% of a flame retardant TF9103, 0-5% of a flame-retardant synergist, 0-1% of a lubricating agent and 0-1% ofan antioxidant. The material and the preparation method thereof disclosed by the invention have the beneficial effects that the prepared environment-friendly and high-CTI flame retardancy enhanced nylon material meeting the environmental protection requirements has excellent mechanical properties and flame retardancy and meets requirements of ROHS and WEEE instructions; and by adding a home-madeefficient flame-retardant synergist, the dosage of the flame retardant can be effectively reduced, the CTI value can be increased, the reduction of the content of the flame retardant has positive significance for improving processability and saving cost, and the high CTI value can increase the application of composite materials and meet application requirements of more products; and the material can be applied to electronic and electrical equipment such as contactors and breaker shells.

Owner:CHONGQNG PRET NEW MATERIAL +4

Polyester having moisture absorption, fire retardation and ultraviolet resistance composite function

ActiveCN104725625AIncrease the amorphous spaceImprove moisture absorptionMelt spinning methodsMonocomponent polyesters artificial filamentChemistryChemical structure

The present invention discloses a polyester having moisture absorption, fire retardation and ultraviolet resistance composite function. According to the present invention, a fire retardation agent, inorganic nanometer anti-ultraviolet powder, a moisture absorption modification monomer and the like are added to the polymerization raw material, wherein the fire retardation agent and the moisture absorption modification monomer have the synergy effect so as to improve the moisture absorption property of the polyester, such that the chemical structure of the polyester is modified so as to make the polyester concurrently have functions of strong moisture absorption, strong fire retardation and strong ultraviolet resistance.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Halogen-free flame retardant environment-friendly flexible cable sheathing compound for portable power source and preparation method of sheathing compound

InactiveCN105131576AIncrease char formationDense carbon layerPlastic/resin/waxes insulatorsChemistryUrea

The invention discloses a halogen-free flame retardant environment-friendly flexible cable sheathing compound for a portable power source. The sheathing compound is characterized by being prepared from the following raw materials in parts by weight: 100-102 parts of polyether urethane, 20-21.5 parts of diethyl aluminium hypophosphite, 17-18 parts of melamine cyanurate, 4.3-4.5 parts of aluminium titanate, 50-52 parts of PVC, 1.6-1.8 parts of a cross-linking agent TAIC, 6-7 parts of calcium stearate, 20-22 parts of acetyl tributyl citrate, 4-5 parts of urea, 5-6 parts of powdered phenolic resin, 7-8 parts of cotton pulp, 1.5-2 parts of magnesium methacrylate, 3-4 parts of white oil, 9-11 parts of carbon nano tubes, 2-3 parts of zinc oxide and 1-1.2 parts of allyltriethoxysilane. The halogen-free flame retardant environment-friendly flexible cable sheathing compound provided by the invention is not liable to cracking, fold-resistant, halogen-free, flame retardant, harmless to the environment and human bodies, long in service life and suitable for manufacture of cable materials of portable power sources and sheathing compounds of mobile phone data cables.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

Novel outdoor power cable sheath material preventing moths and mildew and preparing method thereof

InactiveCN105153681AIncrease char formationDense carbon layerPlastic/resin/waxes insulatorsInsulated cablesMolecular sieveCarbon black

The invention discloses a novel outdoor power cable sheath material preventing moths and mildew. The material is characterized by being prepared from, by weight, 100-102 parts of polyether urethane, 20-21.5 parts of aluminum diethylphosphinate, 17-18 parts of melamine cyanurate, 4.3-4.5 parts of aluminum titanate, 50-52 parts of PVC, 1.6-1.8 parts of cross-linking agent TAIC, 6-7 parts of calcium stearate, 20-22 parts of acetyl tributyl citrate, 0.5-0.6 part of capsaicine, 0.2-0.3 part of imidacloprid, 1-1.2 parts of methyltrimethoxysilane, 2-3 parts of liquid silicone rubber, 9-11 parts of zeolite molecular sieves, 1.5-2 parts of OBPA mildew preventing agents, 3-4 parts of methyl silicone oil and 6-7 parts of high-abrasion-resistance carbon black. The prepared material has excellent flame-retardant performance and is excellent in moth preventing property, mildew preventing property and mechanical property, the technology can be controlled conveniently in an industrialized mode, and the material is suitable for outdoor cables.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

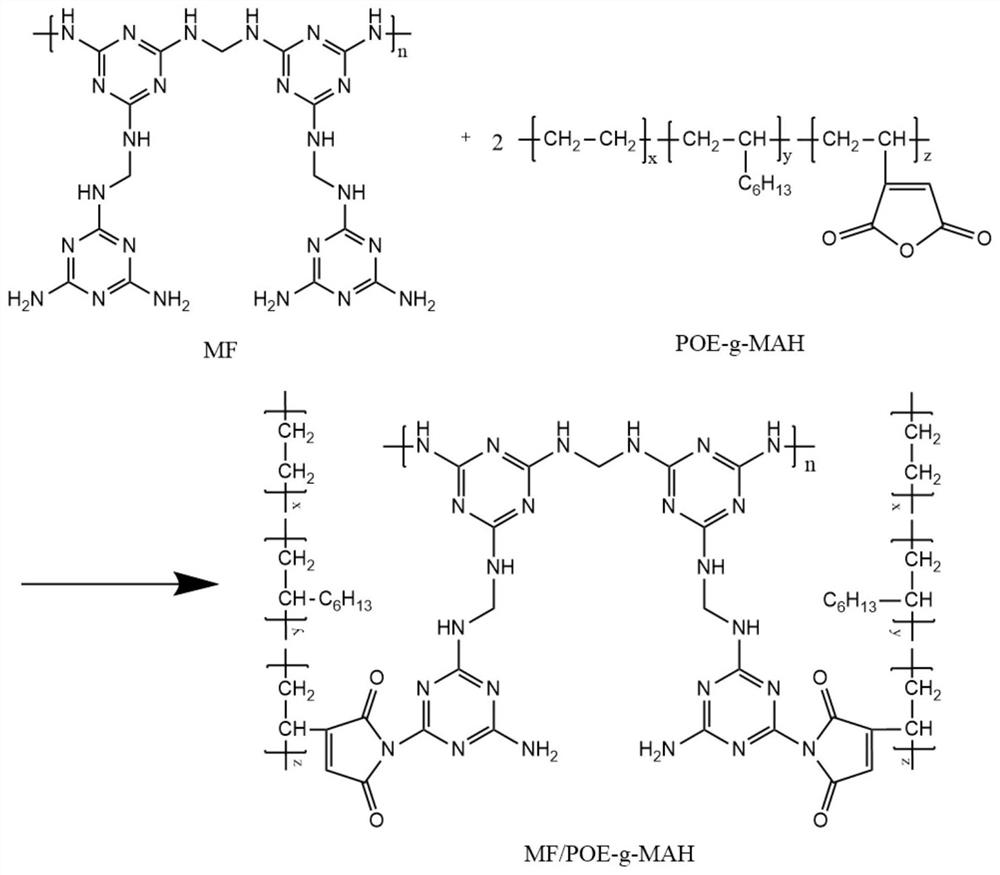

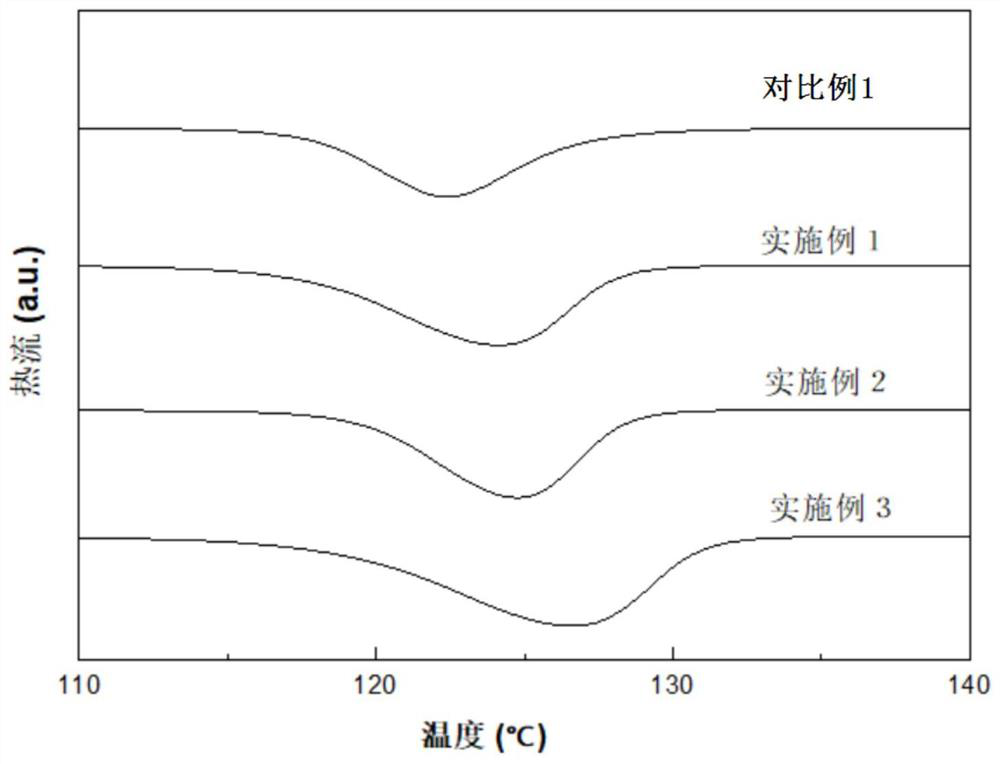

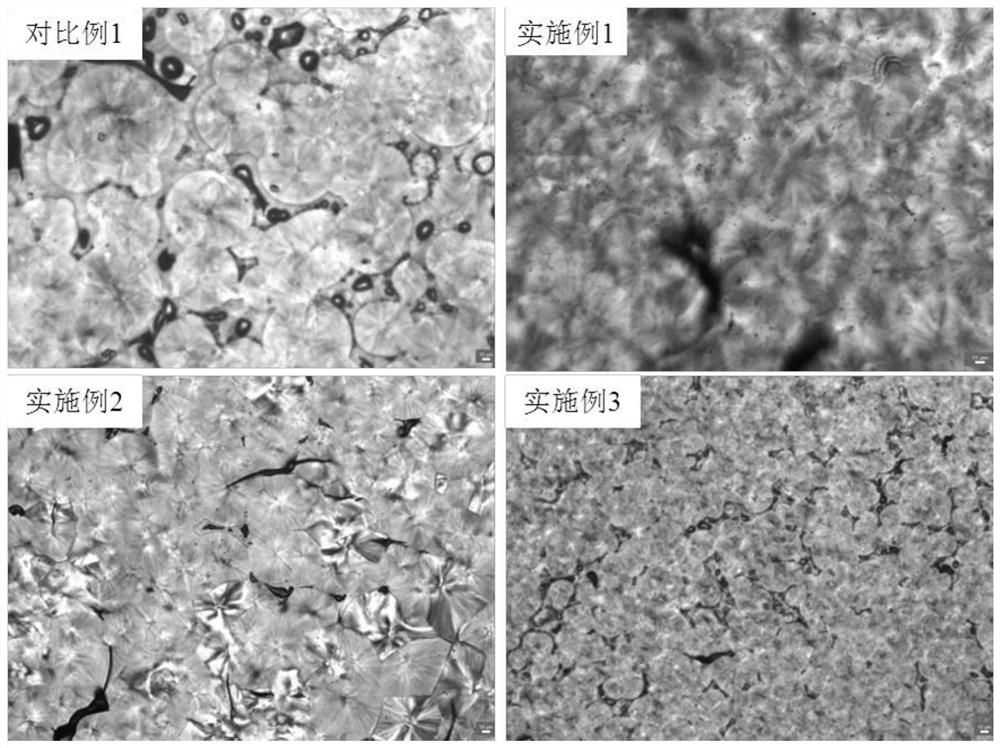

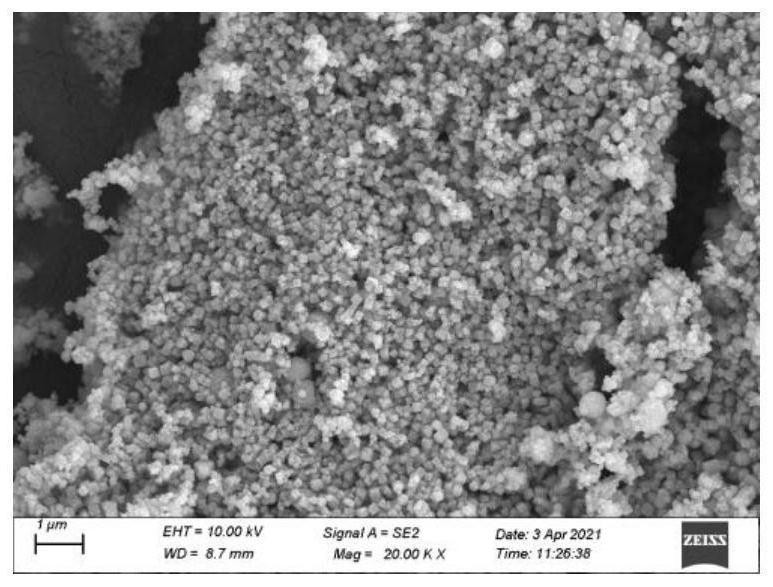

Halogen-free flame-retardant polypropylene foaming composite material and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a halogen-free flame-retardant polypropylene foaming composite material and a preparation method thereof, and the halogen-free flame-retardant polypropylene foaming composite material comprises the following raw materials: polypropylene, melamine resin, maleic anhydride grafted ethylene-octylene copolymer and pentaerythritol polyphosphate melamine salt in a mass ratio of 100: (1-5): (5-10): (5-20). The preparation method comprises the following steps: mixing the raw materials, and carrying out melt blending and extrusion granulation to obtain an unfoamed composite material; and mixing the composite material with a foaming agent, and performing injection molding to obtain the composite material. According to the invention, a large number of amino groups contained in melamine resin react with anhydride groups of POE-g-MAH, a cross-linked network structure with melamine resin particles as the center is generated, the effect of enhancing the strength of polypropylene melt is achieved, the pore diameter of foam pores becomes smaller and is compact, and the prepared PP / POE-g-MAH / MF / MPP foam material is high in flame retardant efficiency, small and uniform in foam pore density, high in strength and toughness, and wide application prospect.

Owner:浙江明江新材料科技股份有限公司

Preventing water and inflaming retarding composite flexible cable sheath material used in wet environment and preparation method thereof

InactiveCN105219065AIncrease char formationDense carbon layerPlastic/resin/waxes insulatorsInsulated cablesBisphenol-A-polycarbonateAluminium

The invention discloses a preventing water and inflaming retarding composite flexible cable sheath material used in wet environment. The flexible cable sheath material is characterized by comprising the following raw materials: be weight, 100-102 parts of polyether urethane, 20-21.5 parts of aluminum diethylphosphinate, 17-18 parts of melamine cyanurate, 4.3-4.5 parts of aluminium titanate, 50-52 parts of PVC, 1.6-1.8 parts of cross-linking agent TAIC, 6-7 parts of calcium stearate, 20-22 parts of acetyl tributyl citrate, 3-4 parts of polydimethylsiloxane, 3-4 parts of glycerin monostearate, 5-7 parts of antimonous oxide, 4-5 parts of emulsified asphalt, 4-5 parts of bisphenol A polycarbonate and 8-10 parts of talcum powder. The prepared product has good water resistance, good mud resistance, good decay resistance, good flame resistance, and has soft material. So that the prepared cable sheath has large bending amplitude, is especially suitable for the places where have high fireproofing requirement in coastal region having high humidity, and is especially suitable for ocean engineering.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

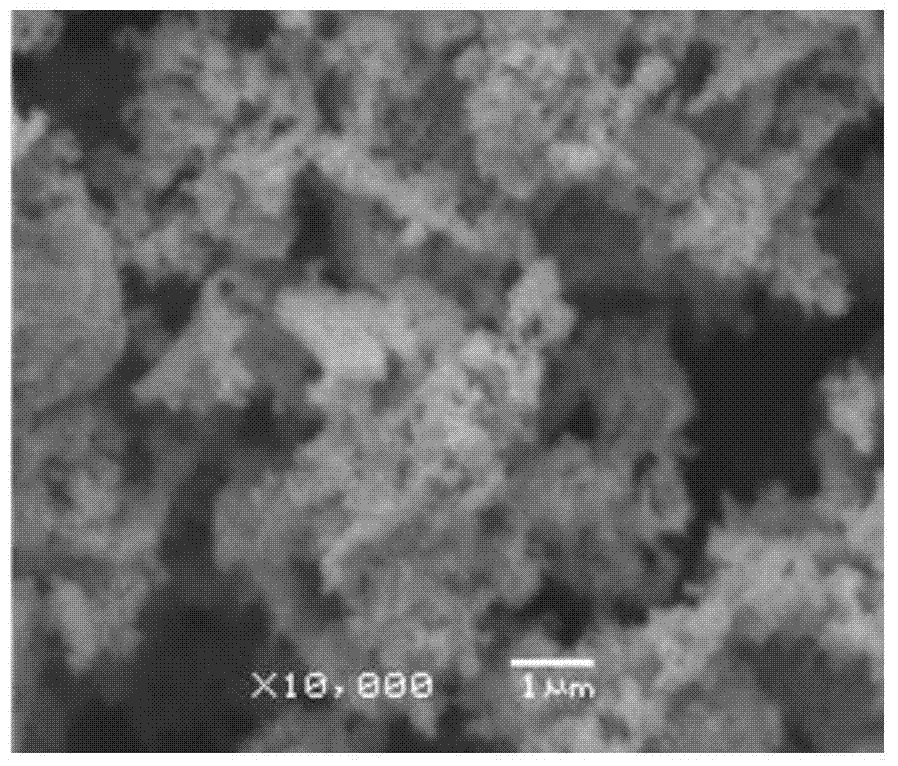

Halogen-free nano composite flame retardant and preparation method thereof

The invention discloses a halogen-free nano composite flame retardant and a preparation method thereof. According to the method, the halogen-free nano composite flame retardant is prepared by coating magnesium hydroxide, zinc hydroxystannate and polyphosphazene layer by layer. Through compounding of magnesium hydroxide and zinc hydroxystannate, the flame retardation effect of the material is improved. Through synergism of polyphosphazene, a compact isolation protection layer is generated on the surface of the material, contact between combustibles and flames is isolated, carbon dioxide, ammonia gas and other nonflammable gases are released, and the oxygen content is reduced. The composite flame retardant nano structure with a large specific surface area improves the carbon residue amount during material combustion, a compact carbon layer plays a barrier role, and the compound halogen-free nano flame retardant can greatly improve the flame retardant property of the material.

Owner:云南锡业集团(控股)有限责任公司研发中心

Ultraviolet-resistant flame-retardant optical cable material and preparation method thereof

InactiveCN105949671APrevent the entry of external fuelIncrease thermal decomposition temperature and char formationCHLORIDE HEXAHYDRATEMagnesium

The invention discloses an ultraviolet-resistant flame-retardant optical cable material which is composed of the following raw materials in parts by weight: 0.6-1 part of 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole, 100-130 parts of polyvinyl chloride, 20-27 parts of polystyrene, 3-4 parts of sodium hypophosphite monohydrate, 2-3 parts of polyformaldehyde, 0.2-0.3 part of 37-37% hydrochloric acid, 4-6 parts of chlorospirophosphate, 5-7 parts of aluminum chloride hexahydrate, 0.1-0.2 part of triethylamine, 10-12 parts of graphite powder, 4-6 parts of polyvinyl butyral resin, 0.1-0.3 part of magnesium oxide, 0.6-1 part of dimethyl chlorophthalate, 1-2 parts of calcium palmitate, 0.1-0.2 part of lauryldimethylamine oxide, 0.3-0.5 part of ethylene glycol monobutyl ether and 0.6-2 parts of aluminum dihydrogen phosphate. The ultraviolet-resistant flame-retardant optical cable material can perform the function of lowering the temperature of the combustion zone, and some phospho-oxygen free radicals and the like generated during pyrolysis can capture free radicals generated by polystyrene segment pyrolysis, thereby lowering the heat release value of the material.

Owner:安徽电信器材贸易工业有限责任公司

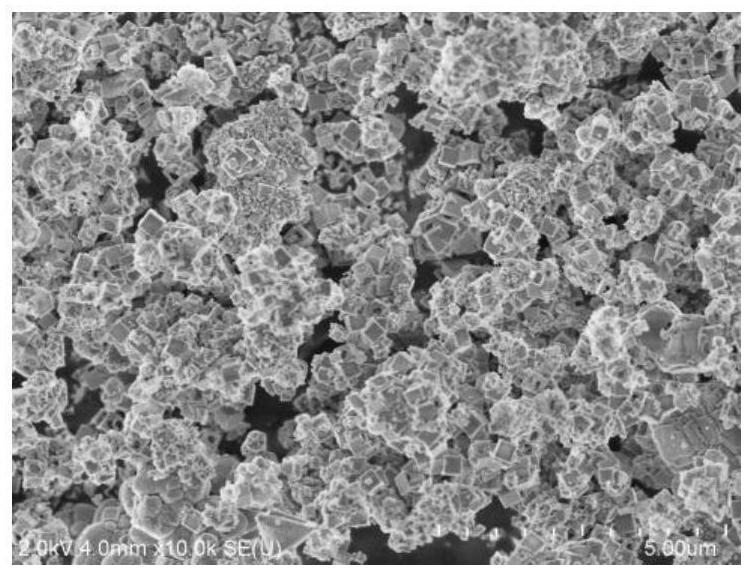

Composite halogen-free flame-retardant smoke suppression agent of PVC wood-plastic composite material and preparation method and application of agent

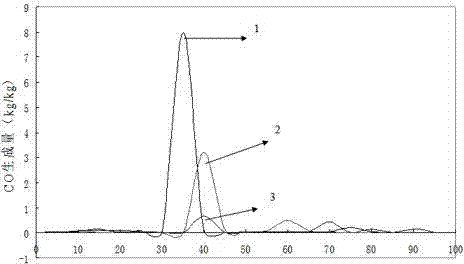

InactiveCN105566811AAdvantages of flame retardant and smoke suppression effectAdd lessPentaerythritolCombustion

The invention relates to a composite halogen-free flame-retardant smoke suppression agent of a PVC wood-plastic composite material and a preparation method and application of the agent, which relate to the composite halogen-free flame-retardant smoke suppression agent and the preparation method and application of the agent, and aim at solving the problems that the PVC wood-plastic composite material is combustible, a great amount of smoke is produced when the composite material is combusted, the addition amount of the existing PVC wood-plastic composite material flame-retardant smoke suppression agent is large, the flame-retardant effect and the smoke suppression effect are poor, and the existing PVC wood-plastic composite material flame-retardant smoke suppression agent is harmful to the health of people. The composite halogen-free flame-retardant smoke suppression agent consists of ammonium polyphosphate, melamine, pentaerythritol and copper oxide. The preparation method comprises the following steps: I, preparing an expansion-type flame-retardant agent; II, preparing the composite halogen-free flame-retardant smoke suppression agent. The application method comprises the following steps: I, weighing raw materials; II, preparing high-temperature materials; III, preparing a premix; IV, extruding and forming. The flame-retardant smoke suppression agent solves the problems that the wood-plastic composite material is combustible, a great amount of smoke is produced when the composite material is combusted, the addition amount of the existing flame-retardant smoke suppression agent is large, the effect is poor, and the existing flame-retardant smoke suppression agent is harmful to the health of people. The composite halogen-free flame-retardant smoke suppression agent is used for resisting the combustion and suppressing the smoke of the PVC wood-plastic composite material.

Owner:白晓艳

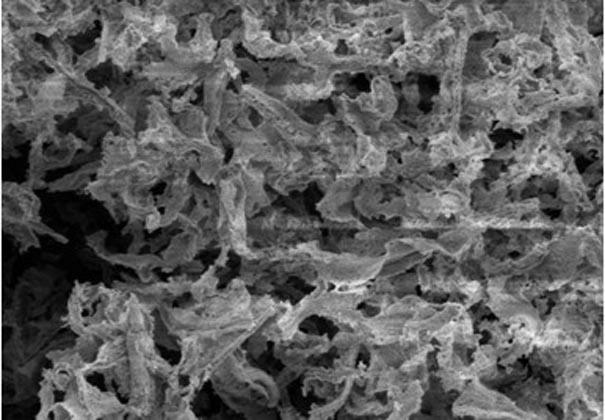

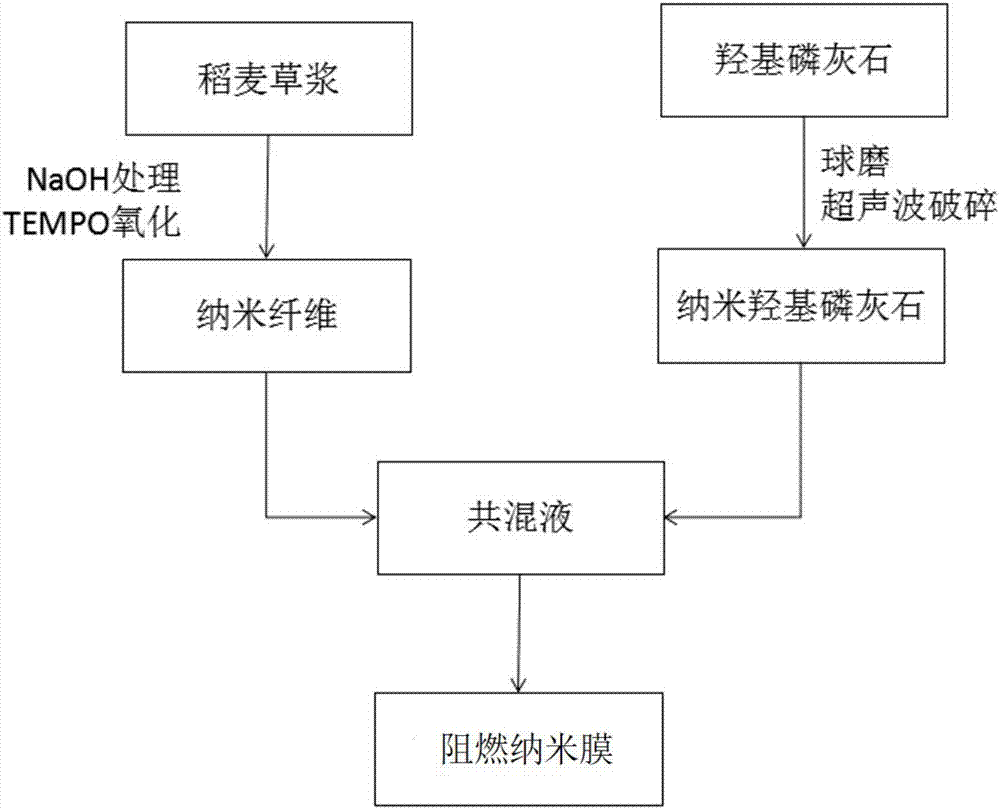

Flame-retardant nanometer film and preparation method and application thereof

ActiveCN107540857AIncrease the speed of formationIncrease char formationEmulsionBiocompatibility Testing

The invention belongs to the field of nanometer materials, and discloses a flame-retardant nanometer film and a preparation method and application thereof. The preparation method of the flame-retardant nanometer film comprises the steps that hydroxyapatite is dried and then subjected to ball milling, and after ultrasionic cell-break treatment is conducted for a period of time, nanometer hydroxyapatite emulsion is obtained; nanocellulose and nanometer hydroxyapatite are prepared into a blend solution according to certain proportion, film formation is conducted under the condition of constant temperature and humidity, and the flame-retardant nanometer film is obtained. The flame-retardant nanometer film has good flame retardance, the nanocellulose and the nanometer hydroxyapatite have the very good biocompatibility, and the flame-retardant nanometer film can be applied to the fields of flame-retardant materials, flexible electronic devices, biological and medical materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

Methods of utilizing elemental sulfur for flame retardant polymers and additives

InactiveUS20180186967A1High yieldHigh sulfur contentMaterial thermal analysisPolymer scienceFire retardant

Compositions of flame retardants and methods of enhancing char formation in a flame retardant-treated substrate. A base material is combined with a flame retardant to form the flame retardant-treated substrate. The flame retardant contains a sulfur copolymer prepared by the polymerization of sulfur monomers with organic monomers. The flame retardant can be deposited on a surface of the base material, coated on the base material, or mixed into the base material. When the flame resistant substrate is on fire, the flame retardant forms a charring layer on the flame retardant-treated substrate. The charring layer can extinguish and prevent the fire from spreading.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Wollastonite powder modified flame-retardant optical cable material and preparation method thereof

InactiveCN105936713APrevent the entry of external fuelReduce the temperatureCHLORIDE HEXAHYDRATEWollastonite

The invention discloses a wollastonite powder modified flame-retardant optical cable material, which is composed of the following raw materials in parts by weight: 10 to 13 parts of wollastonite powder, 0.1 to 0.2 part of stannous sulfide, 4 to 6 parts of triethylene glycol di-2-ethylhexoate, 2 to 3 parts of octabromoether, 100 to 130 parts of polyvinyl chloride, 3 to 4 parts of polystyrene 20-2 sodium hypophosphite monohydrate, 2 to 3 parts of paraformaldehyde, 0.2 to 0.3 part of hydrochloric acid (35-37%), 4 to 6 parts of chlorinated dichloropentate, 5 to 7 parts of aluminum chloride hexahydrate, 0.1 to 0.2 part of triethylamine, 0.4 to 1 part of N,N'-ethylenebisstearamide, 1 to 2 partso f sodium gluconate, 0.1 to 0.2 part of polysorbate 80, and 0.7 to 2 parts of polyvinylpyrrolidone. The provided optical cable material can dilute the flame and reduce the temperature of combustion area; at the same time, phosphor and oxygen free radicals generated during the cracking process can capture free radicals that are generated by cracking polystyrene chain segments, thus the thermal stability of the optical cable material is improved, and the heat release value of the material is reduced.

Owner:安徽电信器材贸易工业有限责任公司

Phosphate ester polymer intumescent flame retardant and preparation method thereof

InactiveCN102417596BImprove thermal stabilityIncrease char formationGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com