Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

980 results about "Limiting oxygen index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The limiting oxygen index (LOI) is the minimum concentration of oxygen, expressed as a percentage, that will support combustion of a polymer. It is measured by passing a mixture of oxygen and nitrogen over a burning specimen, and reducing the oxygen level until a critical level is reached.

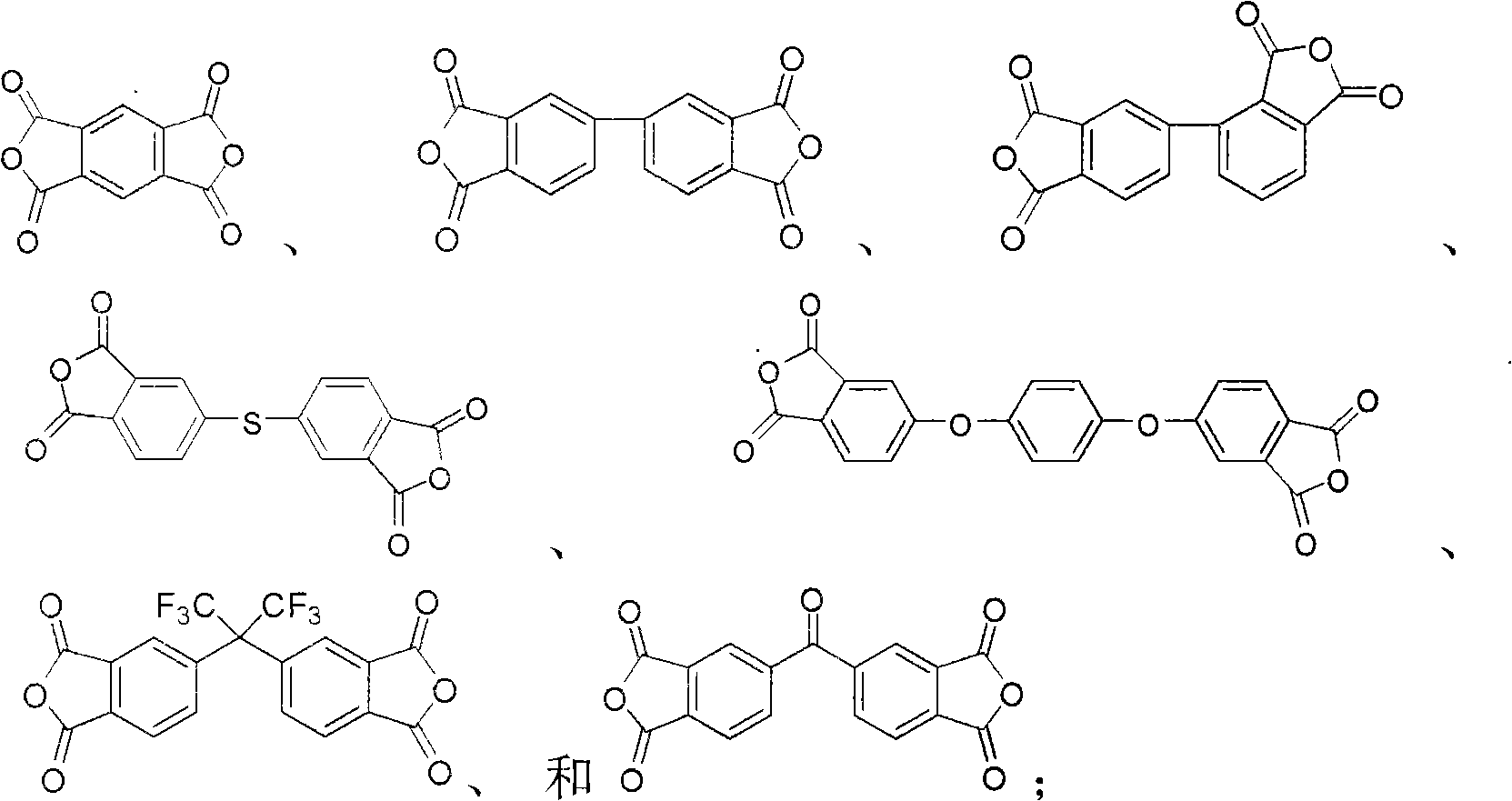

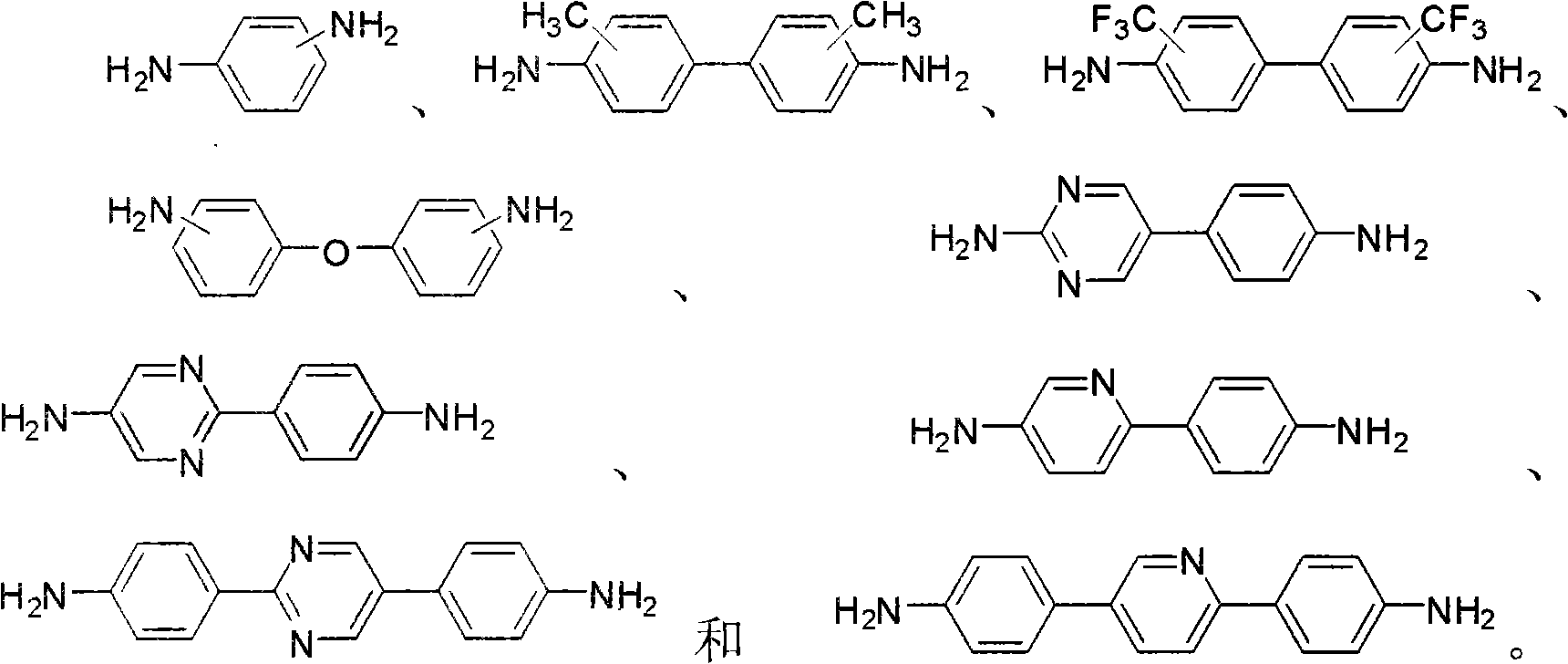

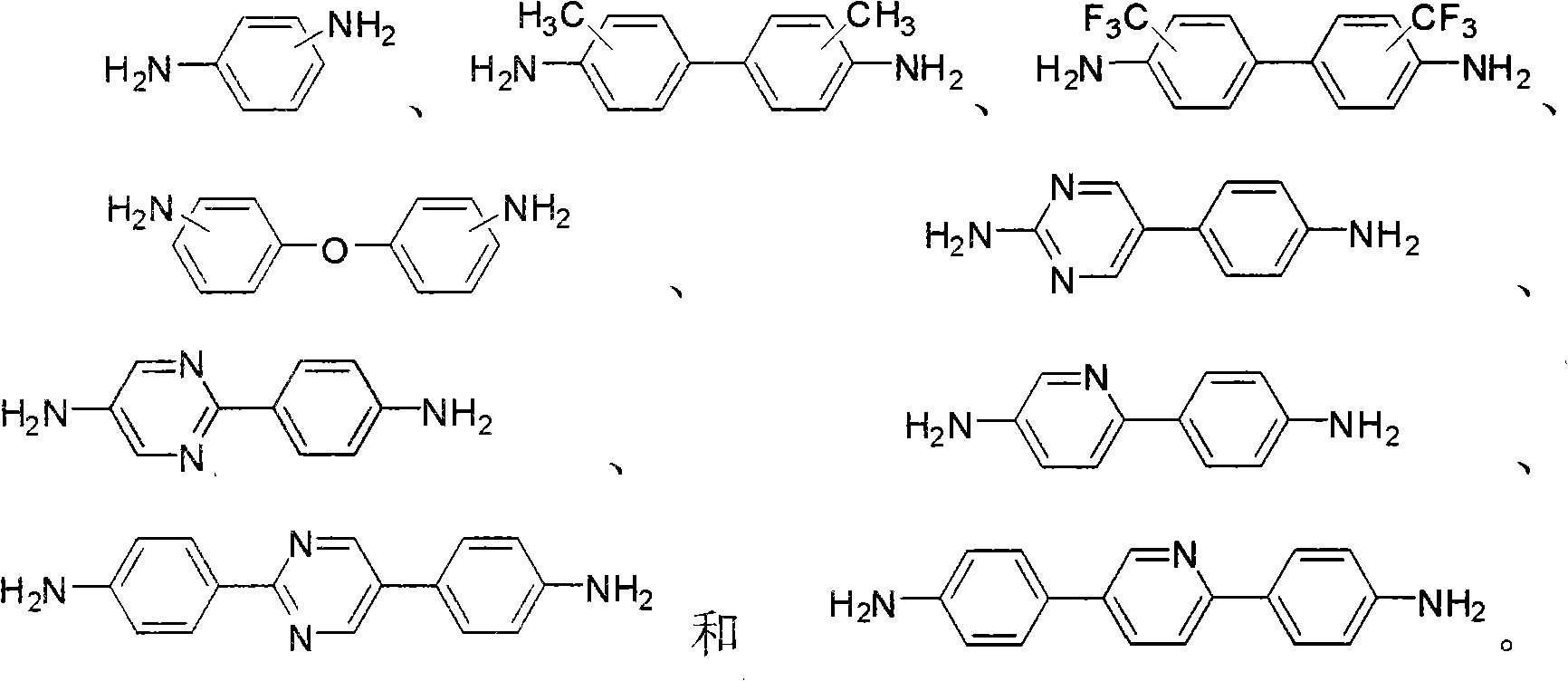

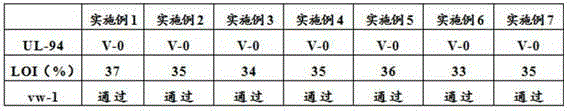

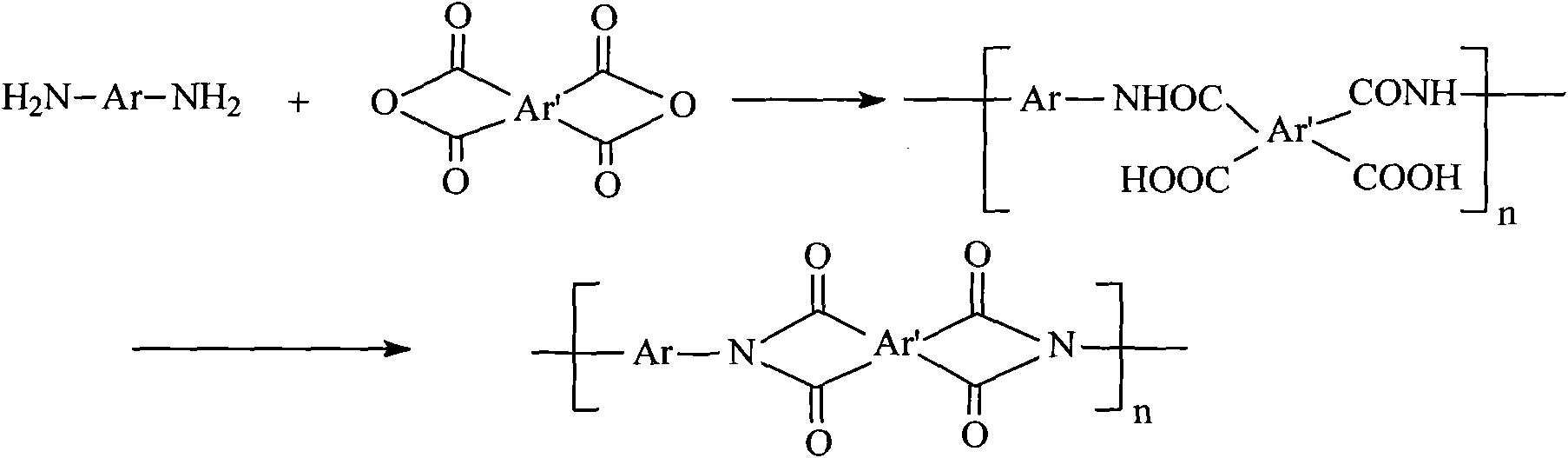

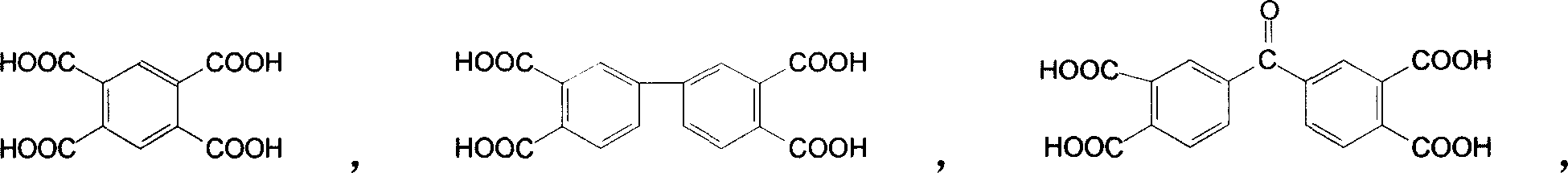

Method for preparing polyimide fiber

ActiveCN101338462AHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberTemperature control

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, the mooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Blended yarn weaved fabric based on novel flame retardant viscose, preparation method and application thereof

InactiveCN101538764AIdeal twistImprove flame retardant performanceWeft knittingFlame-proof filament manufactureYarnChemical treatment

The invention relates to a novel flame retardant fabric, a preparation method and an application thereof, particular to a blended yarn weaved fabric based on novel flame retardant viscose, a preparation method and an application thereof. The flame retardant viscose is prepared by blended spinning with nanometer SiO2 and cellulose solution; wherein the blended ratio of the flame retardant viscose and natural fiber is 20:80 to 80:20. The invention also provides the preparation method of the flame retardant blended yarn weaved fabric. As the nanometer SiO2 particles are adopted as inorganic flame retardant, the novel flame retardant blended yarn weaved fabric is good in fire resistance; limited oxygen index is more than 28%, meltdown or dripping can not appear when combusting, only a small quantity of flue gas which is safe and innoxious is produced, and the fabric is washing resistant and chemical treatment resistant. The invention has air and moisture permeability and soft feel. The blended yarn weaved fabric is mainly composed of the flame retardant viscose and cotton fiber, and can be applied to preparation of bedding such as bed sheet, quilt cover, pajamas, etc.

Owner:上海神九纺织科技有限公司

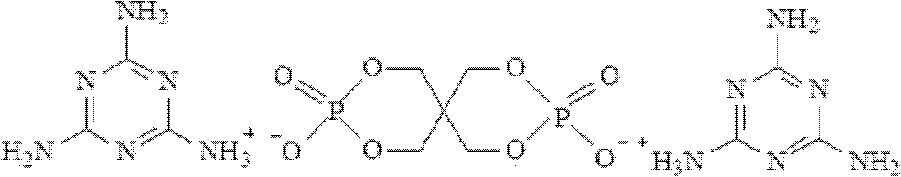

Halogen-free flame retardant polyether thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN104693782AImprove flame retardant performanceGuaranteed mechanical propertiesPolymer scienceMelamine phosphate

The invention relates to a halogen-free flame retardant polyether thermoplastic polyurethane elastomer which is prepared by the following components in parts by weight: 100 parts of polyether thermoplastic polyurethane elastomer resin, 30-50 parts of phosphor-nitrogen flame retardant system and 1-5 parts of flame retardant synergist, wherein the phosphor-nitrogen flame retardant system is prepared by mixing a flame retardant and a char-forming agent with weight ratio of 1-4: 1; and the flame retardant is one or a mixture of phenoxy cycloposphazene, melamine phosphate compound, melamine cyanurate and hypophosphite. The flame retardant performance of the polyether TPU (thermoplastic polyurethane) is modified by selecting the special phosphor-nitrogen flame retardant system; and the obtained flame retardant polyether TPU material is halogen-free, environment-friendly and safe, has a limit oxygen index (LOI) of up to 37% and has excellent flame retardant performance.

Owner:苏州安鸿泰新材料有限公司

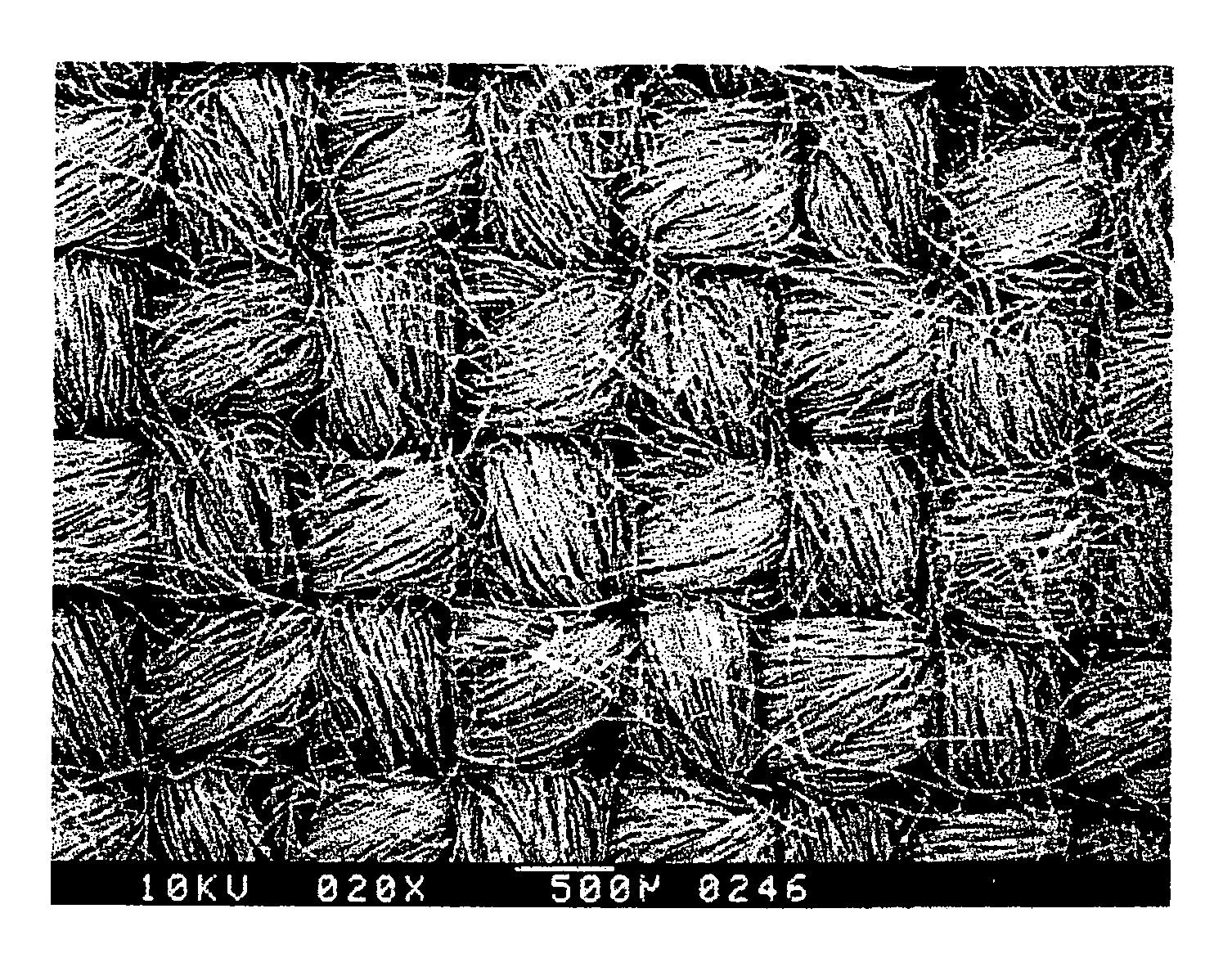

Preparation method of needle punched non-woven fabric

The invention relates to a preparation method of a needle punched non-woven fabric, belonging to the field of non-woven fabric processing. The preparation method of the needle punched non-woven fabric comprises the two following steps: A, preparation of modified polyester staple fiber; B, preparation of the needle punched non-woven fabric. The preparation method is short in technological process, strong in raw material adaptability, and simple in equipment structure, a product has the characteristics of uniform gram weight, high breaking strength, great tear strength, good heat stability and the like, the prepared needle punched non-woven fabric has breaking strength of 250-350N / 5cm, elongation at break of 50-98 percent, a fabric limit oxygen index of 30-34, good properties such as fluffiness, water permeability and air permeability, and a cotton feeling, compared with cotton goods, a non-woven fabric bag is easy to form and low in price, and thus is widely used in various fields, and main application of the needle punched non-woven fabric relates to geotechnical cloth, waterproof materials, filtering materials, synthetic leather base cloth, shoe materials and textiles for automobiles.

Owner:江西大晟节能新材有限公司

Organic silicon fibre retardant containing phosphorus and epoxy radical and its preparation method

The invention relates to organic silicon fire retardant containing phosphor and epoxy radical. It is made up of 100 portions methyl containing hydrogen silicone oil, 1-150 portions allylglycidyl ether, 0-50 portions end reaction contained double organic silane coupler and 1-200 portions active material containing phosphor after compounding. The invention also relates to the manufacturing method of taking polyaddition reaction of methyl containing hydrogen silicone oil, allylglycidyl ether, and end reaction contained double organic silane coupler, and compounding with phosphor contained active material. The condensate compounded by the invention and common epoxy resin the limiting oxygen index would reach 23-29, and vitrifying transforming temperature would reach 168-185degree centigrade.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

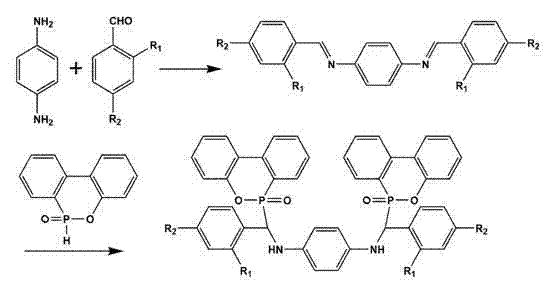

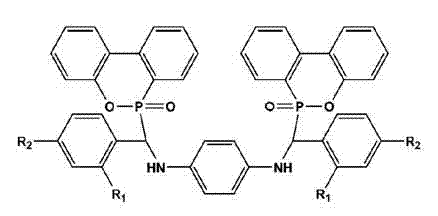

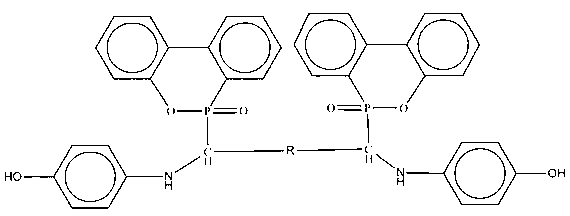

Nitrogen and phosphorus containing flame retardant agent and preparation method thereof as well as application thereof

ActiveCN102391545AHigh yieldSimple post-processingGroup 5/15 element organic compoundsEpoxyPolymer science

The invention relates to a preparation method of a nitrogen and phosphorus containing flame retardant agent, the nitrogen and phosphorus containing flame agent and application thereof. The preparation method comprises the following steps of: carrying out condensation reaction on phenylene diamine and aromatic aldehyde, then carrying out addition reaction with DOPO (9, 10-Dihydro-9-oxa-10-phosphaphenanthrene 10-oxide) to obtain solid nitrogen and phosphorus containing flame retardant agent molecules. The preparation method has the advantages of easiness in control, good repeatability, high yield and suitability for expanded production. The obtained flame retardant agent molecules have amino groups and phenolic hydroxyl active groups and can further react with matters containing expoxy group functional groups. The flame retardant agent molecules contain nitrogen and phosphorus elements and have good expansion char forming characteristic and very good flame retardant effect in the burning process; when the flame retardant agent molecules resist the flaming of the epoxy resin, the flame retardant agent molecules can further undergo cross-linking reaction with resin, thereby increasing the glass transition temperature, the bonding strength, the mechanical property and the like of the resin; meanwhile, the flame retardant agent molecules have good flame retardant property; the limiting oxygen index of the flame retardant agent molecules is substantially increased; and the vertical burning grade of the flame retardant agent molecules reaches a UL-94V-0 grade.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of halogen-free flame retardant high-intensity polyvinyl alcohol fibers

ActiveCN102002770AImprove stabilityImprove filtering effectFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentPolymer sciencePolyvinyl alcohol

Owner:SICHUAN UNIV +2

Method of preparing melamine formaldehyde resin/polyvinyl alcohol flame-proof fiber

InactiveCN101016658AImprove spinnabilityIncrease productivityFlame-proof filament manufactureWet spinning methodsFiberLimiting oxygen index

The invention discloses a method for producing melamine formaldehyde resin / polyvinyl alcohol flameproof fiber. The invention is characterized in that composing melamine and formaldehyde at the mole ratio as 1:1.2-1:6 and 50-100Deg. C into melamine formaldehyde resin water solution, to be mixed with the polyvinyl alcohol water solution at the solid content ratio as 2:8-8:2 to obtain spinning original liquid, then spinning and shaping the original liquid via general wet method, and treating solidifying bath via acid sodium sulfate saturated water solution, and the primary fiber is drawn, shaped via wet and heat method, washed, coiled, oiled, dried, and heated in dry condition to obtain the final melamine formaldehyde resin / polyvinyl alcohol flameproof fiber. The titer of said flameproof fiber is 10detex, while the strength is 1-3cN / dtex, the crack extended rate is 5-15%, the regain ratio is 5-10%, and the limit oxygen index is 30-45.

Owner:SICHUAN UNIV +1

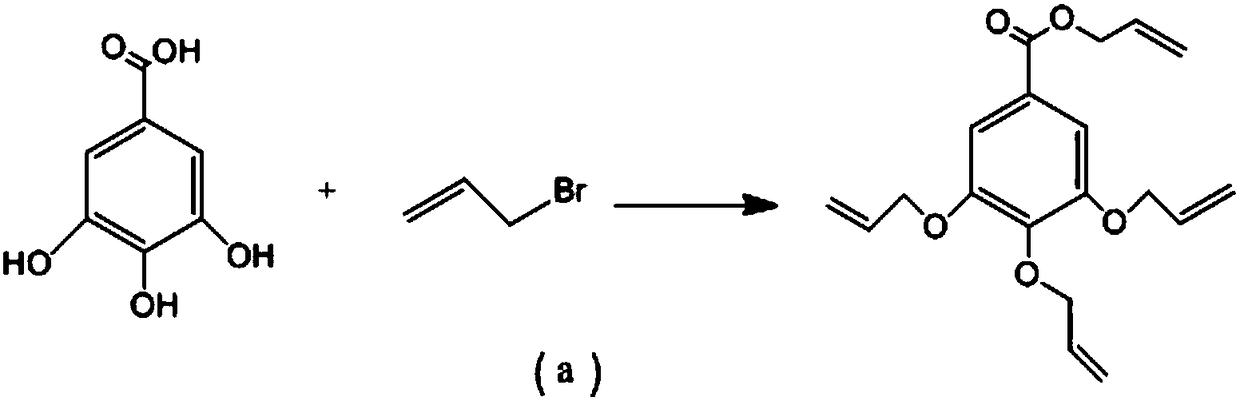

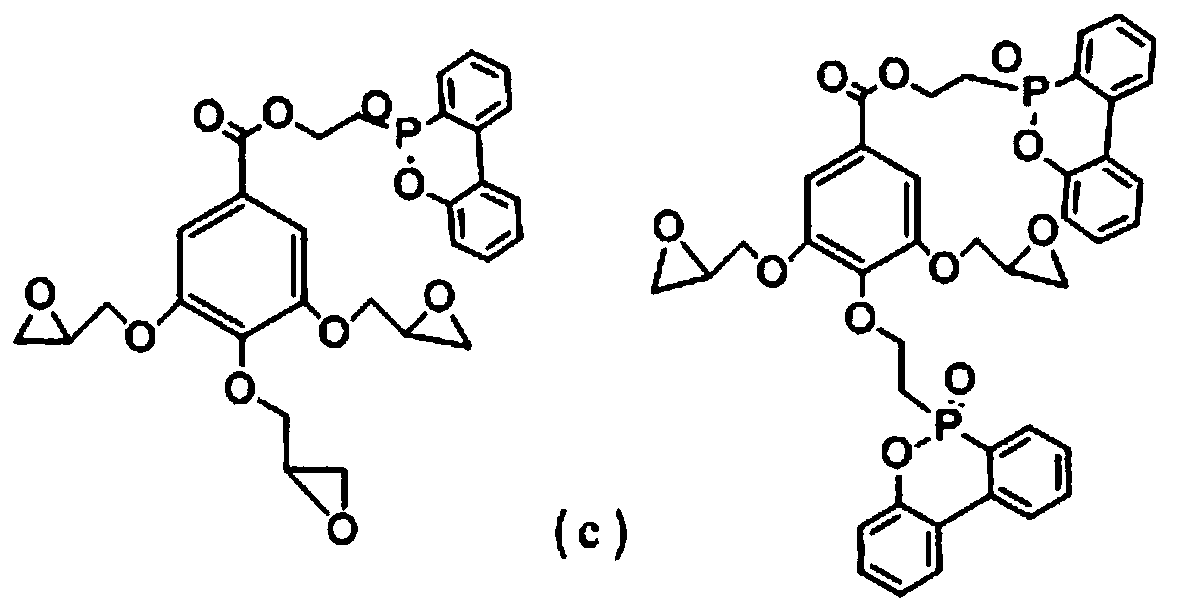

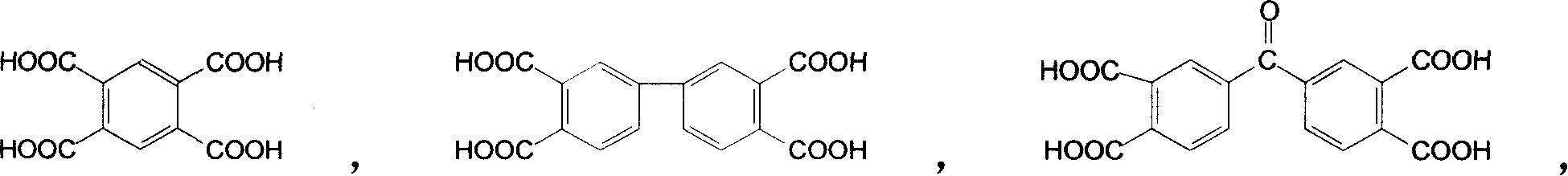

Method for preparing bio-based flame-retardant epoxy resin and prepared bio-based flame-retardant epoxy resin

ActiveCN108192078AThe reaction process is simple and low toxicityImprove thermal stabilityGroup 5/15 element organic compoundsLimiting oxygen indexHigh activity

The invention discloses a total-bio-based flame-retardant epoxy resin. According to the invention, reactive groups on gallic acid are used for introducing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and epoxy groups so as to obtain a bio-based epoxy monomer which is used for replacing bisphenol A epoxy resin DGEBA used in general industries; and a bio-based curing agent, i.e., difurfurylamine, with higher activity is synthesized and subjected to mixing and curing with the prepared epoxy monomer so as to prepare a total-bio-based epoxy resin product with flame retardant properties. The epoxy resin is rich in biological sources, friendly to environment, simple in reaction process and good in flame retardancy, and has a highest limit oxygen index of 34% and a highest vertical burning level of V-0. The invention also discloses a preparation method for the total-bio-based flame-retardant epoxy resin.

Owner:NANJING UNIV

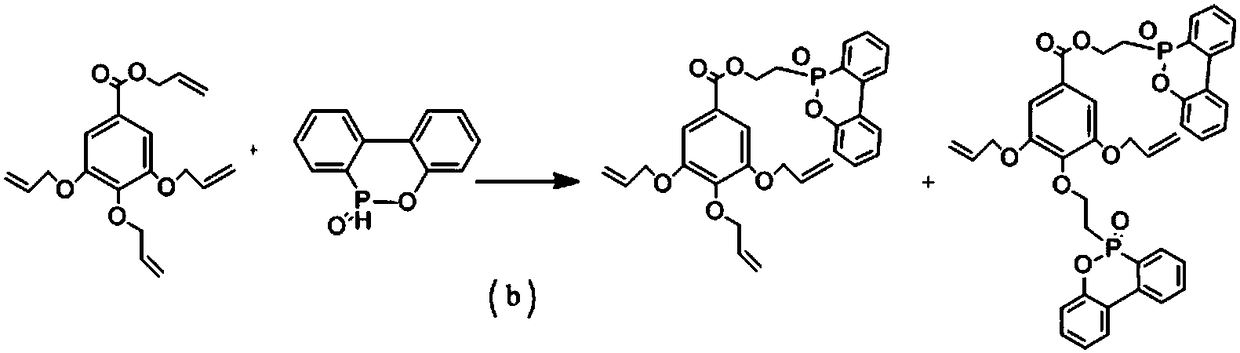

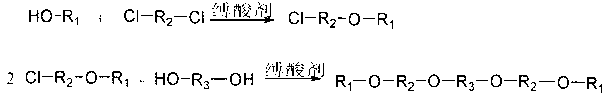

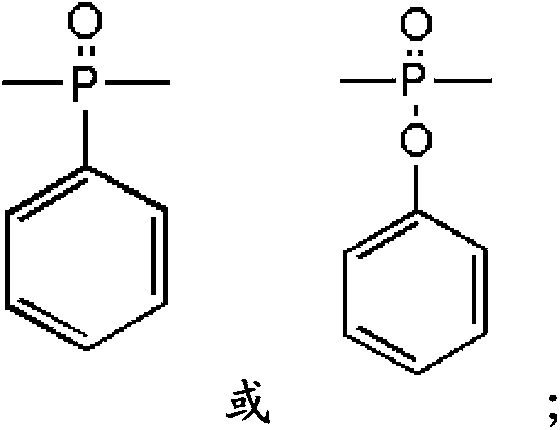

Reactive phosphorus flame retardant containing DOPO and active double bond and preparation method and application thereof

ActiveCN103073746ASimple manufacturing methodImprove reaction conditionsGroup 5/15 element organic compoundsDouble bondPhenol

The invention discloses a reactive phosphorus flame retardant containing DOPO and an active double bond and a preparation method and application thereof. Dichloro replaces phosphate to react with polyhydric alcohols or polyhydric phenol acidifying with propylene or partial methyl propene and then with DOPO modified aryl-dihydric phenol and DOPO modified aryl-dihydric alcohol, and a reactive flame retardant monomer molecule capable of being cured and provided with active double bonds and a DOPO flame retardant group are obtained and can be used in various flame retardants of epoxyacrylates and unsaturated polyester resins and the like containing unsaturated double bond polymer resins. The flame retardant overcomes defects that the compatibility between an additive flame retardant and a matrix is poor, the additive flame retardant and the matrix are easy to lose, the water resistance is poor, and the like, and the LOI (limit oxygen index) value of resins can be improved remarkably and the flame-resistant effect is good when the flame retardant is used for flame retarding in the epoxyacrylates and the unsaturated polyester resins.

Owner:苏州安鸿泰新材料有限公司

Halogen-free flame-retardant polystyrene foam composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant polystyrene foam composite material which is prepared through the following steps: evenly mixing 100 parts of foam particles prepared by a conventional technology with a binder which consists of 10-80 parts of an aerogel matrix, 0-10 parts of an aerogel crosslinking agent, 10-50 parts of nano clay and 10-40 parts of a halogen-free flame retardant so as to obtain a mixture, performing compression-molding refrigeration and drying the mixture, wherein the weight ratio of the foam particles to the aerogel matrix binder in the foam composite material is 1:(0.3-1.8), the density is 21-44kg / m<3>, the vertical burning grade is UL-94V-0, the limit oxygen index is 26-45% and the heat conductivity is 0.031-0.035W / mK. Since the aerogel is low in density and heat conductivity, excellent in binding performance, and capable of jointly acting with nano clay and halogen-free flame retardant to provide outstanding flame retarding performance and charring performance, the foam composite material can keep low density and good heat preserving performance and the flame retarding performance of the composite material is greatly enhanced; besides, the technology is mature, simple to operate, easy to control and beneficial to popularization and application.

Owner:SICHUAN UNIV

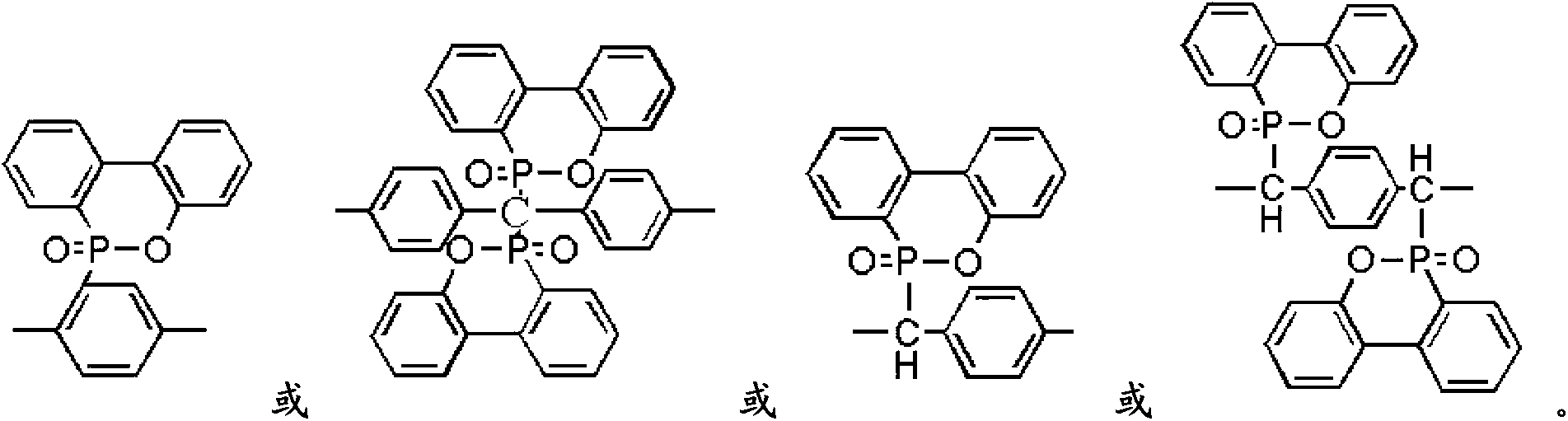

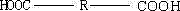

Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

The invention discloses a preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol. The preparation method is characterized by comprising following steps: taking binary acid, dihydric alcohol, halogen-free phosphorous copolymer fire retardant and catalyst to be put into a reaction kettle, stirring and warming up, filling nitrogen to empty, reacting for 2 to 8h when the temperature reaches 125 to 155 DEG C, then warming up to 180 DEG C, vacuumizing to ensure the air pressure to be 100 to 5000 Pa, controlling reaction temperature to be 180 to 245 DEG C, after reacting for 2 to 4h, sampling at an interval of 10 to 40 min to test acid value, stopping heating when the acid value is reduced below 2 mgKOH / g, and stirring for cooling so as to obtain the reaction type halogen-free phosphorous flame retardant polyester polyol. The reaction type halogen-free phosphorous flame retardant polyester polyol is applied to synthesis of rigid or soft polyurethane foamed plastic, and the prepared polyurethane foamed plastic has excellent flame retardant property, and the limit oxygen index can be up to more than 32%.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Two-layer fabric and heat-resistant protective clothing containing the same

InactiveUS20090137176A1Improved satisfactory propertyGood lookingLayered productsMulti-ply fabricsFiberThermal insulation

A two-layer fabric according to the present invention has an integral structure containing a base cloth on the upper side and a reinforcing cloth for reinforcing the entire fabric on the under side, wherein (a) the base cloth of the two-layer fabric is flame-retardant and contains a warp yarn and a weft yarn containing 30% by weight or more of a flame-retardant fiber having a limiting oxygen index (LOI) of 26 or more and a tensile strength of 8 cN / dtex or less, (b) the reinforcing cloth of the two-layer fabric contains a warp yarn and a weft yarn containing a heat-resistant high-strength fiber having a tensile strength of 15 cN / dtex or more as a main component, and (c) the base cloth and the reinforcing cloth are connected by the warp yarn and / or the weft yarn of the base cloth, to form the integral structure.Further, a heat-resistant protective clothing contains an outer fabric layer of the two-layer fabric, stacked and sutured by sewing. The heat-resistant protective clothing has improved properties such as a thermal insulation property and abrasion resistance, in addition to excellent appearance.

Owner:TEIJIN LTD

Method for making carbon fabric and product thereof

ActiveUS7670970B2Improve conductivityHigh densityEngine sealsSynthetic resin layered productsFiberPolymer science

A carbon fabric of high conductivity and high density is formed of oxidized fibers of polypropylene. The oxidized fibers have a carbon content at least 50 wt %, an oxygen content at least 4 wt %, and a limiting oxygen index at least 35%. The carbon fabric is made by preparing a raw fabric obtained from oxidized fibers of polypropylene by weaving and then carbonizing the raw fabric.

Owner:FENG CHIA UNIVERSITY

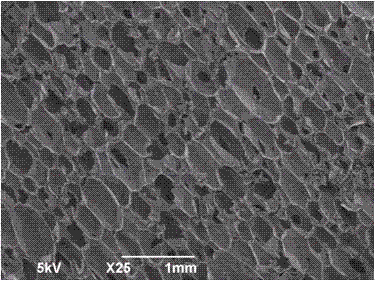

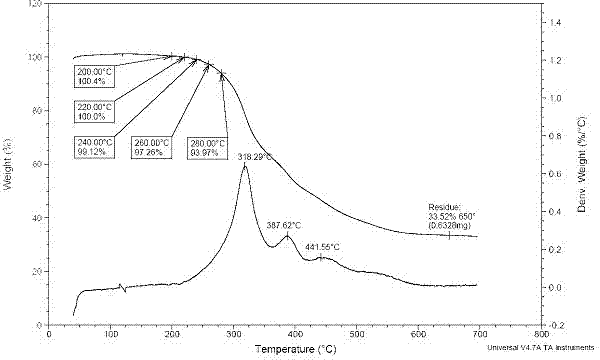

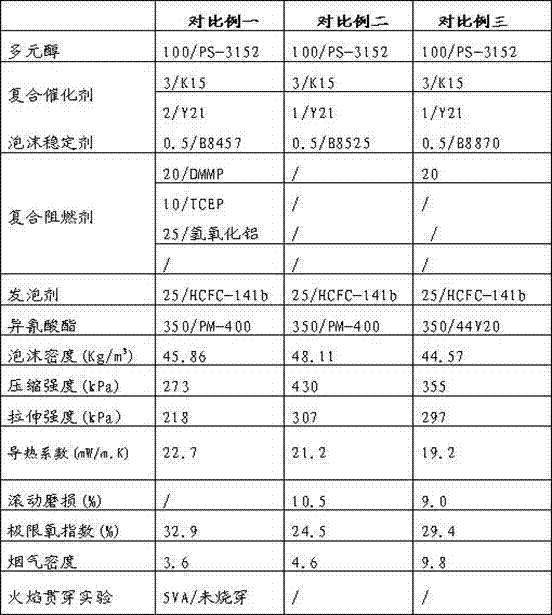

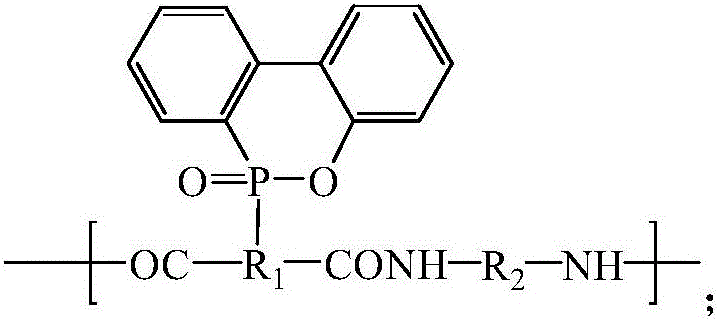

Flame-retardant polyurethane modified polyisocyanurate foam, and preparation method and application of foam

The invention belongs to the field of high molecular materials, and relates to polyurethane foam, and a preparation method and an application of the polyurethane foam, in particular to flame-retardant polyurethane modified polyisocyanurate foam, and a preparation method and an application of the flame-retardant polyurethane modified polyisocyanurate foam. The flame-retardant polyurethane modified polyisocyanurate foam comprises the following components in parts by mass: 100 parts of polyol, 1.5-12.0 parts of composite catalyst, 0.1-3.0 parts of foam stabilizer, 10-50 parts of foaming agent, 30-100 parts of composite flame retardant, and 200-600 parts of isocyanate. With the adoption of the preparation method, a finished product with uniform and consistent aperture size and foam density can be prepared, and the synthesis preparation method is simple, can be applied to both manual foaming and spray forming, and facilitates scale production and application. The polyisocyanurate foam, the preparation method and the application have the advantages that the heat conductivity coefficient is kept less than 25mW / m*K; a foam combustion limit oxygen index (OI) is greater than or equal to 33 and a smoke density ratio (SDR) is less than 15; and the frequent problem that the smoke density ratio is increased synchronously due to the increase of the formula foam oxygen index as an organic flame retardant is only adopted in the prior art is overcome.

Owner:NANJING HONGNUO TECH

Honeycomb from paper having flame retardant thermoplastic binder

This invention relates to an improved flame retardant honeycomb comprising high modulus fiber and a flame retardant thermoplastic binder having a melt point of from 120° C. to 350° C. and a limiting oxygen index of 26 or greater, methods for making the honeycomb, and articles comprising the honeycomb. In a preferred embodiment the paper in the honeycomb has a flame classification of UL-94 V-0.

Owner:DUPONT SAFETY & CONSTR INC

Flame-retarded polyamide 6 and preparation method thereof

The invention relates to flame-retarded polyamide 6 and a preparation method thereof. The preparation method comprises the steps of firstly obtaining flame retardant salt through reaction between a DOPO-based reaction type phosphorus-based flame retardant and diamine; then adding an addition type phosphorus-based flame retardant, the flame retardant salt and other components during a process of polymerizing caprolactam into polyamide 6 so as to prepare the flame-retarded polyamide 6, wherein a molecular chain of the flame-retarded polyamide 6 is formed by a polyamide chain segment and a DOPO-based reaction type phosphorus-based flame retardant chain segment; the content of phosphorus in the molecular chain is 0.4 to 0.8 percent by weight; and the molecular chain contains 3 to 9 percent by weight of the addition type phosphorus-based flame retardant. The flame-retarded polyamide 6 prepared through the invention has the limit oxygen index being larger than 29 percent, the tensile strength ranging from 55 to 69MPa, the elongation at break ranging from 40 to 110 percent, can become gears, bearings, automobile parts and other products through injection molding and other methods, and can also be prepared into polyamide 6 fiber so as to be further processed to be textile, military fabrics, equipment and the like.

Owner:DONGHUA UNIV

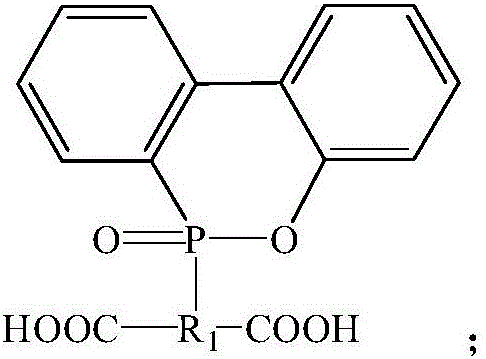

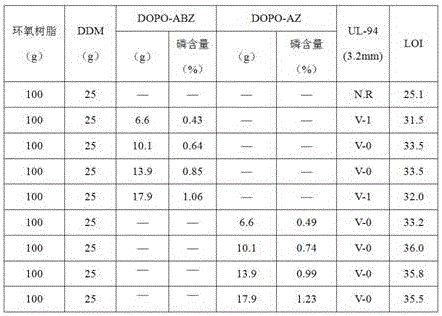

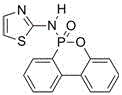

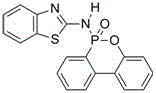

Flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and preparation method of flame retardant

InactiveCN106009040AThe synthesis process is simpleShort cycleGroup 5/15 element organic compoundsEpoxySulfur

The invention discloses a flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and a preparation method of the flame retardant. Firstly, DOPO and aminothiazole are taken as reaction raw materials and subjected to an Atherton-Todd reaction for preparation of the flame retardant containing phosphorus, nitrogen and sulfur. The process steps of the method are simple, the yield and the purity of the flame retardant are high, and the post-treatment process is simple and convenient. The flame retardant containing phosphorus, nitrogen and sulfur and prepared with the method is used for modifying cured epoxy resin and has good compatibility with epoxy resin, and the obtained cured flame-retardant epoxy resin has excellent flame retardancy; when the phosphorus content of the epoxy curing system reaches 0.43wt%-1.23wt%, the vertical burning grade can pass UL-94 V-0 level, and the limit oxygen index is as high as 36%.

Owner:FUJIAN NORMAL UNIV

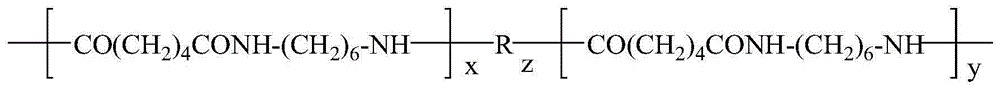

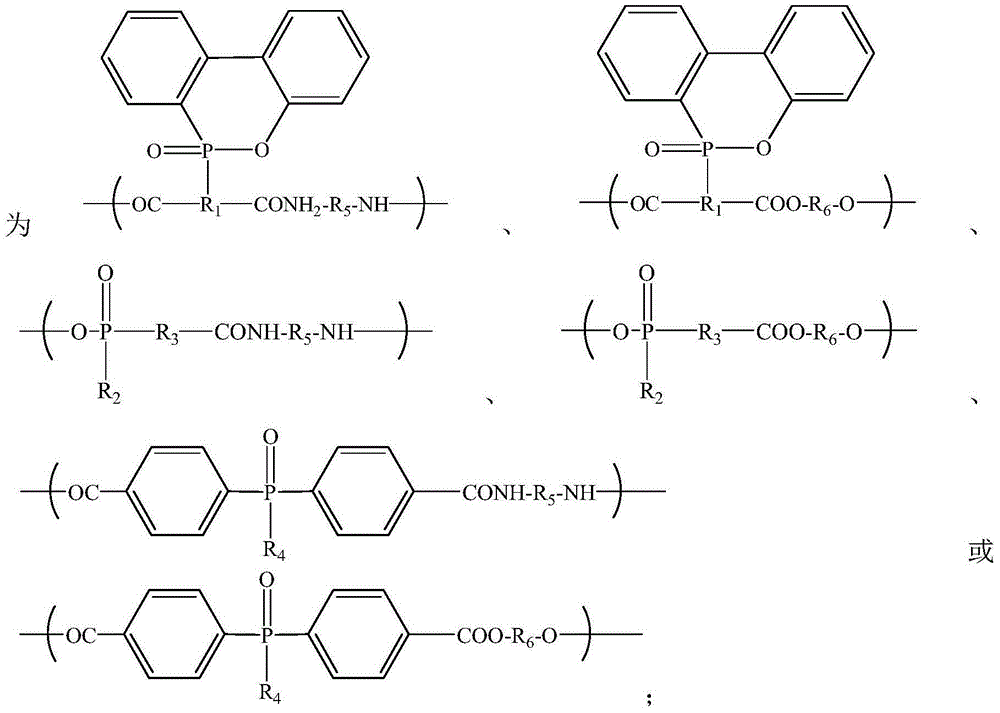

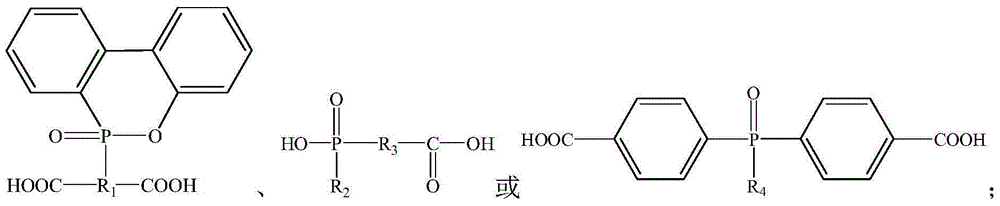

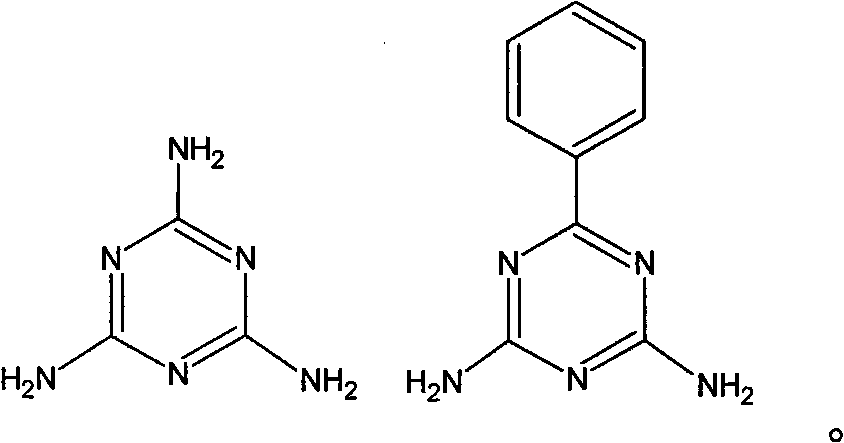

Flame-retardant nylon 66 copolymer material and preparation method therefor

The invention relates to a flame-retardant nylon 66 copolymer material and a preparation method therefor and particularly relates to a block flame-retardant nylon 66 copolymer material obtained through polymerization reaction of a phosphoric reactive flame retardant and a preparation method therefor. The method is characterized by comprising the steps of firstly enabling the flame retardant to react with diamine or dibasic alcohol so as to obtain a flame retardant prepolymer, and then, enabling the flame retardant prepolymer to react with a prepolymer of nylon 66, thereby obtaining the flame-retardant nylon 66 copolymer material. The flame-retardant nylon 66 copolymer material prepared by the method has the advantages of low flame retardant addition level, excellent mechanical properties, good flame retardant durability and the like, the vertical firing test can reach UL94V-0, and the limiting oxygen index is over 32%. The flame-retardant nylon 66 copolymer material not only can be subjected to injection molding directly or form films, but also can be prepared into flame-retardant fibers through melt spinning so as to be applied to the fields of clothing, fabrics and the like.

Owner:DONGHUA UNIV

Preparation method of melt-drip resistant inflaming retarding polyester fiber

InactiveCN101580976AWon't releaseEffective against drippingFlame-proof filament manufactureFibre treatmentSocial benefitsPolyester

The invention discloses a preparation method of melt-drip resistant inflaming retarding polyester fiber, comprising the following steps: mixing melt-drip resistant agent with a polyester slice, performing melt spanning, and processing and post-processing the mixture by alkaline solution and acid solution to form the melt-drip resistant inflaming retarding polyester fiber. The limited oxygen index of the melt-drip resistant inflaming retarding polyester fiber of the invention is 31-34, thereby melt dripping can not occur when the melt-drip resistant inflaming retarding polyester fiber burn, which can resist melt dripping effectively without releasing poisonous gas or smoke. Spinning melt-drip resistant inflaming retarding polyester fiber in accordance with routine melt spinning technology of the polyester fiber, the spanning is simple and easy to operate. The melt-drip resistant inflaming retarding polyester fiber can be directly and widely used as coatings, curtains, bedding articles, interior decoration and various special materials and the like, and has significant economic benefit and social benefit.

Owner:ZHEJIANG SCI-TECH UNIV

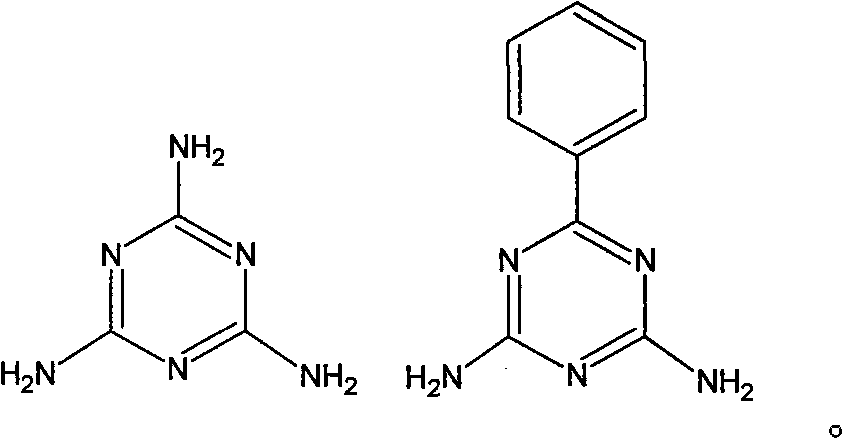

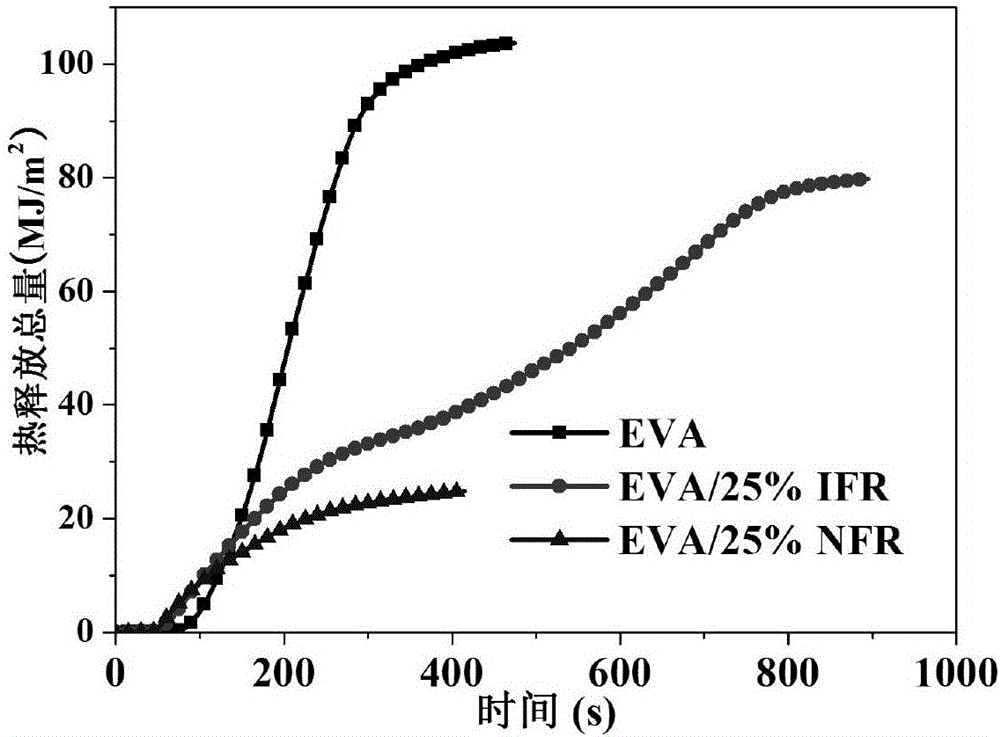

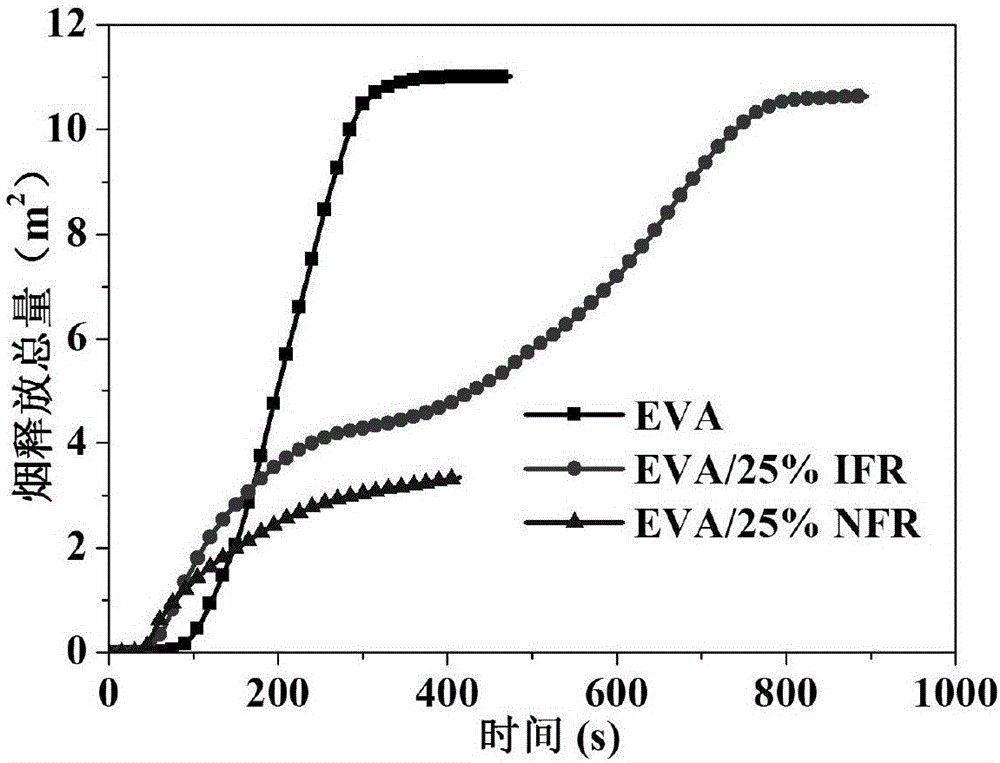

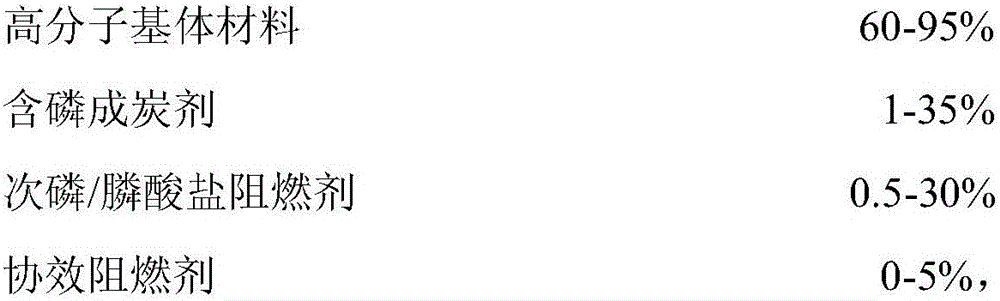

Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

ActiveCN106496729AHigh flame retardant efficiencyGood char formationPolymer scienceLimiting oxygen index

The invention discloses a flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite / phosphonate. The flame-retardant high polymer material is formed by blending, in weight percentage, 60-95% of high polymer base materials, 1-35% of phosphorus containing char-forming agents, 0.5-30% of hypophosphite / phosphonate and 0-5% of synergistic flame retardants. The compound main flame retardants used in the material have double char-forming functions, the material has excellent flame-retardant and smoke suppression properties, limit oxygen index reaches up to 27.0-49.5%, vertical burning test level ranges from UL-94V-1 to V-0, the total heat release of the material in cone calorimeter is reduced by 48.2-90.5% as compared with that of a pure base material, and total smoke release is reduced by 41.6-88.5%. Besides, the flame retardants used in the flame-retardant high polymer material have excellent water resistance, so that the material also has excellent water resistance, after the material is soaked in 70 DEG C for 168 hours and then dried, the vertical burning test level is unchanged, and the oxygen index is only reduced by 0-0.5%.

Owner:SICHUAN UNIV

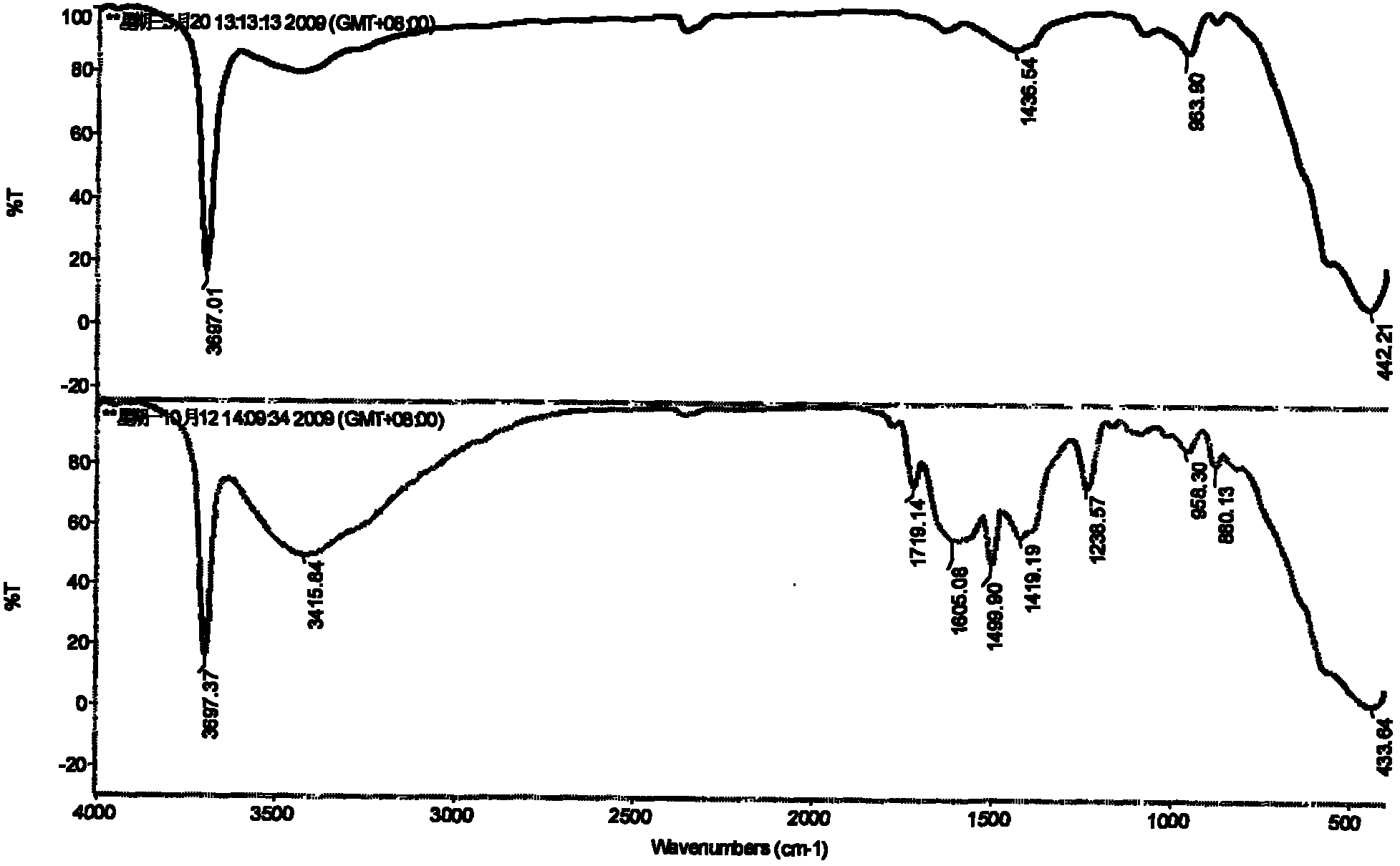

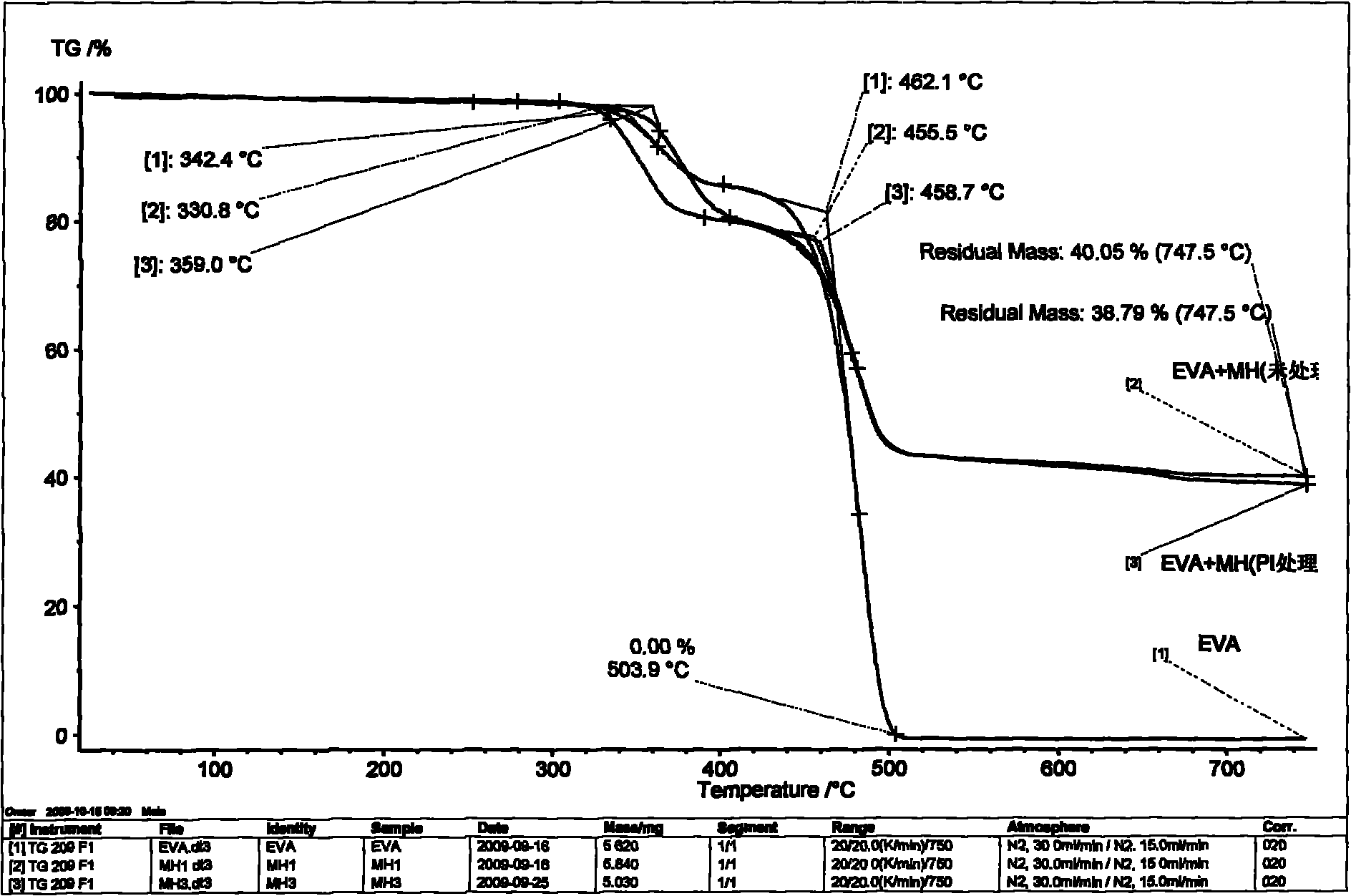

Method for preparing polyimide intercalated grafted magnesium hydroxide flame retardant

InactiveCN101787290AHigh limiting oxygen indexImprove flame retardant performanceFireproof paintsEnd-groupAromatic solvents

The invention relates to a method for preparing polyimide intercalated grafted magnesium hydroxide flame retardant. The method comprises: mixing binary primary amine, amino end-group coupling agent and strong polar non-proton organic solvent; uniformly stirring the mixture at room temperature; adding magnesium hydroxide powder; performing high-speed shearing dispersion for 20 to 30 minutes; adding aromatic dianhydride powder, catalysts and aromatic hydrocarbon solvent; performing water-separating reaction for 6 to 8 hours; and separating out aromatic solvent and part of strong polar non-proton organic solvent to obtain the polyimide intercalated grafted magnesium hydroxide flame retardant. The polyimide intercalated grafted magnesium hydroxide flame retardant has the vertical combustion level at V-0, limiting oxygen index up to 32, tensile strength up to over 13.6 MPa, significant flame retardant effect and good application prospects. In addition, the method has the advantages of simple preparation process, low cost, convenient operation, friendliness to environment, capability of completing preparation in general equipment and help to industrial production.

Owner:DONGHUA UNIV +1

Preparation method for halogen-free flame-retardant polypropylene fibers

InactiveCN102146596AReduce manufacturing costLittle influence on the spinning processFlame-proof filament manufactureMonocomponent polyolefin artificial filamentCross-linkTO-18

The invention discloses a preparation method for halogen-free flame-retardant polypropylene fibers. The preparation method is characterized by comprising the following steps of: melting, mixing, extruding and granulating 30 to 60 weight parts of polypropylene slices, 30 to 68.5 weight parts of intumescent flame retardant and 1.5 to 10 weight parts of additives in a twin-screw extruder at the temperature of 210 to 230 DEG C to obtain intumescent flame-retardant master batches; after mixing 10 to 25 weight parts of the flame-retardant master batches and 75 to 90 weight parts of the polypropylene slices, spinning by using a melt-spinning machine; after beaming the prepared halogen-free flame-retardant polypropylene protofilaments, feeding the beamed halogen-free flame-retardant polypropyleneprotofilaments into electronic irradiation equipment for performing irradiation cross-linking treatment, wherein the thickness of tow is made below 2 mm by using shaping equipment and the irradiationmeasurement is 50 to 400 kGy when irradiating; and obtaining the finished halogen-free flame-retardant polypropylene protofilaments by winding the irradiated fibers, wherein the finished fibers have the fineness of 0.5 to 100 dtex, the strength of 2 to 9 cN / dtex, and the breaking elongation of 5 to 18 percent, and the limiting oxygen index of the fibers is 28 to 34.

Owner:SICHUAN UNIV +1

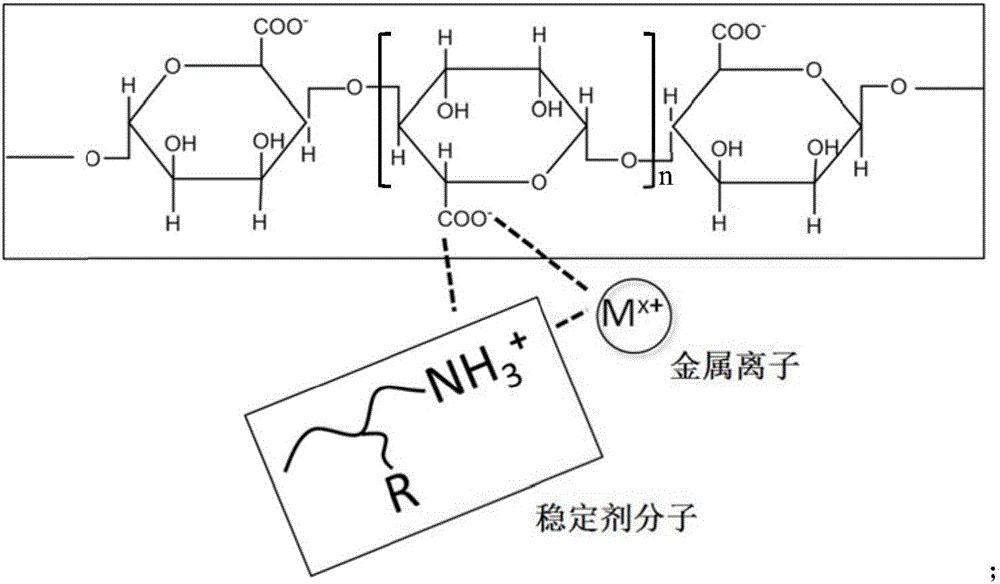

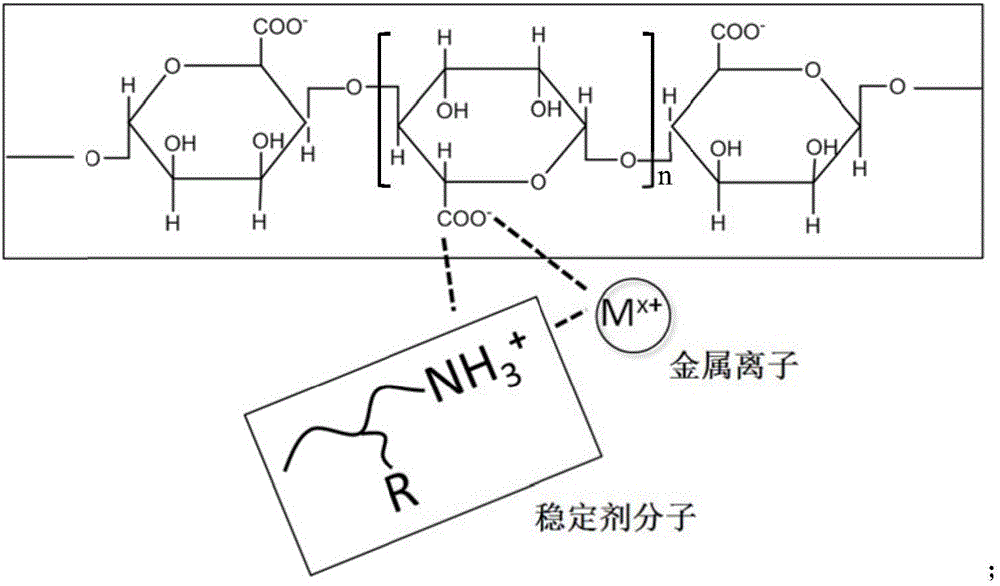

Sodium alga acid flame retardant fibers loaded with metal ions and manufacture method thereof

ActiveCN105821523AHigh breaking strengthBiodegradableFlame-proof filament manufactureAlginate artificial filamentsFiberBreaking strength

The invention provides sodium alga acid flame retardant fibers loaded with metal ions and a preparation method thereof. The sodium alga acid flame retardant fibers are prepared by the following steps: dissolving a water soluble sodium alga acid hybrid material loaded with metal ions in water to prepare a spinning solution, and performing a wet spinning process, wherein the water soluble sodium alga acid hybrid material loaded with metal ions is composed of sodium alga acid, stabilizer molecules and the metal ions with flame retardant effect. The fibers produced by the method disclosed by the invention have the characteristics of high flame retardant property and high breaking strength. The limit oxygen index of the fibers can be 34% and above, the tensile strength of the fibers is higher than 3.5cN / tex, and the linear density is 2.2-3.5dtex.

Owner:DONGHUA UNIV

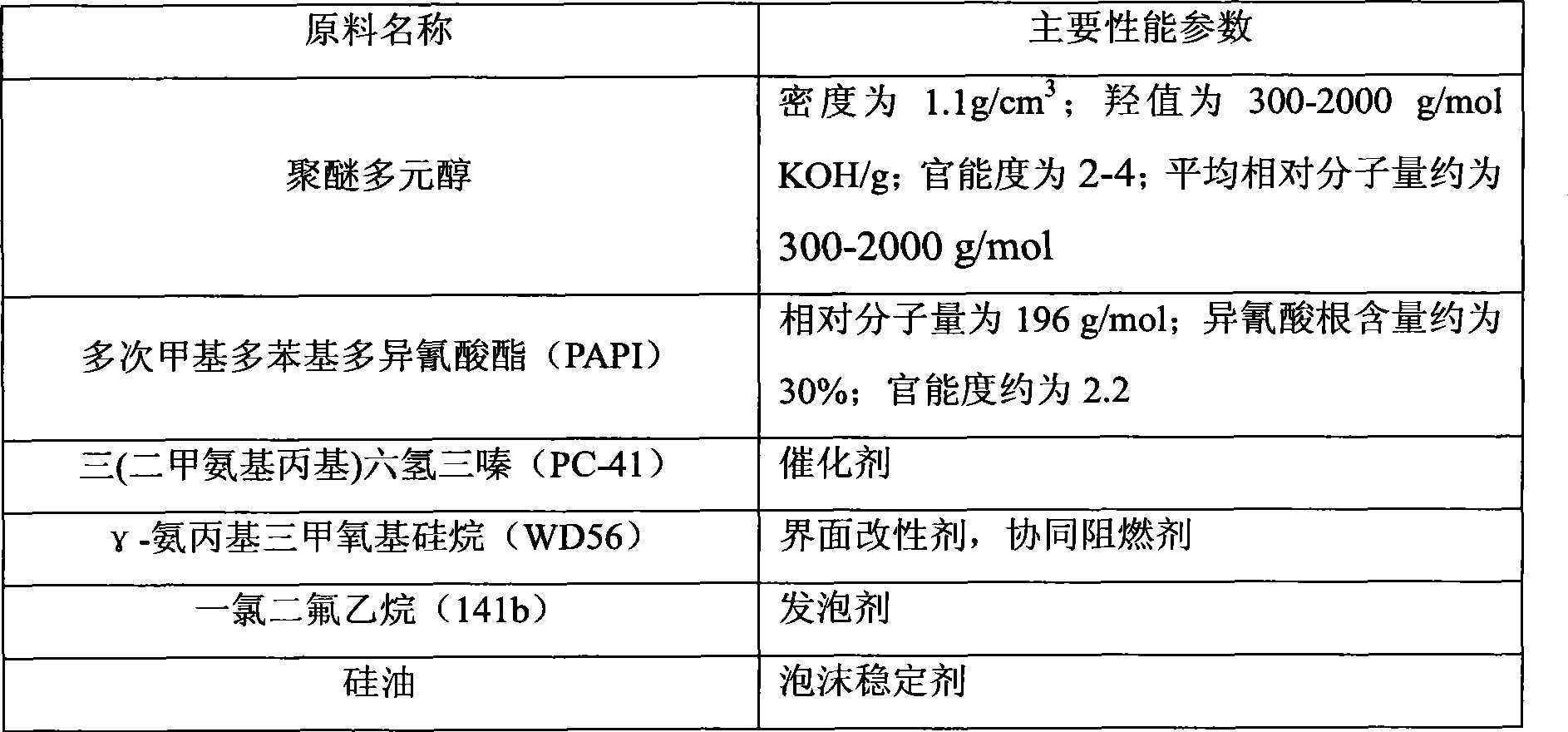

Halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material and preparation method thereof

The invention belongs to the field of high-flame-retardant rigid polyurethane foam insulation materials, which particularly relates to a halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material and a preparation method thereof. The method comprises the following steps: mechanically stirring a mixture formed by polyether (or polyester) polyhydric alcohols, a catalyst, a silicone oil, a silane coupling agent, a foaming agent, expansible graphite and inorganic fillers (one or more than one material selected from magnesium hydrate, kaolin, aluminium hydroxide and calcium carbonate) in certain proportion and evenly mixing; then, fully mixing the mixture with polyisocyanates; pouring into a mould of 50 DEG C to 100 DEG C; closing a mould cover; and finally, foaming and curing, thereby obtaining the halogen-free non-phosphorus high-flame-retardant rigid polyurethane foam insulation material. The flame retardation of the insulation material is improved under the synergistic effect of the expansible graphite and the inorganic fillers, so that the limit oxygen index of the insulation material can reach 90; and the vertical combustion performance of the insulation material can reach the level UL94 V0. According to the insulation material provided by the invention, the defect of a flame retardant containing halogen and phosphorus is overcome; and the flame retardation of the insulation material is improved under the synergistic effect of the environment-friendly fillers. Thus, the application requirement of the insulation material in practical engineering can be satisfied.

Owner:BEIJING ACAD OF BUILDING ENG

Permanent-flame-retardant nylon 6 material and preparation method therefor

InactiveCN105153414AAdd lessGood and long-lasting flame retardantFireproof paintsFiberPolymer science

The invention relates to a permanent-flame-retardant nylon 6 material and a preparation method therefor and particularly relates to a preparation method for a block copolymerized flame-retardant nylon 6 material obtained through continuously and respectively carrying out two-step polymerization reaction on a phosphoric reactive flame retardant. The method is characterized by comprising the steps of firstly enabling the flame retardant to react with diamine or dibasic alcohol so as to obtain a flame retardant prepolymer, and then, enabling the flame retardant prepolymer to react and copolymerize with a prepolymer of nylon 6, thereby obtaining the permanent-flame-retardant nylon 6 material. The flame-retardant nylon 6 material prepared by the method has the characteristics of low flame retardant addition level and durable flame-retardant effect, the limiting oxygen index is over 30%, the vertical firing test reaches UL94V-0, and the mechanical properties are excellent; and the nylon 6 material can be subjected to injection molding directly or form films and can also become into fibers so as to further prepare flame-retardant fabrics.

Owner:DONGHUA UNIV

Flame-retardant polyurethane rigid foam taking melamine as basic characteristic and preparation method of flame-retardant polyurethane rigid foam

InactiveCN104262567ASolve problems such as high generation costImprove flame retardant performancePolymer sciencePtru catalyst

The invention discloses a flame-retardant polyurethane rigid foam taking melamine as a basic characteristic and a preparation method of the flame-retardant polyurethane rigid foam. The flame-retardant polyurethane rigid foam taking melamine as the basic characteristic comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 1: (1.1-1.5); the component A comprises the following components in parts by weight: 20-40 parts of flame-retardant polyether polyol taking melamine as the basic characteristic, 1-5 parts of catalyst, 0.5-1.0 part of foam stabilizer, 1-3 parts of physical foaming agent and 1-3 parts of water; and the component B is isocyanate. The preparation method comprises the following steps: mixing all the raw materials of the component A, then adding the component B, pouring an obtained mixture into a mold, curing for 30-60s, and then continuously curing for 48h at room temperature to obtain the flame-retardant polyurethane rigid foam taking melamine as the basic characteristic, wherein the flame-retardant polyurethane rigid foam has the density of 39.1-42.8kg / m<3>, the compressive strength of 0.15-0.20Mpa and the limit oxygen index of 22.3-24.5%.

Owner:SHANGHAI INST OF TECH

Prepn process of polyimide fiber

InactiveCN1932091AHigh strengthHigh modulusWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The preparation process of polyimide fiber includes the following steps: 1. preparing polyamic acid solution as the spinning precursor through polycondensing maleic anhydride monomer and diamine monomer; 2. dry spinning to prepare polyamic acid fiber; 3. imidating polyamic acid fiber to form polyimide fiber; and 4. hot stretching polyimide fiber at 350-470 deg.c for 3-8 times. Thus prepared polyimide fiber has high strength, high modulus, high heat resistance, high chemical corrosion resistance and relatively high limiting oxygen index, and may be used widely as reinforcing material of composite material and cable, rope for vehicle and ship, filter material, etc.

Owner:DONGHUA UNIV

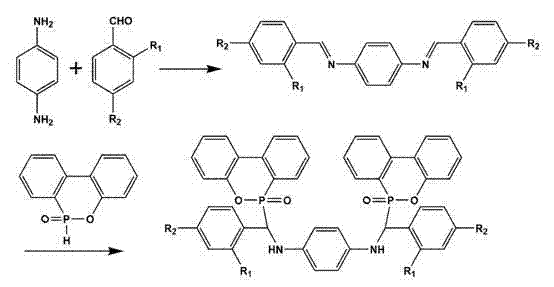

Preparation method of nitrogen and phosphorus fire retardant, nitrogen and phosphorus fire retardant and application thereof

The invention discloses a preparation method of a nitrogen and phosphorus fire retardant, a nitrogen and phosphorus fire retardant and an application thereof. The preparation method comprises the following steps of: carrying out condensation reaction on aromatic dicarboxaldehyde and 4-aminophenol, then carrying out addition reaction with DOPO and obtaining a nitrogen and phosphorus fire retardant molecule. The obtained nitrogen and phosphorus fire retardant molecule has amino and phenolic active groups, and further can react with substances containing epoxy functional groups, so that the defects of low thermal decomposition temperature, poor compatibility with polymer matrix and easy mobility of the traditional small-molecular flame retardant are overcome. After the nitrogen and phosphorus fire retardant is added into an epoxy resin system, the formed cured matter has good flame retardant performance, and the limit oxygen index is greatly improved. The method is simple and easy, does not need to use a catalyst and gas protection, is easy to control, good in repeatability, simple in after-treatment process and high in yield and is suitable for enlarged production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Phosphor nitrogen fire retardant dispersion and preparation method thereof

ActiveCN102383210AGood dispersionImprove stabilityMonocomponent cellulose artificial filamentViscous liquidSpinning

The invention relates to a phosphor nitrogen fire retardant dispersion and a preparation method thereof, and belongs to the field of fine chemical engineering. The invention aims to solve problems of weak stability of a fire retardant dispersion prepared from a fire retardant for viscose fiber of a prior art and difficulty to realize large scale industrial production, and provides a phosphor nitrogen fire retardant dispersion and a preparation method thereof. According to the method of the invention, a certain proportion of wetting agent, high-molecular dispersant, deflocculation dispersant and an antifoaming agent are added into a cylinder scoring for dispersion and stirring, etc., so that the phosphor nitrogen fire retardant dispersion disperses uniformly, has good stability, good compatibility with a viscous liquid and good spinnability, and is an acid resistant and alkali resistant fire retardant dispersion with wide application fields. The phosphor nitrogen fire retardant dispersion is mixed with the viscous liquid and treated with spinning moulding and post-treatment to obtain a fiber, which has a limit oxygen index higher than 30 and good physical machinery performance.

Owner:CHENGDU GRACE FIBER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com