Flame-retardant polyurethane modified polyisocyanurate foam, and preparation method and application of foam

A polyisocyanurate and polyurethane modification technology, applied in polyurethane foam and its preparation, its preparation, flame retardant polyurethane modified polyisocyanurate foam field, can solve the problem of inorganic flame retardants and polyisocyanurate Mixed stability of alcohol components, poor uniformity of foam products, influence of foam product combustion oxygen index and mechanical properties, poor combustion smoke suppression effect, etc., achieve good foam uniformity and density adjustability, realize synergistic flame retardancy, and good industrial productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

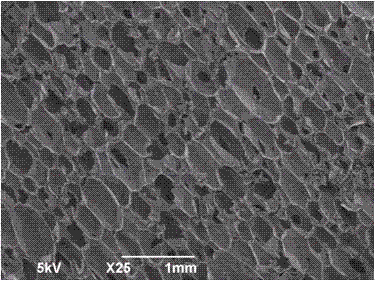

Image

Examples

Embodiment 1

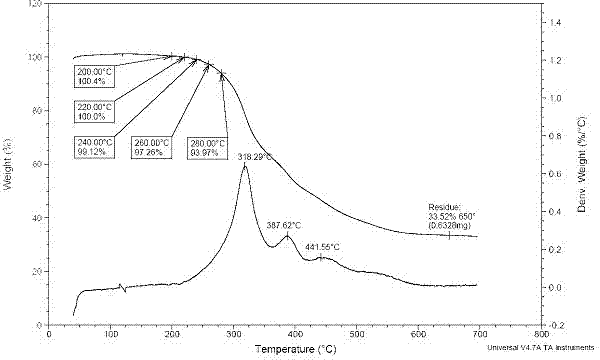

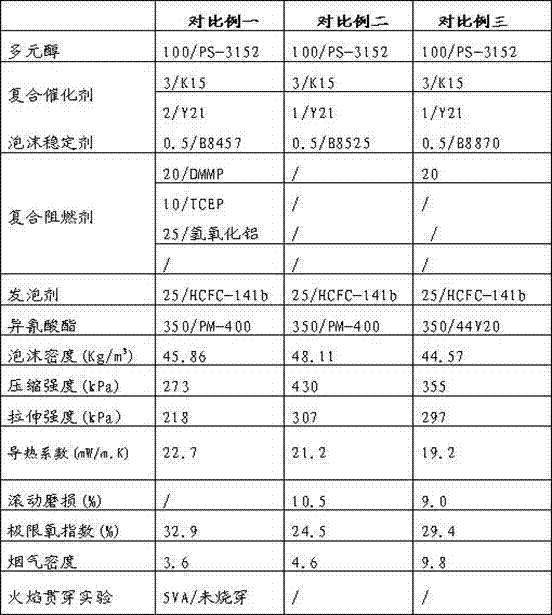

[0043] In this example, flame-retardant polyurethane modified polyisocyanurate foam (hereinafter referred to as PIR foam) was prepared according to the following steps:

[0044] Step 1. Add 100.0 parts by mass of polyester polyol PS-3152 with an average molecular weight of 355 g / mol and a hydroxyl value of 315 mg KOH / g, 20.0 parts by mass of dimethyl phosphate methyl ester (DMMP for short), 10.0 parts by mass of Tris(2-chloroethyl)phosphate (abbreviation: TCEP), 20.0 parts by mass of flake graphite, 5.0 parts by mass of powdered graphite, and 20.0 parts by mass of monofluorodichloroethane (trade name: HCFC-141b) Stir and mix the physical foaming agent at 20-30°C to obtain the composition as component A;

[0045] Step 2, 1.5 parts by mass of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine (trade name: Y21), 2.5 parts by mass of 50-70% potassium octanoate solution (trade name: K15) Stir and mix with 1.5 parts by mass of foam stabilizer (trade name: B8870) at 20-30°C to obt...

Embodiment 2

[0053] The present embodiment prepares PIR foam according to the following steps:

[0054] Step 1. Add 100.0 parts by mass of polyester polyol PS-3152 with an average molecular weight of 355 g / mol and a hydroxyl value of 315 mg KOH / g, 20.0 parts by mass of dimethyl phosphate methyl ester (DMMP for short), 10.0 parts by mass of Tris(2-chloroethyl)phosphate (abbreviation: TCEP), 20.0 parts by mass of flake graphite, 5.0 parts by mass of powdered graphite, and 25.0 parts by mass of monofluorodichloroethane (trade name: HCFC-141b) Stir and mix the physical foaming agent at 20-30°C to obtain the composition as component A;

[0055] Step 2: 2.0 parts by mass of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine (trade name: Y21), 3.0 parts by mass of 50-70% potassium octanoate solution (trade name: K15) , 0.3 parts by mass of triethylenediamine (trade name: A33) and 1.5 parts by mass of foam stabilizer (trade name: B8870) were stirred and mixed at 20-30°C to obtain the composition as...

Embodiment 3

[0061] The present embodiment prepares PIR foam according to the following steps:

[0062] Step 1. Add 100.0 parts by mass of polyester polyol PS-2412 with an average molecular weight of 468 g / mol and a hydroxyl value of 240 mg KOH / g, 20.0 parts by mass of dimethyl phosphate methyl ester (DMMP for short), 10.0 parts by mass of Tris(2-chloroethyl)phosphate (abbreviation: TCEP), 20.0 parts by mass of flake graphite, 5.0 parts by mass of powdered graphite, and 25.0 parts by mass of monofluorodichloroethane (trade name: HCFC-141b) Stir and mix the physical foaming agent at 20-30°C to obtain the composition as component A;

[0063] Step 2: 2.0 parts by mass of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine (trade name: Y21), 3.0 parts by mass of 50-70% potassium octanoate solution (trade name: K15) Stir and mix with 0.5 parts by mass of foam stabilizer (trade name: B8457) at 20-30°C to obtain the composition as component B;

[0064] Step 3, using 300.0 parts by mass of polymethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com