Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

294results about How to "Good char formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

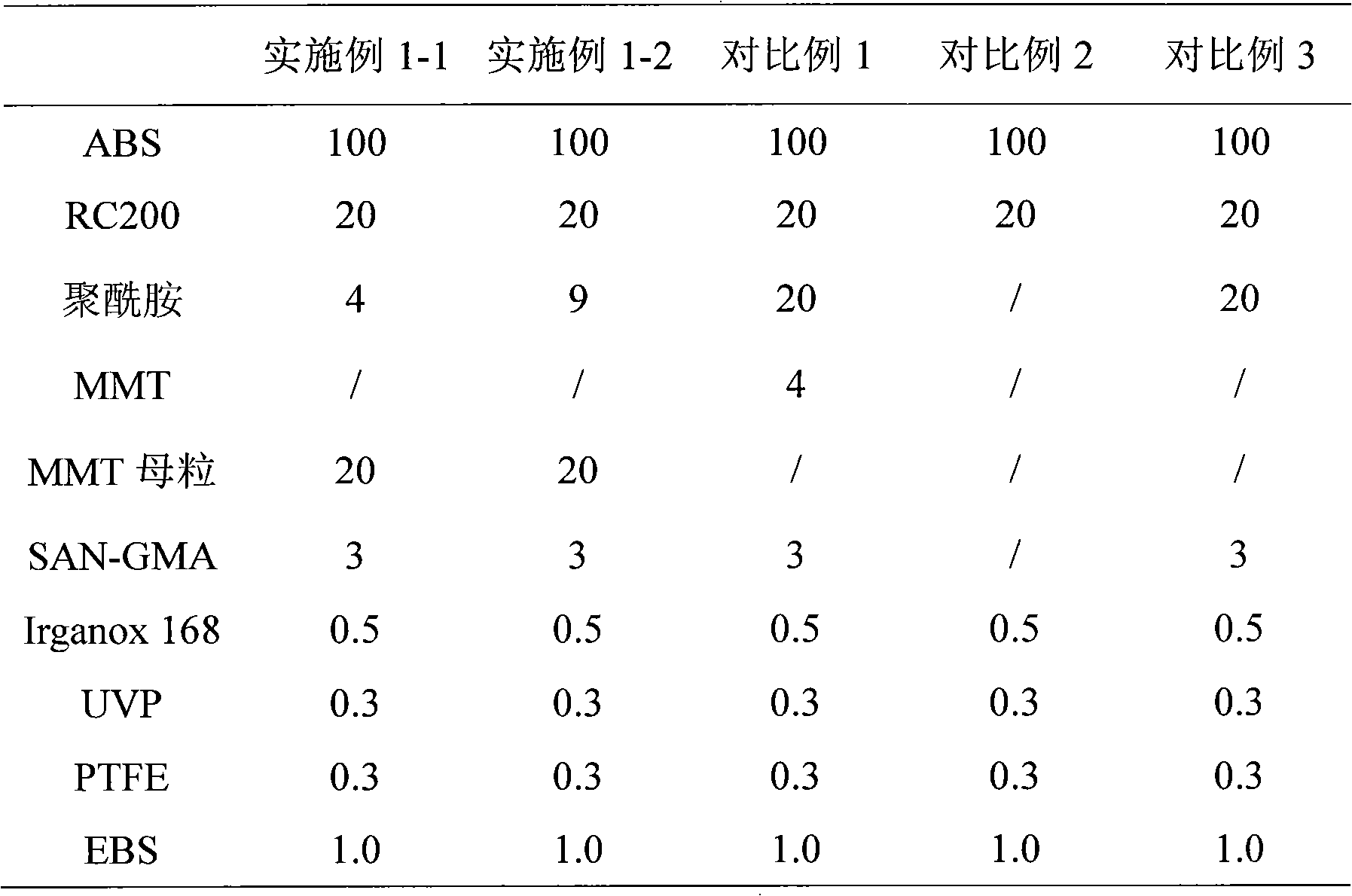

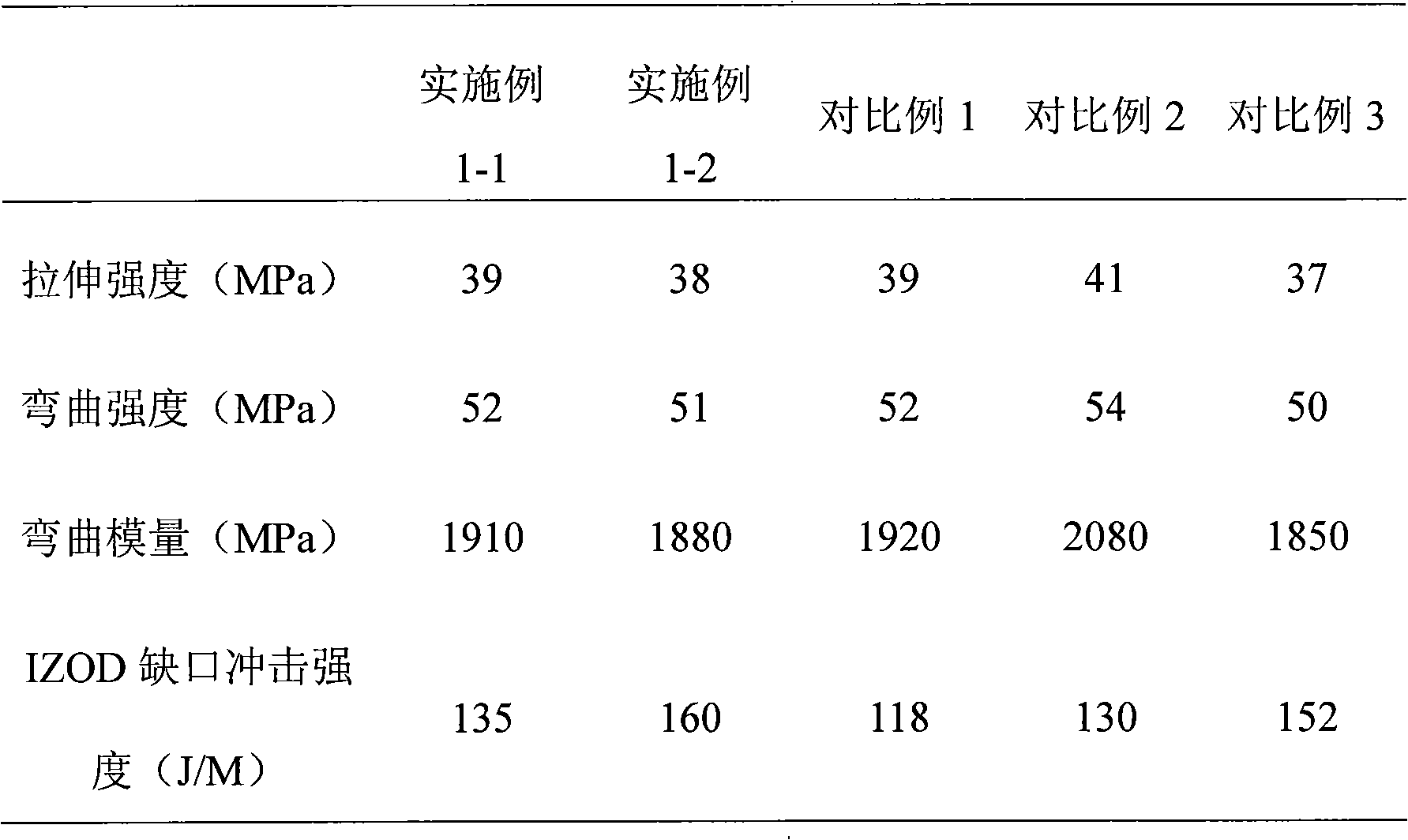

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

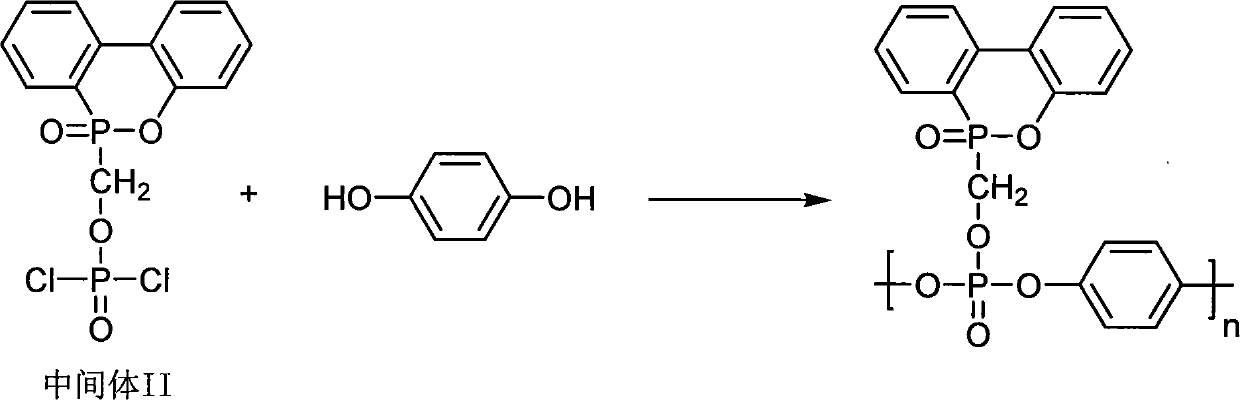

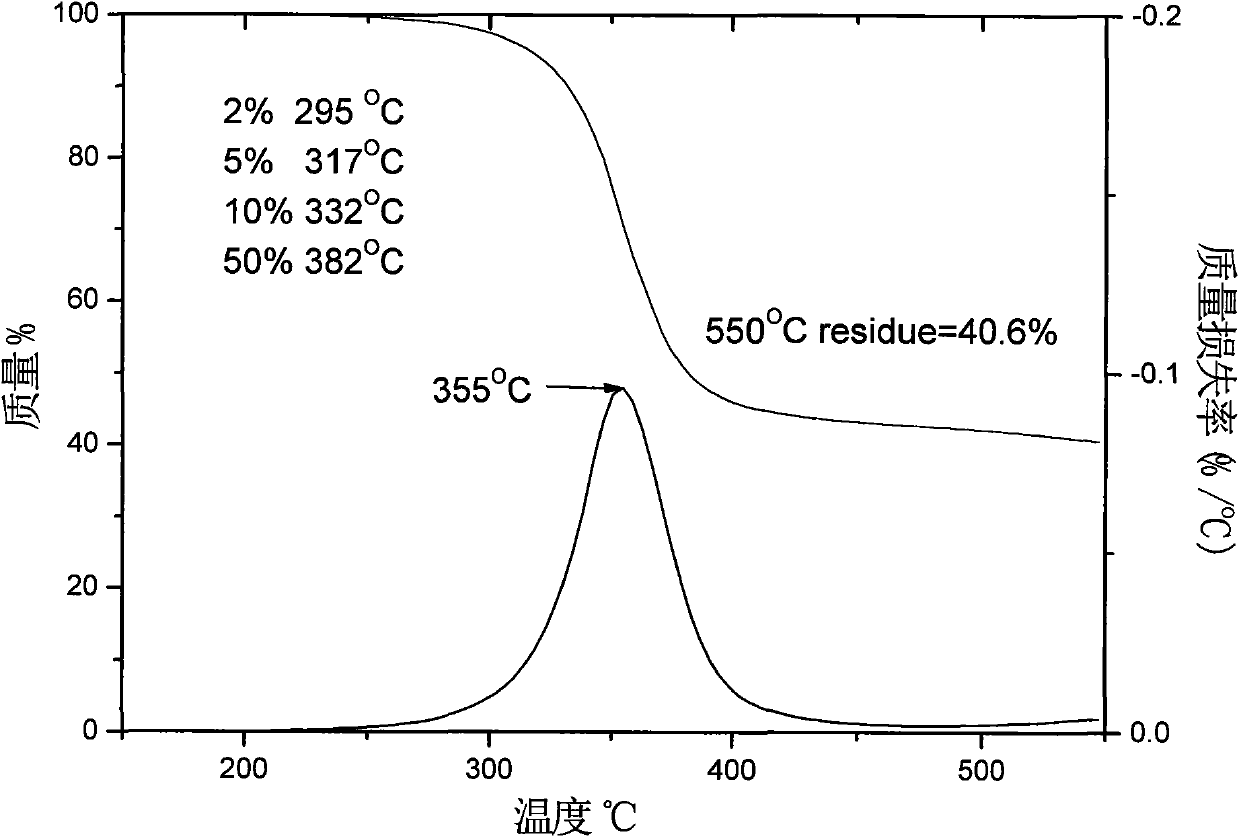

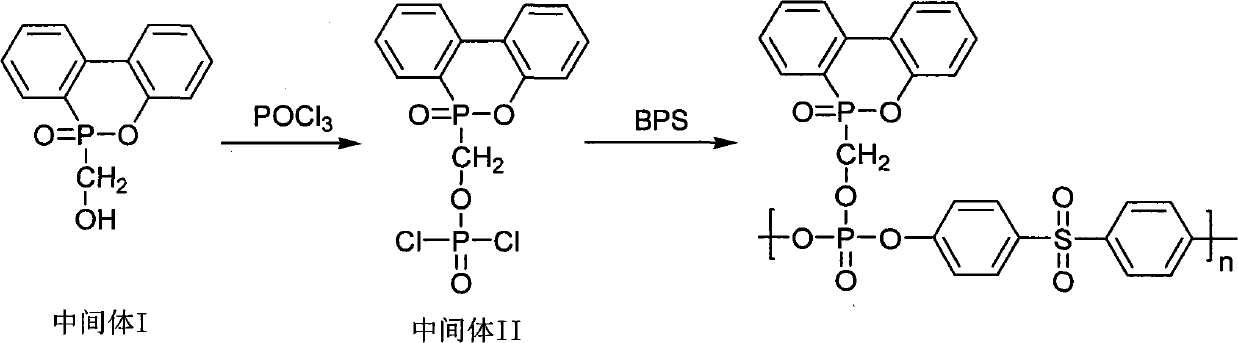

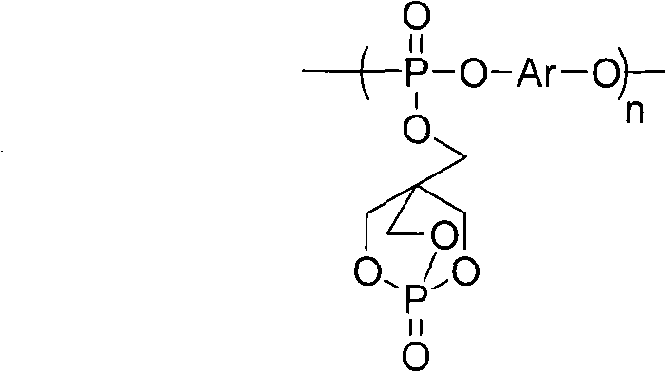

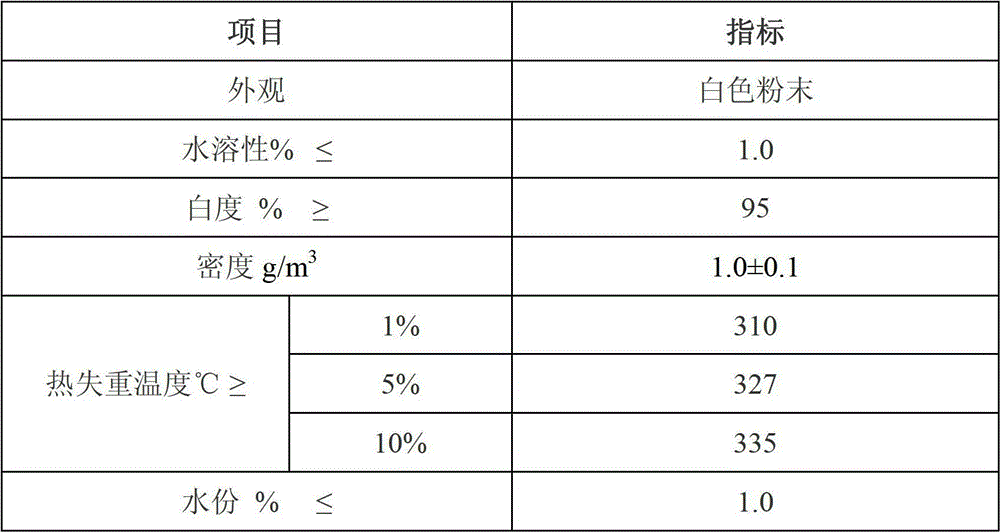

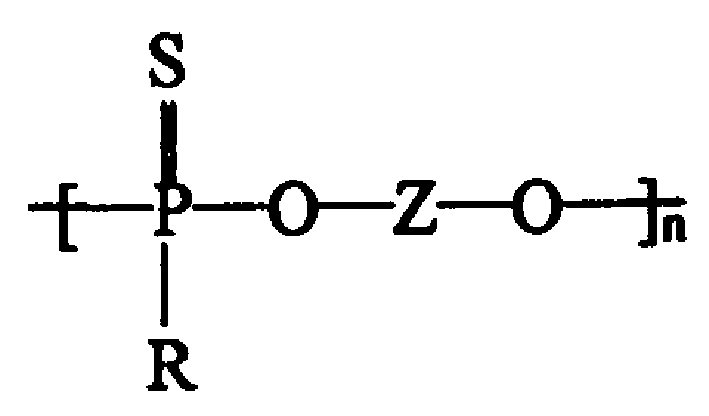

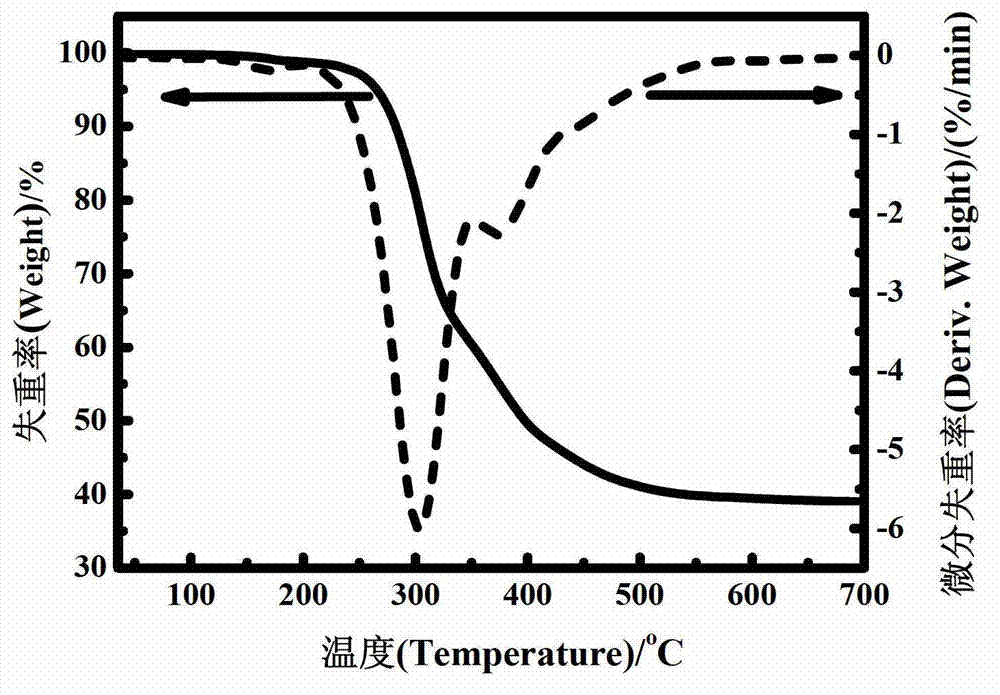

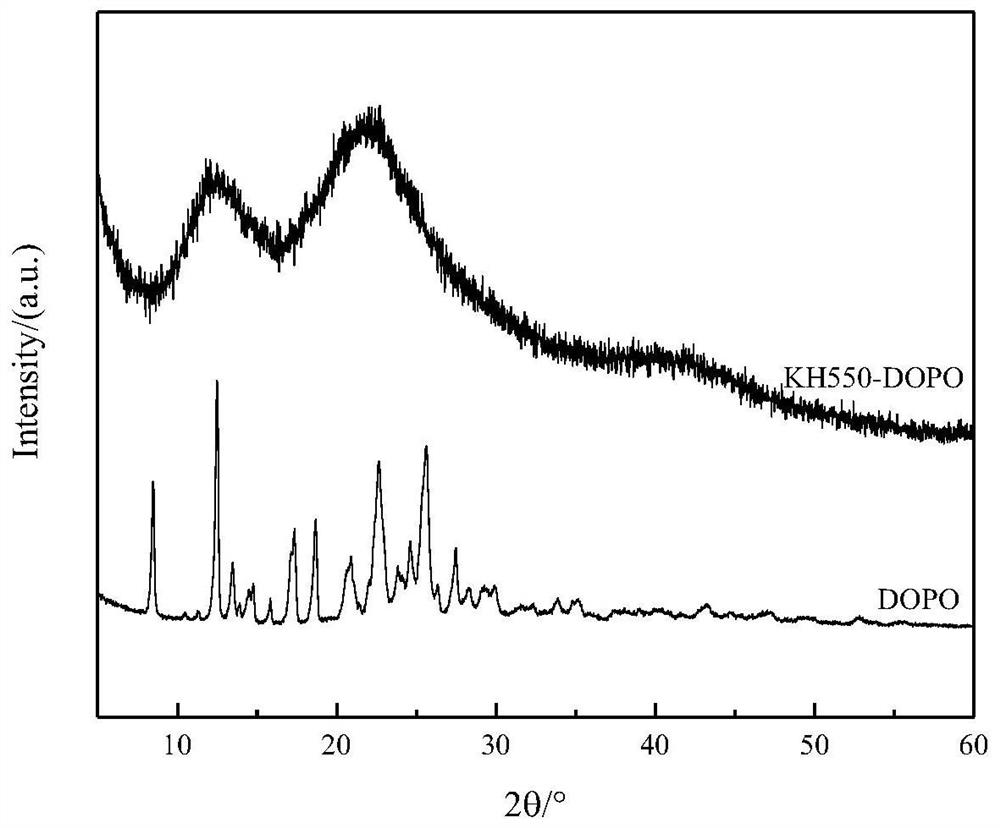

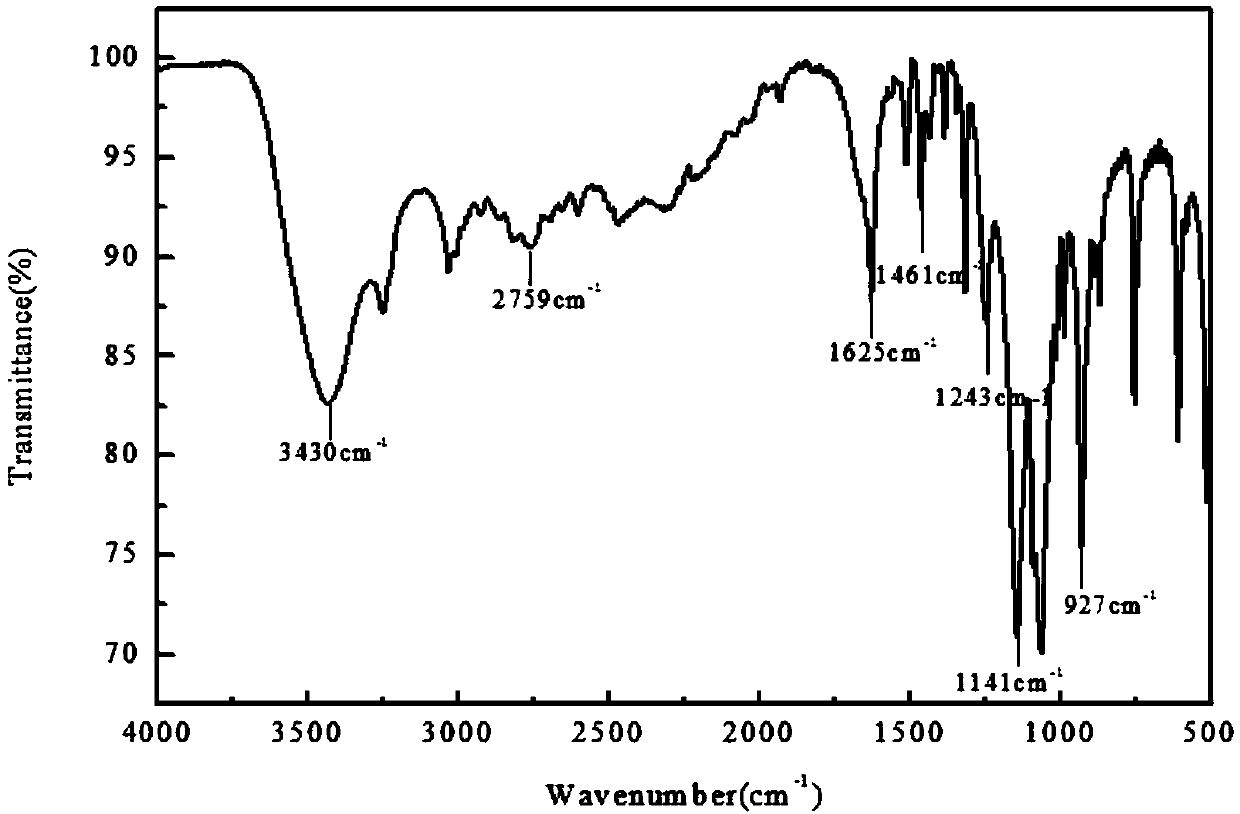

Poly-phosphate flame retardant containing DOPO side-chain structure and preparation method thereof

InactiveCN101838538AImprove thermal stabilityGood char formationGroup 5/15 element organic compoundsPolyesterSide chain

The invention discloses a poly-phosphate flame retardant containing a DOPO side-chain structure and a preparation method thereof, belonging to the technical field of polymeric organic phosphorus flame retardant structures and the preparation method thereof. The flame retardant is characterized by comprising the following repeating unit structure: wherein n=5-50. The preparation method of the poly-phosphate flame retardant comprises the following steps of: reacting an intermediate I containing the DOPO structure with phosphorus oxychloride to obtain an intermediate II containing phosphorus oxychloride, and fusing and polymerizing the intermediate II and a bisphenol compound to obtain the poly-phosphate flame retardant containing the DOPO side-chain structure. The preparation method is simple, and through adjusting Ar categories and ratios, the phosphorus content can be controlled at 11.5-15.5% and the sulfur content can be controlled at 0-5.9%. The flame retardant has the characteristics of favorable thermal stability, high decomposition temperature, favorable char-forming property, and the like, and can be used for flame retardance modification of materials, such as polyester, polyamide, polycarbonate and blends thereof, and the like, with higher processing temperature.

Owner:DALIAN UNIV OF TECH

Thermosetting resin composition and application thereof

ActiveCN103694642ALow dielectric constantExcellent dielectric propertiesSynthetic resin layered productsElectrical equipmentDielectric lossCopper foil

The invention relates to a thermosetting resin composition which comprises (A) epoxy resin with a naphthol structure on a molecular main chain; (B) cyanate ester compound or / and cyanate ester prepolymer; and (C) phosphonate or / and phosphonate-carbonic ester copolymer. The thermosetting resin composition provided by the invention is low in dielectric constant and dielectric loss tangent, a prepreg and a copper clad laminate prepared by using the above thermosetting resin composition has excellent dielectrical property, humidity resistant property and craft processability, and the fire resistance is up to the UL94 V-0 level.

Owner:GUANGDONG SHENGYI SCI TECH

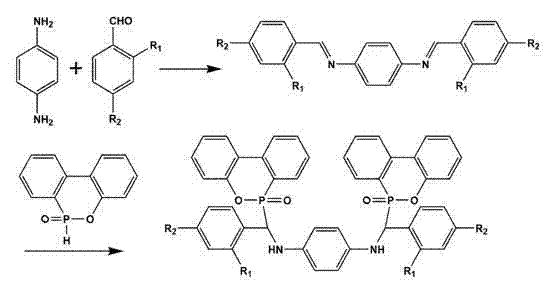

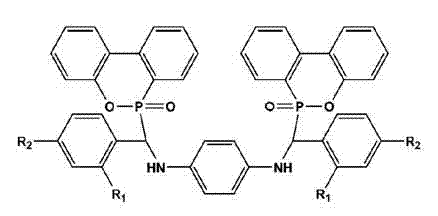

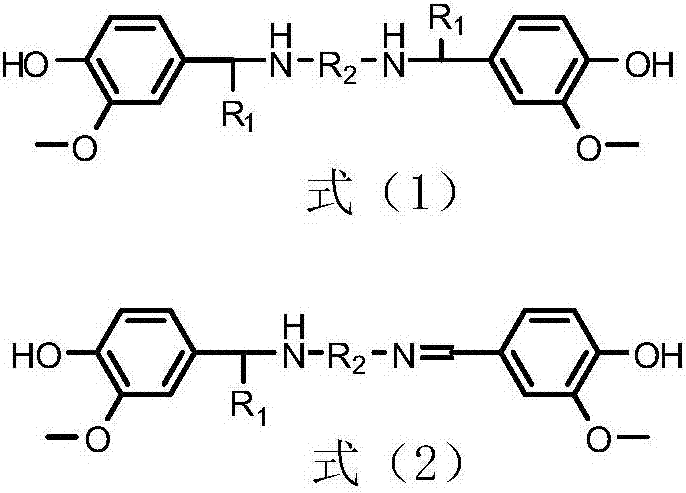

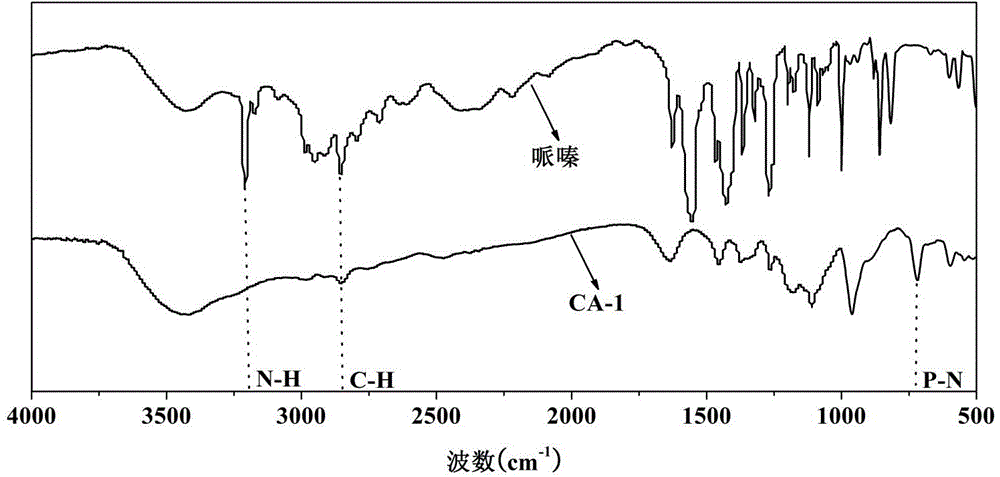

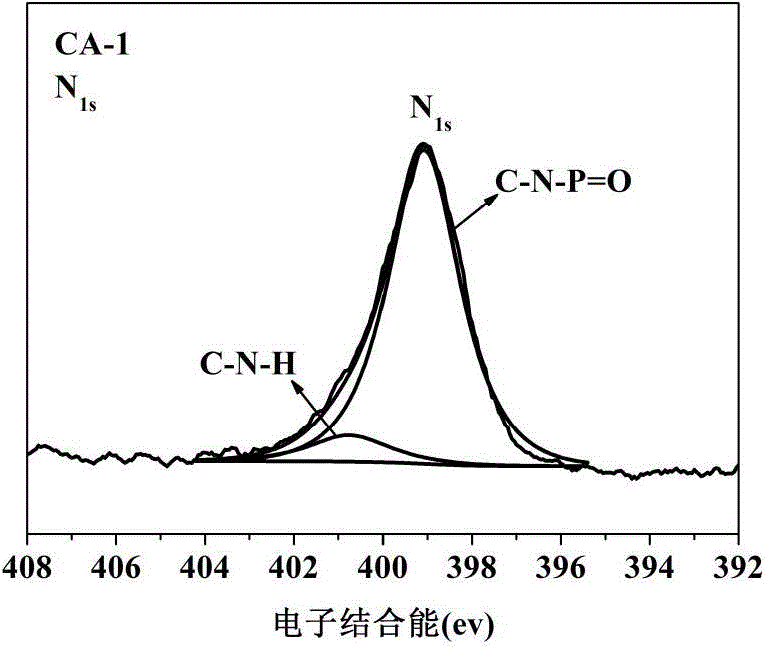

Nitrogen and phosphorus containing flame retardant agent and preparation method thereof as well as application thereof

ActiveCN102391545AHigh yieldSimple post-processingGroup 5/15 element organic compoundsEpoxyPolymer science

The invention relates to a preparation method of a nitrogen and phosphorus containing flame retardant agent, the nitrogen and phosphorus containing flame agent and application thereof. The preparation method comprises the following steps of: carrying out condensation reaction on phenylene diamine and aromatic aldehyde, then carrying out addition reaction with DOPO (9, 10-Dihydro-9-oxa-10-phosphaphenanthrene 10-oxide) to obtain solid nitrogen and phosphorus containing flame retardant agent molecules. The preparation method has the advantages of easiness in control, good repeatability, high yield and suitability for expanded production. The obtained flame retardant agent molecules have amino groups and phenolic hydroxyl active groups and can further react with matters containing expoxy group functional groups. The flame retardant agent molecules contain nitrogen and phosphorus elements and have good expansion char forming characteristic and very good flame retardant effect in the burning process; when the flame retardant agent molecules resist the flaming of the epoxy resin, the flame retardant agent molecules can further undergo cross-linking reaction with resin, thereby increasing the glass transition temperature, the bonding strength, the mechanical property and the like of the resin; meanwhile, the flame retardant agent molecules have good flame retardant property; the limiting oxygen index of the flame retardant agent molecules is substantially increased; and the vertical burning grade of the flame retardant agent molecules reaches a UL-94V-0 grade.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

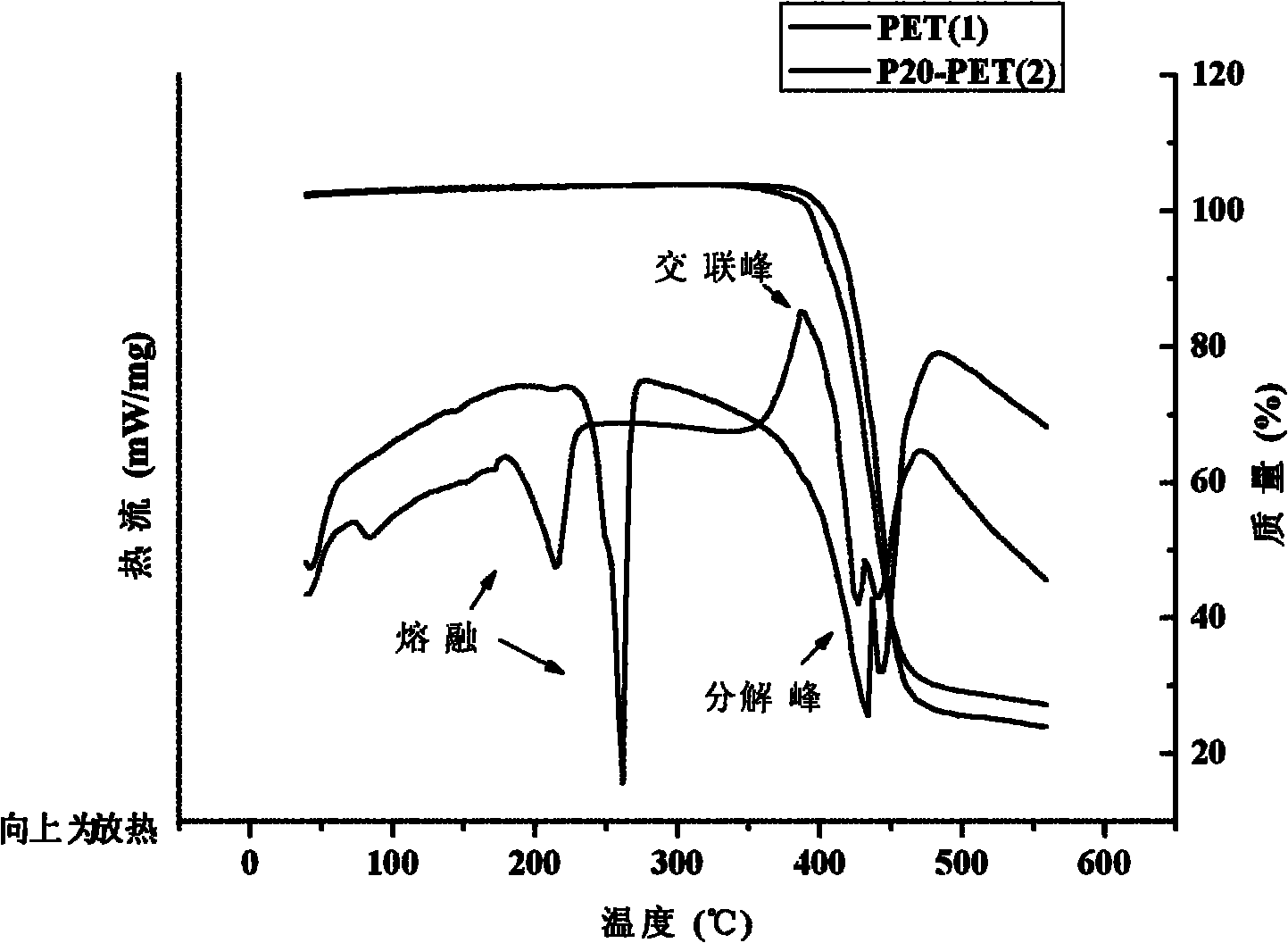

High-temperature self-crosslinking flame-retardant anti-dripping copolyester and preparation method thereof

The invention discloses a high-temperature self-crosslinking flame-retardant anti-dripping copolyester which is prepared by introducing a structural unit shown as IV in the specification or introducing structural units shown as III and IV in the specification by random copolymerization on the basis of structural units of synthetic polyester shown as I and II in the specification, and the intrinsic viscosity [eta] of the prepared high-temperature self-crosslinking copolyester is 0.25-1.25dL / g. The invention also discloses the preparation method of the high-temperature self-crosslinking copolyester. Because the crosslinking group introduced in the invention is a high-temperature self-crosslinking group, on the premise of not affecting the preparation and forming of the polyester, self-crosslinking can be realized at higher temperature, and the melt viscosity of the polyester is improved through the char formation effect and stable chemical crosslinking of the self-crosslinking group, thereby performing combined action with the phosphorus-containing flame-retardant structural unit IV and endowing the polyester with better flame-retardant and anti-dripping properties.

Owner:SICHUAN UNIV

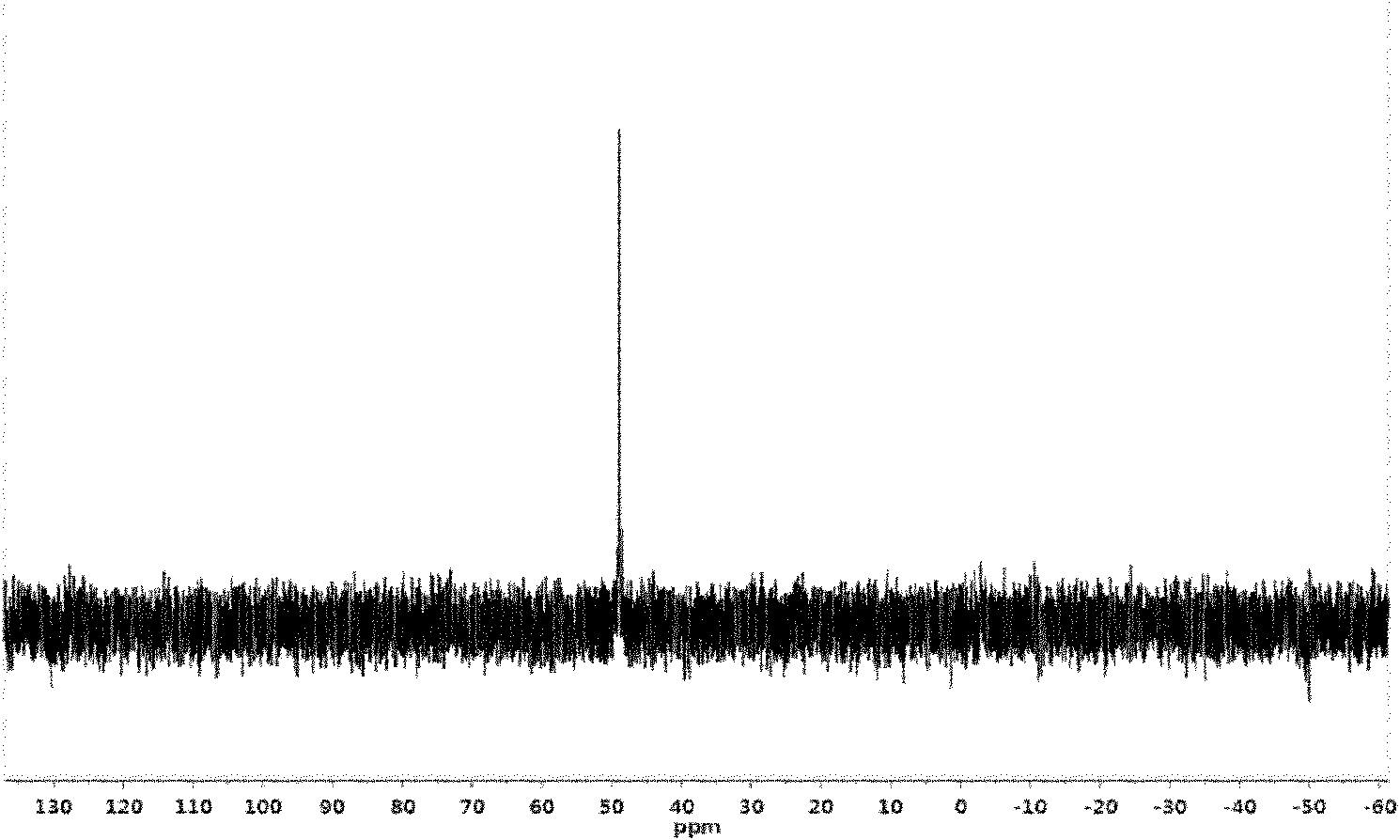

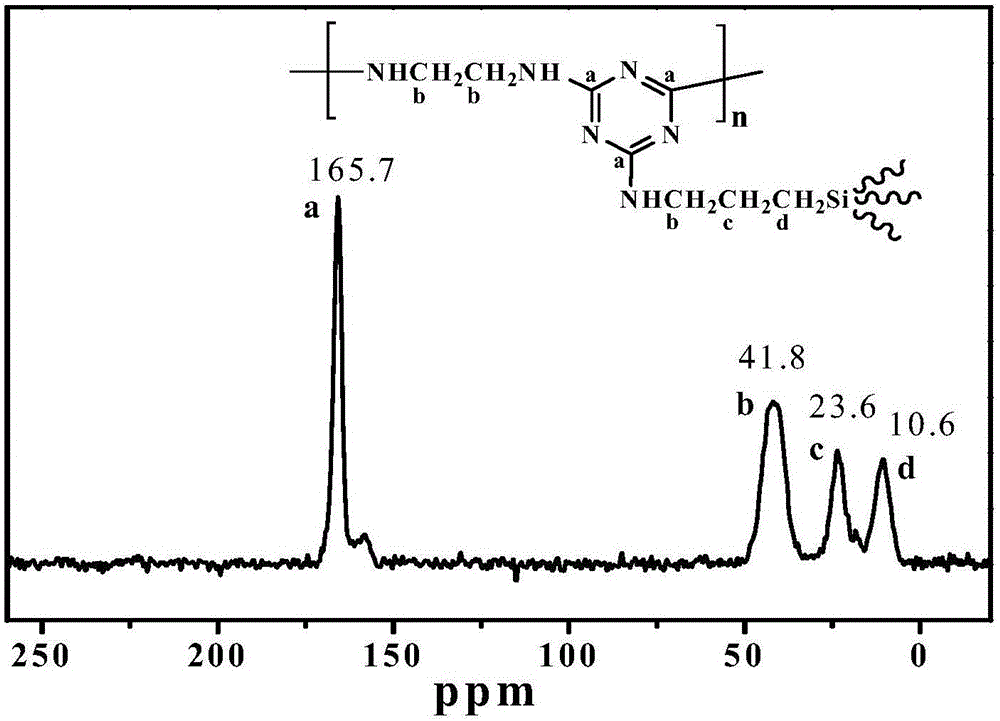

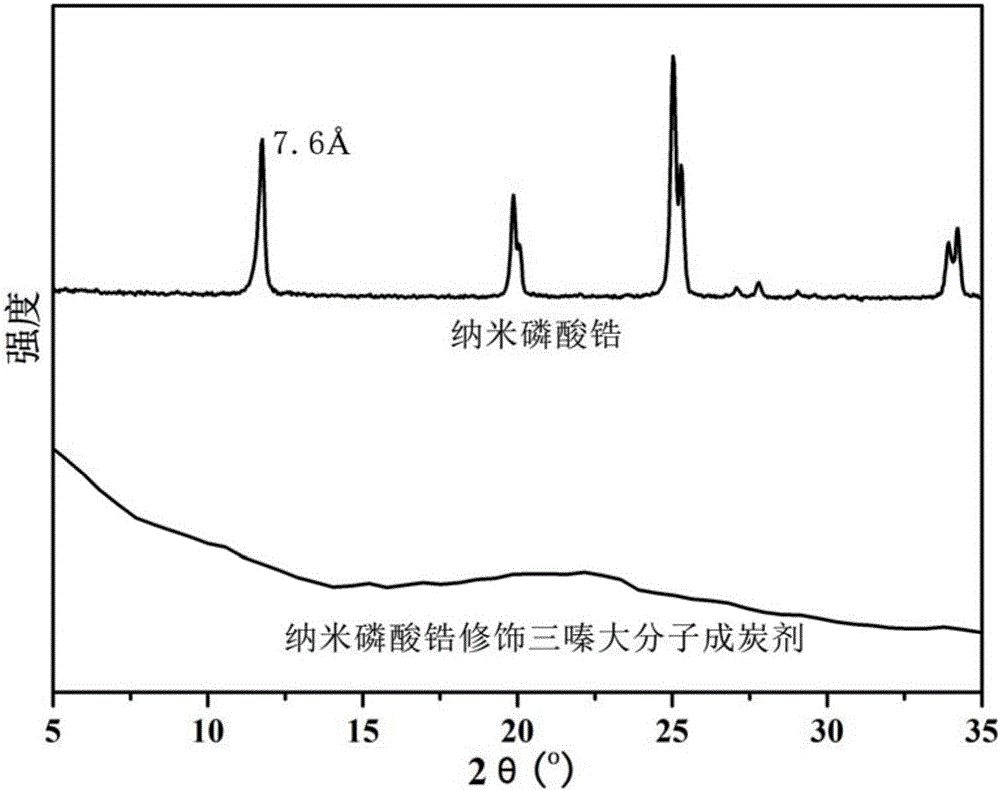

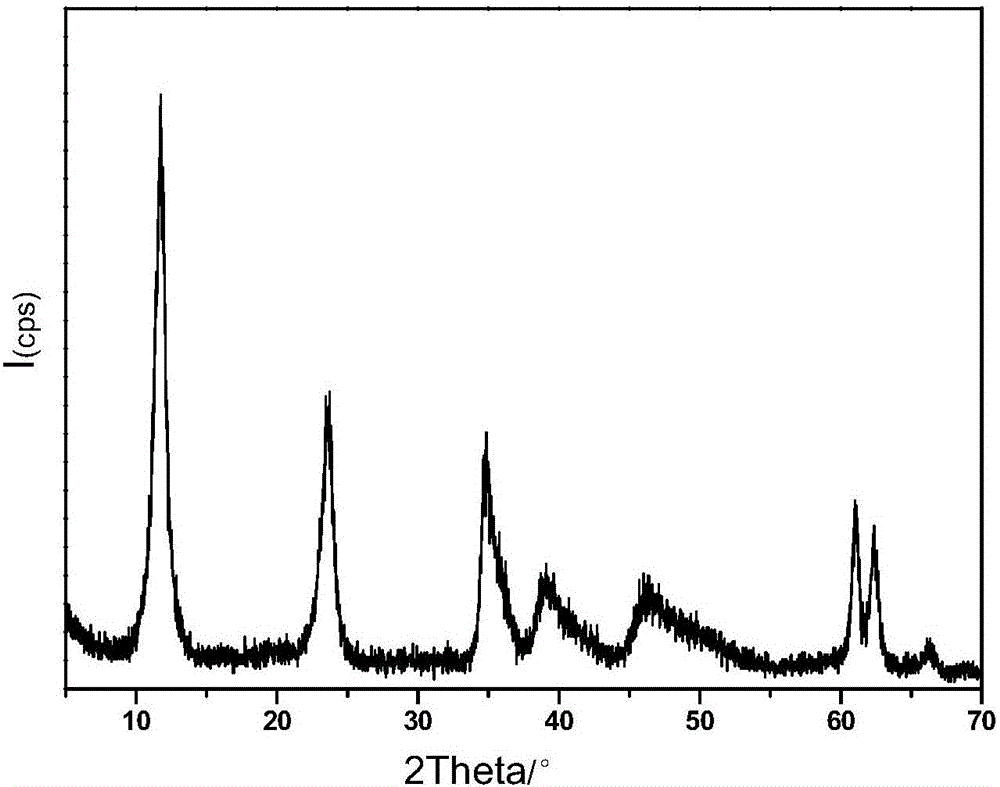

Nano zirconium phosphate-modified triazine macromolecular charring agent, and preparation method and application thereof

The invention discloses a nano zirconium phosphate-modified triazine macromolecular charring agent, and a preparation method and application thereof. The preparation method comprises the following steps: using a silane coupling agent to modify nano zirconium phosphate in an intercalation manner, and preparing an intermediate product through an organic solvent, cyanuric chloride, the silane coupling agent-modified nano zirconium phosphate through intercalation, a diamine monomer and an acid-binding agent; performing in-situ polymerization reaction on the organic solvent, the intermediate product, the diamine monomer and the acid-binding agent to prepare the nano zirconium phosphate-modified triazine macromolecular charring agent. Compared with the prior art, the macromolecular charring agent prepared by the invention is excellent in thermal stability and charring property, has a good synergistic flame-retardant effect with ammonium polyphosphate, and can effectively improve the thermal stability and the compactness of an expandable carbon layer under the high temperature condition, so that the flame-retardant efficiency of an intumescent flame retardant is remarkably improved. A prepared flame-retardant polypropylene material can be widely used in fields of automotive exteriors, furniture, appliances, wires, cables, construction materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

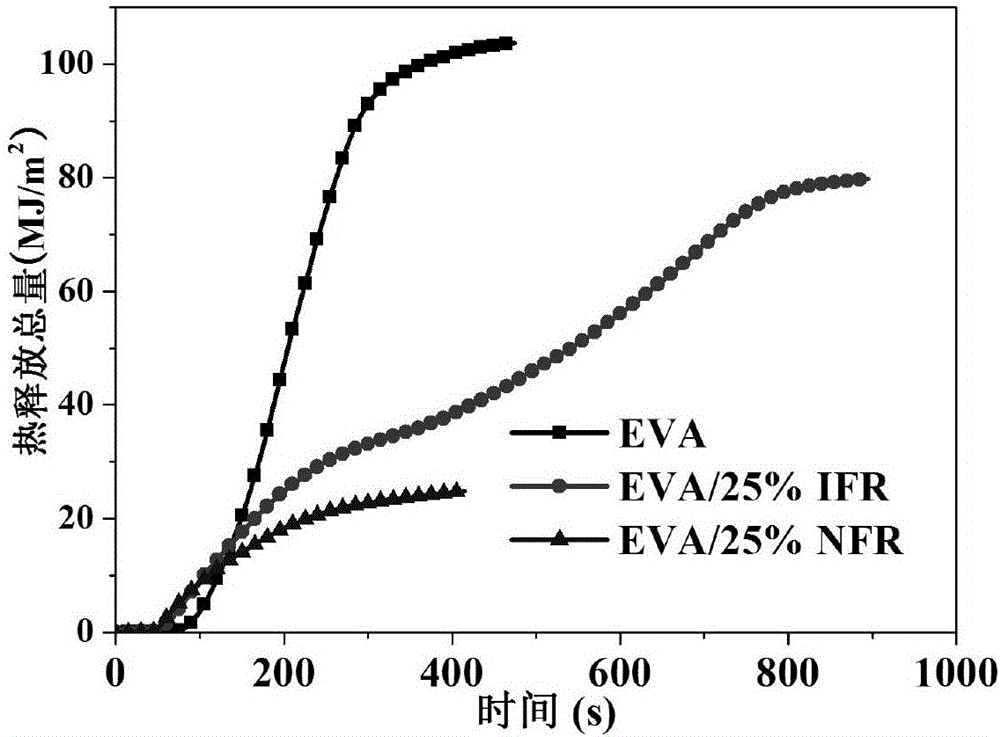

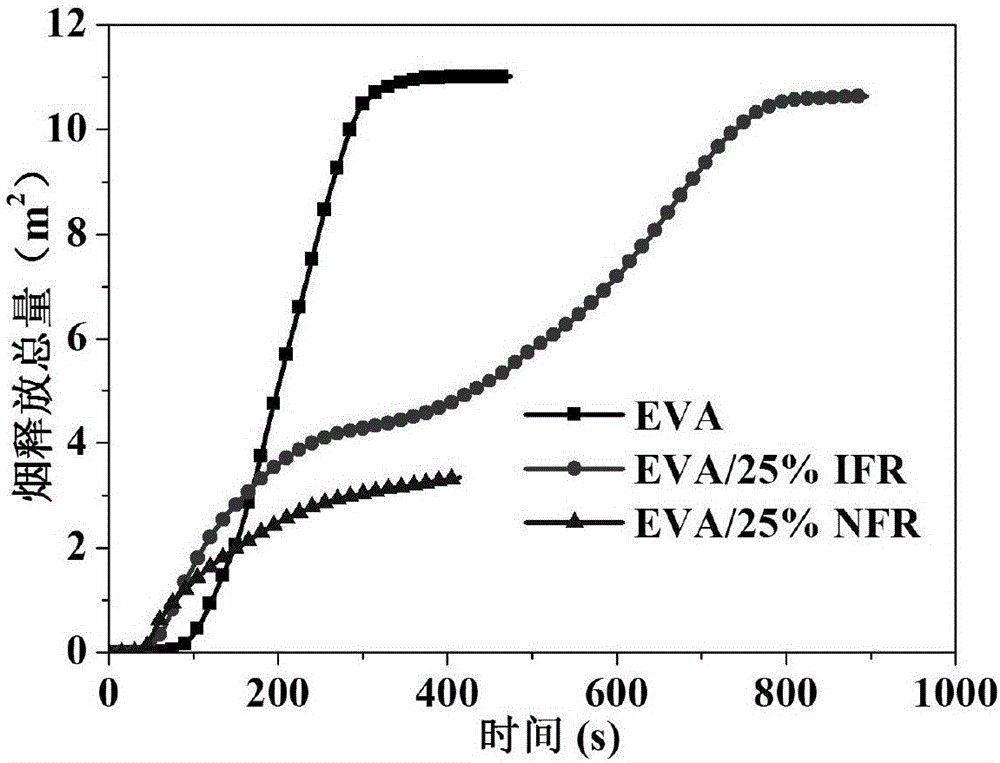

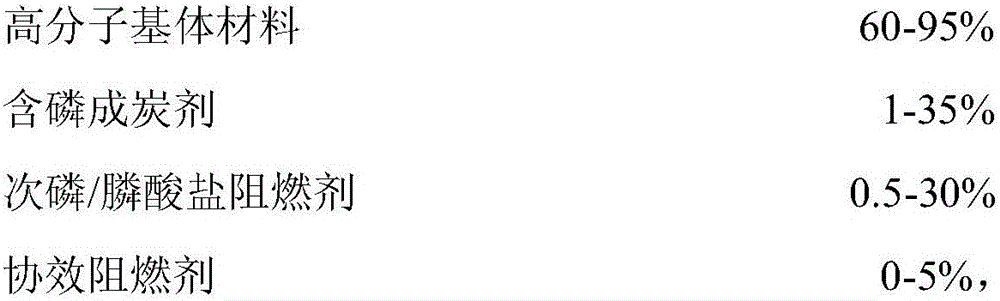

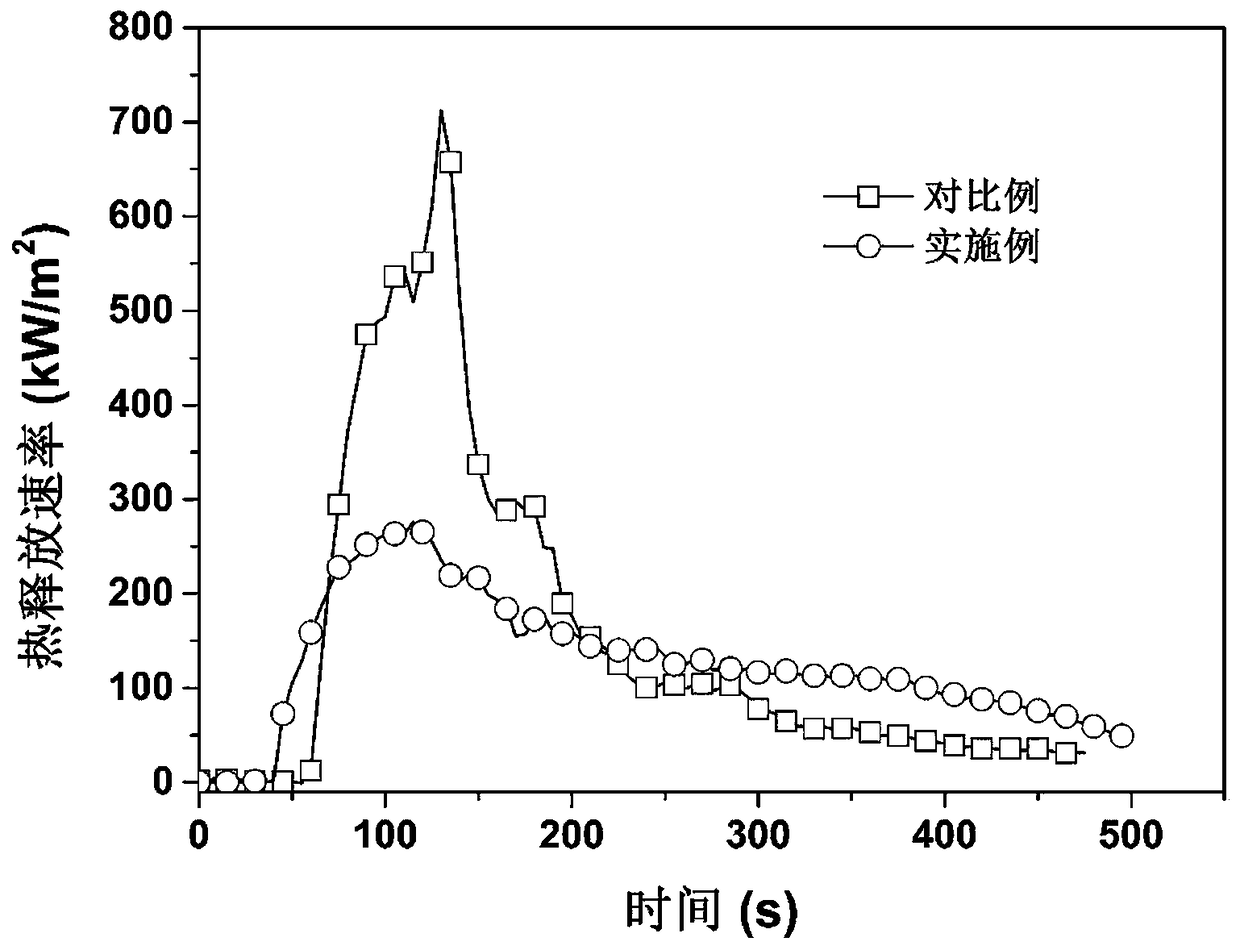

Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

ActiveCN106496729AHigh flame retardant efficiencyGood char formationPolymer scienceLimiting oxygen index

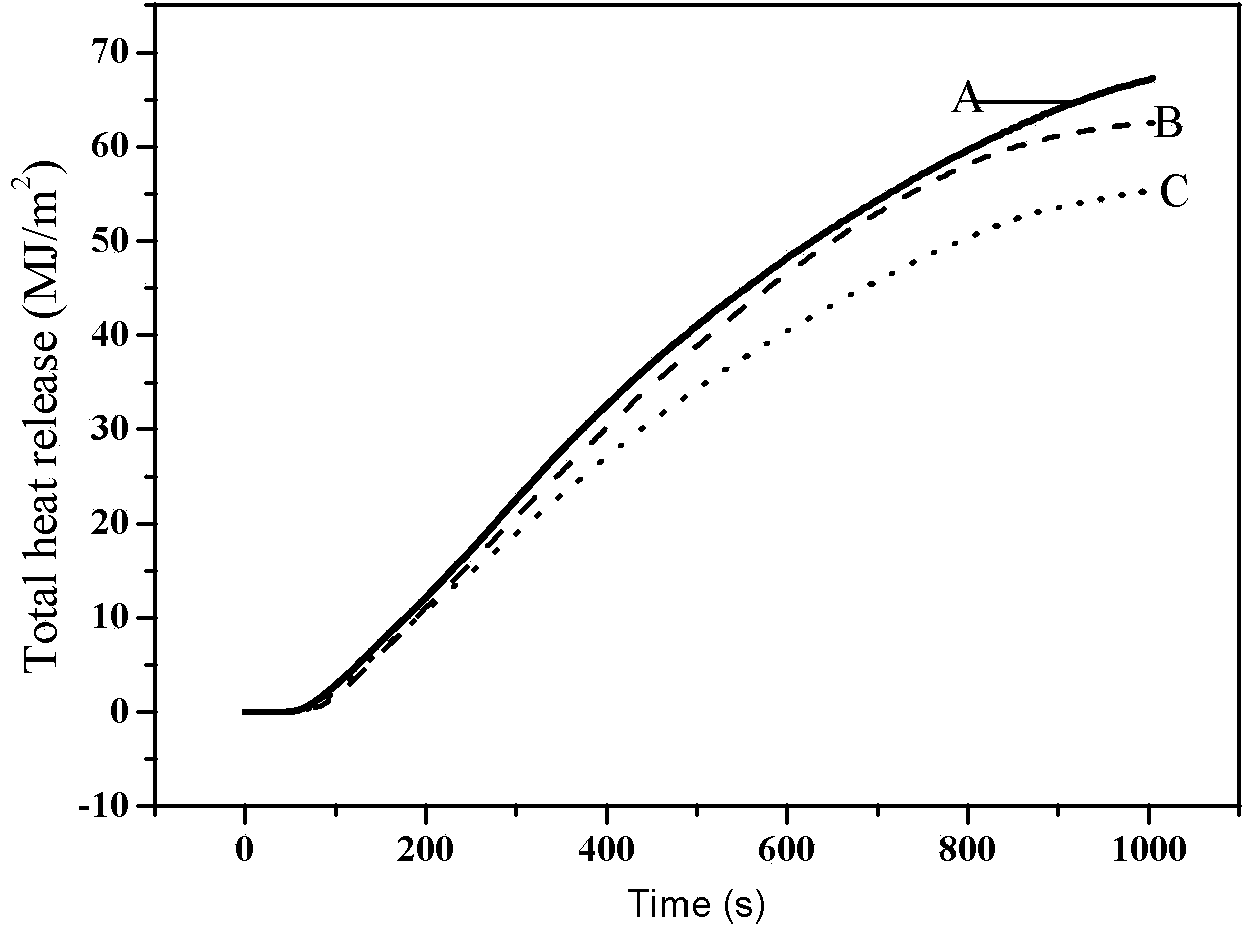

The invention discloses a flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite / phosphonate. The flame-retardant high polymer material is formed by blending, in weight percentage, 60-95% of high polymer base materials, 1-35% of phosphorus containing char-forming agents, 0.5-30% of hypophosphite / phosphonate and 0-5% of synergistic flame retardants. The compound main flame retardants used in the material have double char-forming functions, the material has excellent flame-retardant and smoke suppression properties, limit oxygen index reaches up to 27.0-49.5%, vertical burning test level ranges from UL-94V-1 to V-0, the total heat release of the material in cone calorimeter is reduced by 48.2-90.5% as compared with that of a pure base material, and total smoke release is reduced by 41.6-88.5%. Besides, the flame retardants used in the flame-retardant high polymer material have excellent water resistance, so that the material also has excellent water resistance, after the material is soaked in 70 DEG C for 168 hours and then dried, the vertical burning test level is unchanged, and the oxygen index is only reduced by 0-0.5%.

Owner:SICHUAN UNIV

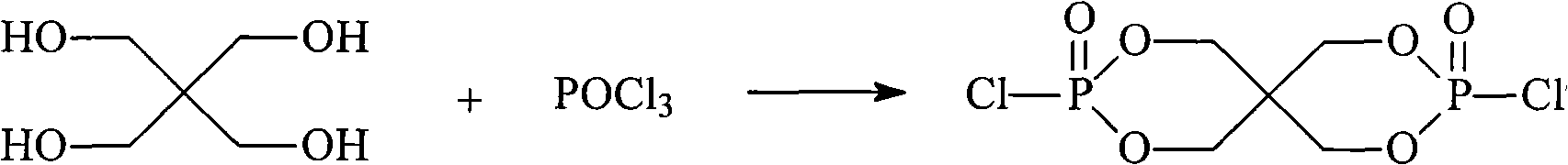

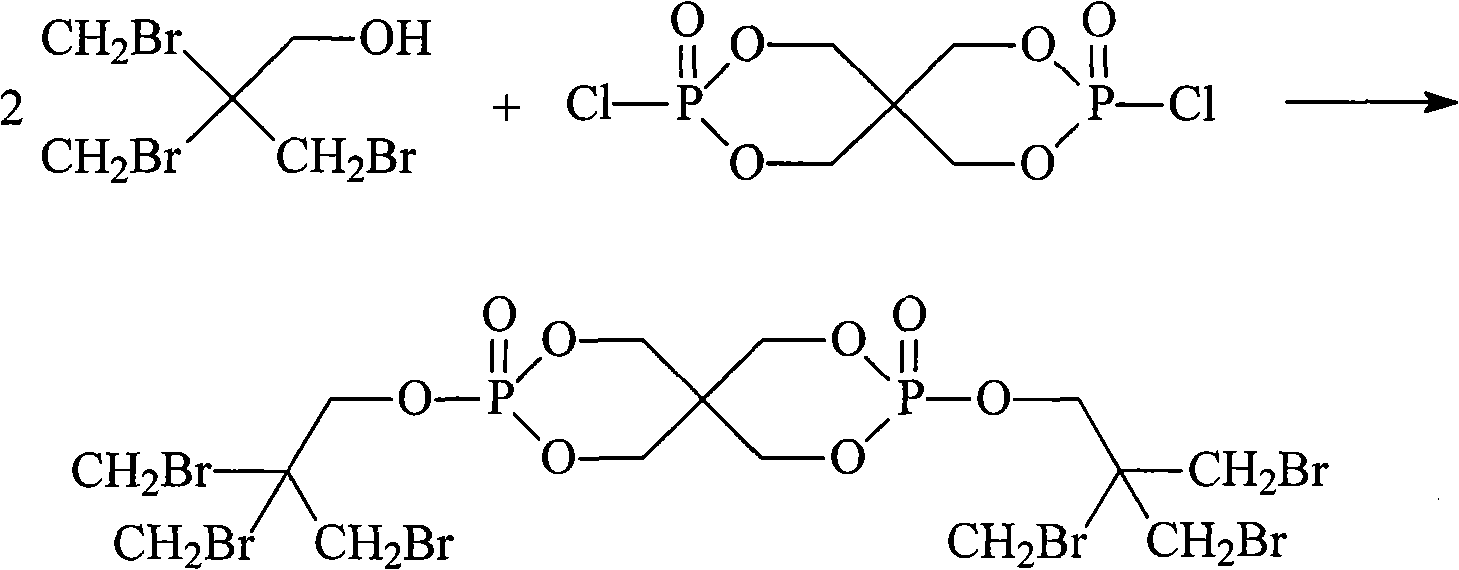

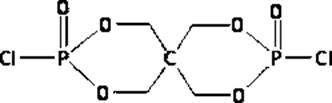

Bromine-containing pentaerythritol phosphoester retardant and preparation method thereof

InactiveCN101921407AToxicBring health risksGroup 5/15 element organic compoundsBulk chemical productionTribromoneopentyl alcoholQuaternary ammonium cation

The invention relates to a bromine-containing pentaerythritol phosphoester fire retardant and a preparation method thereof. The bromine-containing pentaerythritol phosphoester fire retardant is pentaerythritol double-spiro phosphoryl double-tribromo neopentyl alcohol ester. The preparation method of the novel bromine-containing pentaerythritol phosphoester comprises the following steps of: 1, reacting pentaerythritol with phosphorus oxychloride to generate an intermediate pentaerythritol double-spiro double-phosphorus oxychloride; and 2, reacting the pentaerythritol double-spiro phosphorus oxychloride with tribromo neopentyl alcohol to generate the pentaerythritol double-spiro phosphoryl double-tribromo neopentyl alcohol ester, wherein in the reaction, quaternary ammonium salt cation ionic liquid serves as a solvent and a catalyst. The invention discloses a new synthesis method of the bromine-containing pentaerythritol phosphoester fire retardant. The ionic liquid serves as the solvent, so the synthesis yield is improved; and a phosphorus-bromine synergistic flame retardant technique is adopted in the design of a molecular structure, so the anti-flaming efficiency of the flame retardant for high molecular materials is improved.

Owner:DONGHUA UNIV

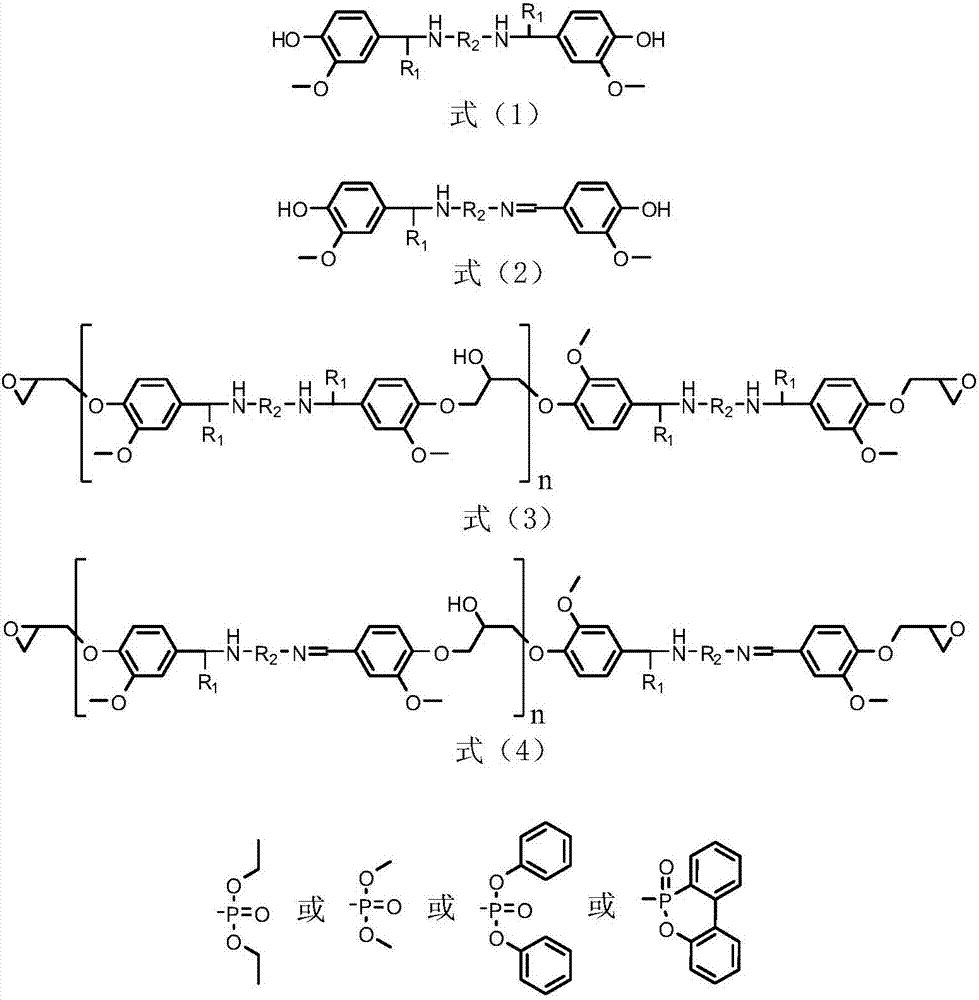

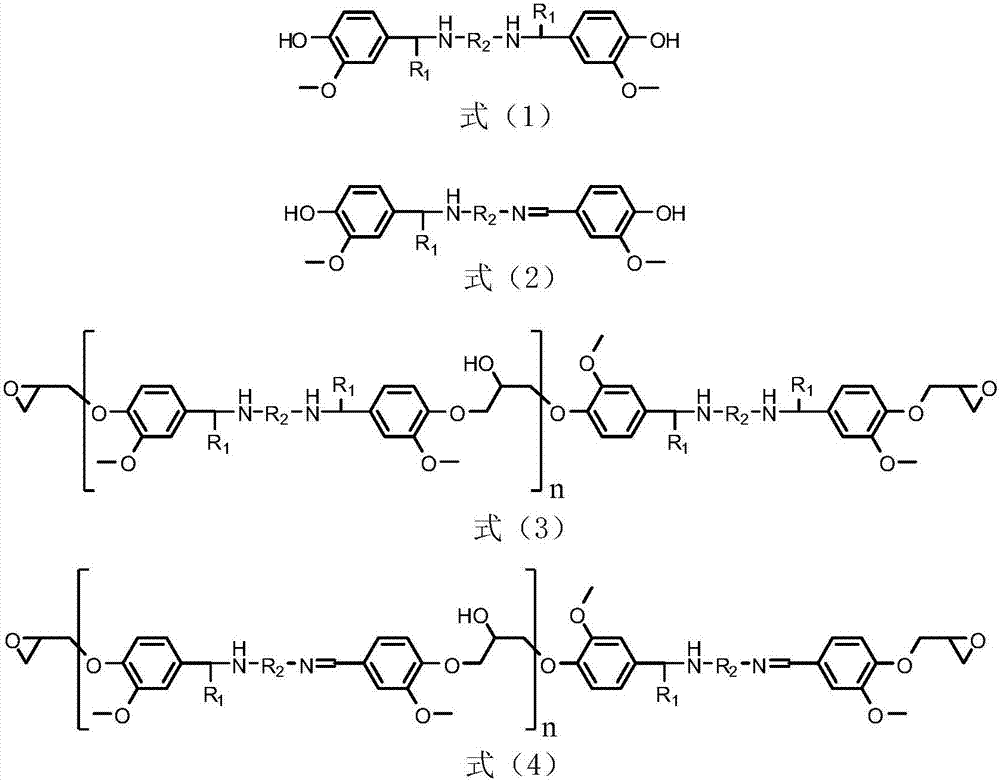

Epoxy resin composition containing vanillic aldehyde-based phosphorus containing flame retardant and application thereof

The invention discloses an epoxy resin composition containing a vanillic aldehyde-based phosphorus containing flame retardant. The epoxy resin composition comprises epoxy resin, a curing agent, a curing accelerant, a primary flame retardant and a flame retardant additive and etc. The flame retardant additive is the vanillic aldehyde-based phosphorus containing flame retardant The invention also discloses an application of the epoxy resin composition, for example, an application of the epoxy resin composition or a cured product thereof as a flame retardant material. When the epoxy resin composition disclosed by the invention is cured and used as a flame retardant material, compared with an existing intumescent fire retardant epoxy system, the epoxy resin composition not only is more excellent in flame retardant property and mechanical property, but also has double functions of saving resources and protecting the environment as the flame retardant additive uses sustainable vanillic aldehyde as a raw material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

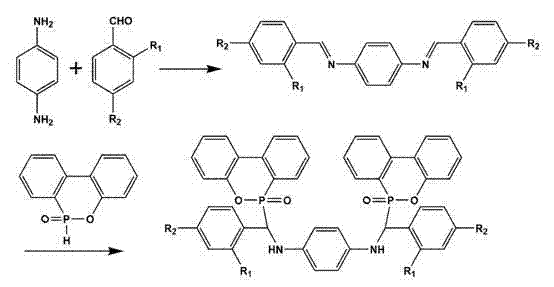

9,10-dihydro-9-oxa-10-phosphenanthrene-10-oxide (DOPO) group phosphorus-nitrogen flame retardant and preparation method and application thereof

InactiveCN103059339ASimple methodThe synthesis process is simpleGroup 5/15 element organic compoundsPolymer sciencePolymer

The invention relates to a 9,10-dihydro-9-oxa-10-phosphenanthrene-10-oxide (DOPO) group phosphorus-nitrogen flame retardant and a preparation method of the DOPO group phosphorus-nitrogen flame retardant. According to the preparation method, 4,4'-diaminodiphenyl and aromatic aldehyde undergo condensation reaction to obtain an imine intermediate product, and the imine intermediate product and DOPO undergo addition reaction to obtain the solid flame retardant. The preparation method is easy to control, good in repeatability, high in yield and suitable for large-scale production. The molecule of the flame retardant contains two flame retarding elements including phosphorus and nitrogen, and thus the flame retardant has good flame retarding effect and coal forming performance. Due to the fact that the molecules of the flame retardant have reactive hydrogen atoms of different numbers, the flame retardant can further react with resin with reactivity to obtain flame retarding resin. When the flame retarding resin is added to a polymer, the flame retarding property and the oxygen index of the polymer can be promoted, and the flame retarding level can reach Underwriters Laboratories (UL) 94V0.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

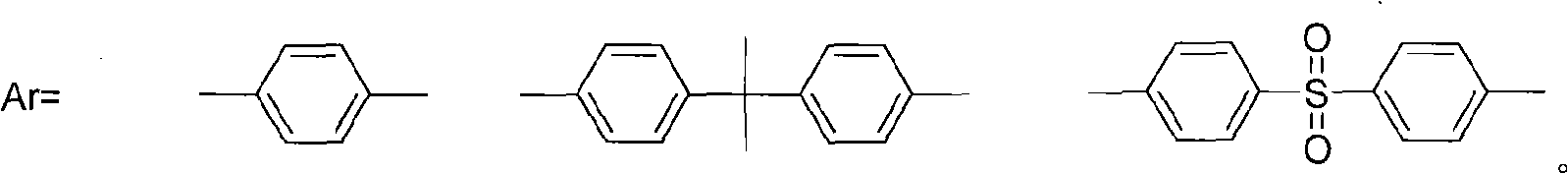

Preparation of polyphosphate flame retardant having dicyclic phosphoric acid ester structure

InactiveCN101328269AImprove thermal stabilityHigh decomposition temperatureGroup 5/15 element organic compoundsPolyesterPhosphoric Acid Esters

The invention discloses a method for preparing olyphosphate ester flame retardant with a bicyclic phosphate ester structure, which belongs to the polymerization type organophosphorous flame retardant structure and preparation method technical field. The invention is characterized in that: polyphosphate ester provided with a repeating unit structure shown at right is prepared, wherein, Ar is equal to bisphenol A, bisphenol S or hydroquinone. The method has the advantages that: the flame retardant has the characteristics of good heat stability, high decomposition temperature, narrow decomposition intervals, good char-forming property and so on. The method can be used for the flame-retarding modification of materials with higher processing temperature such as polyester, polyamide, polycarbonate, a blend of the polyester, the polyamide and the polycarbonate and so on. The preparation method is simple and easy to control.

Owner:DALIAN UNIV OF TECH

Special environmental-friendly halogen-free flame retardant for ABS (acrylonitrile butadiene styrene) resin

The invention discloses a special environmental-friendly halogen-free flame retardant for ABS (acrylonitrile butadiene styrene) resin. The flame retardant consists of aluminum hypophosphite as a main flame retardant and auxiliary flame retardants. The flame retardant can completely replace antimony bromide flame retardants and has the performance of better flame retardance, low smoke, low corrosion, good carbon formation performance, no toxicity and the like; in addition, when the flame retardant is applied to ABS, hydroplaning phenomenon cannot occur during extrusion processing, and no molten dripping phenomenon exists after combustion; and in addition, the cost is low.

Owner:JINAN TAIXING FINE CHEM

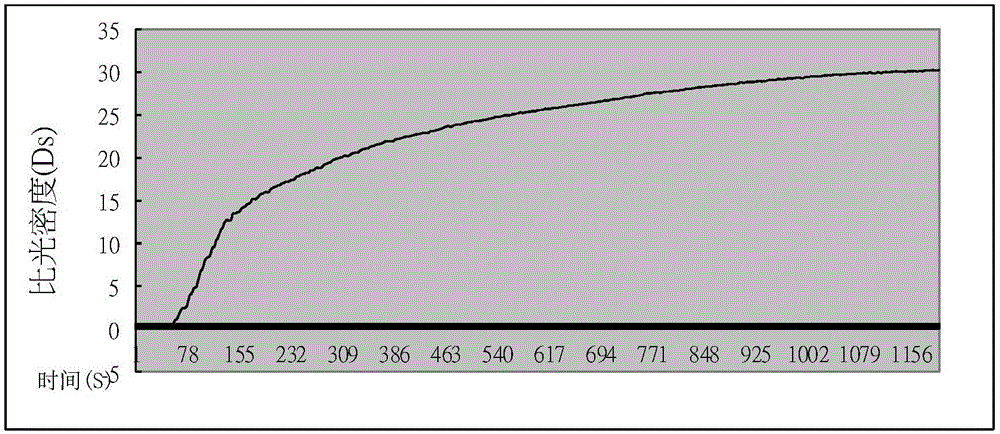

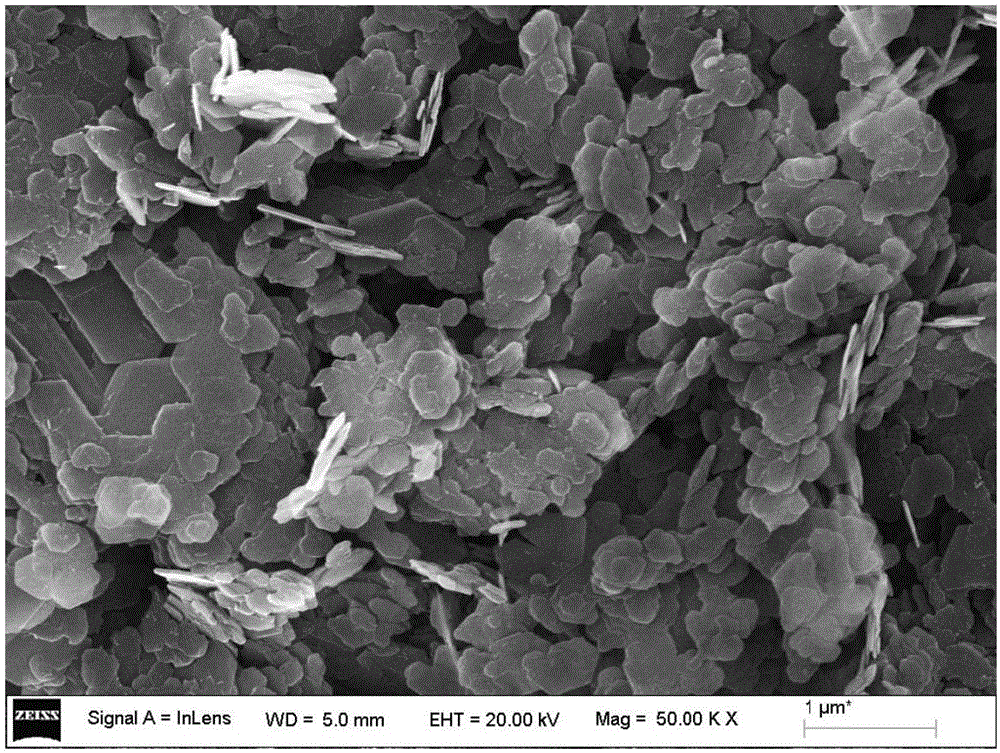

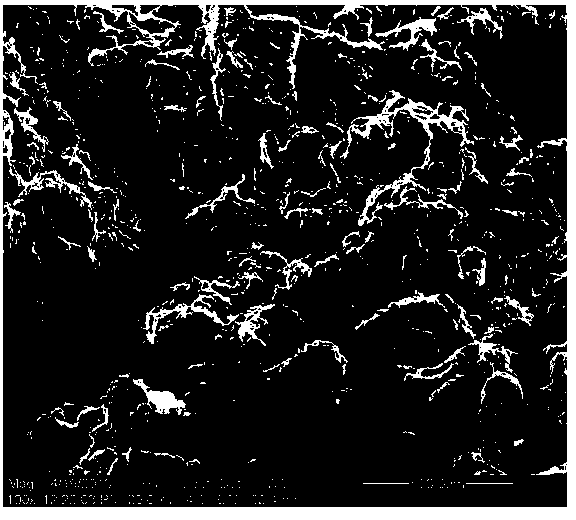

Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

The invention discloses an intercalated layered double hydroxide smoke inhibitor and a preparation method thereof. The smoke inhibitor is a layered structural material formed by assembling a laminated sheet consisting of metal cations and interlayer anions, wherein a specific composition general formula of the smoke inhibitor is M<2+>1-xM<3+>x(OH)2(A<n->)n / 2.mH2O. According to the preparation method disclosed by the invention, the intercalated layered double hydroxide smoke inhibitor is prepared by adopting a one-step coprecipitation method or a clean hydrothermal reaction at one step; the preparation method is simple and practical; according to the obtained intercalated layered double hydroxide smoke inhibitor, smoke inhibiting groups such as molybdate anions, an octamolybdate radical, a cuprate radical and a stannate radical are arranged at an interlayer, and smoke inhibiting elements such as iron and copper are introduced into the laminated sheet, so that a good carbon forming effect is realized, the smoke generating amount can be reduced, and the smoke inhibiting effect is synergically enhanced; meanwhile, a layered double hydroxide laminated sheet forms an alkaline porous substance at high temperature; the alkaline porous substance has greater specific surface area and can effectively adsorb smog; the prepared intercalated layered double hydroxide smoke inhibitor is applied to an ordinary rubber-plastic product and a high-temperature rubber-plastic product; the maximum density (Ds, max) at low additive amount (1phr) can be reduced by 87.3 percent; the intercalated layered double hydroxide smoke inhibitor is remarkable in smoke inhibiting effect and is a smoke inhibitor material with excellent performance.

Owner:BEIJING UNIV OF CHEM TECH

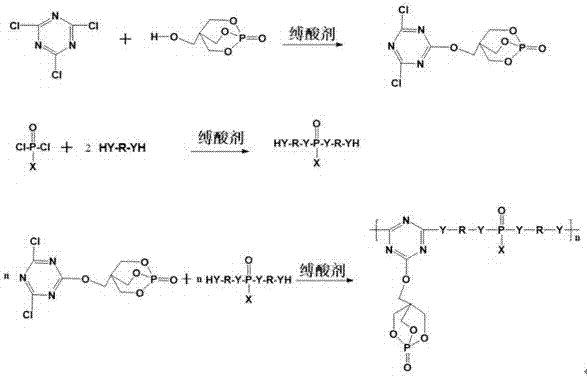

Trine expansion type flame retardant and synthetic method thereof

ActiveCN107118347AGood char formation and thermal stabilityGood flame retardant performanceSolventDiamine

The invention relates to a trine expansion type flame retardant and a synthetic method thereof. The synthetic method is characterized by comprising the following steps: adding a solvent into a container, adding cyanuric chloride and 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2] octane into the container, cooling to 0-45 DEG C in water bath or oil bath and stirring and dispersing, dropwise adding an acid-binding agent to react step by step, thereby obtaining unary substitute; adding matters containing aliphatic diamine or aliphatic dihydric alcohol and a mixture of the solvent and the acid-binding agent into another container, cooling to -10 to 10 DEG C in ice bath or a freezing reactor, slowly dropwise adding a phosphorus-containing compound to react, thereby obtaining phosphorus-containing intermediate; adding the obtained unary substitute (CNC-PEPA) and the obtained phosphorus-containing intermediate into a reaction container with the solvent, dropwise adding the acid-binding agent, heating to 80-130 DEG C to react, cooling, washing and drying to obtain powder solid, namely the trine expansion type flame retardant. The trine expansion type flame retardant has the advantages of being great in molecular weight, relatively moderate in proportion of an acid source, a carbon source and a gas source in a molecular structure, relatively high in char forming content, relatively good in thermal stability and the like.

Owner:蕉岭金鹏精细化工有限公司

Phosphoric flame-proof copolyester ionomer and preparation method thereof

The invention discloses a phosphorus-containing flame retardant copolyester ionomer and the preparation method, which is characterized in that: based on a plurality of building units synthesizing polyester represented by I and II, a plurality building units represented by IV or a plurality building units represented by III and IV are introduced and the copolyester ionomer is prepared by random copolymerization; wherein, the number of the building units represented by III is 0 to 20 percent of the number of the building units represented by I, the number of the building units represented by IV is 0.1 to 20 percent of the number of the building units represented by I, the number of the building units represented II: the number of the building units represented by [I+III+IV] equals 1, the intrinsic viscosity of the prepared copolyester ionomer [Eta] is in the rang of 0.25 to 0.95dL / g. The phosphorus-containing flame retardant copolyester ionomer has the advantages that: because the ionic groups are phosphorus-containing groups, the flame-retardance modification and the ionization modification of polyester are realized simultaneously; meanwhile, the melt viscosity of polyester is enhanced by the incarbonization produced by the phosphorus-containing ionic groups and the ''physical crosslinking'' produced by the ''ionic aggregate'', thus, the flame retardant and anti-dripping performance is given to polyester.

Owner:SICHUAN UNIV

Polylactic acid/starch expansion flame-resistant composite material, and preparation method thereof

ActiveCN106496975AImprove charcoal abilityImprove high temperature thermal stabilityMaleic anhydrideChemistry

The invention discloses a polylactic acid / starch expansion flame-resistant composite material with excellent flame resistance, and a preparation method thereof. The polylactic acid / starch expansion flame-resistant composite material is composed of, by weight, 60 to 89% of polylactic acid, 5 to 30% of an acid source, 5 to 30% of a modified starch, and 1 to 15% of a gas source. In a preferred embodiment, the modified starch is phosphorized maleic anhydride grafting modified starch (bio-based phosphorus containing starch). According to the preparation method, polylactic acid possesses excellent compatibility with the modified starch; synergistic effect of the acid source, the carbon source (the modified starch), and the gas source is capable of improving charring forming capability of the polylactic acid matrix, and improving high temperature stability and flame resistance of polylactic acid greatly. According to the preparation method, adoption of an existing double-screw extruder is enough for production; preparation is simple and convenient; and the preparation method is convenient for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Phosphorus-containing macromolecular intumescent flame-retardant charring agent with cross-linked structure as well as preparation method and application thereof

ActiveCN104559204ASolve the problems caused by poor water resistanceImprove solubilityEpoxyCross-link

The invention discloses a phosphorus-containing macromolecular intumescent flame-retardant charring agent with a cross-linked structure as well as a preparation method and an application thereof. A structural general formula of the phosphorus-containing macromolecular intumescent flame-retardant charring agent is as shown in the specification, wherein X, Y and Z are any one of diamine, diol group, alkylol amine or diphenol, and can be the same, and can also be different. The invention further relates to a preparation method of the flame-retardant charring agent, and an application of the flame-retardant charring agent as a carbon source of a novel intumescent flame-retardant system, and an application of novel intumescent flame-retardant system in polyolefin, polyurethane, polylactic acid, polyamide and epoxy resin. The intumescent flame-retardant charring agent prepared by the method has good charring property, and is free of halogen, low in toxicity and high in water resistance, good in compatibility with a plurality of flame-retardant high polymers, relatively small in effects on mechanical property, simple in synthesis process, easy to control, and easy to put into industrial production.

Owner:SICHUAN UNIV

Reactive intumescent flame retardant for polyurethane and synthesis method of reactive intumescent flame retardant

InactiveCN102585135ADoes not affect mechanical propertiesHigh phosphorus and nitrogen flame retardant ingredientsGroup 5/15 element organic compoundsHalogenHigh carbon

The invention discloses a reactive intumescent flame retardant for polyurethane and a synthesis method of the reactive intumescent flame retardant, relates to a flame retardant technology, in particular to a novel intumescent flame retardant which contains an acid source, a carbon source and a gas source simultaneously and contains a hydroxyl group serving as an active group. The chemical name ofthe reactive intumescent flame retardant for polyurethane is 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane. The structure of the reactive intumescent flame retardant is shown as a formula (I). The synthesis method comprises the following steps of: adding 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane into water; dropwise adding diethanolameine and triethylamine at the temperature of 0-5 DEG C; reacting at the temperature of 50-60 DEG C for 4-6 hours; concentrating under reduced pressure; purifying; and performing vacuum drying to obtain the flame retardant. The flame retardant and the synthesis method of the reactive intumescent flame retardant have the advantages of integration of phosphorus, nitrogen and carbon, high phosphorus and nitrogen flame-retardant ingredients, no containing of halogen, nontoxicity, environmental friendliness, high carbon forming property, high compatibility with apolyurethane system, simple process, mild synthesis condition and suitability for industrial implementation.

Owner:ZHONGBEI UNIV

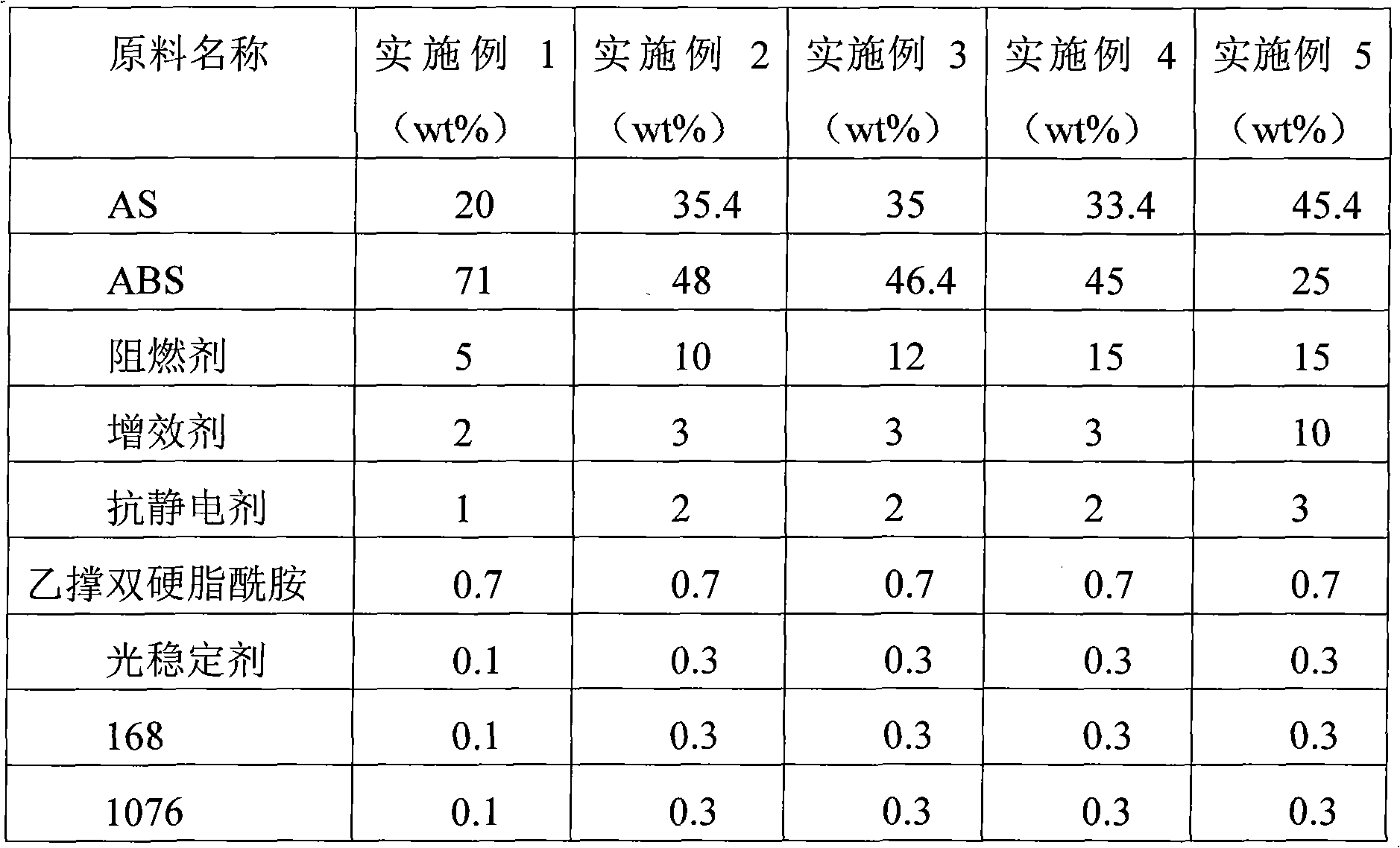

Fireproof anti-ultraviolet anti-static ABS material and preparation method thereof

The invention relates to a fireproof anti-ultraviolet anti-static ABS material and a preparation method thereof. The preparation method comprises the following steps: weighing the following raw materials: 25 to 71 weight percent of ABS, 20 to 45 weight percent of AS, 5 to 15 weight percent of fire retardant, 2 to 10 weight percent of synergist, 1 to 5 weight percent of antistatic agent, 0.1 to 3 weight percent of lubricating agent, 0.1 to 1 weight percent of antioxidant and 0.1 to 1 weight percent of light stabilizer; adding 0 to 0.3 weight percent of white oil into the raw materials, putting the mixture into a high mixing machine to mix for 2 to 5 minutes and discharging; carrying out extrusion granulation on the discharged mixture by a double-screw extruder to obtain a product, wherein the cylinder temperature of the double-screw extruder is between 190 and 250 DEG C and the rotating speed of screws is between 180 and 600 revolutions per minute. Compared with the prior art, the ABS material of the invention has outstanding impact resistance, high glossiness, mouldability and chemical resistance and can meet testing standards of a safety helmet (GB 2811 / GB 2812).

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

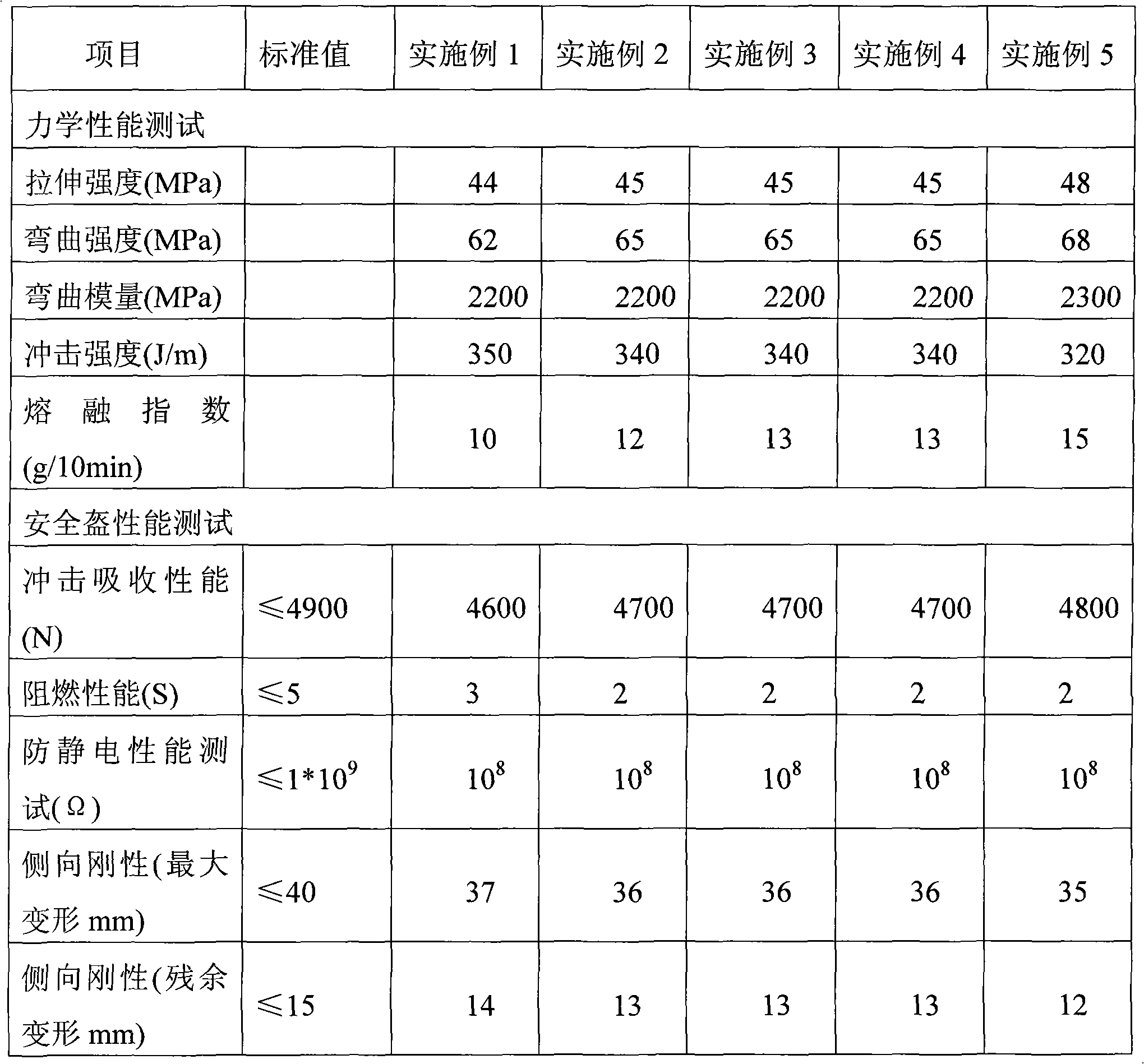

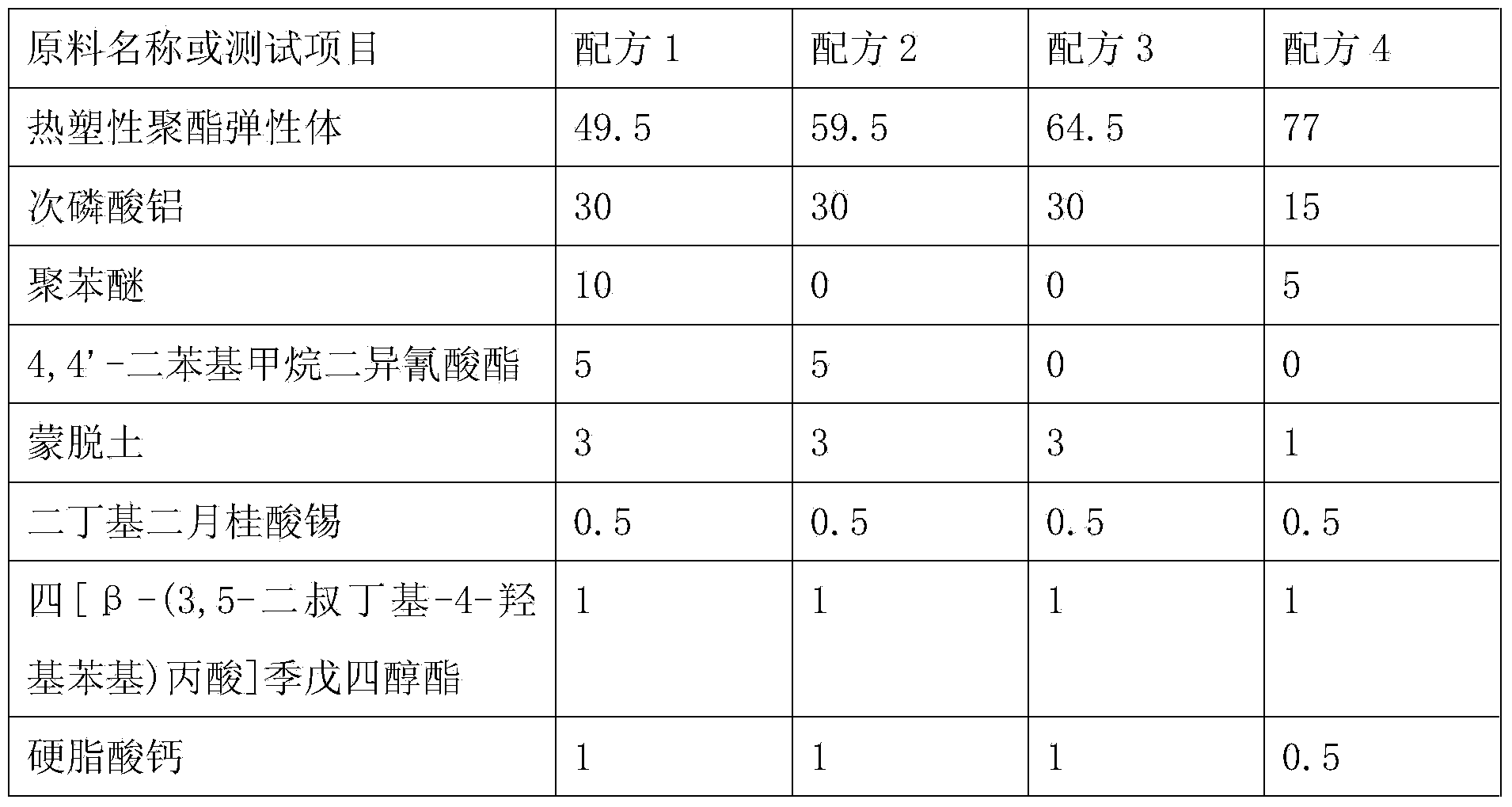

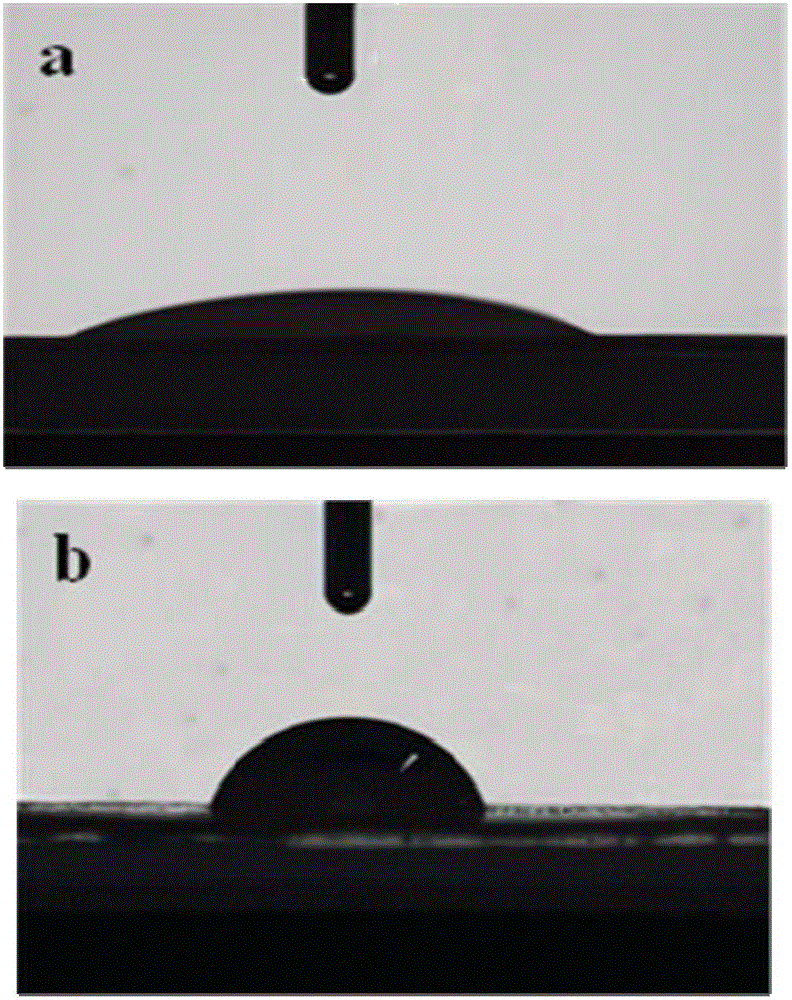

Halogen-free flame-retardant thermoplastic polyester elastomer nano composite material and preparation method thereof

ActiveCN103642178AImprove flame retardant performanceImprove mechanical propertiesElastomerPolyester

The invention discloses a halogen-free flame-retardant thermoplastic polyester elastomer nano composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing 50.5-81.5 percent of thermoplastic polyester elastomer, 15-30 percent of halogen-free flame retardant, 1-10 percent of charring agent, 1-5 percent of reactive compatibilizer, 1-3 percent of nucleating agent, 0.1-0.5 percent of heat stabilizer, 0.1-1 percent of antioxidant and 0.3-1 percent of lubricating agent according to the total mass percentage of the composite material, heating to the temperature of 210-225 DEG C, performing melt blending, extruding, bracing, cooling, sized dicing and drying to obtain the halogen-free flame-retardant thermoplastic polyester elastomer nano composite material. The nano composite material has excellent flame-retardant property and physical performance, the defects that a halogen-containing flame retardant is high in environmental hazard, the addition amount of an inorganic flame retardant is high, the physical performance of the material is poor and the like in the conventional composite material modification technology are overcome, and the composite material has high application prospects.

Owner:合肥安聚达新材料科技有限公司

Modified ammonium polyphosphate composite intumescent flame retardant and preparation method and application thereof

The invention discloses a modified ammonium polyphosphate composite intumescent flame retardant and a preparation method and application thereof. According to the intumescent flame retardant, ammoniumpolyphosphate serves as a matrix, chitosan derivatives and phytic acid are used for coating and modifying the ammonium polyphosphate through electrostatic interaction, a chitosan derivative / phytic acid composite layer rich in carbon, nitrogen and phosphorus is formed on the surface of the ammonium polyphosphate, and the three-in-one composite intumescent flame retardant is formed. The modified ammonium polyphosphate composite intumescent flame retardant disclosed by the invention fully utilizes carbon-rich chitosan as a carbon source and phosphorus-rich phytic acid as an acid source to modifyammonium polyphosphate, so that the water resistance and the intumescent flame retardant efficiency of ammonium polyphosphate are improved, and the modified ammonium polyphosphate composite intumescent flame retardant is simple in preparation method, environment-friendly and good in flame retardant property, and can be used for flame retardance of polyolefin.

Owner:HUBEI ENG UNIV

Non-halogen polymer-type additive resisting smelting-dropping and combustion, and its preparing process and usage

A non-halogen polymer type additive for resisting fusion dropping and firing is prepared from arylthiophosphonic dihalogen and diphenol compounds in mole ratio of 1:(0.9-1.1) through fusing and polycondensating, and can be used to synthesize polyester or polyamide compounds by polycondensation. Its advantages include high chairing performance, fusion dropping resistance and flame-retarding efficiency, good compatibility to polymer substrate, and environmental pollution.

Owner:SICHUAN UNIV

Low-addition-amount halogen-free flame-retardant polypropylene material and preparation method thereof

The invention discloses a low-addition halogen-free flame retardant polypropylene material and a preparation method thereof. The flame retardant polypropylene material specifically involves the following components: polypropylene, an intumescent flame retardant and a flame retardant synergist. Among them, the mass fraction of the intumescent flame retardant is 14% to 18%, the mass fraction of the flame retardant synergist is 0.5% to 3%, and the addition amount of the entire flame retardant system does not exceed 20%. The flame-retardant polypropylene material can reach the V-0 level of UL-94, the oxygen index can reach 33.5%, and it has excellent mechanical properties and low cost.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of halogen-free composite flame retardant polypropylene/thermoplastic polyurethane elastomer composite material

The invention discloses a preparation method of a halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The method mainly consists of: A. mixing 80 parts by weight of polypropylene, 20 parts by weight of a thermoplastic polyurethane elastomer, 3 parts by weight of dry polypropylene grafted maleic anhydride and 0.2 part by weight of an antioxidant fully, then employing a double-screw extruder to perform mixing and granulating, and conducting drying to obtain a modified polypropylene masterbatch; B. then fully mixing 100 parts by weight of modified polypropylene masterbatches, 6.7-15 parts by weight of modified expandable graphite, and 4-13.3 parts by weight of red phosphorus flame retardant masterbatches to obtain a mixture; and then subjecting the mixture to mixing and granulating by the double-screw extruder, drying the extruded granules, and then carrying out injection molding by an injection molding machine, thus obtaining the halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The flame retardant polypropylene / thermoplastic polyurethane elastomer composite material prepared by the method has good flame retardance, and the flame retardant level can reach vertical burning UL-94V-0.

Owner:SOUTHWEST JIAOTONG UNIV

Ionic liquid-type phosphate fire retardant and preparation method thereof

ActiveCN102924749ALow halogen contentPromote environmental protectionGroup 5/15 element organic compoundsBulk chemical productionPhosphatePhosphoric acid

The invention discloses an ionic liquid-type phosphate fire retardant and a preparation method thereof. The formula of the ionic liquid-type phosphate fire retardant is shown in the description. The R in the formula is equal to CnH2n+1, wherein n may be 1, 3 or any even number between 2 and 18; and X may be Cl, Br, BF4, PF6 or N(CF3SO2)2. As the module of the fire retardant disclosed by the invention contains a 1-oxo-4-hydroxymethyl-2,6,7-trioxa-1-phabicyclo[2.2.2]octane(PEPA) framework, the fire retardant combines the acid source and the carbon source of an intumescent flame retardant (IFR). The fire retardant has the characteristics of high thermostability and high charring performance. The fire retardant can combine external gas sources such as ammonium polyphosphate to form a new IFR, which has high fire retarding efficiency and high compatibility with polymeric substrates.

Owner:HEFEI UNIV OF TECH

Toughened-flame-retardant epoxy resin material and preparation method thereof

The invention discloses a toughened-flame-retardant epoxy resin and a preparation method thereof. The toughened epoxy resin material comprises an epoxy resin monomer, a curing agent, expanded graphite and flame-retardant microcapsules. The toughened epoxy resin material is prepared by curing the following components in parts by weight at 100-220 DEG C: 70-95 parts of epoxy resin monomer, 5-25 parts of flame-retardant microcapsule, 10-30 parts of curing agent and 0.3-1 part of expanded graphite. The flame-retardant microcapsules are prepared by using ammonium polyphosphate with the molecular weight of greater than 1500 as a core and a benzoxazine crosslinked network as a shell. The diameter of the expanded graphite lamellae is 3-15 mu m, and the expanded graphite mainly performs the functions of synergic toughening and flame retardancy. The toughened-flame-retardant epoxy resin material implements synchronous enhancement of toughness and flame retardancy, and effectively overcomes the defect of the single performance improvement mode for the material. The toughened-flame-retardant epoxy resin can be used in the occasions with higher requirements for toughness and flame retardancy.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

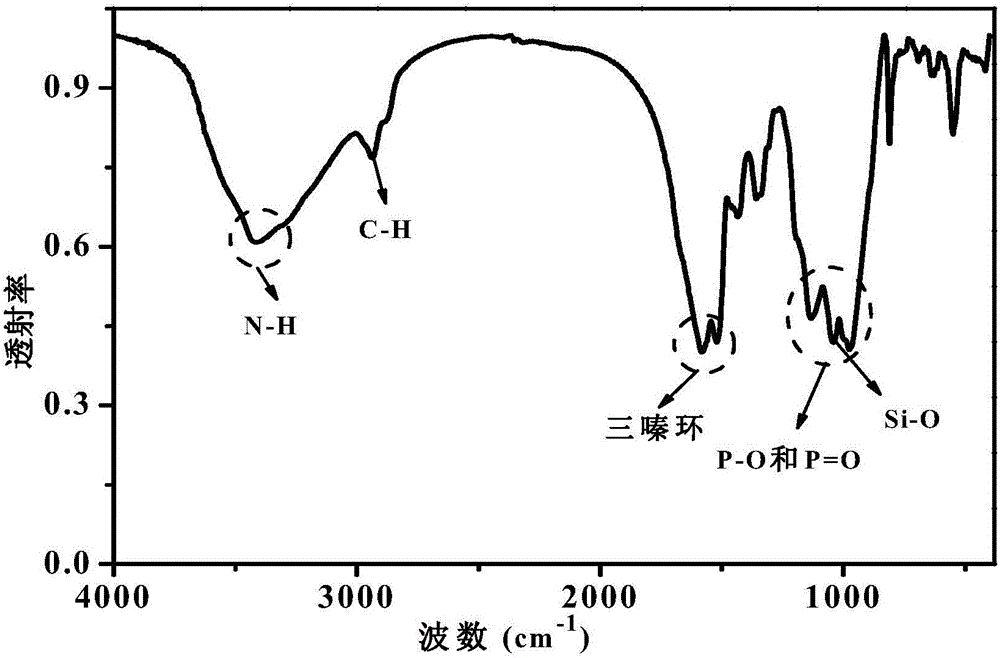

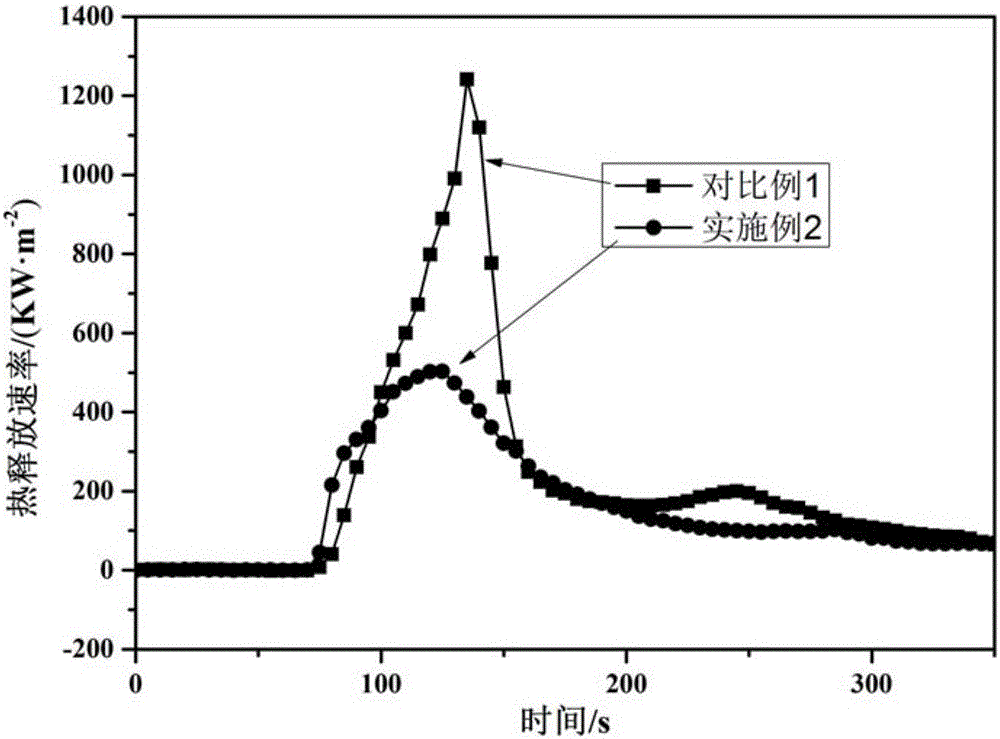

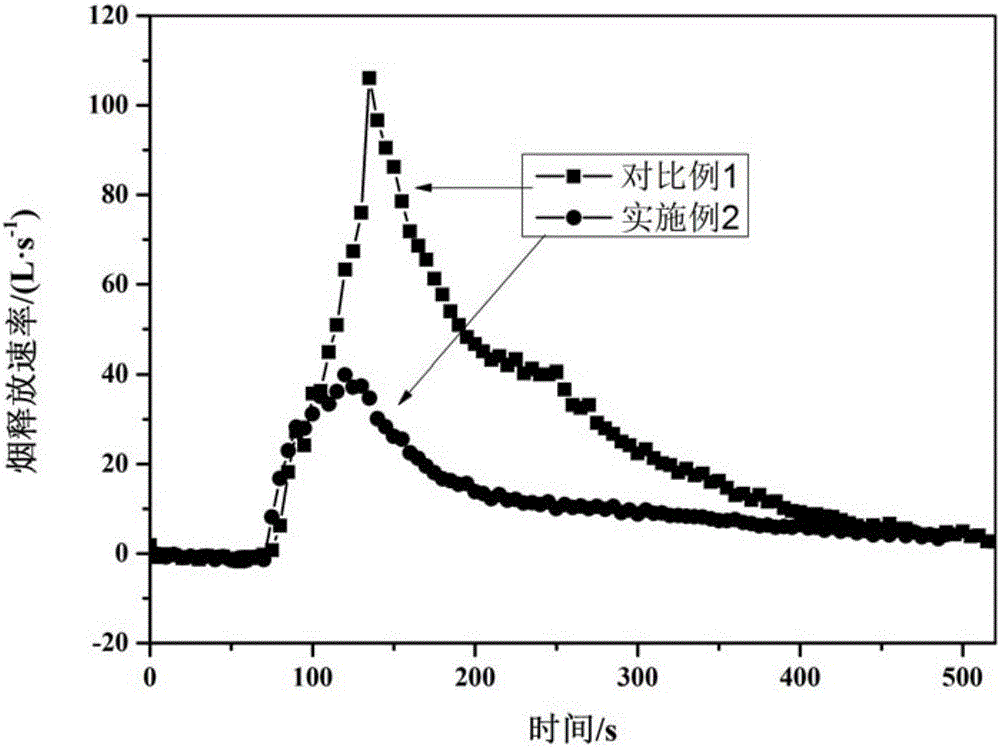

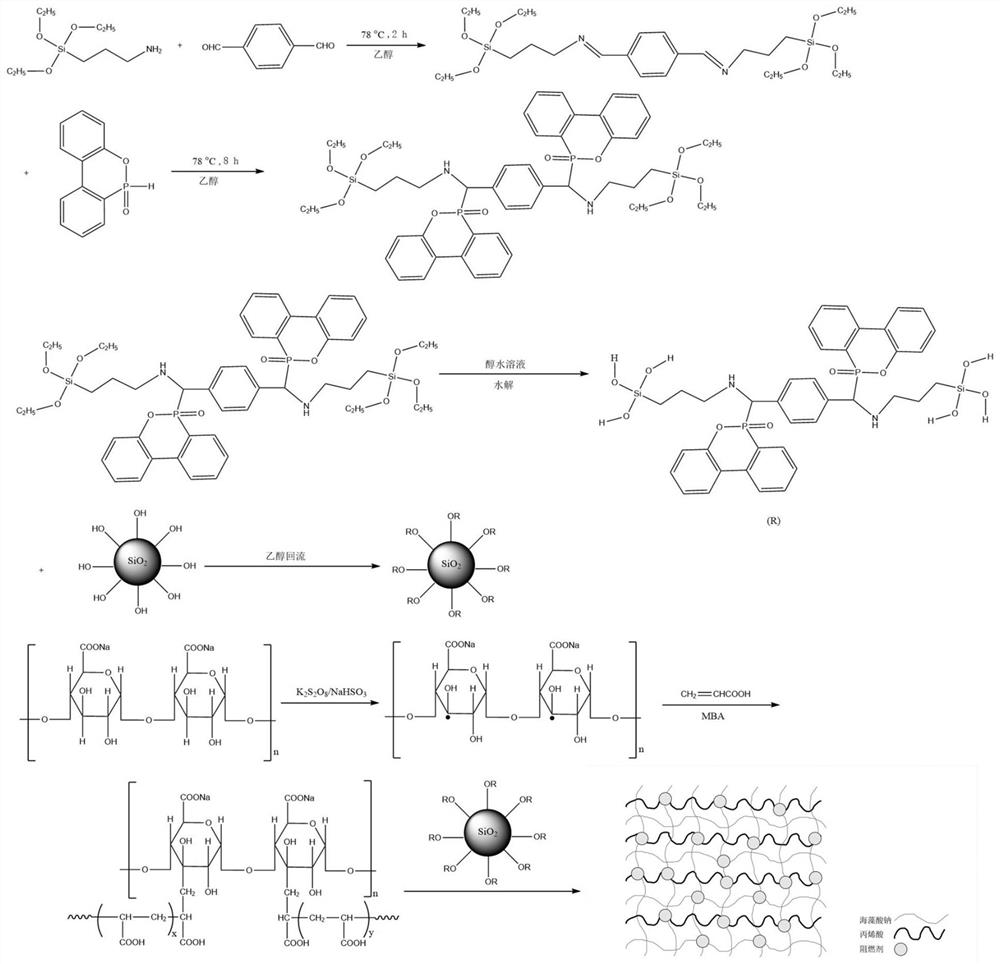

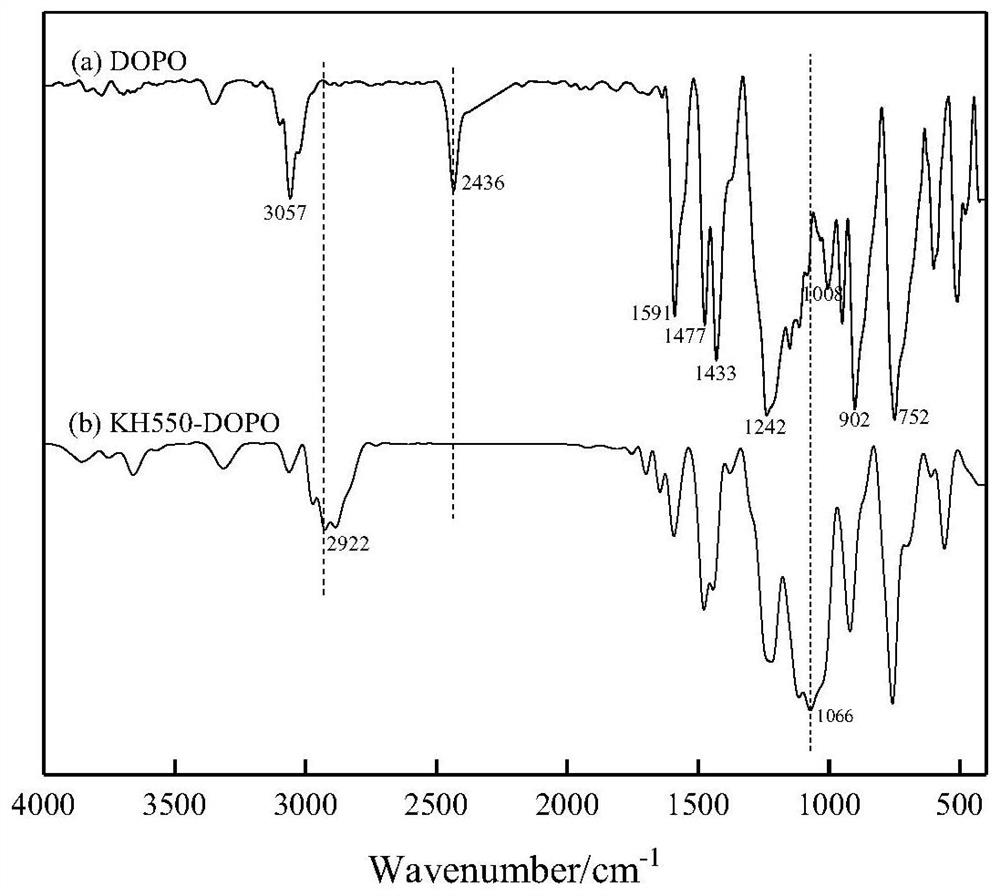

Nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and preparation method thereof

ActiveCN111849270AAvoid breakingNot easy to driftFireproof paintsOther chemical processesSilanesActive agent

The invention belongs to the field of coal flame-retardant dust suppressants. The invention specifically discloses a nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and apreparation method thereof. The nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant comprise the following components: 0.08 to 0.12 part of a phosphorus-based flame retardant, 0.10 to 0.14 part of a nitrogen-containing silane coupling agent, 0.01 to 0.05 part of an aldehyde compound, 100.0 to 200.0 parts of a solvent, 0.18 to 0.36 part of a silicon flame retardant, 0.1-0.4 part of a pH regulator, 83.0 to 125.0 parts of deionized water, 57.0 to 95.0 parts of alcohol, 1.0 to 2.0 parts of a natural polymer, 10.0 to 20.0 parts of a monomer, 4.0 to 8.0 parts of a pH buffer agent, 0.1 to 0.4 part of an initiator, 0.02 to 0.08 part of a cross-linking agent, 0.2 to 0.4 part of a surfactant and 0.2 to 1.0 part of a plasticizer. The preparation method comprises the following steps: grafting a nitrogen-containing silane coupling agent onto phosphorus flame retardant molecules by using an aldehyde compound, then hydrolyzing the silicon-based flame retardant, carrying outdehydration reaction between hydroxyl groups on the hydrolyzed silicon-based flame retardant and surface hydroxyl groups on the silicon-based flame retardant to obtain a nitrogen-phosphorus-silicon synergistic flame retardant, and finally organically combining the nitrogen-phosphorus-silicon synergistic flame retardant with dust suppression components such as a natural polymer, a monomer, glycerol and a surfactant in the same system through a polymer free radical polymerization reaction, so that the flame retardant has flame retardance and dust suppression properties.

Owner:SHAANXI UNIV OF SCI & TECH

Flame-retardant polyolefin composition and preparation method thereof

ActiveCN113956572AImprove high temperature stabilityImprove heat resistancePolymer sciencePolyolefin

The invention relates to a flame-retardant polyolefin composition and a preparation method thereof, and belongs to the technical field of olefin resin. The composition comprises 100 parts of polyolefin resin, 5-8 parts of a flame retardant and 6-10 parts of a processing aid, and the processing aid comprises 2-5 parts of a compatibilizer, 0.5-1 part of a lubricant and 6-8 parts of a filler. The preparation method comprises the following steps: uniformly mixing the polyolefin resin, the flame retardant and the processing aid, and extruding and granulating to obtain the flame-retardant polyolefin composition. According to the filler, talcum powder serves as a raw material and is modified through a common silane coupling agent, a rigid C=N imino group of Schiff base is introduced, and resonance stability has a good promoting effect on the thermal stability of a polymer; and then a phosphorus-containing reactant is introduced, namely, a phosphate flame-retardant structure is introduced, so that a synergistic effect is achieved on the flame-retardant effect of the talcum powder, and meanwhile, the compatibility between the talcum powder and a polymer is improved.

Owner:湖南省新基源新材料科技有限公司

Three-sources-integrated intumescent flame retardant, and synthesis method and application thereof

InactiveCN107652324AMild reaction conditionsOperational securityGroup 5/15 element organic compoundsSolventFire retardant

The invention relates to an intumescent flame retardant, and a synthesis method and an application thereof, and concretely relates to a three-sources-integrated intumescent flame retardant, and a synthesis method and an application thereof. The problems to be solved are low flame retardation efficiency, poor thermal stability and difficulty in processing of existing intumescent flame retardants. The three-sources-integrated intumescent flame retardant is a methylphosphonic acid-piperazine-neopentyl glycol phosphate oligopolymer. The method comprises the following steps: 1, heating piperazine and distilled water, adding saturated methylphosphonic acid, and carrying out heating, reacting, concentrating and drying to obtain a white crystal intermediate di-methylphosphonopiperazine; and 2, adding neopentylene glycol and a solvent, carrying out heating, adding the white crystal intermediate di-methylphosphonopiperazine, heating the obtained solution to reflux the solution, cooing the refluxed solution, carrying out suction filtration and washing, and drying the obtained product to obtain the three-sources-integrated intumescent flame retardant. The flame retardant has the advantages ofgood char forming performance, high thermal stability, and high-efficiency flame retardation to polyethylene resin, and the preparation method has the advantages of mild reaction conditions, simplicity in operation, and safety. The flame retardant is used for realizing the flame retardation of the polyethylene resin.

Owner:NORTHEAST FORESTRY UNIVERSITY

Benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance and preparation method of copolyester

ActiveCN108359084APreserve thermoplastic processabilityIncrease melt viscosityStructural unitStructure based

The invention discloses a benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance. Copolyester is prepared from structural units represented by I, II and III or structural units represented by I, II and IV through random copolymerization, wherein the characteristic viscosity [eta] of copolyester is 0.41-1.12 dL / g, and the limit oxygen index is 24.2%-38.7%; the vertical combustion class is in a range from V-2 to V-0; the p-HRR (peak of heat release rate) in a cone calorimetry test is reduced by 7.1%-72.1% as compared with that of pure PET, and total smoke release is decreased by 2.0%-59.2% as compared with that of pure PET. The invention further discloses a preparation method of copolyester. Ahigh-temperature self-crosslinking group introduced in the preparation process is a benzene imide group, and prepared copolyeste cannot be subjected to crosslinking during processing and polymerization, so that thermoplastic processability of polyester is retained; meanwhile, due to the tackifying effect and high charring property brought by the self-crosslinking action at high temperature or during combustion, prepared copolyester has excellent flame retardancy, smoke suppression and melt drop resistance effects.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com