Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "Promote charcoal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

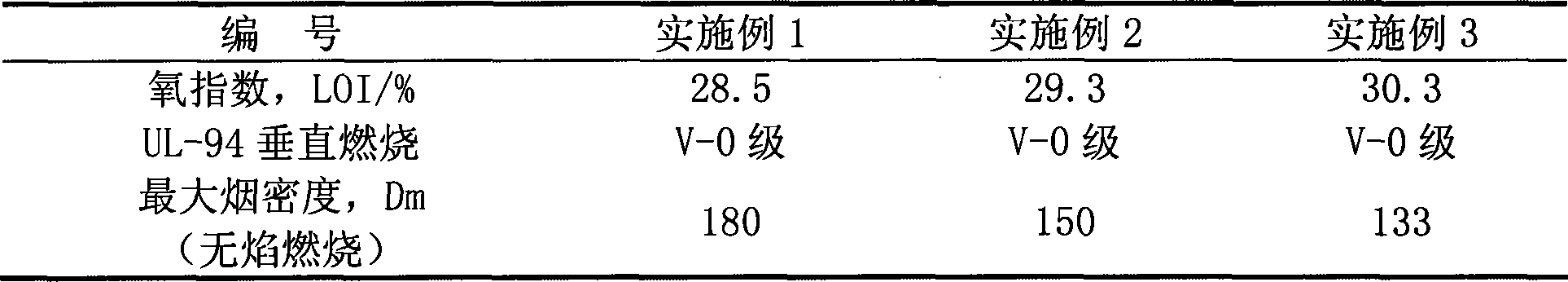

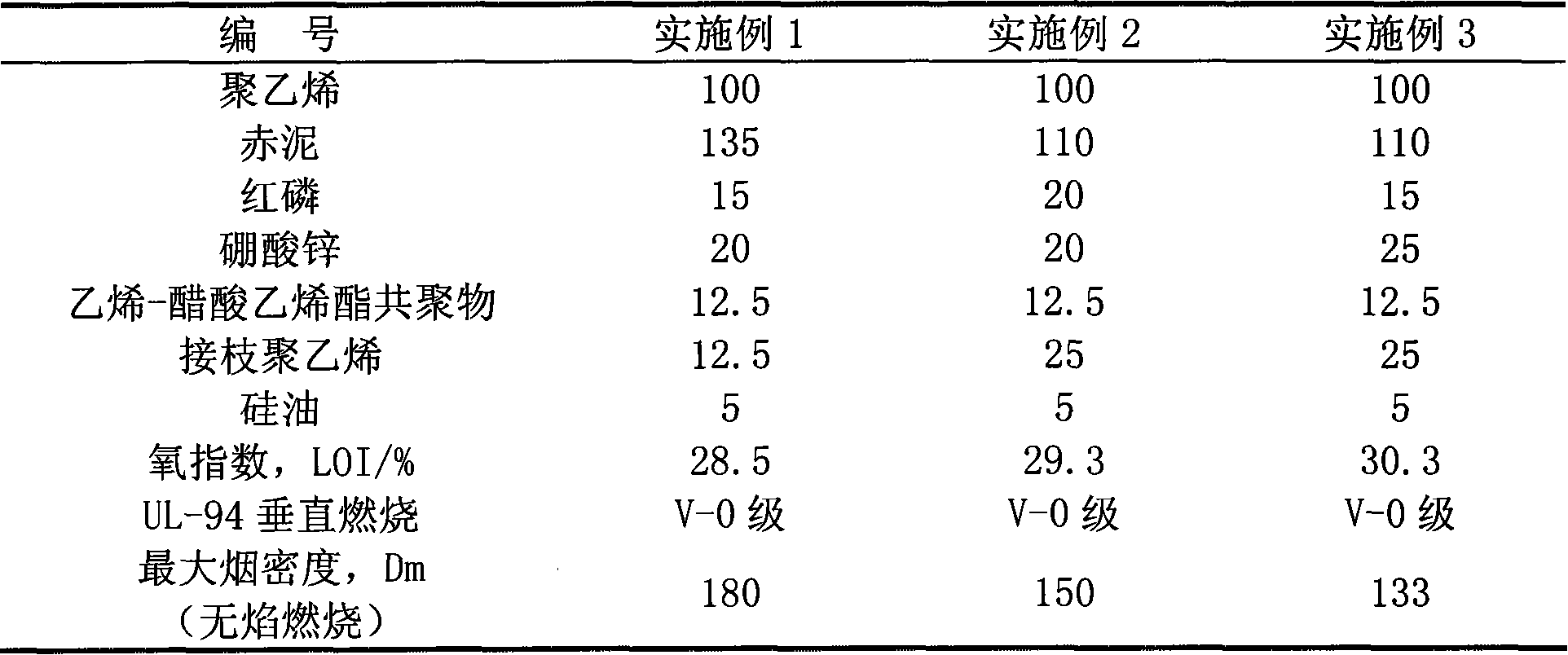

Environmental protection based red mud combination modification synergism fire-retardant polyethylene

InactiveCN101624457AIncrease added valueMeet environmental protection requirementsRed mudCarvacryl acetate

The invention relates to an environmental protection based red mud combination modification synergism fire-retardant polyethylene, and belongs to the technical field of compressive utilization and fire-retardant plastics. The fire-retardant polyethylene is suitable for fire safety protection in important public places in the fields of electric products, building materials and transportation. The fire-retardant polyethylene consists of the following components in percentage by weight: 30 to 35 percent of polyethylene, 34 to 39 percent of red mud, 6 to 13 percent of red phosphorus, 5 to 17 percent of zinc borate, 3 to 8 percent of ethylene-vinyl acetate copolymer, 2 to 7 percent of grafted polyethylene, and 2 to 8 percent of silicone oil. The preparation process comprises the following steps of: grinding and drying the red mud; blending the ground red mud with other raw materials according to the blending ratio; mixing the mixture with polyethylene resin by fully stirring at a high speed; fusing, co-mixing and processing the mixture; and preparing a sample. The processing conditions comprise that: the roll temperature of a double-roller mixing mill is between 140 and 150 DEG C; and the forming temperature of the flat vulcanizing machine sample is between 120 and 130 DEG C, the heating time is between 4 and 8 minutes, and the pressure is between 10 and 20MPa. The fire-retardant system meets the requirements of industrial application on mechanical property, and simultaneously has comprehensive properties such as good fire-retardant effect, low cost, environmental protection and the like; moreover, the application field of the red mud is widened, and the red mud product with high added value is prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

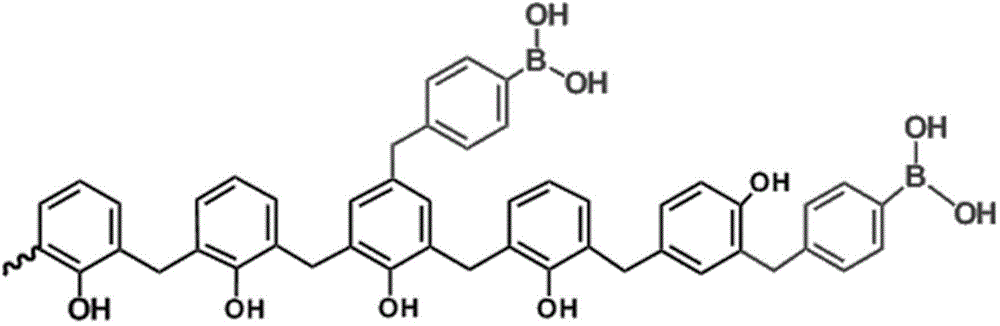

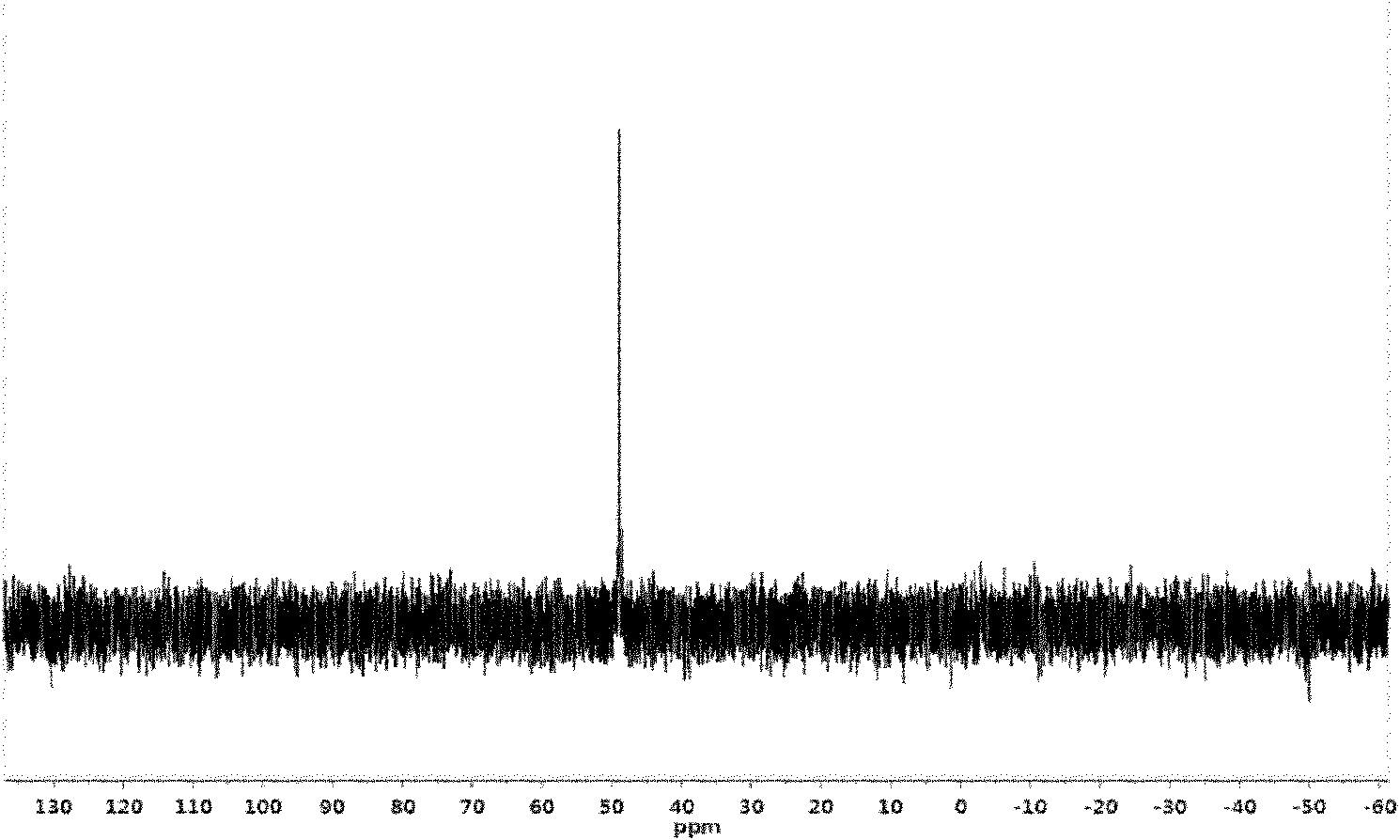

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

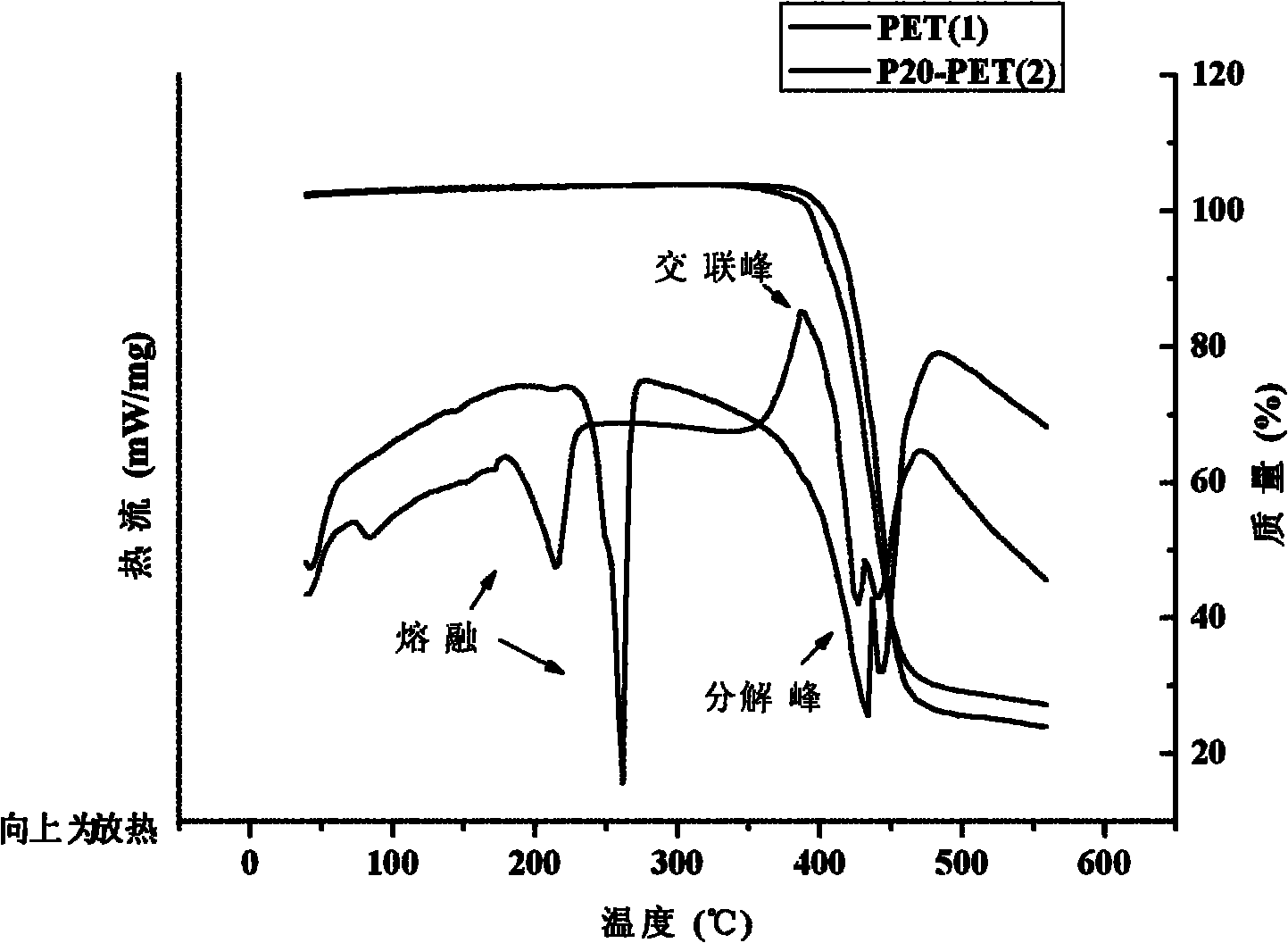

High-temperature self-crosslinking flame-retardant anti-dripping copolyester and preparation method thereof

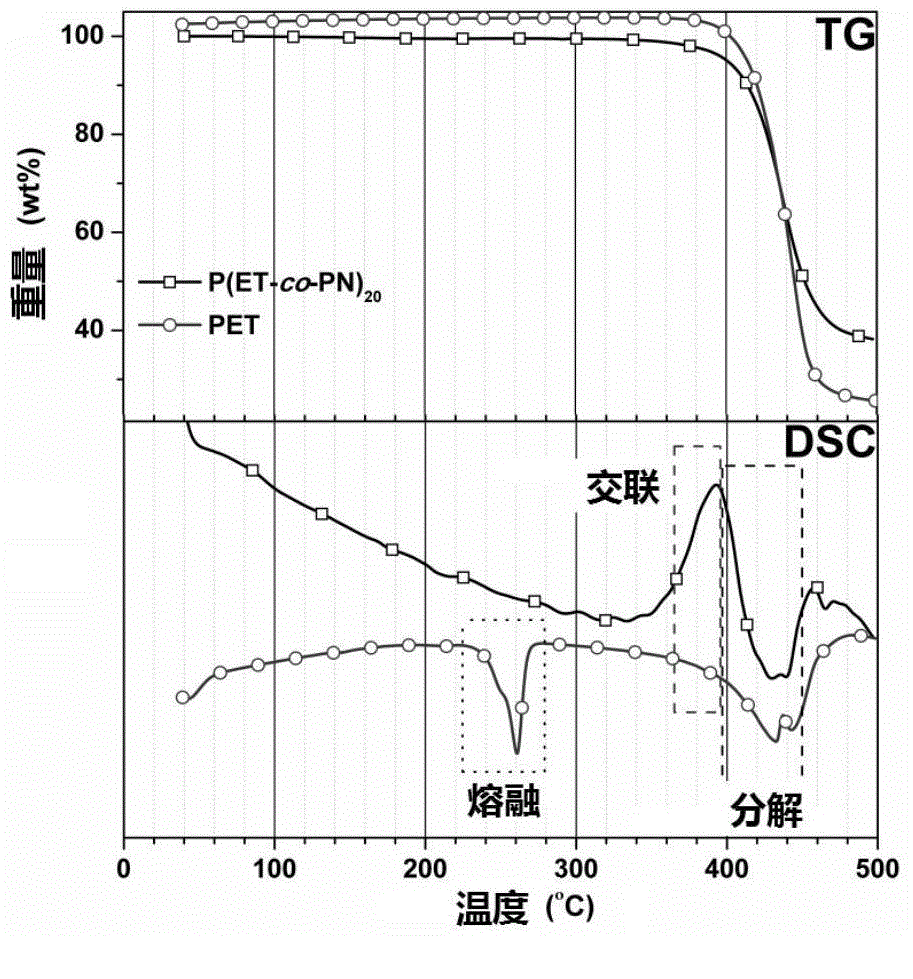

The invention discloses a high-temperature self-crosslinking flame-retardant anti-dripping copolyester which is prepared by introducing a structural unit shown as IV in the specification or introducing structural units shown as III and IV in the specification by random copolymerization on the basis of structural units of synthetic polyester shown as I and II in the specification, and the intrinsic viscosity [eta] of the prepared high-temperature self-crosslinking copolyester is 0.25-1.25dL / g. The invention also discloses the preparation method of the high-temperature self-crosslinking copolyester. Because the crosslinking group introduced in the invention is a high-temperature self-crosslinking group, on the premise of not affecting the preparation and forming of the polyester, self-crosslinking can be realized at higher temperature, and the melt viscosity of the polyester is improved through the char formation effect and stable chemical crosslinking of the self-crosslinking group, thereby performing combined action with the phosphorus-containing flame-retardant structural unit IV and endowing the polyester with better flame-retardant and anti-dripping properties.

Owner:SICHUAN UNIV

Flame-retardant composite material with DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified nano mesoporous molecular sieve

InactiveCN102675895AImprove compatibilityGood resistance to precipitationMolecular-sieve and base-exchange compoundsPigment treatment with organosilicon compoundsMolecular sieveChemistry

The invention discloses a flame-retardant composite material with DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified nano mesoporous molecular sieve, belongs to the fields of nano mesoporous molecular sieve flame-retardant synergists and halogen-free flame-retardant composite materials, and particularly relates to the preparation method of the DOPO modified nano mesoporous molecular sieve and the flame-retardant composite material with the DOPO modified nano mesoporous molecular sieve. The DOPO is of a hexahydric phosphorus-heterocyclic-ring structure, and is a novel flame retardant intermediate. The nano mesoporous molecular sieve is the flame-retardant synergist. The invention discloses the method for preparing the DOPO modified nano mesoporous molecular sieve and the flame-retardant composite material with the DOPO modified nano mesoporous molecular sieve. Since the compound flame-retardant synergist plays a role in phosphorus / silicon synergistic flame retardance, the obtained product has good expandable carbon forming property, the flame-retardant efficiency of the material is obviously increased, the remaining amount of the residual carbon and the compact degree of a carbon layer are increased, and further the flame redardancy of the composite material is improved to a greater degree.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Silicon phosphonate containing fire rotardant and its synthesis method

A Si-contained phosphonate as fire retarding agent used for fabrics is prepared through proportionally mixing methylvinyl dichlorosilane with solvent, stirring, adding dimethyl phosphite and catalyst, stirring under protection of N2, heating, reflux, collecting fraction, cooling, adding water, stirring, oil-water separating, and distilling water phase to obtain fire retarding agent SP.

Owner:ZHEJIANG HENGYI GRP CO LTD +1

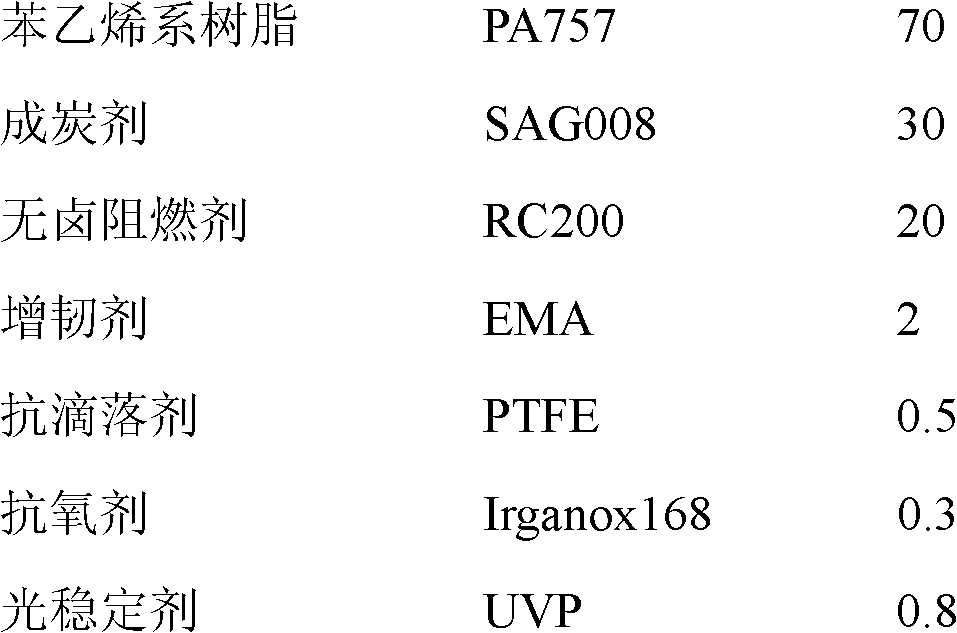

Halogen-free flame-retardant styrene-series resin composition and preparation method thereof

The invention relates to a halogen-free flame-retardant styrene-series resin compound and a preparation method thereof. The resin composition comprises the following components in parts by weight: 40-80 parts of styrene system resin, 20-60 parts of a char forming agent, 0-5 parts of a compound char forming agent, 5-25 parts of a halogen-free flame retardant, 0.5-10 parts of a toughening agent, 0.1-0.5 part of an anti-falling agent, 0.1-1 part of an antioxidant and 0.2-2 parts of a lubricating agent. The preparation method comprises the following steps of: premixing the raw materials through a high mixer; performing melt extruding through a dual-screw extruder; and cooling and granulating to obtain a product. The obtained product is accordant with the requirements of halogen freeness and environmental friendliness, has superior flame retardance and mechanical performance, and can be used for office equipment such as copiers, printers, fax machines and the like, and household electrical appliance products such as displays, cameras, air conditioners, refrigerators and the like with requirements of halogen freeness and environmental friendliness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Flame-retardant polymer composite material

The invention discloses a flame retarding polymer composite material which is compounded by resin system, intumescent flame retardant and flame retardant synergist which are melted by a extruding machine or a mill mixer. The intumescent flame retardant comprises a triazine compound and polyphosphate. The flame retardant synergist is silicon magnetism containing inorganic substance. The triazine compound has good thermal stability and water resisting property, is used as carbon source and air source and compounded with ammonium polyphosphate to constitute the intumescent flame retardant which is applied in the flame-retardant polymer which has good flame retardant effect. The obtained coal bed reveals out compact and continuous structure. The silicon magnetism containing inorganic substance is added as the flame retardant synergist, thus promoting the formation of the coal bed, improving the quality of the coal bed, obtaining the flame retarding polymer materials with higher flame retardance in the condition of keeping the same addition of the flame retardant.

Owner:SOUTH CHINA UNIV OF TECH

Thermoplastic low-fume halogen-free high-flame retardance polyolefin insulation material and preparation method thereof

InactiveCN103059403AImprove heat resistanceImproved processability and elongation at breakPlastic/resin/waxes insulatorsInsulated cablesChemistrySmoke

The invention provides a thermoplastic low-fume halogen-free high-flame retardance polyolefin insulation material and a preparation method thereof. The thermoplastic low-fume halogen-free high-flame retardance polyolefin insulation material comprises the following principal components in parts by weight: 30-40 parts of ethylene-vinyl acetate copolymer resin, 30-40 parts of polyolefine elastomer resin, 20-30 parts of polyethylene resin, 10-20 parts of compatilizers, 200-250 parts of hydrate fire retardants, 5-10 parts of charring agents, 1-2 parts of flame-retardant synergists, 0.5 parts of antioxidants A, 0.5 parts of antioxidant B and 5-10 parts of lubricants. The preparation method comprises the following steps of: preparing the materials contained in a raw material formula in parts by weight respectively, and then feeding the materials into a milling machine for uniform mixing; then feeding the mixture into an extruder to extrude cut granules; then screening through a vibrating screen; and finally cooling and packaging to obtain a finished product. The thermoplastic low-fume halogen-free high-flame retardance polyolefin insulation material provided by the invention has the advantages of better heat-resistant property and processing property and flame-retardant grade enhancement. The preparation method of the thermoplastic low-fume halogen-free high-flame retardance polyolefin insulation material, which is provided by the invention, is reasonable in design and easy and convenient to operate.

Owner:天津市普立泰高分子科技有限公司

Halogen-free flame-retardant and cold-resistant PC material suitable for charging pile charging gun and preparation method thereof

The invention discloses a halogen-free flame-retardant and cold-resistant PC material suitable for a charging pile charging gun and a preparation method thereof. The material comprises the following components in percentage by weight: 92-94 percent of polycarbonate polydimethylsiloxane, 0.1-0.12 percent of a flame retardant, 4-6 parts of a toughening agent, 0.5-0.6 percent of an anti-dripping agent, 0.1-0.2 percent of a main antioxidant, 0.3-0.4 percent of an auxiliary antioxidant, 0.4-0.5 percent of a lubricating agent and 0.3-0.5 percent of a weather resistance agent. A polycarbonate polydimethylsiloxane block copolymer is excellent in low temperature resistance as a dimethylsiloxane segment is introduced; meanwhile, polydimethylsiloxane can promote PC carbon forming during combustion, has a good synergistic flame-retardant effect together with an additive type flame retardant agent and can effectively reduce the consumption of the additive type flame retardant agent. The halogen-free flame-retardant and cold-resistant PC material suitable for the charging pile charging gun is prepared by taking the polycarbonate polydimethylsiloxane as a main body and through the addition of the sulfonate flame retardant, the organic silicon type toughening agent, the anti-dripping agent, the antioxidant, the weather resistance agent, the lubricating agent and the melt blending of a double-screw extruder.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Preparation method of microcapsule fire retardant

InactiveCN109181004AUniform pore structureLarge specific surface areaAmmonium polyphosphateMolecular sieve

The invention relates to a preparation method of a microcapsule fire retardant, and belongs to the technical field of fire retardant. According to the preparation method, magnesium hydroxide, ammoniumpolyphosphate, and melamine phosphate are mixed for coating of zeolite molecular sieve, wherein melamine phosphate is capable of achieving flame resistance at a condensed phase and a gas phase, a large amount of latent heat is absorbed through sublimation, volatilization, and evaporation, inert gas is generated, and gas state substances such as MA steam, water vapor, N2, CO2, and NH4 are generated, the concentrations of oxygen and combustible gas at a combustion zone are reduced through dilution, and at the same time, coating of material surface is realized; charing is promoted, formation ofmolten drops from some polymers is promoted, so that a part heat energy is taken away, and combustion reaction is terminated; the zeolite molecular sieve is a crystal aluminosilicate formed by SiO4 and Al2O3 tetrahedrons through oxygen bridges; not only uniform pore structures, and large specific surface area, but also extremely high surface polarity is achieved. The zeolite molecular sieve possesses excellent absorption effect and certain catalyst effect, and flame resistance of the microcapsule fire retardant is improved.

Owner:黄旭东

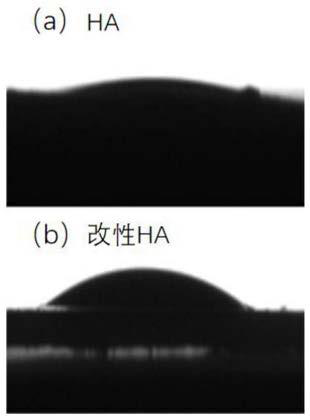

Modified hydroxyapatite and application in water-based fireproof coating material

ActiveCN111303665AImprove thermal stabilityImprove hydrophobicityFireproof paintsPigment treatment with organosilicon compoundsPolymer sciencePolymer modified

The invention discloses modified hydroxyapatite. The preparation method comprises the following steps: pre-treating hydroxyapatite by using citric acid, adding a silane coupling agent, and carrying out a grafting reaction. According to the invention, the modified hydroxyapatite has characteristics of excellent thermal stability, excellent hydrophobicity, good dispersibility and good compatibilitywith a high-molecular polymer; and when the modified hydroxyapatite as an inorganic flame retardant additive is applied to prepare a water-based intumescent fire-retardant coating material, the modified hydroxyapatite can play a flame retardant role in a gas phase and a condensed phase at the same time, promote charring, effectively play a synergistic flame retardant role of an expansion system and modified hydroxyapatite, can significantly improve the water resistance and durability of the coating material, and has a wide application prospect in the aspects of intumescent flame retardant coatings, polymer modification and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Phosphorus-containing flame-retardant polyester ionomer/nanocomposite material and preparation method thereof

The invention discloses a phosphorus-containing flame-retardant polyester ionomer / nanocomposite material and a preparation method thereof. The phosphorus-containing flame-retardant polyester ionomer / nanocomposite material is prepared by in-situ polymerization of terephthalic acid or dimethyl terephthalate, ethylene glycol, phosphorus-containing ion monomers (i) or phosphorus-containing ion monomers (ii), inorganic nanoparticles or / and organic modified inorganic nanoparticles. The numbers of phosphorus-containing ion group structure units in the composite material account for 2% to 5% of the numbers of structure units of the terephthalic acid or the dimethyl terephthalate in the composite material. The content of the inorganic nanoparticles or / and organic modified inorganic nanoparticles accounts for 0.5 to 10% of the total mass of the composite material. Meanwhile, the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material is excellent in flame retardance, melt drip resistance and crystallization resistance. The intrinsic viscosity of the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material can reach 0.6dL / g to 1.0dL / g. Thus, the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material can be directly taken as a raw material used for preparing fibers, engineering plastics, thin films and the like.

Owner:SICHUAN UNIV

Conductive additive and application, conductive composite material and preparation method and application thereof

InactiveCN110511429ADoes not affect mechanical propertiesAchieving spatial complementarityMicro nanoConductive polymer composite

The invention discloses a conductive additive and application, a conductive polymer composite material and a preparation method and application thereof, relates to the technical field of polymer nanocomposite materials, and aims to improve the mechanical strength of the conductive composite material and reduce the flammability and melting rate of the conductive composite material. The conductiveadditive at least comprises micro-nano hybrid conductive materials, and the micro-nano conductive materials comprise zero-dimensional conductive materials, one-dimensional conductive materials and two-dimensional conductive materials. The conductive composite material comprises the conductive additive. The conductive additive is used in conductive polymer products.

Owner:内蒙古信敏惠纳米科技有限公司

A preparing method of an environmental friendly flame-retardant polycarbonate composite material

InactiveCN105348763AChange surface propertiesGood compatibilityPotassium perfluorobutanesulfonatePhosphate

A preparing method of an environmental friendly flame-retardant polycarbonate composite material is disclosed. The method includes mixing nanometer zinc oxide, nanometer titanium dioxide, nanometer aluminium hydroxide, glass fibre, kaolin, nanometer zinc stannate, ferrocene, zinc molybdate, basic sodium aluminium carbonate, calcium stearate, zinc stearate and a silane coupling agent KH-540 to obtain a modified filler; melting and extruding polyvinyl butyral, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, styrene-acrylonitrile copolymer, melamine resin and the modified filler in a twin-screw extruder to obtain dispersed master batch; adding polycarbonate, the dispersed master batch, tris(2,4-diisobutyl) phosphate, hexaphenoxycyclotriphosphazatriene, potassium perfluorobutanesulfonate, bisphenol A bisphthalonitrile, a plasticizer and an oxidant into a twin-screw extruder, melting and extruding. The composite material prepared by the method is good in heat resistance and excellent in flame retardance.

Owner:ANHUI GUANGYUAN TECH DEV

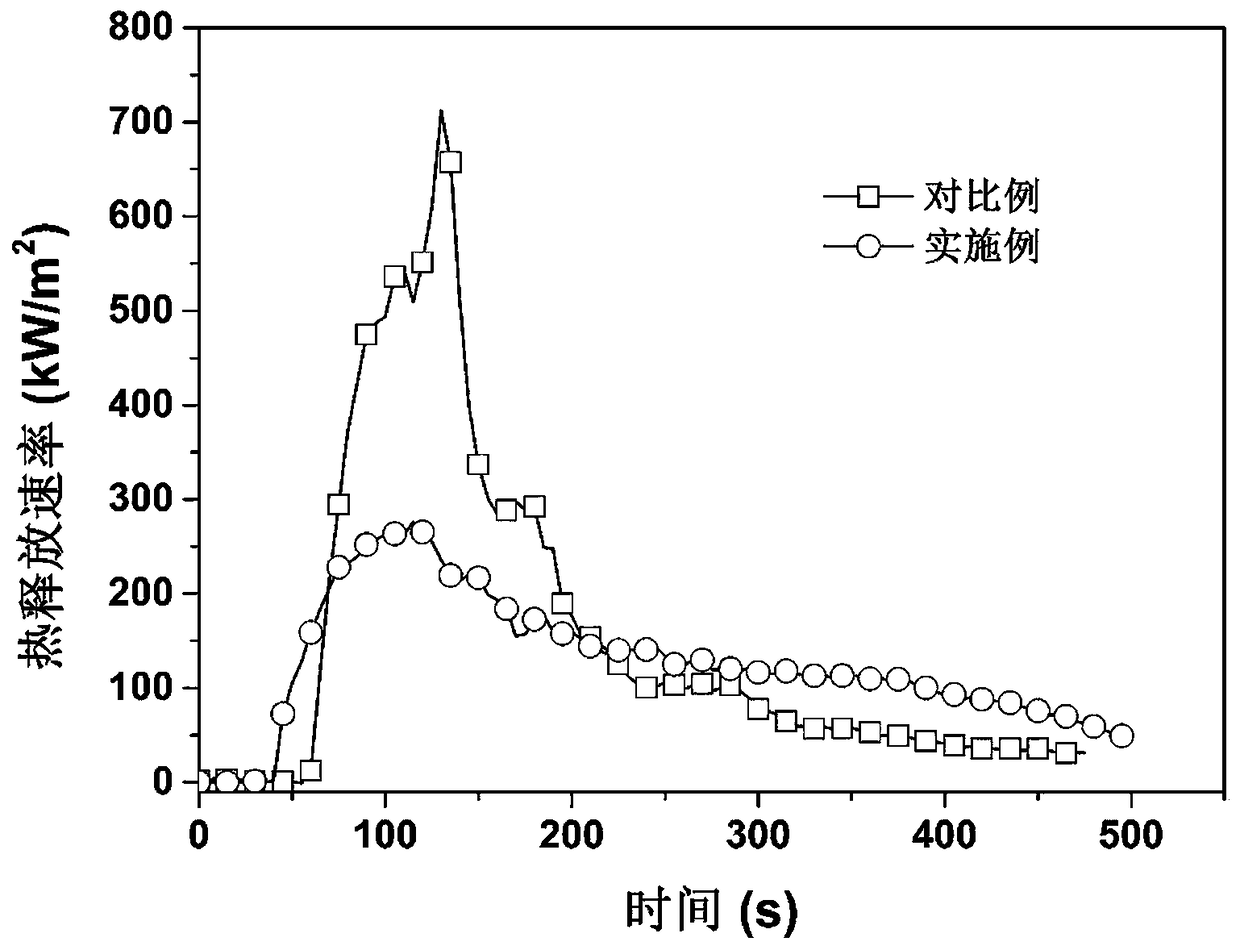

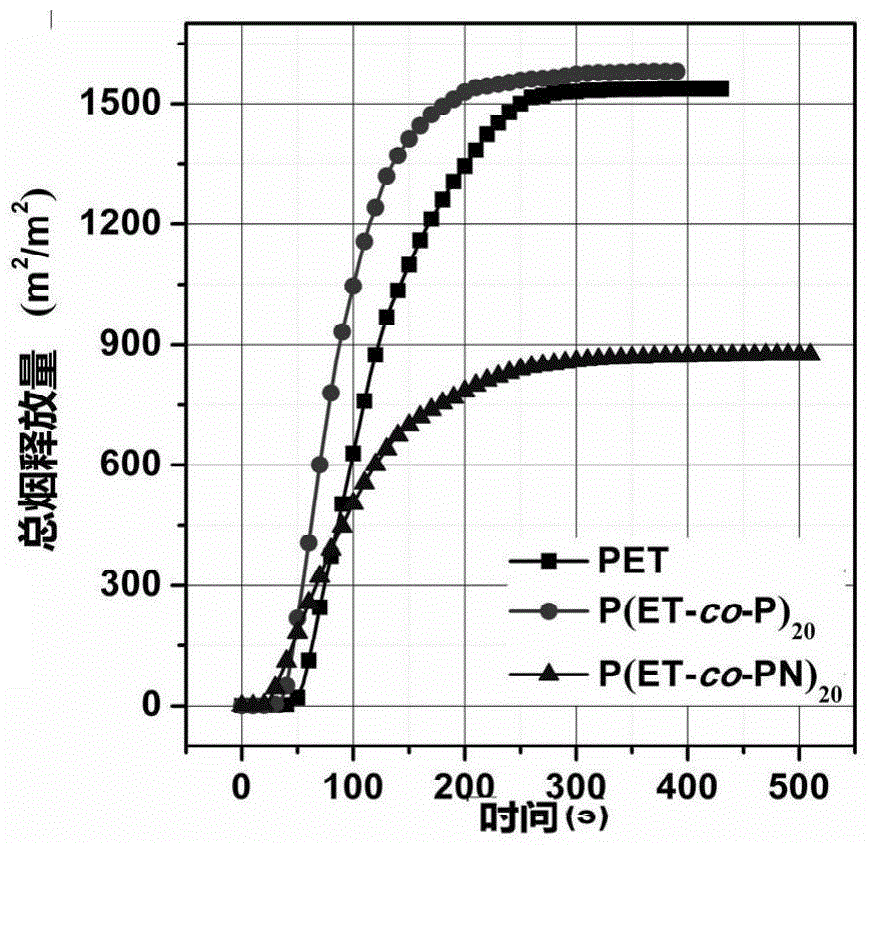

Benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance and preparation method of copolyester

ActiveCN108359084APreserve thermoplastic processabilityIncrease melt viscosityStructural unitStructure based

The invention discloses a benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance. Copolyester is prepared from structural units represented by I, II and III or structural units represented by I, II and IV through random copolymerization, wherein the characteristic viscosity [eta] of copolyester is 0.41-1.12 dL / g, and the limit oxygen index is 24.2%-38.7%; the vertical combustion class is in a range from V-2 to V-0; the p-HRR (peak of heat release rate) in a cone calorimetry test is reduced by 7.1%-72.1% as compared with that of pure PET, and total smoke release is decreased by 2.0%-59.2% as compared with that of pure PET. The invention further discloses a preparation method of copolyester. Ahigh-temperature self-crosslinking group introduced in the preparation process is a benzene imide group, and prepared copolyeste cannot be subjected to crosslinking during processing and polymerization, so that thermoplastic processability of polyester is retained; meanwhile, due to the tackifying effect and high charring property brought by the self-crosslinking action at high temperature or during combustion, prepared copolyester has excellent flame retardancy, smoke suppression and melt drop resistance effects.

Owner:SICHUAN UNIV

Preparation method of high-flame-retardancy expandable graphite

The invention relates to a preparation method of high-flame-retardancy expandable graphite, which comprises the following steps: oxidizing graphite by using concentrated sulfuric acid / nitric acid mixture, nitric acid / phosphoric acid mixture, fuming nitric acid or concentrated sulfuric acid together with a solid strong oxidizer which accounts for 5-60 wt% of graphite, wherein the reaction temperature is 15-50 DEG C, and the reaction time is 10-100 minutes; after the reaction finishes, filtering, and washing with water until the pH value is 4-7, thereby obtaining the primary expandable graphite; and reacting the primary expandable graphite with guanidine salt solution at 20-80 DEG C for 20-200 minutes, carrying out repeated vacuum filtration, washing with water until the pH value is 6-7, and baking at 40-80 DEG C for 10-72 hours to obtain the high-flame-retardancy expandable graphite. The method provided by the invention intercalates guanidine salts into the interlayer of the expandable graphite, enhances the expansion ratio and flame retardancy, and can be widely used for flame retardancy for plastics, rubber, paint, foam and various other materials.

Owner:SOUTH CHINA UNIV OF TECH

Layered-hypophosphite flame-retardant and reinforced polypropylene composite material and preparation method thereof

InactiveCN107254106AImprove bending strengthHigh strengthNanotechnologyHypophosphorous acidDispersityPolypropylene composites

The invention provides a layered-hypophosphite flame-retardant and reinforced polypropylene composite material and a preparation method thereof and relates to the technical field of high polymer materials. The layered-hypophosphite flame-retardant and reinforced polypropylene composite material is prepared by polypropylene resin, layered hypophosphite, a toughening agent, antioxidant, a light stabilizer and a lubricating agent. The preparation method has the advantages that the layered hypophosphite is synthesized through a hydrothermal method, layered hypophosphite nanosheets are well combined with a polypropylene matrix and are evenly distributed in the polypropylene matrix and good in dispersity, influence on material mechanical performance is low, and polypropylene composite material prepared by adding the layered hypophosphite is high in strength and good in thermal stability.

Owner:ORINKO NEW MATERIAL CO LTD

Irradiation cross-linked thermoplastic polyester elastomer cable material and cable production method

InactiveCN105199329AImproved drip resistanceHigh char formationPlastic/resin/waxes insulatorsPolyesterVinyl acetate

The invention discloses an irradiation cross-linked thermoplastic polyester elastomer cable material. The irradiation cross-linked thermoplastic polyester elastomer cable material comprises, by weight, 100 parts of thermoplastic polyester elastomer (TPEE), 15-40 parts of ethylene-vinyl acetate copolymer (EVA), 50-80 parts of a fire retardant, 0.3-2 parts of a lubricant, 0.3-3 parts of an antioxidant and 0.1-1 part of an ultraviolet light stabilizer. The invention also discloses a method for producing cables through using the cable material. Cable products produced by using the cable material have excellent room temperature and high temperature mechanical performances; irradiation crosslinking realizes good flame retardation performance on the premise of meeting environmental protection, and also realizes cost reduction; and the cable material can reach 125DEG C temperature resistance level, has excellent scratch and wear resistance, and can be widely used in the fields of automobile wires and high and low temperature resistant cables.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

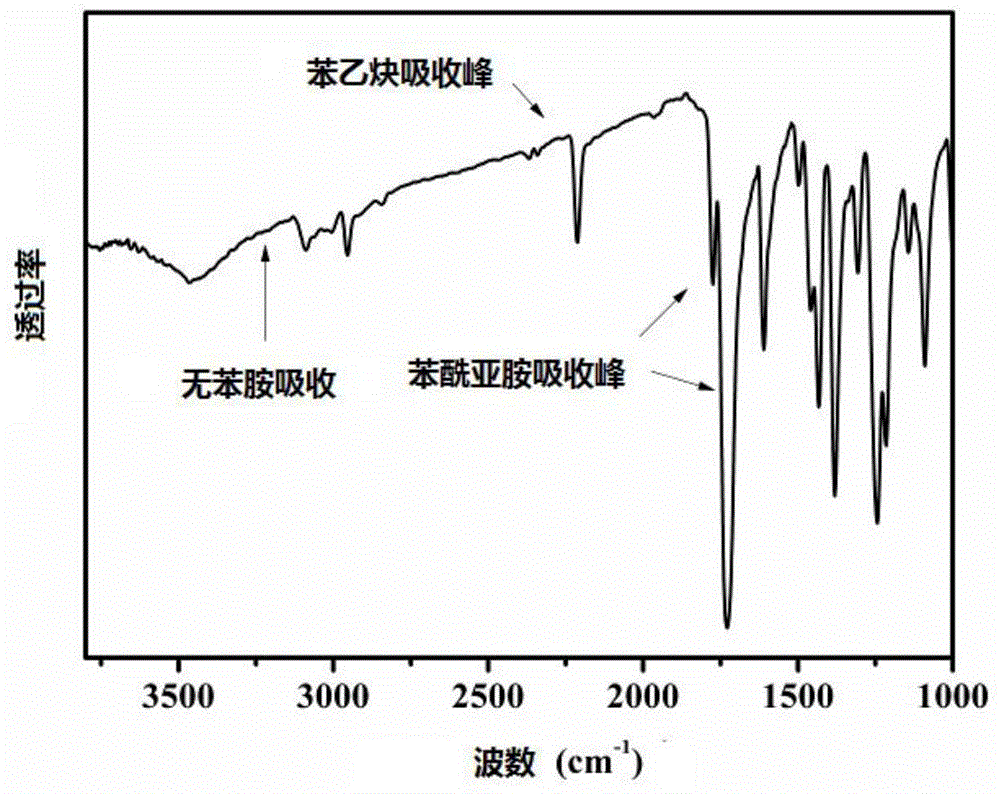

Monomer containing benzimide phenylacetylene structure, high temperature self-crosslinked copolyester and preparation method thereof

ActiveCN104592094AHigh self-crosslinking flame retardant efficiencyGood flame retardantOrganic chemistryPolymer scienceChemical reaction

The invention discloses a monomer containing a benzimide phenylacetylene structure. The monomer can enable self-crosslinking chemical reaction of a synthesized polymer under high temperature. The monomer containing a benzimide phenylacetylene structure and the structural units represented by I and II for synthesis of polyester can undergo random copolymerization to obtain high temperature self-crosslinked copolyester, and when the copolyester contains a PET structural unit, the characteristic viscosity number [eta] is 0.44-1.38dL / g, the vertical combustion UL-94 grade is from V-2 to V-0, the oxygen index LOI is 24.0-35.0%, and the cone calorimeter test peak heat release rate PHRR and the smoke release total amount are both lower than pure polyester. The invention also discloses a preparation method of the copolyester. The benzimide and phenylacetylene in the copolyester involved in the invention can generate synergistic cross-linking effect, so that the copolyester has very high flame-retardant and anti-dripping efficiency, and also the copolyester is endowed with excellent flame retardant, anti-dripping and smoke suppressing performance. The method provided by the invention is basically consistent with the synthesis method of conventional polyester, not only is mature in technology, and easy and convenient to operate, but also is easy to control and convenient for industrial production.

Owner:SICHUAN UNIV

Hybrid modified aluminum hypophosphite and preparation method thereof

The invention relates to hybrid modified aluminum hypophosphite and a preparation method thereof. The hybrid modified aluminum hypophosphite is prepared by hybrid modification of aluminum hypophosphite with cyanuric acid, melamine, a two-dimensional layered material and an organic coating material; the organic coating material is a coupling agent and / or silicone resin. The finally prepared hybridmodified aluminum hypophosphite is mainly composed of aluminum hypophosphite and a coating layer on the surface; the coating layer is a multi-layer organic-inorganic hybrid structure. The temperatureof the hybrid modified aluminum hypophosphite is more than or equal to 300 DEG C when the thermal weight loss is 1 wt%, the temperature is more than or equal to 345 DEG C when the thermal weight lossis 5 wt%, and the carbon residue rate at the temperature of 750 DEG C is more than or equal to 50 wt%; the smoke density of a high molecular material during combustion after the hybrid modified aluminum hypophosphite is added is decreased by 20% or more. The preparation method has the advantages of simple process and low cost; the prepared product has the advantage of excellent flame retardant performance, good thermal stability, low water solubility, no agglomeration phenomenon during addition, and great application prospect.

Owner:DONGHUA UNIV +1

Flame-retardant microcapsule phase-change material

InactiveCN105112020AWon't happenNot volatileHeat-exchange elementsMicroballoon preparationBenzoyl peroxideSolvent

The invention relates to a flame-retardant microcapsule phase-change material. The flame-retardant microcapsule phase-change material is prepared from a core material, a flame-retardant wall material, an emulsifier, benzoyl peroxide (BPO) and deionized water, wherein the core material is fatty acid ester, the flame-retardant wall material is a crosslinking polymer of reactive phosphonate monomer and tetramethylol methane tetraacrylate, and the emulsifier is a mixture of nonionic surfactant and ionic surfactant. The flame-retardant microcapsule phase-change material provided by the invention has excellent performance and is safe and environment-friendly; since reactive phosphonate-modified acid ester polymer is used as the microcapsule wall material, good flame retardation effect, good water resistance and good solvent resistance are obtained, and reduction in phase change enthalpy of the phase-change material caused by an additive flame retardant can be avoided; and since aliphatic ester is used as a phase-change material, better thermal stability and chemical stability are obtained, and a heat release rate is lower.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

Composite flame retardant for plywood and application of plywood

InactiveCN105291222ALow hygroscopicityNo low smokeOther plywood/veneer working apparatusAldehyde/ketone condensation polymer adhesivesSocial benefitsZinc borate

The invention discloses a composite flame retardant for plywood and application of the plywood. The flame retardant comprises, by weight, 8-15 parts of ammonium phosphate, 3-5 parts of ammonium sulfate, 1.5-2.5 parts of sodium tetraborate, 0.2-0.6 part of zinc borate, 0.1-0.5 part of ammonium molybdate and 0.1-0.5 part of dicyandiamide. The composite flame retardant is prepared by compounding an inorganic boron-containing retardant and a nitrogen and phosphorous retardant; all the components are reasonable in ratio and have a synergistic effect; the oxidization numerical value of the produced retardant reaches more than 52% and meets the B-grade fire-retardant requirement of the national standard; a very good fire-retardant effect is achieved; and meanwhile production cost can be reduced. The stability of the retardant in the use process is good, and the influence on the mechanical performance of the plywood is small and is only about 5%. The fire-retardant plywood produced through the retardant can be widely applied to the fields of indoor decoration, fire-retardant furniture, building structures, wood fireproof doors, fire-retardant floors and the like and has good economic benefits and social benefits.

Owner:GUANGXI UNIV

Stepped flame retardant plastic and preparation method thereof

The invention discloses a stepped flame retardant plastic and a preparation method thereof. The stepped flame retardant plastic comprises the following components by weight: 800-1200 parts of plastic,30-120 parts of inorganic flame retardant powder, 3-8 parts of zinc borate, 2-5 parts of silica powder, 1-2 parts of antismoke agent, 1-2 parts of calcium carbonate, 0.3-1.2 parts of polymeric dispersant, and 0.3-2 parts of auxiliary; the preparation method comprises the following steps: preparing the inorganic flame retardant powder, modifying a flame retardant material, preparing a composite flame retardant material, and preparing the flame retardant plastic. Through the provided stepped flame retardant plastic and the preparation method of the stepped flame retardant plastic, the obtainedplastic forms different flame retardant shells at different temperatures, so that the plastic has a multi-level flame retarding effect, and the stepped flame retarding protection is formed over a plastic base material.

Owner:FOSHAN YUEJIAXIN WIRE & CABLE

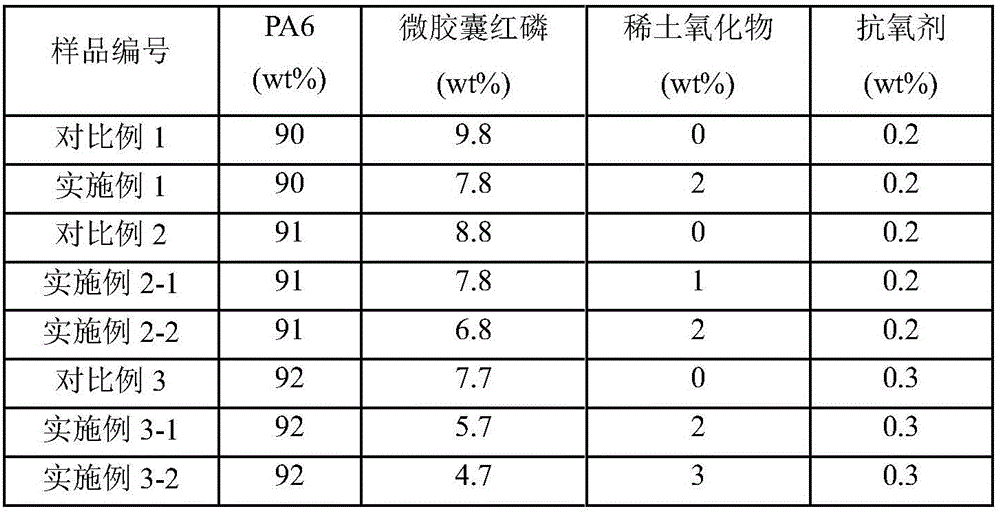

Rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite and preparation method thereof

ActiveCN106751778AImproved Density and ContinuityCondensed phase flame retardant effect is goodChemistryMass transfer

The invention provides a rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite and a preparation method thereof. The rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite is characterized by being prepared from PA6, microencapsulated red phosphorus and rare-earth oxide. Rare-earth oxide is introduced into a red phosphorus flame-resistant polymer material system, rare-earth oxide can catalyze dehydrated carbonization of red phosphorus, a more compact and continuous charcoal layer structure can be formed, the mass transfer process of volatile products generated by polymer degradation to a gas phase is blocked, feedback of heat generated by gas phase combustion to a condensed phase is also blocked, and flames are prevented from propagating and spreading.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Hybridization catalyst for curing cyanate ester and preparing method thereof

The invention discloses a hybridization catalyst for curing cyanate ester and a preparing method of the hybridization catalyst. The prepared hybridization catalyst is a hybridization material composed of oxidized graphene and a manganese base metal organic skeleton. The manganese base metal organic skeleton is formed by manganous ions and organic ligand through the coordinate bond combination effect. The preparing method for the hybridization catalyst comprises the steps that oxidized graphene, potassium hydroxide, an imidazole compound and the organic ligand are dissolved into deionized water, and dispersed in an ultrasonic mode to form mixed liquid; the obtained mixed liquid are slowly dripped into a manganous acetate tetrahy water solution, and reacts for 20-25 hours under the condition that the temperature ranges from 70 DEG C to 80 DEG C; a product is filtered, washed and dried to obtain the oxidized graphene and manganese base metal organic skeleton hybridization material which is used as a hybridization catalyst for curing the cyanate ester. The source of raw materials of the hybridization catalyst is wide, and the preparing method has the advantages of being simple in process and easy to control.

Owner:SUZHOU UNIV

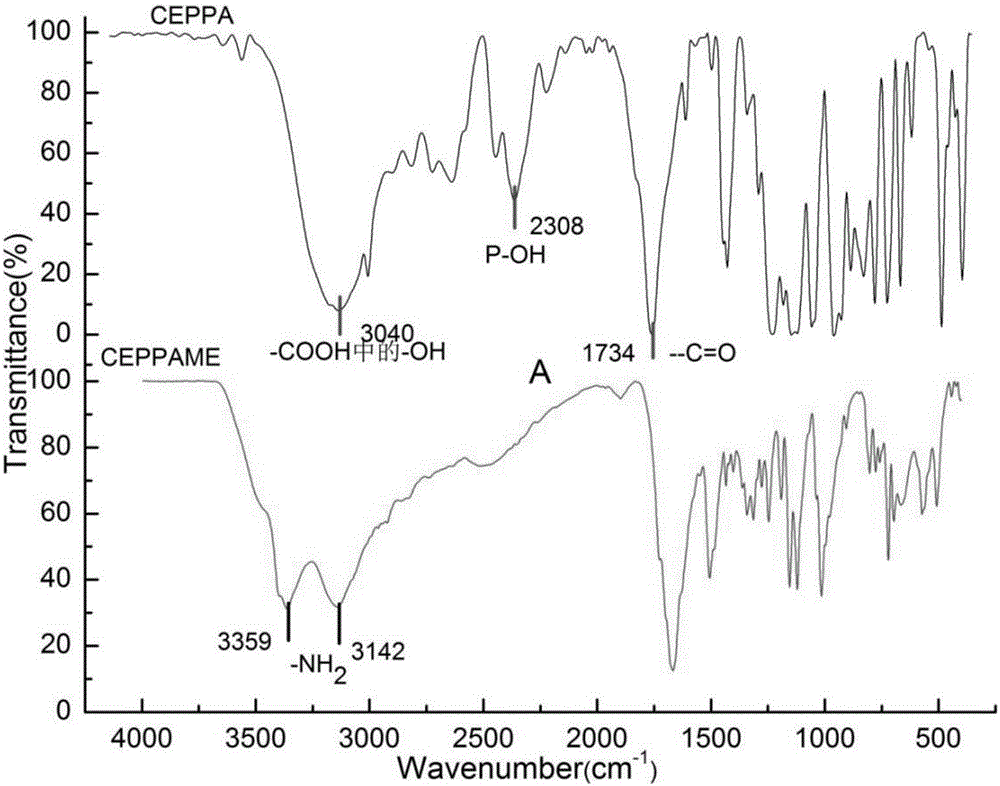

Novel phosphorus-based flame retardant and halogen-free intumescent anti-flaming ABS (Acrylonitrile Butadiene Styrene) resin containing same

The invention relates to a novel phosphorus-based flame retardant and halogen-free intumescent anti-flaming ABS (Acrylonitrile Butadiene Styrene) resin containing the same. Organic phosphinate (2-carboxyethyl phenyl melamine phosphinate) is selected as a main body of the flame retardant, the novel phosphorus-based flame retardant has the advantages of white color, less addition amount, good mechanical performance, low smoke density, good flame-retardant performance and the like, and the high-efficiency flame-retardant effect can be obtained in both condensed phase and gas phase; meanwhile, polyamide 66, poly terephthaloyl ethylene diamine and the like are added as charring agents, so that charring of the ABS resin in combustion is promoted; meanwhile, synergistic agents-organic modified montmorillonoid, rare-earth metal oxide and the like are also added, so that the flame-retardant effect is enhanced; the influence on mechanical property of the halogen-free intumescent anti-flaming ABS resin is smaller while higher flame-retardant level is obtained.

Owner:TIANJIN UNIV OF SCI & TECH

Fireproof type gypsum-based spraying material and preparation method thereof

The invention relates to the technical field of building materials and in particular relates to a fireproof type gypsum-based spraying material and a preparation method thereof. The fireproof type gypsum-based spraying material is prepared by grinding modified cellulose ether, a thixotropic lubricant, pearlite, a composite retarder, a flame retardant and a chlorine ion controlling agent until thegranularity is 0.6 to 1.0mm, and mixing powder with gypsum, sand and portland cement, so that the fireproof type gypsum-based spraying material provided by the invention has characteristics of convenience for working, water prevention and heat insulation, high temperature resistance, no hollowing, no cracking, strong binding power, good anti-sagging performance, bug and ant biting resistance, metal rusting prevention, greenness and environment protection and the like; furthermore, the flame retardant has the effect of keeping the average breaking strength of the gypsum-based spraying materialbeing 2.2MPa or more and the average compressive strength being 4.6MPa or more through a reasonable design and a dosage test of magnesium hydroxide, zinc borate and chitosan tetramethylene phosphine sulfate; the fireproof type gypsum-based spraying material keeps relatively good mechanical strength and also has the fireproof effect with the average fireproof degree of 560 DEG C or more.

Owner:深圳摩盾环保新材料有限公司

Preparation method of flame-retardant modified polyvinyl acetate used for expanded polystyrene beads

ActiveCN105153366AHigh nitrogen contentHigh flame retardant efficiencyGroup 5/15 element organic compoundsSolventEmulsion

The invention discloses a preparation method of flame-retardant modified polyvinyl acetate used for expanded polystyrene beads. In an existing method, 6-(4-formylphenoxy) cyclotriphosphazene and DOPO are prepared into a compound comprising phosphazene and DOPO double-effect functional groups through a solution and a fusion method, wherein the nitrogen content of the compound is 1.9%, the nitrogen content is small, and flame retardance is low. According to the preparation method, 1-thiourea ethyl acrylate-6-aminophenoxy cyclotriphosphazene reacts with vinyl acetate and chloroform under the action of a catalyst and polar solvent to prepare 1-thiourea ethyl acrylate-6-aminophenoxy cyclotriphosphazene vinyl acetate comprising phosphazene and DOPO double-effect functional groups. The features that the product contains phosphate and nitrogen and is free of halogens, and compared with an existing double-effect functional group compound of the type, the nitrogen content is greatly increased and are utilized for sufficiently exerting the synergistic action of phosphate and nitrogen; the flame-retardant modified polyvinyl acetate is applied to preparing emulsion wrapping the polystyrene beads, and achieves the expected effects of higher flame-retardant efficiency and smaller toxin.

Owner:HANGZHOU FANGYUAN PLASTICS MASCH CO LTD

Environmental-friendly & flame-retardant polycarbonate composite material

The invention discloses an environmental-friendly & flame-retardant polycarbonate composite material, which comprises the following raw materials: polycarbonate, polyvinyl butyral, polypropylene, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, an ethylene / vinyl acetate copolymer, nano titanium dioxide, nano aluminium hydroxide, carbon nanofibers, montmorillonite, nano zinc oxide, a silane coupling agent KH-560, tri(2,4-diiso-butyl benzene) phosphate, hexaphenoxy cyclotriphosphazene, potassium perfluorobutanesulfonate, nano zinc stannate, ferrocene, molybdenum disulfide, a plasticizer and an antioxidant. The environmental-friendly & flame-retardant polycarbonate composite material provided by the invention is excellent in flame resistance, and can meet the requirements of many fields of television and computer and the like; and the material is good in comprehensive performance and long in service life.

Owner:ANHUI GUANGYUAN TECH DEV

Preparation method of POSS-DOPO-triazine derivative flame retardant with self-assembled enhancement effect and application thereof

The invention discloses a preparation method of a POSS-DOPO-triazine derivative flame retardant with a self-assembled enhancement effect and application thereof. The flame retardant has the followingmolecular structural formula as shown in the specification, wherein R and R1 are as shown in the specification. The heat stability and flame retardant property of an epoxy resin matrix are improved onthe basis of ensuring mechanical property of the matrix, and the flame retardant has the advantages of being excellent in flame-retardant effect, wide in application range and the like.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com