Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

751results about How to "High thermal decomposition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fusion tray of thermal transmission and storage medium, and preparation method

InactiveCN101050355AHigh Safe Operating Temperature Upper LimitSafe operating temperature upper limit expandedHeat-exchange elementsHigh energyWorking temperature

This invention discloses a method for preparing molten salt heat-transfer and heat-storage medium, which comprises potassium nitrate, sodium nitrate, sodium nitrite and additives. The additives are cesium nitrate and potassium chloride at a weight ratio of (0.1-0.8):1. The molten salt heat-transfer and heat-storage medium has such advantages as good heat transfer property, wide working temperature range, high heat stability, high upper limit of safe usage temperature, low melting point, high phase-change latent heat, low requirement for system size and energy, and high energy utility.

Owner:SUN YAT SEN UNIV +1

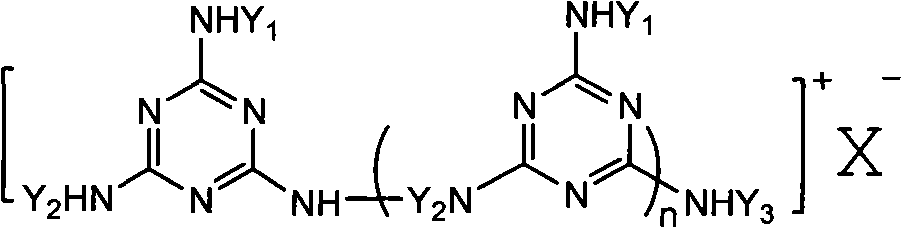

Materials of high flame-retardancy organic intercalation layered clay and preparation method thereof

InactiveCN101786637ASimple preparation technologyImprove solubilitySilicon compoundsOrganic acidChemistry

The invention relates to materials and a method for preparing high flame-retardancy organic intercalation layered clay. The method is performed by inserting melamine or derivatives of melamine into layered clay, especially montmorillonite layers, and the invention is characterized in that the inserted material is at least one compound of salt formed by melamine or derivatives of melamine and an organic acid and is inserted in the clay by cation exchange. The invention also relates to a method for preparing the materials. In the method, the materials are prepared from melamine, derivatives of the melamine and the layered clay by the steps of material mixing, dispersing, cation exchange, grinding and the like. The organic layered clay prepared by the invention can disperse in polymers, has excellent expansion performance and flame retardancy, and can be used as an expansion type fire prevention additive, or used as an expansion type flame retardant component for preparing additives of flame retardant plastic, rubber, thin films, coating, foam plastic and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

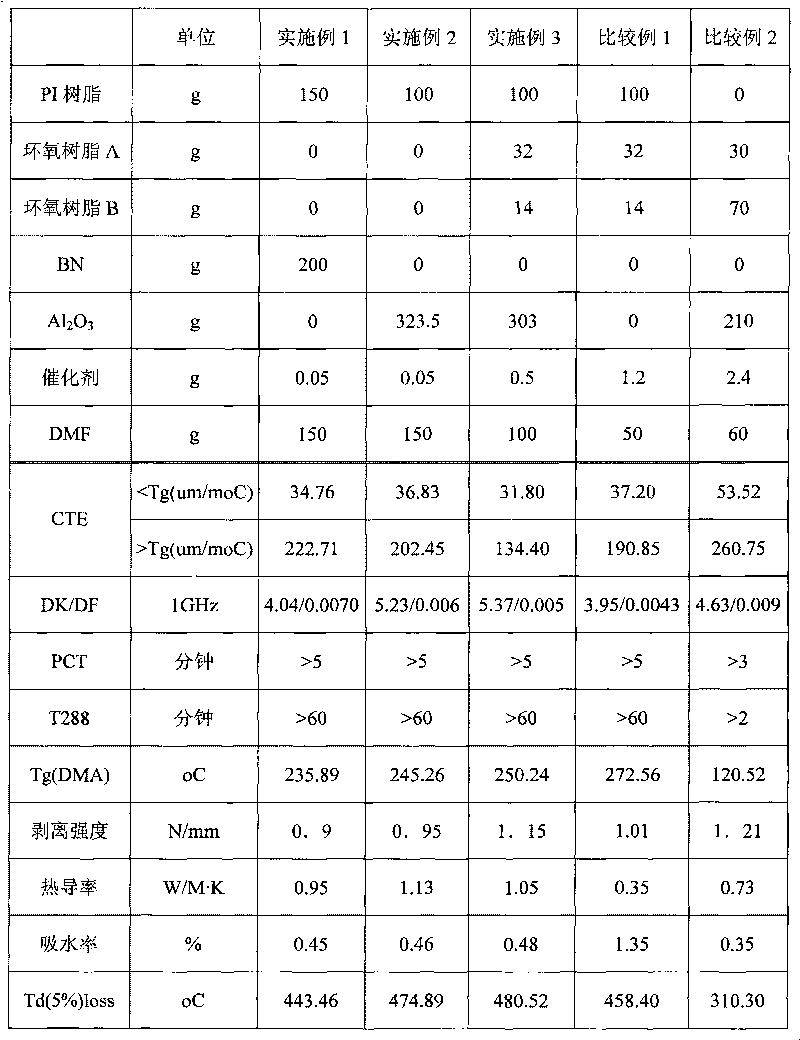

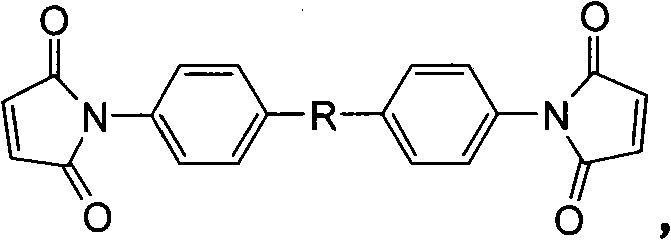

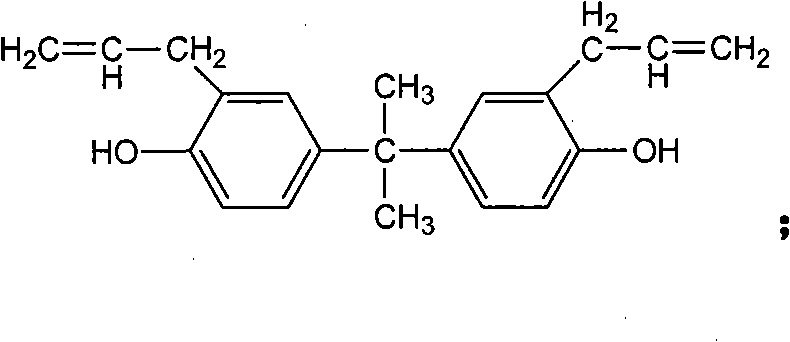

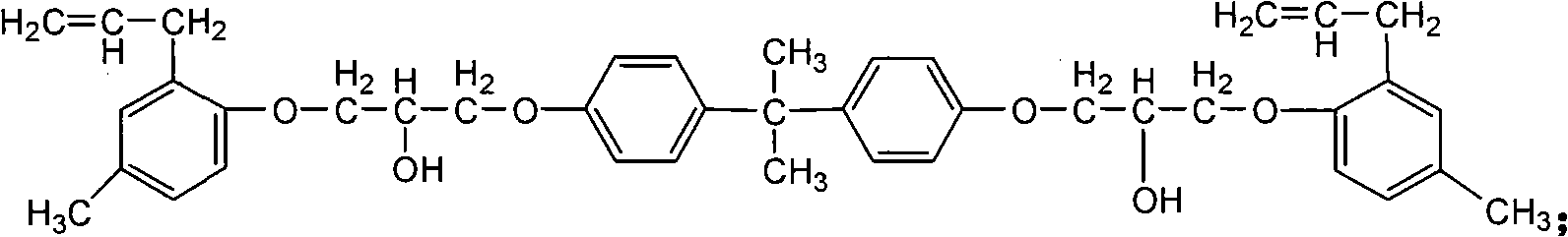

Thermosetting resin composition with high heat conductivity, prepreg manufactured by adopting same and copper-clad laminate

InactiveCN101735611AImprove thermal conductivityHigh glass transition temperatureFibre treatmentPaper coatingPolymer scienceDecomposition

The invention relates to a thermosetting resin composition with high heat conductivity, a prepreg manufactured by adopting the same and a copper-clad laminate. The thermosetting resin composition with high heat conductivity comprises the following components in parts by mass: 5 parts of allyl phenolic compound, 5-40 parts of bismaleimide compound, 0-30 parts of modified resin, 25-85 parts of filler and 1-8 parts of catalyst. The thermosetting resin composition with high heat conductivity, which is provided by the invention, has the superior properties of high heat conductivity, high glass transition temperature, low CTE, high heat decomposition temperature, favorable process deformability and the like; the prepreg is simple to manufacture and has better heat resisting effect and high heat conductivity; and the copper-clad laminate can be applied to the manufacture of a high multi-layer circuit with high-temperature resistance and has simple manufacture process and lower cost.

Owner:GUANGDONG SHENGYI SCI TECH

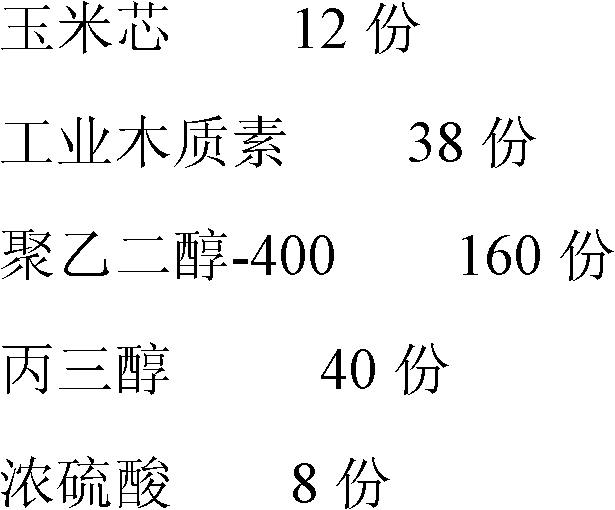

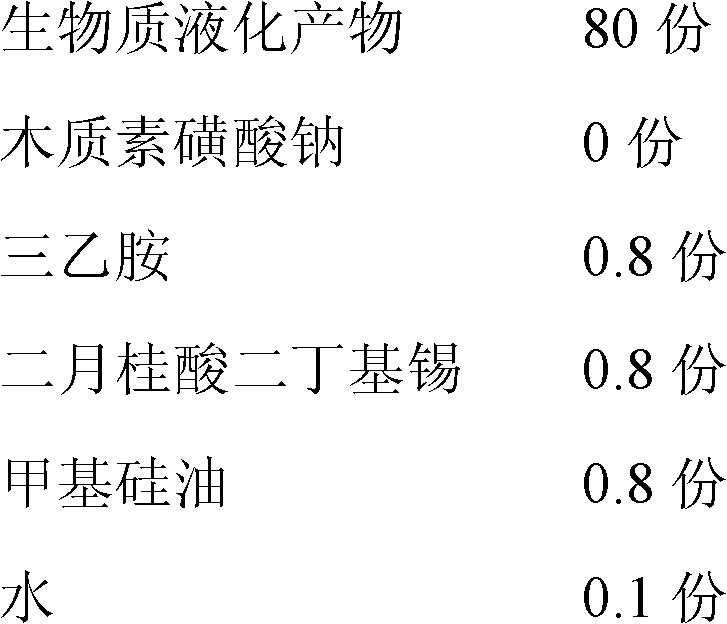

Preparation method of biomass-base polyurethane foam material

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

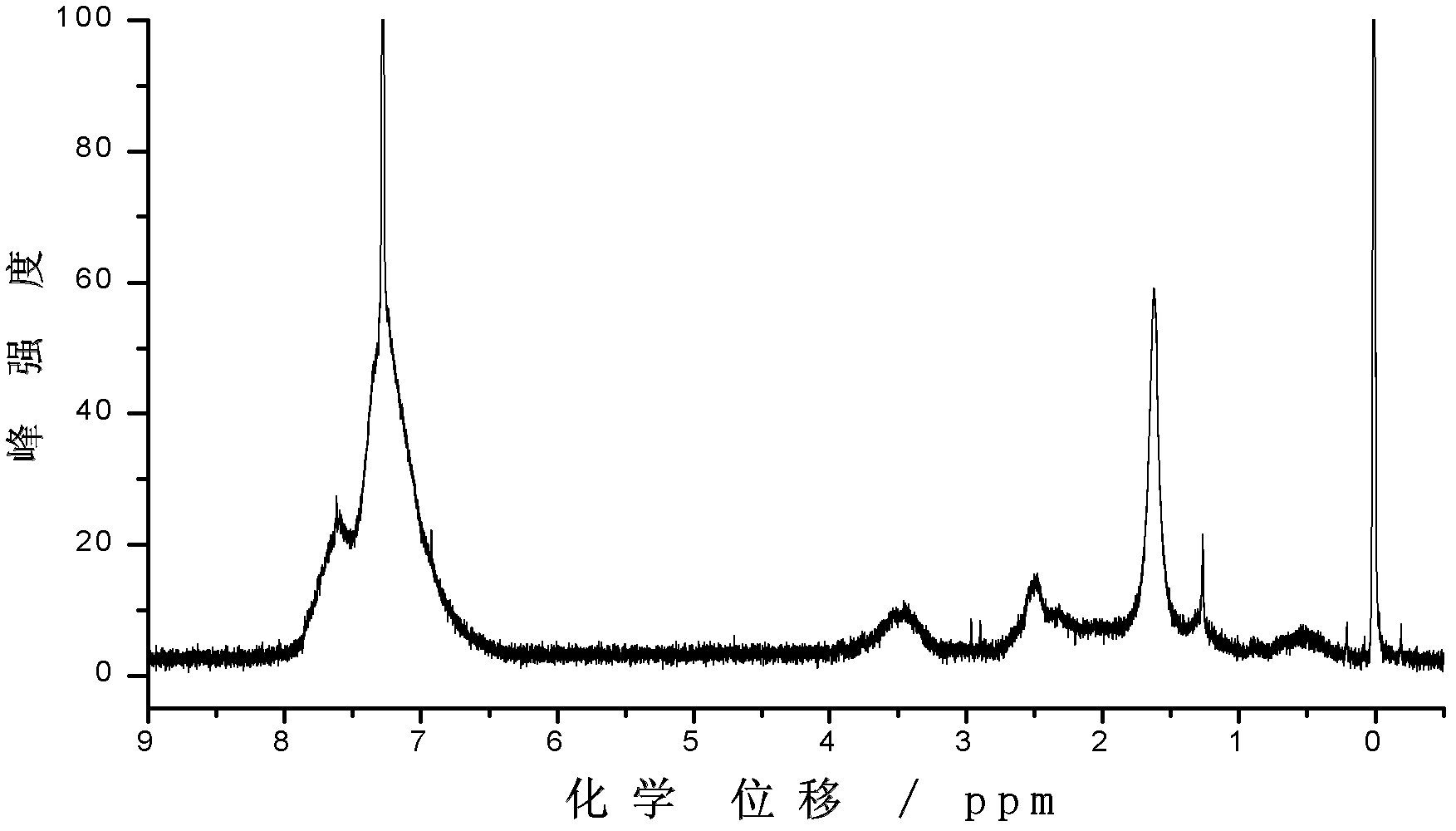

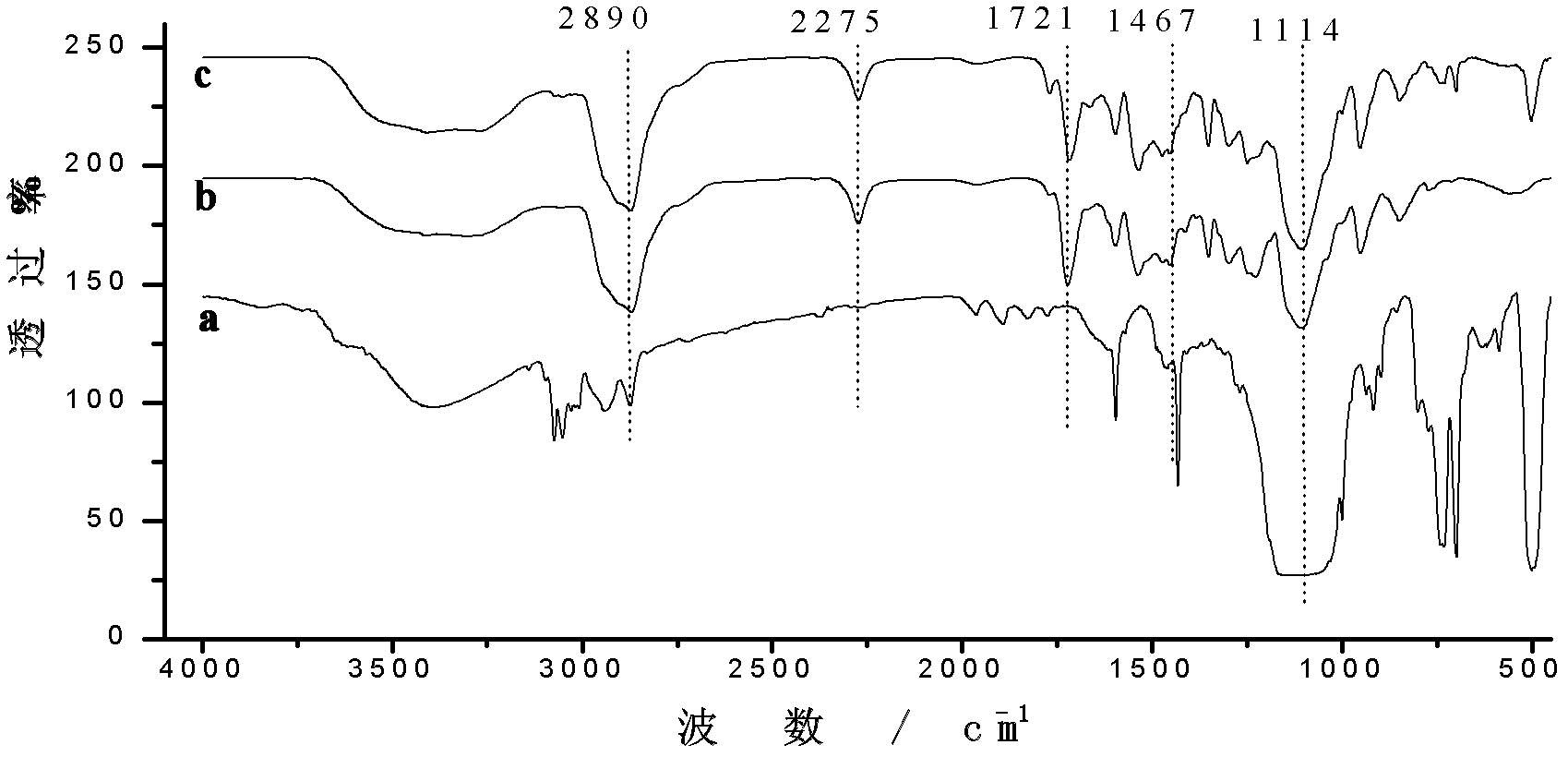

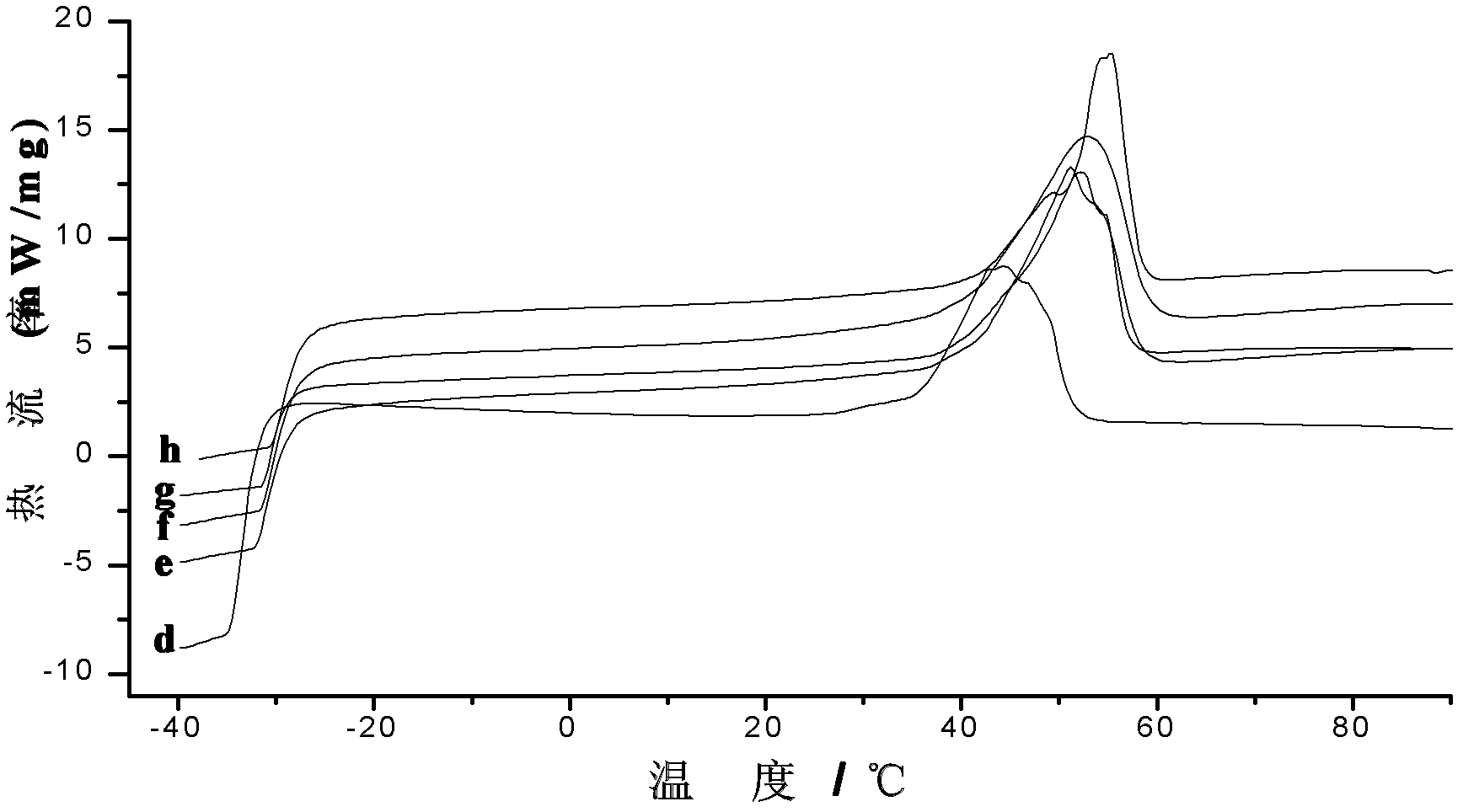

Process for preparing hydroxyl polyhedral oligomeric silsesquioxane modified polyurethane

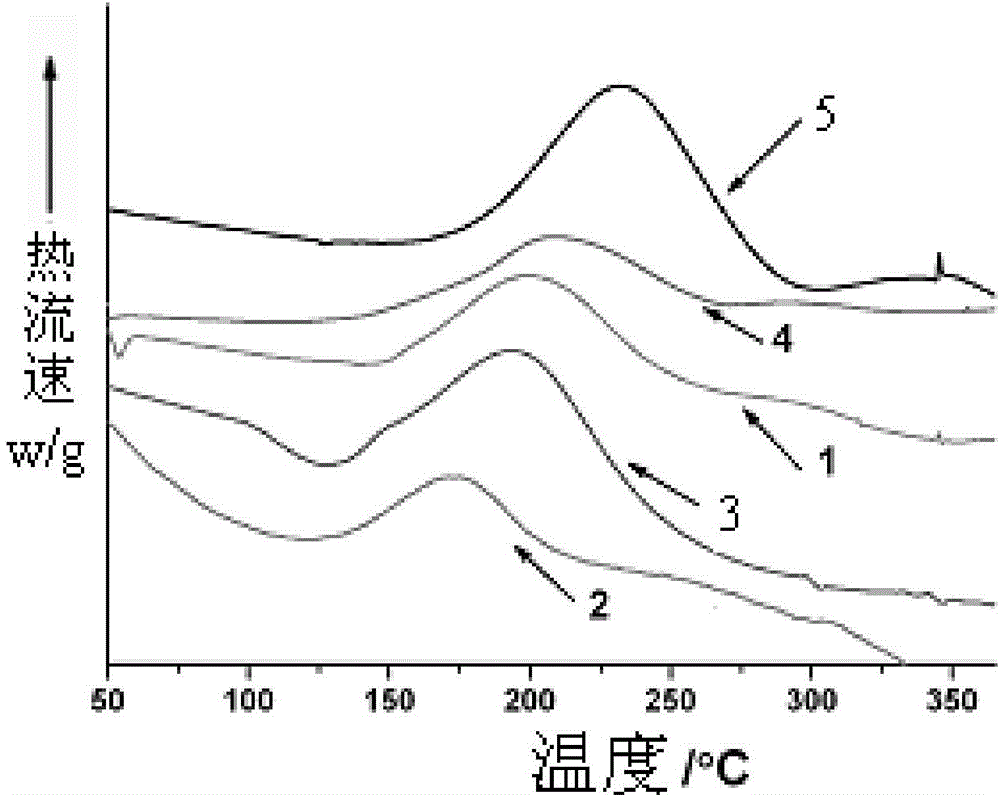

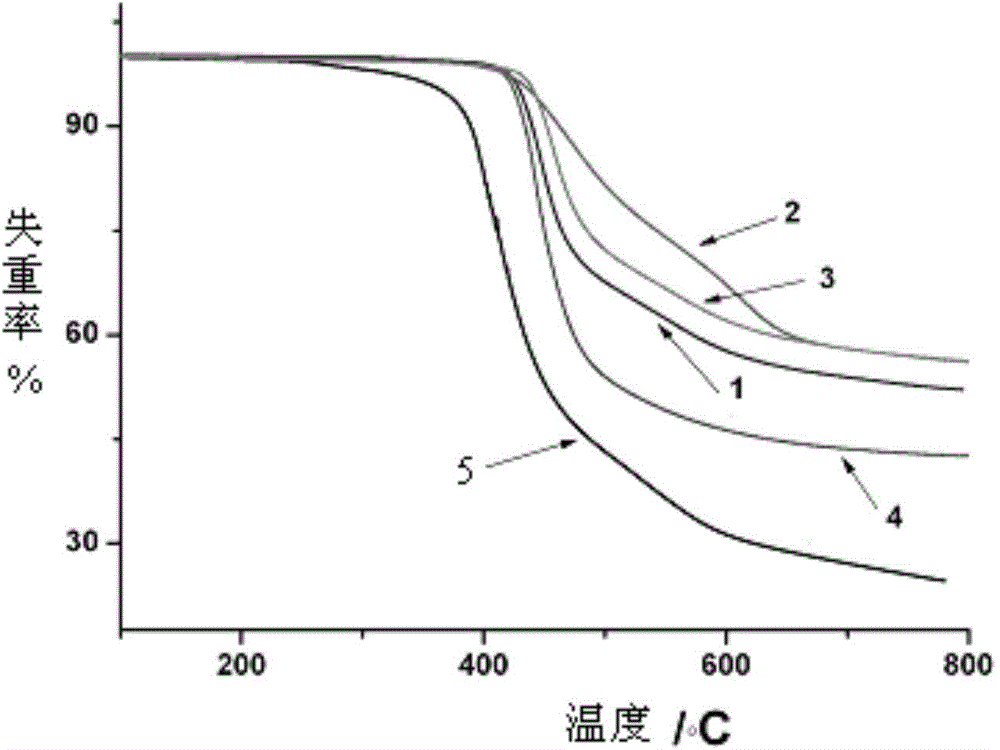

The invention discloses a process for preparing hydroxyl polyhedral oligomeric silsesquioxane modified polyurethane, which includes the steps of reacting diisocyanate with polyether diols in the presence of catalyst and under protection of nitrogenous atmosphere to obtain prepolymer, adding 1, 4-butanediol and polyhedral oligomeric silsesquioxane to serve as chain extenders to fully react, and preparing modified polyurethane having good film forming property and heat resistance through chemical bonding modification, so that defects of poor abrasion resistance and heat resistance of traditional polyurethane are overcome. When the content of the hydroxyl polyhedral oligomeric silsesquioxane is increased from 0 to 10%, the glass-transition temperature of the modified polyurethane is increased by 4.7 DEG C, i.e. from -33.5 DEG C to -28.8 DEG C, the melting temperature is increased by 10.2 DEG C, i.e. from 44.3 DEG C to 54.5 DEG C, and the thermal decomposition temperature of the modified polyurethane is respectively increased by 35.5 DEG C and 11.9 DEG C.

Owner:HEFEI UNIV OF TECH

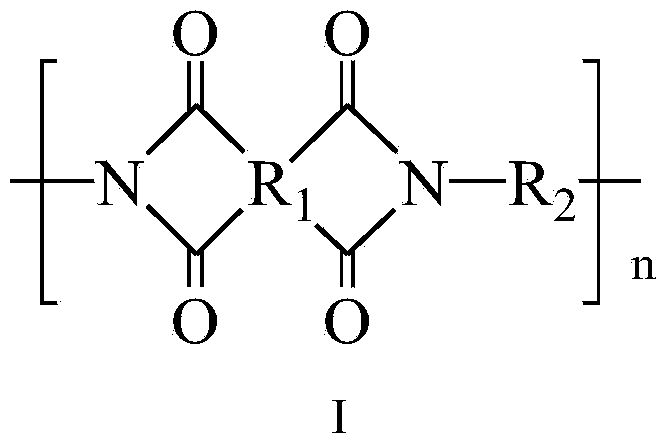

Colorless and transparent polyimide film and preparation method thereof

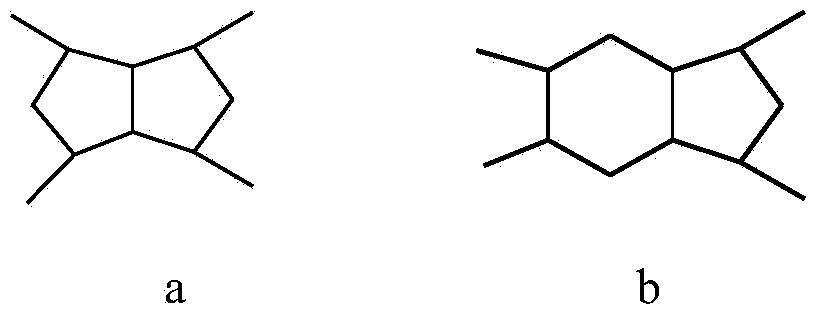

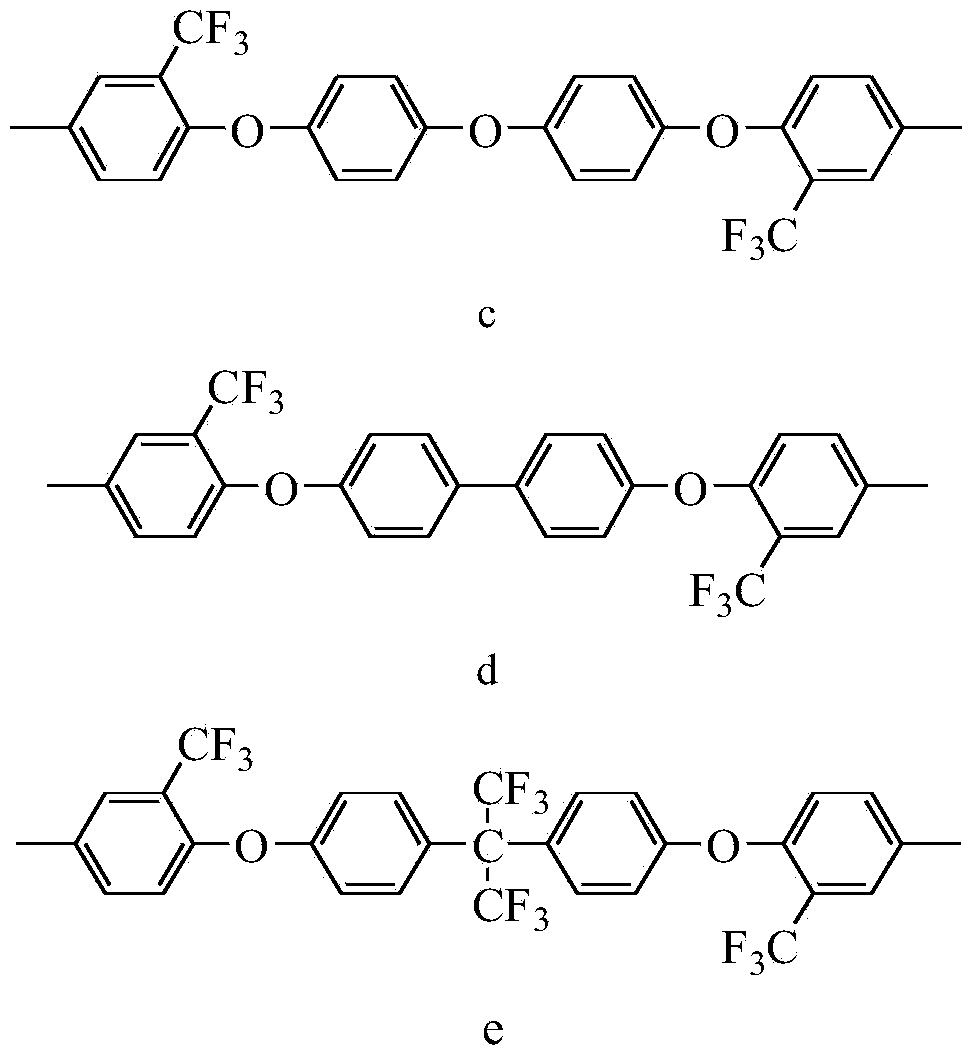

ActiveCN103788650AHigh glass transition temperature and thermal decomposition temperatureReduce intermolecular interactionsDiamineTransmittance

The invention discloses a colorless and transparent polyimide film, the molecular structural formula as shown in a formula I. A preparation method of the polyimide film comprises the following steps: polymerizing a fluorine-containing diamine monomer and a dianhydride monomer which have same moles in a polar aprotic solvent to produce a colorless and transparent poly(amicacid) solution, carrying out dehydration and ring closing on the colorless and transparent poly(amicacid) solution by using a hot imidization method or a chemical imidization method to produce the colorless and transparent polyimide film, wherein the dianhydride monomer is one or two of compounds selected from bicyclic (3,3,0)octane-2,4,6,7-tetracid dihydride or bicyclic (4,3,0)nonane-3,4,7,9-tetracid dihydride, the fluorine-containing diamine monomer is one or a combination of two of compounds selected from 4,4'-di(4-amino-2-trifluoromethylphenoxy)diphenyl ether, 4,4'-di(4-amino-2- trifluoromethylphenoxy) biphenyl and 2,2'-di(4-(4-amino-2- trifluoromethylphenoxy) phenyl) hexafluoropropane. The colorless and transparent polyimide film produced by using the alicyclic type dianhydride monomer has excellent performances such as good heat resistance, good solubility and high light transmittance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

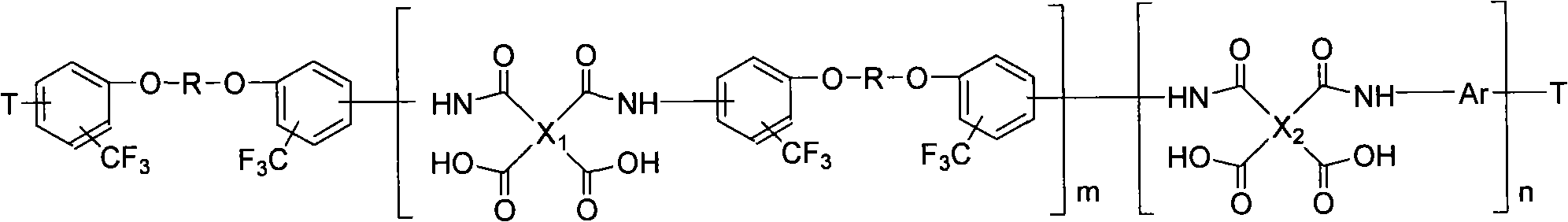

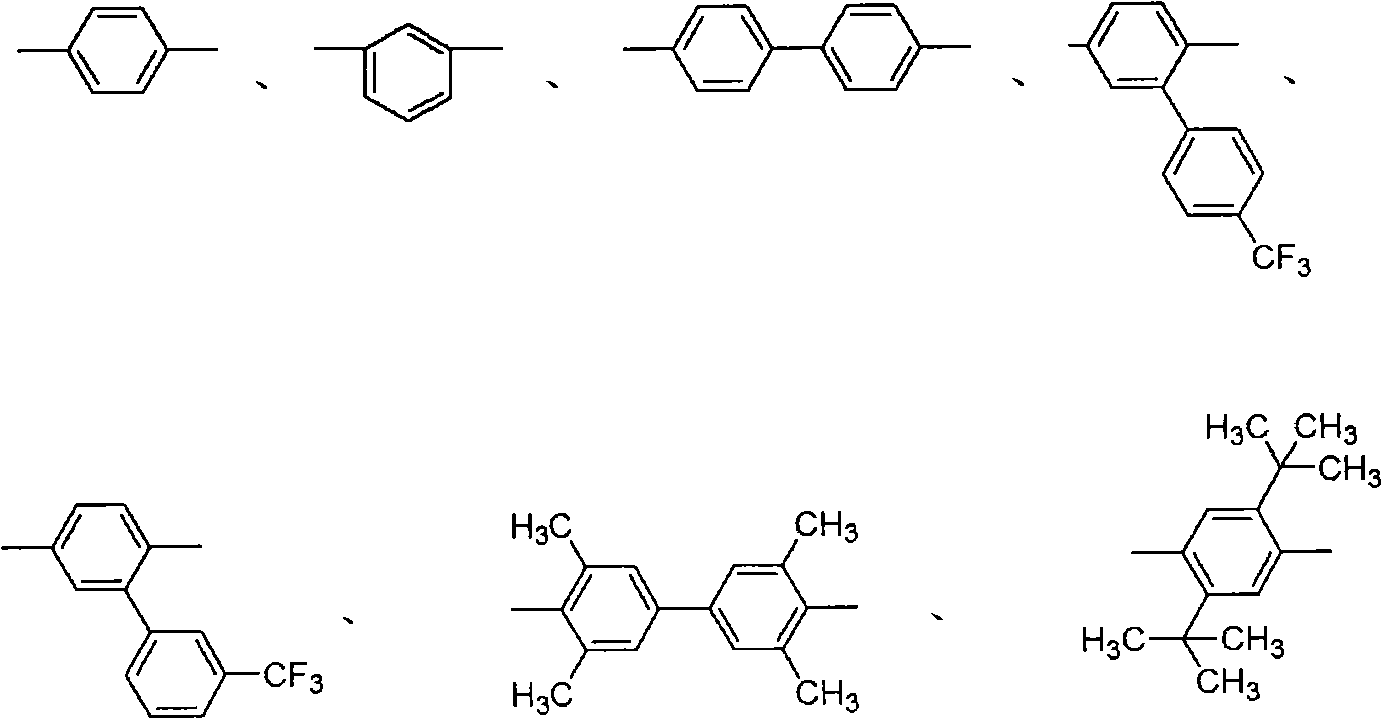

Polyimide resin, its midbody, preparation method and application thereof

ActiveCN101343362AImprove heat resistanceImprove mechanical propertiesLamination ancillary operationsSynthetic resin layered productsChemical structureMetal foil

The invention discloses polyamide resin and intermediate compound thereof as well as the preparation method and the application. The polyamide resin is provided with the chemical structure shown in formula II, wherein, X1 and X2 can be identical or different, representing quadrivalent aryl; Ar represents bivalent aryl, and T represents end capping reagent. The polyamide resin is obtained by polyamic acid shown in formula I structure general formula through chemical imidization or thermal imidization. The polyamide resin is dipped through prosomatic polyamic acid solution or polyamic acid solution being obtained after being dissolved with solvent with a low-boiling point, the basal body is strengthened, and the prepreg is obtained. After the heat-press forming operation is performed, a metal foil layer is covered, and a metal foil layer pressing plate is obtained. The polyamide resin provided by the invention has the advantages of excellent heat resisting property, high mechanical property, low dielectric constant and dissipation, high electrical insulation property and low water absorbing capacity, thereby being especially suitable for manufacturing core plates of packaging subsctrates for packaging super large-scale integrated circuits.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of copper clad plate

ActiveCN101652026AGuaranteed performanceGuaranteed flame retardant performanceLaminationLamination apparatusEpoxyCopper foil

The invention discloses a preparation method of copper clad plate and the method comprises the following steps: (1) adopting bismaleimide resin and allyl compound in a weight ratio of 100:40-100 to react at 110-160 DEG C for 10-120min and obtain prepolymer, cooling to room temperature after finishing the reaction, using acetone to prepare prepolymer solution; (2) adding 15-150 parts of epoxy resinwith phosphorous, 10-100 parts of compound curing agent and 0-5 parts of curing accelerator in the solution obtained in the step 1, stirring evenly to obtain a glue solution, selecting a flat E-glassfibic cloth, coating the glue solution evenly on the glassfibic cloth, then roasting to prepare B-stage prepreg; (3) cutting the B-stage prepreg to proper size according to the size of a pressing machine, overlying five prepregs while placing two high impact copper foils with the same size separately on the top and bottom of the prepregs, placing the prepregs with copper foils in a vacuum hot pressing machine to press and obtaining the copper clad plate. The obtained copper clad plate can meet the demand for halogen-free and flame resistance, the heat resistance and humidity resistance are excellent, and the low dielectric loss and pressing toughness are good.

Owner:SHENGYI TECH SUZHOU

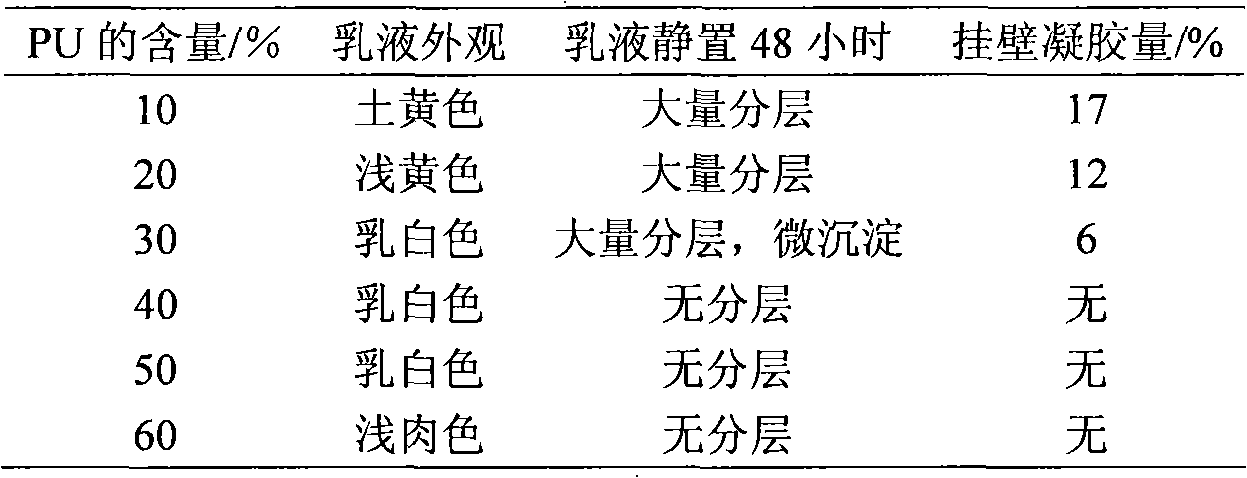

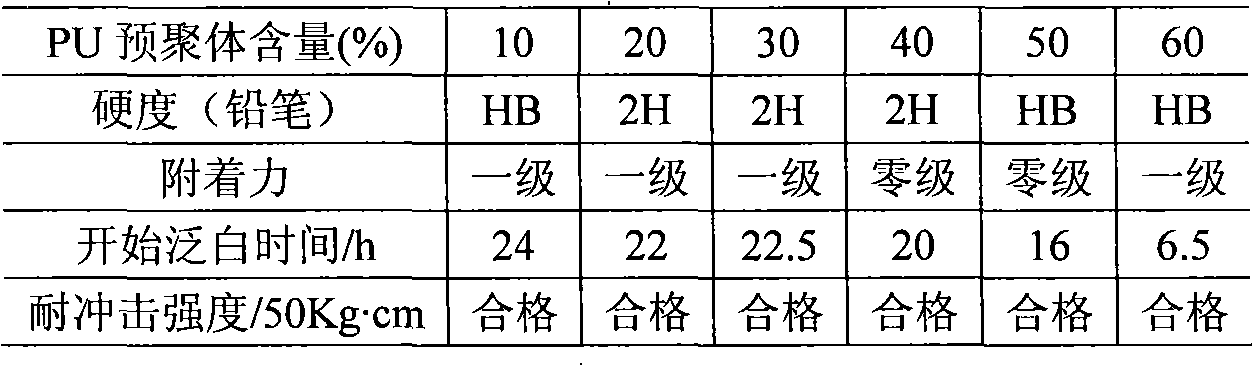

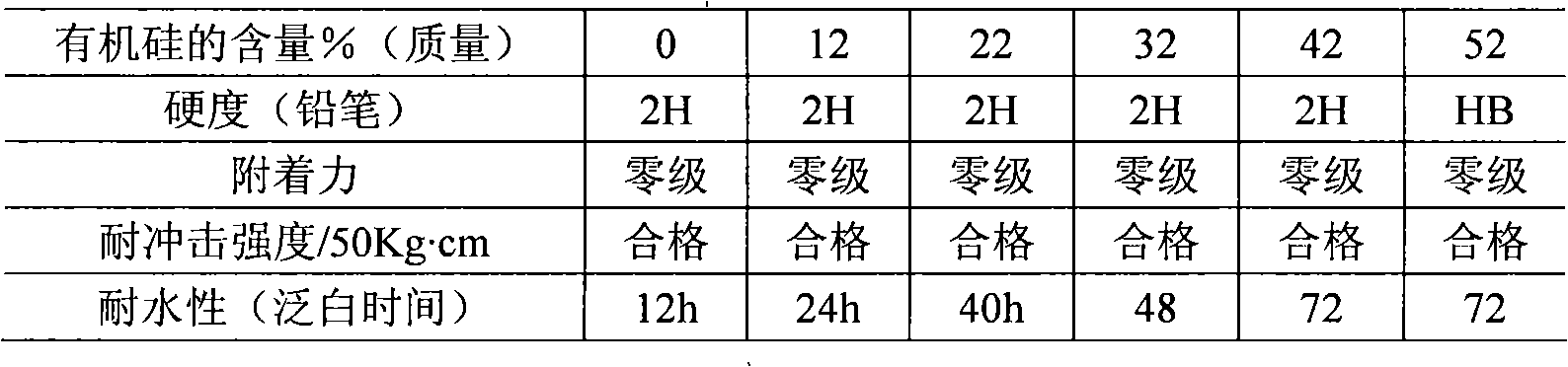

Synthetic method of organosilicon polyurethane-acrylic ester ternary composite ionomer emulsion

The invention relates to a synthesis method of silicone-polyurethane-acrylate ternary composite ionomer emulsion as follows: first, hydroxy-terminated poly-dimethylsiloxane, N-methyl-diethanolamine, toluene diisocyanate, polypropylene glycol and others are used to prepare water-based silicone modified polyurethane; under the condition that the silicone modified polyurethane serves as emulsifier, the silicone modified polyurethane is polymerized and reacted with acrylic monomer to prepare stable silicone-polyurethane-acrylate ionomer emulsion. The silicone-polyurethane-acrylate ionomer emulsion is dried to obtain the silicone-polyurethane-acrylate coating. The synthesis method of the invention has simple process and low cost. The prepared ternary composite ionomer product combines the outstanding performances of the three components and can be applied to automobiles, household appliances, metal tools, buildings, textiles, paints and many other fields.

Owner:SHANGHAI UNIV

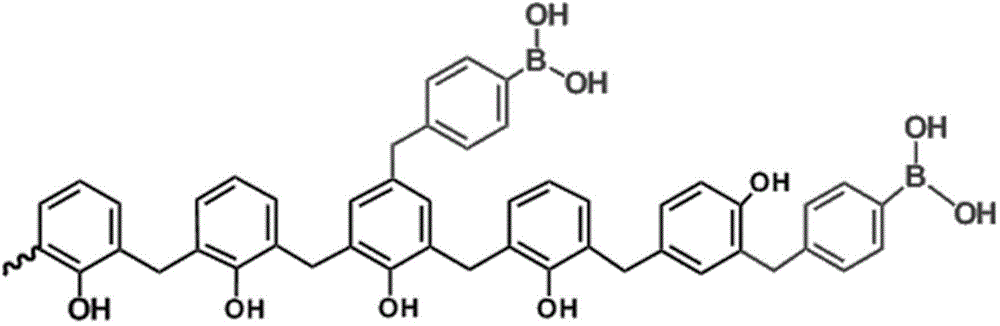

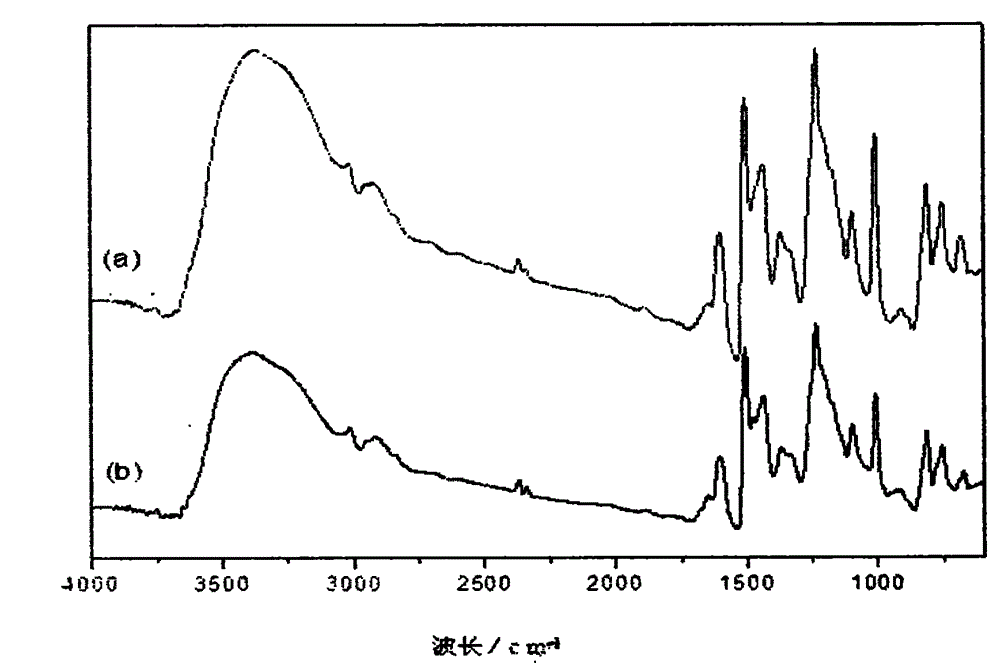

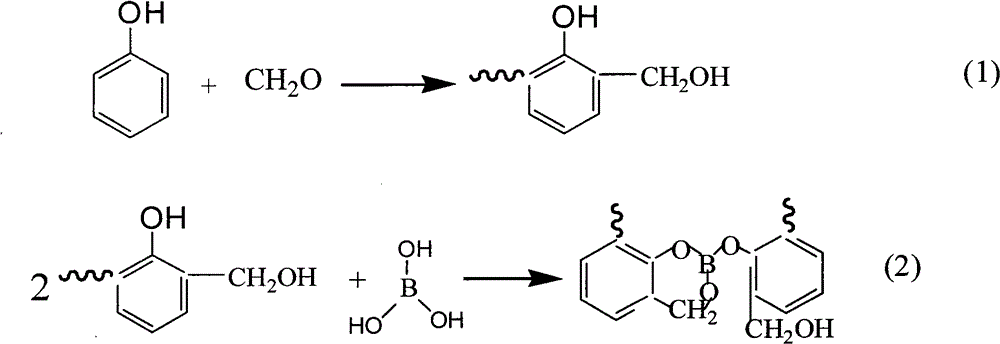

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

Functional cellulose fiber containing graphene and preparation method thereof

ActiveCN105603554AReduce the use of reducing agentsImprove performanceArtificial filaments from viscoseArtifical filament manufactureAlpha-CelluloseGraphene

The invention provides a functional cellulose fiber containing graphene. The functional cellulose fiber containing the graphene is obtained by mixing graphene dispersion liquid with a cellulose spinning solution to prepare a graphene / cellulose spinning solution and then subjecting the graphene / cellulose spinning solution to wet spinning, wherein mass content of the graphene, in the graphene / cellulose spinning solution, accounting for Alpha cellulose in the graphene / cellulose spinning solution ranges from 2.0% to 6.0%. The invention further provides a preparation method of the functional cellulose fiber containing the graphene. In the graphene / cellulose spinning solution prepared by the method, uniformity in dispersion and difficulty in agglomeration of the graphene are achieved. According to the method, the step that oxidized graphene is reduced by a reducing agent in a follow-up process is omitted, so that fiber performance is improved. Content of the graphene in the functional cellulose fiber containing the graphene is 2.0-6.0%. The functional cellulose fiber containing the graphene is uniform in graphene distribution, high in temperature rise rate, excellent in far-infrared and anti-ultraviolet performance and better in thermal stability performance.

Owner:潍坊欣龙生物材料有限公司

Arc extinction slurry for fuse protector

ActiveCN103606497AEffectively extinguishedQuick breakdownEmergency protective devicesSurface mountingOrganosolv

The invention relates to arc extinction slurry for a fuse protector. The arc extinction slurry comprises, by weight, 5-40 parts of gas production materials, 0-10 parts of phenol formaldehyde resin, 20-60 parts of quartz sand, 0.6-10 parts of organic solvents and15-30 parts of deionized water. The gas production materials are mainly urea-formaldehyde resin and other powder materials; the phenol formaldehyde resin can be boron-modified phenol formaldehyde resin and other high-temperature-resistant resin which is soluble in organic solvents, and the main effect of the phenol formaldehyde resin is to improve the heat-resistant performance of urea-formaldehyde resin; the periphery of a melt is covered with the arc extinction slurry in a filling mode or a thick film printing mode or the like, and gas will be produced under the action of an electric arc so as to extinguish the electric arc; fast cooling of the metallic melt is guaranteed by adding the quartz sand, and therefore the arc extinction slurry can be used on the breaking occasion of high voltage and great current of more than 250VAC / 100A. The arc extinction slurry has the predominant advantages of being low in production cost, easy to operate, free of halogen, friendly to environment, high in arc extinction ability and the like, thereby being suitable for being used in a current common tube shell type or thick film printing type surface-mounted miniature fuse protector.

Owner:NANJING SART SCI & TECH DEV

Thermal-sublimation water-based intaglio printing ink and preparation method thereof

InactiveCN102585606AGood storage stabilityClear patternTransfer printing processInksOrganic solventPolymer science

The invention discloses thermal-sublimation water-based intaglio printing ink and a preparation method thereof. The thermal-sublimation water-based intaglio printing ink is composed of components in percentage by weight: 15-35% of disperse dye size, 24-50% of an N-vinylamide-acrylic ester copolymer emulsion, 0.3-2.5% of a thickening agent, 0.1-2% of an antifoaming agent, 0.1-3% of a neutralizer, 0.1-0.5% of a preservative and 10-42% of de-ionized water. The thermal-sublimation water-based intaglio printing ink has high heat resistance; and transferred printing paper is not adhered to a cloth material in a transfer printing process. The thermal-sublimation water-based intaglio printing ink also has excellent storage stability; patterns printed on various transferred printing paper are clear; the printing patterns transferred onto dacron, nylon cloth material and textile have clear profiles without any friction ghosting and transfer ghosting and are bright in color; and color fastness complies with wearing requirements. The thermal-sublimation water-based intaglio printing ink has no any toxic organic solvent residue, can be diluted with water and is good for safe production and environment protection.

Owner:SUN YAT SEN UNIV +1

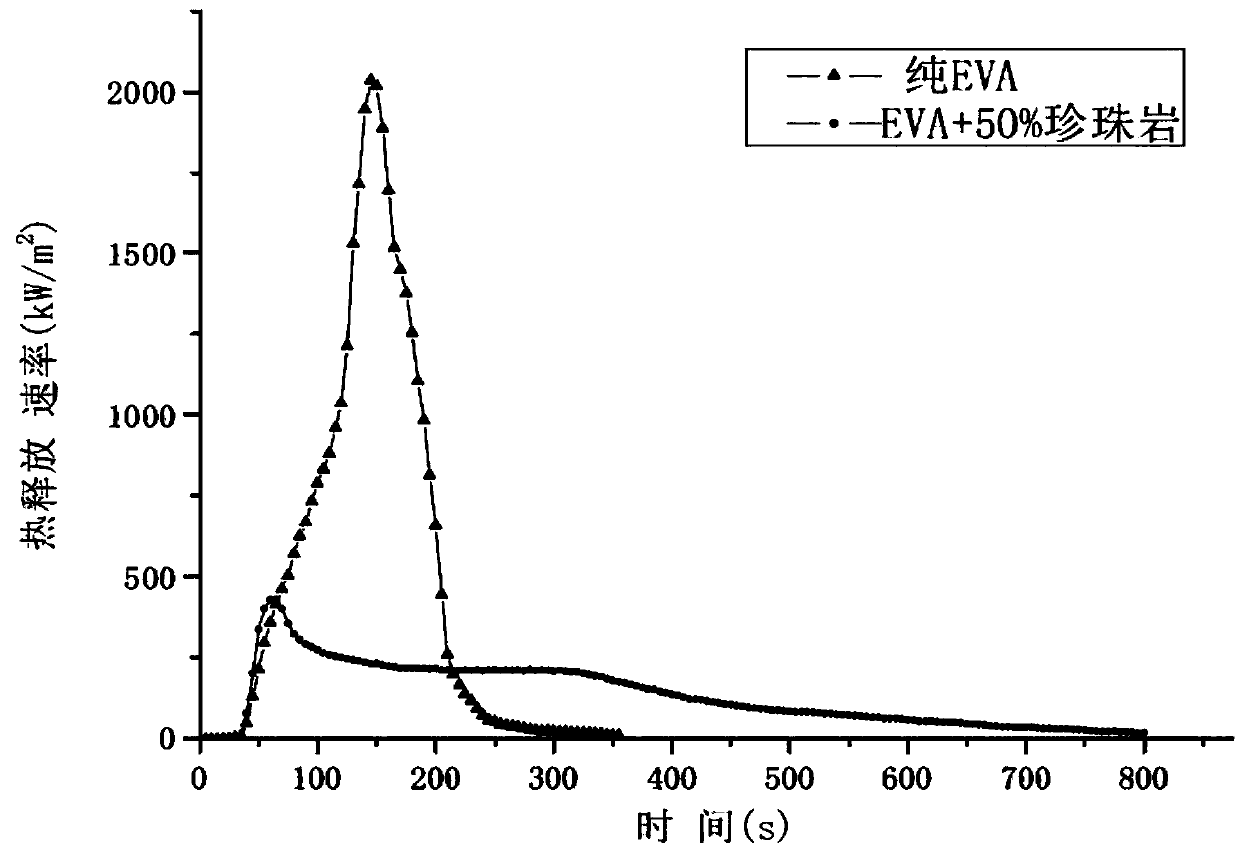

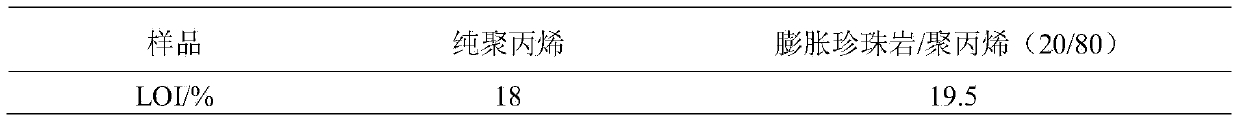

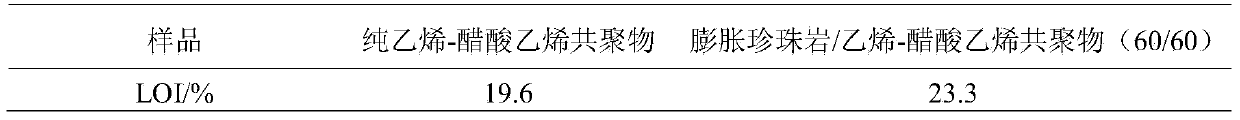

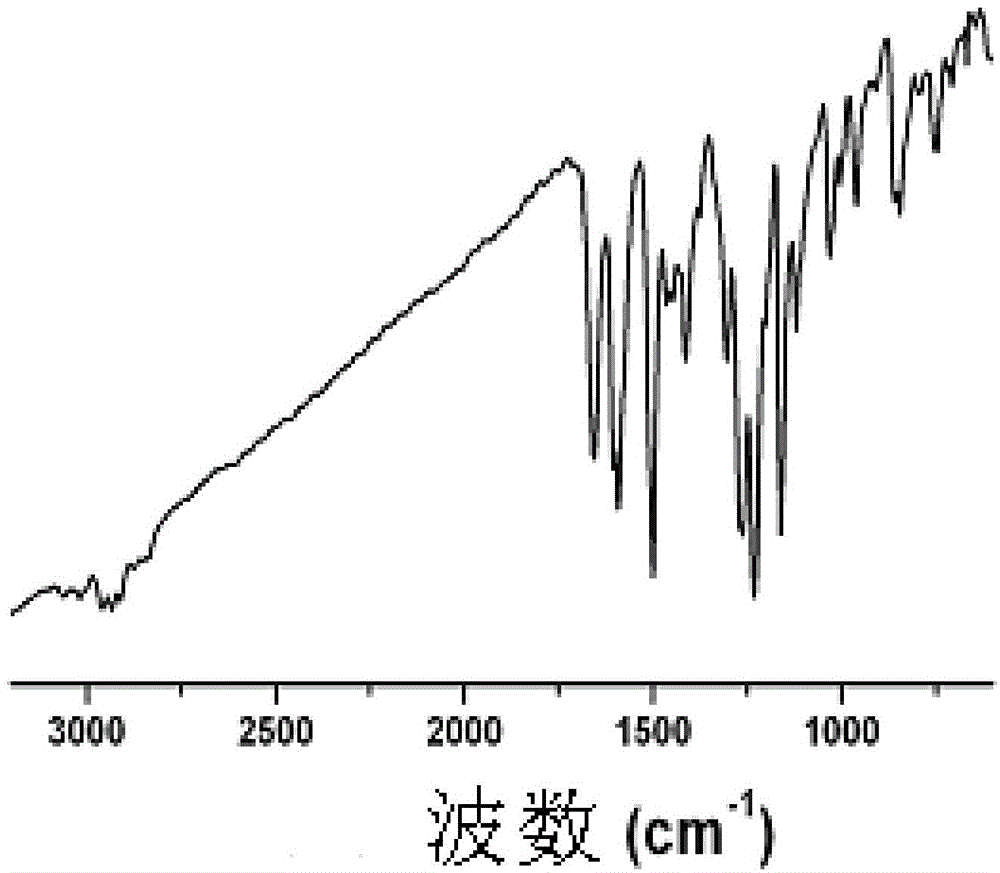

Method for preparing polymer composite material by expanded perlite

The invention relates to a method for preparing a polymer composite material by expanded perlite. The method comprises the following steps: mixing the expanded perlite and a polymer in a weight ratio of (2-60) to (98-60) to uniformly disperse the expanded perlite in the polymer matrix; and molding to obtain a polymer composite material product, wherein the expanded perlite is a product formed by carrying out high-temperature expansion on natural mineral perlite, and a honeycomb porous structure is formed inside the expanded perlite; and the polymer is one or more of universal plastic, engineering plastic and rubber. The polymer composite material has excellent heat-insulation and flame-retardant performances, is capable of overcoming the defect that the flame-retardant performance cannot be remarkably improved by existing clay type additives, is environmental-friendly and non-toxic, and does not cause dust pollution; and the packing is low in cost and easily available.

Owner:BEIJING UNIV OF CHEM TECH

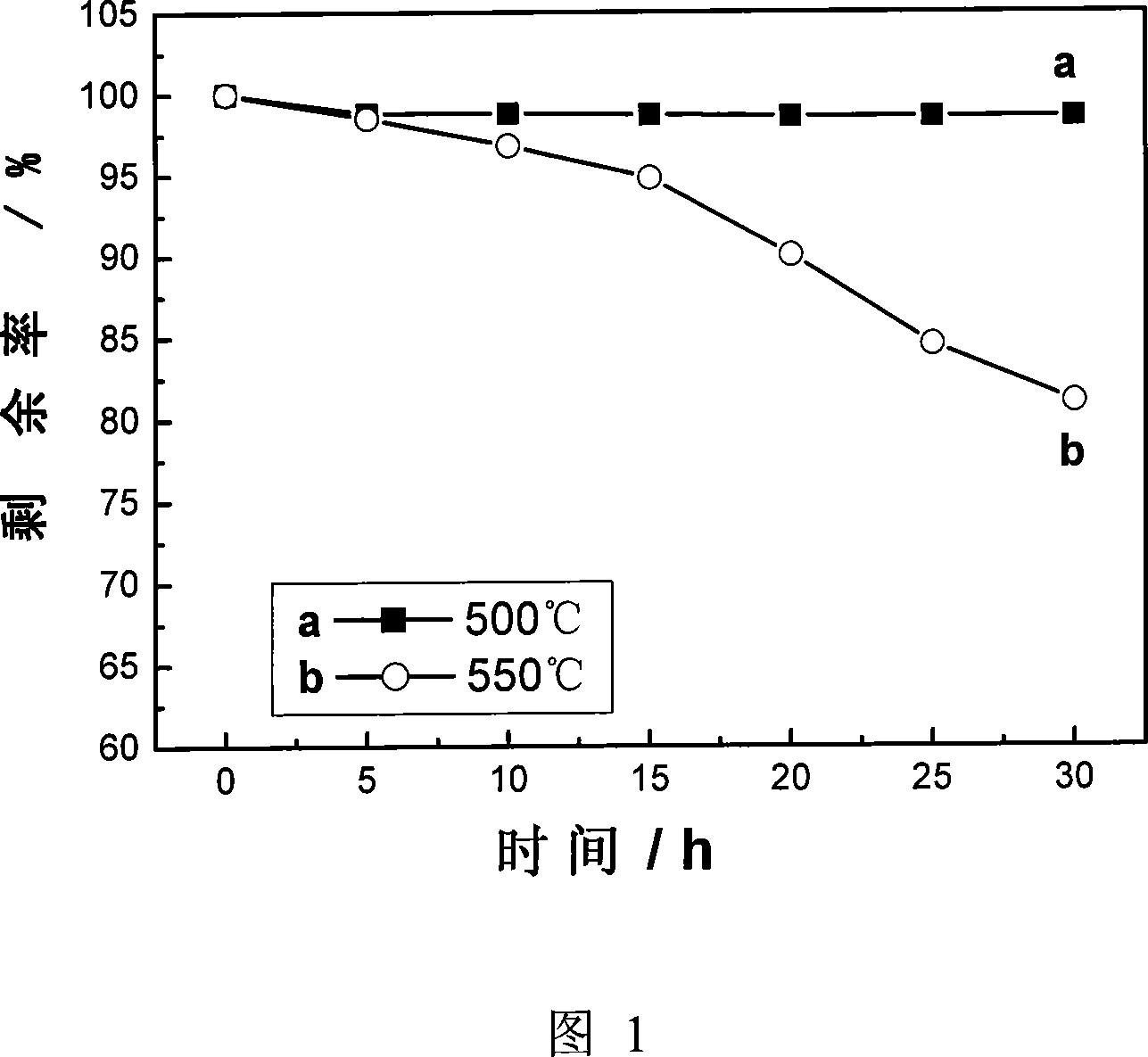

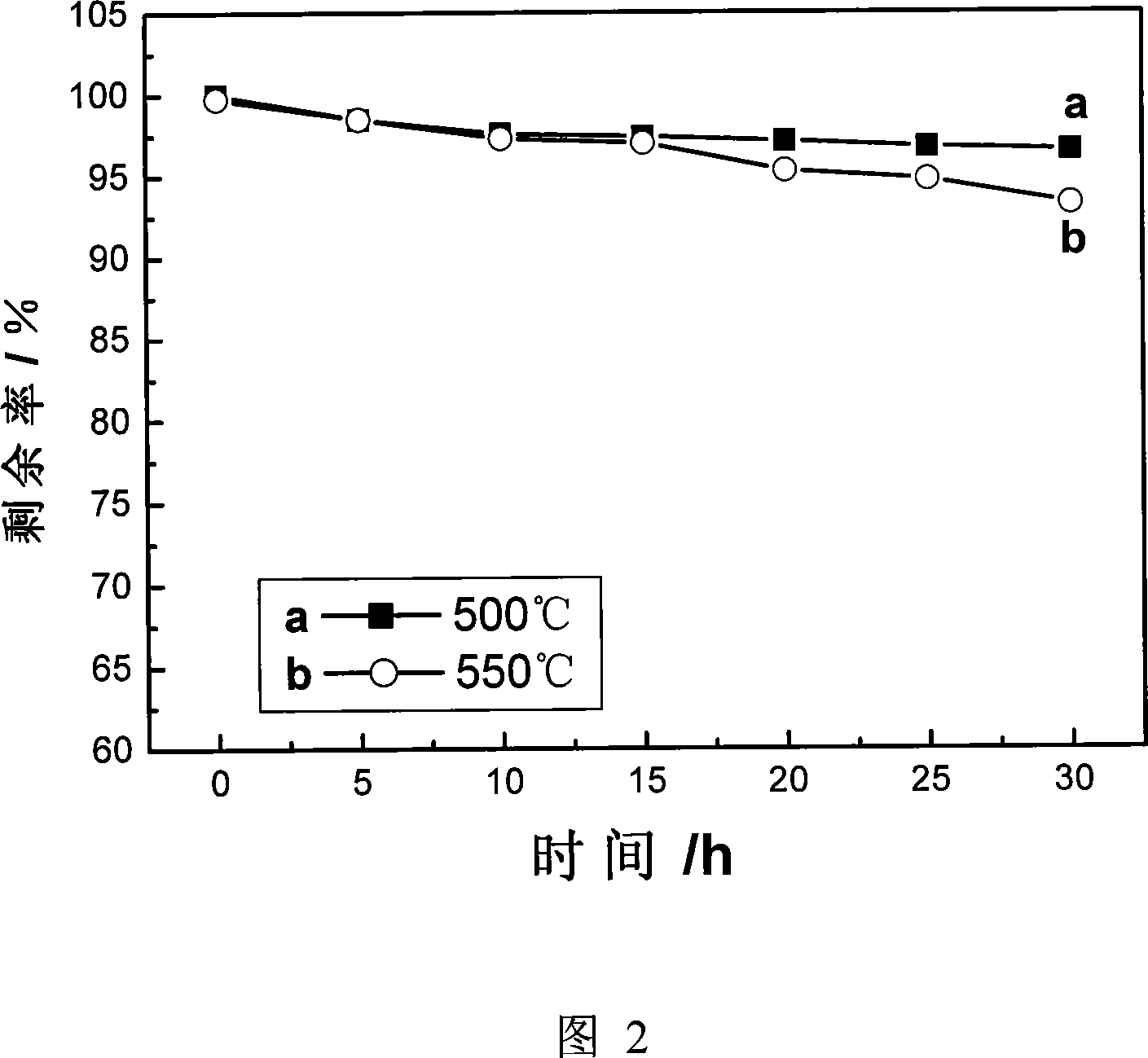

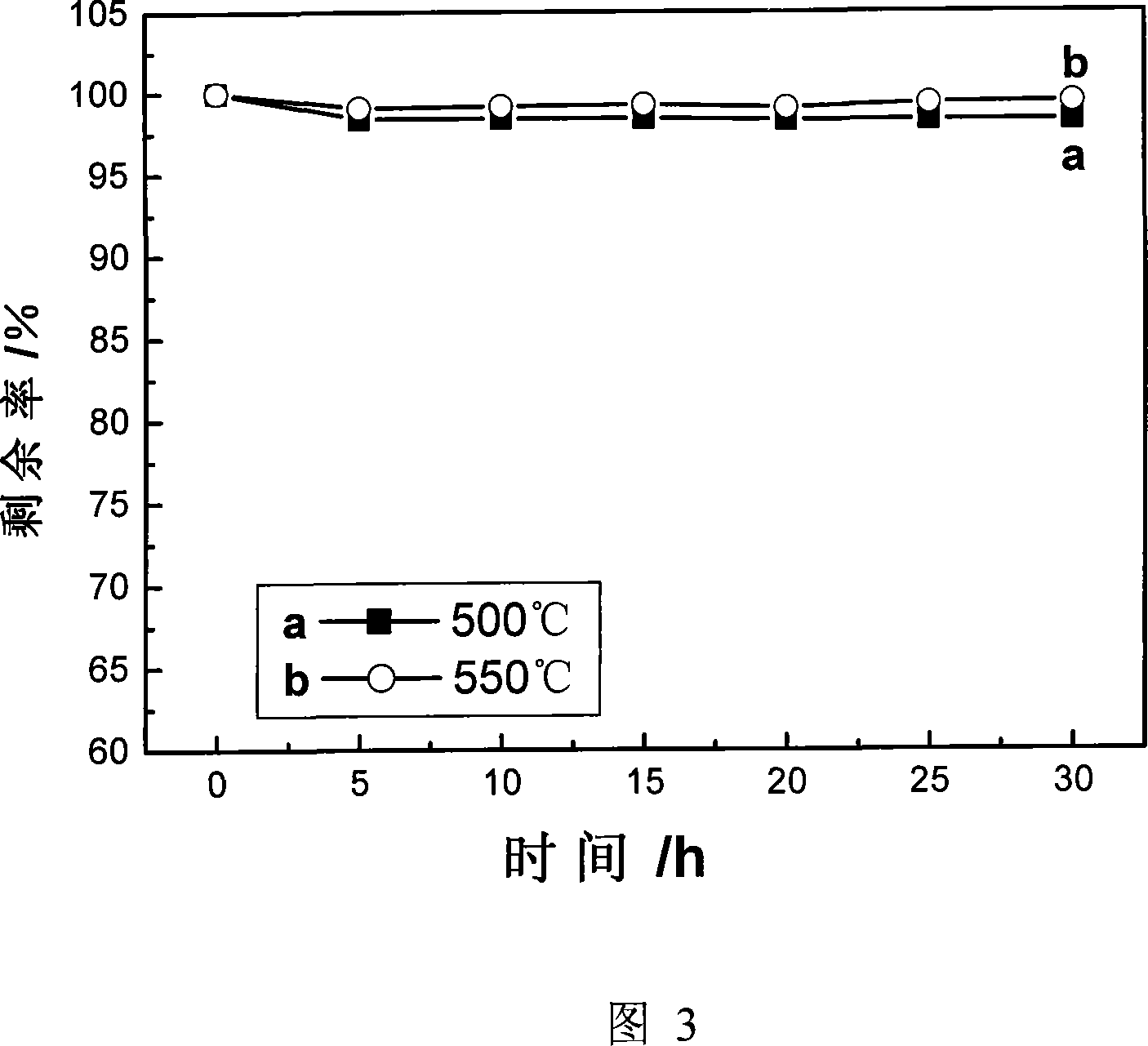

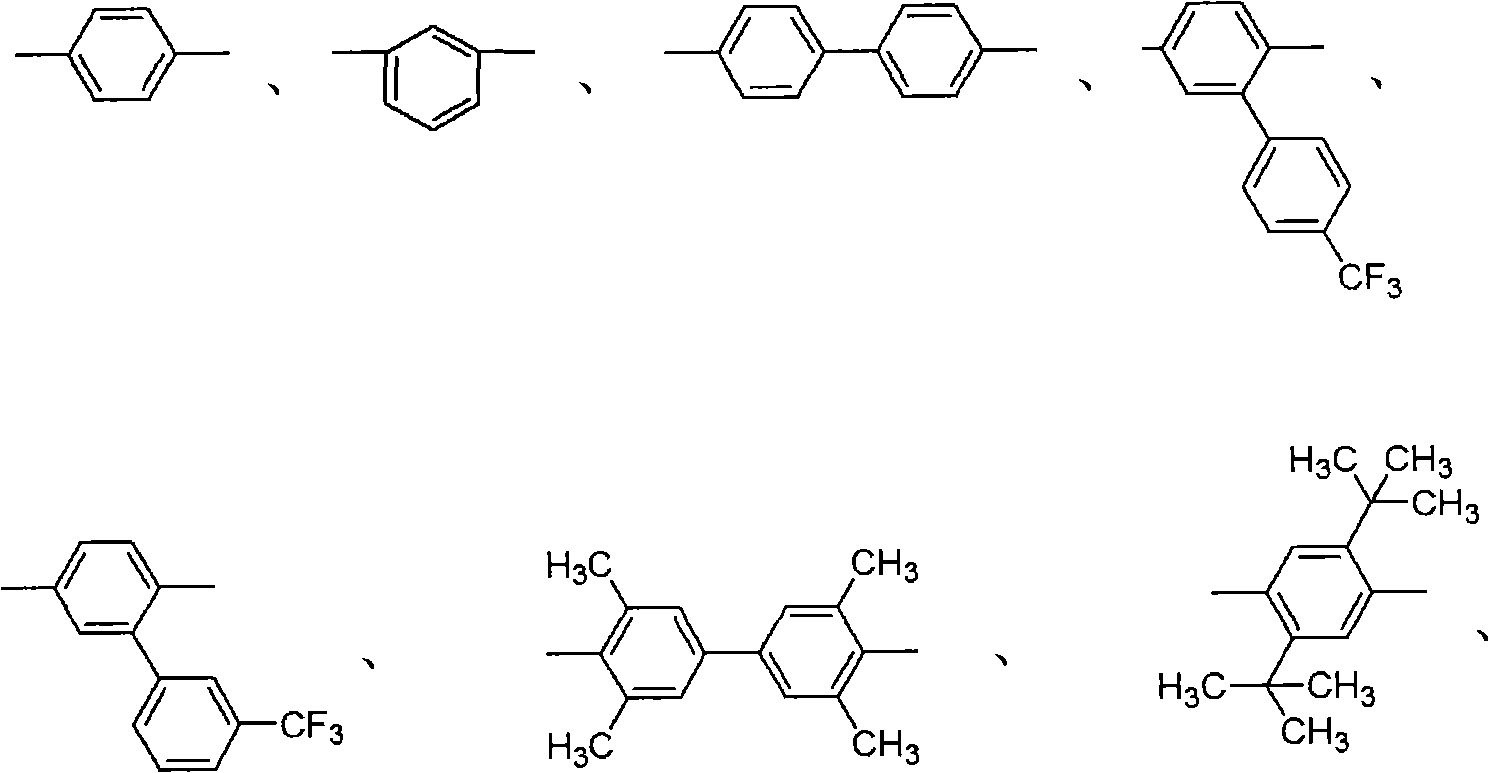

Propenyl phenoxy compounds with three-branch aromatic structure and preparation method thereof, and bismaleimide resin modified by propenyl phenoxy compounds

ActiveCN104628544ALower curing temperature effectIncreased reactivity collision chanceOrganic compound preparationCarbonyl compound preparationCooking & bakingReflux

The invention provides propenyl phenoxy compounds with a three-branch aromatic structure and a preparation method thereof, and a bismaleimide resin modified by the propenyl phenoxy compounds, relating to the field of thermosetting resins and adhesives for high-temperature-resistant composite materials. The invention aims to solve the problems of higher curing temperature and higher after-treatment temperature in the existing bismaleimide resin and the problem of poor long-time thermal aging resistance of the cured resin at high temperature. The structural general formula is disclosed in the specification. The preparation method comprises the following steps: adding trifunctional fluoro ketone, allyl phenol and a catalyst into a solvent, heating to react under reflux, filtering, cooling, precipitating, washing with water and baking. The bismaleimide resin modified by the propenyl phenoxy compounds is prepared from bismaleimide, propenyl phenoxy compounds with three-branch aromatic structure, and diallylphenyl compounds. The invention mainly discloses a propenyl phenoxy compounds with three-branch aromatic structure and a preparation method thereof, and a bismaleimide resin modified by the propenyl phenoxy compounds.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

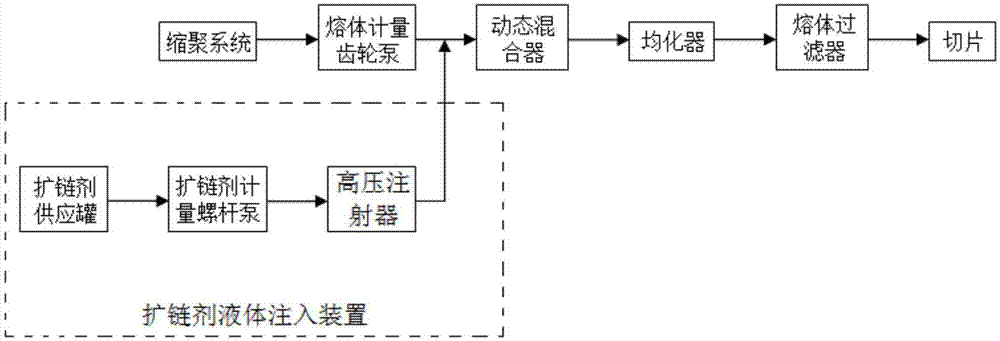

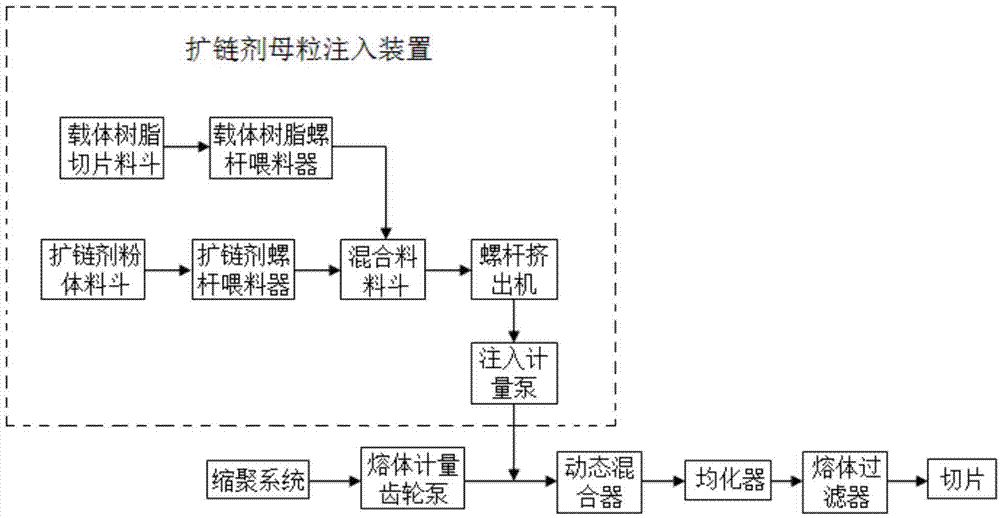

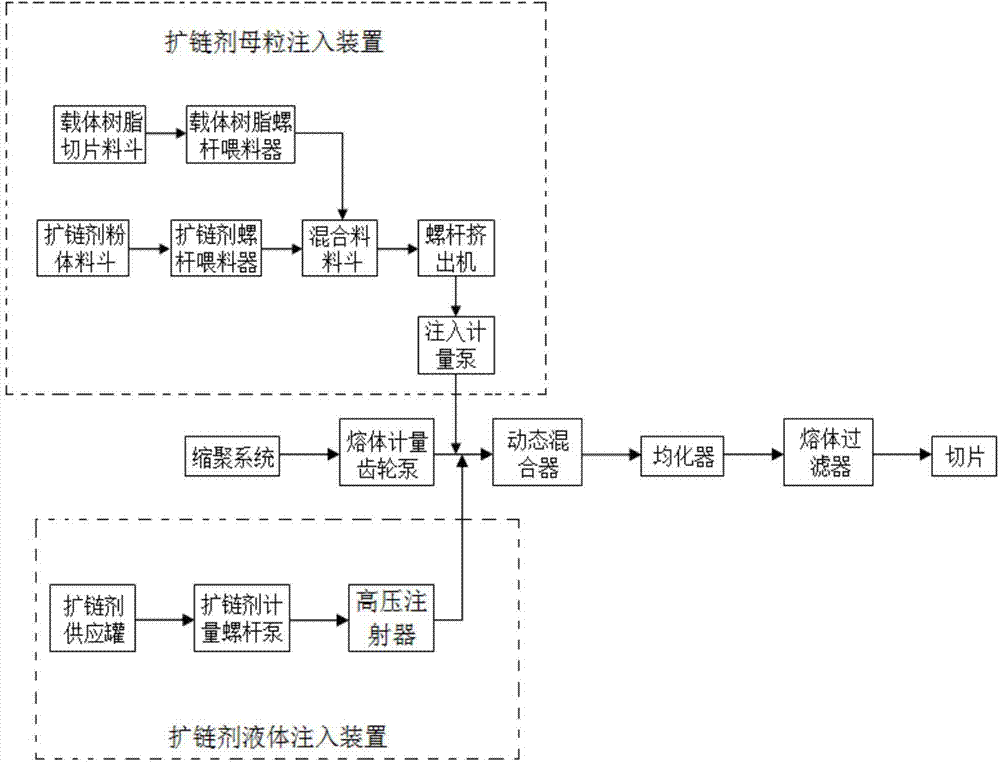

Method for continuously polymerizing chain extension modified polyester

The invention relates to a method for continuously polymerizing chain extension modified polyester. The method mainly comprises the following steps of directly conveying polyester melt from a condensation polymerization system by a melt metering gear pump to a melt pipeline, then allowing the polyester melt and the chain extender injected into the melt pipeline by a chain extender injection device to enter a dynamic mixer, after mixing uniformly by the dynamic mixer, entering a homogenizer for chain extension homogenizing reaction so as to obtain the chain extension modified polyester melt, filtering the obtained melt by a melt filter, then transferring the filtered melt to a casting belt head for cooling and curing, and finally, pelletizing by a pelletizer so as to obtain chain extension modified polyester chips. The method for continuously polymerizing chain extension modified polyester guarantees the stability of the product quality, improves production efficiency, lowers production cost, and realizes large scale industrial production.

Owner:CHINESE TEXTILE ACAD

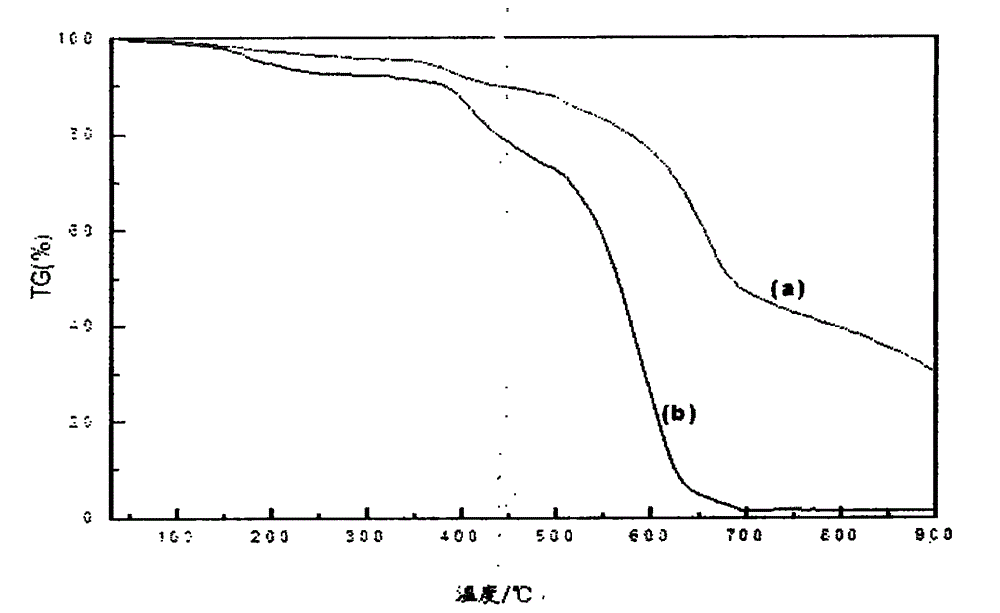

Modified phenol formaldehyde resin and preparation method thereof

ActiveCN102757618AImprove toughnessHigh strengthAldehyde/ketone condensation polymer adhesivesToughnessPhenol formaldehyde resin

The invention discloses a modified phenol formaldehyde resin and a preparation method thereof, relating to the field of phenol formaldehyde resins. The preparation method comprises the following steps: reacting 100 parts of phenol, 10-200 parts of lignin and 1-20 parts of acidic catalyst at 80-200 DEG C for 2-8 hours to form a reaction liquid; regulating the temperature of the reaction liquid to 60-110 DEG C, adding 50-200 parts of formaldehyde and 2-20 parts of composite catalyst, and reacting for 1-5 hours to form a sticky matter; washing the sticky matter in 60-70 DEG C water 2-5 times, and dehydrating to obtain a lignin phenol formaldehyde resin; and pulverizing the lignin phenol formaldehyde resin to 200 meshes, and evenly mixing with 2-20 parts of powder nitrile-butadiene rubber to obtain the modified phenol formaldehyde resin. The free phenol content of the modified phenol formaldehyde resin is 2-5%, the thermal decomposition temperature is 400-490 DEG C, the toughness and strength are high, and the friction material prepared from the modified phenol formaldehyde resin has high adhesive property and frictional property.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

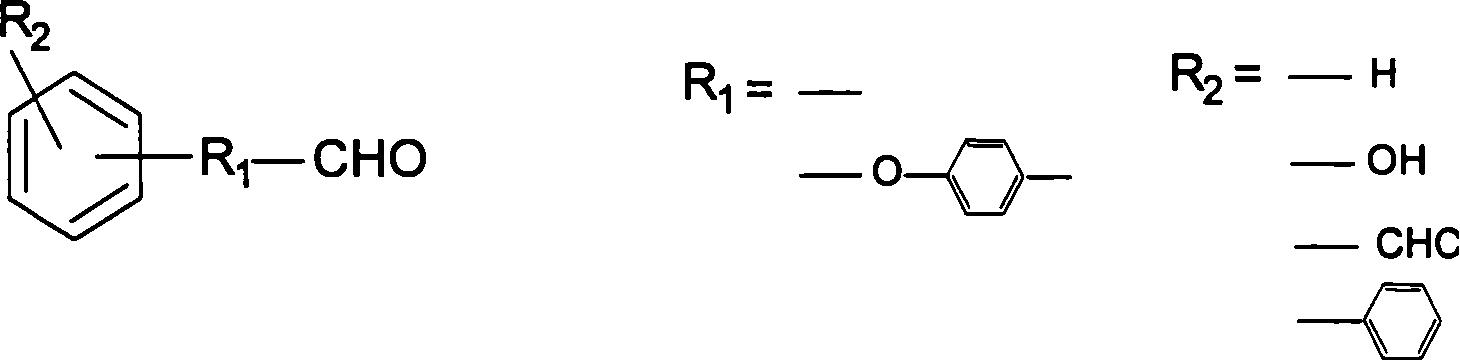

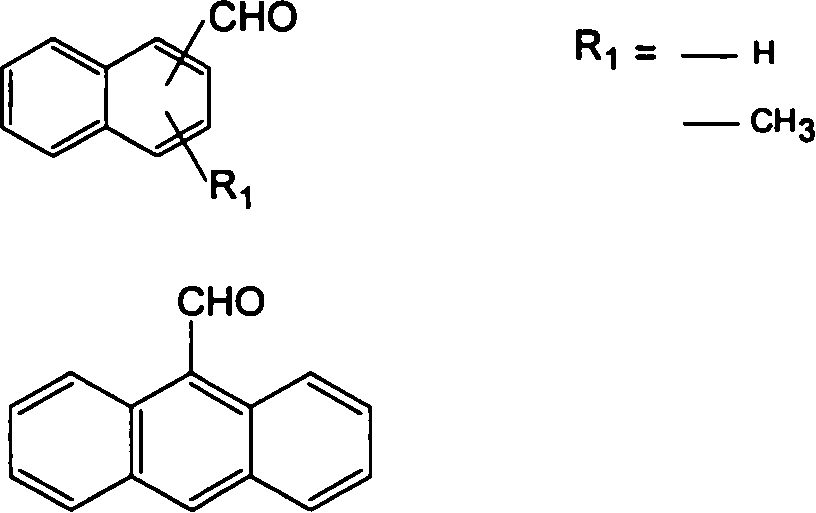

Thermostable benzoxazine resin compound and its preparation method and uses

InactiveCN1884376AIncrease crosslink densityImprove heat resistancePlastic/resin/waxes insulatorsOther chemical processesSolventAldehyde

The invention relates the heat-durability benzoxazine resin compound and preparing method, comprising the following steps: dissolving 50-95wt% benzoxazine resin intermediate, 0-50wt% aromatic compounds liquid resin with aldehyde group and 0-50wt% benzoxazine resin with aldehyde group into solvent between room temperature and 50Deg.C, getting heat-durability benzoxazine resin compound solvent, carrying out coating or dipping technology, getting prepreg, or mixing and getting solid resin compound, forming at 150Deg.C, carrying out heat treatment at 180Deg.C, and getting the product.

Owner:SICHUAN UNIV

Novel sea-island fiber synthetic leather base cloth and production technology thereof

ActiveCN108589028ASolve pollutionNo emissionsConjugated synthetic polymer artificial filamentsNon-woven fabricsPolyethylene terephthalate glycolDecomposition

The invention discloses novel sea-island fiber synthetic leather base cloth. The novel sea-island fiber synthetic leather base cloth is a net which is prepared from water-soluble sea-island fibers byneedle punching and is of a three-dimensional network structure; a sea-island fiber needle-punched fabric layer is prepared from the sea-island fibers with water-soluble PVA (polyvinyl acetate) as a marine component and a PA (polyamide) or PET (polyethylene terephthalate) material as an island phase component by lapping and needle punching, wherein the island phase component accounts for 60%-85% of a fiber section area, the marine component accounts for 40%-15% of the fiber section area, denier of the sea-island fibers is 1.6-14 dtex, breaking strength is 3-6 cN / dtex, elongation at break is 7%-10%, single fiber denier of the island phase component is 0.8 dtex or lower, PVA is water-soluble PVA mater batch, and the melting point is 180-190 DEG C; the melting range is 175-195 DEG C, and thethermal decomposition temperature is 210-220 DEG C. The invention further discloses a production technology of the base cloth. The problem of pollution caused by the fact that complex fibers are treated and prepared from traditional PVA chips by adopting an organic solvent is solved, and the purpose of composite melt spinning with island phase resin is achieved.

Owner:浙江泓泰德建新纤维有限公司

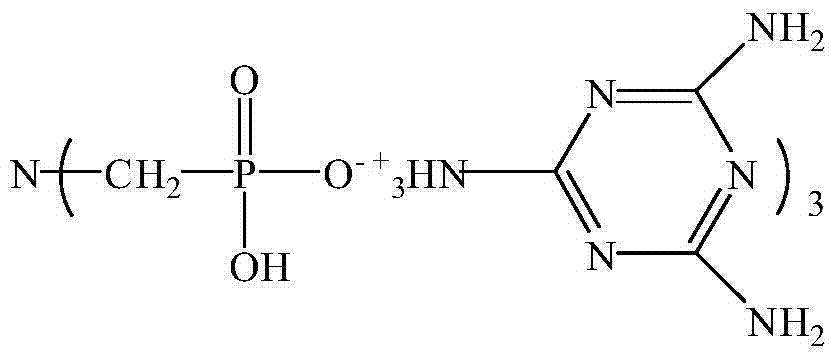

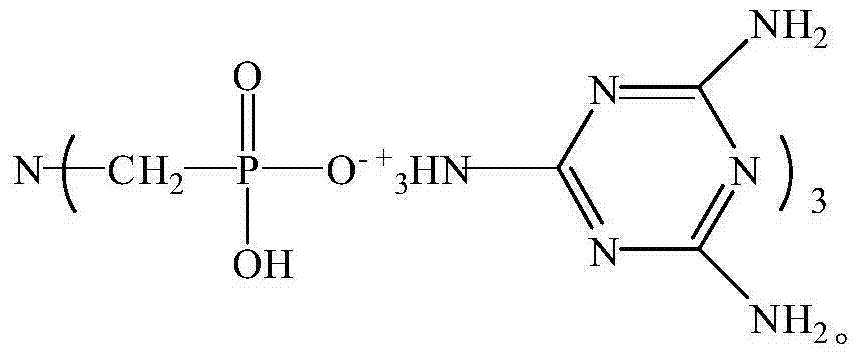

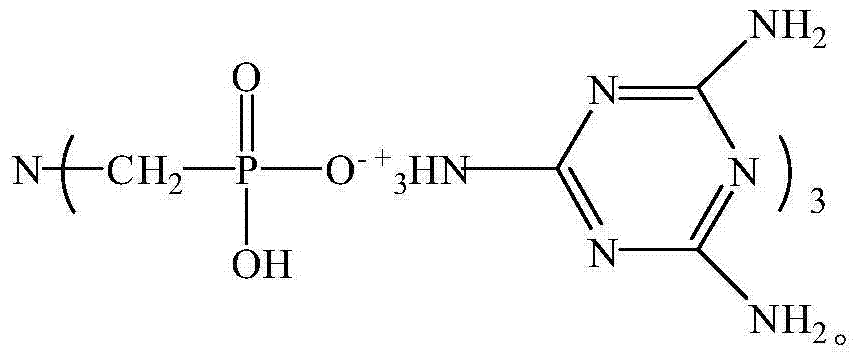

Melamine aminotrimethylene phosphonate and preparation method thereof

InactiveCN104497041AHigh thermal decomposition temperatureUnusual char formationGroup 5/15 element organic compoundsNitrogenHeat stability

The invention relates to a melamine aminotrimethylene phosphonate and a preparation method thereof. The preparation method comprises the following synthesis steps: adding measured melamine and an appropriate amount of deionized water in a reaction kettle with a stirring device, raising a temperature and stirring to obtain the completely-dissolved melamine solution, then slowly dripping aminotrimethylene phosphonic acid aqueous solution with a proper concentration, reacting for a period of time with heat, after the reaction is ended, filtering, washing and drying to obtain the target compound. The raw materials in the preparation method disclosed by the invention are melamine and aminotrimethylene phosphonic acid, rich in source and low in price; the preparation process is simple in flow and low in cost. The melamine aminotrimethylene phosphonate obtained by the preparation method disclosed by the invention is good in heat stability and good in compatibility with polymers, simultaneously has the characteristics of nitrogen-containing and phosphorous-containing flame retardants, and has high flame-retardant efficiency, wide application range (applicable to the flame retardance of many plastics, rubbers, fibres and coatings), and a wide market prospect.

Owner:DONGHUA UNIV

Preparation method of graphene oxide/nano cellulose/polyvinyl alcohol composite film

ActiveCN106700110AHigh oxygen barrierHigh thermal decomposition temperatureComposite filmTransmittance

The invention relates to a preparation method of a graphene oxide / nano cellulose / polyvinyl alcohol composite film. The method aims to solve the problems of poor mechanical properties and poor barrier properties of the existing degradable polyvinyl alcohol packaging film. The method comprises the following steps: 1. preparing nano cellulose; 2. preparing graphene oxide; 3. preparing a nano cellulose / polyvinyl alcohol mixed solution; 4. preparing a graphene oxide solution; and 5. preparing the composite film. The composite film has favorable mechanical properties; the tensile strength can reach 101.49 MPa which is enhanced by 42.4% as compared with the PVA (polyvinyl alcohol) film; the oxygen barrier property is enhanced by 2.08 times as compared with the pure PVA film; the thermal decomposition temperature is enhanced by 10-20 DEG C; and the composite film has higher light transmittance. The method belongs to the field of preparation of composite packaging films.

Owner:NORTHEAST FORESTRY UNIVERSITY

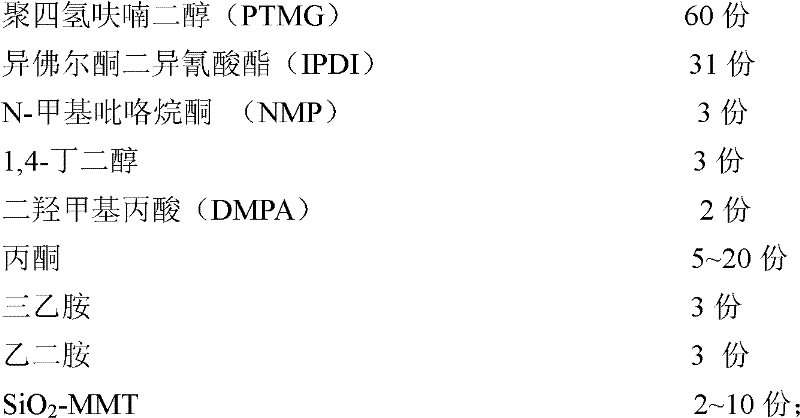

Nano-grade silica modified montmorillonite particle preparation method, and method for applying nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with in-situ method

ActiveCN102344699AGood compatibilityImprove stabilityPigment treatment with organosilicon compoundsSilicon dioxideMechanical property

The invention relates to a nano-grade silica modified montmorillonite particle preparation method, and a method for applying the nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with an in-situ method. According to the invention, tetraethoxysilane, a silicane coupling agent and montmorillonite are subject to a modification reaction, such that anano-grade silica layer is modified on the surface of montmorillonite, and active amino-groups are modified. Therefore, the compatibility of montmorillonite in aqueous polyurethane resin is better, such that the emulsion can be more stable. According to the invention, silica modified montmorillonite is prepared through an in-situ method, a silica layer comprising a large amount of silanol is modified on the surface of montmorillonite, and lamella parts of montmorillonite are peeled. When the modified particles are positioned in an aqueous polyurethane system, high molecular chains of polyurethane are subject to an intercalation reaction with montmorillonite, such that free movements of polyurethane molecular chains are restricted, and mechanical properties and thermal stability of the material are improved. Compared to simple polyurethane, tensile strength of the material is improved by 1-2 times, and thermal decomposition temperature of the material is improved by 30 to 50 DEG C.

Owner:徐州光头强木业有限公司

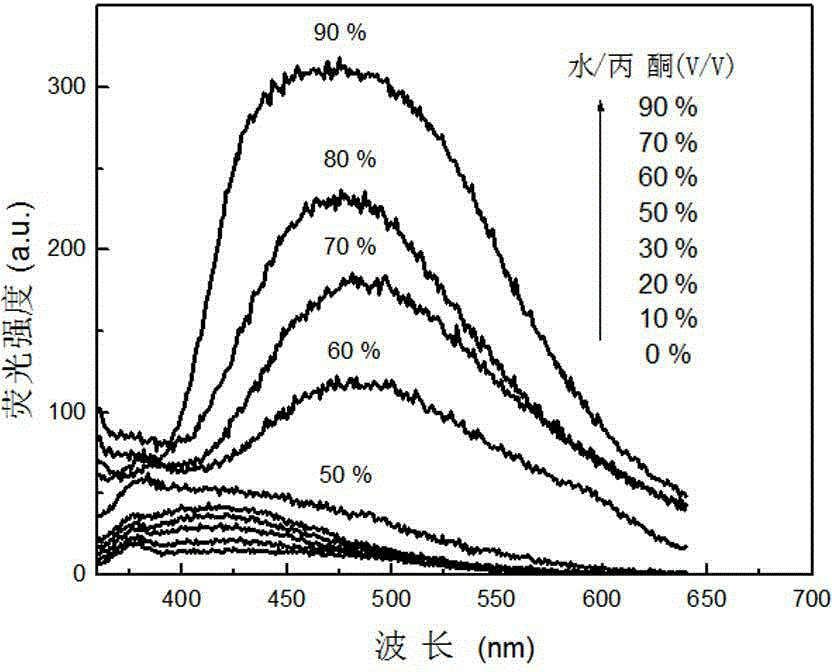

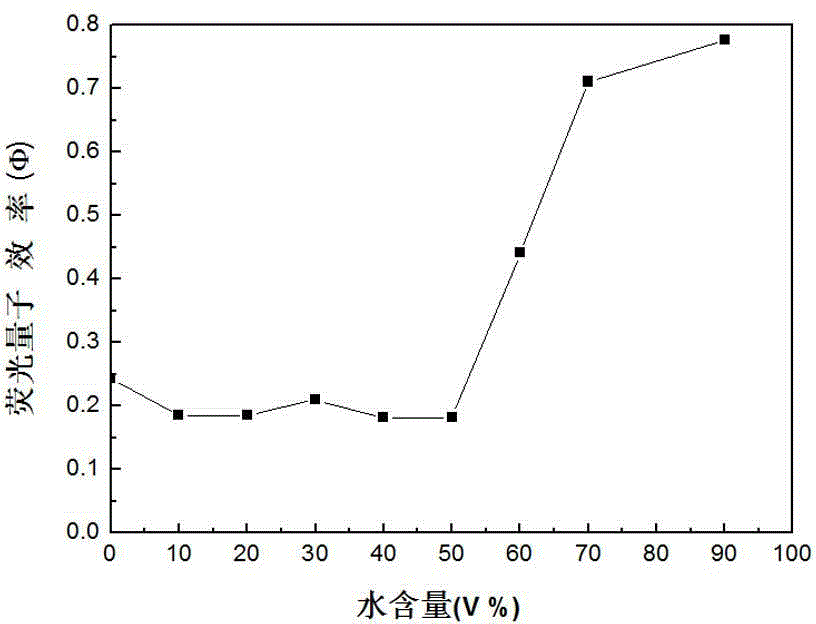

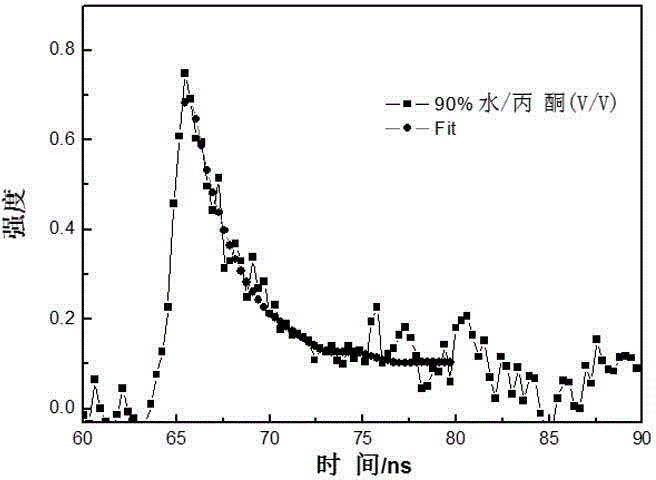

Tetraphenyl ethylene derivative and white organic electroluminescent apparatus containing same

InactiveCN103601614AAvoid aggregation-induced fluorescence quenchingSignificant H-aggregated fluorescence enhancement propertiesSilicon organic compoundsAmino preparation from aminesConformational isomerismLevel structure

The invention belongs to the field of electroluminescence, and specifically discloses a tetraphenyl ethylene derivative and a white organic electroluminescent apparatus containing the same. According to the tetraphenyl ethylene derivative disclosed by the invention, a tetraphenyl ethylene derivative matrix is taken as a luminescent main body structure, and same substituents are connected to 4,4',4'',4'''-sites of an end group, so that the level structure of molecules is conveniently adjusted through a full-guache conformational isomer, a semi-guache conformational isomer and a plane guache conformational isomer so as to obtain a plurality of luminous zones. A remarkable H-aggregation state fluorescence enhancement characteristic is displayed, and a white luminescent apparatus can be obtained by compounding the luminous zones in multiwave bands as a single luminescent layer component to obtain the white organic electroluminescent apparatus which is high in thermal decomposition temperature, excellent in electroluminescent performance, short in synthetic line and easy to industrialize. The white organic electroluminescent apparatus prepared by the tetraphenyl ethylene derivative has important application value in the field of organic electroluminescence.

Owner:SUZHOU UNIV OF SCI & TECH

Preparation method of boron-containing phenolic resin for friction materials

InactiveCN102746479AImprove heat resistanceImprove stabilityOther chemical processesAcid catalysisReaction temperature

The invention discloses a preparation method of a boron-containing phenolic resin for friction materials, used for preparing the boron-containing phenolic resin. The method adopts a two-stage process, characterized by firstly reacting phenol with formaldehyde under the effect of acid catalysis to generate a phenolic resin with small molecular weight, and reacting the phenolic resin with small molecular weight with boric acid to generate a boron modified phenolic resin. By adjusting the ratio of raw materials, controlling the reaction temperature, time and other conditions, the boron modified phenolic resin is obtained. Various technical indicators of the boron-containing phenolic resin of the invention all meet the requirements of phenolic resin for friction materials GB / T2441-2009. Compared with the common phenolic resin, the friction materials prepared by using the boron-containing phenolic resin of the invention as a binder of friction materials have better high temperature stability of the friction coefficient and lower wear rate. The preparation method of the invention is similar to the process of the common phenolic resin, and the method is easy to popularize and apply.

Owner:XIANGFAN UNIVERSITY

Method for producing high-performance rubber type chlorinated polyethylene by water-phase method

The invention discloses a manufacturing method for high-performance rubber-type chlorinated polyethylene with the water-phase method. The manufacturing method comprises the following steps of: softening hot water, dispersing agent, emulsifying agent and polyethylene powder are added in a proportioning tank in turn and are stirred to form suspension feed liquid, then completing discharging; the suspension feed liquid in the proportioning tank is fed in a chlorination reaction kettle, and then initiator is added; when the mixture is heated to 75 DEG C under a sealed condition, chlorine gas is pumped into the reaction kettle, thereby obtaining the mother liquor of rubber-type chlorinated polyethylene after 2 to 3 hour reaction under 75 to 140 DEG C and pressure less than or equal to 0.45MPa; and the mother liquor is fed to a rinsing kettle to be filtered and then is neutralized through a neutralization kettle, and is made into a high-performance rubber-type chlorinated polyethylene finished product after washing, dehydration and drying. The manufacturing method has high production efficiency and stable product quality and can realize the recycling of waste water after treatment.

Owner:江苏天腾化工有限公司

Organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and preparation method thereof

InactiveCN102251400AImprove surface microenvironmentImprove wettabilityFibre treatmentPigment treatment with organosilicon compoundsIn situ polymerizationWater vapor permeability

The invention discloses an organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and a preparation method thereof. The method comprises the following steps: firstly, carrying out organic modification on Li-based bentonite so as to prepare organic Li-based bentonite; and then, dispersing the organic Li-based bentonite into a WPU matrix in nano scale by using a latex commixing or in-situ polymerization method so as to obtain the organic Li-based bentonite-WPU leather finishing agent. In the invention, because quaternary ammonium salts, organic amines, a coupling agentand polyisocyanates are selected to carry out organic modification on Li-based bentonite, the surface microenvironment of a chain-connected silicate layer of the Li-based bentonite and the wetting action (on polymers) of the Li-based bentonite are improved, thereby enhancing the dispersibility of the Li-based bentonite in organic polymers and the compatibility of the Li-based bentonite and the organic polymers, and better facilitating the expression of nano effects; and because the Li-based bentonite with a two-dimensional nanostructure is introduced into the WPU matrix by using a latex commixing or in-situ polymerization method, therefore, due to the unique structure and properties of a nano-clay, while the transparency of a finishing material is not affected, the thermal stability, friction-resistant strength and water vapor permeability of the finishing material can be improved markedly, and the mechanical properties of the finishing material are also enhanced and toughened.

Owner:SICHUAN UNIV

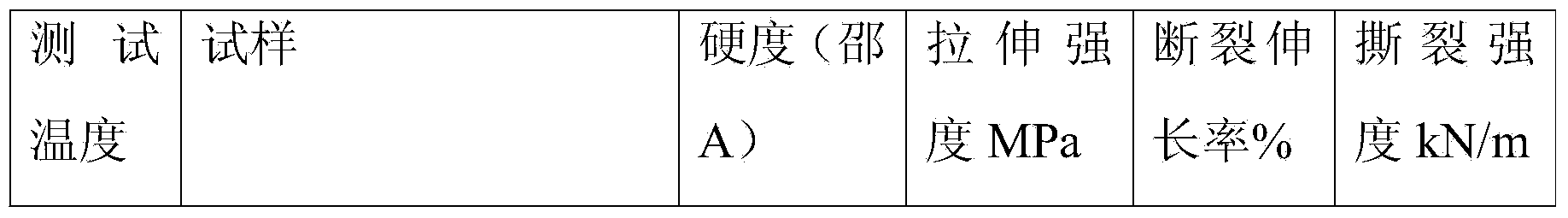

Preparation method of heat-resistant polyester plastic polyurethane elastomer

The invention discloses a preparation method of a heat-resistant polyester plastic polyurethane elastomer, which comprises the following steps: 1) adding polyester polyol and a catalyst into a reaction kettle, and dehydrating under the conditions of heating and vacuum to obtain a component A; respectively heating 1,5-naphthyldiisocyanate and a chain extender, evenly mixing with the component A, and carrying out extrusion reaction with a double screw extruder to obtain a polyester polyurethane elastomer; and 2) blending an epoxy resin with the polyester polyurethane elastomer obtained in the step 1) to obtain a blend, and drying the blend at 80-150 DEG C under the pressure of -0.08 to -0.1 MPa for 4-24 hours to obtain the heat-resistant polyester thermoplastic polyurethane elastomer. The heat-resistant polyester thermoplastic polyurethane elastomer prepared by the method is mainly used in the field of application of TPU (thermoplastic polyurethane) at higher temperature.

Owner:苏州奥斯汀新材料科技有限公司

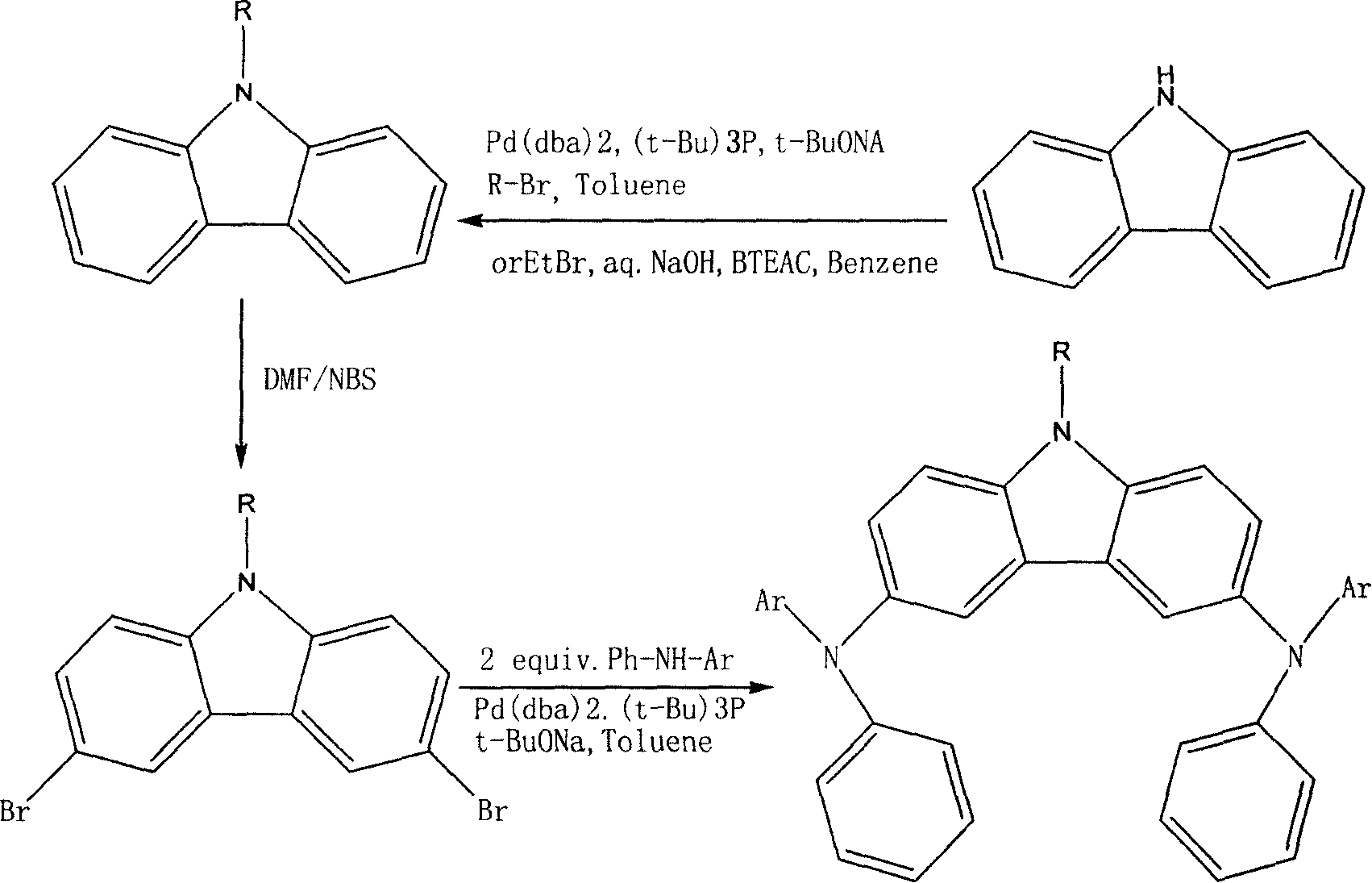

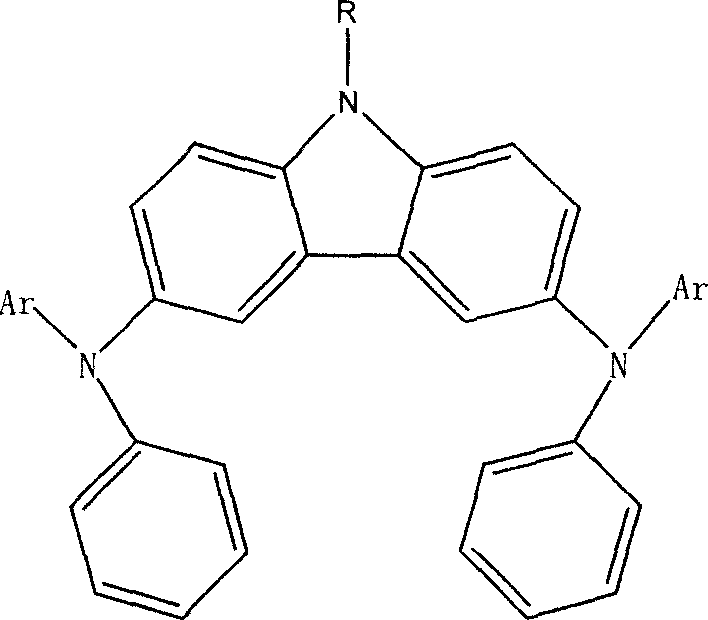

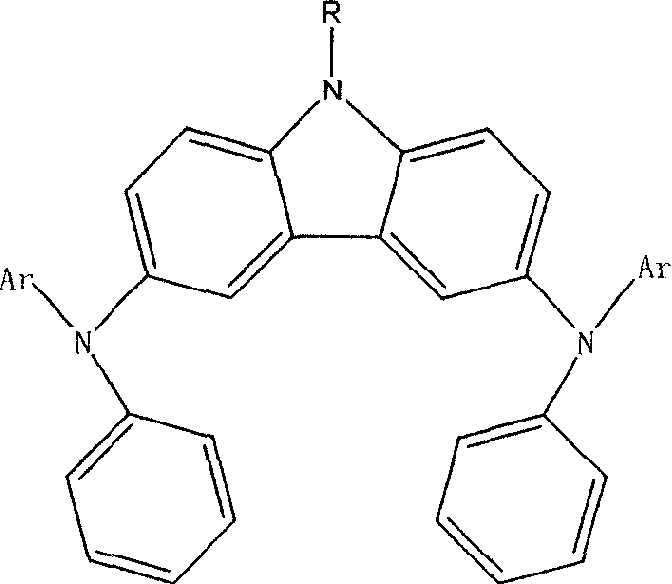

Compound for organic luminescent material and method for producing the same

InactiveCN101172963AHigh glass transition temperatureHigh thermal decomposition temperatureOrganic chemistryLuminescent compositionsCharge carrierLength wave

The invention relates to a compound for organic luminous material, and comprises a structure of carbazole derivative substituted by arylamines. The compound has quite high glass transition temperature, and Tg ranges from 120 to 200 DEG C; and the thermal decomposition temperature is also quite high, and Td is higher than 450 DEG C. The invention has good carrier transport performance, and the luminous wavelength changes from green light to blue light, ranging from 400 to 560nm.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

Lithium-ion battery electrolyte taking LiBF2SO4 as basic lithium salt

InactiveCN103531845AImprove high temperature performanceImprove high pressure performanceSecondary cellsElectrolytic agentPhysical chemistry

The invention discloses a lithium-ion battery electrolyte taking LiBF2SO4 as basic lithium salt. The electrolyte comprises the following components: electrolyte lithium salt and an aprotic solvent, wherein the electrolyte lithium salt can be unitary LiBF2SO4 and also can be a mixture of LiBF2SO4 and other common lithium salts; the aprotic solvent is one or a mixture of some of common carbonic ester, sulphite, sulfone compounds and the like. Through the lithium-ion battery electrolyte, disclosed by the invention, the compatibility between the electrolyte and the electrode materials can be improved; meanwhile, the rate performance, the high-temperature performance and the cycle performance of the lithium-ion battery can be effectively improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Modified phenolic resin, preparation process thereof and brake pad cementing agent prepared by using same

ActiveCN101838437AHigh thermal decomposition temperatureStable emergency braking performanceOther chemical processesAldehyde/ketone condensation polymer adhesivesHigh velocityBrake pad

The embodiment of the invention discloses a modified phenolic resin. Phenolic resin is modified by adopting tung oil and nano particles, wherein the tung oil accounts for 10-15 wt% of the weight of the phenolic resin, and the nano particles account for 20-45 wt% of the weight of the phenolic resin. The thermal decomposition of the phenolic resin is remarkably increased by comprehensive modification on the phenolic resin, and a brake pad including the phenolic rein has stable braking performance and less heat fading during emergent braking at high speed. The invention also discloses a preparation process of the modified phenolic resin, a brake pad cementing agent, a preparation process thereof, and a brake pad using the brake pad cementing agent as a cementing agent.

Owner:SHANDONG GOLD PHOENIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com