Thermosetting resin composition with high heat conductivity, prepreg manufactured by adopting same and copper-clad laminate

A technology of copper-clad laminates and resin compositions, applied in coatings, circuit substrate materials, paper coatings, etc., can solve problems such as low heat resistance, low thermal decomposition temperature, and large thermal expansion coefficient, and achieve cost Low, simple manufacturing process, good thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

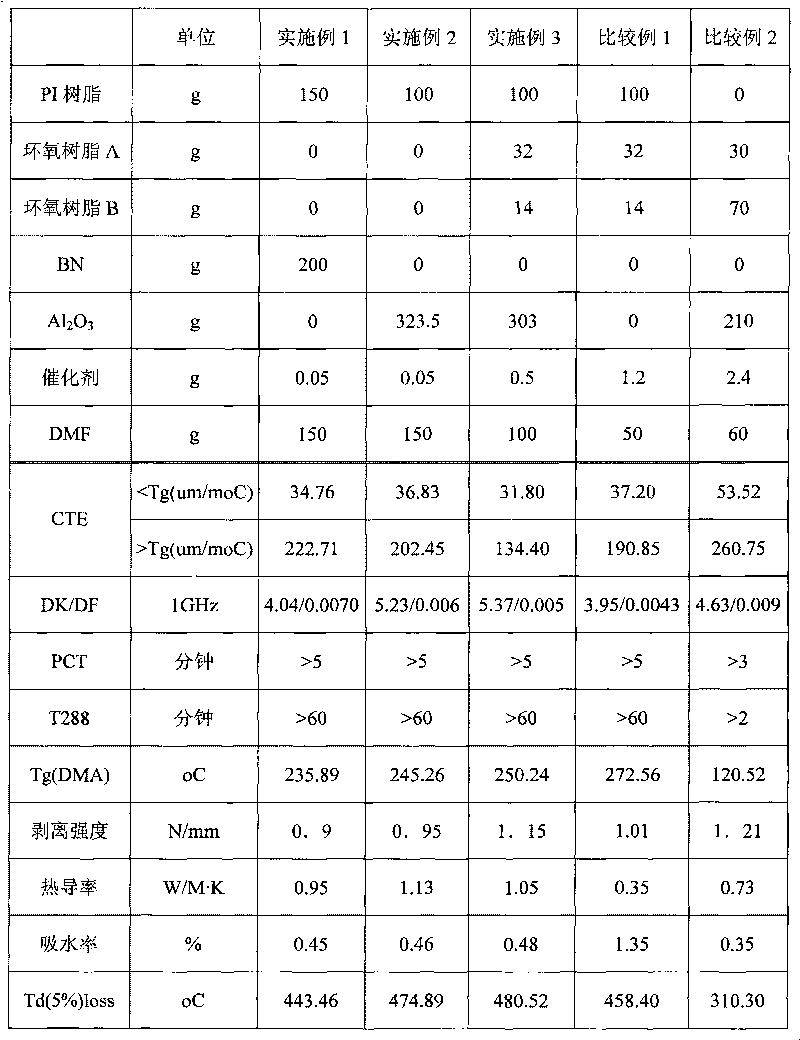

Examples

Embodiment 1

[0037] Step 1: PI resin synthesis

[0038] Add 100 g of diallyl bisphenol A (DABPA) and 250 g of diphenylmethane bismaleimide (BDM) into a three-necked flask, raise the temperature to 130°C for 2 hours, and then naturally cool to room temperature to obtain viscous liquid PI resin.

[0039] Step 2:

[0040] Add 150 g of the PI resin synthesized above into a 1 L flask with a stirring paddle, then add 20 g of DMF (N, N-dimethylformamide), and stir for about half an hour. Then add 200g of boron nitride and 130g of DMF into another 1L dry clean flask, and stir the filler for half an hour until the filler is in a homogeneous state in the solvent. Then pour the mixed resin into the filler, stir for one hour, and add 0.05 g of catalyst. Use a ball mill to grind for 24 hours to get the glue used for gluing. Use 1080 cloth for gluing, and bake at 155°C for about 3 minutes to obtain a semi-cured adhesive sheet. Stack 10 adhesive sheets together, cover both sides with copper foil, an...

Embodiment 2

[0042] Add 100 g of PI resin synthesized in Step 1 of Example 1 above into a 1 L flask with a stirring paddle, then add 20 g of DMF (N, N-dimethylformamide), and stir for about half an hour. Then add 323.5g of alumina and 130g of DMF into another 1L dry clean flask, and stir the filler for half an hour until the filler is in a homogeneous state in the solvent. Then pour the mixed resin into the filler, stir for one hour, and add 0.05 g of catalyst. Use a ball mill to grind for 24 hours to get the glue used for gluing. Use 1080 cloth for gluing, and bake at 155°C for about 3 minutes to obtain a semi-cured adhesive sheet. Stack 10 adhesive sheets together, cover both sides with copper foil, and laminate in a vacuum press at 200°C for 150 minutes to obtain a high Tg and high thermal conductivity copper clad laminate. The properties of the board are shown in Table 1.

Embodiment 3

[0044] Step 1: PI resin synthesis

[0045] Add 100g of diallyl bisphenol A (DABPA) and 400g of diphenylmethane bismaleimide (BDM) into a three-necked flask, raise the temperature to 135°C for a constant temperature reaction for 2 hours, and then naturally cool to room temperature to obtain a viscous liquid resin .

[0046] Step 2:

[0047] Add 100g of the PI resin synthesized above in a 1L flask with a stirring paddle, 32g of high bromine epoxy resin A (epoxy equivalent 400g / mol, solid content 61%), 14g isocyanate modified epoxy resin B (solid content 76%) , epoxy equivalent 360g / mol), then add 20g DMF (N, N-dimethylformamide), stir for about half an hour. Then add 303g of alumina and 80g of DMF into another 1L dry clean flask, and stir the filler for half an hour until the filler is in a homogeneous state in the solvent. Pour the mixed resin into the filler and stir for one hour, and add 0.05 g of catalyst. Use a ball mill to grind for 24 hours to get the glue used for gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com