Process for preparing hydroxyl polyhedral oligomeric silsesquioxane modified polyurethane

A technology of silsesquioxane and hydroxyl cage type, which is applied in the field of preparation of hydroxyl cage type silsesquioxane modified polyurethane, can solve the problem of limited improvement of thermal stability and the effect of octaphenyl cage type silsesquioxane on the preparation of polyurethane. Polyurethane reinforcement is not very obvious and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

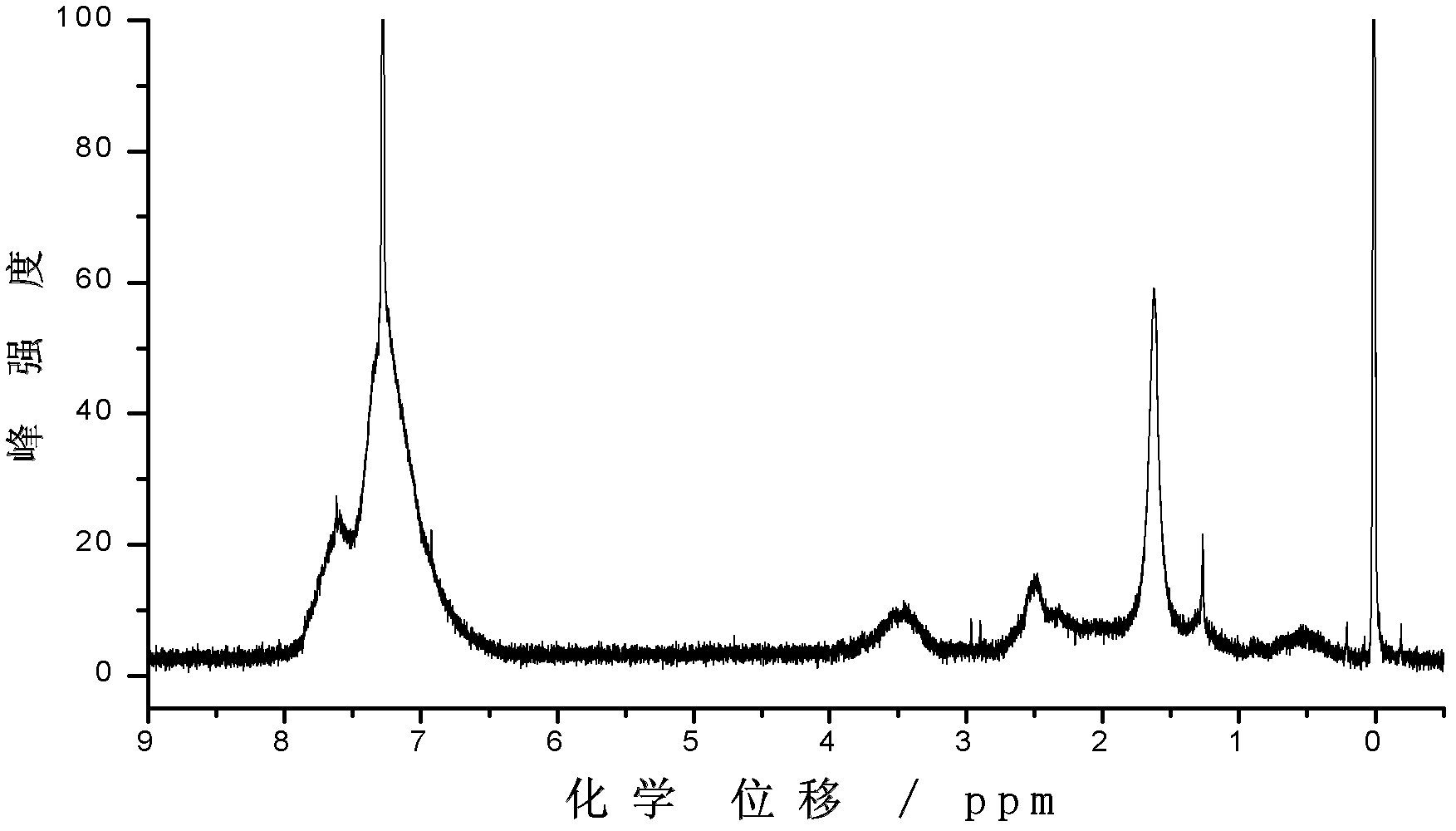

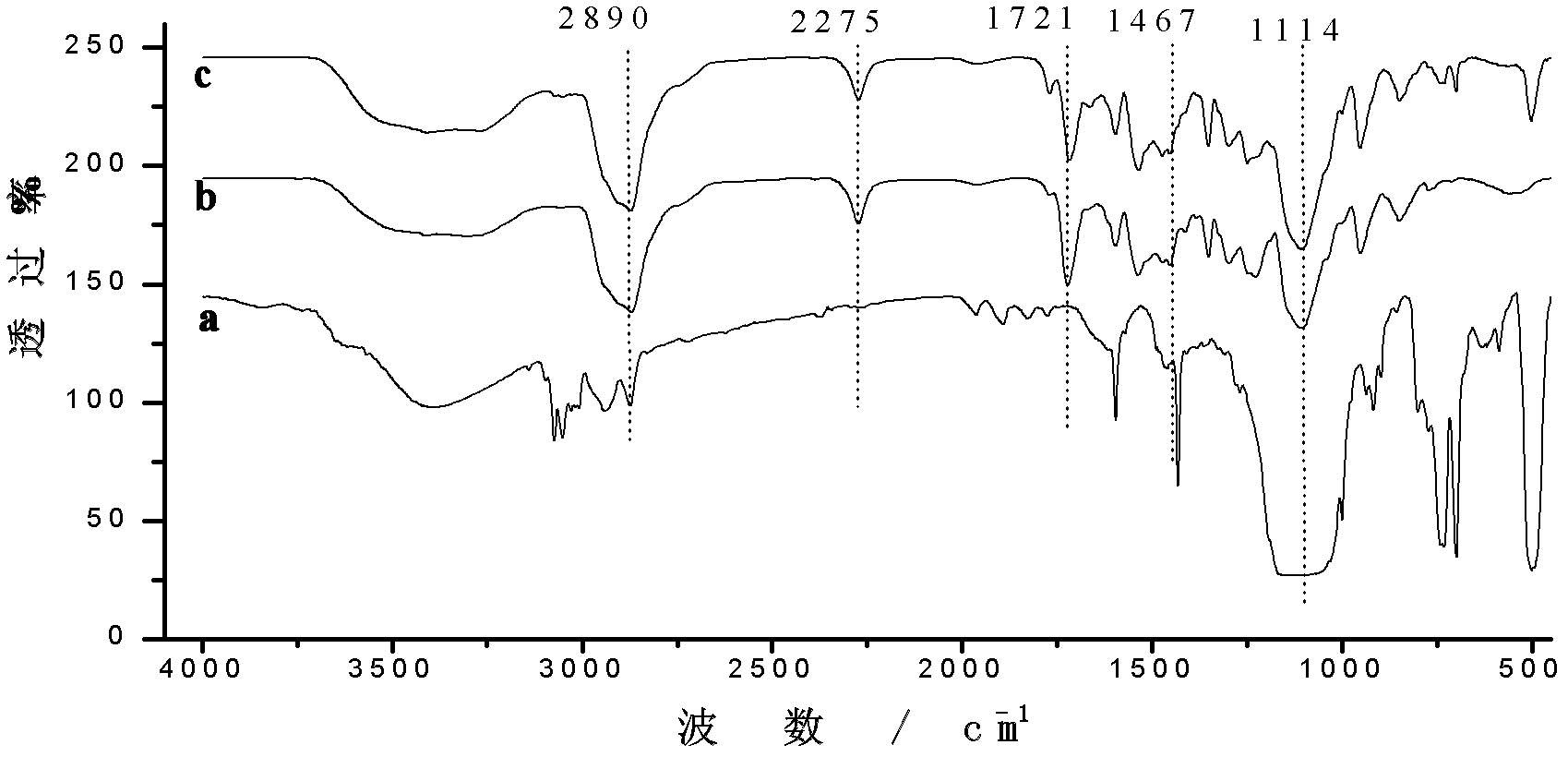

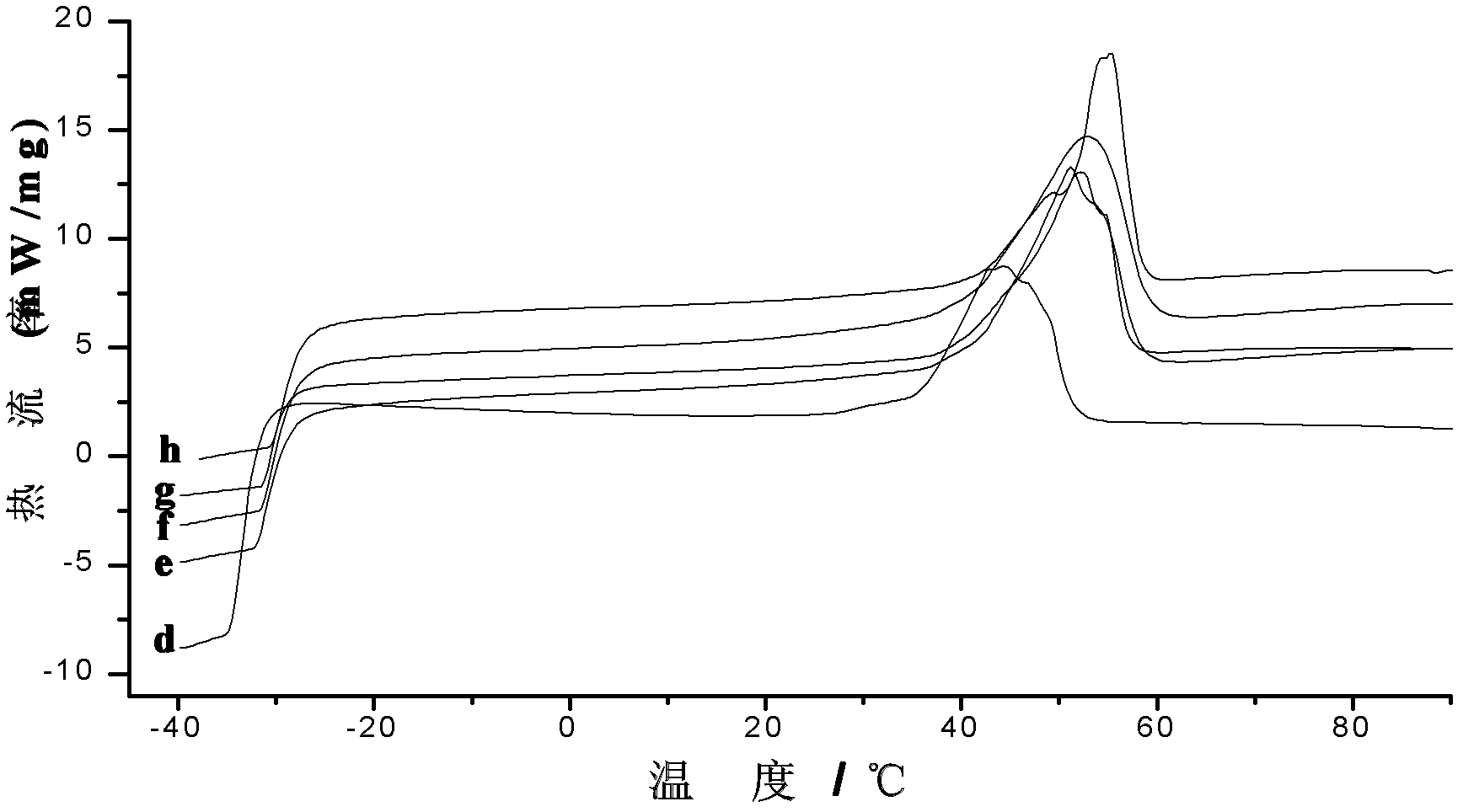

[0019] First, dissolve 1.0682g of toluene-2,4-diisocyanate and 12.0000g of polyethylene glycol with a molecular weight of 4000 in 30mL of anhydrous tetrahydrofuran, place them in a reactor under the protection of a nitrogen atmosphere, and drop them under stirring at a temperature of 60°C. Add 0.0035g dibutyltin dilaurate, and react until prepolymer is obtained; then continue to dropwise add 0.1376g dihydroxy-heptaphenyl cage silsesquioxane (2.5% by mole fraction) and 0.1690g 1 A solution prepared by dissolving 4-butanediol in 6 mL of anhydrous tetrahydrofuran until the molar ratio of the total NCO groups and OH groups in the reaction system is 1.2:1, and then continue to react at 60 ° C for 3 h, the The reaction solution was poured into a glass mold uniformly coated with a vegetable oil release agent, and formed into a film in an oven at 80° C. for 48 hours to obtain a polyurethane film modified by hydroxyl cage silsesquioxane.

[0020] In order to compare the advantages of t...

Embodiment 2

[0024] First, dissolve 1.0682g of toluene-2,4-diisocyanate and 12.0000g of polyethylene glycol with a molecular weight of 4000 in 30mL of anhydrous tetrahydrofuran, place them in a reactor under the protection of a nitrogen atmosphere, and add them dropwise at a temperature of 60°C under stirring. 0.0035g dibutyltin dilaurate, react to obtain prepolymer; Continue to add dropwise under stirring by 0.2752g dihydroxyl-heptaphenyl cage silsesquioxane (5.0% molar fraction) and 0.1577g 1, A solution prepared by dissolving 4-butanediol in 6 mL of anhydrous tetrahydrofuran until the molar ratio of the total NCO groups and OH groups in the reaction system is 1.2:1, and then continue to react at 60 ° C for 3 h, the reaction Pour the solution into a glass mold evenly coated with vegetable oil release agent, and form a film in an oven at 80°C for 48 hours to obtain a polyurethane film modified by hydroxyl cage silsesquioxane.

Embodiment 3

[0026]First, dissolve 1.0682g of toluene-2,4-diisocyanate and 12.0000g of polyethylene glycol with a molecular weight of 4000 in 30mL of anhydrous tetrahydrofuran, place them in a reactor under the protection of a nitrogen atmosphere, and drop them under stirring at a temperature of 60°C. Add 0.0035g dibutyltin dilaurate, and react until prepolymer is obtained; then continue to dropwise add 0.4129g dihydroxyl-heptaphenyl cage silsesquioxane (mole fraction 7.5%) and 0.1465g 1 A solution prepared by dissolving 4-butanediol in 6 mL of anhydrous tetrahydrofuran until the molar ratio of the total NCO groups and OH groups in the reaction system is 1.2:1, and then continue to react at 60 ° C for 3 h, the The reaction solution was poured into a glass mold uniformly coated with a vegetable oil release agent, and formed into a film in an oven at 80° C. for 48 hours to obtain a polyurethane film modified by hydroxyl cage silsesquioxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com