Preparation method of heat-resistant polyester plastic polyurethane elastomer

A thermoplastic polyurethane, polyester polyurethane technology, applied in the field of thermoplastic polyurethane elastomer preparation, can solve the problems of limited wide application, softening deformation, weakened mechanical properties, etc., achieves high thermal decomposition temperature, improves heat resistance, and thermal stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

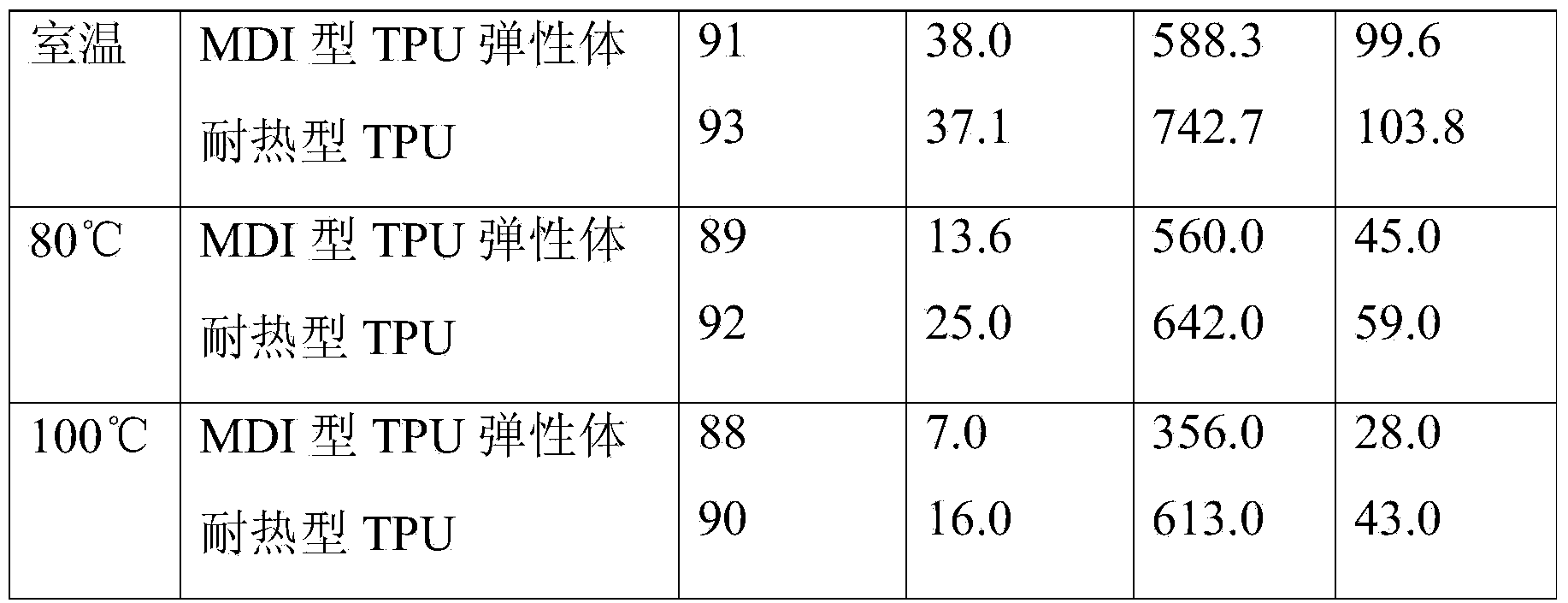

Embodiment 1

[0025] Add 500g of polyhydric alcohol formed by polycondensation of adipic acid and 1,6-hexanediol into a 2-liter reactor, add 2g of n-butyl orthotitanate, slowly raise the temperature at a rate of 5°C / min, pump while heating Vacuum to vacuum degree 0.04MPa, vacuum dehydration 2h. 280g of dehydrated polyol, 173g of 1,5-naphthalene diisocyanate and 35g of 2-methylbutanediol were respectively heated to 50°C and mixed by a pouring machine and then entered into a twin-screw extruder. Extrude while reacting. In this embodiment, the temperatures of each zone of the screw are set as follows: 80°C, 120°C, 180°C, 200°C, 180°C, 150°C, and the entire reaction extrusion time is 55 seconds.

[0026] Add 65g of E-51 and 650g of the above elastomer and ultrasonically disperse for 3 minutes in an ultrasonic instrument with a power of 1200w to obtain a heat-resistant thermoplastic polyurethane elastomer.

Embodiment 2

[0028] Add 500g of polyols formed by polycondensation of suberic acid and 1,4-butanediol into a 2-liter reactor, add 1.9g of n-butyl orthotitanate, and slowly raise the temperature at a rate of 5°C / min. While evacuating to a vacuum degree of 0.04 MPa, the temperature was raised to 220° C., and the reaction was carried out at this temperature for 1.5 hours.

[0029] 300g of dehydrated polyol, 190g of 1,5-naphthalene diisocyanate and 40g of 4-ethyl heptanediol were heated to 50°C respectively, mixed by pouring machine and then entered into twin-screw extruder. Extrude while reacting. In this embodiment, the temperature settings for each zone of the screw are as follows: 80°C, 120°C, 180°C, 200°C, 180°C, 150°C, and the entire reaction extrusion time is 58 seconds.

[0030] Add 44g of E-51 and 550g of the above elastomer in an appropriate amount of solvent N, N-dimethylformamide (DMF) and stir for 5 minutes while heating with a magnetic stirrer, then pour it into a clean and dry ...

Embodiment 3

[0032] Add 500g of polyols formed by polycondensation of adipic acid and 1,4-butanediol into a 2-liter reactor, add 2.1g of propyl titanate, and 20g of organic bentonite, and slowly heat up at a rate of 6°C / min. While raising the temperature, evacuate to a vacuum degree of 0.045 MPa, and at the same time, the temperature rises to 210° C., and react at this temperature for 2 hours.

[0033] Heat 288g of the above reaction product, 160g of 1,5-naphthalene diisocyanate and 43g of 3-methyl hexanediol to 50°C respectively, mix them with a pouring machine, and then enter the twin-screw extruder, and react in the twin-screw extruder while extrude. In this embodiment, the temperatures set in each zone of the screw are as follows: 80°C, 150°C, 190°C, 220°C, 180°C, 150°C, and the entire reaction extrusion time is 45 seconds.

[0034] 72g of E-51 and 600g of the above elastomer were extruded while reacting in a twin-screw extruder. In this embodiment, the temperatures set in each zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com